Cornelius IMD300-15A, IMD300-30W, IMD302-15A, IMD300-30A, IMD301-30A Installation Manual

...

IMI CORNELIUS INC g One Cornelius Place g Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (612) 422-3246

Installation Manual

COUNTERTOP ICEMAKER

IMD SERIES

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of

the Installer to ensure that

the water supply to the

dispensing equipment is

provided with protection

against backflow by an air

gap as defined in

ANSI/ASME A112.1.2-1979;

or an approved vacuum

breaker or other such

method as proved effective

by test.

Water pipe connections

and fixtures directly

connected to a potable

water supply shall be

sized, installed, and

maintained according to

Federal, State, and Local

Codes.

Part No. 638085277

Revisied October 16, 2000

Revision B

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 94-2000Ó

PRINTED IN U.S.A

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATION CHART 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GUIDE TO SERVICE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICEMAKER CLEANING AND SANITIZING PROCEDURES 9. . . . . . . . . . . . . . . . .

MAINTENANCE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MONTHLY 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

QUARTERLY 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEMI--ANNUALLY 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER LEVEL CONTROL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW WATER LEVEL CONTROL WORKS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PURPOSE OF WATER LEVEL CONTROL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE WATER LEVEL CONTROL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE WATER LEVEL SAFETY SWITCH 11. . . . . . . . . . . . . . . . . . . . . . . . . .

ICE LEVEL CONTROL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEMPERATURE / PRESSURE CHARTS* 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR TEMPERATURE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 LBS. DISCHARGE PRESSURE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER TEMPERATURE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMD300--5 & IMD300--15 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMD300--30 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMD600--30, IMD600--90 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION SYSTEM ADJUSTMENTS 12.. .. .. .. .. .. .. .. .. .. .. .. .. .. .

EXPANSION VALVE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT AND TROUBLESHOOTING 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER MODULATING VALVE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER MODULATING VALVE REMOVAL 13.. . . . . . . . . . . . . . . . . . . . . . . . .

GEAR MOTOR 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHAFT SEAL INSTALLATION AND REPLACEMENT (SEE FIGURE 7.) 14. . . . .

AUGER & EXTRUDING HEAD REMOVAL 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION AND SHAFT SEAL REPLACEMENT (SEE FIGURE 9.) 15. . . . . .

UPPER NUT AND BEARINGS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE BEARINGS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING COMPRESSOR 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CHECKOUT 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVERLOAD CHECK -- FIGURE 10. 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR CHECK -- FIGURE 11. 17. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

CAPACITOR CHECK 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

i 638085277

TABLE OF CONTENTS (cont’d)

TROUBLESHOOTING GEAR MOTORS 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE GEARMOTOR WILL NOT RUN 17.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE GEARMOTOR STAR TS BUTS TRIPS REPEATEDLY ON THE

OVERLOAD PROTECTOR: 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE MOTOR RUNS BUT OUTPUT SHAFT DOES NOT ROTATE: 17. . . . . . .

OVERLOAD CHECK: 17. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

MOTOR CHECK: 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY CONTROLS 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GUIDE TO GOOD ICE 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING CHART -- ICEMAKER NOT OPERATING 21. . . . . . . . . . . . . . . .

PARTS LIST 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION AND FRAME ASSEMBLY IMD 300-15 PARTS LIST 29. . . . . . .

REFRIGERATION AND FRAME ASSEMBLY IMD 300--30 AND IMD 600--30

PARTS LIST 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION AND FRAME ASSEMBLY IMD 600--90 PART LIST 33. . . . . . . .

ICE LEVEL CONTROL ASSEMBLY PARTS LIST FOR PAR T NO

32770 IMD 300--15 AND 32770--002 IMD302--15 37. . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE LEVEL CONTROL ASSEMBLY PARTS LIST IMD300--30 AND IMD600--30

PART NUO 31494--001 (115V) PART NO. 31494--002 (208V/220V) 39. . . . . . . . . . .

ICE LEVEL CONATROL ASSEMBLY PARTS LIST IMD 600--90

PART NO. 31892 41. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

BIN AND FRONT END ASSEMBLY PARTS LIST IMD 300-15, IMD 300-30

AND 600-30 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BIN AND FRONT END ASSEMBLY IMD PARTS LIST 600-90 45. . . . . . . . . . . . . . .

ELECTRICAL BOX ASSEMBLY PARTS LIST, PART NO. 32776 IMD 300--15

AND PAR T NO. 32776-002 IMD 302-15 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL BOX ASSEMBLY PARTS LIST IMD 300--30,

IMD 600--30 AND IMD 600-90 (ALL VOLTAGES) 49. . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSE MECHANISM ASSEMBLY PARTS LIST IMD 300-15, IMD300-30,

IMD 600-30 AND IMD 600-90 PARTS LIST 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR MOTOR ASSEMBLY PARTS LIST 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 60.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

Page

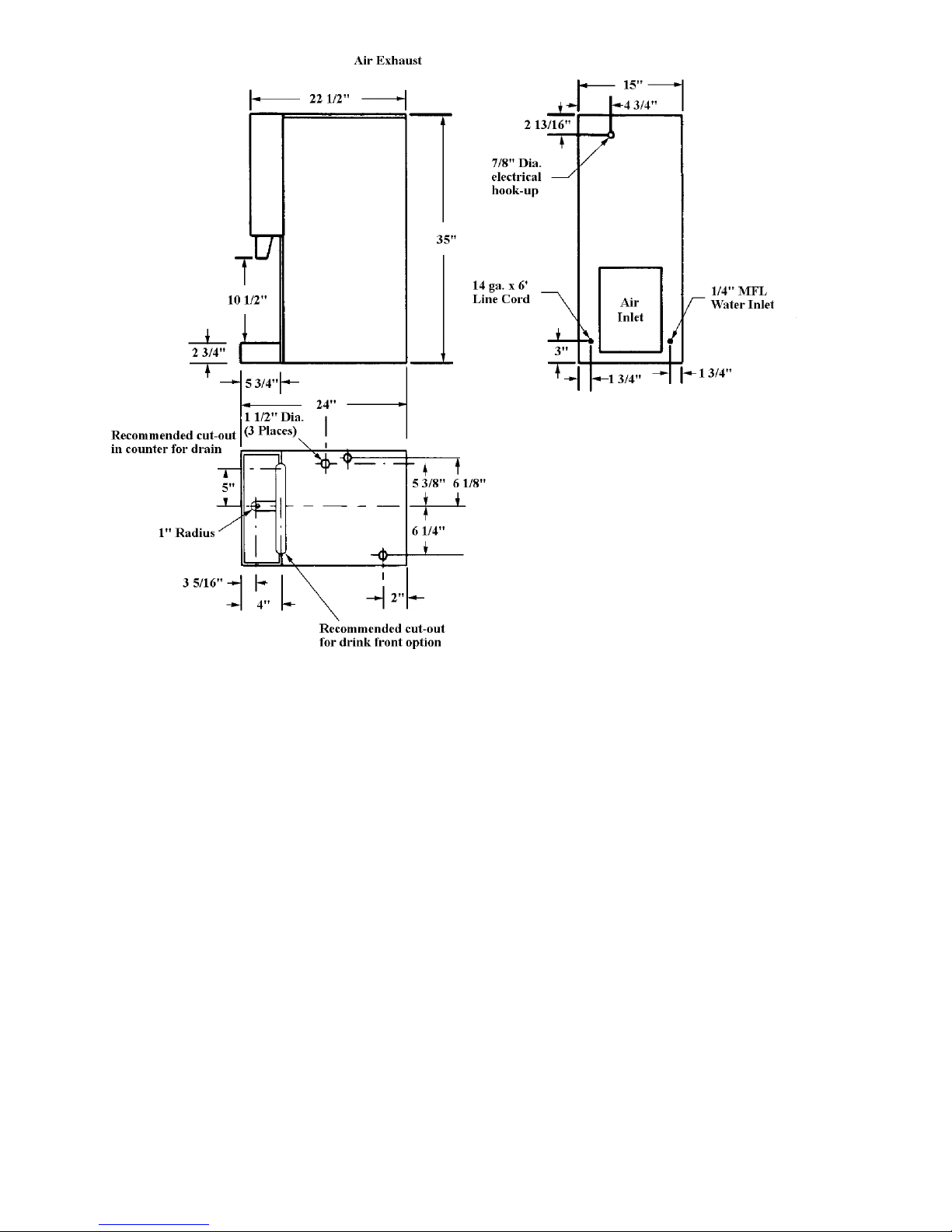

FIGURE 1. DIMENSION DRAWING (15 LB.) IMD 300--15 4. . . . . . . . . . . . . . . . . . .

