Cornelius QLT 180 BEVERAGE DISPENSER Installation Manual

INSTALLATION

&

SERVICE

MANUAL

MODEL

QLT180/1000-1,

1002-1, & 1001-1

IMI

CORNELIUS INC.

One Cornelius Place

Anoka,

MN

55303

Tel:

1-800-238-3600 / 763-421 -61 20

Fax:

763-422-3226

Part

No.

8531 2001

Revision-

July

C

22,2002

Installation & Service Manual

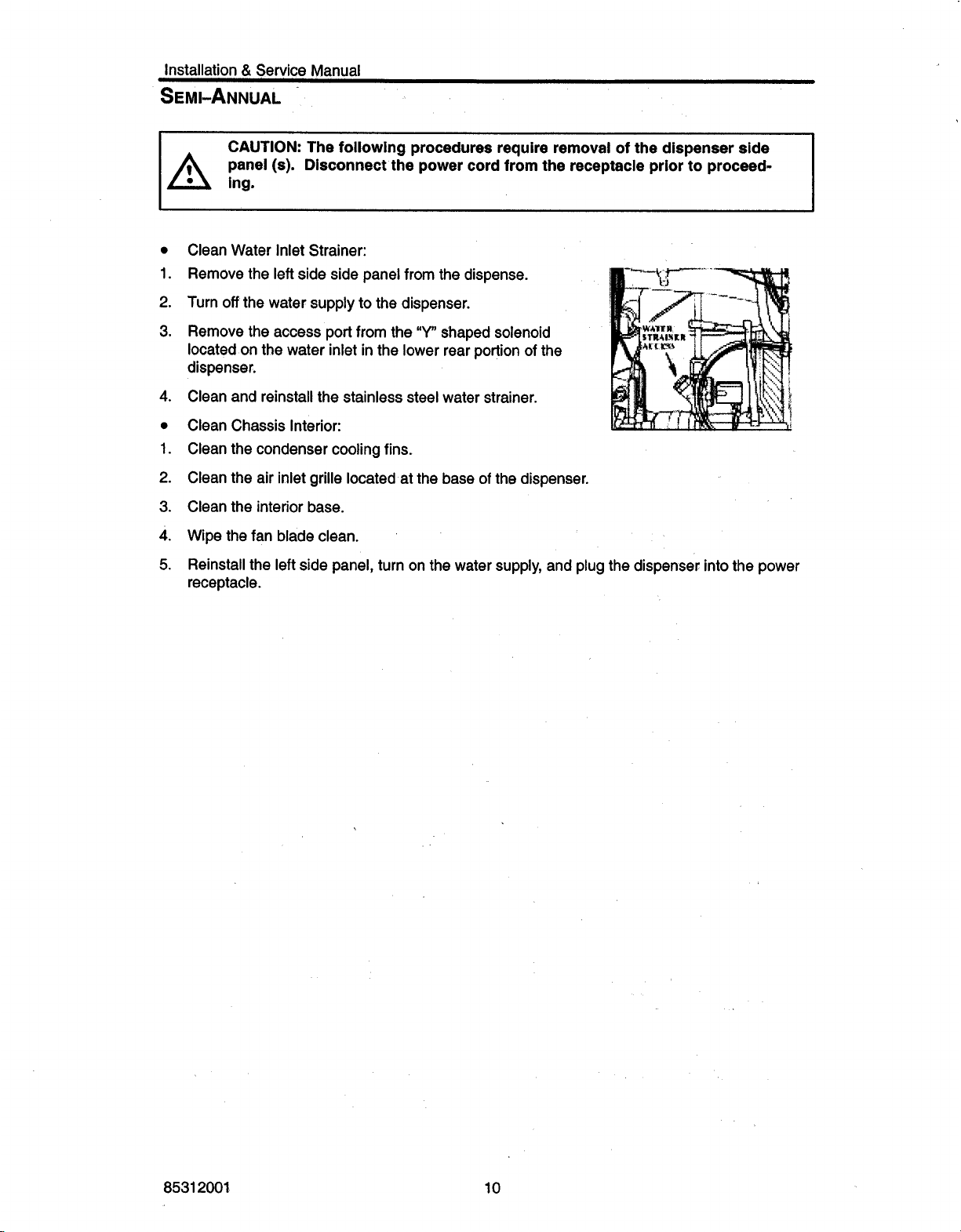

SEMI-ANNUAL

CAUTION: The following procedures require removal of the dispenser side

panel

A

0

1.

2.

3.

4.

0

1.

2.

3.

4.

ing.

Clean Water Inlet Strainer:

Remove the left side side panel from the dispense.

Turn

off

the water supply to the dispenser.

Remove the access port from the

located on the water inlet in the lower rear portion

dispenser.

Clean and reinstall the stainless steel water strainer.

Clean Chassis Interior:

Clean the condenser cooling fins.

Clean the air inlet grille located at the base

Clean the interior base.

Wipe the fan blade clean.

"

(8).

Disconnect the power cord from the receptacle prior to proceed-

"Y"

shaped solenoid

of

the

of

the dispenser.

5.

Reinstall the left side panel, turn on the water supply, and plug the dispenser into the power

receptacle.

