H

H

ygrocontrol

GmbH

HYGROCONTROL TYPE 86-EX TRANSMITTER

MANUAL

Feuchte- und Temperatur-Meßtechnik Moselstraße 2 B, D-63452 Hanau,

e-mail:

info@hygrocontrol.de

Version 06 / 05

06181-92790

Tel.:

Internet:

Fax.:

www.hygrocontrol.de

06181-927930

HYGROCONTROL Manual for Type 86 Ex Page 1

Table of Contents

1. General Informations

1.1 Intention of this Manual 3

1.2 Before Using / Safe Operation under EX-Conditions 3

1.2.1 Unpacking and Checking 3

1.2.2 Setup for Operation 3

1.2.3 On-Site Preparations to fullfill Ex-Regulations 4

1.3 Instructions for Dispatch 4

2. Technical Data 5

2.1 Humidity Detection 5

2.2 Temperature Detection 5

2.3 Power Supply 5

2.4 Maximum operating Temperatures 5

2.5 Power Consumption 5

2.6 EX-Labels and Fabrication Labels 6

Explanation of EX-Labels 7

2.7 Electrical Connections 8

2.8 Options 8

2.9 Applied Ex-Rules 8

Concept of Realisation 9

3. Operation 10

3.1 Operational Mode "MEASURING" 11

3.1.1 Analogue Outputs 11

3.1.2 Tables of analogue Outputs 12

3.1.3 Optional Display 15

3.1.4 Digital Output 15

3.2 Operational Mode "CALIBRATION" 15

3.2.1 General Notes about Calibration 16

3.2.2 Mounting of the Calibration Chamber 16

3.2.3 When makes a Calibration Sens? 17

3.2.4 Calibrating more Fixpoints 17

3.2.5 Calibration Procedure 18

3.2.5 Escape the running Calibration 19

3.2.6 Delete all stored Calibration Values 19

3.3 Operational Mode "CONFIGURATION" 19

HYGROCONTROL Manual for Type 86 Ex Page 2

4. Practical Instructions and Limits 22

4.1 Contact with Liquids 22

4.2 Filters 22

4.2.1 Protection against high Air Velocities 22

4.2.2 Protection against Dust and Aerosols 22

4.3 Withstanding chemical Attack 23

4.4 Protection of Transmitter Electronics 23

4.5 Influence of Temperature on Humidity Measurements 23

4.6 Humidity Measurements over Ice 23

4.7 Measurements under Pressure and Vacuum 24

5. Operating the Instrument with Display-Option 26

5.1 Calibration Data 26

5.2 Configuration Data 27

5.3 Calibration 29

5.4 Configuration 30

5.5 Display Setup 30

HYGROCONTROL Manual for Type 86 Ex Page 3

1. General Informations

1.1 Intention of this Manual

This manual describes the proper use of type 86-EX instruments, their

maintenance and limits.

We want to beware any user from errative measurements and give

examples for the usage.

Please be aware that these high precision electronic instruments for

humidity and temperature must have very sensitive sensors and

electronics which need some care.

Try to reduce the external mechanical and thermal stresses to a minimum

to prolong the lifetime of the instruments.

If any malfunction or technical problems occur, please contact the

manufacturer, representative or dealer of the instrument.

For our Humidity- and Temperature-Instruments we grant warranty

according to the "Allgemeinen Lieferbedingungen für Erzeugnisse und

Leistungen der Elektro-Industrie.”

1.2 Before Using / Safe Operation under EX-Conditions

1.2.1 Unpacking and Checking

Every instrument has been examined before dispatch in respect to its

electrical and mechanical functions. After receipt of instrument, please

check its operation. In case of any malfunction or damage, return the

instrument with a detailed description of faults.