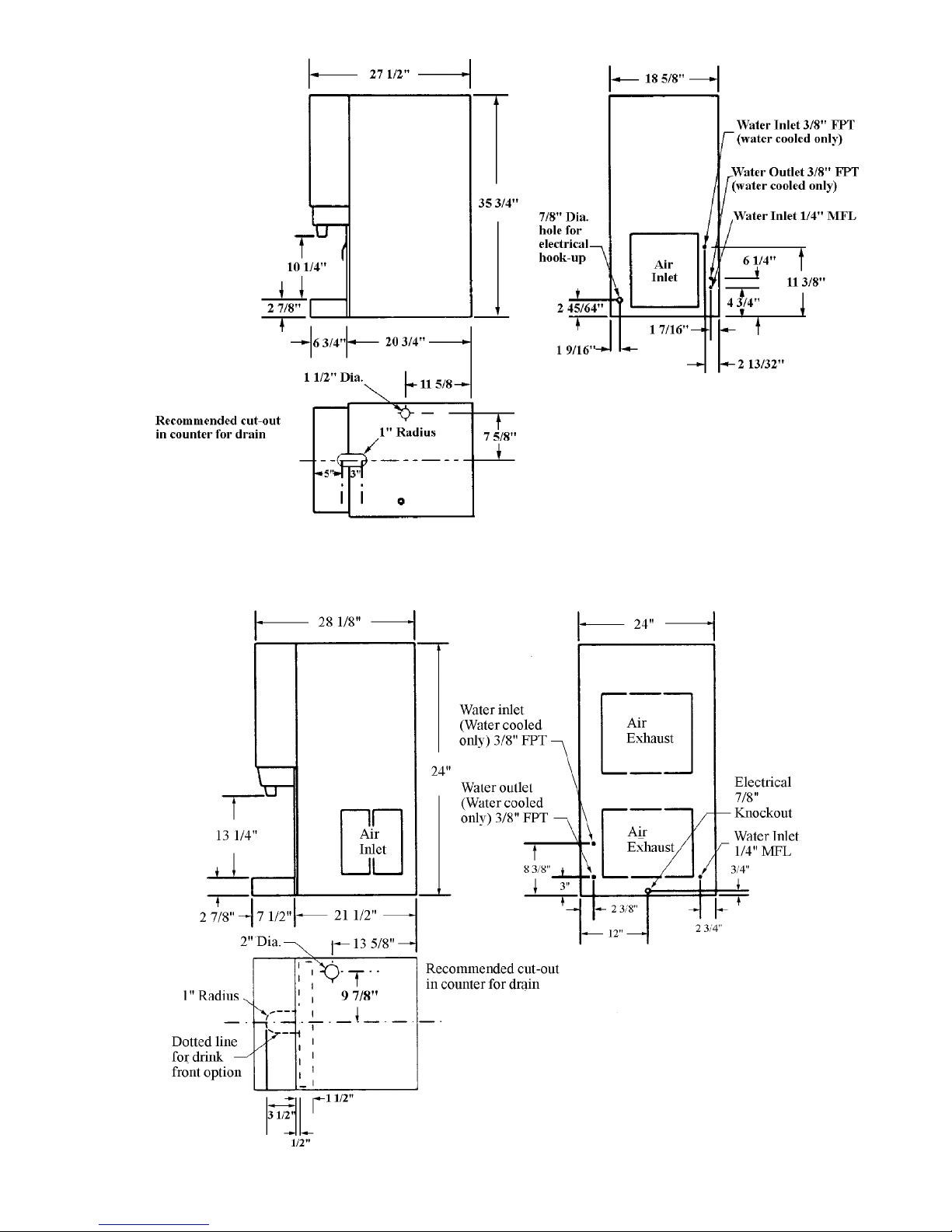

FIGURE 2. DIMENSION DRAWINGS (30 LBS.) IMD300--30 AND IMD600--30 5.

FIGURE 3. DIMENSION DRAWINGS (90 LBS.) IMD600--90 5. . . . . . . . . . . . . . . . .

FIGURE 4. FLOAT ASSEMBLY 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. UPPER BEARING AND AUGER ASSEMBLY 10. . . . . . . . . . . . . . . . . . .

FIGURE 6. ADJUSTMENT SCREW 13.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. IMD 300 SHAFT SEAL 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 8. AUGER AND EXTRUDING HEAD REMOVAL 14. . . . . . . . . . . . . . . . . .

FIGURE 9. IMD 600 SHAFT SEAL 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 10. OVERLOAD CHECK 16.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 11. COMPRESSOR CHECK 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

638085277

LIST OF FIGURES

ii

TABLE OF CONTENTS (cont’d)

FIGURE 12. PIN NUMBERS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 13. GEAR MOTOR OVERLOAD 19.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 14. SCHEMATIC IMD 300--15 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 15. SCHEMATIC IMD 300--30, IMD600--30, IMD601--30, IMD600--90,

AND IMD601--90 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 16. SCHEMATIC IMD302--30, IMD602--30, AND IMD602--90 24. . . . . . . .

FIGURE 17. IMD 300--15 CABINET PARTS ASSEMBLY AND PARTS LIST 25. . .

FIGURE 18. IMD300--30 AND IMD600--30 CABINET PARTS ASSEMBLY

AND PAR TS LIST 26.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

FIGURE 19. IMD600--90 CABINET PAR TS ASSEMBLY AND PARTS LIST 27. . . .

FIGURE 20. REFRIGERATION AND FRAME ASSEMBLY IMD 300--15 28. .. .. ..

FIGURE 21. REFRIGERATION AND FRAME ASSEMBLY IMD 300--30

AND IMD 600--30 30.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 22. REFRIGERATION AND FRAME ASSEMBLY IMD 600--90 32. .. .. ..

FIGURE 23. WATER CONTROL ASSEMBLY AND PAR TS LIST PART NO.

04643-04 IMD 300-30 AND IMD 600-30 34.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 24. WATER CONTROL ASSEMBLY AND PARTS LIST

PART NO. 32843 IMD 300--15 32545 IMD 600-90 35. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 25. TOP VIEW ICE LEVEL CONTROL ASSEMBLY

PART NO. 32770 IMD 300-15 AND 32770-002 IMD 302--5 36. . . . . . . . . . . . . . . . . .

FIGURE 26. SIDE VIEW ICE LEVEL CONTROL ASSEMBLY

PART NO. 32770 IMD 300-15 AND 32770-002 IMD 302--5 36. . . . . . . . . . . . . . . . . .

FIGURE 27. TOP VIEW ICE LEVEL CONTROL ASSEMBLY IMD 300-30 AND

IMD 600-30PAR T NO. 31494-001 (115V) PART NO. 31494-002 (208V/220V) 38. .

FIGURE 28. SIDE VIEW ICE LEVEL CONTROL ASSEMBLY IMD 300-30 AND

IMD 600-30PAR T NO. 31494-001 (115V) PART NO. 31494-002 (208V/220V) 38. .

FIGURE 29. TOP VIEW ICE LEVEL CONTROL ASSEMBLY IMD 600-90

PART NO. 31892 40. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 30. SIDE VIEW ICE LEVEL CONTROL ASSEMBLY IMD 600-90

PART NO. 31892 40. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 31. BIN AND FRONT END ASSEMBLY IMD 300-15, IMD 300-30

AND 600-30 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 32. BIN AND FRONT END ASSEMBLY IMD 600-90 44. . . . . . . . . . . . . . . .

FIGURE 33. ELECTRICAL BOX ASSEMBLY PART NO. 32776 IMD 300--15

AND PAR T NO. 32776-002 IMD 302-15 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 34. ELECTRICAL BOX ASSEMBLY IMD 300--30

AND IMD 600--30 IMD 600-90 (ALL VOLTAGES) 48. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 35. COMPRESSOR ELECTRICAL BOX ASSEMBLY AND PAR TS LIST

IMD 300-30, 600-30 AND 601-30 50.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 36. COMPRESSOR ELECTRICAL BOX ASSEMBLY AND PAR TS LIST

IMD 302-30 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 37. COMPRESSOR ELECTRICAL BOX ASSEMBLY AND PAR TS LIST

IMD 602-30 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 38. COMPRESSOR ELECTRICAL BOX ASSEMBLY AND PAR TS LIST

IMD 600-90 AND IMD 601--90 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 39. COMPRESSOR ELECTRICAL BOX ASSEMBLY IMD 602-90

EXPLODED VIEW AND PARTS LIST 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 40. DISPENSE MECHANISM ASSEMBLY IMD 300-15, IMD300-30,

IMD 600-30 AND IMD 600-90

EXPLODED VIEW 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii 638085277

Page

TABLE OF CONTENTS (cont’d)

FIGURE 41. GEAR MOTOR ASSEMBLY 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 42. GEAR MOTOR ASSEMBLY WIRING DIAGRAM (ALL VOLTAGES)

EXPLODED VIEW 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

SPECIFICATION CHART 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEMPERATURE/PRESSURE CHARTS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

638085277

iv

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identifies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly . Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2(Carbon Dioxide) Warning

CO2Displaces Oxygen. Strict Attention must be observed in the prevention of CO2(carbon dioxide)

gas leaks in the entire CO2and soft drink system. If a CO2gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be sanitized and

all sanitizing solution must be purged from the syrup systems. All water must also be purged from

the plain and carbonated water systems. A freezing ambient temperature will cause residual water

remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

CAUTION: Very high discharge pressure is present in system. Quick disconnects on your

gauges will minimize Danger and loss of refrigerant.

1

638085277

CAUTION: Unit requires a separate electrical line. See Manual for proper fuse size.

WARNING: There Must Be Adequate Clearance Around Ice Maker. Allow Minimum 6” Air

Intake and 4” For Air Exhaust on all sides and open to the front.

NOTICE Unit must be installed per local plumbing and electrical codes. See Installation Manual for unit

requirements. Failure to do so may cause damage to unit, which would void the warranty.

NOTICE Using Any Parts Other Than Genuine Factory Manufactured Parts Relieves the Manufacturer

of all Liability.

NOTICE Manufacturer Reserves The Right To Change Specifications At Any Time.

