Page 1

IMPULSE

Non-Carbonated Post-Mix Beverage Dispenser

Installation & Operation Manual

Release Date: December 16, 2003

Publication Number: 859000159INS

Revision Date: June 01, 2012

Revision: B

Visit the IMI Cornelius web site at

www.cornelius.com for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation, operation or maintenance of

son(s) working on the equipment have been trained and are skilled in w

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in

ject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius’ Commercial Warrant applicable to this Product and is sub-

this equipment. This manual assumes that the per-

orking with electrical, plumbing, pneumatic,

Cornelius will not be responsible for any repair, replacement or

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

other service required by or loss or damage resulting

“non-authorized” parts (i.e., parts that are not 100%

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

-238-3600

800

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

This document contains the original instructions for the unit described.

IMI CORNELIUS INC

101 Regency

Glendale Heights, IL

Tel: + 1 800-238-3600

Drive

Printed in U.S.A.

Page 3

TABLE OF CONTENTS

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Different Types of Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CO

2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Requirements Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Counter-top Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connect Concentrate and Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Adjust Water-to-Concentrate Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Adjusting Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Starting and Stopping the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dispensing Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replenishing Concentrate Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Water-to-Concentrate Ratio Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning & Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Daily Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Sanitizing Concentrate Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Reference Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 4

Page 5

Non-Carbonated Impulse Installation & Operations Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

WARNING:

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit (decals, labels or

laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety regulations before

operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

DIFFERENT TYPES OF ALERTS

Indicates an immediate hazardous situation which if not avoided WILL result in serious injury, death or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in serious injury, death, or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury or equipment

damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young children or

infirm persons without supervision. Young children should be supervised to ensure that they do not play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL WIRING

AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD

RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

Publication Number: 859000159INS - 1 - © 2003-2012, IMI Cornelius Inc.

Page 6

Non-Carbonated Impulse Installation & Operational Manual

!

WARNING:

CAUTION:

!

CAUTION:

!

!

WARNING:

!

DANGER:

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued protection

observe the following:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the user. Verify

all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may result in

injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must be drained

from the system. A freezing ambient environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

MOUNTING IN OR ON A COUNTER

When installing the unit in or on a counter top, the counter must be able to support a weight in excess of 430 lbs. to

insure adequate support for the unit. FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH OR

EQUIPMENT DAMAGE.

NOTE: Many units incorporate the use of additional equipment such as icemakers. When any

addition equipment is used you must check with the equipment manufacturer to determine the

additional weight the counter will need to support to ensure a safe installation.

CO2 (CARBON DIOXIDE) WARNING

CO2 displaces oxygen. Strict attention MUST be observed in the prevention of CO2 gas leaks in the entire CO2 and

soft drink system. If a CO

contaminated area before attempting to repair the leak. Personnel exposed to high concentrations of CO

experience tremors which are followed rapidly by loss of consciousness and DEATH.

2 gas leak is suspected, particularly in a small area, IMMEDIATELY ventilate the

2 gas

© 2003-2012, IMI Cornelius Inc. - 2 - Publication Number: 859000159INS

Page 7

Non-Carbonated Impulse Installation & Operations Manual

!

WARNING:

!

DANGER:

!

WARNING:

CAUTION:

!

INSTALLATION

It is the responsibility of the installer to ensure that the water supply to the dispensing equipment is provided with

protection back flow by an air gap as defined in ANSI A 112.1.2-1979; or an approved vacuum breaker or other such

method as proved effective by test and must comply with all federal, state and local codes.

Failure to comply could result in serious injury, death or damage to the equipment.

Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed and

maintained according to Federal, State and Local laws.