Series 86-EX instruments are normally combined by 3 parts, which are

„Transmitter“, „Probe“ and „Connecting Cable“. The Transmitter has to

supply an intrinsic safe power supply for the probe. The probe is sending

sensor signals which are temperature compensated and are transfered

into linearized analog or digital outputs by digital electronics in the

transmitter. We use a microprocessor for the control of all internal

functions. Using the probe under EX-conditions you only should use an

intrinsically safe cable to connect the probe to the transmitter. These blue

4-wire cables are shielded and confirm with EN 90079-14. The intrinsically

safe power supply and signal wires are not connected to earth-potential

but the cable shield, the housing of the probe and the SS-316 tube of the

probe are connected to earth.

1.2.2 Setup for Operation

The instrument is to be connected to main powers either by a connector or

by using the terminals inside the housing. The correct voltage is marked

HYGROCONTROL Manual for Type 86 Ex Page 4

on the type label you find on one side of the housing. Do not use voltages

other than the marked one! Severe damage would be the result of

applying the wrong voltage.

If your instrument is equipped with screw terminals, the cross section of

your conductors should meet the dimensions of 0.5 up to 1.5 mm2 (AWG

16 to AWG 20). You will find these terminals on the ground PC-board after

opening the housing by turning the four screws (quick-release types) with

a screwdriver to the left. Please take care that cable diameter corresponds

with cable gland dimension and so will guarantee a dense screwing.

If connectors are used for power supply and outputs, we always ship the

neccessary connectors together with the instrument.

1.2.3 On-Site Preparations to fullfill Ex-Regulations

During operation the housing of the instrument should be closed and

the connections between transmitter and probe may not be opened

as long as the cable is in a hazardous area of dust explosion type.

Make sure that before the power supply is activated, an intrinsically

safe cable is used to connect the probe to the transmitter and that all

plugs are thoroughly tightened to assure safe contacts.

User of the instrument have to take care, that not only the power

supply, but also any instrumentation connected to the transmitter is

protected by a fuse of max. 16A, which has a shut-down current of at

least 1500A. If all other instrumentation connected to the transmitter

is powered by the same line, this allows to use one single fuse for

this protection.

Whatever supply is used for the instrument, the PE-contact of the

transmitter must be connected to PE! This is also true, if low voltage

or DC voltage is applied! The tube of the probe has to be connected

to the local potential of the machinery.

Our probes are secure against pressure and vacuum by a glass

feed-through which is specificated from 30 mbar to 30 bar. Use

compression fittings of SS-316 material if applications may have

pressures of more than 1,5 bar.

1.3 Instructions for Dispatch

If there are any problems you are not able to correct, we ask you to

contact our technical department or to return the instrument with a short

description of the fault. When returning please pack the instrument safely

in a cardboard box and fill up holes with soft packing material to avoid

damage.

HYGROCONTROL Manual for Type 86 Ex Page 5

2. Technical Data

2.1 Humidity Detection

Ranges are possible from 0-100 %RH

as well as absolute Humidities, Dewpoints

and Enthalpie, programed is a range of ...........................