638085277

2

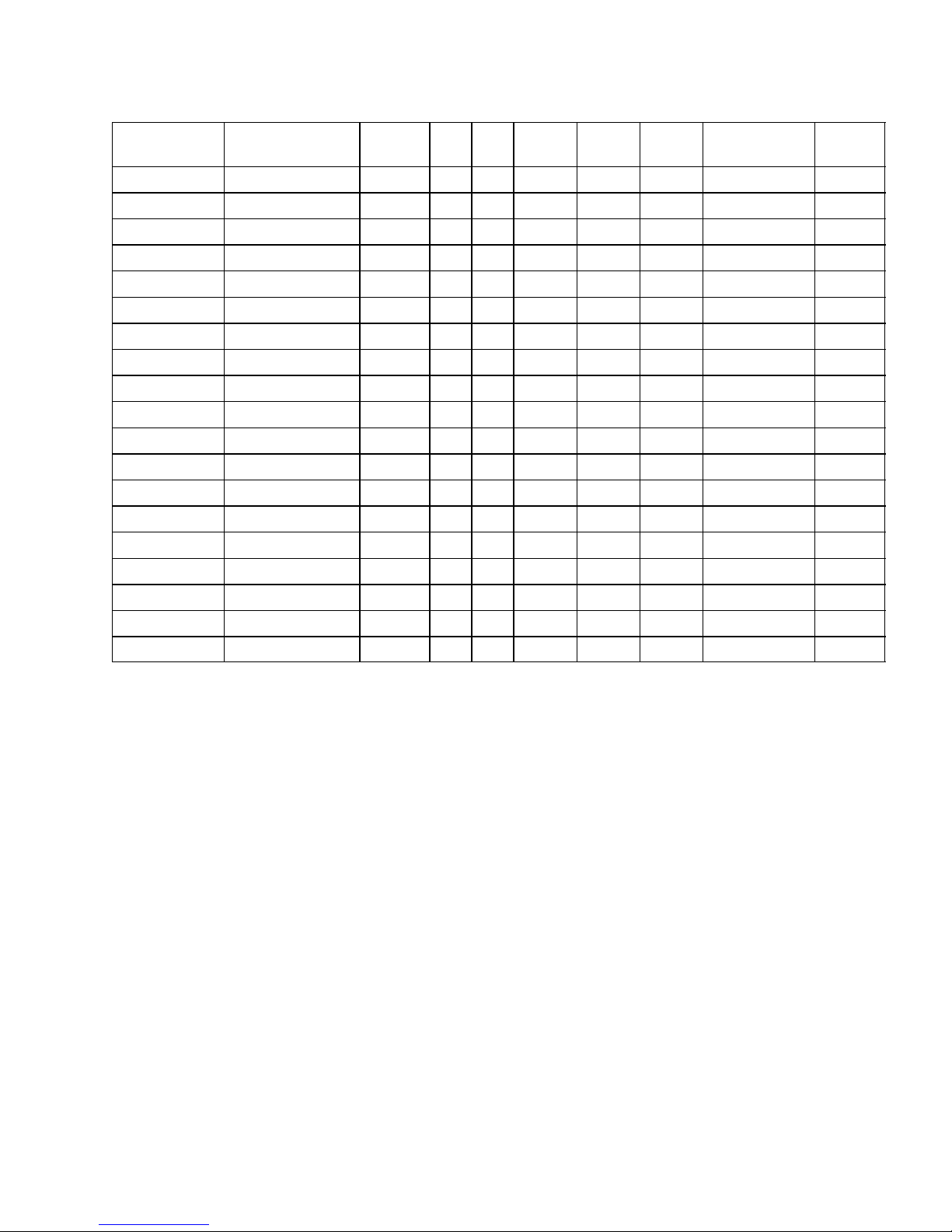

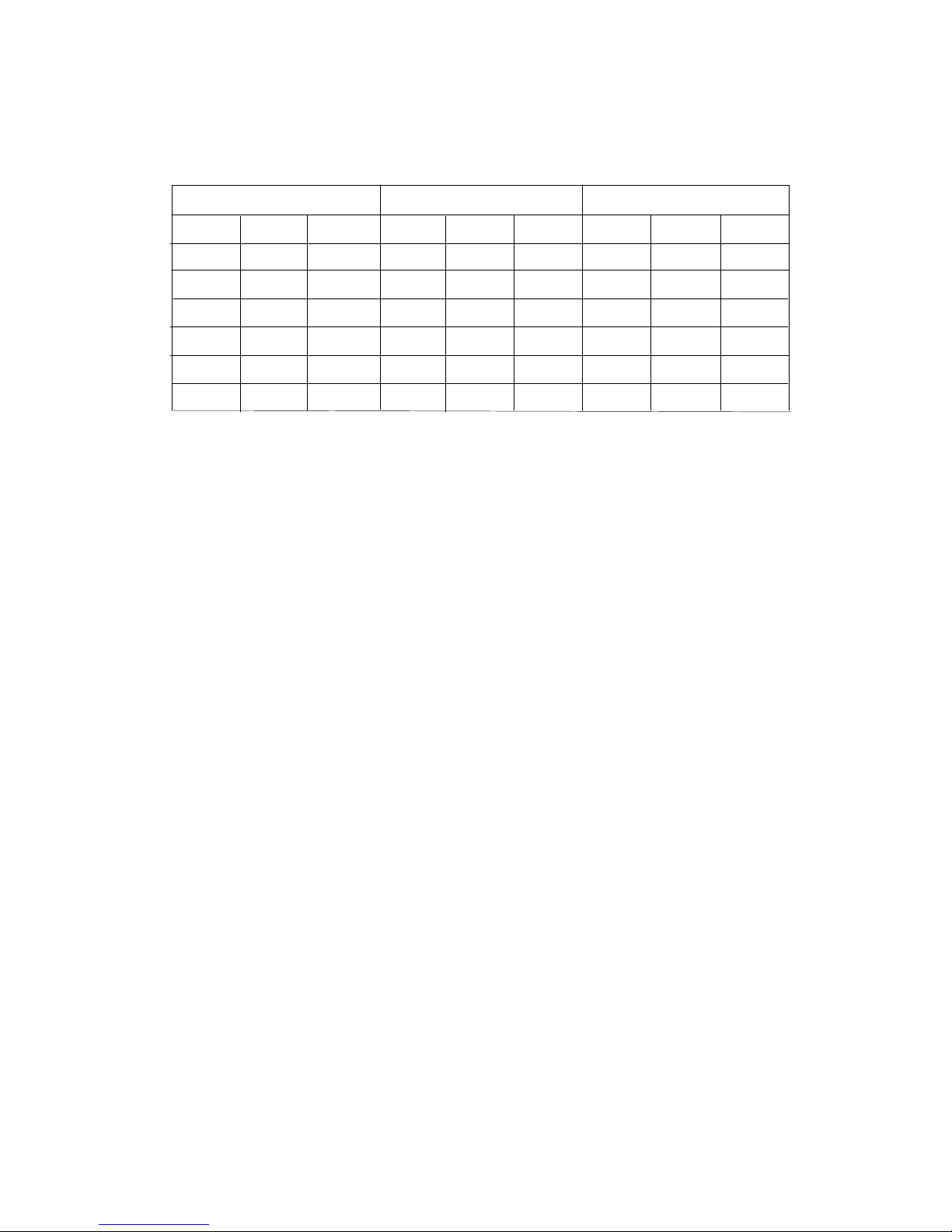

SPECIFICATION CHART

Models Condensing

Unit

IMD300--15A Air Cooled 115 60 1 6 0.82 2 12 R134a 15

IMD302--15A Air Cooled 220/240 50 1 3 0.5 1.6 12 R134a 15

IMD300--30A Air Cooled 115 60 1 10.1 1 2 28 R404A 20

IMD300--30W Water Cooled 115 60 1 10.1 N/A 2 13 R404A 20

IMD301--30A Air Cooled 208/230 60 1 5.7 1 1.6 28 R404A 20

IMD301--30W Water Cooled 208/230 60 1 5.7 N/A 1.6 13 R404A 20

IMD302--30A Air Cooled 220/240 50 1 5.3 0.5 1.6 28 R404A 20

IMD302--30W Water Cooled 220/240 50 1 5.3 N/A 1.6 13 R404A 20

IMD600--30A Air Cooled 115 60 1 12 1 2 28 R404A 20

IMD600--30W Water Cooled 115 60 1 12 N/A 2 14 R404A 20

IMD601--30A Air Cooled 208/230 60 1 7.7 1 1.6 28 R404A 20

IMD601--30W Water Cooled 208/230 60 1 7.7 N/A 1.6 14 R404A 20

IMD602--30W Water Cooled 220/240 50 1 8.2 N/A 1.6 14 R404A 20

IMD600--90A Air Cooled 115 60 1 12 1 2 24 R404A 20

IMD600--90W Water Cooled 115 60 1 12 N/A 2 14 R404A 20

IMD601--90A Air Cooled 208/230 60 1 7.7 1 1.6 24 R404A 20

IMD601--90W Water Cooled 208/230 60 1 7.7 N/A 1.6 14 R404A 20

IMD602--90A Air Cooled 220/240 50 1 8.2 0.5 1.6 24 R404A 20

IMD602--90W Water Cooled 220/240 50 1 8.2 N/A 1.6 14 R404A 20

NOTE: FOR UNITS NOT LISTED IN ABOVE CHART, REFER TO NAMEPLATE OR CONTACT FACTORY

SERVICE.

VAC Hz Ph Comp

RLA

Fan

Amps

Grmtr

Amps

Refrigerant

Oz. Type

Circuit

Fuse

3

638085277

SHIPPING WT. 189 LBS. (APPROX.)

FIGURE 1. DIMENSION DRAWING (15 LB.) IMD 300--15

638085277

4

SHIPPING WT. (IMD300--30) 220 LBS. (APPROX.)

SHIPPING WT. (IMD600--30) 240 LBS. (APPROX.)

FIGURE 2. DIMENSION DRAWINGS (30 LBS.) IMD300--30 AND IMD600--30

FIGURE 3. DIMENSION DRAWINGS (90 LBS.) IMD600--90

SHIPPING WT. 225 LBS. (APPROX.)

5

638085277

INSTALLATION INSTRUCTIONS

A.. REMOVE ICEMAKER FROM CARTON:

1. Keep unit in the upright position, remove carton and pallet from unit and inspect unit for damage. Upon

inspection of unit, if any damage is found, file a claim with carrier immediately.

2. Locate Startup Card either on outside of container or on plastic liner. Fill in proper information and

send one copy to factory, and other copy to Distributor. Postage is prepaid.

B.. CABINET REMOVAL

1. Locate and remove the (2) screws from under the front cover. Lift cover forward and up to remove.

2. Lift up front edge of top cover. Slide back about 1/2 inch and remove.

3. Remove (6) screws from the front of the machine.

4. Remove side panels by sliding the front edge out and then back slightly to disengage.

5. Remove the front splash panel by lifting slightly to disengage the front, then tilt forward and remove.

6. Remove bin top and remove shipping insert.

C.. PREPARATION OF INSTALLATION SITE

1. The refrigeration system on air cooled units requires airflow, so a well ventilated area should be chosen. A minimum of (6) inches must be maintained, free of any obstruction, for air intake. A minimum of

(4) inches clearance is required for air exhaust.

2. With template provided make the necessary provisions in the counter for water, drain and the electrical

hook--up. Provisions are available for rear and bottom connections of water and electrical. Use hole

plugs provided to plug unused holes.

D.. WATER INLET HOOK--UP:

1. Water Inlet -- Fitting is a 1/4” SAE male flare located at the rear of the unit. Connect water supply with

a 1/4”or larger copper or flexible tubing.

2. Water Pressure -- Unless otherwise specified, the unit is designed to operate on water pressures between 10 P.S.I. and 90 P.S.I. (NOTE: for pressures above 90 P.S.I. a regulator must be installed).

3. Water Cooled Condensers

a.. Inlet to modulating valve uses 3/8” FPT. Use separate 3/8” or larger water line.

b.. Outlet is 3/8” FPT.

4. Filter Conditioners are recommended on supply lines to icemakers. Never run the water supply to water cooled Condenser through Filter/Conditioner, it uses up the cartridge unnecessarily and a saturated

cartridge can starve the icemaker causing premature component damage. Separate water supplies

are recommended.

NOTE: Unit must be installed per local plumbing code.

E.. ELECTRICAL SUPPLY

1. Power Access -- Is provided by way of a 7/8” dia. hole in both the base and the rear panel. Route incoming power in conduit, to icemaker electrical control box. Make connections to wires provided in

control box and ground lug/screw. Plug unused hole.

