Cornelius IWC522, IAC330, IWC322, IWC530, IAC630 Pocket Manual

...

ICE MAKER

POCKET GUIDE

“I” SERIES CUBE

ICE MAKERS

IMI CORNELIUS

One Cornelius Place

Anoka, MN 55303

1–800–238–3600

TD 204(Metric)

TABLE OF CONTENTS

introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original Owner, End-user responsibility 1. . . . . . . . . . . .

Serial Plate Locations 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model and Serial Number Defined 2. . . . . . . . . . . . . . . . . . . .

Serial Number Defined After January 1, 1995 3. . . . . . . . . .

Electrical Specification 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Condenser 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE CAPACITY INFORMATION 11. . . . . . . . . . . . . . . . . . .

Ice Capacity 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ice Production Check 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF ICE BRIDGE THICKNESS 12. . . . . . . .

Ice production capacities and charts 14-29. . . . . . . . . . . .

IAC322/IAC330 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC322/IWC330 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC522/IAC530 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC522/IWC530 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC630 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC630 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC630 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC830 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC830 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC830 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC1230 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC1230 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC1230 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC1448 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC1448 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC1448 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Operation 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Functions 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED status indicator chart 32-34. . . . . . . . . . . . . . . . . . . .

Reset Operation 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Selector Switch 34. . . . . . . . . . . . . . . . . . . . . . . .

Stacking Cable 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Plug 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dump Cycle Options 35. . . . . . . . . . . . . . . . . . . . . . . . . .

Condenser Fan Cycling Control (Intergal Condenser) 36.

Harvest Safety Termination 36. . . . . . . . . . . . . . . . . . . . .

Circuit Board Diagnosis 36. . . . . . . . . . . . . . . . . . . . . . . .

PAGE

i

TD 204

TABLE OF CONTENTS (CONT’D)

Sensors 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensor [Thermistor] Diagnosis 38. . . . . . . . . . . . . . . . . . . . . . .

Evaporator Switches 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Notes 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Checks 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Regulating Valve 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Pressure Safety Switch 40. . . . . . . . . . . . . . . . . . . . . . . . .

Float Valve with Flow Washer 41. . . . . . . . . . . . . . . . . . . . . . .

Service Stem Valves 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostatic Expansion Valves 41. . . . . . . . . . . . . . . . . . . . . .

diagnosis 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starving TXV - Product Symptoms 42. . . . . . . . . . . . . . . . . . .

Flooding TXV - Product Symptoms 42. . . . . . . . . . . . . . . . . . .

Head Pressure Control Valve [Headmaster} Fan Cycle Switch

Contactor Compressor 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor & Starting Component Check-Out Procedure 45

Relay 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitors 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moisture Contamination 47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 49-54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Procedures 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prep – Cleaning 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Water System & Evaporator 59. . . . . . . . . . . . . .

Sanitizing Procedures 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Remote Units Only) 43. . . . . . . . . . . . . . . . . . . . . .

Potential – 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current – 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

iiTD 204

introduction

This guide is published as an aid to the Service Technician. It is no t

intended to replace the service manual. In it you will find useful information not found in the service manual. This information will

help you more quickly identify specific problems, however not all

problems or situations may be listed. W e appreciate your comments

or suggestions, or if you have a specific problem not addressed in

this guide or service manual.

Please feel free to contact our service department at:

IMI CORNELIUS

One Cornelius Place

Anoka, MN 55303

1–800–554–3526

The warranty on Cornelius icemakers begins on the date of installation, as reported on the warranty registration card to the original

owner/user. If no warranty card is received by the factory, the date

of shipment from the factory will determine the start of the warranty.

Warranty labor will be paid per the labor rate guide and is subject to

change without notice. Call the Service Department for a copy of the

current Labor Rate Guide and/or applicable Warranty Document

Copy.

ORIGINAL OWNER, END-USER RESPONSIBILITY

1. To verify the equipment installation date by the return

of the warranty registration card to the factory within

five days of the installation.

2. To pay freight or handling charge.

3. To pay for service labor and/or parts required to correct improperly installed equipment. Installation must

comply with the installation instructions.

4. To pay for normal maintenance, adjustments and

cleaning.

5. To pay for service labor and/or parts required to correct unit modification or the use of non-approved remote condensers.

6. To pay for service labor and/or parts required because

of neglect, abuse, misuse, accident, fire, flood, freezing or any act of God.

7. To pay for mileage, truck charges, travel time, premium labor for holidays, weekends or after hours

work, flat rate service call charges, miscellaneous tool

charges, use of diagnostic meters or equipment and all

material not listed on the Warranty Time Rate Guide.

1 TD 204

Serial Plate Locations

Exterior: Left side, Lower Front corner.

Interior: Firewall, Front.

Model and Serial Number Defined

IAC 1230

IAC1230

Product

Identifica-

tion

94 A C E 0000

Year

(the first 2

digits

indicates

year of

produc-

tion)

Month of production code will be:

Note: The letter (I) is not used to avoid being confused with the

number(1)

Product Code:

A = Accessory* D = Dispenser (motel/hotel)

B = Bin (storage) E = External condenser (Remote)

C = Cuber F = Flaker

* Any accessory determined to be required to have a serial number.

A=Air

Cooled

Condenser

W=Water

Cooled

R=Remote

Month

Production

A = January G = July

B = February H = August

C = March J = September

D = April K = October

E = May L = November

F = June M = December

Cuber Series

Product

Code

Manufac-

turing

Tracking

Code

30” Wide

3

5

6

8

10

12

14

Cabinet

22 = 22”

Wide

48 = 48”

wide

Unit

Serial

Number

2TD 204

Serial Number Defined

after January 1, 1995

AF 95 01 BC 0000

Eng

change

level

Engineering change level can be either 1 or 2 digits depending

on the revision level.

Month of production code will be:

01 = January 07 = July

02 = February 08 = August

03 = March 09 = September

04 = April 10 = October

05 = May 11 = November

06 = June 12 = December

Note: The Month must always be 2 digits.

Product Code:

BA = Accessory* BD = Dispenser (motel/hotel)

BB = Bin (storage) BE = External condenser (Remote)

BC = Cuber BF = Flaker

* Any accessory determined to be required to have a serial number.