INSTALLATION REQUIREMENTS

Requirements Summary

Weight

Environment

Temperat ure

Clearance

CO2:

Concentrate:

Water

Electrical:

Front or rear counter must be level and able to support 400 lbs

Indoor Installation only

40° To 110° F Ambient Temperature

18-Inches above 6-Inches on Sides and Rear

75 Psi (5.25 Bar) At Unit With Internal Carbonator

60 Psi

50 Psi Maximum

See Nameplate On Unit For Electrical Requirements

ELECTRICAL REQUIREMENTS

Before connecting electrical power to the unit refer to nameplate to verify power requirements

To avoid possible serious injury or death the ELCB (earth leakage circuit breaker) must be installed in electrical circuit of all 50 Hz units.

To avoid possible electrical shock the unit must be electrically grounded using the green grounding screw provided

inside the electrical contractor box.

The wiring must be properly grounded and connected through a 10-amp disconnect switch (slow–blow fuse or

equivalent HVAC/R circuit breaker). ALL WIRING MUST CONFORM TO NATIONAL AND LOCAL CODES. MAKE

SURE UNIT IS PROPERLY GROUNDED

Publication Number: 859000159INS - 3 - © 2003-2012, IMI Cornelius Inc.

Page 8

Non-Carbonated Impulse Installation & Operational Manual

INSTALLATION PROCEDURE

COUNTER-TOP INSTALLATION

NOTE: Optional 4-inch legs (p/n 3184) will elevate the unit 4 inches above counter (order 4 legs).

1. Place the unit on a level counter capable of supporting at least 400 pounds.

2. Remove drip tray and front access panel.

3. Turn power switch off then remove screw located next to the power switch and the screw at top of front panel.

Next, remove front panel, disconnect wires to valve key lock switch, and peal back magnetic decals from the

top. Lift off top center section.

4. Pull water, concentrate, and CO

the unit must be sealed to the counter top and all access holes in the unit base must be sealed, or the unit can

be installed using the optional 4-inch legs (P/N 3184). Caulk/seal the unit to the counter using Dow Corning

RTV 731 or equivalent approved sealant.

5. Pull plastic “wire tie” to remove hitch pin from condenser fan motor assembly (this pin is only needed during

shipping).

lines through counter or wall. To comply with NSF International requirements

2

Figure 1.

6. Fill the water bath with clean water until it comes out the overflow tube. Make sure the overflow tube is not

blocked or plugged. Use low-mineral tap water, not distilled or deionized water.

Figure 2.

NOTE: Water bath must be filled with water before the unit will run.

© 2003-2012, IMI Cornelius Inc. - 4 - Publication Number: 859000159INS

Page 9

Non-Carbonated Impulse Installation & Operations Manual

GLOBAL ICE BANK CONTROL (GIBO) THEORY OF OPERATION

Once electrical power is supplied to the Unit,

the agitator motor will start. There will be a

three-minute time delay before the refrigeration

compressor and the condenser fan motor will

start. This three-minute time delay will take

place each time electrical power to the Unit is

interrupted.

evaporator coil becomes thick enough, it

covers the three stainless-steel pins on the

ice bank control probe. The control module

senses there is enough ice and turns the

refrigeration compressor and the

condenser fan motor off.

The Unit will continue to operate until ice

covers all three stainless-steel pins on the ice

bank control probe. The ice bank control

module senses this by measuring the

difference in electrical resistance between the

water and the ice. When the ice on the

NOTE: Make sure that the electrical power circuit breaker is switched off or the fuse removed.

Before connecting electrical power to the unit, refer to nameplate to verify the power requirements.

A. Remove the following:

• front merchandiser by removing two screws on the top and lifting up

• key switch wires

• hood by removing two screws on the top and lifting up and forward.

B. Remove second valve from the left to facilitate routing of the new cord.

C. First route the new cord up behind the valve panel and through the cutout in the pump deck. Use the

already attached wire tie/fastener on the deck to secure the cord.

D. Connect cord to the receptacle on the refrigeration deck.

E. Turn the circuit breaker on and then the units power switch. Check to see that the agitator motor has

started. After about three minutes the compressor should start. If the agitator or compressor do not start call

Technical Services.

