Page 1

ãIMICorneliusInc;1988-9

1

INSTALLATION MANUAL

PRESSURIZED LIQUID-BASE

Beverage Dispenser

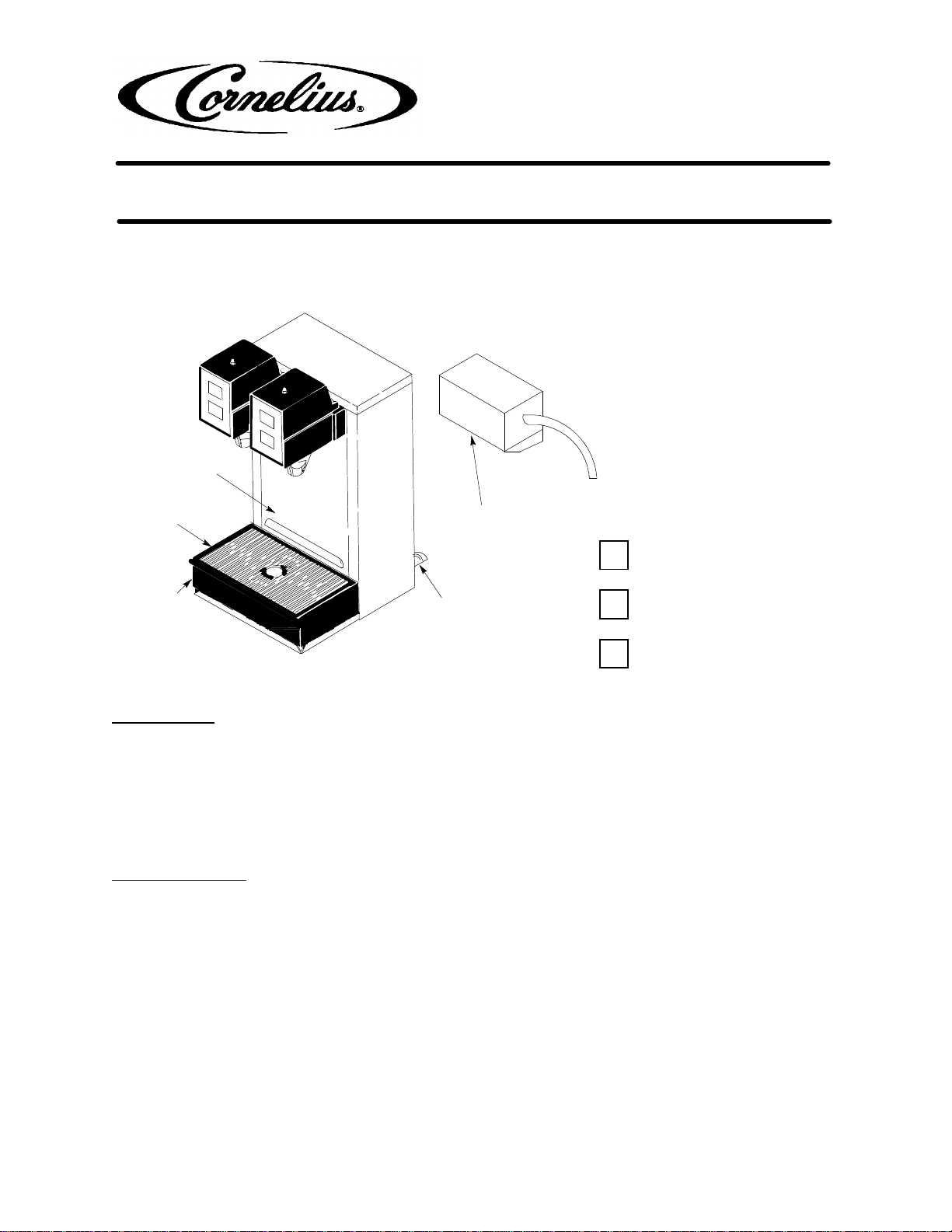

FRONT

ACCESS PANEL

CUP

REST

24VOLT

TRANSFORMER

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN. 55303--6234

Telephone(612)421--6120

Facsimile (612) 422--3232

Design data

Overall Dimensions:

Width 7 3/4”

Height 15 1/2”

Depth 8 5/8”

Weight 9 lbs

Electrical Requirements:(if applicable)

15 Amp Circuit, 115v 60hz

.52 Amp Unit Curent Draw

24v 60hz, Dispensing valves

Installation Check List :

Counter Top with asscess to route

concentrate supply lnes.