year Month Product

Code

Unit

Serial

Number

3 TD 204

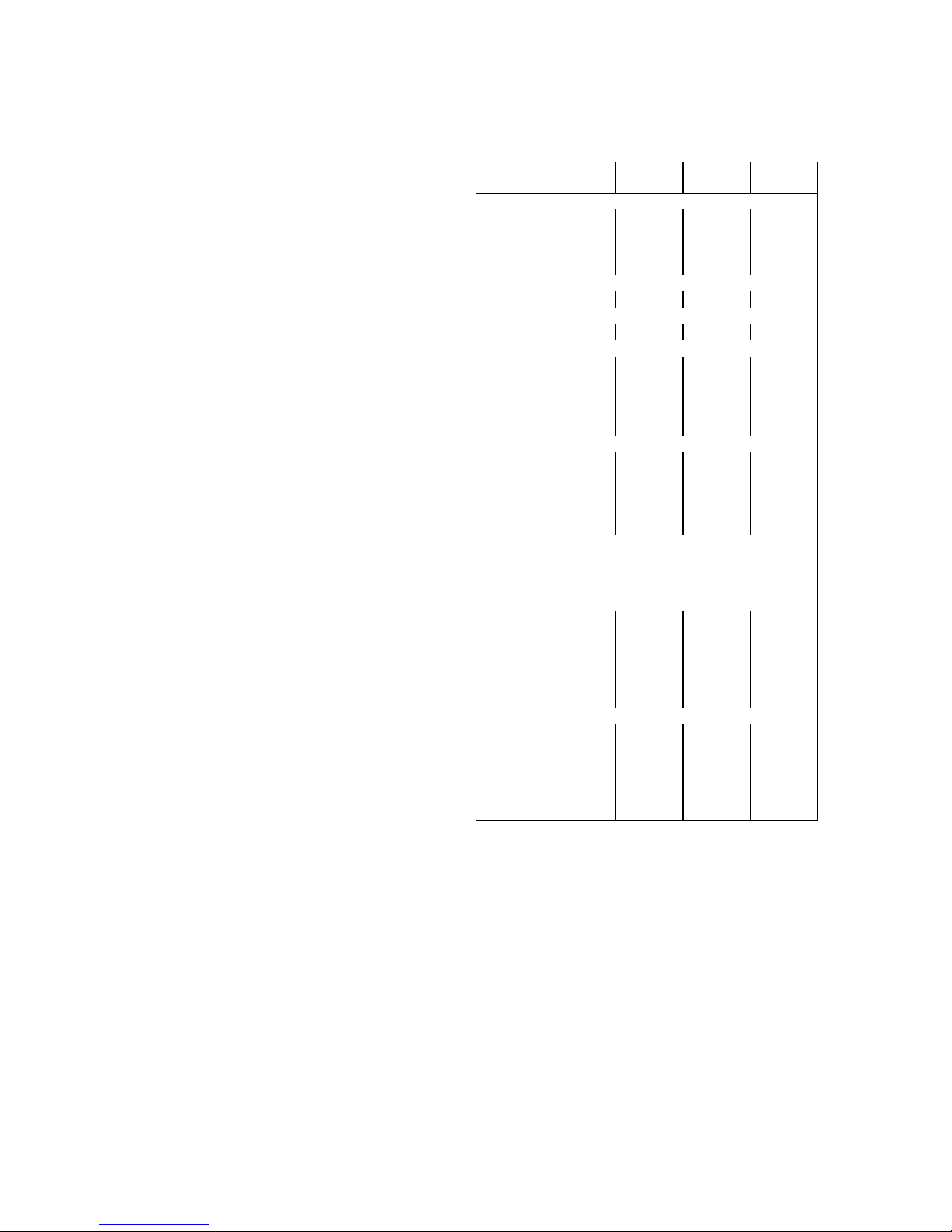

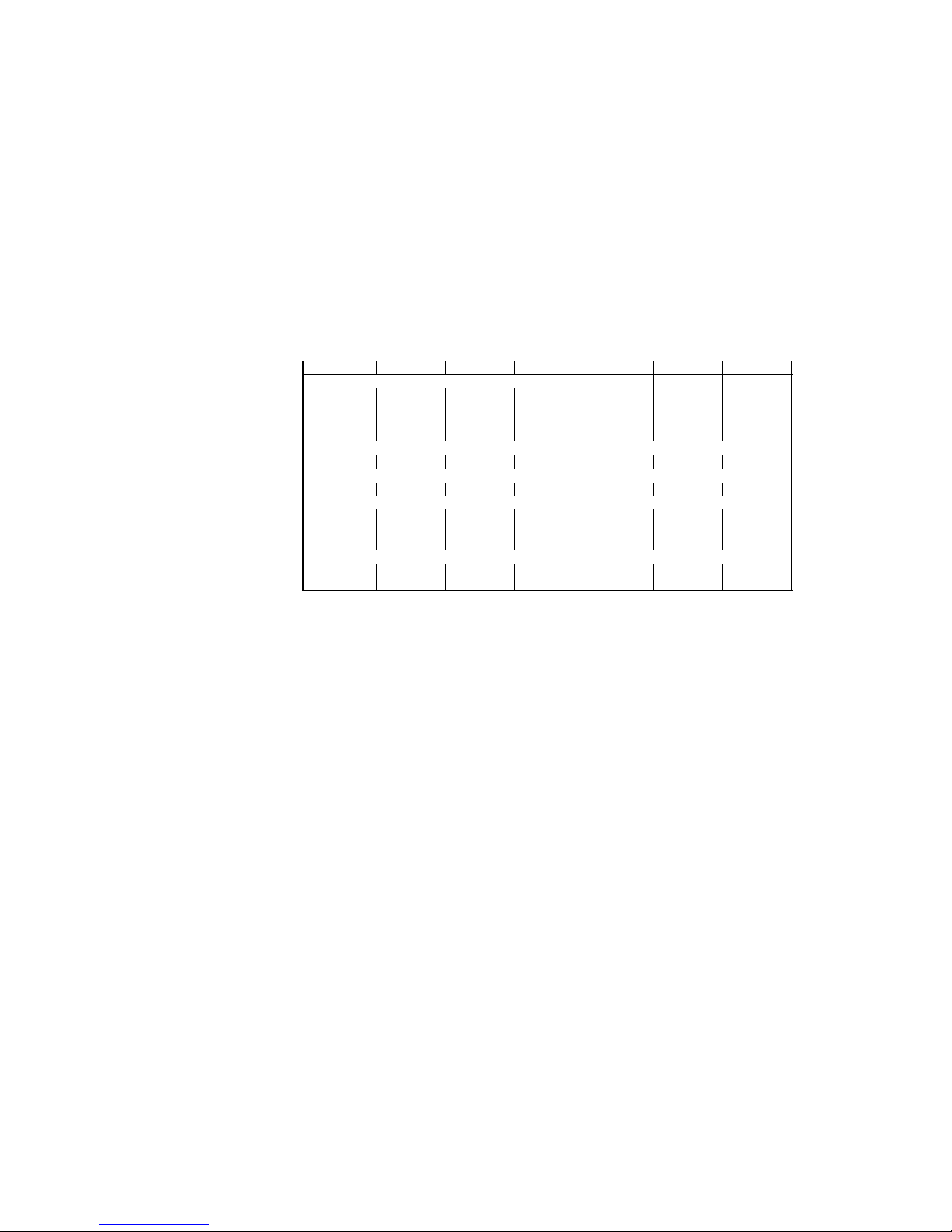

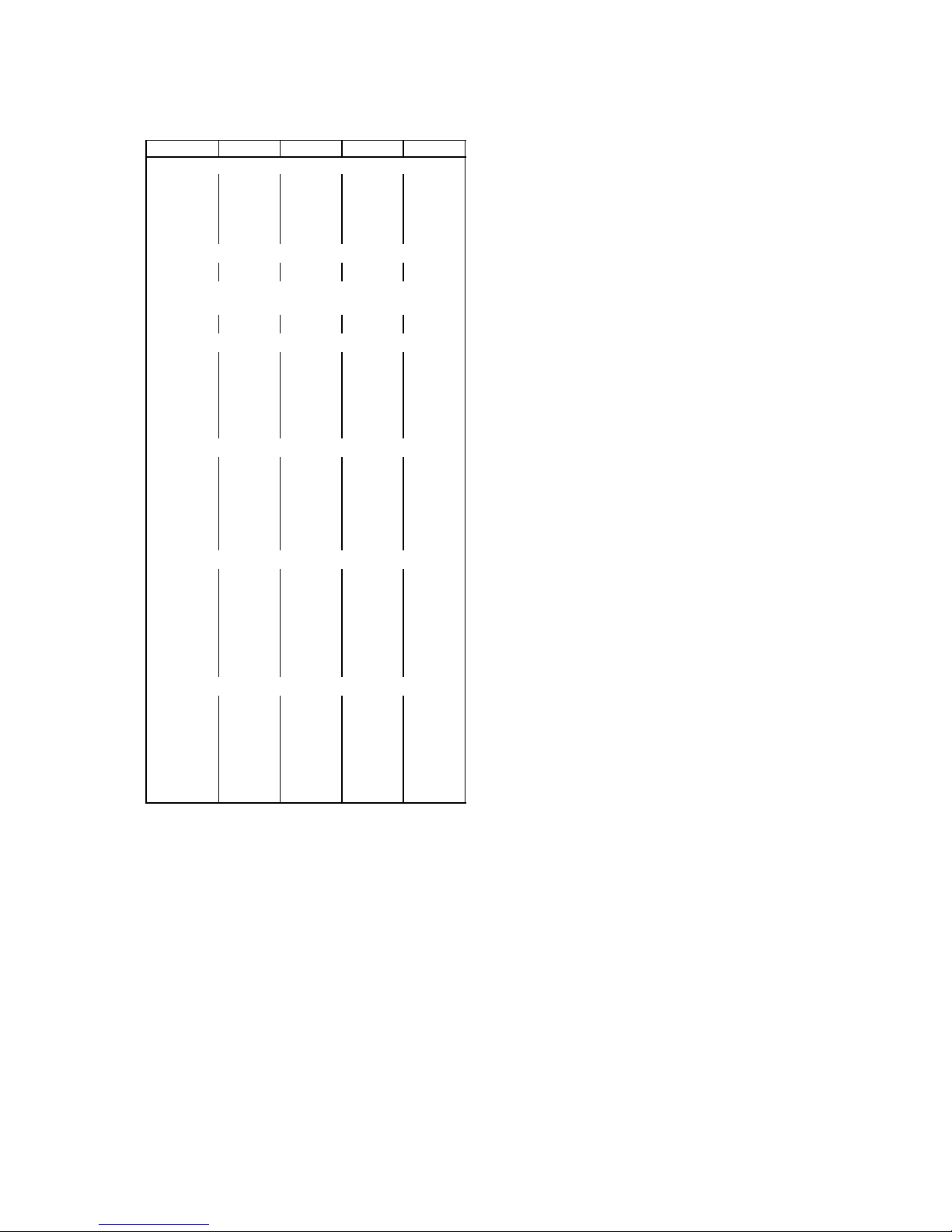

Electrical Specification

MODEL

UNIT

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 20

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQ)

Amps 20 20 20 20

REFRIGERANT

Type

Weight

(oz)

Weight (g) 482 425 737 652

COMPRESSOR

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

LRA 51 51 59 59

RLA 11.5 11.5 11.6 11.6