8531

2001

10

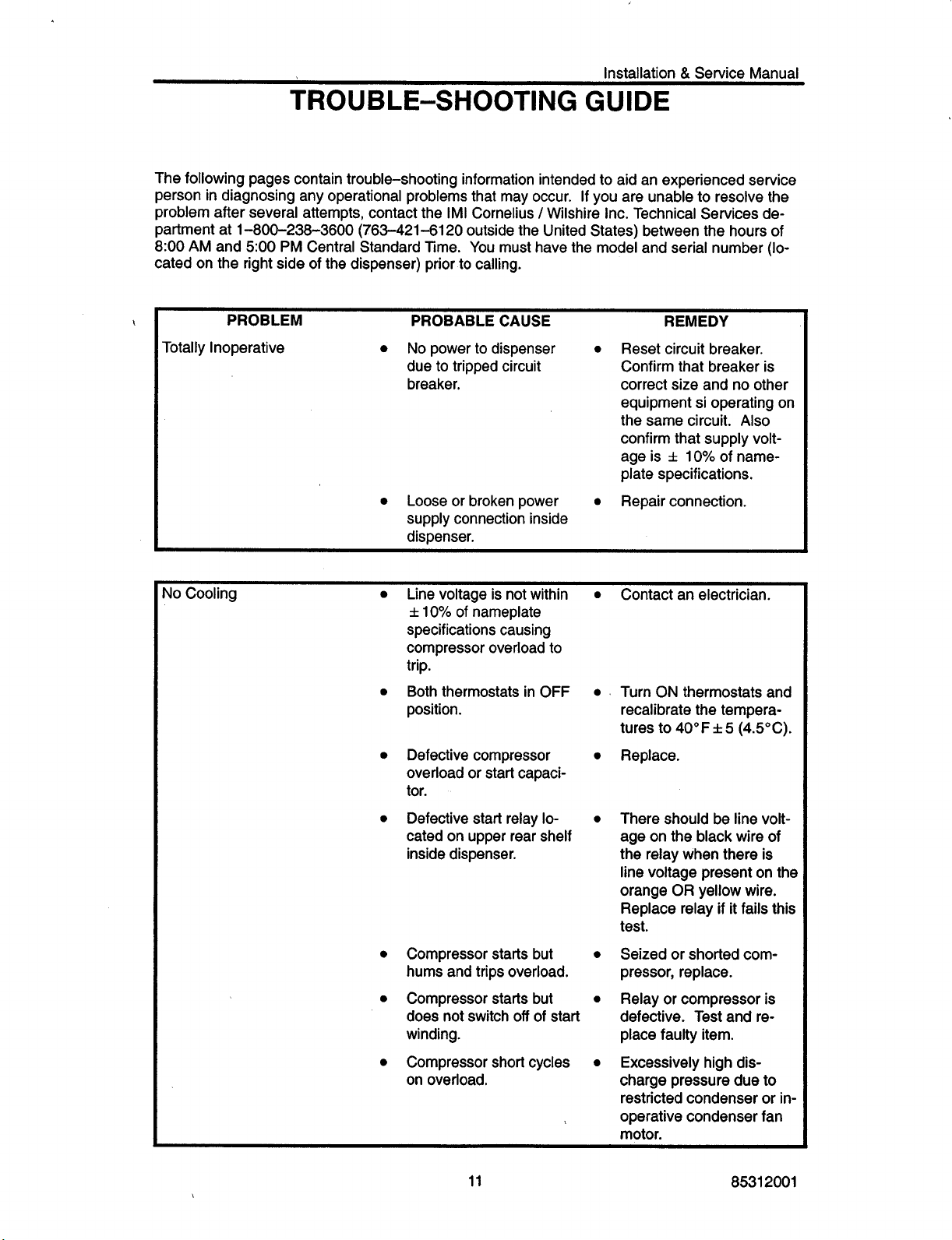

Installation & Service Manual

TROU

BLE-SHOOTING

GUIDE

The following pages contain trouble-shooting information intended to aid an experienced service

If

person in diagnosing any operational problems that may occur.

problem after several attempts, contact the IMI Cornelius

/

you are unable to resolve the

Wilshire Inc. Technical Services department at 1-800-238-3600 (763-421-6120 outside the United States) between the hours of

8:OO AM and

PM Central Standard Time. You must have the model and serial number

(lo-

300

cated on the right side of the dispenser) prior to calling.

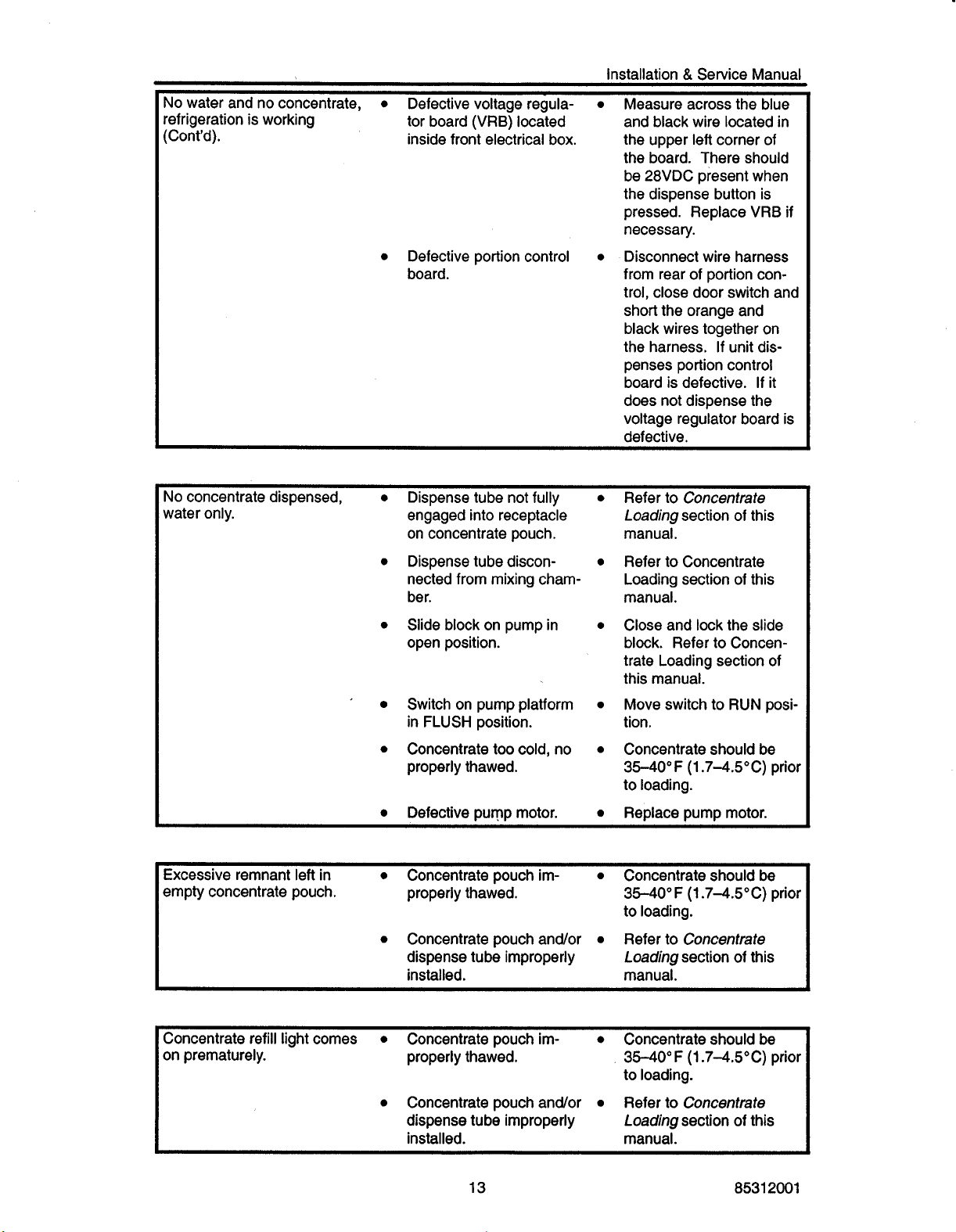

PROBLEM PROBABLE CAUSE REMEDY

Totally Inoperative

No

power to dispenser

due to tripped circuit

breaker.