2. Fused Line -- Should be a dedicated circuit checked and sized according to electrical rating shown on

unit nameplate.

638085277

6

NOTE: Unit must be installed per local electrical code.

F.. DRAIN CONNECTION

1. Install splash panel on machine and hold in place with (2) screws. Do not tighten at this time.

2. Remove drain tray mounting bracket from their shipping carton.

3. Clip the drain tray mounting bracket onto the bottom of the splash panel in the brackets provided.

4. Hook the drain tray into the splash panel and onto the mounting bracket.

5. Push the drain elbow securely onto the drain tray. Do not glue in place.

6. Complete the drain hookup according to the instructions provided with unit

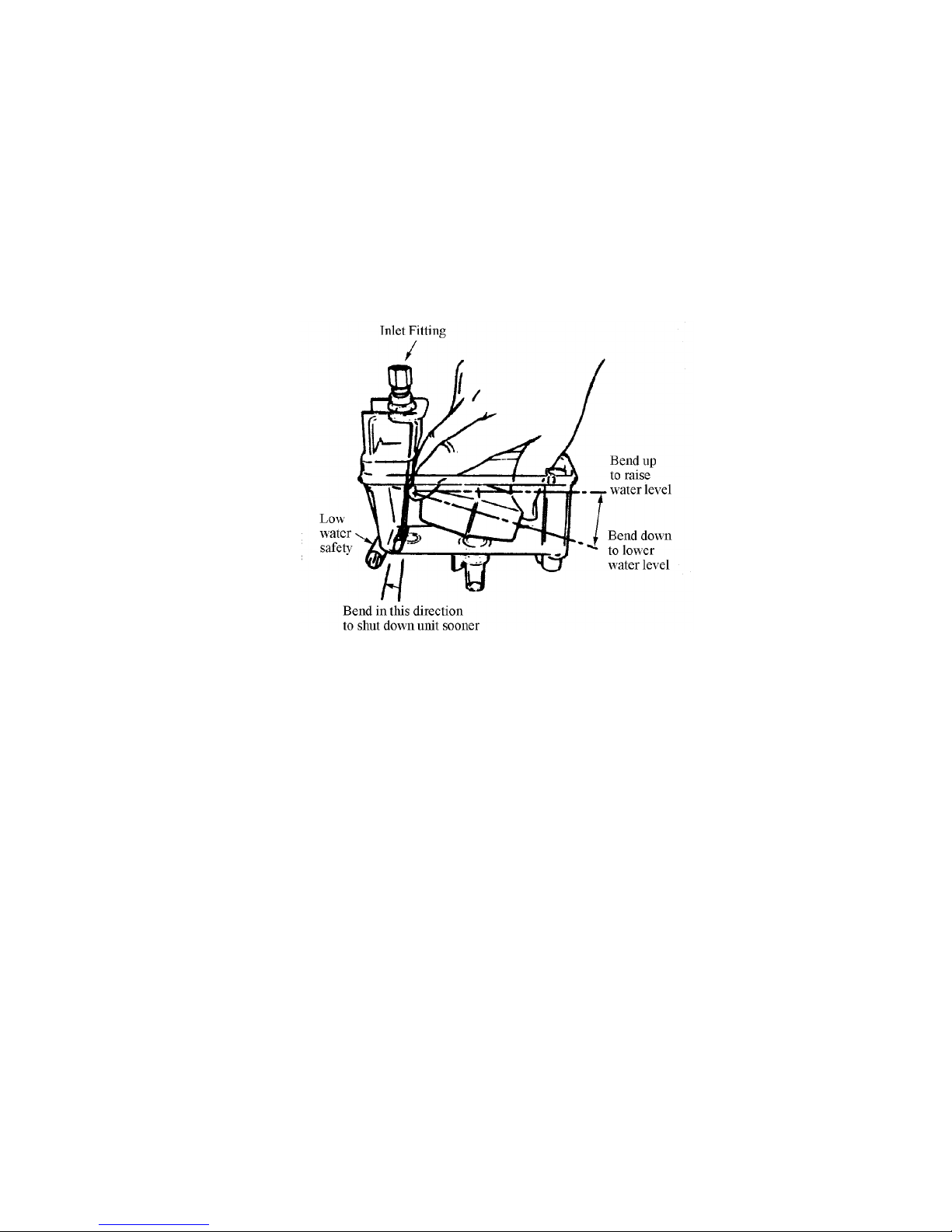

FIGURE 4. FLOAT ASSEMBLY

NOTE: Steps 7 and 8 to be completed only after all start up checks and adjustments are performed.

7. Replace side panels tightening all (6) screws (including splash panel screws left loose).

8. Replace top panel and front cover and secure with (2) screws.

NOTE: In those cases where the unit is base mounted and not on legs it should be sealed all around the base

with NSF listed sealant. (IMI Wilshire P/N 04815--B).

G.. AUGER ENGAGEMENT

Be certain that auger is fully engaged to lower drive and that extruding head is fully engaged to evaporator.

H.. INITIAL START UP, CHECKS & ADJUSTMENT INSTRUCTIONS

NOTE: Do not start unit before completing Installation steps A--G.

Turn on water supply and main power switch (located on top of electrical box). All IMD 30 lb. and 90 lb. series

units are equipped with a 45 second delay timer. This means that the refrigeration system will not start until 45

seconds of dispense are accumulated in the timer. Start the refrigeration system by depressing the ice dis-

pense button for 45 seconds. Make the following system checks:

NOTE: If unit will not start be sure water reservoir is full. Low water safety control must be properly adjusted to

start and shut down unit. If water level drops below bottom of reservoir, unit must shut down. Adjustment is

made by moving magnet up or down.

Water Level -- If necessary adjust Float by bending float arm up or down as needed, push float assembly down

until unit stops running. Release float and unit will restart. Keep water in reservoir at level line while unit is in operation. See Figure 1.

7

638085277

Low Water Safety Control -- Adjust magnet by bending magnet arm as shown in figure 1 to shut down unit if

the water level drops below the line on the side of the reservoir.

Bin Control -- Remove four screws from top of bin cover and lift cover so bin control plate can be manually lifted

until unit shuts down. Release plate and unit will restart (On IMD300--30, IMD600--30 and IMD600--90 the dispense button must be depressed for 45 seconds before unit will start). Replace screws.

Dispense Switch and Mechanism -- By depressing the dispense switch, the dispense mechanism door on the

storage bin will open, and chain, sprockets, and agitator will rotate counterclockwise.

NOTE: If any of these checks or adjustments cannot be achieved, refer to Troubleshooting Section of this

manual or call our technical support center for assistance at 1--800--238--3600.

638085277

8

GUIDE TO SERVICE

ICEMAKER CLEANING AND SANITIZING PROCEDURES

Do not use any of the ice made during cleaning operations.

Clean and sanitize ice storage area when cleaning icemaker.

1. Turn machine off.

2. Shut off water supply.

3. Remove ice from storage bin.

4. Mix approved cleaner (2 gallons as directed). Recommended cleaner: Calgon Corp. of Virginia Chemicals, ice machine cleaner. Mixture: 3-1/3 ounces per gallon of water. Do not use nickel safe cleaners.

5. Turn machine on and add cleaner solution to water level control (float reservoir) until 2 gallons have been

used.

6. Turn on water supply and run machine for 15 minutes.

7. Turn off machine and remove and discard all ice.

8. Sanitize using household liquid bleach (50 ppm chlorine). Mixture: 1 fluid ounce per gallon room temperature water. 2 minute exposure time.

9. Sanitize pre--cleaned inside areas of storage bin liner, door frame, door, as well as exposed surfaces of the

evaporator assembly and bin shutoff assembly with sanitizing solution and allow to air dry .

MAINTENANCE

Preventive maintenance can increase the trouble free life of your icemaker. Many authorized service agencies

offer service contracts for your icemaker. Contact your local distributor for further information.

MONTHLY

1. Clean the condenser. Use a brush, vacuum cleaner or blow from inside with air or CO2gas. If unit is provided with and air filter, clean or replace.

2. Inspect water feed reservoir at lease once a month until a definite pattern for cleaning and sanitizing has

been established.

QUARTERLY

This is the maximum period of time between cleaning and sanitizing the icemaker. In addition to recommended

monthly procedure, and if a more frequent cleaning and sanitizing pattern has not been established, unit must

be cleaned and sanitized.

SEMI--ANNUALLY

Semi-Annually in addition to all previously established service procedures perform the following:

1. Check for water leaks in tube connections, water fittings and lower icemaker water seal.

2. Check drain tubes for clogs and “aged” tubes. Replace if tubes are stained or brittle.

3. Check for signs of condensation. Clean where necessary and replace insulation properly.

9

638085277

4. Check safety circuits for proper operation.

5. Check refrigeration system (see page12 12).

6. Check unit for abnormal noise. Tighten machine and cabinet screws, if necessary .

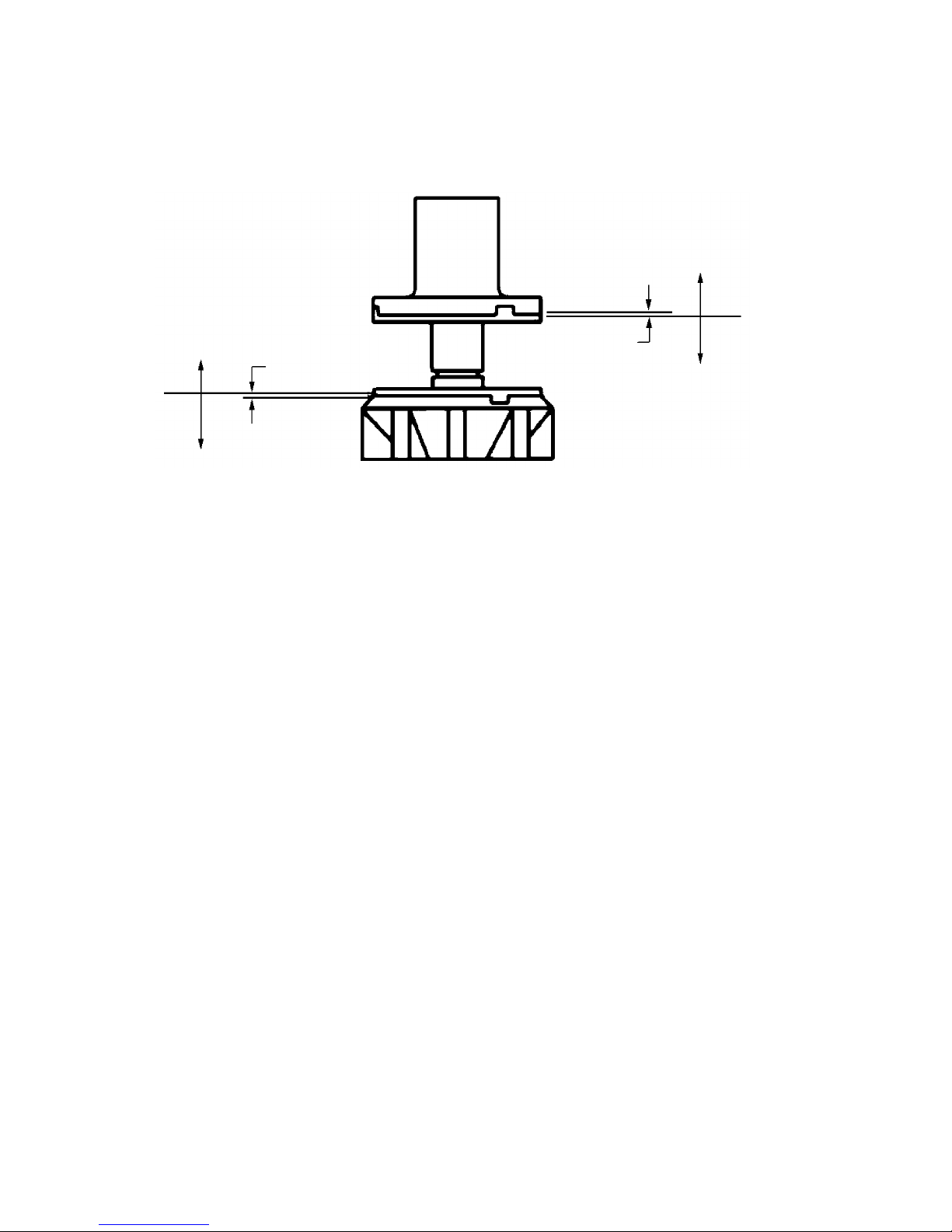

7. Check white upper bearings on auger assembly . If bearings are less than 1/16? thick, replace. See Figure 5

REPLACE

OK

1/16?

REPLACE

1/16?

OK

FIGURE 5. UPPER BEARING AND AUGER ASSEMBLY

NOTE: preventive maintenance can increase the trouble--free life of your ice maker. Failure to perform

preventive maintenance could void your equipment warranty

638085277

10

WATER LEVEL CONTROL

HOW WATER LEVEL CONTROL WORKS

When water is introduced through the inlet fitting the float rises. the float pushes against a lever which in turn

forces the poppet assembly against the inlet fitting valve seat which seals the water off, (See Figure 4). Before

the water inlet is sealed the safety switch is operated. In the event of a water failure the float would drop down

and operate the safety switch to shut off the machine.

If water level control will not shut off and seal at level as indicated, be sure inlet pressure does not exceed recommended factory operating range.

Under ordinary circumstances adjustment should not be necessary providing it was properly adjusted when unit

was installed or relocated. If, however, the control becomes inoperative, repair or replace. See Start-Up Adjustment, page 7 .

PURPOSE OF WATER LEVEL CONTROL

1. To automatically maintain proper water level in the evaporator when unit is running and making ice.

2. A safety switch is operated in the event of an interruption in water supply. The switch shuts off the electrical

power to the icemaker and its refrigeration system. Switch will reset as soon as cause of water failure has

been corrected and proper water level in icemaker has again been reached.

3. The transparent bowl not only provides a visible check of water level, but also is a good guide to the internal conditions which exist within the icemaker assembly itself. (See Cleaning Procedure.)

TO REPLACE WATER LEVEL CONTROL

1. Shut off the water supply . Shut off the main power switch or unplug the ice dispenser from electrical outlet.

2. Remove the flexible tubing from bottom of water level control and drain water from water level control and

evaporator.

3. Remove flexible tubing at bottom of water level bowl connected to the overflow.

4. Hold water inlet fitting with proper tool to prevent it from rotating when disconnecting the water inlet.

5. Remove wing nut holding water control to its mounting bracket. Control can be removed by lifting straight

up.

TO REPLACE WATER LEVEL SAFETY SWITCH

1. Shut off main power switch or unplug the ice dispenser from electrical outlet.

2. Unplug molex connector connecting switch to electrical box.

3. Remove the 2 screws anchoring the water level safety switch to the bottom of the water level control

mounting bracket.

ICE LEVEL CONTROL

The ice level control assembly is secured to the top of the ice storage container cover. The cover is secured to

the storage container with four screws. The level control switch is operated by a plate assembly located beneath

the diaphragm. When the plate assembly is down due to lack of ice in storage container, electrical impulse is

sent to compressor, starting the ice making cycle. As ice level increases in storage container, the plate assembly

is pushed up. When storage container is full, it de--actuates the switch, stopping the compressor and ice making

cycle.

11

638085277

The operating positions of the switch are fixed, no adjustments are necessary. If switch replacement becomes

necessary , simply disconnect cable at connector, remove wires from switch.

TEMPERATURE / PRESSURE CHARTS*

±10 lbs. Discharge Pressure

Water Temperature

IMD300 --5 & IMD300--15 IMD300--30

IMD600 --30, IMD600--90

40_ 65_ 90_ 40_ 65_ 90_

162

188

214

245

275

309

166

192

218

249

279

313

168

194

220

251

281

315

174

202

230

265

300

328

177

205

233

269

304

334

180

208

236

272

307

340

50_

60_

70_

80_

90_

Air Temperature

100_

40_ 65_

80

92

114

124

161

187

NOTE: The thermostatic expansion valve is non--adjustable on all models.

85

97

120

120

167

193

90_

90

102

124

147

171

195

REFRIGERATION SYSTEM ADJUSTMENTS

A complete understanding of the icemaker and hermetic refrigeration system is necessary before any adjustments are made. The refrigeration technician must use high and low side pressure readings, water and air temperatures, plus general conditions of cleanliness to assess the refrigeration system status when making any

adjustments.

All icemaker products are tested and adjusted at the factory prior to shipment where the ambient temperature

ranges from 65_F to 90_F, depending on the season of the year.

Whenever a new icemaker is initially installed and started--up, it is imperative that the start --up operator make

the following checks and readjustments for local conditions.

EXPANSION VALVE

You will find a thermal expansion valve on ice makers, which is used to control the amount of refrigerant flowing

through the evaporator. Improperly installed or defective expansion valves may cause low production, soft ice,

squeaking from evaporator and excessive load inside evaporator.

By using general refrigeration trouble shooting along with the pressure charts, you can easily determine whether

or not the expansion valve is working properly.

ADJUSTMENT AND TROUBLESHOOTING

When troubleshooting the expansion valve, you must;

1. Be sure you have adequate water flowing into the evaporator, a clean and properly ventilated condenser,

and the system is properly charged and free of any restrictions. Also be sure compressor is operating properly .

2. Take reservoir water temperature and air temperature from condenser inlet and determine at what pressure

unit should be running. On machines equipped with thermostatic valve there is NO adjustment. If correct

pressure cannot be obtained, be sure system has time to stabilize, 10--15 minutes.

3. Be sure sensing bulb is located at outlet side of evaporator about 3--4 inches away from evaporator and be

sure to insulate well and clamp tightly to tubing. If system pressures are still not adequate, take a second

water and air temperature reading and go over other parts of the system for possible problems. If proper

charge is questionable evacuate and recharge to nameplate and leak check. If valve still malfunctions replace valve.

638085277

12

Use general refrigeration system practices when replacing and recharging unit. After new valve is in place, go

through previous monitored adjustments and troubleshooting to be sure valve is functioning properly .

NOTE: On water cooled units adjust condenser modulating valve before troubleshooting expansion

valve.

CAUTION: Very high discharge pressure is present in system. Quick disconnects on your

gages will minimize Danger and loss of refrigerant. Comply with federal regulations for

reclaiming refrigerant.

CONDENSER MODULATING VAL VE

The reason for using a water modulating valve is to supply the correct amount of water to the condenser to

maintain the proper operating pressure in the refrigeration system high side. The flow of water through the valve

is increased as the high side pressure rises and decreases as high side pressure lowers.

To calibrate the amount of water flow with the refrigeration system high side pressure, turn adjustment screw

located on end of valve opposite of bellows See Figure 4. Turn screw counterclockwise to raise opening point.

Opening point of valve should be set to maintain proper operating pressure in refrigeration system high side.

Refer to Pressure Chart on Page 11. Closing point of valve should be set low enough to close valve during compressor stand by periods.

NOTE: Cold water will absorb more heat faster than warm water. The water flow will therefore

automatically increase as inlet temperature increases.

CONDENSER MODULATING VAL VE REMOVAL

1. Disconnect power to unit, then shut off water supply to condenser and reclaim refrigerant from system.

2. Remove inlet water line from Condenser modulating Valve. Also remove tube from refrigerant high side line.

3. Remove Condenser Modulating Valve and bracket.

4. Remove valve from bracket.

5. Replace Condenser Modulating Valve by reversing Steps 2 thru 4. Then pull system into vacuum.

FIGURE 6. ADJUSTMENT SCREW

13

638085277

6. Recharge unit with refrigerant per nameplate.

7. Turn power and water On to unit.

8. With unit running adjust modulating valve to proper setting.

9. Go through a complete system check.

GEAR MOTOR

The gear motor is equipped with a start relay and a manual reset overload. When current is applied, the relay

energizes and completes the circuit to the start winding. The motor reaches a predetermined speed and the

relay drops out, disconnecting the start winding. The run winding remains in the circuit as long as current is applied.

The purpose of the overload is to automatically shut off the motor in the event of a mechanical bind of the transmission, an overload condition within the evaporator or an electrical malfunction. It does this by sensing amperage draw. If the motor stalls the start relay would energize and stay energized. The amperage would surge to 5

to 6 times greater than normal draw. In this event the overload would shut off the transmission in 4 to 8 seconds.

If the motor is subjected to an abnormal load, but does not reach stall condition, the overload will react, but over

a greater period of time. The reaction time depends upon the amperage to which it is subjected.

The overload, through the safety circuit, also shuts off the compressor.

Refer to Troubleshooting Guide.

