COSA Xentaur 83 User Manual

H

H

ygrocontrol

HYGROMESS TYPE 83 TRANSMITTER

GmbH

MANUAL

Feuchte- und Temperatur-Meßtechnik Moselstraße 2 B, D-63452 Hanau,

e-mail:

info@hygrocontrol.de

Version 06 / 10

06181-92790

Tel.:

Internet:

Fax.:

www.hygrocontrol.de

06181-927930

HYGROCONTROL Manual for Type 83 Page - 1 -

TABLE OF CONTENTS:

1. Fundamental Features of Series 83 2

2. Preparations before operating 2

2.1. Unpacking and Checking 2

2.2. Set-up for Operation 2

2.3. Instructions for Dispatch 3

3. Technical Data 3

4. HART 4

5. Operation 4

5.1 Mode "MEASUREMENT" 5

5.2 Mode "CALIBRATION" 5

5.2.1 General Notes concerning Calibration 5

5.2.2 How often Calibrations should be done 5

5.2.3 Calibration Chamber 6

5.2.4 Mounting the Calibration Device 6

5.2.5 Operation via BUS Commands 7

5.2.6 List of possible Commands 8

5.2.7 Output Examples 8

5.2.8 List of used Abbreviations 9

6. Practical Instructions and Limits 10

6.1 Direct Contact with Liquids 10

6.2 Filters 10

6.2.1 Resistance against high Air Velocities 10

6.2.2 Resistance against Dust and Aerosols 10

6.3 Resistance against Chemical Attack 11

6.4 Protection of Transmitter Electronics 11

6.5 Influence of Temperature on Humidity 11

6.6 Humidity Measurements over Ice 11

6.7 Measurements under Pressure and Vacuum 12

HYGROCONTROL Manual for Type 83 Page - 2 -

1. Fundamental Features of Series 83 Transmitters

HYGROMESS Humidity and Temperature Meters detect relative

Humidity and Temperature. For this purpose the probes are

equipped with a capacity type humidity sensor of very small mass.

The temperature detection is done by a Pt-1000 RTD , which is

placed very close to the humidity sensor to avoid differences in

temperature between the two sensors.

Incoming sensor signals are temperature compensated and

transferred into linearised analogue or digital outputs by digital

electronics. We use a microprocessor for the control of all internal

functions.

The electronics for transmitting the temperature and humidity sensor

signals are built into a IP-65 housing of 80 x 160 x 55 mm.

Two different operational modes may be chosen by the user which

are:

"MEASURING" and "CALIBRATION"

"MEASURING" is the normal mode for picking up humidities and

temperatures, compensating, linearising and transferring the values

to the outputs.

"CALIBRATION" mode is used for recalibration of sensor

characteristics by special prepared LiCl solutions.

2. Preparations before Operating

2.1 Unpacking and Checking

Every instrument has been examined before dispatch in respect to its

electrical and mechanical functions. After receipt of instrument,

please check its operation. In case of any malfunction or damage,

return the instrument with a detailed description of faults.

