Page 1

QUEST ELITE QLT 2000

Operator’s, Installation and Service Manual

Release Date: December 10, 2013

Publication Number: 620058442

Revision Date: January 08, 2015

Revision: C

Visit the Cornelius web site at www.cornelius.com for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possi

ble contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warranty applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained per

sons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

-

-

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency Drive

Glendale Heights, IL

Tel: + 1 800-238-3600

Printed in U.S.A.

Page 3

TABLE OF CONTENTS

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Counter Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recommended Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Booster System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electric Booster Installation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Gas-operated Booster Installation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Booster Installation Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Flushing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Filling the Water Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Programming the Portion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Loading With Concentrate Pouches – 6.5 Liters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Loading with Concentrate Pouches – 3.0 & 4.5 Liters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting the silicone tube onto the Mixing Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Planned Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Daily – Flushing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Weekly – Sanitizing Dispense Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Weekly – Check Ratio (Prodecure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Monthly - Clean the Air Condenser Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Semi-Annually - Clean the Water Inlet Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring Drawing for Quest Elite Qlt-2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Qlt 2000 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Qlt 2000 Door Assembly Reference (Pushbutton & Portion Control) . . . . . . . . . . . . . . . . . . . . . . . 25

Page 4

Cabinet Assembly Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Tank Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Refrigeration Frame Assembly Qlt 2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Platform Assembly QLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Valve Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Electrical Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

P/N 720521000 (For QLT Dispensers Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Pouch Holder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Recommended Spare Parts Based on 10 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Page 5

Quest Elite QLT 2000

!

DANGER:

!

WARNING:

CAUTION:

!

!

WARNING:

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit (decals, labels or

laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety regulations before

operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

DIFFERENT TYPES OF ALERTS

Indicates an immediate hazardous situation which if not avoided WILL result in serious injury, death or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in serious injury, death, or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury or equipment

damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young children or

infirm persons without supervision. Young children should be supervised to ensure that they do not play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL WIRING AND

PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

Publication Number: 620058442 - 1 - © 2013-2015, Cornelius Inc

Page 6

Quest Elite QLT 2000

!

WARNING:

CAUTION:

!

CAUTION:

!

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued protection

observe the following:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the user. Verify

all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may result in

injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must be drained

from the system. A freezing ambient environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

© 2013-2015, Cornelius Inc. - 2 - Publication Number: 620058442

Page 7

Quest Elite QLT 2000

24.85

29.30

2.10

8.65

19.30

30.7

30.04

15.15

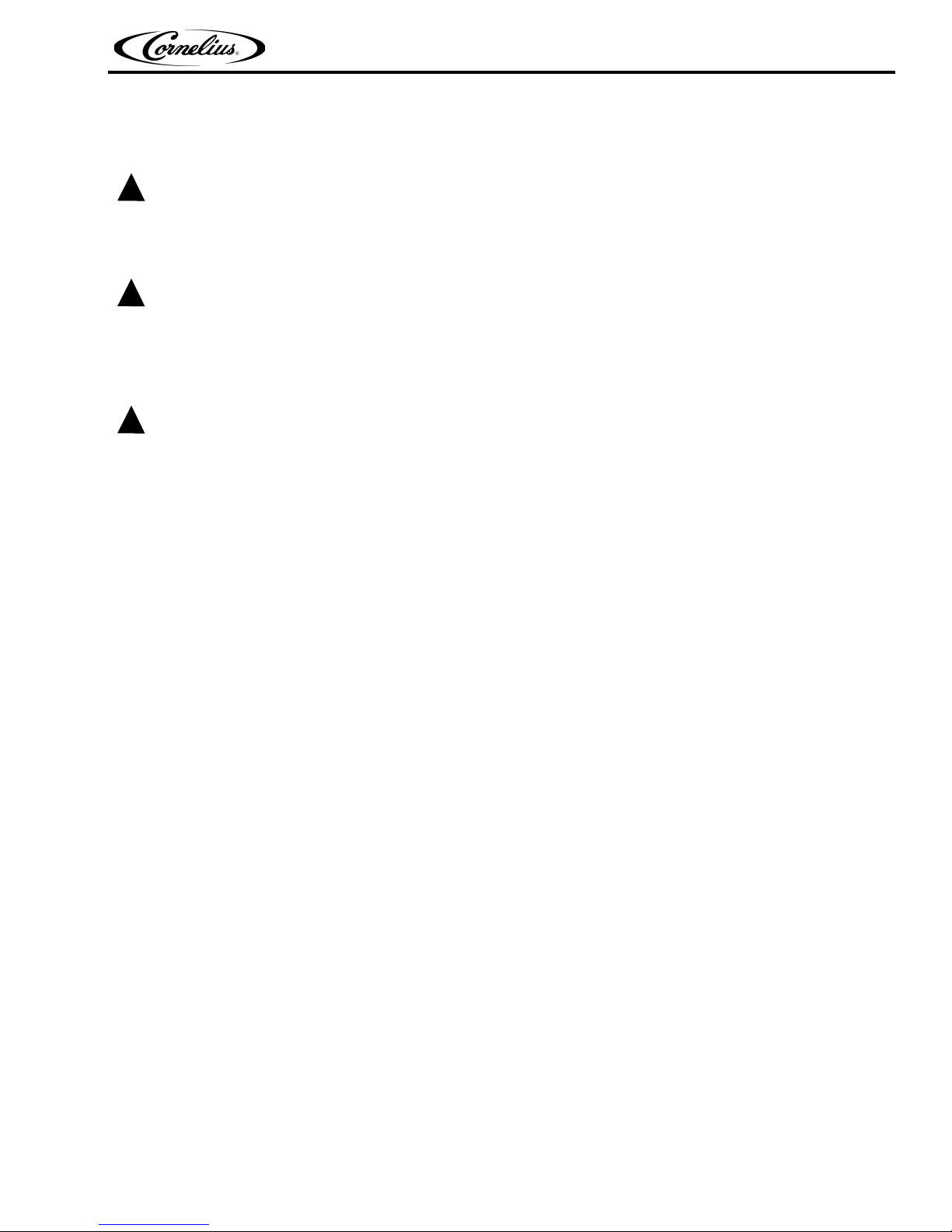

UNIT SPECIFICATIONS

Figure 1. Unit Dimension

Model QUEST ELITE QLT - 2000, 115 VAC, 5 amps, 1 phase 60 hertz, 5.64 oz. (160 gms) R-134a refrigerant.

Test press: High side 400 psi (2757.9 kilo pascals), (27.6 bar). Low side 88 psi (606.7 kilo pascals), (6.1 bar).

Model QUEST ELITE QLT - 2000, 230 VAC,

2 amps, 1 phase 50 hertz, 5.64 oz. (160 gms) R-134a refrigerant.

Test press: High side 400 psi (2757.9 kilo pascals), (27.6 bar). Low side 88 psi (606.7 kilo pascals), (6.1 bar).

Model QUEST ELITE QLT - 2000, 220 VAC,

Test press: High side 400 psi (2757.9 kilo pascals), (27.6 bar). Low side 88 psi (606.7 kilo pascals), (6.1 bar).

2 amps, 1 phase 60 hertz, 5.64 oz. (160 gms) R-134a refrigerant.

Publication Number: 620058442 - 3 - © 2013-2015, Cornelius Inc

Page 8

Quest Elite QLT 2000

4”

4”

4”

12”

INSTALLATION INSTRUCTIONS

RECEIVING

Each unit is completely tested and inspected before shipment. At time of shipment, the carrier accepts the unit and

any claim for damage must be made with the carrier.

Upon receiving from the carrier, please, inspect the carton for visible damage. If damage exists, have the carrier make

note on the bill of lading and file a claim with the carrier.

a

UNPACKING

• Remove staples securing carton to pallet.

• Lift carton up and off of unit.

• Remove top insert and shipping bag.

• Open upper cabinet door and remove installation kit.

• Remove bolts securing unit to pallet.