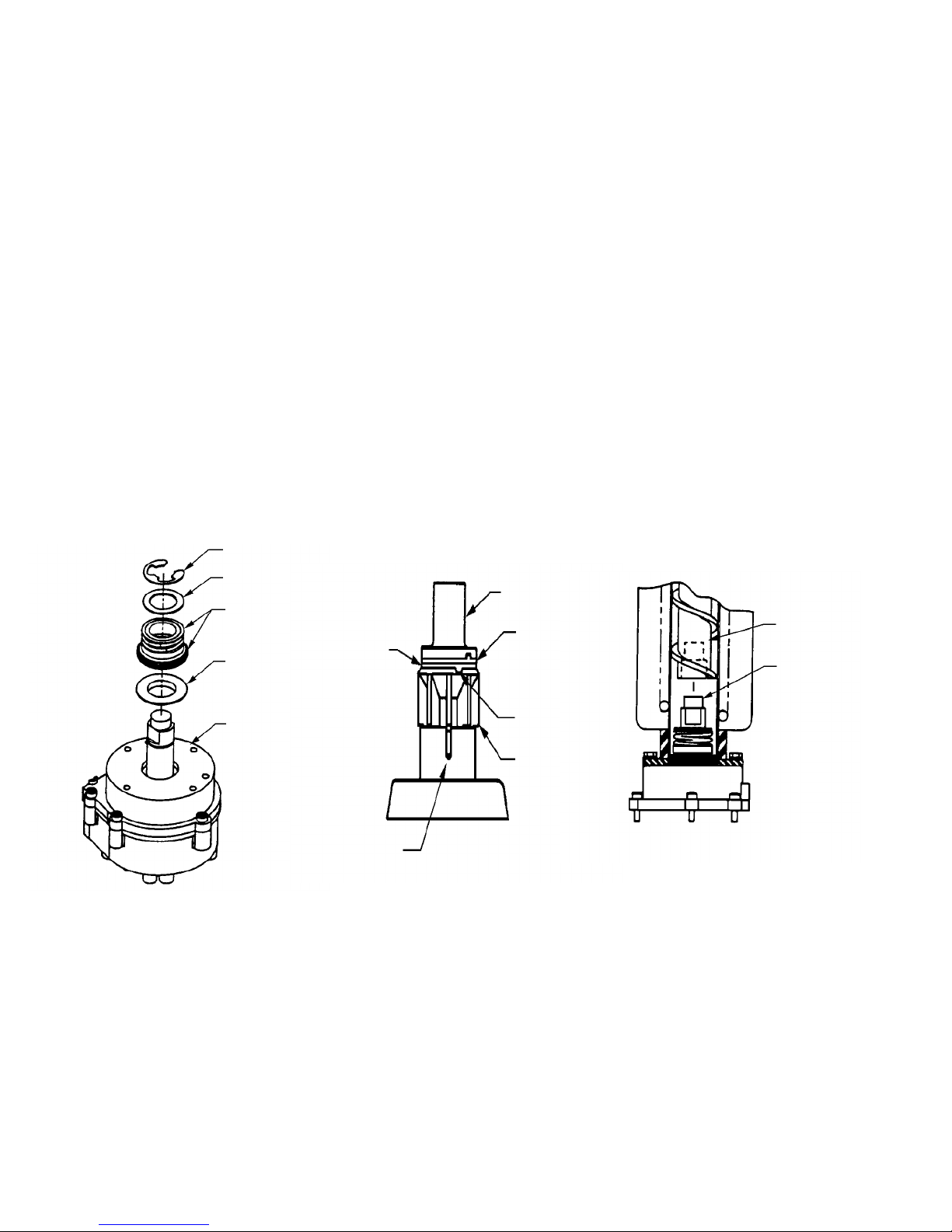

E--RING

WASHER, PLAIN FLAT

SHAFT SEAL

LOCATOR SEAL

GEARMOTOR

FIGURE 7. IMD 300 SHAFT SEAL

BEARING DELRIN

COLLAR WITH

ANTI--ROTATION RIB

FIGURE 8. AUGER AND EXTRUDING HEAD REMOVAL

AUGER NUT

BEARING NYLON

GROOVE

EXTRUDING

HEAD

AUGER

“D” DRIVE

SHAFT SEAL INSTALLATION AND REPLACEMENT (SEE FIGURE 7.)

1. Place shaft seal locator seat over gear motor output shaft, embossed side down, and push down until shaft

seal seat rests flush on top of gear motor.

2. Place rubber coated ceramic seal (important: ceramic face up) over output shaft and push down until seal

rests on top of the shaft seal seat. (Lubricate rubber on ceramic seal with [#06195] rubber lubricant.)

3. Place shaft seal with carbon face down(spring up) over output shaft and push (gently) downward until seal

rests on carbon face of the output shaft seal.

4. Push down on the washer compressing the spring on the output shaft seal. While holding the seals (down)

in place slide the E--ring into the groove on the output shaft.

638085277

14

AUGER & EXTRUDING HEAD REMOVAL

1. Disconnect unit from power supply.

2. Remove storage container cover and put aside.

3. Turn off water supply to icemaker.

4. After ice has melted from head take hold of the auger nut and lift straight up to disengage from icemaker.

5. When replacing the auger assembly, make certain that both the auger engages the output shaft drive and

the extruding head ribs engage the evaporator tube collar. See Figures 8.

E--RING

WASHER, PLAIN FLAT

SHAFT SEAL

MOUNT ,SHAFT SEAL

LOCATOR SEAT

GEARMOTOR

FIGURE 9. IMD 600 SHAFT SEAL

INSTALLATION AND SHAFT SEAL REPLACEMENT (SEE FIGURE 9.)

1. Place shaft seal locator seat over gear motor output shaft, embossed side down, and push down until shaft

seal seat rests flush on top of gear motor.

2. Place rubber coated ceramic seal (important: ceramic face up) over output shaft and push down until seal

rests on top of the shaft seal seat. (Lubricate rubber on ceramic seal with [#06195] rubber lubricant.)

3. Place shaft seal with carbon face down(spring up) over output shaft and push (gently) downward until seal

rests on carbon face of the output shaft seal.

4. Place flat washer over output shaft and let rest on the output shaft seal. Push down on the washer compressing the spring on the output shaft seal. While holding the seals (down) in place slide the E--ring into

the groove on the output shaft.

UPPER NUT AND BEARINGS

The upper bearings located on top of the auger is used to absorb the force between the auger and extruding

head.

The bearings are 3/32” thick. When they wear below 1/16” they should be replaced. Bearings to be

inspected for wear during quarterly maintenance. See Figure 5.

15

638085277

TO REPLACE BEARINGS

1. Dispense all ice from unit.

2. Disconnect unit from electrical power.

3. Remove panels.

4. Unplug Dispense Motor and Ice Level Switch.

5. Remove four screws holding dispense cover in place.

6. Remove dispense cover assembly .

7. Use an open end wrench on auger nut connected to bearing and turn and turn counterclockwise to remove

assembly .

8. Remove worn bearings. Replace with new bearings and then reinstall assembly.

NOTE: If auger turns with nut, remove cover on top of gear motor stator and hold rotor while loosening nut.

9. Reconnect power to icemaker.

TROUBLESHOOTING COMPRESSOR

Basically the compressor problems can be narrowed down to three areas of checkout--

1. THE COMPRESSOR WILL NOT RUN

No voltage to the compressor terminals -- check circuit.

Low voltage -- below 90% of nameplate rated voltage.

Problems in the compressor electrical circuit. See Electrical Checkout instructions.

2. THE COMPRESSOR STARTS BUT TRIPS REPEATEDLY ON THE OVERLOAD PROTECTOR

Check for proper fan operation and clean condenser.

Check the compressor suction and discharge pressures.

Voltage -- The voltage should be within 10% of the rated nameplate voltage.

High compressor amperage draw, it should never exceed 120% of the rated nameplate amperage. See

Electrical Checkout Instructions.

3. THE COMPRESSOR RUNS BUT WILL NOT REFRIGERATE

Check the compressor suction and discharge pressures. See Chart on Page 12.

ELECTRICAL CHECKOUT

1. Be sure the unit is disconnected from the power source. Remove the compressor electrical box cover.

Check for obvious damage and loose wires.

2. Disconnect the fan motor leads. Since capacitors store energy, short the capacitor with a screwdriver. This

will prevent shocks.