The Unit remains turned off until the ice

bank control three stainless-steel pins are

free of ice. Once this happens, the ice bank

control module starts the refrigeration

compressor and the condenser fan motor.

CONNECT CONCENTRATE AND WATER LINES

1. Route concentrate and plain water lines from the back side of the unit and under the unit to the front. Connect

them to the appropriate inlet connections.

NOTE: If water supply pressure to the unit is less than 40 psi, a water pressure booster is

required. If water supply pressure to the unit is more than 50 psi, a water pressure regulator must

be installed in the supply line.

NOTE: A water shutoff valve and water filter in the water supply line are recommended.

2. Make the connection behind the splash panel to the marked 3/8 water tubes.

3. Connect optional drip tray drain hose (if used). Be sure the knock-out in the drip pan has been removed if drain

hose is used.

4. Bleed each valve into a bucket until water comes out.

5. Be sure that all concentrate sources are connected and on. Bleed each valve into a bucket until concentrate

comes out.

6. Reinstall drip tray and position water bath overflow hose in drip tray indent.

Publication Number: 859000159INS - 5 - © 2003-2012, IMI Cornelius Inc.

Page 10

Non-Carbonated Impulse Installation & Operational Manual

7. Check the system for gas leaks by pressurizing the system and then turning off the cylinder valve. Wait a couple of minutes and check the cylinder gauge to see if the pressure has dropped.

8. Check the system for water and concentrate leaks.

ADJUST WATER-TO-CONCENTRATE RATIO

1. Remove valve front cover and install concentrate diversion assembly in place of nozzle.

Figure 3.

2. Adjust carbonated water flow to the desired rate (such as 2.50 oz./sec.).

Turn the adjuster 1/4 of a turn at a time and recheck the flow.

To increase flow turn clockwise.

3. Adjust the concentrate-to-water ratio of each valve using the concentrate adjuster on the left side of each valve.

Hold cup under valve and dispense beverage for a specific time (such as 4 seconds).

ADJUSTING FLOW RATES

Flow rates of the water and concentrate are adjusted based on the desired ratio. For example: if the desired ratio is

5:1, then the flow rate of the water is 5 times that of the concentrate.

If the desired finished drink flow rate is 3.0 ounces per second, then the water flow rate is 2.5 oz./sec. and the concentrate flow rate is 0.5 oz./sec. (The water at 2.5 oz./sec. is five times the 0.5 oz./sec. concentrate flow rate.)