0

Reset circuit breaker.

Confirm that breaker is

correct size and no other

equipment si operating on

the same circuit.

Also

confirm that supply voltage is

f

10% of name-

plate specifications.

0

Loose or broken power

0

Repair connection.

supply connection inside

dispenser.

Yo

Cooling

Line voltage is not within

f

10%

of

nameplate

specifications causing

compressor overload to

trip.

Both thermostats in

OFF

position.

Defective compressor

overload or start capacitor.

Defective start relay

lo-

cated on upper rear shelf

inside dispenser.

Compressor starts but

hums and trips overload.

Compressor starts but

does not switch

off

of

start

winding.

0

Contact an electrician.

0

Turn

ON

thermostats and

recalibrate the temperatures to

0

Replace.

There should

0

40°F f 5

be

age on the black wire of

the relay when there is

line voltage present

OR

orange

Replace relay

yellow wire.

if

test.

0

Seized or shorted compressor, replace.

0

Relay or compressor is

defective. Test and replace faulty item.

(45°C).

line volt-

on

the

it fails this

Compressor short cycles

on overload.

11 8531 2001

0

Excessively high discharge pressure due to

restricted condenser or

operative condenser fan

motor.

in-

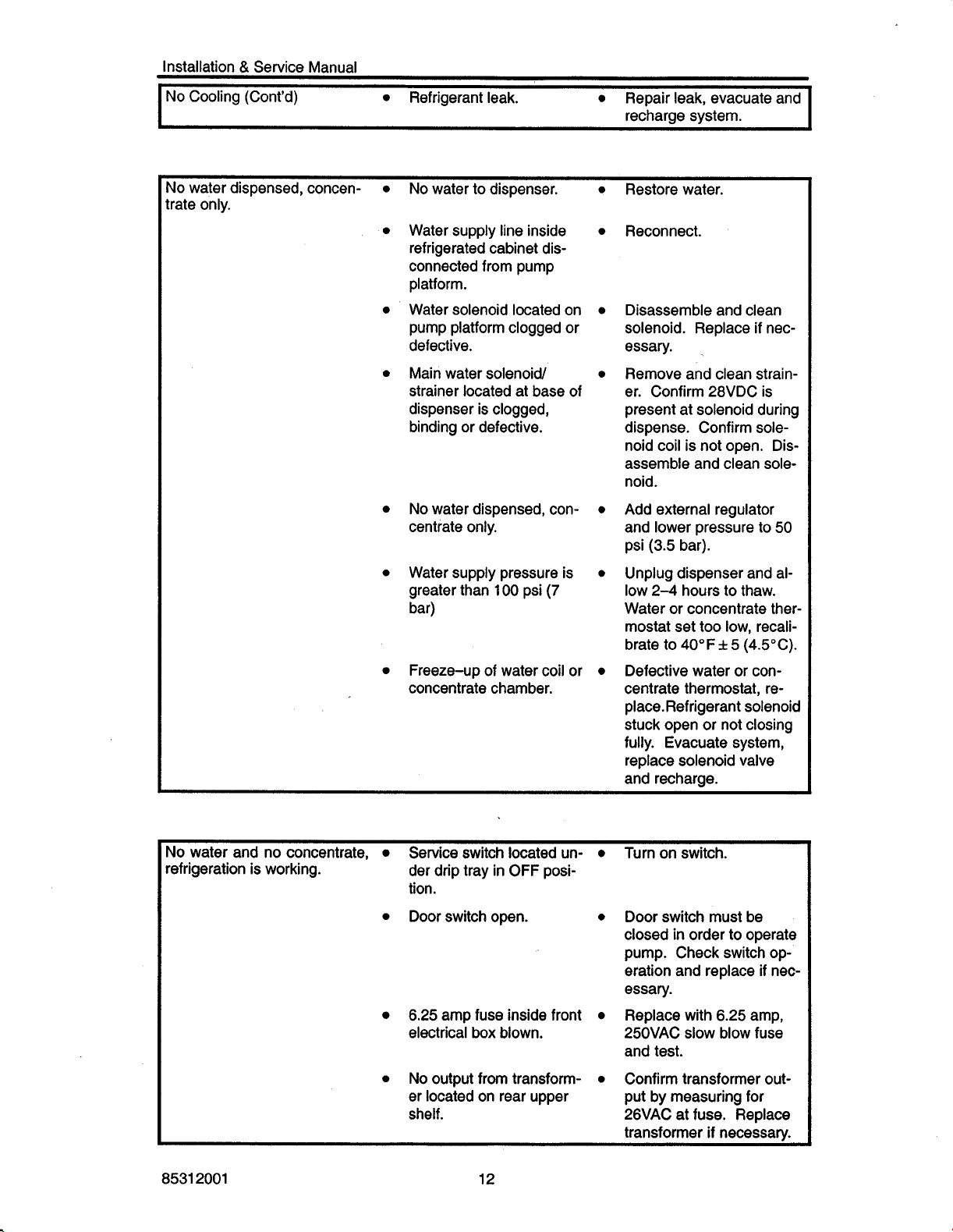

Installation & Service Manual

No Cooling (Cont'd)

Yo

water dispensed, concen-

trate only.

0

Refrigerant leak.

0

No

watertodispenser.

0

Water supply line inside

refrigerated cabinet disconnected from pump

platform.

Water solenoid located on

pump platform clogged or

defective.

Main water solenoid

strainer located at base of

dispenser is clogged,

binding or defective.

No

water dispensed, con-

centrate only.

0

Repair leak, evacuate and

recharge system.

0

Restore water.

0

Reconnect.