• Lift unit off of pallet.

• Open the package, take the legs and secure them to the bottom of the unit.

NOTE: Do not lay the unit on sides or on the back. This may cause vital oils to drain from the compressor

resulting in damage during start-up and consequently voiding the warranty.

Tilt the unit only when securing legs.If the unit is to be t

remove the unit from the pallet. Transport it on the pallet to the installation site.

ransported from the place where it was unpacked, do not

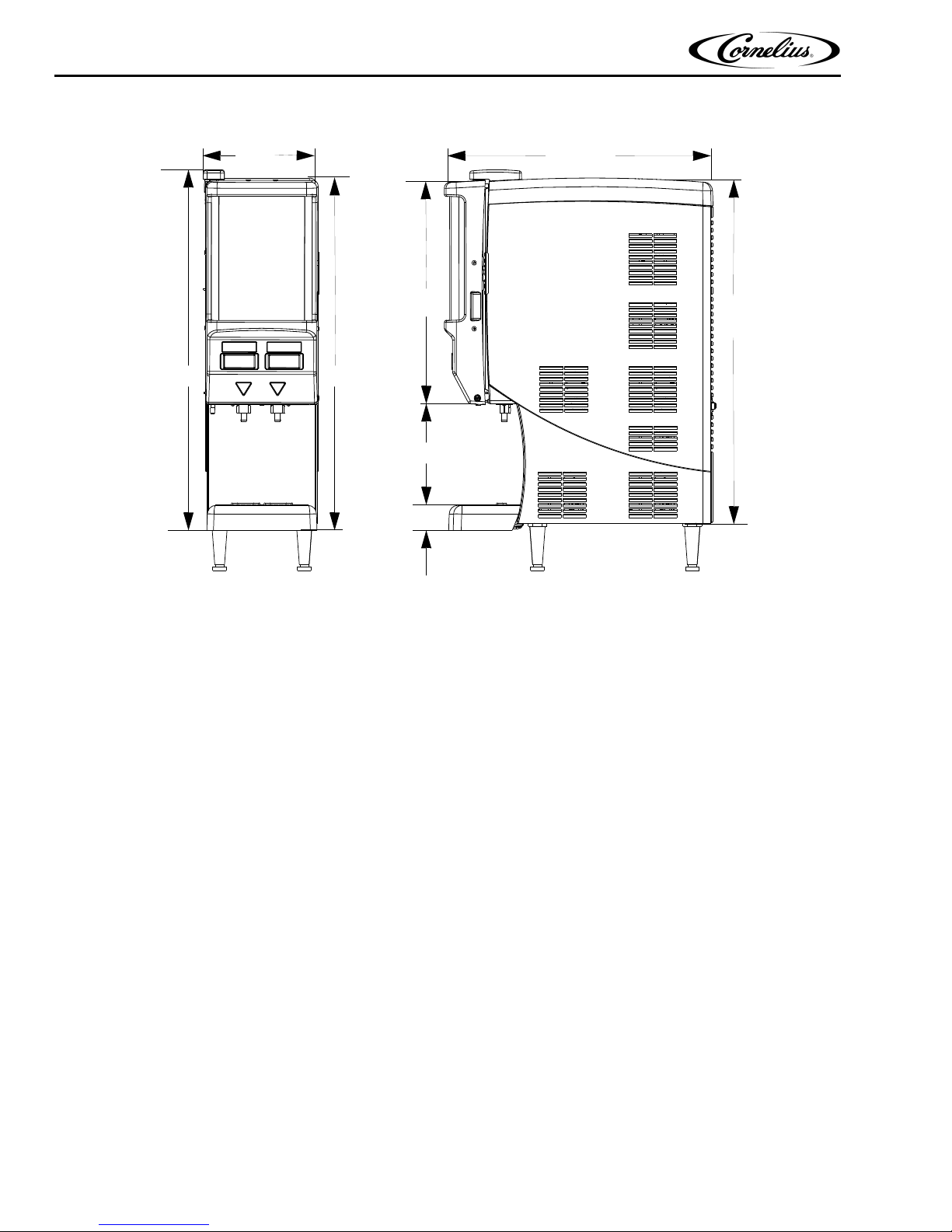

COUNTER LOCATION

Select a location in a well ventilated area, close to a grounded electrical outlet. If possible do not place the unit close

to hot and/or steaming machines. The minimum Airflow clearance is: 4" (10.16 cm) in back and 12" (30.48 cm) on top,

4” (10.16cm) on sides and open to the front is required. The space between bottom of the unit and counter cannot be

obstructed.

IMPORTANT: Condenser air is drawn from the rear and discharged out the top. Failure to maintain

learance space will reduce capacity of the unit and cause premature compressor failure.

c

Recommended Clearance

12” (30.48 cm) on top and 4” (10.16 cm) required in back for air circulation and 4”(10.16cm) at the sides of the unit.

© 2013-2015, Cornelius Inc. - 4 - Publication Number: 620058442

Figure 2.

Page 9

Quest Elite QLT 2000

CAUTION:

!

INSTALLATION

Electrical Connection

6 ft. long (1.83 m) power cord with 3-prong plug attached to dispenser. Export models are shipped with a European

plug. The plug is accessible after installation

Only trained and certified electrical technicians should replace the power cord or the unit should be returned to an

Authorized Service Center for power cord replacement.” The replacement cord must meet all requirements of the

original equipment manufacturer.

Failure to comply could result in serious injury, death or damage to the equipment.

Power Supply

10 amps at 230 volts dedicated power supply.