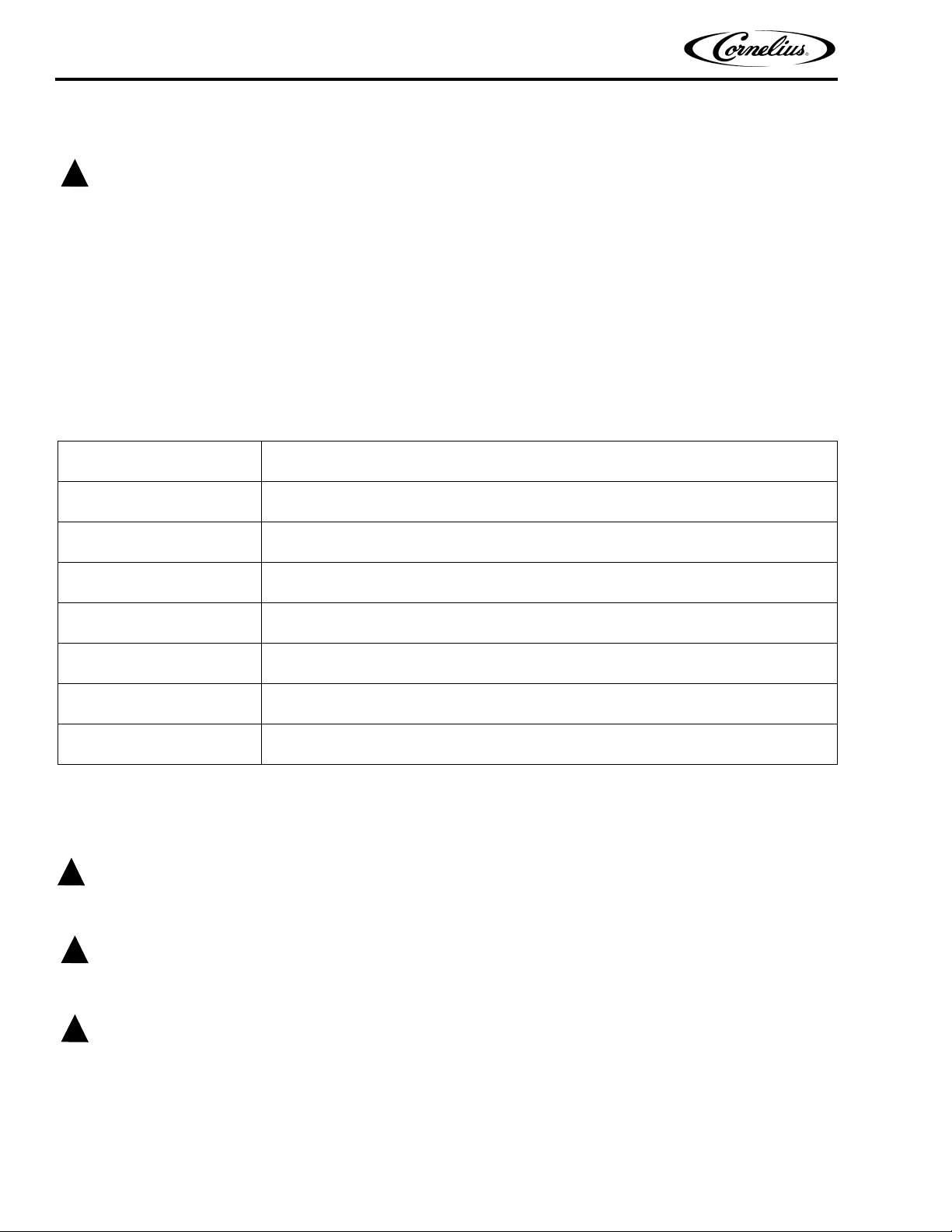

Flow Rates oz./sec. Based on 5:1 Ratio

inished Drink oz./sec. Water oz./sec. Concentrate oz./sec.

F

1.5 1.25 .25

2.0 1.67 .33

2.5 2.08 .42

3.0 2.5 .50

3.5 2.92 .58

4.0 3.33 .67

4.5 3.75 .75

© 2003-2012, IMI Cornelius Inc. - 6 - Publication Number: 859000159INS

Page 11

Non-Carbonated Impulse Installation & Operations Manual

OPERATIONS

STARTING AND STOPPING THE UNIT

Figure 4.

1. Push power ON/OFF switch to ON to power on the unit.

2. Insert key into key lock and turn to the

ON to activate valves.

DISPENSING PRODUCT

To dispense beverage press a cup or glass against the lever or push the button on the valve cover.

REPLENISHING CONCENTRATE SUPPLY

Bag-In-Box System:

1. Disconnect the concentrate tube from the empty bag-in-box and remove the empty box.

Rinse the disconnects in warm water to remove any concentrate residue.

2.

3. Install a full bag-in-box and connect the concentrate tube.

ADJUSTMENTS

WATER-TO-CONCENTRATE RATIO ADJUSTMENT

The ratio adjustment should only be done by a qualified service person.

Publication Number: 859000159INS - 7 - © 2003-2012, IMI Cornelius Inc.

Page 12

Non-Carbonated Impulse Installation & Operational Manual

CLEANING & CHECKS

Daily Cleaning

1. Remove nozzle assembly and rinse with warm (not hot) water. If possible, soak nozzle assembly over night in

carbonated water then rinse with warm water.