0

Disassemble and clean

solenoid. Replace

essary.

0

Remove and clean strainer. Confirm 28VDC is

present at solenoid during

dispense. Confirm solenoid coil is not open. Disassemble and clean solenoid.

0

Add external regulator

and lower pressure to

psi

(3.5

bar).

if

nec-

50

No

water and no concentrate,

refrigeration is working.

Water supply pressure is

greater than

100

bar)

0

Freeze-up of water coil or

concentrate chamber.

0

Service switch located under drip tray in OFF position.

0

Door switch open.

0

6.25 amp fuse inside front

box

electrical

blown.

psi

(7

0

Unplug dispenser and al-

low 2-4 hours to thaw.

Water or concentrate thermostat set too low, recali-

f

brate to 40" F

0

Defective water or con-

5

centrate thermostat, replace. Refrigerant solenoid

stuck open or not closing

fully. Evacuate system,

replace solenoid valve

and recharge.

0

Turn on switch.

0

Door switch must be

in

closed

order to operate

pump. Check switch operation and replace

essary.

0

Replace with 6.25 amp,

25OVAC

slow

blow fuse

and test.

(4.5"C).

if

nec-

8531 2001

0

No output from transform-

0

Confirm transformer out-

er located on rear upper put by measuring for

shelf. 26VAC at fuse. Replace

transformer

if

necessarv.

12

Installation & Service Manual

No water and no concentrate,

refrigeration is working

0

Defective voltage regula-

tor board (VRB) located

0

Measure across the blue

and black wire located in

(Cont'd). inside front electrical box. the upper left corner of

the board. There should

be 28VDC present when

the dispense button is

pressed. Replace VRB

necessary.

0

Defective portion control

board.

0

Disconnect wire harness

from rear of portion control, close door switch and

short the orange and

black wires together on

If

the harness.

unit dis-

penses portion control

board

is

defective.

If

does not dispense the

voltage regulator board is

defective.

No

concentrate dispensed,

water only.

0

Dispense tube not fully

engaged into receptacle

0

Refer to

Loading

Concentrate

section of this

on concentrate pouch. manual.

if

it

0

Dispense tube disconnected from mixing chamber. manual.

0

Slide block on pump in

open position.

'

Switch on pump platform

in FLUSH position. tion.

0

Concentrate too cold, no

properly thawed. 3540°F (1.74.5"C) prior

I

Excessive remnant left in

0

Defective pump motor.

0

Concentrate pouch im-

empty concentrate pouch. properly thawed.

0

Concentrate pouch and/or

dispense tube improperly

installed. manual.

0

Refer to Concentrate

Loading section of this

0

Close and lock the slide

block. Refer to Concentrate Loading section of

this manual.

0

Move switch to RUN posi-

0

Concentrate should be

to loading.

0

Replace pump motor.

0

Concentrate should be

3540°F (1.7-4.5"C) prior

to loading.

0

Refer to

Loading

Concentrate

section of this

Concentrate refill light comes

on prematurely.

0

Concentrate pouch im-

0

Concentrate should

properly thawed. 3540°F (1.7-4.5"C) prior

to loading.

0

Concentrate pouch andlor

dispense tube improperly

installed. manual.

_____

0

Refer to

Loading

Concentrate

section of this

13 8531 2001

be

Installation & Servicg Manual

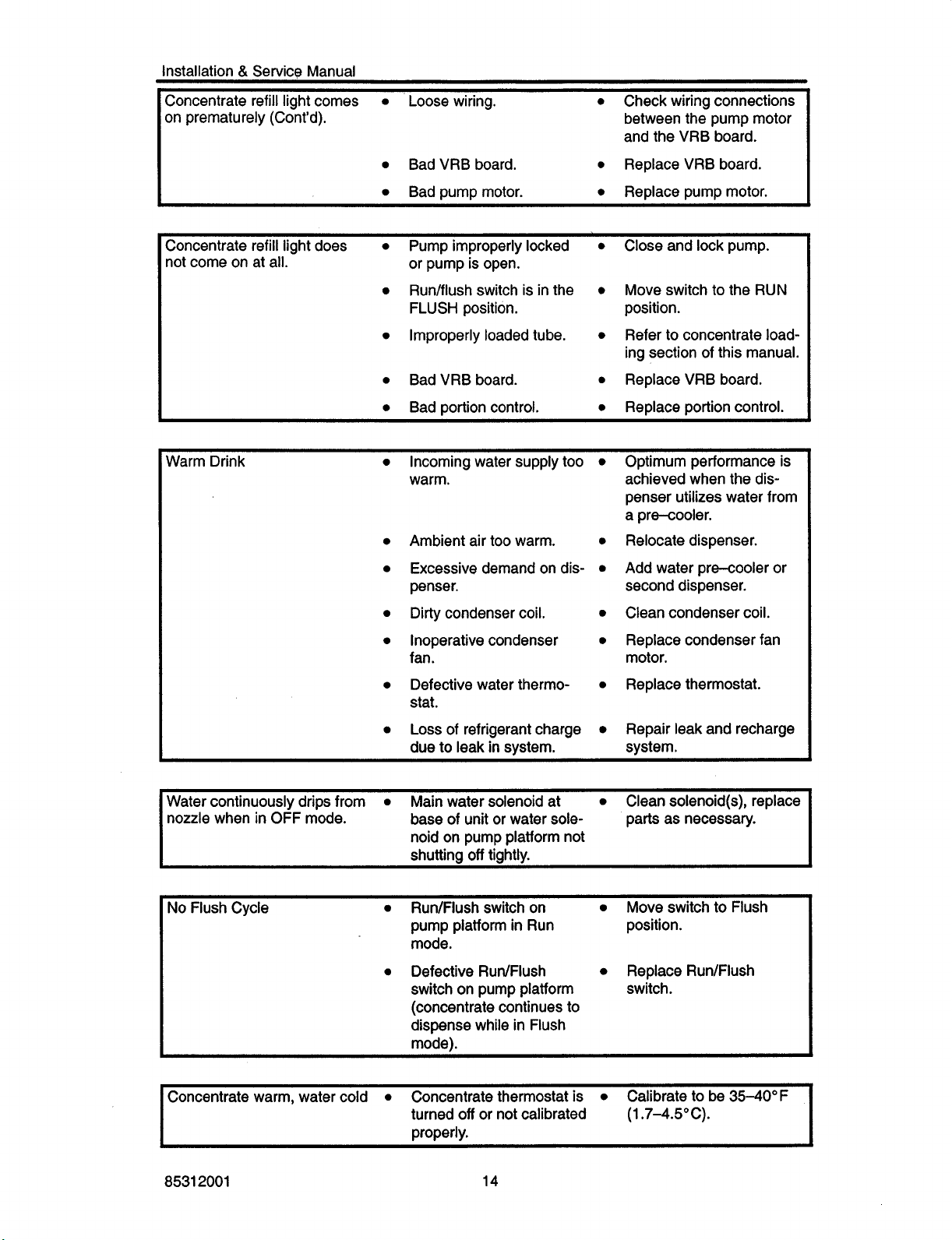

Concentrate refill light comes

on prematurely (Cont'd).