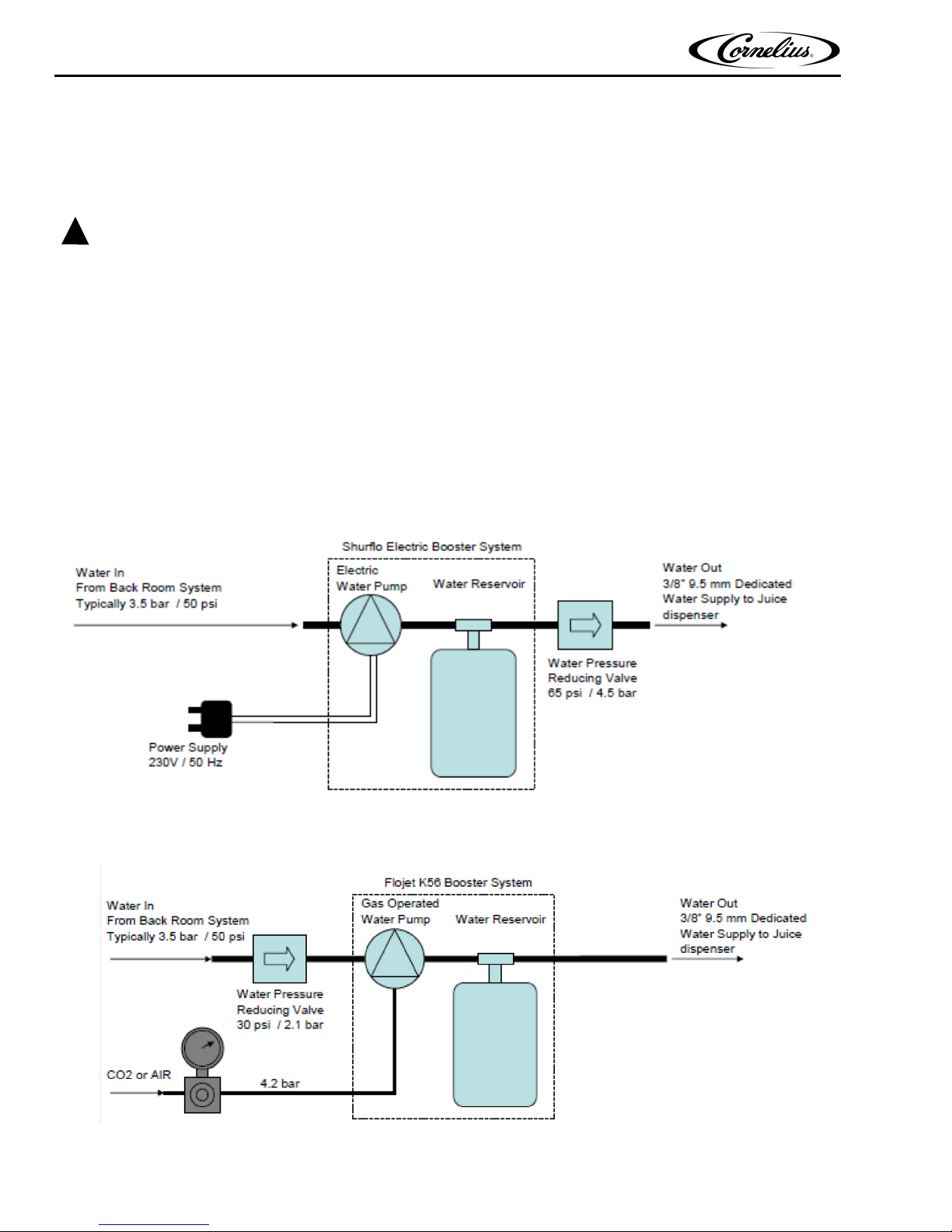

Water Booster System

Install the Water Booster system on the dedicated Quest Elite Water supply line.Preferred location is in the Back

Room Area and close to water- gas and/or electricity supply.

Electric Booster Installation Details

Gas-operated Booster Installation Details

Figure 3.

Publication Number: 620058442 - 5 - © 2013-2015, Cornelius Inc

Figure 4.

Page 10

Quest Elite QLT 2000

Booster Installation Notes:

Refer to the OEM manufacturers installation instructions

Boosters and accumulator tanks should be fed with AMBIENT

equipment failure, do not install the water booster assembly in the refrigerated water supply circuit.

water only. To avoid condensation and premature

To prevent pressure drops in the water supply line, use 3/8”

restrictions s.a. shut-off valves, manifolds and/or fitting.

/ 9.5 mm ID supply lines only. Limit the amount of flow

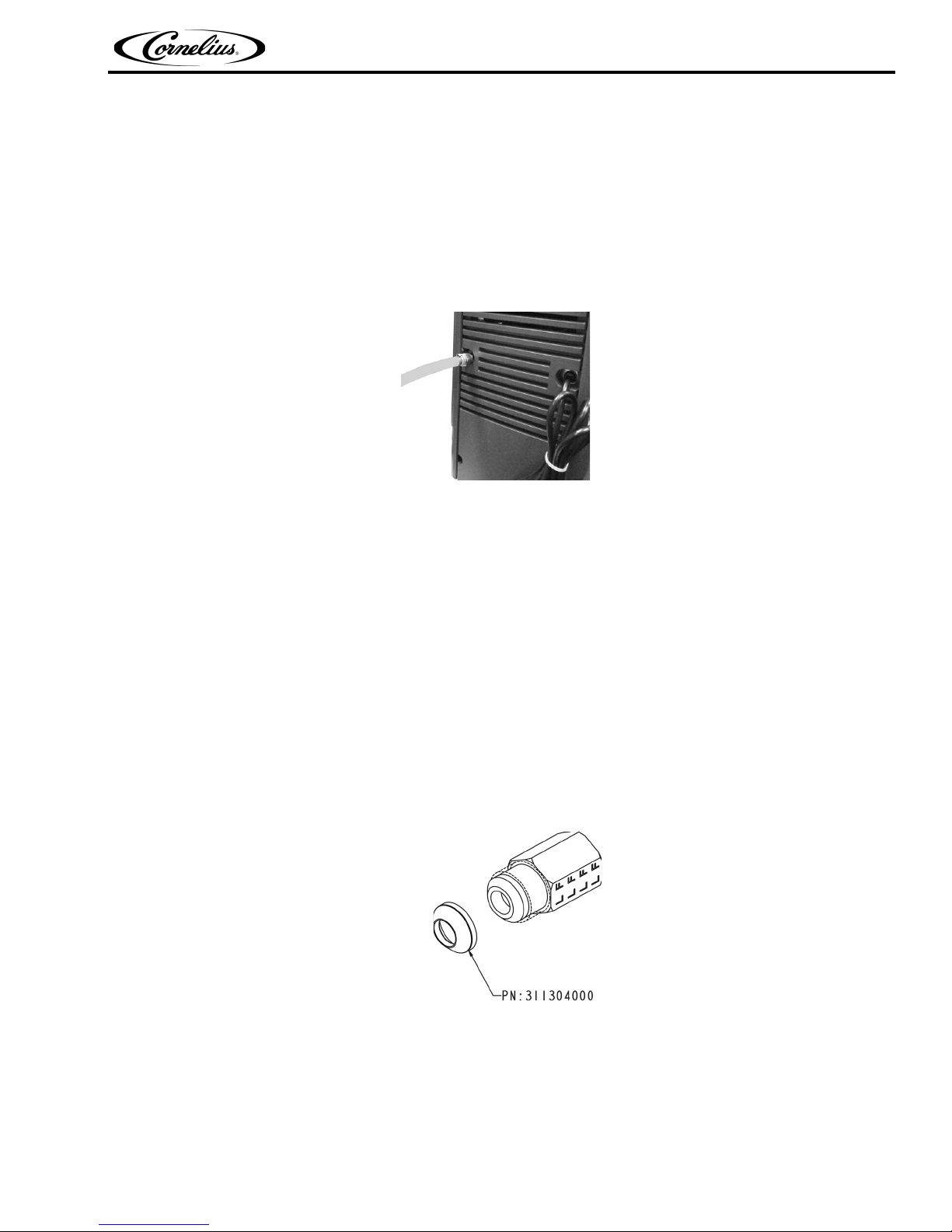

Water Connection

3/8 in. (0.95 cm) SAE male flare fitting on dispenser (see figure 5).

Figure 5.

The Quest Elite QLT 2000 series Juice Dispensing machine is designed to dispense juice at a high flow rate. It is very

important that the incoming water line is dedicated for the unit, or at least does not have other machines connected

which could cause a water surge, i.e., a dish washing or coffee machine.

Notes:

The unit should be fed by an insulated chilled water line from the soft drink beverage system. To achieve both optimal

brix control and sanitation, assure that the incoming water pressure is at least 60 psi (4.2 bar) dynamic coming from

the water booster system.

IMPORTANT:The water supply should be consistent with proper w

and should not be connected to a water softener. It is the installer’s responsibility to ensure that all water connections

to the dispenser are sized, installed with adequate backflow protection and maintained to comply with Federal, State,

and Local Laws.

A. Secure the 3/8” (0.95 cm) swivel nut on the flexible supply tubing to the water inlet located at the rear of the

ispenser. Make sure that the flared gasket is used (flared gasket P/N 311304000 is included with the

d

installation kit)

.

ater quality standards (neutral pH of 7.0 to 8.0),

B. When securing flare nut, use backup wrench on male side of the inlet fitting (unit side) to prevent twisting of

the copper tube inside the unit and/or possible damage to the water strainer/solenoid.

© 2013-2015, Cornelius Inc. - 6 - Publication Number: 620058442

Figure 6.

Page 11

Quest Elite QLT 2000

Flushing System

To properly prime the unit with water and remove air pockets in the

system, open the cabinet door and make sure the protective dust cap

is in place on top of the mixing chamber. Close the door and push the

“STOP” Button for a few seconds. Repeat until a steady flow of water is

observed.

NOTE: Water splashing may occur during this purge cycle.

Figure 7.

Filling the Water Bath

1. Remove the Splash Panel (2 screws next to drip tray brack-

ets) .

2. Release filling tube.

3. Remove the red cap.

4. Install the filling tube onto the RH

dispense nozzle.