Figure 5.

2. Wash external surfaces with mild soap solution, rinse with clean water, and wipe dry. Remove the drip tray,

wash with mild soap solution, rinse and dry.

NOTE: Do not use abrasive or harsh cleaners on the unit.

Daily Checks

1. Check CO2 supply.

2. Check concentrate supply.

SANITIZING CONCENTRATE SYSTEMS

The concentrate systems should be sanitized at least every 120-days and before or after storage. Use a nonscented liquid household bleach containing a 5.25% sodium hypochlorite concentration per the following procedure:

NOTE: Only qualified Service Personnel should perform sanitizing procedure on the post-mix

. Rinse bag-in-box connectors (concentrate bag-in-box systems) in warm potable water.

1

STEP 1. Wash Concentrate Systems

1. Using a five-gallon container

o

gent by using 70

one gallon of potable water. Stir detergent solution to thoroughly mix the solution.

2. Bag-in Box Concentrate Systems.

A. Install bag valves, cut from empty bag-in-box concentrate containers, on ends of concentrate containers

concentrate outlet tubes connectors.

B. Place all concentrate outlet tubes, with bag valves on their ends, in container containing detergent solution.

3. Flush the concentrate system and dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all concentrate and flush out the concentrate system.

F (21oC) to 100oF (38oC) potable water and 0.5 oz. (15 ml) of liquid dishwasher detergent to

(bag-in-box system), prepare a full tank or container of liquid dishwasher deter-

4. Repeat the process for each concentrate circuits.

5. Remove detergent solution source from the concentrate system.

STEP 2. Flush Concentrate Systems

Fill five-gallon container with potab

tubes in container containing potable water.

1. Flush detergent solution out of the concentrate system and dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

© 2003-2012, IMI Cornelius Inc. - 8 - Publication Number: 859000159INS

le water, then place all bag-in-box concentrate containers concentrate outlet

Page 13

Non-Carbonated Impulse Installation & Operations Manual

!

WARNING:

B. Activate the dispensing valve for one minute to purge all detergent solution and flush out the concentrate

system.

2. Connect potable water source to the remaining concentrate systems and flush detergent solution out of the

concentrate systems as instructed in step 9 preceding.

3. Remove potable water source from the concentrate system.

STEP 3. Sanitize Concentrate Systems

1. Using five-gallon container (bag-in-box system), prepare

potable water and 0.5 oz. (15 ml) of non-scented household liquid bleach that contains a 5.25% sodium hypochlorite concentration to one gallon of potable water. This mixture must not exceed 200 PPM of chlorine. Stir

sanitizing solution to thoroughly mix.

2. Bag-in-Box Concentrate System.

Place all bag-in-box concentrate containers concentrate outlet tubes in container containing sanitizing solution.

3. Sanitize the concentrate system and dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all water from and install sanitizing solution in the con-

centrate system and dispensing valve.

C. Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for 15-seconds).

Repeat “ON” and “OFF” cycles for 15-cycles.

4. Repeat step 3 to flush water out of and install sanitizing solution in the remaining concentrate systems and dispensing valves.

5. Remove sanitizing solution source from the concentrate system.

6. Allow sanitizing solution to remain in the concentrate systems for not less than 10 or no more than 15-minutes.

STEP 4. Water Flush Concentrate Systems

Flush sanitizing solution from the concentrate systems as instructed. Residual sanitizing solution left in the

concentrate systems could create a health hazard.

1. Bag-in-Box Concentrate System.

A. Place all bag-in-box concentrate containers concentrate outlet tubes in container containing potable water.

2. Flush sanitizing solution from the concentrate system and the dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all sanitizing solution out of the concentrate system

and the dispensing valve.

sanitizing solution using 70oF (21oC) to100oF (38oC)

3. Repeat this process for each concentrate circuit.

4. Remove potable water source from the concentrate system.

STEP 5. Purge Water out of Concentrate Systems (Restore Operation)

1. Bag-in-Box Concentrate System.

Remove all bag valves from bag-in-box concentrate containers outlet tubes connectors.