I

Concentrate refill light does

not come on at all.

Warm Drink

I

0

Loose wiring.

0

Check wiring connections

between the pump motor

and the VRB board.

0

Bad VRB board.

0

Bad pump motor.

0

Pump improperly locked

0

Replace VRB board.

0

Replace pump motor.

0

Close and lock pump.

or pump is open.

0

Run/flush switch is in the

0

Move switch to the RUN

FLUSH position. position.

0

Improperly loaded tube.

0

Refer to concentrate loading section of this manual.

0

Bad VRB board.

0

Bad portion control.

0

Incoming water supply too

0

Replace VRB board.

0

Replace portion control.

0

Optimum performance is

warm. achieved when the dis-

penser utilizes water from

a pre-cooler.

0

Ambient air too warm.

0

Excessive demand on dis-

penser.

0

Relocate dispenser.

0

Add water pre-cooler or

second dispenser.

I

I

Water continuously drips from

nozzle when in OFF mode.

No

Flush Cycle

0

Dirty condenser coil.

0

Inoperative condenser

0

0

fan. motor.

0

Defective water thermo-

0

stat.

0

Loss of refrigerant charge

0

due to leak in system.

0

Main water solenoid at

0

base of unit or water solenoid on pump platform not

off

shutting

0

Run/Flush switch on

pump platform

tightly.

in

Run position.

0

mode.

0

Defective Run/Flush

0

switch on pump platform switch.

(concentrate continues to

dispense while in Flush

mode).

Clean condenser coil.

Replace condenser fan

Replace thermostat.

Repair leak and recharge

system.

Clean solenoid(s), replace

parts as necessary.

Move switch to Flush

Replace Run/Flush

Concentrate warm, water cold

0

Concentrate thermostat is

off

turned

or not calibrated

properly.

8531 2001 14

0

Calibrate to be 3540°F

(1 -7-4.5"C).

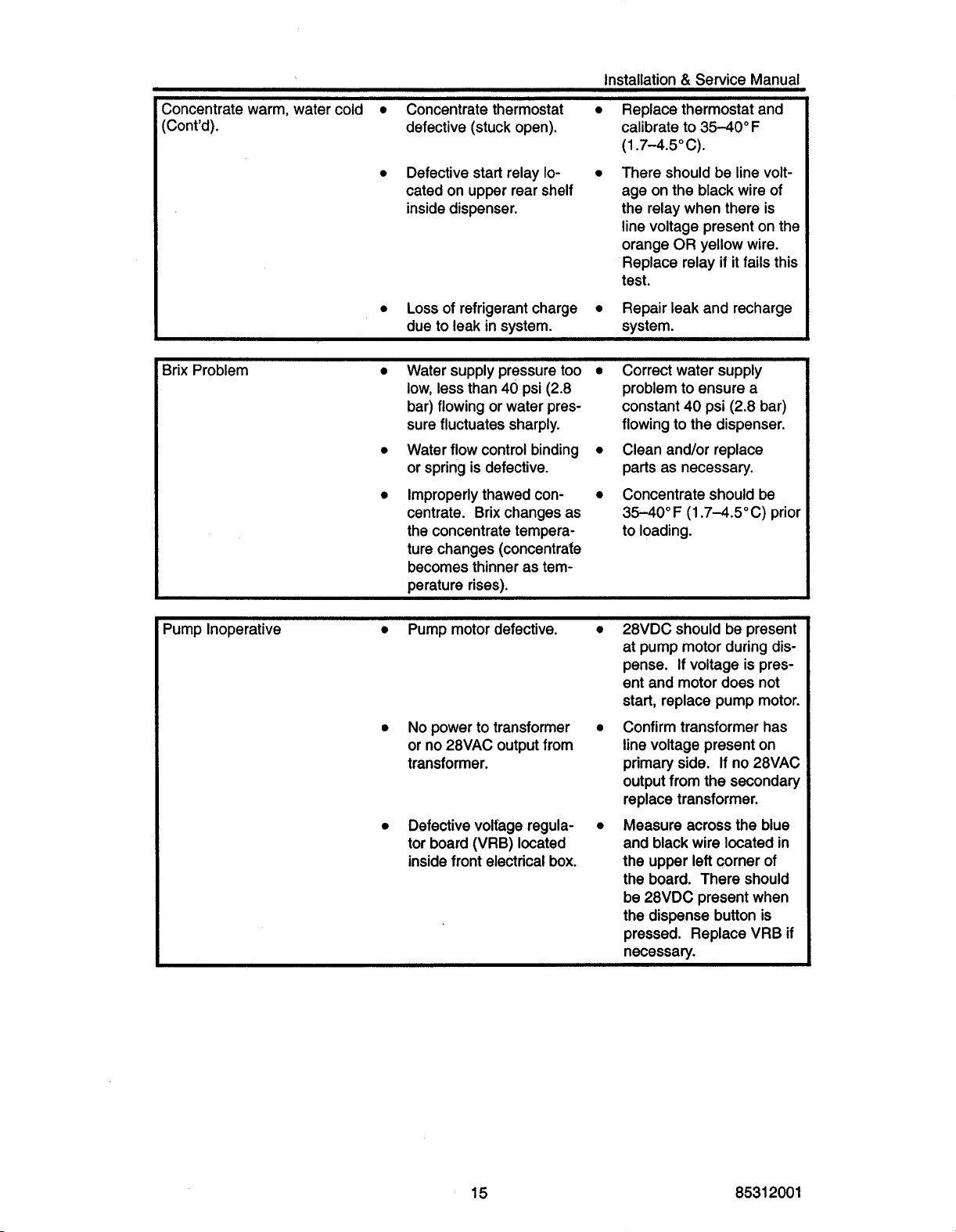

Installation & Service Manual

Concentrate warm, water cold

(Cont'd).