5. Assure that the RH mixing chamber is capped off to prevent

he cabinet flooding with water.

t

6. Close the cabinet door, and push the dispenser button – dis-

pense water only

7. Fill the water bath until water e

vacuates from the overflow

8. Evacuate approx. ½ liter of water. This Eliminates dripping

rom the overflow when building the ice bank

f

9. Install the red cap onto the filling

tube, and replace into the

bracket

10. Allow the cabinet to reach 4°C prior to load any concentrate

to the cabinet. This takes approx. 1 hour

in

Figure 8.

Publication Number: 620058442 - 7 - © 2013-2015, Cornelius Inc

Figure 9.

Page 12

Quest Elite QLT 2000

REFILL

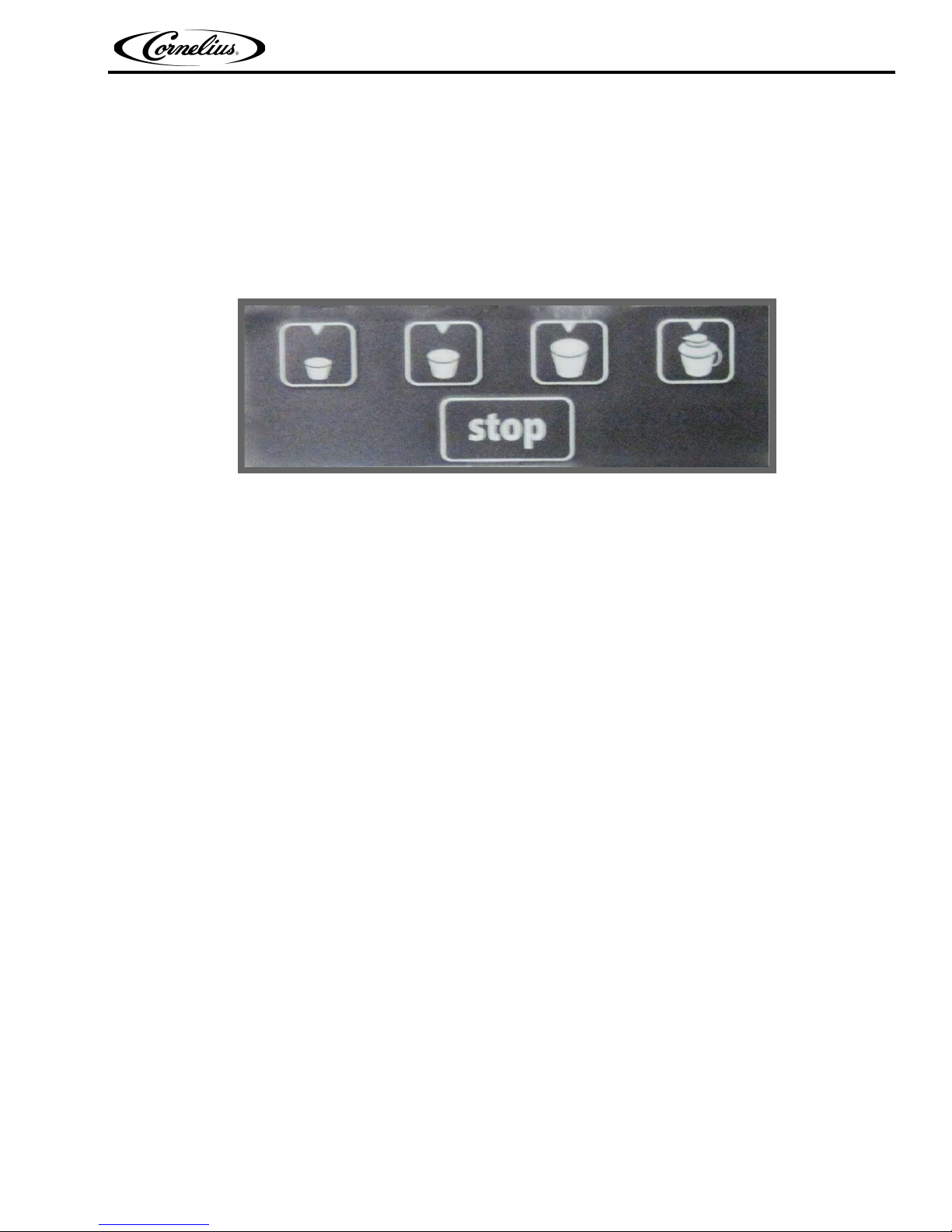

Programming the Portion Control

1. Simultaneously, press and hold “small” and “extra large” push button switches on the Portion Control Module until the “REFILL” light in the corner of the module starts blinking. Release the switches. The blinking

ht indicates the programming mode is active.

lig

2. Place the cup under the white mixing valve nozzle and push the selected size button (small, medium, large,

xtra large). Hold the button in until the cup fills to the desired portion, then release the button. Repeat

or e

the above procedure for the remaining sizes.

3. After programming all the drink sizes, press and release the “STOP BUTTON” to return the Portion Control

o the operational mode. The blinking REFILL light will go out.

t

Figure 10.

If in future it is decided to change the portion size of the drinks, the individual sizes can be adjusted by the above

procedure. It is not necessary to re-program every size. Additionally the portion control has a full memory retention in

case of a power failure.

To pour a drink without using a pre-programmed portion control size, simply push and hold the STOP BUTTON.

Release when the

glass is full.

© 2013-2015, Cornelius Inc. - 8 - Publication Number: 620058442

Page 13

Quest Elite QLT 2000

Loading With Concentrate Pouches – 6.5 Liters

1. Place the empty pouch holder on its back onto the counter.

2. Grab the pouch by the tube connector and place it vertically on the counter next

o the pouch holder.

t

3. Locate the silicon tube through the slot, and slide the top of the pouch inwards.

o not pull the silicone tube to guide the pouch into the pouch holder.

4. D

5. Tilt the pouch holder forward whilst pushing the connector and tube into the

p

roper slot position.

Figure 11.

Figure 12.

6. Slide the pouch connector upwards / towards the front of the pouch holder

7. Massage the pouch to f

ill the pouch holder

NOTE: Improper loading of the pouch into the pouch holder can cause:

• Unable to load the pouch holder into the cabinet.

• Excess remnant.

• Ratio/Brix variations above standards.

8. Open the Quest Elite Cabinet Door and slide the pouch holder onto the shelf.

Figure 13.

Figure 14.

Figure 15.

Publication Number: 620058442 - 9 - © 2013-2015, Cornelius Inc

Figure 16.

Page 14

Quest Elite QLT 2000

Loading with Concentrate Pouches – 3.0 & 4.5 Liters

1. Place the pouch holder on its side onto the counter.If applicable, first

remove the empty pouch and discard.

2. To open, push the sides of container slightly inwards on both sides

see arrows) and simultaneously turn open the lid.

(

3. Turn the lid to face upwards or all the way down to the counter.

4. Locate the silicon tube through the slot, and

place the pouch into the

pouch holder.

NOTE:

• Do not pull the silicone tube

• Load the concentrate pouch properly into the pouch holder

• Avoid concentrate being trapped in the corners

Figure 17.

Figure 18.

5. Close the pouch holder lid.

© 2013-2015, Cornelius Inc. - 10 - Publication Number: 620058442

Figure 19.

Figure 20.

Page 15

Quest Elite QLT 2000

6. Open the cabinet door, open the QLT pump and slide the pouch holder onto

the pouch holder shelf.

7. Locate the silicone tube into the pump and close the pump slide.

Connecting the silicone tube onto the Mixing Chamber

1. Remove the Nozzle with the Static Mixer, remove the Mixing Chamber and

place onto the drip tray

2. Position the silicone tube into the QLT pump

Figure 21.

3. Close the pump and remove the red stopper from the silicone tube

NOTE:

• Verify that the tube is properly loaded, not jammed between the pump

slides

• With single 6.5 liter pouch operation, the left hand valve might be either

led or used for dispensing still / chilled water

disab

Publication Number: 620058442 - 11 - © 2013-2015, Cornelius Inc

Figure 22.