CONDENSER FAN MOTOR (Air-Cooled System

Y OR

onl

AIR CIRCULATION FAN MOTOR (Water-Cooled

and Remote Systems only)

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

Watts 50 6 50 6

WATER PUMP

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

HP 1/40 1/40 1/40 1/40

IAC322/330IWC322/330IAC522/530IWC522/5

R404a

(HP62)

17 15 26 23

1.7 0.38 1.75 0.38

0.88 0.88 0.76 0.88

R404a

(HP62)

R404a

(HP62)

R404a

(HP 62)

30

4TD 204

5 TD 204

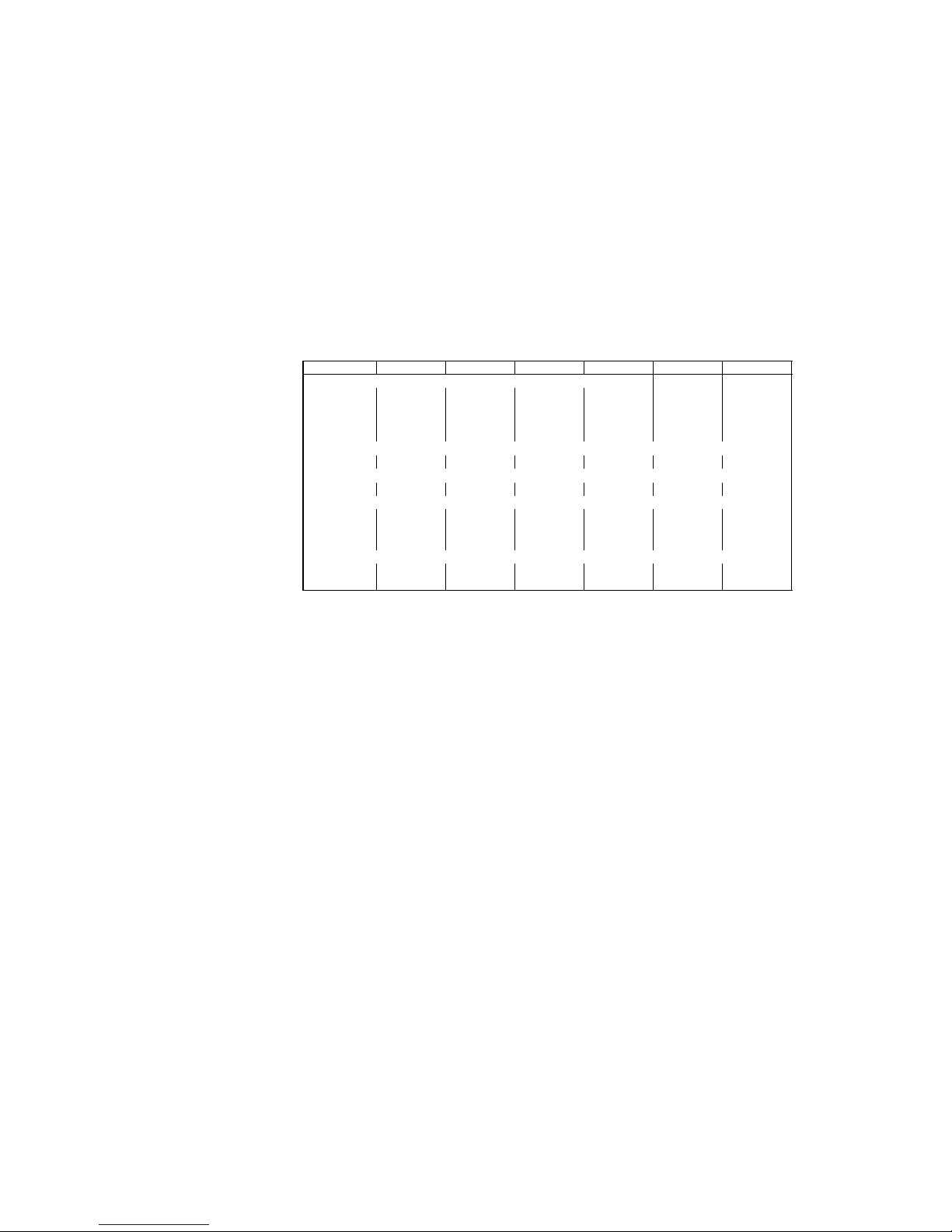

MODEL IAC630 IWC630 IRC630 IAC830 IWC830 IRC830

UNIT ELEC.