Resolution 0,1 % RH

Sensing Element (capacity type) SE – 02

Influence of Temperature on the Humidity ± 0,01 % RH / °C

Repeatability < 0,5 % RH

Hysteresis for 4 hours Cycle

10 % - 95 % - 10 % RH < 0,5 % RH

Unlinearity of Electronics / Humidity < 1 % RH

2.2 Temperature Detection

Ranges are possible from –50°C to

+150°C, programed range is ..................°C

Resolution 0,1 °C

Temperature sensing Element Pt - 1000

System Accuracy of Temperature ± 0,35 °C

Unlinearity of Electronics / Temperatur < 0,15 °C

2.3 Power Supply

Standard Power Supply 90-240 VAC,

or Low Voltage Supply 10-30 VDC/9-25 VAC

2.4

2.5 Power Consumption

Maximum Operational Temperatures

Transmitter Electronics -20....+40 °C

Probe Electronics -40....+60 °C

Probe Tube with Sensors -40....+120 °C

Max. Power Consumption approx. 5 VA

47-63 Hz

HYGROCONTROL Manual for Type 86 Ex Page 6

H

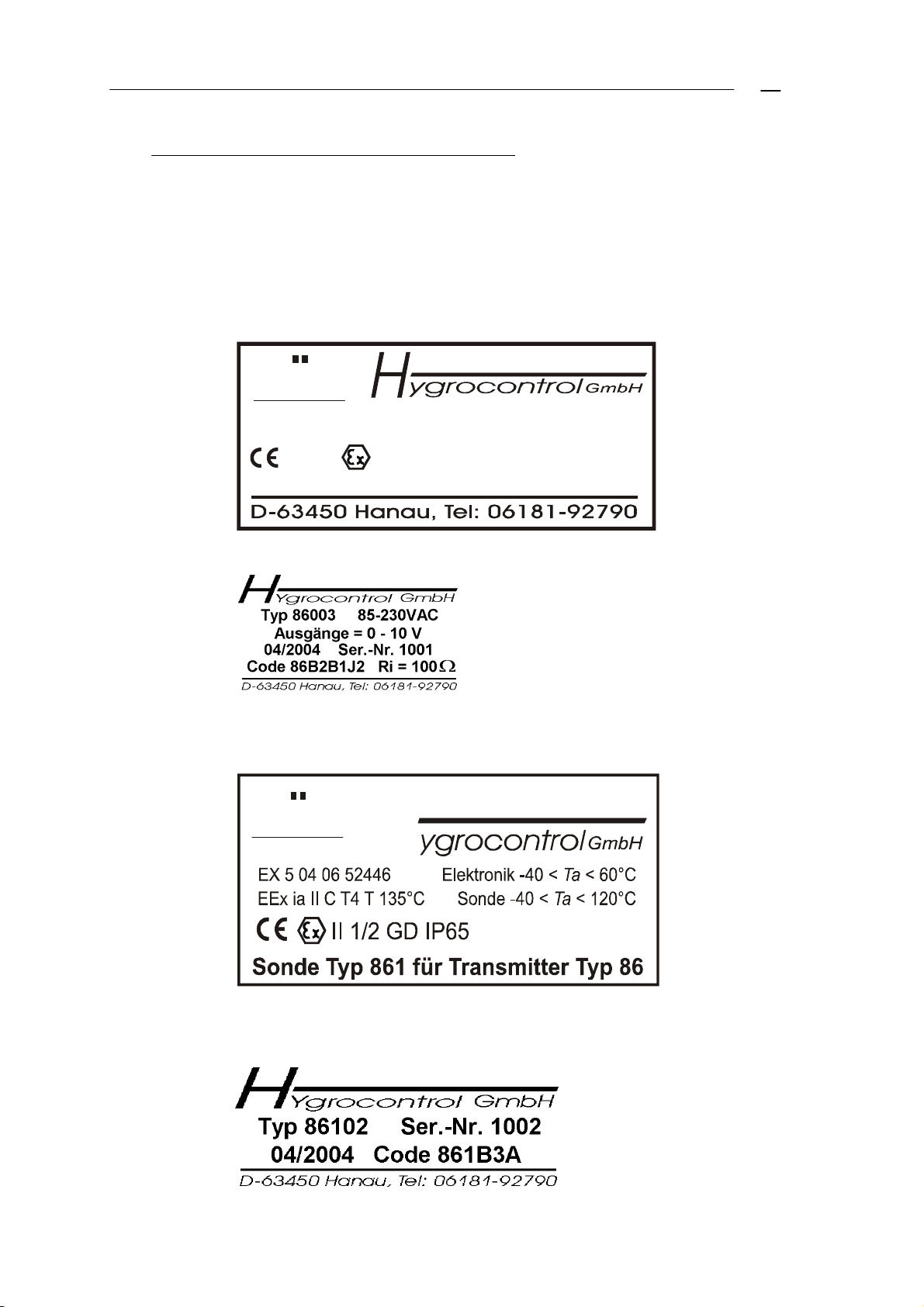

2.6 EX-Labels and Fabrication Labels

Transmitter and probe have a fabrication label and an EX-label as

shown on this page:

EX-Label of the Transmitters

T

PRODUCT SERVICE

Ex5 04 06 52446 001

[EEx ia] II C

Fabrication Label of the Transmitters:

EX-Label of the Probes:

T

PRODUCT SERVICE

U

ATEX

U

V

V

Transmitter Typ 86 2004/10001

U

L

II (2) GD

i 10 µH

L

o 100 µH

m 230 VAC

C

i 1 µF

C

o 5 µF

J/SN: 2004/10002

Fabrication Label of the Probes:

HYGROCONTROL Manual for Type 86 Ex Page 7

Explanation of EX-Labels

TVU

PRODUCT SERVICE

H

J/SN: 2004/10002

EX-Class of Instrument

Ex-Zone + Temp.-class

Number of Certificate

Prooving Authority

TVU

PRODUCT SERVICE

EX5 04 06 52446 001

ATEX

[EEx ia] II C

Class of intrinsic Safety

EX-Class of Instrument

Number of Certificate

Prooving Authority

Transmitter Typ 86 2004/10001

II (2) GD

Year of Production/Serialnumber

Environmental Temperatures

of Electronics and Probe Tube

m 230 VAC

U

i 10 µH

L

L

o 100 µH

Max. Inner Capacity/Inductivity

Max. Inner Capacity/Inductivity

Year of Production/Serialnumber

C

i 1 µF

C

o 5 µF

Max. Power Supply

HYGROCONTROL Manual for Type 86 Ex Page 8

2.7 Electrical Connections

2.7.1 Screw Terminals

3 Terminals for AC- X1/1 = L, X1/2 = PE, X1/3 = N

or DC-Power Supply X1/1 = -, X1/2 = PE, X1/3 = +

3 Terminals for Output X2/1 = + Humidity (mA),

Humidity X2/2 = GND,

X2/3 = + Humidity (V)

3 Terminals for Output X2/4 = + Temp. (mA),

Temperature X2/5 = GND,

X2/6 = + Temp. (V)

2.7.2 Connector Options

7pol. round Plug according to DIN 43651 for Power (max. 42 V) and

Outputs

or:

1 rectangular Connector 4 pol. for Power (95 - 230 VAC)

+ 1 rectangular Connector 6 pol. for Outputs analog

or 1 rectangular Connector 6 pol. for Outputs digital

or:

1 rectangular Connector 4 pol. for Power(10-30 VDC or 9-25 VAC)

+ 1 rectangular Connector 6 pol. for Outputs analog

or 1 rectangular Connector 6 pol. for Outputs digital

2.8 Options

LC-Display for Humidity and Temperature

2.9 Applied Ex-Rules

The type 86-EX instruments are built and certified for applications in the

following EX-Zones and protection Classes:

Probes: Tubes and tips of the probes may be used in Zones 0.

Electronics of probes and connection cables may be used in Zones 1.

Protection Class is EEx ia IIC T4. ATEX-Category for probes is 2G or 2D,

eventually also 1G or 1D, but then a certification of each single instrument

must be done by the proofing authority. Maximum surface temperature of

probe housing and intrinsically safe connection cables is restricted to

60°C.

HYGROCONTROL Manual for Type 86 Ex Page 9

Transmitter: Transmitters built according to EN 50020 as intrinsically safe

supply instruments. Intrinsically safeness is given by Zener Barriers which

are encapsulated together with the connector for the cable to the probe

and therefore may not be manipulated by a user. These Barriers separate

the intrinsically safe power supply for the probes from the internal and

external current and voltage loops which are not intrinsically safe.