Figure 23.

Page 16

Quest Elite QLT 2000

CAUTION:

!

4. Connect the nipple of the mixing chamber onto the silicone tube

5. Hold the mixing chamber sideways when sliding the nipple onto the silicone tube

6. Slide the Mixing chamber in position and push firmly into the pump deck.

Make sure that the lid of the mixing chamber is properly installed and screwed on

tight.

Failure doing so will cause the entire chamber to flood with drinks and

eliminating the anti-splattering effect.

Figure 24.

7. Replace the Nozzle and Static Mixer, and close the cabinet door

Priming:

Place a small cup onto the drip tray and press the cancel/Pour button for 2 seconds

to prime the mixing system

If only water leaves the nozzle, check if the RUN/FLUSH switch onto the pump

orm is placed in the RUN position

platf

Figure 25.

Figure 26.

© 2013-2015, Cornelius Inc. - 12 - Publication Number: 620058442

Page 17

Quest Elite QLT 2000

PLANNED MAINTENANCE

Daily – Flushing the system

1. Set both flush switches to “Flush” position.

2. Open the cabinet door. Move both LH and RH flush switches from the

“Run” position to the “Flush” position. Close the cabinet door.

3. Place small cold-drink cup under each dispensing nozzle.

4. Place a small, empty, cold-drink cup on the drip tray under the nozzles.

5. Flush nozzles.

6. Push the Cancel/Pour dispenser switches and hold down for 2 or 3 seconds, until clear water is dispensed from both nozzles

Figure 27.

Figure 28.

7. Reset the flush switches to “Run” position.

8. Open the cabinet door. Move the flush switches from the “Flush” position to

the “Run” position. Close the cabinet door.

9. Clean nozzles and mixers.

10. Turn the nozzle to the left or right ¼ turn and pull down to remove the noz-

zle and static mixer. Take the nozzles and static mixers to the three-compartment-sink. Rinse both with hot tap water to remove any pulp.

11. Replace nozzles and mixers.

12. Reinstall the nozzles and static mixers on the dispenser.

Figure 29.

Figure 30.

Figure 31.

Figure 32.

Publication Number: 620058442 - 13 - © 2013-2015, Cornelius Inc

Page 18

Quest Elite QLT 2000

13. Clean outside of cabinet.

14. Wipe down the outside of the cabinet and the splash panel with a cleaned

towel. Place the towel in the soiled towel bucket.

Weekly – Sanitizing Dispense Parts

1. Perform the DAILY Cleaning Procedures

2. Disconnect mixing chambers from concentrate pouch tubes and remove mixing

chambers.

3. Remove the chambers by pulling it firmly toward you.

NOTE:Do not open the pump while the concentrate tube is disconnected

from the mixing chamber.

4. Disassemble the mixing chambers

Figure 33.

Figure 34.

5. Screw off the lids counter-clock-wise from the mixing chambers bodies prior to

sanitizing.

6. Wash, rinse, and sanitize mixing chamber, nozzle, and static mixer.

7. Wash the mixing chamber, nozzle, and static mix at the three-compartment-sink.

Be sure all pulp is removed. Rinse with hot tap water and sanitize the parts.

8. Reassemble the mixing chambers and reconnect to concentrate pouch tubes.

9. Reinstall the parts in the juice dispenser.

10. Reinstall nozzles and static mixers.

11. Reinstall the parts in the juice dispenser.

12. Clean outside of cabinet.

13. Wipe down the outside of the cabinet and the splash panel with a cleaned towel.

Figure 35.

Figure 36.

Figure 37.

© 2013-2015, Cornelius Inc. - 14 - Publication Number: 620058442

Figure 38.

Page 19

Quest Elite QLT 2000

14. Dispense a small portion juice to prime the mixing chambers.

15. Press the dispense button to fill a small c

old-drink cup with juice. Discard the

juice.

Weekly – Check Ratio (Prodecure)

1. Turn the nozzles to the left or right ¼ turn and pull down to remove the nozzles

and static mixers.

2. Disconnect mixing chambers from concentrate pouch tubes and remove mixing

chambers

3. Remove the mixing chambers by pulling firmly toward you.

.

Figure 39.

Figure 40.

4. Check the concentrate supply

NOTE:Assure that the concentrate pouch is not near empty, properly

loaded into the pouch holder and that the silicone tubes are properly installed into the pumps

5. Install the QLT syrup splitter assembly and

connect the silicone tube onto the

syrup tube.

6. To prevent incorrect ratio readings, do not pull or stretch the silicone tube while

nnecting to the splitter tube.

co

7. Close the cabinet door, place a medium cup onto the drip tray and under the splitter tubes and push the Cancel/Pour button for 1 second to prime the splitter tube

ill with concentrate

and f

Figure 41.

Figure 42.

Figure 43.

Publication Number: 620058442 - 15 - © 2013-2015, Cornelius Inc

Figure 44.

Page 20

Quest Elite QLT 2000

8. Place the RVC onto the drip tray and the water and concentrate chambers

locating under the splitter tubes

9. Dispense Water and Concentrate into the RVC

10. Push the Cancel/Pour button until approx. 300 ~ 350 ml of water has dispensed into the RVC water chamber.

11. Read the RATIO from the RVC

12. Place the RVC onto a flat surface and read both water and syrup volumes.

Figure 45.

Figure 46.

13. Calculate the Water to Concentrate Ratio.

14. With standard Orange Juice, the Ratio 5 to 1 with a maximum of 5.2 and a

minimum of 4.8.

15. Ratio too low: Increase water flow.

16. To correct too low ratio, increase the water flow.

17. Turn the water flow control screw to the right (clockwise) ¼ turn. Check

the Ratio again by repeating above steps with a new sample in the RVC.

18. Ratio too high: Reduce water flow.

19. Turn the water flow control screw to the left (counterclockwise) ¼ turn.

Check the Ratio again by repeating above steps with a new sample in the

RVC.

Figure 47.

Water ml/

Ratio =

Concentrate ml

Figure 48.

Figure 49.

© 2013-2015, Cornelius Inc. - 16 - Publication Number: 620058442

Page 21

Quest Elite QLT 2000

20. Replace the mixing chambers and reconnect to concentrate pouch tubes.

21. Reinstall the parts in

the juice dispenser.

22. Sanitize the syrup splitter and put aside in a safe and clean location

Monthly - Clean the Air Condenser Filter

1. Pull the magnetic filter off the rear panel of the juice dispenser.

2. Clean the filter in a bucket of warm soapy water.

Figure 50.

Figure 51.

3. Place the filter on a clean, sanitized towel to allow it to air dry.

4. Place the filter on the rear panel of the juice dispenser.

Figure 52.

Figure 53.

Figure 54.

Publication Number: 620058442 - 17 - © 2013-2015, Cornelius Inc

Page 22

Quest Elite QLT 2000

Semi-Annually - Clean the Water Inlet Strainer

1. Pull the AC plug from the wall outlet

2. Remove the right side panel from the dispenser.

3. Turn off the water supply to the dispenser.

4. Remove the access port from the “Y” shaped water inlet solenoid

cated on the right side of the dispenser.

lo

5. Clean and reinstall the stainless steel water strainer.

Figure 55.

Figure 56.

Annually - Cleaning the cabinet

The cabinet bottom surface and walls should be inspected and cleaned annually following the instructions below.

1. Remove natural rubber nozzle bushing gasket

and inspec

cleam off RTV and re-apply using kit P/N

729011013 per instructions provided with the

Kit.

2. Re-apply nozzle bushing gaskets so that the

ges lie flat ont the floor of the cabinet.

ed

3. Clean the cabinet floor and w

juice and let dry. Use a mild soap/detergent

and plain water.

4. Re-install the pump platform in the reverse

der given above.

or

For more information, refer to the Planned Maintenance Cards found in the Appendix of this Manual.

Daily maintenance tasks

BE 20 D1Flush orange juice system.