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 20 20 20

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQUIRED)

Amps 20 20 20 20 20 20

REFRIGERANT

Type R404a(HP62) R404a(HP62) R404a(HP62) R404a(HP 62) R404a(HP 62) R404a(HP 62)

Weight (oz) 43 35 170 55 33 170

Weight (g) 1219 992 4820 1559 936 4820

COMPRESSOR

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

6

TD 204

COMPRESSOR (CONT’D)

Hertz 60 60 60 60 60 60

LRA 69 69 69 61 61 61

RLA 8.8 8.8 8.8 12.5 12.5 12.5

CONDENSER FAN MOTOR (Air-Cooled System only) or

AIR CIRCULATION FAN MOTOR (Water-Cooled and Remote Systems only)

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

Amps Running 1.09 0.36 0.36 1.09 0.36 0.36

Watts 75 6 6 75 6 6

WATER PUMP

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

Amps Running 0.5 0.5 0.5 0.5 0.5 0.5

HP 1/30 1/30 1/30 1/30 1/30 1/30

7 TD 204

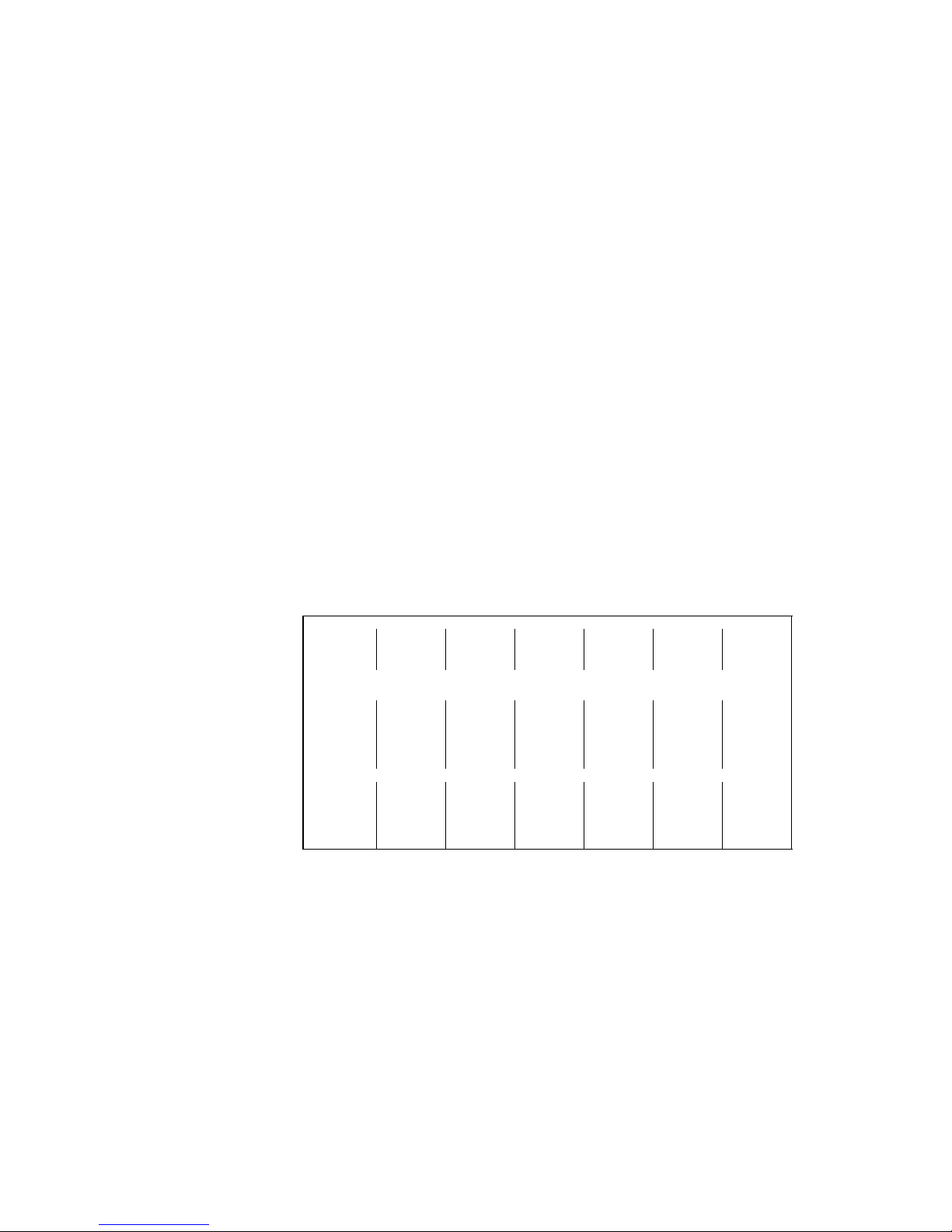

MODEL IAC1230 IWC1230 IRC1230 IAC1448 IWC1448 IRC1448

UNIT ELEC.

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 25 25 25

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQUIRED)

Amps 20 20 20 25 25 25

REFRIGERANT

Type R404a(HP62) R404a(HP62) R404a(HP62) R404a(HP 62) R404a(HP 62) R404a(HP 62)

Weight (oz) 49 45 210 92 44 250

Weight (g) 1389 1276 5954 2608 1247 7088

COMPRESSOR

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

8

TD 204

COMPRESSOR (CONT’D)

Hertz 60 60 60 60 60 60

LRA 96 96 96 95.6 95.6 95.6

RLA 13.5 13.5 13.5 23.9 23.9 23.9

CONDENSER FAN MOTOR (Air-Cooled System only) or

AIR CIRCULATION FAN MOTOR (Water-Cooled and Remote Systems only)