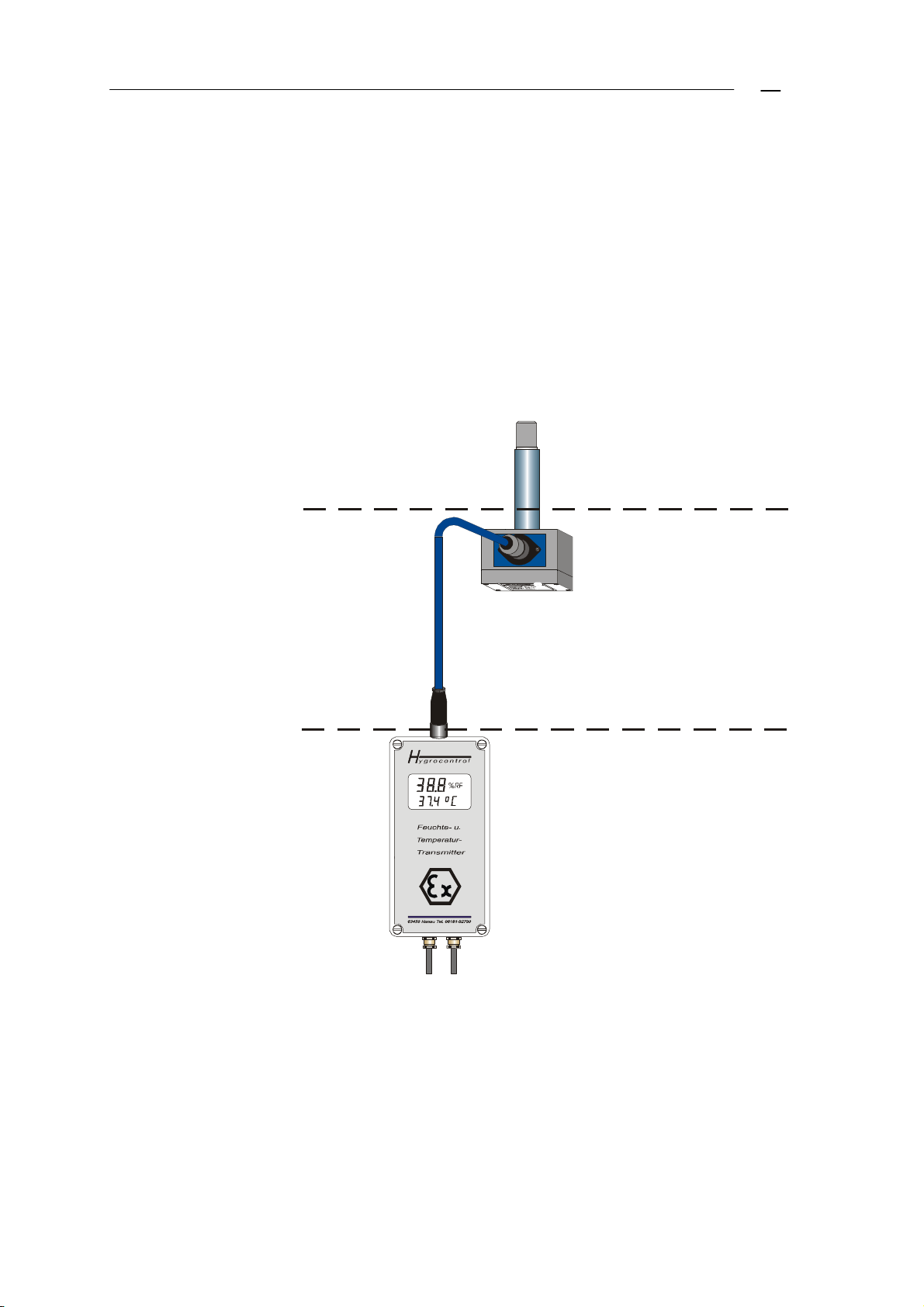

Concept of Realisation

Conception for Humidity Detectors Type 86-EX

EX - Environment (Zone 0)

Category 1 GD

-40°C <= ta <= +120°C

30 mbar < P < 30 bar

Connection Cable

(intrinsically safe)

Power Cable Signal Cable

Probe Type 861

EX - Environment (Zone 1)

Category 2 GD

-20°C <= ta <= +60°C

Transmitter Type 86

No EX but intrinsically safe

Supply for Probes 861

-20°C <= ta <= +40°C

Environment

Loading...

Loading...