Weekly maintenance tasks

BE 20 W1Sanitize orange juice system.

t it and Silicone RTV.If cracked,

alls of any spilled

BE 20 W2Check orange juice Ratio.

Monthly maintenance tasks

BE 20 M1Clean condenser filter.

© 2013-2015, Cornelius Inc. - 18 - Publication Number: 620058442

Page 23

Quest Elite QLT 2000

TROUBLESHOOTING GUIDE

The following tables contain trouble-shooting information intended to aid an experienced service person in diagnosing

operational problems that may occur. For further assistance, contact the Cornelius Customer Services department at

800-238-3600 between the hours of 7:30A.M. and 5:00P.M. Central Standard Time. You must have the model and

serial number (Located on the right side of the dispenser) when calling.

Symptom Probable Cause Remedy

Unit totally inoperative

No Cooling

No water dispensed, concentrate only

A. No power to dispenser due to tripped cir-

cuit breaker.

B. Loose or broken power supply connection

inside dispenser.

A. Line voltage not within nameplate specifi-

cation causing compressor overload to trip.

B. No water in water ice bath or water level

extremely low, exposing ice bank sensing

probe.

C. Defective Ice Bank Control or sensing

probe.

D. Cabinet fan inoperative resulting in warm

concentrate (water continues to cool).

E. Compressor short cycles on overload.

F. Compressor starts but hums & trips over-

load.

G. Defective compressor overload or start

capacitor.

H. Compressor starts but does not switch off

of start winding.

I. Refrigerant leak.

A. No water in dispenser.

B. Water supply line inside refrigerated cabi-

net disconnected from pump platform.

C. Water solenoid located on pump platform

clogged or defective.

D. Main water solenoid/strainer located at the

rear of dispenser is clogged, binding or

defective.

E. Water supply pressure is greater than 80

psi (5.5 bar) forcing BRIX flow control

closed.

F. Freeze-up of water coil in ice bath.

A. Reset circuit breaker. Confirm that breaker

is correct size & no other equipment is

operating on the same circuit. Also confirm

that supply voltage is +/-10% of nameplate

specification.

B. Repair connection.

A. Contact an electrician.

B. Fill ice bath to proper water level.

C. Replace.

D. Replace.

E. Excessively high discharge pressure due

to restricted condenser or inoperative condenser fan motor.

F. Seized or shorted compressor, replace.

G. Test & replace.

H. Relay or compressor is defective. Test &

replace faulty item.

I. Repair leak, evacuate & recharge system.

A. Restore water.

B. Reconnect

C. Disassemble & clean solenoid. Replace if

necessary.

D. Remove & clean strainer. Confirm 24VDC

is present at solenoid during dispense.

Confirm solenoid coil is not open. Disas

semble & clean solenoid.

E. Add external regulator & lower pressure to

50 psi (3.5 bar).

F. Unplug dispenser & allow 2-4 hrs. to thaw.

Check operation of agitator motor & ice

bank control.

Refrigeration system may be low on

charge resulting in a deformed ice bank &

freeze-up of water coil in ice bath.

-

Publication Number: 620058442 - 19 - © 2013-2015, Cornelius Inc

Page 24

Quest Elite QLT 2000

Symptom Probable Cause Remedy

A. Black service switch located on the rear of

A. Turn on switch.

the cabinet door in OFF position.

No water & no concentrate,

refrigeration is working.

No concentrate dispensed,

water only.

Warm drinks

Water continuously drips

from nozzle in OFF mode.

B. White door switch open

C. 6.25 amp fuse inside front electrical box

blown.

D. No output from transformer.

E. Defective voltage regulator board (VRB)

located inside front electrical box.

F. Defective dispense push button or portion

control board.

A. Concentrate container not fully engaged

into receptacle on pump platform.

B. Dispense/Flush lever in FLUSH position

C. Concentrate too cold, not properly thawed.

D. Defective pump motor.

A. Ambient air around dispenser is too warm.

B. Excessive demand on dispenser.

C. Dirty condenser coil.

D. Inoperative condenser fan.

E. Defective Ice Bank Control.

F. Loss of refrigerant charge due to leak in

system.

A. Main water solenoid at base of unit or

water solenoid on pump platform not shut

ting off completely.

A. Cabinet fan inoperable.

B. Door switch must be closed in order to dis-

pense. Check switch operation & replace if

necessary.

C. Replace with 6.25, 250VAC slow blow fuse

& test.

D. Confirm transformer output of 24VAC +/-2.

Replace transformer if necessary.

E. Measure across the VDC output of the

board. There should be 28VDC present

when the dispense button is pressed.

Replace VRB if necessary.

F. Test & replace if necessary.

A. Refer to Concentrate Loading section of

this manual.

B. Move lever to DISPENSE position

C. Concentrate should be 35 to 40°F (1.7 to

4.5

°C) prior to loading.

D. Replace pump motor.

A. Relocate dispenser.

B. Add water pre-cooler or second dispenser

C. Clean condenser coil.

D. Replace condenser fan motor.

E. Test & replace if necessary.

F. Repair leak and recharge system.

A. Clean solenoid(s), replace parts as neces-

-

sary (refer to Planned Maintenance section).

A. Check/replace fan.

Concentrate warm, water

B. Agitator motor/pump inoperable or

cold.

C. Loss of refrigerant charge due to leak in

A. Water supply pressure too low, less than

B. Water flow control binding or spring is

BRIX problem

C. Improperly thawed concentrate. BRIX

© 2013-2015, Cornelius Inc. - 20 - Publication Number: 620058442

restricted.

system.

20 psi (1.4 bar) flowing water pressure.

defective.

changes as concentrate temperature

changes (concentrate becomes thinner as

temperature rises)

B. Check/replace agitator motor.

C. Repair leak & recharge system.

A. Correct water supply problem to ensure a

constant 50 psi (3.5 bar) flowing to dis

-

penser.

B. Clean and/or replace parts as necessary.

C. Concentrate should be 35 to 40°F (1.7 to

4.5

°C) prior to loading.

Page 25

Quest Elite QLT 2000

Symptom Probable Cause Remedy

A. Pump motor defective.

A. 28VDC should be present at pump motor

during dispense. If voltage is present &

motor does not start, replace motor.

Pump inoperative

Machine continues to dispense after dispense button

is released or dispenses

without operator input.

Water leaking from the cabinet through the cabinet

drain into the drip tray.

B. No power to transformer or no 24VAC out-

put from transformer.

C. Defective voltage regulator board (VRB)

located inside front electrical box.

D. Defective dispense control board (Push

button or portion control).

A. Push button or portion control pad stuck in

ON position.

B. Relay on voltage regulator board (VRB)

stuck on.

A. The O-ring from the cabinet quick connec-

tor might be damaged or missing.

B. Confirm transformer has line voltage pres-

ent on primary side. If no 24VAC output

from secondary, replace transformer.

C. Confirm board produces 28VDC present

when dispense button is pressed (refer to

Electrical Box Wiring Diagram for VDC output location). Replace VRB if necessary.

D. Test & replace if necessary.

A. Disconnect wire harness from rear of por-

tion control and close the door. If unit does

not dispense on its own, dispense control

board is bad (stuck on).

B. Disconnect 4-wire harness from lower right

comer of VRB. If unit continues to dis

pense on its own VRB is defective (relay

stuck on).

A. Replace the O-ring

Publication Number: 620058442 - 21 - © 2013-2015, Cornelius Inc

Page 26

Quest Elite QLT 2000

WIRING DRAWING FOR QUEST ELITE QLT-2000

© 2013-2015, Cornelius Inc. - 22 - Publication Number: 620058442

Figure 57.

Page 27

Quest Elite QLT 2000

Figure 58.

Publication Number: 620058442 - 23 - © 2013-2015, Cornelius Inc

Figure 59.