DRIP

TRAY

SUPPL YINLET

Cold Water Supply, With Shutoff

15 Amp,115v60hz Outlet, Within 5’

(if applicable)

RECEIVING

Each Unit is completely tested under operating conditions and thoroughly inspected before shipment. At time of

shipment, the carrier accepts the Unit and any claim for damage in transit must be made with the carrier. Upon

receiving Unit from the delivering carrier, carefully inspect the carton for visible indication of damage. Any damage or irregularities should be noted at time of delivery (or not later than 15 days from date of delivery) and immediately reported to the delivering carrier. Request a written inspection report from the Claims Inspector to

substantiate claim. File claim with the delivering carrier, not with IMI Cornelius Inc.

INSTALLATION

Place Unit in selected location and make connections as follows:

Plain Water Source Connections:

1. Flush plain water source thoroughly before connecting to Unit.

2. Connect plain water source to middle 1/4 inch flare fitting labeled ‘‘WATER’’. Use tapered plastic gasket.

Concentrate Line(s) Connection:

1. Connect .265 I.D. concentrate lines to the appropriate inlet fittings. Seal connections using tapered plastic

gaskets. DO NOT CONNECT SOURCE LINES TO CONCENTRATE TANKS AT THIS TIME.

Transformer Connections:

1. On Units with electric valves; connect Unit cord two-pin connector to the mating connector on the transformer output (24V) cord.

300387001

Page 2

Steps of final installation:

1. Plug transformer power cord into electrical outlet with proper electrical requirements.

2. Open shutoff valve in plain water source line.

3. Inspect connections for leaks.

4. Place a waste container under each nozzle and operate valve(s) to remove air from the plain water line.

5. Connect concentrate tanks to concentrate system.

6. Connect nitrogen pressurization lines to the concentrate tanks.

7. Open nitrogen cylinder shutoff valve to apply the calculated pressure to the concentrate.

8. Adjust the concentrate nitrogen regulator according to these guidelines: Set the nitrogen gas regulator at

30 PSI plus one pound for every five feet over ten feet of concentrate line length, and one pound for every

two feet of vertical lift.

As an example, if total concentrate line length is 20 feet, and total vertical lift is 6 feet then 30 PSI plus two

PSI (one pound for every 5 feet over 10 feet) plus three PSI (one pound for every two feet of vertical lift)

totals 35 PSI, the correct setting.

9. Operate each dispensing valve to remove air from the lines.

10. Check all lines for leaks.

11. Adjust Dispensing Valves for Water-To-Concentrate “Ratio” of dispensed drinks as instructed on ”BRIXING

VALVES” instructions.

NOTE: Concentrate system must be sanitized before Unit is put into operation. Refer to

Owners/Opereators Manual for procedure.