A.

B. Connect bag-in-box concentrate containers into the concentrate systems.

2. Place waste container under dispensing valves. Dispense from all dispensing valves to permit concentrate to

purge all potable water from the concentrate systems and the dispensing valves. Continue to dispense from the

dispensing valves until only concentrate is dispensed from the concentrate systems and valves.

3. Dispose of waste sanitizing solution in a sanitary sewer, not in a storm drain, then thoroughly rinse the inside

and the outside of the container that was used for sanitizing solution to remove all sanitizing solution residue.

Publication Number: 859000159INS - 9 - © 2003-2012, IMI Cornelius Inc.

Page 14

Non-Carbonated Impulse Installation & Operational Manual

REFERENCE MATERIAL

Figure 6. Wiring Diagram

© 2003-2012, IMI Cornelius Inc. - 10 - Publication Number: 859000159INS

Page 15

Non-Carbonated Impulse Installation & Operations Manual

Figure 7. Plumbling Diagrams - Internal Carbonator

Figure 8. Plumbing Diagrams - External Carbonator

Publication Number: 859000159INS - 11 - © 2003-2012, IMI Cornelius Inc.

Page 16

Non-Carbonated Impulse Installation & Operational Manual

Figure 9.

© 2003-2012, IMI Cornelius Inc. - 12 - Publication Number: 859000159INS

Page 17

Non-Carbonated Impulse Installation & Operations Manual

TROUBLESHOOTING

Trouble Probable Cause Remedy

Troubleshooting Dispensing System

WATER-TO-CONCENTRATE

“RATIO”TOO LOW OR TOO HIGH.

ADJUSTMENT OF DISPENSING

VALVE CONCENTRATE FLOW REGULATOR DOES NOT INCREASE TO

DESIRED WATER-TO-CONCENTRAT E “RAT IO” .

ADJUSTMENT OF DISPENSING

VALVE CONCENTRATE REGULATOR DOES NOT DECREASE TO

DESIRED WATER-TO-CONCENTRAT E “RAT IO” .

NO PRODUCT DISPENSED.

ONLY CONCENTRATE DISPENSED.

• Dispensing valve concentrate

flow regulator not properly

• Adjust Water-to-Concentrate

“Ratio” as instructed.

adjusted.

2 gas pressure to concen-

• CO

trate pumps insufficient to

• Adjust concentrate pumps CO2

regulator as instructed.

operate pumps.

• No concentrate supply. • Replenish concentrate supply

as instructed.

• Concentrate supply container

not securely connected into

concentrate system.

• Concentrate pumps CO

2 reg-

ulator out of adjustment.

• Dispensing valve syrup flow

regulator, syrup tank quick

• Securely connect concentrate

supply container into concentrate system.

• Adjust concentrate pumps CO2

regulator as instructed.

• Sanitize syrup system as

instructed.

disconnect, or syrup line

restricted.

• Improper Baume of concen-

• Replace concentrate supply.

trate.

• Dirty or inoperative concentrate flow regulator.

• Disassemble and clean dispensing valve concentrate flow

regulator.

• Tapered plastic washer inside

tube swivel nut connection

• Replace plastic washer. Make

sure it seats properly.

distorted from being over

tightened restricting concentrate flow.

• Dirty or inoperative concentrate flow regulator.

• Disassemble and clean dispensing valve concentrate flow

regulator.

• Dispensing valves keyed lockout switch in “OFF” position.

• Place keyed lock-out switch in

“ON” position.

• No electrical power to Unit. • Plug in Unit power cord or

check for blown fuse or tripped

circuit breaker.

• Disconnected dispensing

valve power cord.

• Disconnected or broken wir-

• Connect dispensing valves

power cord.

• Connect or replace wiring.

ing to dispensing valves.

• Inoperative transformer or

• Replace inoperative part.

dispensing valve solenoids.