Page 28

QLT 2000 FINAL ASSEMBLY

Quest Elite QLT 2000 Illustrated Parts List

Item Part No. Description

1 620047969 Hinge Top Cover, Quest Elite 2/4 FL

2 620047744 Merchndsr Assy Qst2 2FL

3 620054876 Side Panel LH. Quest Elite 2/4 FL

4 620049855

5 620708562 Cup Rest W/LOC Quest 2 STND 8.1 X

6 620048648 Splash Panel Guard, Quest Elite 2 FL

7 620715835 Nozzle Static Mixer ASMB

8 620049092 Tank Foamed Qste Finish 2FL

9 620054875 Side Panel RH. Quest Elite 2/4 FL

10 620050923 Rear Panel, Quest 2 FL

13 620048898 Top Panel W/Cut, QST Elite 2 FL

14 720704004 Door Catch, Female 2FL / 4FL

16 620049566 Washer- Hinge Bottom QST Elite 2/4FL

17 620047782 Pin Latch Cabinet Qst2 2FL/4FL

Drip Tray, Black W/Texture, Quest Elite 2

FL

Figure 1.

Item Part No. Description

18 0704105 Screw MA #8-32 TRPH 16 SS

19 70178 Screw MA #8-32 TRPH 16 SS

620047429 Brkt, Drip Tray, Right, QST 2/4 FL

20

620047428 Brkt, Drip Tray, Left, QST 2/4 FL

21 37958 Leg Level 4”

22 720201440 Brkt, Catch Strike Plate QST-NT

23 720701405 Screw TB D6-18 PAPH 12 SS

24 620048922 Kit Literature Pkg QST 2FL (not shown)

25 620048649 Label System Wiring Diagram QS

26 620047943 Harness Door, QST2, 2FL (not shown)

27 620048959

28 11732

29 620049320

Harness to Power Cord QST2, 2/4FL

(Not Shown)

Harness Assembly Platform SLJ 1000

(Not shown)

Harn Combined Compressor Condenser

QST Elite 2/4FL (Not Shown)

© 2013-2015, Cornelius Inc - 24 - Publication Number: 620058442

Page 29

Quest Elite QLT 2000 Illustrated Parts List

1

2

3

12

13

4

15

14

5

7

6

8

9

17

10

16

QLT 2000 DOOR ASSEMBLY REFERENCE (PUSHBUTTON & PORTION

ONTROL)

C

Item Part No. Description

620047753 Overlay Assembly, Pushbutton Control, Quest

1

620047750

620047751

2

620047968

3 620047745 Merchandiser, Quest Elite, 2FL

45018001 Board Push button SLJ

4

49280001 Board Portion Control SLJ

620047679-

5

100

6 620047754 Assembly, Door Foamed, Quest Elite, 2FL

7 620051427 Switch Rocker Unmarked Qste 2FL/4FL

8

720704005 Latch Door Male

9 620047759 Seal, Door, Quest Elite, 2FL

10 720500713 Switch Cut off 10 A MOM E6900A

11 620049097

Overlay Assembly, Portion Control, Quest Elite,

2/4

Bezel, Push button, Silver, Quest Elite, 2FL /

4FL

Bezel, Portion Control, Silver, Quest Elite, 2FL /

4 L

LED Quest PCBA Backlight Family

Label Triangle Nozzle Indicator Mirror Finish

QST2 2FL/4FL

Figure 2.

Item Part No. Description

12 729011214 Kit, Lock & Key Door Quest Elite 2FL/4FL

13 620047748 Latch Mounting Lock

62004776126

14

620047761 Graphic- Merch Generic QST2 2FL

15 620047760 Lens, Quest Elite, 2FL

16 0704101 Screw MA 8-32 TRPH 12 SS

620052150 Label Daily Flush & Cleaning Quest Elite Qlt

17 620052151 Label Daily Flush & Cleaning SLJ Flush

620052153 Label Daily Cleaning QSTE Non Flush

629097007

18

629097008

729011218

19

729011219

NS 620050925 Label Rocker Switch Details, Qste,230v, 2/4FL

Graphics Merchndsr MM Europe Qste 2FL

Kit 1, Flavor Strip Quest Elite, 2/4FL (Not

shown)

Kit 2, Flavor Strip Quest Elite, 2/4FL (Not

shown)

Kit, Conversion PB to PC, QSTE 2FL (Not

Shown)

Kit, Conversion PC to PB, QSTE 2FL (Not

Shown)

Publication Number: 620058442 - 25 - © 2013-2015, Cornelius Inc.

Page 30

CABINET ASSEMBLY REFERENCE

14

15

Quest Elite QLT 2000 Illustrated Parts List

Item Part No. Description

1

620049842

720506104 Fan Assembly 115/60/50 4.7 X 4.7X1.0

2

720506105 Fan Assembly 230/50/60 4.7 X 4.7 X1.0

3

620047512 Guard, Fan EBM 9000 & 4000

4

620049556

5

720509206

Cabinet Assy QST Elite 2FL Modified

Drain

Cabinet Heat Exchanger, Quest Elite,

2FL

Fitti

ng Push, Union Elbow, 3/8”X 1/2”

LG

Figure 3.

Item

Part No. Description

6

620047970 Trim Bottom W/Insert, Quest Elite, 2FL

7

720201479 Bracket Dual Nozzle Block Quest

8

07040007 Screw Machine, #8-32 PAPH 28SS

9

720522100X Platform Asy Qlt Qst 2000

11

S3354 Gasket Sealing Bowl Spout

14

720200206

15

620047775 Brkt Hinge QST2 2FL/4FL

Fitg Insrt 3/8"NPT PP

© 2013-2015, Cornelius Inc - 26 - Publication Number: 620058442

Page 31

Quest Elite QLT 2000 Illustrated Parts List

3

2

4

5

TANK COVER ASSEMBLY

P/N 620047892

Figure 4.

Item Part No. Description

729011222 Kit Service Ice Probe Assy QSTE 2FL

2

3 720521000 Box Elec Asy Dc QST2 QLT

4 720501502 Coil, Water, QUEST 2, 2FL

5 620049563 Coil, Refrigeration QUEST Elite 2FL

Publication Number: 620058442 - 27 - © 2013-2015, Cornelius Inc.

Page 32

REFRIGERATION FRAME ASSEMBLY QLT 2000

Quest Elite QLT 2000 Illustrated Parts List

Item Part No. Description

629097391 Kit Comp 115V/60HZ QST 2 FL

1

629097392 Kit Comp 230V/50HZ QST 2 FL

629097393 Kit Comp 220V/60HZ QST 2 FL

3 620048659 Adapter, 1/4”FPT x 3/8”MF

620049959- 001

620049959- 003 Cord, Service 230V

4 620049959- 007 Cord Serv 200V 60 HZ IEC 60906-1

620049959- 008 Cord Pwr ME Version QSTE 2/4FL

620049959- 009

620042742 Agitator Motor Assembly 115V

5

620042741 Agitator Motor Assembly 230V

6

620047892 Tank Cover Assembly, Quest Elit, 2FL

729011138 Kit GIBC Field Quest (Not Shown)

7

440000901 Control Ice Bank 230V Global

440000902 Control Ice Bank 120/60 QST

8 620047891

9 620049857 Reducer, Elbow, 1/4” FPT x 3/8” Barb

10 620047114 2 Cubic Inches, Filter Dryer

Cord Power Straight IEC60320-C13

Family

Cord PWR QSTE 2/4FL Cei-16/Vii Italian Plug

Valve Water W/Solenoid, Quest Elite, 2/

4FL

Figure 5.