3. Disconnect the compressor terminal wires.

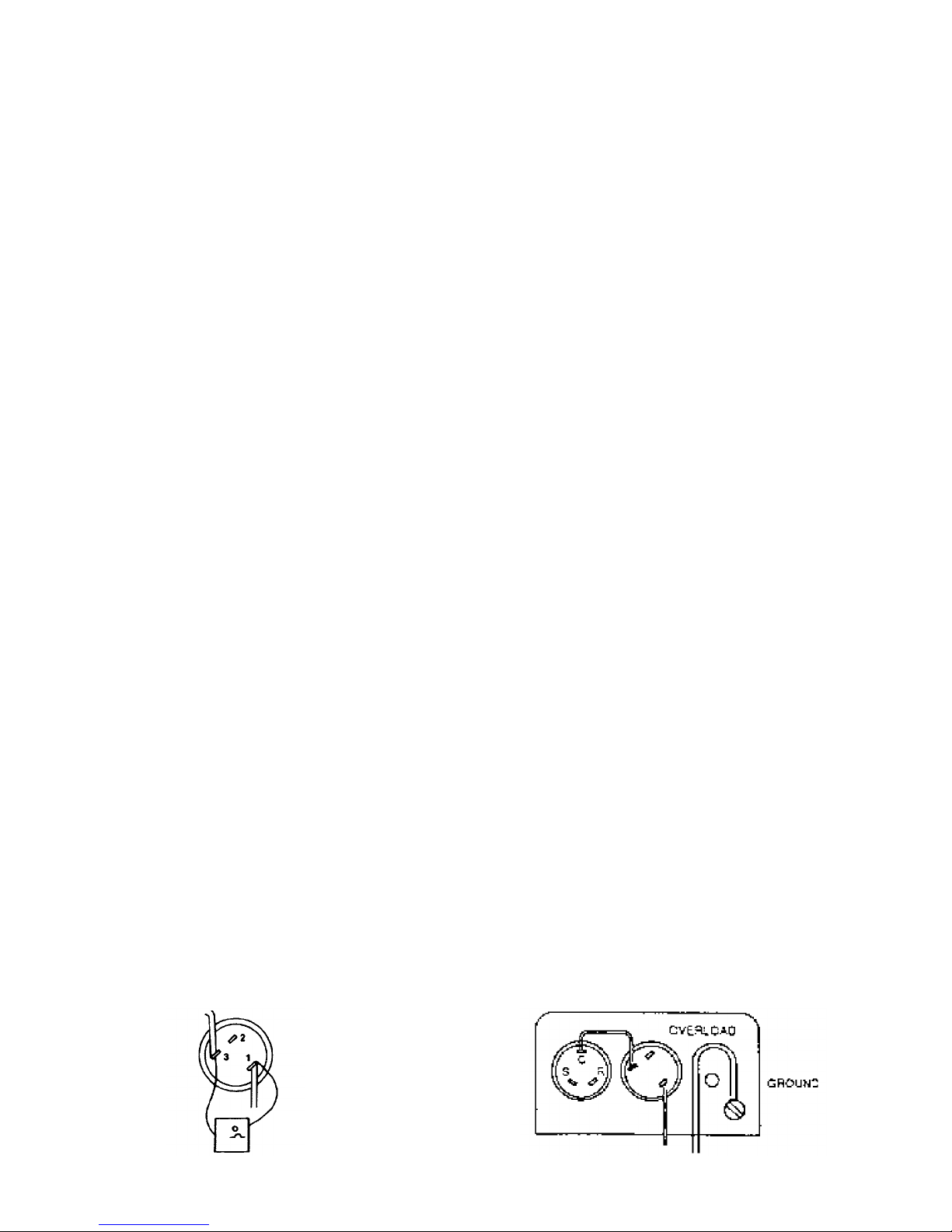

FIGURE 10. OVERLOAD CHECK FIGURE 11. COMPRESSOR CHECK

638085277

16

OVERLOAD CHECK -- FIGURE 10.

4. Using a volt --ohm meter check the continuity across the overload, contacts #1 & #3. If none, wait for unit to

cool down and try again. If still no continuity, the overload protector is defective and should be replaced.

COMPRESSOR CHECK -- FIGURE 11.

The resistance readings on the windings will be between 0.25 and 10.00 ohms, a meter capable of these low

readings must be used.

5. Check between ”C” & ”R.” Replace compressor if there is no continuity as the run windings are open.

6. Check between ”C” & ”S.” Replace the compressor if there is no continuity as the start windings are open.

7. Check between ”C” & ”R”, or ”S” and shell of the compressor. If there is continuity replace the compressor

as the motor is grounded.

8. Check between screw terminal on the overload and ”C” on the compressor. Check and repair the lead or

connections if there is no continuity.

CAPACITOR CHECK

9. Check or replace start capacitor, disconnect bleed resistor before checking for shorted capacitor.

10. Check or replace run capacitor (if supplied) check or shorted capacitor or either terminal grounded to case.

TROUBLESHOOTING GEAR MOTORS

Basically , Gear motor problems can be narrowed down to three areas of checkout.

THE GEARMOTOR WILL NOT RUN

1. No voltage to the transmission terminals -- check external circuit.

2. Low voltage -- check supply.

3. Problems in the gear motor electrical circuit. See Figure 6

THE GEARMOTOR STARTS BUTS TRIPS REPEATEDLY ON THE OVERLOAD

PROTECTOR:

1. Voltage -- high or low voltage can cause the overload to trip.

2. High Gear motor amperage draw, see Specification Chart for ratings and Troubleshooting Guide Pages 1 &

20

THE MOTOR RUNS BUT OUTPUT SHAFT DOES NOT ROTATE:

1. Replace defective gear motor.

CAUTION: Be sure unit is disconnected from the power source

Disconnect the transmission cable.

OVERLOAD CHECK:

1. Allow motor to cool and reset overload if necessary.

17

638085277

2. Remove motor end bell and stator, if necessary.

3. Check terminals 1 and 3 on overload. No continuity replace overload. Use a volt--ohm meter. See Figures

10 and NO TAG

NOTE: Gear motor and related components can be checked from Pin Connector. See Figures 10 and

NO TAG.

MOTOR CHECK:

The resistance readings on the windings will be between 5 to 25 ohms. A meter capable of these low readings

must be used. The Start Relay cover must be removed.

If no continuity on start or run winding test, replace stator. If continuity on grounded motor test, replace stator.

638085277

FIGURE 12. PIN NUMBERS

18

SAFETY CONTROLS

Your Icemaker unit has several safety and control devices incorporated into its design.

WARNING: None of the below described devices should ever be ”bypassed” to allow the

unit to function.

The safety and control system shut --off devices are:

FIGURE 13. GEAR MOTOR OVERLOAD

1. Low water shut off reed switch located in icemaker float assembly . (Automatic reset type).

2. Gear motor thermal overload, manual reset type (red button on motor). See Figure 12.

3. Compressor thermal overload, automatic reset type.

4. Main service switch located on top of the control box.

5. Hopper shut--off.

6. High pressure cut out (water cooled only).

WARNING: Do not reset gear motor overload if ice is present in the evaporator.

19

638085277

GUIDE TO GOOD ICE

CUSTOMER

COMMENTS

“It runs but the ice is

too soft.”

“The icemaker is not

producing enough ice.”

“The ice is too wet.”

CHECK ICEMAKER

LOCATION CONDITIONS

FIRST

S Proper air flow for condens-

ing system.

S Location too close to high

units such as coffee urns,

deep fryers, grills, etc.

S Supply water conditions

Water too warm

(above 90_F).

Water artificially softened

above 262 ppm sodium chloride.

Normal water supply too high

in total dissolved solids

(above 500 PPM).

CHECK ICE MAKER

S Use gauges for checking

suction and head

pressures. See manual

for correct reading and

conditions. Check frost

line and sight glass.

S Check water level for

proper adjustment and

restrictions. See

Manual.

S Check evaporator

assembly for worn

parts, bearings, scored

evaporator and auger,

bad expansion valve.

etc.

“It makes too much

noise.”

(With this comment

the ice is usually

extremely hard and

larger than normal.)

Over

Compression

S Check to see if noise

objection is normal fan and

air flow noise.

S Supply water conditions.

Water too cold (below

50_F). (Possibly running

from pre-cooler.)

S Obstructions partially

blocking ice exit from top of

evaporator.

S Check fan and fan shroud.

S Check for loose parts

and screws rattling.

S Check evaporator

assembly for worn

parts, bearings, scored

evaporator and auger,

bad expansion valve,

etc.

638085277

20

2

1

YesYes

TRIPPED

see

CLEAN

instructions.

reset.

Will not

again.

hot try

Overload

reset

replace

Will not

overload

Check water level control

GEARMOTOR OVERLOAD

Soft Ice

ICEMAKER OPERATING BUT

Switch Open

Storage Container Bin

SWITCH OPEN

LOW WATERSAFETY

and evaporator water tube

Poor dispensing

Check bin switch

trol plate moves freely

Check to see if ice con-

TROUBLESHOOTING CHART -- ICEMAKER NOT OPERATING

DOES NOT MAKE ICE

ICEMAKER RUNS BUT

Condenser fan running

but compressor not running

No

for lime build up restriction.

moves freely

Check bin switch

Check to see if ice control plate

Check that water is turned on.

Check for restriction in water line.

& components.

Check line voltage.

Check compressor winding

CAUTION

No

Refer to guide

Clean all related

(minimum 10 lbs.).

Check water safety switch.

Check incoming water pressure

Clear air bubble from

Evaporator water tube

may have an air bubble.

load.

Reset

overload.

setting over-

Clear ice from

evaporator and

auger before re-

to Good Ice in

service manual.

drain lines.

TXV bulb

lost charge.

(20 lbs. or below).

Low suction pressure

not

insulated.

Suction line

TXV not

properly.

operating

(30 lbs. or above).

High suction pressure

high.

Head

Pressure

tube.

Reset but

Icemaker runs

evacuate and

Replace valve

Bulb

uninsulated.

Bulb

loose.

stuck

Valve

open.

Check

not run.

motor does

recharge.

circuit.

gearmotor

motor circuit.

Short run trips

again in 2 min-

utes. Check gear-

found.

IMPORTANT

but problem has not been

Icemaker runs when reset

insulate.

Clean and

and

Clean

tighten.

valve.

Replace

problems

guard against future

Continue checking for

overload as follows to

High or low voltage weak power lines can cause overloads on icemaker restarts

High running current. Check motor circuits and start relay -- Auger delay failed.

Mechanical parts worn. Scored evaporator or auger. Worn thrust bearing.

Ice maker not turning off. Failed ice level control.

Over compression. Low water inlet temperature. Restriction in water line from

reservoir.

Contaminated charge or bad compressor.

Low charge or gas leak.

Low suction pressure. Improper expansion valve sensing bulb. Location or insulation

and/or defective expansion valve

OVERLOAD GUIDE

ELECTRICAL

ICEMAKER

turning.

auger is

Check if

froze up.

Icemaker

and

valve.

Plugged or

Restricted

Replace

faulty TXV.

liquid line.

Check for

system.

recharge

Evacuate

kinks or

liquid line.

damage to

REFRIGERANT

head is down in

evaporator tube.

Check if extruding

No

gearbox.

Check gears in

gearmotor.

Check drive on

timer

Icemaker Off

Dispense Timer Keeping

NO POWER

secongs

Check for faulty dispense

Hold dispense button for 45

tions.

switch or relay.

Check for failed service

trol box for loose connec-

Check electrical wiring in con-

Check power to machine.

dryer.

Plugged

liquid line

dirty or

restricted.

Condenser

Low on

fan not

running.

Condenser

system.

Too much

refrigerant in

in system.

Non-condensible

to fan motor.

Check fan motor.

Check electrical circuit

Evacuate and

Clean condenser.

recharge system.

refrigerant.

and

dryer.

Replace

Check for

system.

recharge

Evacuate

leaks.

638085277

FRONT OPTION

ONLYON DRINK

LIGHT

1

2

TAN

ICE

BLACK

SELECTOR

DISPENSE

SOLENOID

GROUND

DISP.

MOTOR

SWITCH

DISPENSE

WATER

SELECTOR

NOT USED WITH DRINK FRONT OPTION

BLACK

1

LIGHT

4 2

5

3

WATER

PINK

SOLENOID

LOW

WATER

GRAY

ICE

LEVEL

BROWN

1

HEATER

BI-METAL

GROUND

YELLOW

2

1

ORANGE

ANTI-

RELAY

FREEZE

3

START

3

RED

BLUE

YELLOW

2

BLACK

START RUN

FAN

RELAY

4

GEAR MOTOR

WHITE

638085277

R

M

START

6

4

ILLUM.