Brix Problem

0

Concentrate thermostat

0

Replace thermostat and

defective (stuck open). calibrate to 3540°F

(1.7-4.5"C).

0

Defective start relay

cated on upper rear shelf

inside dispenser.

lo-

0

There should be line voltage on the black wire of

the relay when there is

line voltage present on the

orange

OR yellow wire.

Replace relay

test.

0

Loss of refrigerant charge

0

Repair leak and recharge

system. due to leak in system.

0

Water supply pressure too

low, less than 40 psi (2.8

bar) flowing or water pressure fluctuates sharply.

0

Water flow control binding

or spring is defective.

0

Improperly thawed concentrate. Brix changes as

0

Correct water supply

problem to ensure a

constant

40

flowing to the dispenser.

0

Clean and/or replace

parts as necessary.

0

Concentrate should be

3540°F (1.74.5"C) prior

the concentrate tempera- to loading.

ture changes (concentrate

becomes thinner as tem-

perature rises).

if

it fails this

psi (2.8 bar)

Pump Inoperative

0

Pump motor defective. 28VDC should be present

at pump motor during dis-

pense.

If

voltage is present and motor does not

start, replace pump motor.

0

No power to transformer

or no 28VAC output from

transformer.

Confirm transformer has

line voltage present on

primary side. If no 28VAC

output from the secondary

replace transformer.

0

Defective voltage regula-

tor board (VRB) located

inside front electrical box.

Measure across the blue

and black wire located

the upper

left

corner of

the board. There should

be 28VDC present when

the dispense button is

pressed. Replace VRB

necessary.

in

if

15

8531 2001

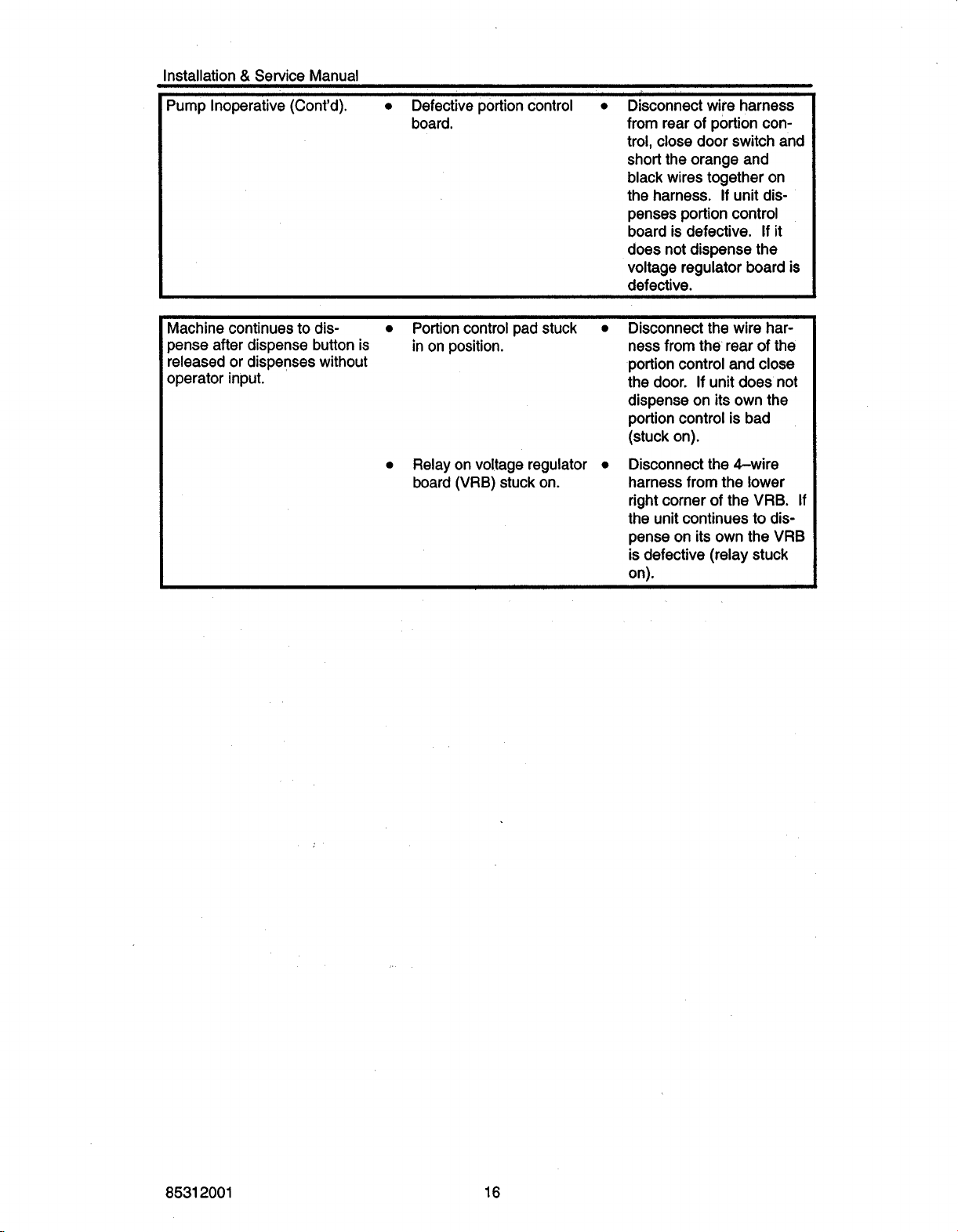

Installation & Service Manual

Pump Inoperative (Cont’d).

Machine continues to dispense after dispense button is

released or dispenses without

operator input.

0

Defective portion control

board.

0

Portion control pad stuck

in on position.

0

Relay on voltage regulator

board (VRB) stuck on.

0

Disconnect wire harness

from rear of portion control, close door switch and

short the orange and

black wires together on

If

the harness.

unit dispenses portion control

board is defective.

does not dispense the

voltage regulator board is

defective.

0

Disconnect the wire harness from the rear of the

portion control and close

the door. If unit does not

dispense on its own the

portion control is bad

(stuck on).