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

Amps Running 0.89 X 2 0.36 0.36 0.4 0.36 0.36

Watts 50 W X 2 6 W 6 W 1/15 HP 6 W 6 W

WATER PUMP

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

Amps Running 0.5 0.5 0.5 0.5 0.5 0.5

HP 1/30 1/30 1/30 1/30 1/30 1/30

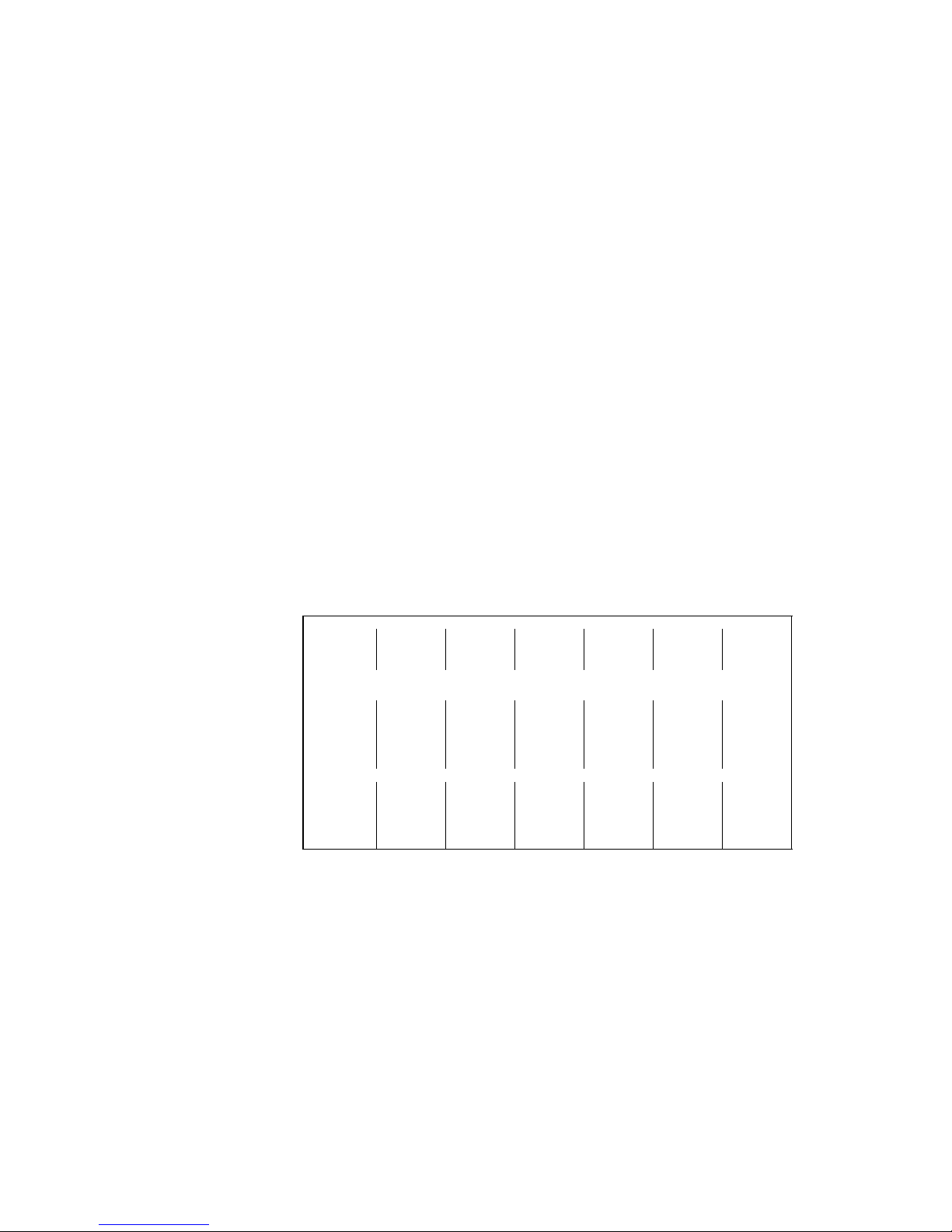

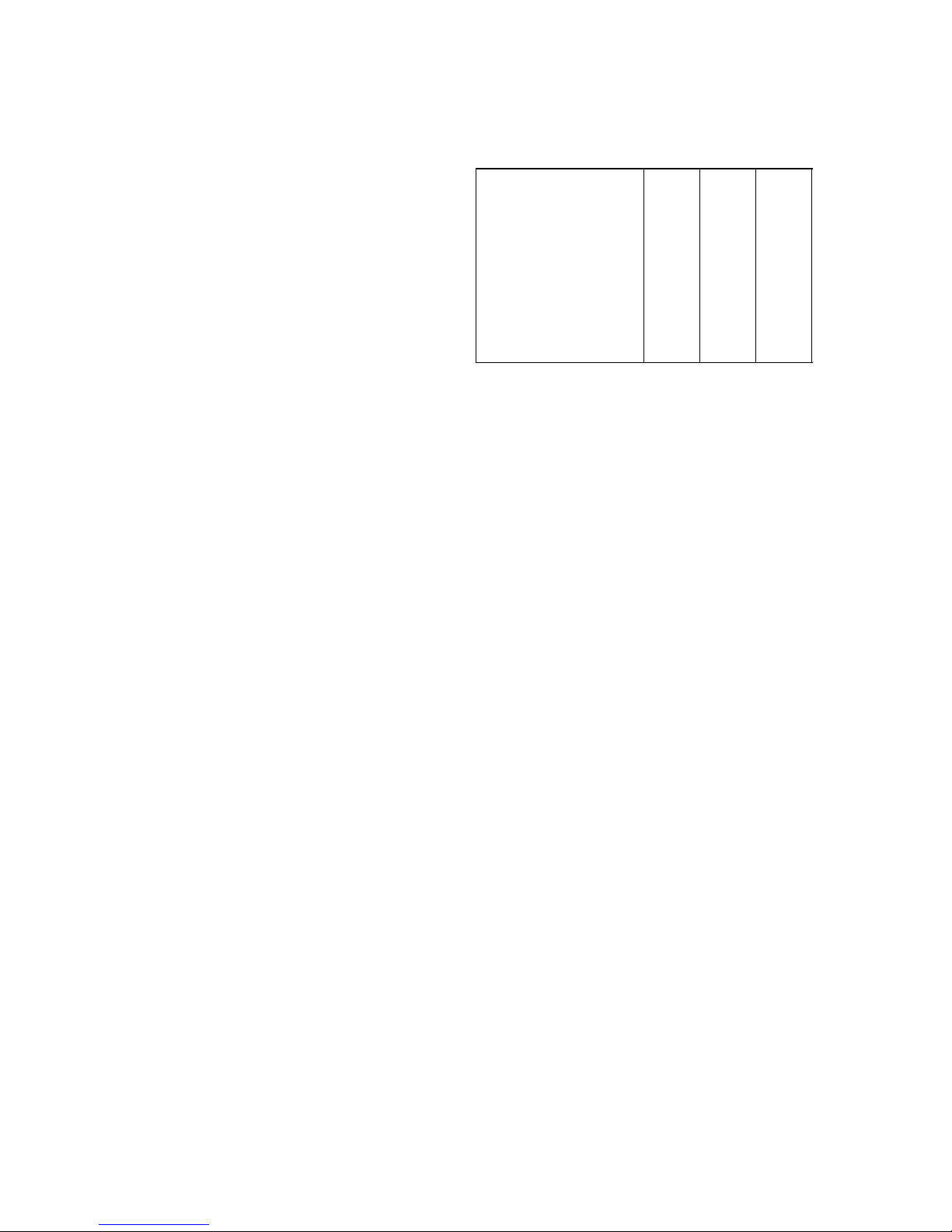

MODEL IRC630 IRC830. IRC1230 IRC1448

UNIT

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 25

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQUIRED)