12. On four-flavor Units, apply decals to touch-switches following Decal Installation Sheet Instructions.

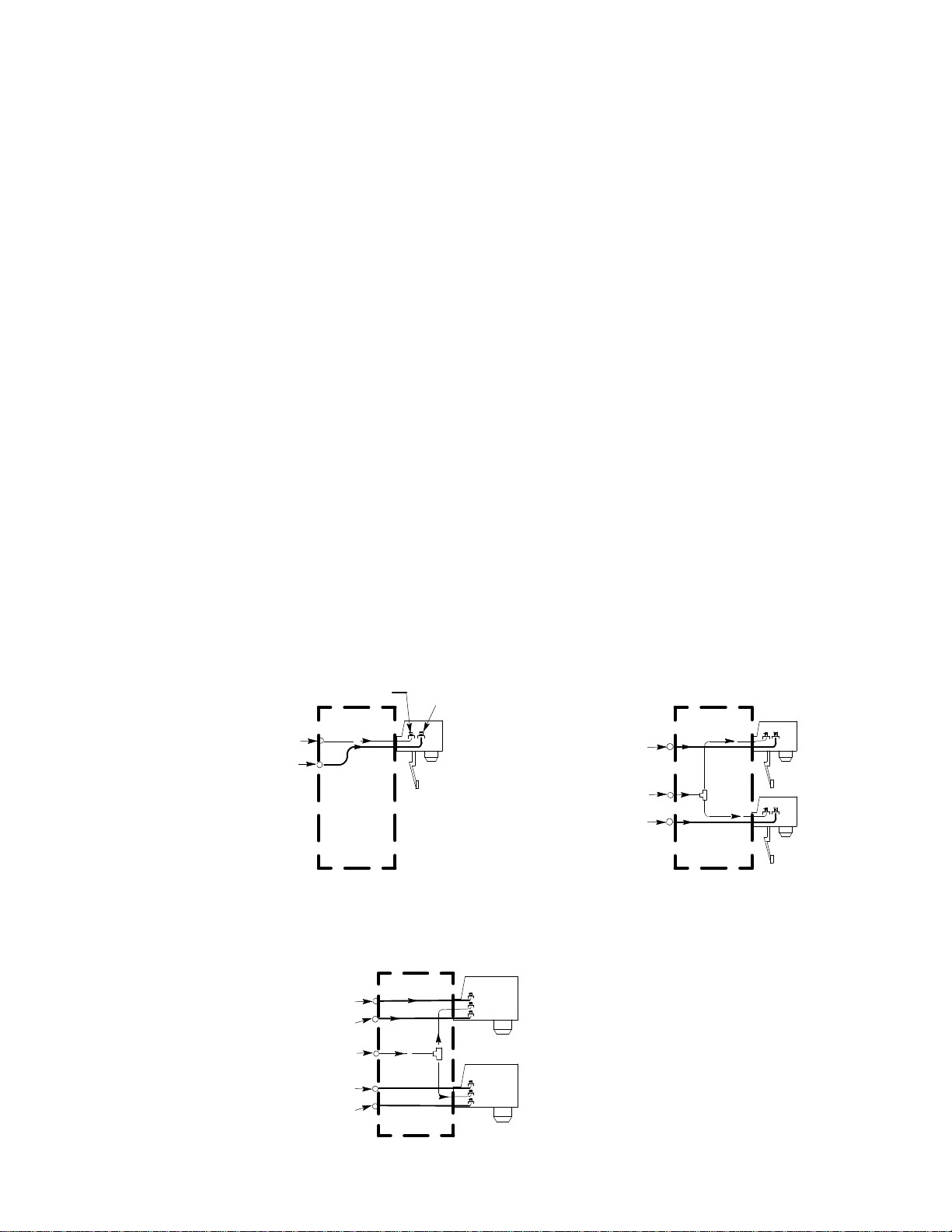

ADJUSTABLE WATER

FLOW REGULATOR

WATER OR

CARBONATED WATER IN

CONCENTRATE IN

ONE SINGLE-FLAVOR

DISPENSING VALVE

ADJUSTABLE CONCENTRATE

FLOW REGULATOR

CONCENTRATE NO. 1 IN

WATER IN

CONCENTRATE NO. 2 IN

1

2

TWO SINGLE-FLAVOR

DISPENSING VALVES

CONCENTRATE NO. 1 IN

CONCENTRATE NO. 2 IN

WATER IN

CONCENTRATE NO.3 IN

CONCENTRATE NO.4 IN

1

2

3

4

FLOW DIAGRAMS

2

TWO TWO-FLAVOR

DISPENSING VALVES

300387001

September 6, 1994

Loading...

Loading...