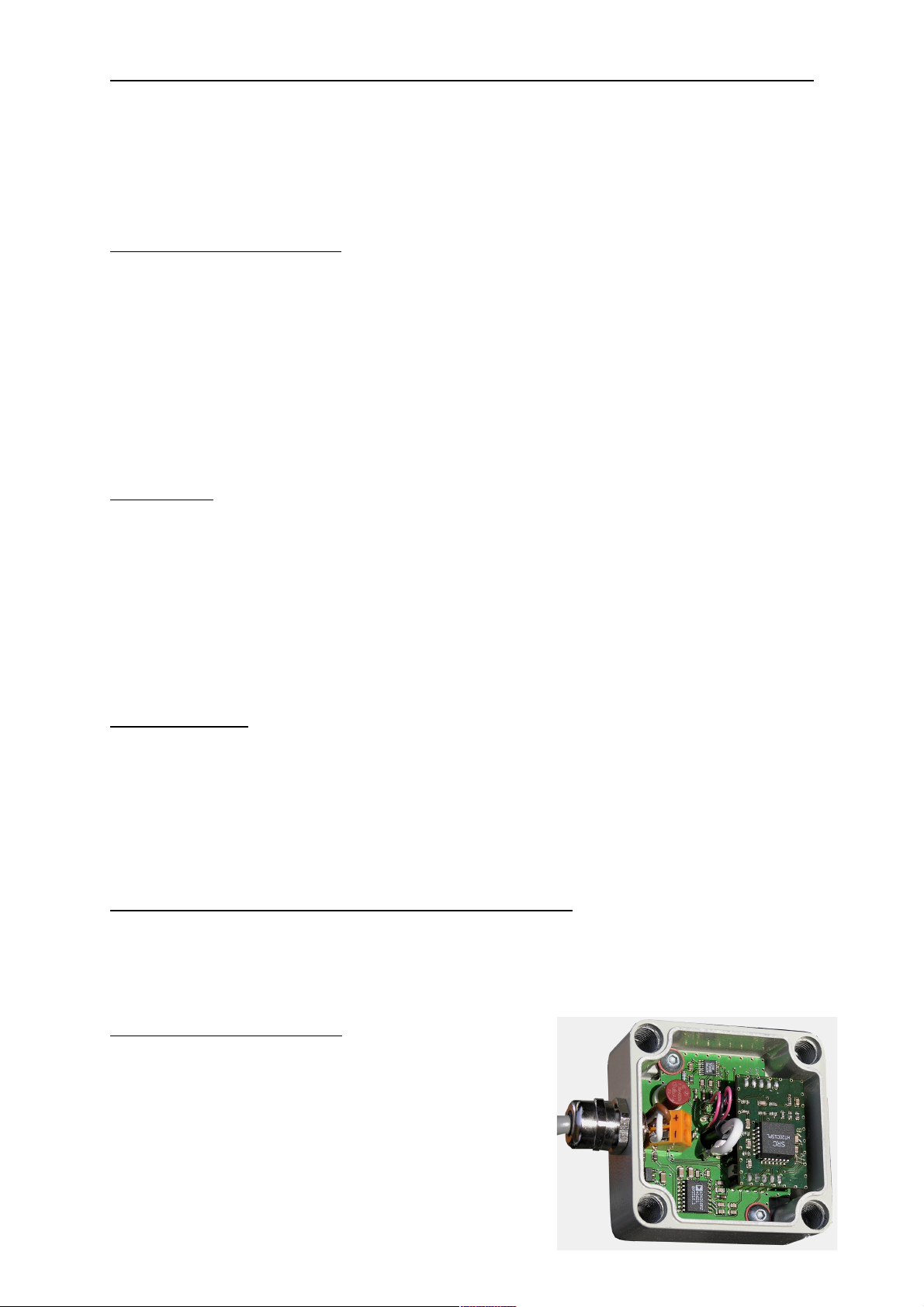

2.2 Set-up for Operation

The instrument has to be connected to a power supply of 9 to 36

VDC. The correct voltage is marked on the type label you find on one

side of the housing. Do not use voltages other than the marked one!

Severe damage would be the result of applying the wrong voltage.

The cross section of your conductors should meet the dimensions of

0.5 up to 1.5 mm2 (AWG 16 to AWG 20). You will have to connect

the 2 wires to the terminals marked (+) and (-), the shield should be

connected at the cable gland. Opening of the housing is done by

turning the four screws (quick-release types) with a screwdriver to

the left.

HYGROCONTROL Manual for Type 83 Page - 3 -

Please take care that cable diameter corresponds with the dimension

of the gland and so will guarantee a dense screwing. During

operation the housing of the instrument should be closed.

2.3 Instructions for Dispatch

If there any problems you are not able to correct, we ask you to

contact our technical department or to return the instrument with a

short description of the fault. When returning please do not forget to

pack the instrument safely in a cardboard box and fill up holes with

soft packing material to avoid damage.

3. Technical Data

3.1 Humidity

Humidity Range 0....100 % RH.

Resolution 0,1 % RH.

Humidity Sensor SE - 02

Temperature Error of Humidity ± 0,01 % RH./ °C

Repeatability < 0,5 % RH.

Hysteresis after 4 hour Cycle

10 % - 95 % - 10 % r. F. < 0,5 % RH.

Linearity of Electronic / Humidity < 1 % RH.

3.2 Temperature

Range -50.....+150 °C

Resolution 0,01 °C

Temperature Sensor RTD: Pt-1000

System Accuracy for Temperature

over the total Range ± 0,35 °C

Linearity of Electronic / Temperature ± 0,15 °C

3.4 Maximum environmental conditions during operation

Transmitter Electronics -10...+ 50 °C

Probe Tube with Sensors -50...+150 °C

Max. Humidity 95%RH

3 .5 Connections

Screw Terminals

Marked with + and –

HYGROCONTROL Manual for Type 83 Page - 4 -

4. HART

Following universal commands are available:

0 Read unique identifier

1 Read primary variable

3 Read current and four variables

12 Read message

13 Read tag, description, date

14 Read primary variable sensor information

15 Read output information

16 Read finally assembly number

17 Write message

18 Write tag, description, date

19 Write finally assembly number

34 Write damping value

35 Write range values

44 Write primary variable units

49 Write primary variable sensor serial number

59 Write numbers of response preambles

109 Burst mode control

Sending following user messages will not cause their storage but

result in starting the functions below:

%Hxxx starts a humidity calibration with xxx * 0,1 %RH

%Txxxx will do a temperature adjustment to xxxx * 0,01 °C

%Y positive confirmation of humidity calibration

%N negative confirmation of humidity calibration

%F end of calibration and show of original users message

Command 3 results in the output of measurement values as follows:

primary variable Humidity in %RH shown unit = %

secondary variable Temperature in °C

tertiary variable Humidity digits shown unit = none

quaternary variable Reference digits shown unit = none

5. Operation

HYGROCONTROL Humidity and Temperature Meters detect relative

Humidity and Temperature. For this purpose the probes are

equipped with a capacity type humidity sensor of very small mass.

The temperature detection is done by a Pt-1000 type RTD , which is

placed very close to the humidity sensor to avoid differences in

temperature between the two sensors.

Incoming sensor signals are temperature compensated and

transferred into linearised analogue or digital outputs by digital

Loading...

Loading...