Amps 20 20 20 25

REFRIGERANT

Type

Weight

(oz)

Weight (g) 4820 4820 5954 7088

COMPRESSOR

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

LRA 69 61 96 95.6

RLA 8.8 12.5 13.5 23.9

AIR CIRCULATION FAN MOTOR

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

Watts 6 6 6 6

WATER PUMP

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

HP 1/30 1/30 1/30 1/30

R404a

(HP62)

170 170 210 250

0.36 0.36 0.36 0.36

0.5 0.5 0.5 0.5

R404a

(HP62)

R404a

(HP62)

R404a

(HP 62)

9 TD 204

Remote Condenser

MODEL CR800 CR1200 CR1400

Volts 230 230 230

Phase 1 1 1

Hertz 60 60 60

Amps 1.0 1.0 1.0

Output, HP 1/6 1/6 1/6

Max. fuse size, Amps (HVAC

circuit breaker

required)

20 20 20

10TD 204

ICE CAPACITY INFORMATION

Ice Capacity

Ice capacity of any ice maker is affected by many operating conditions, such as water and air temperature and location factors. Please

review the capacity tables in this manual for average 24–hour capacity under various conditions.

NOTE: All printed capacity ratings are 10% except 50

HZ units these products have 12% increase in cycle

time and capacity decrease of approximately

17%.All printed capacity ratings are 10% except

50 HZ units these products have 12% increase in

cycle time and capacity decrease of approximately

17%.

Ice Production Check

If air cooled, take air temperature at the intake of the condenser, 2I

from the condenser fins.. Incoming water temperature at the outlet

of the “float” valve.*

Cycle time (CT) = freeze time plus harvest time, in minutes and seconds. 1440 divided by CT = number of cycles per 24 hours.

Measure weight of ice from one cycle in pounds and fractions of a

pound.

Example: Weight/cycle x cycles/day = total production/24 hrs.

* If water cooled be certain water regulator valve is set to maintain

300/310 PSI (20.68/21/37 Bars) head pressure.

Compare to the production tables.

11 TD 204

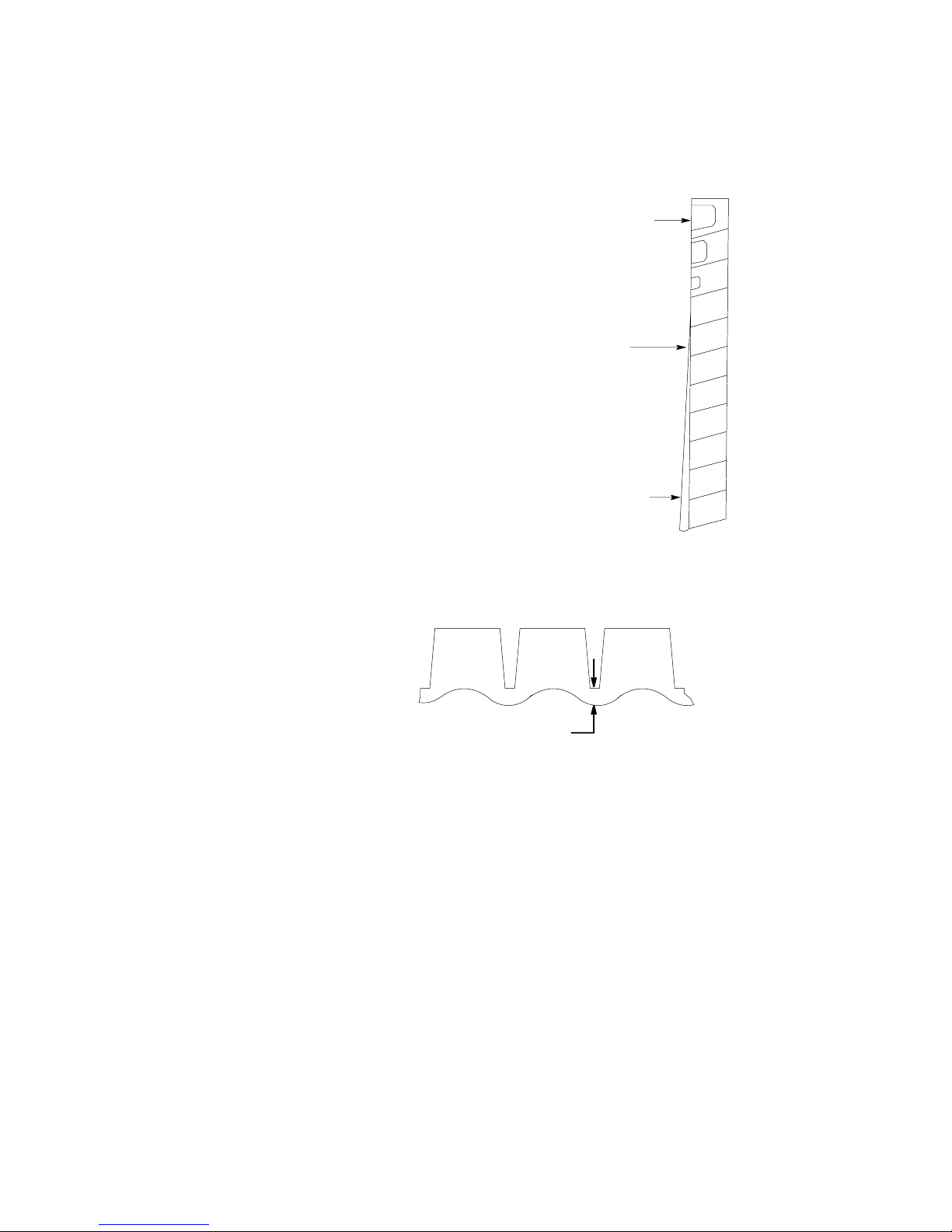

ADJUSTMENT OF ICE BRIDGE

THICKNESS

TOP ROW

.95 CM - 1.59 CM

DIMPLE

CENTER

.32 CM BRIDGE

BOTTOM 2 ROWS

.48 CM - .64 CM BRIDGE

For optimum ice production and maximum cube separation, the ice

connecting the individual cubes should be a minimum of 1/8”

(.32cm) thick at the center area of the ice waffle.

BRIDGE 1/8I (0.32 CM)

It is normal for the ice slab to be slightly thicker at the bottom and

taper off in a slight wedge pattern at the top. The top row of cubes

must have a complete pattern of ice on all four sides and the back

wall. Remember, when you operate the product with the panels off

during testing the additional heat at the top of the evaporator will

cause thinner ice at the top than when the panels are in place.