0

Disconnect the &wire

harness from the lower

right corner of the VRB.

the unit continues to dis-

pense on its own the VRB

is defective (relay stuck

on).

If

it

If

8531

2001

16

Installation

&

Service

Manual

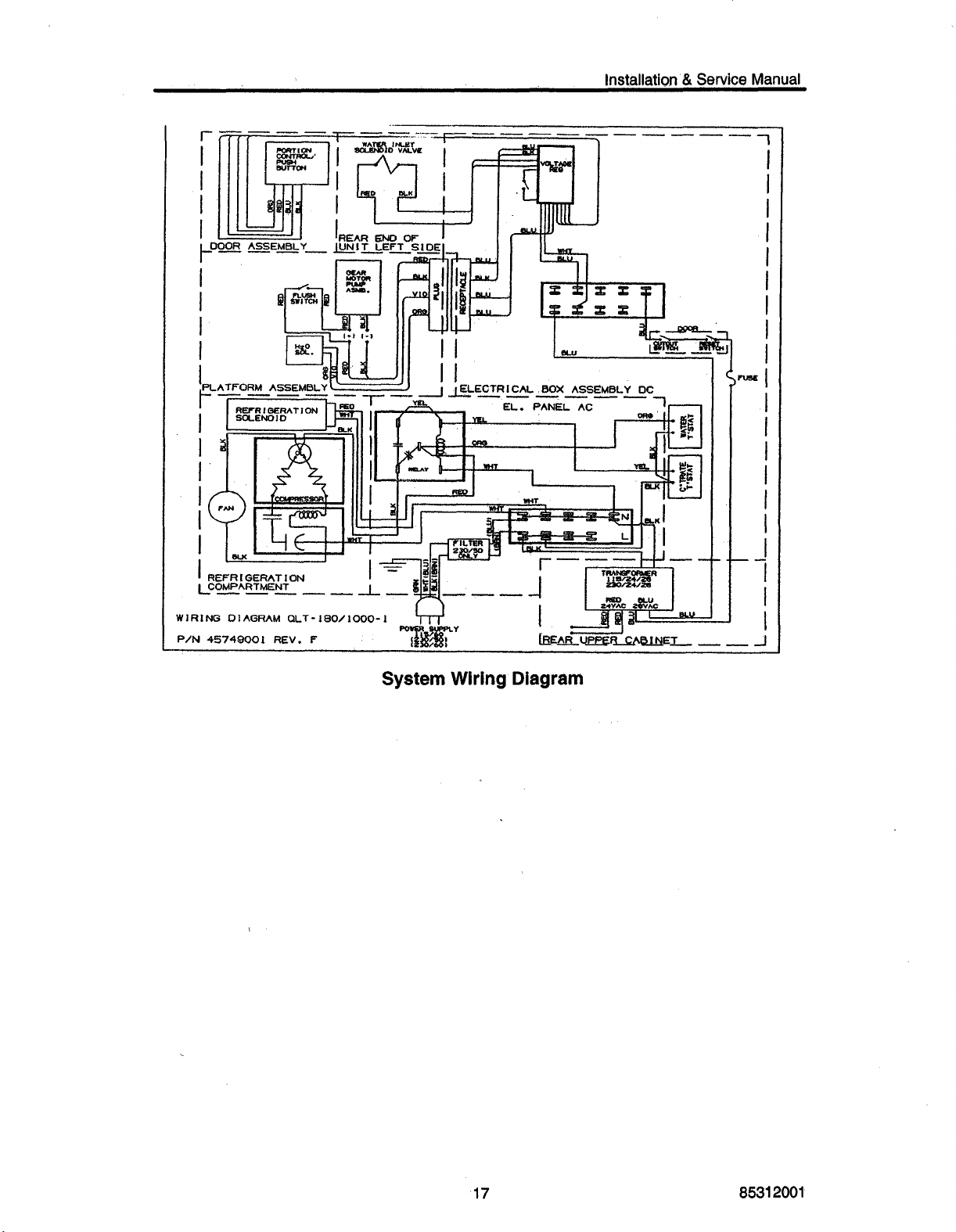

System

Wiring

Diagram

17

8531

2001

Installation & Service Manual

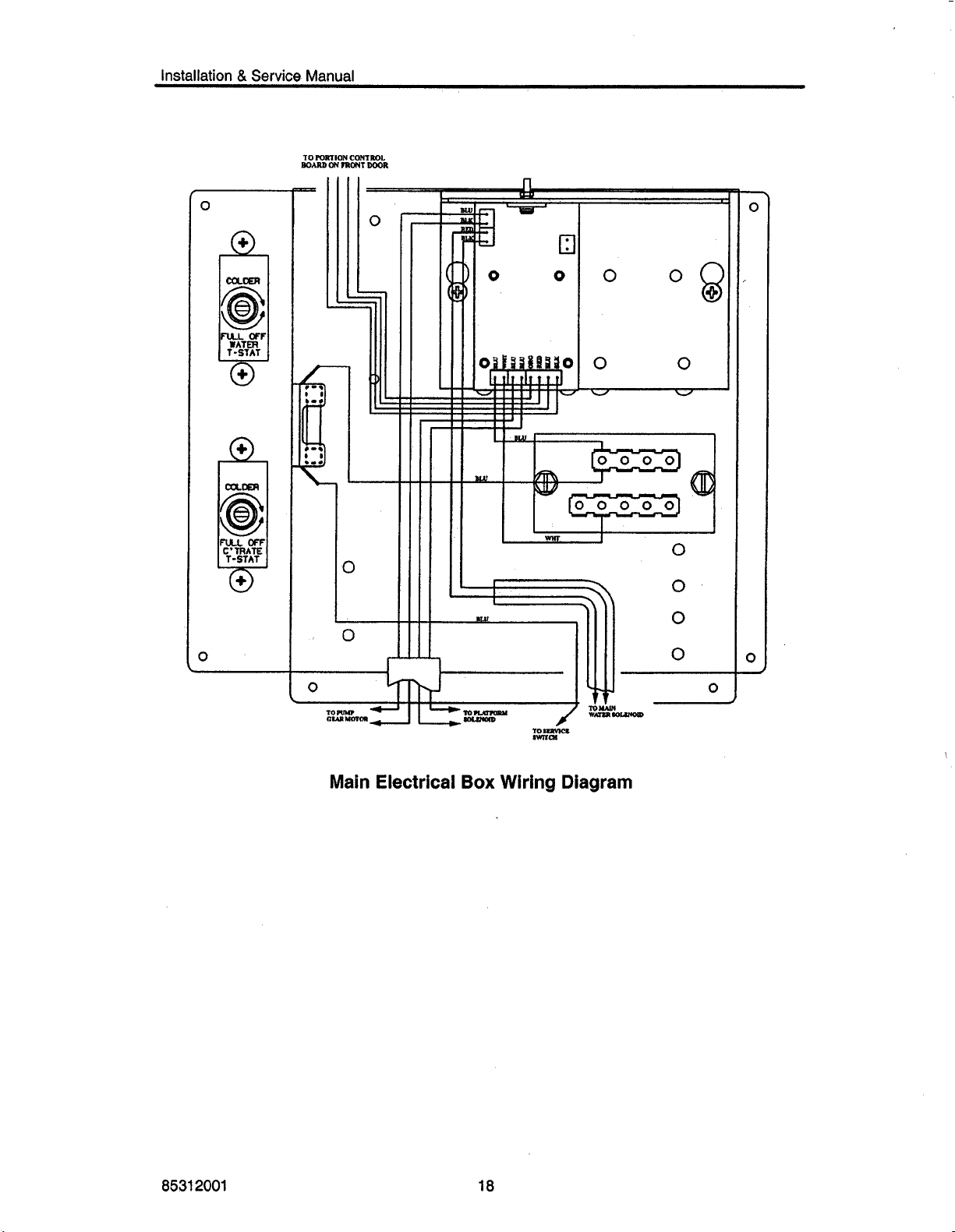

0

0

0

0

Main Electrical

Box

Wiring Diagram

0

0

0

0

0

8631 2001

18

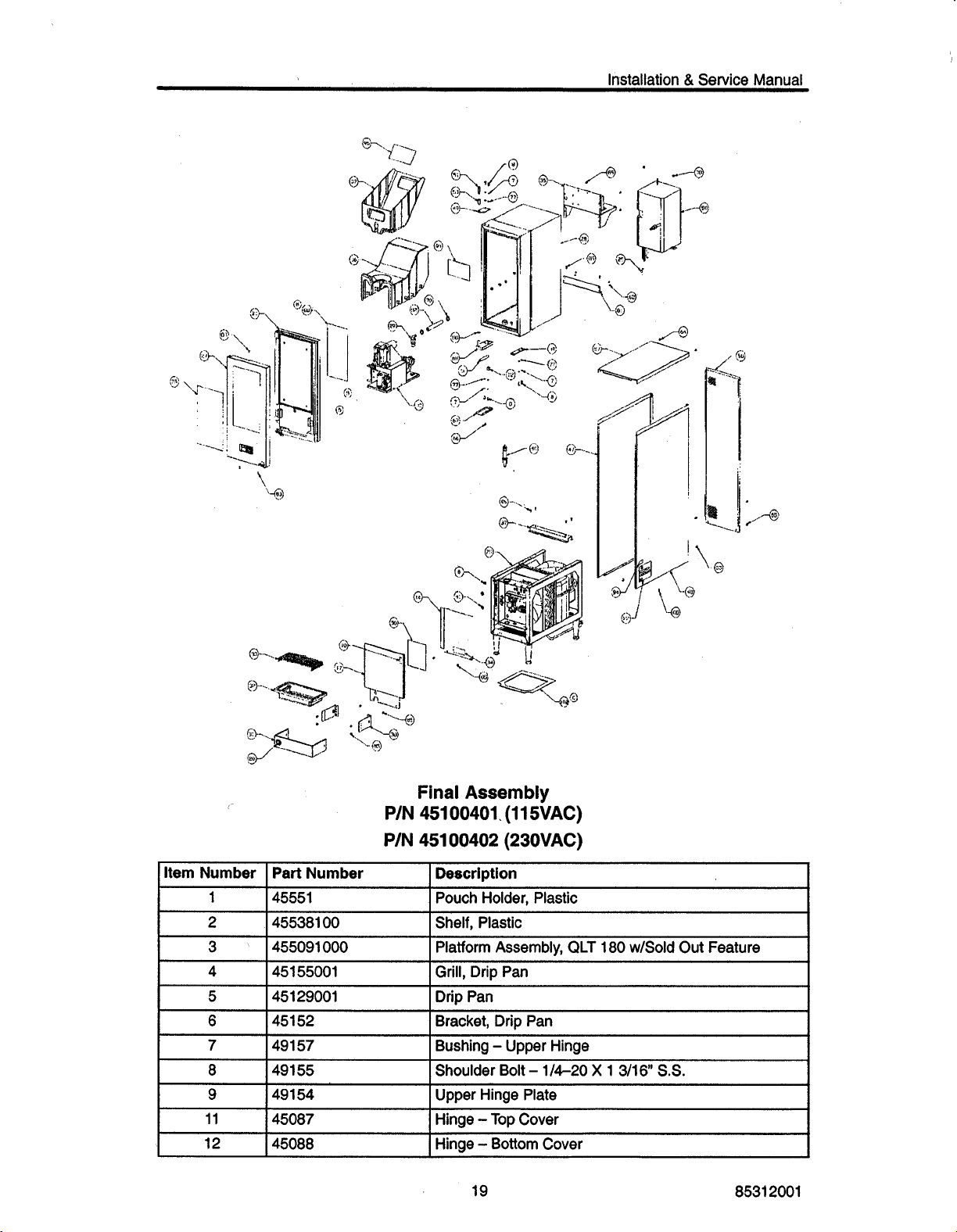

Installation & Service Manual

I

Item Number

I

I

1

6

Part Number

45551

455381

455091

451 55001

451 29001

451 52

491 57

49155

49154

45087

45088

00

000

Final

Assembly

P/N

45100401. (115VAC)

P/N

451 00402 (23OVAC)

I

Description

Pouch Holder, Plastic

Shelf, Plastic

Platform

Grill, Drip Pan

I

Drip Pan

Bracket, Drip Pan

Bushing

I

I

Shoulder Bolt - 1/4-20 X 1 3/16 S.S.

I

I

Upper Hinge Plate

..

I

Hinge - Top Cover

I

Hinge - Bottom Cover

Assembly,

-

-

19 85312001

QLT

Upper Hinge

180

w/Sold

I

Out Feature

I

1

I

I

I

Loading...

Loading...