Item Part No. Description

560004366 Fan Axial Small

560003706

11 560004360 Motor- Fan 08W 120/60 Service

560004368 Grille Cond Fan Small

560004364 Shroud Cond Olympus Small

6775 Clip Tin CB14-832-4

12

047655 Transformer, 115V, Quest Elite 2/4FL

620

13

620047654 Transformer, 230V, Quest Elite 2/4FL

14 9649 Washer Comp Mount

15 317781000 Bushing, Split

17 08474 Clip Spring

18 620058691 Suction HX Assembly, Quest Elite 2FL

19 620049560 Grommet Ae Comp QST2

20 620058692 Line Discharge Quest 2Fl

21 49034 Tube Tygon 3/8ID X 5/8

22 620054202 Brkt Solenoid Quest Elite 2/4FL

23 620049859 Tube Asy Water Inlet To HX QST2FL

Fan, Condenser Assembly, 230V, Quest

Elite 2FL

© 2013-2015, Cornelius Inc - 28 - Publication Number: 620058442

Page 33

Quest Elite QLT 2000 Illustrated Parts List

PLATFORM ASSEMBLY QLT

P/N 720522100X

Item Part No. Description

1

07032001 Screw #8-18X 7/16 Type 25 HHW

2

0704105 Screw MA #8-32 TRPH 16SS

3

720701001 Rivet Platform Base Quest

4

11877

5

11887

6

11888

45046 Latch #2 Medium SS

7

45047 Guide Latch #2 MED

8

45048 Washer Latch #2 MED

9

10 45364001X

Publication Number: 620058442 - 29 - © 2013-2015, Cornelius Inc.

Jumper Assembly Read Flush QLT

180(Not Shown)

Jumper Assembly Red Flush Switch

AL (Not Shown)

ness Assembly Platform

Har

SLJT1000-2(Not Shown)

Chamber Mixing Assembly QLT 180

Day

Figure 6.

It

em Part No. Description

45432 Switch Rocker Sealed

11

45508200X Valve Block Assembly QLT Generic

12

45514100X Pump Assembly QLT 180

13

45542 Manifold Bracket QLT 180 2 FLAV

14

55145

15

720509312 Manifold Assembly Water QLT/QST2

16

720520301 Base Platform QLT QST2

17

720522011 Bracket Support Platform QST2

18

7245541 Label Run Flush QLT 180

19

7245821 Label Clean

20

720501429 Bracket Water Adjustment Cover QS

21

07115001 Screw TF 8-32 TRPH 12SS

22

Wrap, Tye 5 1/2 inch Long (Not

Shown)

Page 34

VALVE BLOCK ASSEMBLY

P/N 45508200X

Quest Elite QLT 2000 Illustrated Parts List

Item Part No. Description

1

45506100 Valve Block

2

45586 Hold Down Washer

3

49612 Valve Port, Water

4

620711131 Seal Armature - Water Side

5

71860290 Armature

6

71815321 Retaining Ring, 0.242 ID

7

18367 Coil Spring, SS

8

31525020 O-Ring 5/16” OD X 0.176 ID

9

19695001 Guide

10

620710107 Gasket FFV/SEV

11

45518 Bracket, Valve Block

Figure 7.

Item

Part No. Description

07032001

12

16779003 “C” Frame, Solenoid

13

48520001 Coil, 24VDC

14

0720406 Not #10-32 KEPS

15

60281001 Ceramic Sleeve, Syrup, FFV

16

60280002 Ceramic Piston, Water, FFV

17

31525060 O-Ring 0.539” X0.459” X0.875” OD

18

48979103

*

7245699 Flow Control/Bonnet Assembly

19

48258005 Spring, Zero, FFV

20

45587 Hold Down Washer

23

Screw, #8-18 X 7/16” Type “25” HHWF

SS

ve & Piston Asy Water Ceramic

Slee

(Include items 16, 17&18)

© 2013-2015, Cornelius Inc - 30 - Publication Number: 620058442

Page 35

Quest Elite QLT 2000 Illustrated Parts List

ELECTRICAL BOX ASSEMBLY

P/N 720521000 (FOR QLT DISPENSERS ONLY)

Item Part No. Description

1

07115001 Screw TF, #8-32 TRPH, 12 SS

2

45621 Label Pump Speed Switch

3

720901002 Label Wiring E-Box

4

45758 Label Fuse Rating

5

720522003

720521001 Electrical Box Quest 2000

6

Publication Number: 620058442 - 31 - © 2013-2015, Cornelius Inc.

Wire Ha

QST 2000 QLT

rness Internal Electrical Box

Figure 8.

Item

7

8

9

10

11

12

Part No. Description

720521500

45432001 Rocker Switch Assembly

720521201 Cover Electrical Box Quest 2000

59328001 Fuse 6.25 AMP 250V SLJ

7245059 Fuse Holder

734801 Rivet, Pop

Reg. Voltage Assembly QLT Quest

2000

Page 36

POUCH HOLDER ASSEMBLY

Item Part Number Description

620053167 Pouch Holder 6.5 liters – Stainless Steel (for 1 x 6.5 L)

620053165 Pouch Holder 3.0 liters – Stainless Steel (for 3 + 6 L)

1

620053166 Pouch Holder 6.0 liters – Stainless Steel (for 3 + 6 L)

Quest Elite QLT 2000 Illustrated Parts List

Figure 9.

620053164 Pouch Holder 4.5 liters – Stainless Steel (for 2 x 4.5 L)

2 620051471 Pouch Holder Shelf

© 2013-2015, Cornelius Inc - 32 - Publication Number: 620058442

Page 37

Quest Elite QLT 2000 Illustrated Parts List

RECOMMENDED SPARE PARTS BASED ON 10 UNITS

Qty. Part No. Description

Qty. Part No. Description

1 620042742 Agitator Motor - 115/60 VAC

Agitator Motor - 230/50 VAC

1 620042741

Agitator Motor - 220/60 VAC

620058690 Compressor 115/60 QE 2/4

1

620059657 Compressor 220/60 QE 2/4

620058693 Compressor 230/50 QE 2/4

1 560003706 Cond-Coil & Fan 07W 230/5/6.2

1 560004360 Condenser Fan, Motor 115 VAC

1 560004361 Condenser Fan, Motor 230 VAC

1 560004364 Fan Shroud

1 560004368 Grill Fan

1 560004360 Motor-Fan 08W 120/60 Service

2 18367 Spring, Coil S/S-Water Solenoid

4 45098 Pump Tubing Kit

1 620051427

1 720301104 Switch Rocker Sealed

2 720521500 Voltage Regulator Board, QLT

2 45016001 Pump Dear Motor

1 45026100

Switch Rocker Unmarkedv QSTE 2/

4FL

Bottle Adapter O-Ring Kit (all O-rings

in bottle adapter)

1 720520501 Drip Tray Grill

1 720500102 Drip Tray

1 720502800 Agitator Motor

2 720506104 Cabinet Fan, 115VAC

1 620042741 Agitator Motor Assembly 230V/50Hz

1 720507101

1 720508801 Push Button Control Board

2 720508802 Portion Control Board

1 620047654 Transformer 230 V 50/60 VAC QE 2/4

1 620047655 Transformer 120 V 60Hz 26V@4A2

1 620047891 Valve Water W/solenoid QS T2 2/

1 620049856 Drip Tray Black W/texture QS T

1 620047654 Transformer 230V 60 230V 26V@4A2

1 720506104 Fan Assembly 115/60/50 4.7X4.7X1.0

1 620059661

1 620062280

1 620062281

1 620062282

1 620062283

Dispense Nozzle, Static Mixer, & ORing

Relay Compressor TH0410YXA,115/

60

Overload Olp For Compressor

THA0410Y XA,115/60

Relay Compressor THA0412YXC ,

230/50

Overload Olp For Compressor

THA0412YXC, 230/5

Relay Compressor AZA0395YXP,

220/60

1 45728001 Pump Rotor Assembly

1 48520001 Coil, 24 VDC, Valve Block

2 48979103

1 440000902 Global Ice Bank Control

Publication Number: 620058442 - 33 - © 2013-2015, Cornelius Inc.

Spool & Sleeve Assembly W/31525060 O-Ring

1 620062284

Overload Olp Compressor

AZA0395YXP, 220/60

Page 38

Page 39

Cornelius Inc.

www.cornelius.com

Loading...

Loading...