12TD 204

Should a different thickness of the bridge be desired, it will be required to adjust the ice thickness “POT”, located on the circuit

board, as follows:

1. Thinner Bridge – turn the ice thickness “pot” adjustment screw CW one full turn. Allow two cycles

before determining if additional adjustments are required.

2. Thicker Bridge – turn the ice thickness “pot” adjusting

screw CCW one full turn. Allow two cycles before

determining if additional adjustments are required.

NOTE: Never judge the thickness of the ice from the first

batch of the ice produced – the first cycle is a bal-

ance cycle. Always wait for the second cycle before

making any adjustments.

13 TD 204

14

TD 204

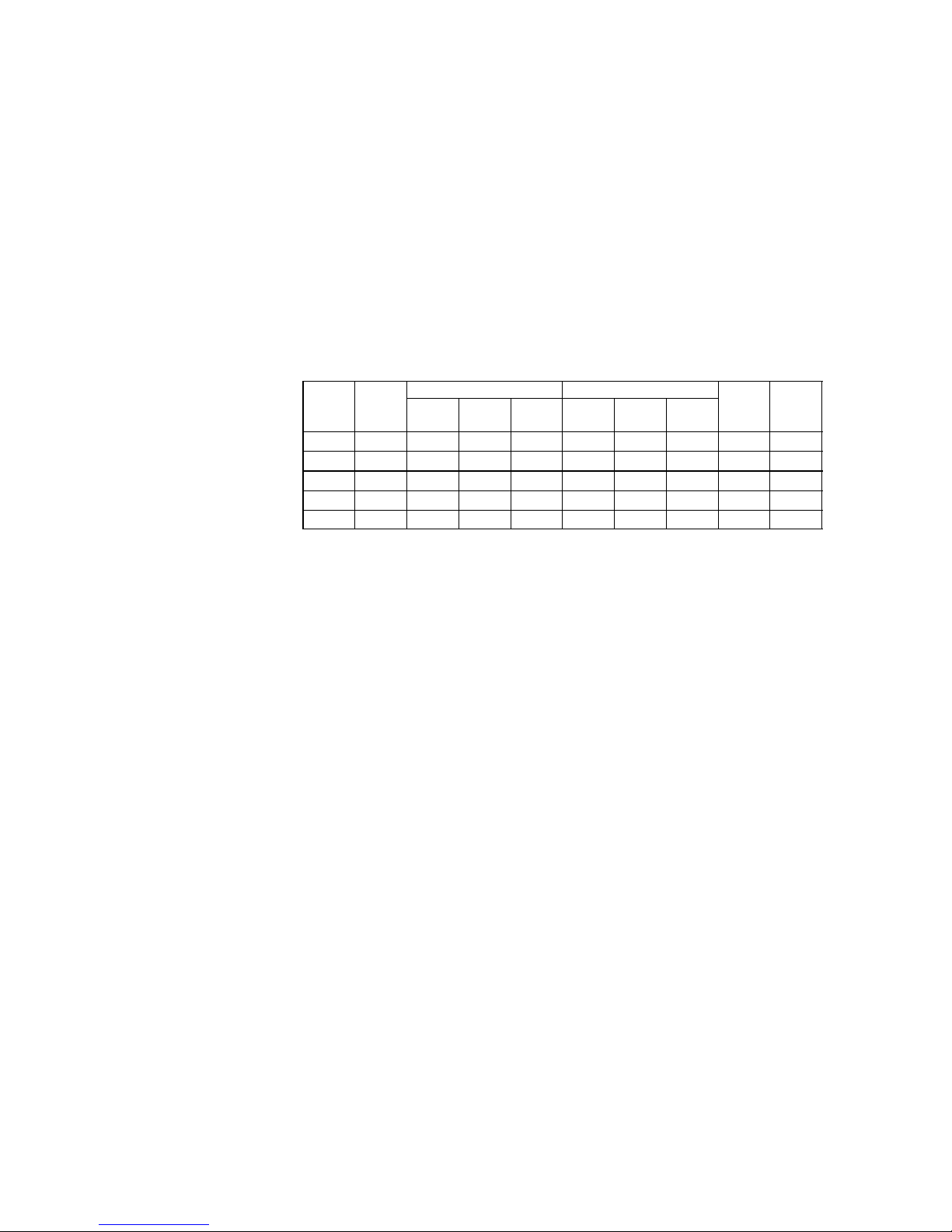

IAC322/IAC330

FREEZE CYCLE HARVEST CYCLE

AMBIENT

TEMP

_C

WATER

TEMP

_C

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

kg/Cycle

AVERAGE

ICE

WEIGHT

kg/day

21 10 1379 269 9:5 1034 724 1:1 1.1 147

27 21 1572 290 12:4 1103 758 0:9 1.1 118

32 21 1841 303 14:3 1262 917 0:7 1.1 109

32 27 1862 310 15.1 1248 896 0.7 1.1 100

38 21 2062 324 19:8 1372 979 0:6 1.3 91

15 TD 204

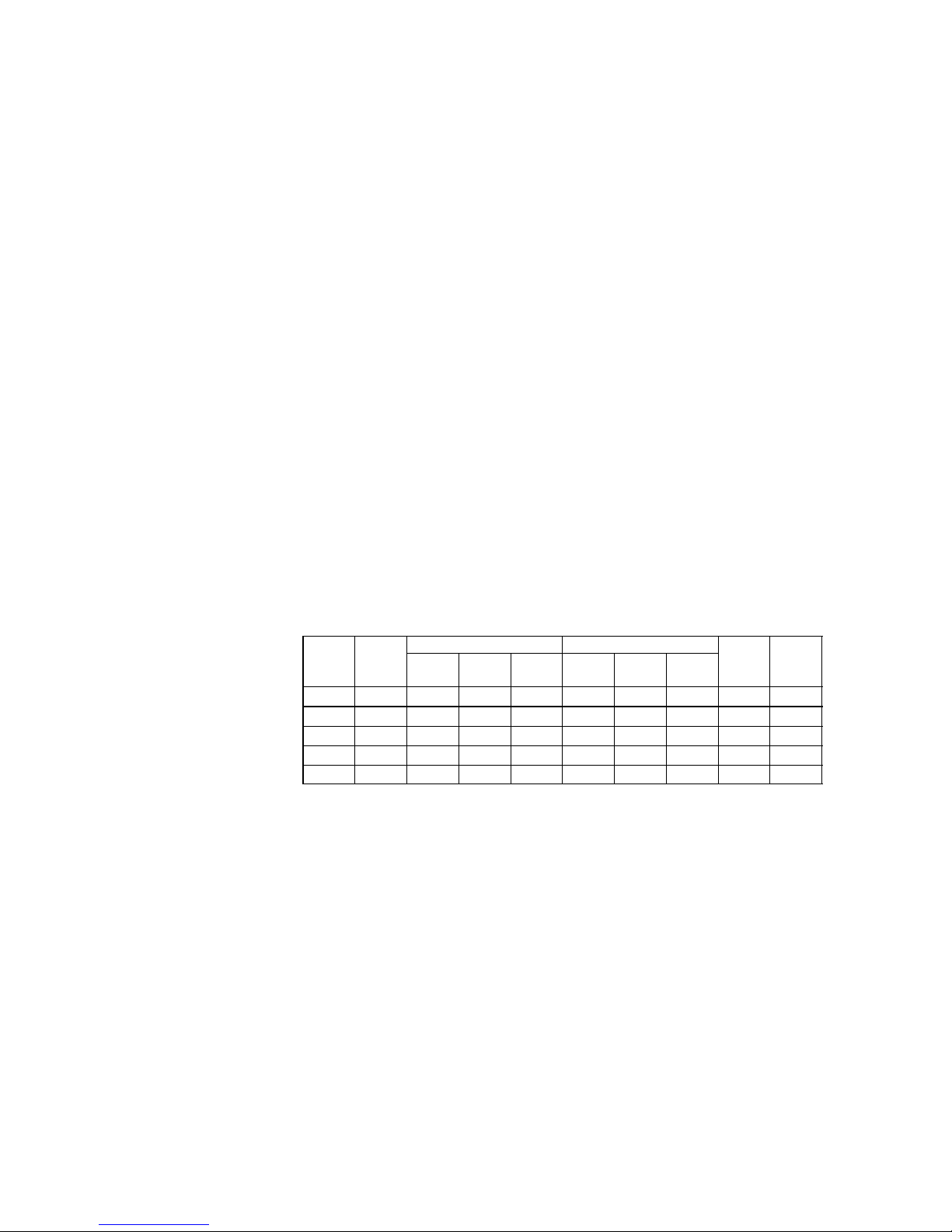

IWC322/IWC330

FREEZE CYCLE HARVEST CYCLE

AMBIENT

TEMP

_C

WATER