• Water inlet supply line shutoff

valve closed.

• Open water inlet supply line

shutoff valve.

Publication Number: 859000159INS - 13 - © 2003-2012, IMI Cornelius Inc.

Page 18

Non-Carbonated Impulse Installation & Operational Manual

Troubleshooting Refrigeration System

COMPRESSOR DOES NOT OPERATE.

COMPRESSOR WILL NOT STOP

AFTER SUFFICIENT ICE BANK IS

FORMED.

COMPRESSOR OPERATED CONTINUOUSLY BUT DOES NOT FORM

SUFFICIENT ICE BANK.

NOTE: The ice bank freezes from the bottom of the evaporator upward. A refrigerant leaks or

insufficient charge might show an ice bank at bottom and not at the top of evaporator.

NOTE: If overload protector cuts our compressor, condenser fan motor will continue to operate,

otherwise, troubleshooting condenser fan motor problems are the same as “COMPRESSOR

DOES NOT OPERATE” paragraph plus the preceding.

CONDENSER FAN MOTOR NOT

OPERATING.

AGITATOR MOTOR NOT OPERATING.

• Ice bank sufficient. • Refrigeration not called for.

• Unit power cord unplugged or

control board power switch in

• Plug in power cord or place

switch in “ON” position.

“OFF” position.

• No power source (blown fuse

or tripped circuit breaker).

• Replace fuse or reset circuit

breaker (note: Fuse or circuit

breaker are not part of unit).

• Low voltage at compressor

terminals.

• Voltage must be at least 103

volts at the compressor terminals when compressor is trying

to start.

• Loose, disconnected or broken wiring.

• Overload protector cut out;

over heated compressor.

Condenser fan motor not

operating as required.

• Tighten connections or replace

broken wiring.

• Compressor will cool enough to

restart. Do not overdraw cooling capacity of unit. Refer to

“CONDENSER FAN MOTOR

NOT OPERATING” in this section.

• Inoperative overload protector

• Replace inoperative part as

or start relay.

• Inoperative ice bank control. • Replace ice bank control.

• Inoperative compressor. • Replace compressor.

• Inoperative thermistor. • Replace thermistor.

• Damaged ice bank control

• Repair ice bank control.

wire.

• Inoperative control board. • Replace control board.

• Cooling capacity is exceeded

by overdrawing.

• Unit located in excessively hot

area or air circulation through

condenser is restricted.

• Reduce amount of drinks drawn

per given time.

• Relocate unit or determine and

correct condenser coil restrictions.

• Refrigeration system leak. • Repair refrigeration system.

• Jumper cord loose or disconnected from motor or terminal

• Tighten connections or replace

cord.

block. Broken wire in cord.

• Fan blade obstructed. • Remove obstruction.

• Inoperative condenser fan

• Replace condenser fan motor.

motor.

• Unit power cord or refrigera-

• Plug in power cord.

tion system power cord

unplugged.

© 2003-2012, IMI Cornelius Inc. - 14 - Publication Number: 859000159INS

Page 19

Non-Carbonated Impulse Installation & Operations Manual

• No power source. Blown fuse

or. tripped circuit breaker

• Replace fuse or reset circuit

breaker (note: Fuse or circuit

breaker are not part of unit).

• Agitator motor propeller

• Remove obstruction.

obstructed.

• Low voltage at compressor

terminals.

• Voltage must be at least 103

volts at the compressor terminals when compressor is trying

to start.

• Loose, disconnected, or broken wiring.

• Tighten connections or replace

broken wiring.

• Inoperative agitator motor. • Replace agitator motor as

instructed.

Publication Number: 859000159INS - 15 - © 2003-2012, IMI Cornelius Inc.

Page 20

Non-Carbonated Impulse Installation & Operational Manual

© 2003-2012, IMI Cornelius Inc. - 16 - Publication Number: 859000159INS

Page 21

Page 22

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...