TEMP

_C

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

kg/Cycle

AVERAGE

ICE

WEIGHT

kg/day

21 10 2068 276 12:1 986 710 0:9 1.3 141

27 21 2068 290 15:3 1103 800 1:1 1.3 111

32 21 2068 296 16:2 1103 814 1:2 1.3 109

32 27 2089 303 16.4 1193 827 1.1 1.3 104

38 21 2068 303 16:3 1103 807 1:3 1.2 98

16

TD 204

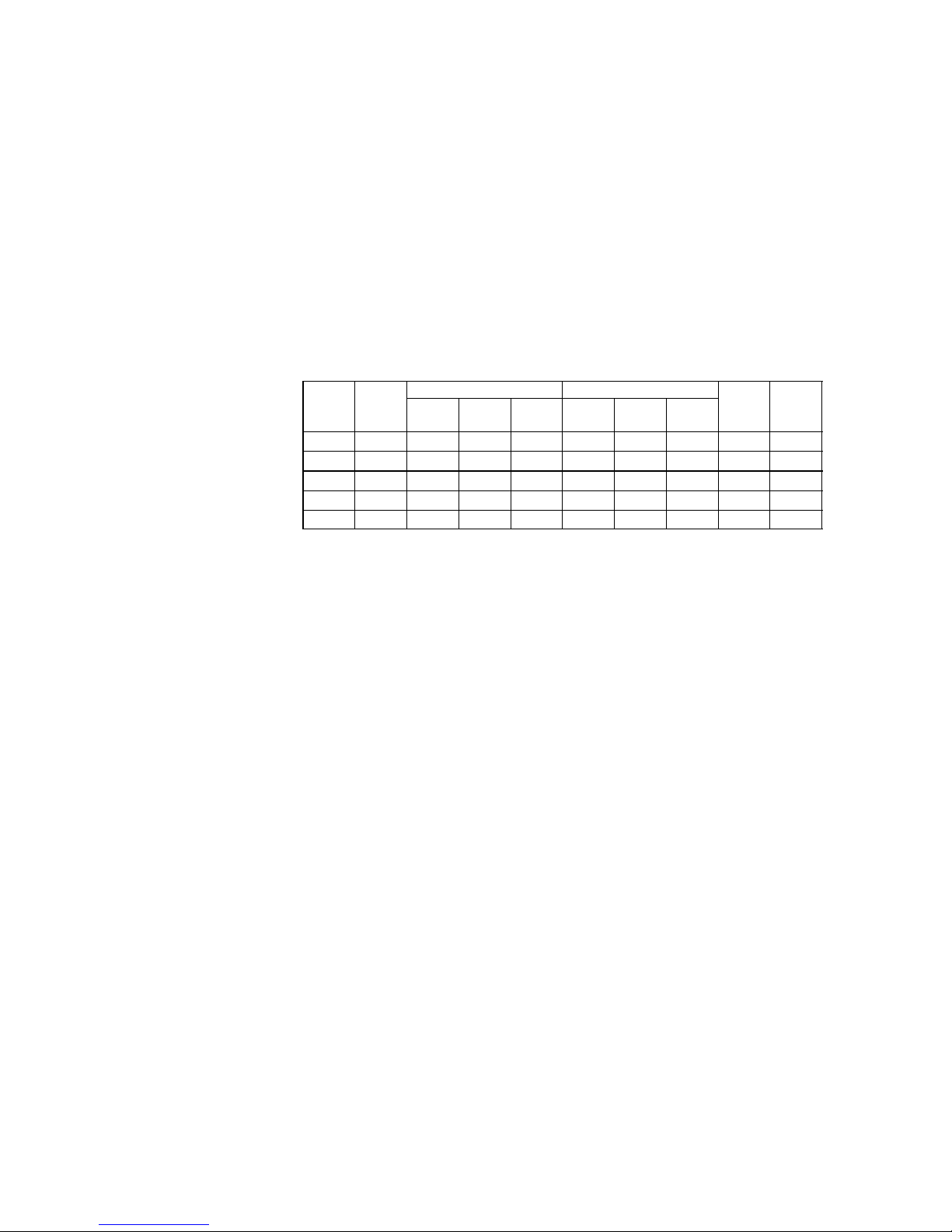

IAC522/IAC530

FREEZE CYCLE HARVEST CYCLE

AMBIENT

TEMP

_C

WATER

TEMP

_C

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

kg/Cycle

AVERAGE

ICE

WEIGHT

kg/day

21 10 1517 262 12.5 1069 655 1:0 2.3 245

27 21 1724 290 14.6 1207 765 0.9 2.2 204

32 21 1896 283 17.4 1344 827 0.7 2.3 184

32 27 1999 310 17.9 1379 827 0.6 2.3 176

38 21 2206 317 20.9 1517 827 0.6 2.4 159

17 TD 204

IWC522/IWC530

FREEZE CYCLE HARVEST CYCLE

AMBIENT

TEMP

_C

WATER

TEMP

_C

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

kPa

SUCTION

PRESSURE

kPa

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

kg/Cycle

AVERAGE

ICE

WEIGHT

kg/day

21 10 2227 303 11:3 1076 731 1:3 1.9 222

27 21 2255 310 13:7 1158 793 1:2 2.0 193

32 21 2248 310 13:8 1193 807 1:1 2.0 191

32 27 2261 324 15:2 1269 876 1:1 2.0 174

38 21 2255 310 13:9 1207 820 1:1 2.0 188

Loading...

Loading...