OPTION

MERCH.

BLACK

OPTION

DRINK FRONT

TRANSFORMER

24V

VALVES

3

I

C

24V

GROUND

CAP.

S

START

BLACK

WHITE

RELAY

COMPRESSOR

L

S

SWITCH

SERVICE

FIGURE 14. SCHEMATIC IMD 300--15

22

2

3

FIGURE 15. SCHEMATIC IMD 300--30, IMD600--30, IMD601--30, IMD600--90, AND IMD601--90

638085277

FIGURE 16. SCHEMATIC IMD302--30, IMD602--30, AND IMD602--90

638085277

24

Part # Corrections/Update Document

Unit Type/Model # Manual #

INSTALLATION

MANUAL COUNTERTOP

ICEMAKER IMD SERIES

Page Item Old Part Desc. New Part Desc. Agent Date Notes

25 4 638032768-001 Splash Panel

Asmb-Lever

25 638038589001 Disp Switch

638031500 Manual water

638009376001 Water glass

26 4 32030002 Splash Panel

Lever Activated

27 n/a 638083373 Drain Pan Elbow 83373 Drain Elbow

31 5 638008646 Fan Motor 115V 638036225

31 n/a 631500016 Compressor Kit

31 n/a 631500017 Compressor Kit

31 n/a 631500018 Compressor Kit

31 n/a 631500020 Compressor Kit

31 n/a 631500019 Compressor Kit

33 n/a 638031108 Dispense

33 n/a 638090226 Expansion

638032768-003 Splash Panel

638032030-002 Splash Panel –

638085277

Asmb-Lever

w/Glass Filler

Rect PB Black

glass fill kit

repair kit

Lever Activated

Fitting

1/2hp 120/60

404A for

IMD300-30

1/2hp 230/50

404A for

IMD302-30

3/4hp 120/60

404A for IMD

600-30

3/4hp 240/60

404A for

IMD601-30

3/4hp 230/50

404A for IMD

602-30

Mechanical

Assy 120/60

Valve

Jls 06/03/03

Jls 06/03/03 Teal color disp

switch is

638038589

Jls 06/03/03

Jls 06/03/03 Kit contains lever,

spring and other

hardware

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03 Includes start

components and

drier

Jls 06/05/03 Includes start

components and

drier

Jls 06/05/03 Includes start

components and

drier

Jls 06/05/03 Includes start

components and

drier

Jls 06/05/03 Includes start

components and

drier

Jls 06/05/03 Includes

solenoid, gasket,

door and

hardware

Jls 06/05/03 For 600-90

33 n/a 638090221 600-90

Compressor

33 n/a 638090241 601-90

Compressor

33 n/a 638090231 602-90

Compressor

34 n/a 04643-04 Water Level

Control Asy

34 7 638007002-01 Screw 161168017 Screw MA 06-

35 n/a 32545 Water Level

Control Asy

35 5 638032515 Water Level

Bracket

36 n/a 32770 Ice Level Control

Asy

36&37 n/a 32770-002 Ice Level Control

Asy

37 19 638007088-03 Screw 27103 Bolt MA ¼-20 Jls 06/05/03

38&39 n/a 31494-001 Ice Level Control

Asy

38&39 n/a 31494-002 Ice Level Control

Asy

39 6 11396 Bin Control

Cable

39 19 638007088-03 Screw 27103 Bolt Jls 06/05/03

39 22 638007069-02 Screw 630900138 Screw Jls 06/05/03

39 24 07051-07 Screw 638007051-02 Screw Jls 06/05/03

39 n/a 638011620-001 Main Power

Cable

40 n/a 31892 Ice Level Control

Asy

41 3 36645-02 Gasket 638036645 Gasket Strip Jls 06/05/03

41 12 638007301-19 Flat Washer 638007301-18 Flat Washer Jls 06/05/03

41 18 638007109-01 Pop Rivet 164005001 Pop Rivet Jls 06/05/03

41 38 638007088-03 Screw 27103 Bolt Jls 06/05/03

631500018 Compressor Kit

3/4hp 120/60

404A for IMD

600-90

631500020 Compressor Kit

3/4hp 240/60

404A for

IMD601-90

631500019 Compressor Kit

3/4hp 230/50

404A for

IMD602-90

638004643-04 Water Level

Control Asy

32

638032545 Water Level

Control Asy

638030024 Water Level

Bracket

638032770 Ice Level

Control Asy

638032770-002 Ice Level

Control Asy

638031494-001 Ice Level

Control Asy

638031494-002 Ice Level

Control Asy

638011396 Bin Control

Cable

638011620 Main Power

Cable

638031892 Ice Level

Control Assy

Jls 06/05/03 Includes start

Jls 06/05/03 Includes start

Jls 06/05/03 Includes start

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03 OBS. Can

Jls 06/05/03 OBS. Can

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03

Jls 06/05/03 OBS. Can

components and

drier

components and

drier

components and

drier

purchase parts

within the assy.

purchase parts

within the assy.

purchase parts

within the assy

43 1 638032744

and

638031110-01

and

638031110

43 6 638031143

and

638031017

43 7 638007088-05 Screw 638007088-06 Screw Jls 06/05/03

43 15 638007302-06 Lock Washer 168833000 Lock Washer Jls 06/05/03

43 17 638032055-001

and

638031719-001

43 19 638040018 Evaporator 630900766 Storage Bin Jls 10/01/03 See Serial

Storage Bin Asy 630000717

and

630000716

and

630000715

Retainer Ring 630900769

and

630900765

Evaporator Assy 630000633

and

630000650

Storage Bin Asy Jls 10/01/03 See Serial

Retainer Ring Jls 10/01/03 See Serial

Evaporator

Assy

Jls 10/01/03 See Serial

Number Cut-Off

Info Below

Number Cut-Off

Info Below

Number Cut-Off

Info Below

Gasket Gasket Number Cut-Off

Info Below

43 23 638090117

and

638090217

43 n/a 638090120 Delrin Bearing,

Extruding Head

Assy

630900609

and

630900608

Extruding Head Jls 10/01/03 See Serial

Number Cut-Off

Info Below

Jls 06/05/03 Used on IMD

2”

300-15 and 30030

43 n/a 638090220 Delrin Bearing,

2.5”

Jls 06/05/03 Used on IMD600-

30

43 n/a 638032177-01 Bearing Kit 2” Jls 06/05/03 For IMD300-15

and 300-30.

Includes delrin

and nylon bearing

and extruding

head

43 n/a 638032177 Bearing Kit 2.5” Jls 06/05/03 For IMD600-30.

Includes delrin

and nylon

bearings and

extruding head

45 9 638031719-001 Evaporator Assy 630000650 Evaporator Asy Jls 10/02/03 See Serial

Number Cut-Off

Below

45 15 638031759 Storage Bin Asy 630000714 Storage Bin Asy Jls 10/02/03 See Serial

Number Cut-Off

Below

45 12 638090217 Extruding Head 630900608 Extruding Head Jls 10/02/03 See Serial

Number Cut-Off

Below

45 10 638031021 Evaporator

Gasket

630900764 Storage Bin

Gasket

Jls 10/02/03 See Serial

Number Cut-Off

Below

45 19 638031017 Retainer Ring 630900765 Retainer Ring Jls 10/02/03 See Serial

Number Cut-Off

Below

n/a N/A 638009603 Upper Extruding

Jls 06/05/03 Bronze bearing

Head Bearing

47 n/a 32776 Elec Box Assy 638032776 Elec Box Assy Jls 06/05/03

47 n/a 32776-002 Elec Box Assy 638032776-002 Elec Box Assy Jls 06/05/03 OBS. Can

purchase parts

within the assy

47 7 638007352-01 Bushing 163529000 Bushing Jls 06/05/03

49 n/a 638031796 Delay Timer,

115v

Jls 06/05/03 Also called Solid

State Timer

52 10 638090244 Start Capacitor 25335 Start Capacitor Jls 06/05/03

59 n/a 638041829 Output Shaft 638090002 Output Shaft Jls 06/05/03

Serial Number Information

MODEL NAME MODEL PART NUMBER SERIAL NUMBER

IMD300-15 638090701, 638090730-001 63M00xxxxxxxx and after

IMD302-15 638090702, 638090703 63L00xxxxxxxx and after

These serial numbers will use the following part numbers:

Retainer Ring 630900769

Evaporator 630000633

Storage Bin 630000717

Extruding Head 630900609

Bin Gasket 630900766

MODEL NAME MODEL PART NUMBER SERIAL NUMBER

IMD-300-30 638090500, 638090501 63M00xxxxxxxx and after

IMD-302-30 638090503 63K00xxxxxxxx and after

These serial numbers will use the following part numbers:

Retainer Ring 630900769

Evaporator 630000633

Storage Bin 630000716

Extruding Head 630900609

Bin Gasket 630900766

MODEL NAME MODEL PART NUMBER SERIAL NUMBER

IMD600-30 638090400, 638090401 63P00xxxxxxxx and after

IMD600-30 638090450, 638090451 63O00xxxxxxx and after

IMD602-30 638090402, 638090403 63R00xxxxxxx and after

These serial numbers will use the following part numbers

Retainer Ring 630900765

Evaporator 630000650

Storage Bin 630000715

Extruding Head 630900608

Bin Gasket 630900764

MODEL NAME MODEL PART NUMBER SERIAL NUMBER

IMD600-90 638090600, 638090601 63Q00xxxxxxxx and after

IMD600-90 638090650, 638090651 63T00xxxxxxxx and after

IMD602-90 638090602, 638090603 63S00xxxxxxxx and after

IMD601-90 638090604, 638090605 63Q00xxxxxxxx and after

These serial number will use the following part numbers:

Retainer Ring 630900765

Evaporator 630000650

Storage Bin 630000714

Extruding Head 630900608

Bin Gasket 630900764

2

1

3

5

10

8

9

4

7

6

FIGURE 17. IMD 300-- 15 CABINET PARTS ASSEMBLY AND PARTS LIST

ITEM

PART NO. DESCRIPTION

NO.

1 638032724 Panel -- Left Side

2 638032731 Panel -- Top

3 638032721 Panel -- Right Side

4 638032768--002 Splash Panel Asmb -- Push Button

638032768--001 Splash Panel Asmb -- Lever

638032722--005 Spl. panel Asmb – Lever w/ Glass Filler

5 638032715--007 Front Panel -- Push Button

638032715--006 Front Panel – Lever

6 638032766 Drain Tray Kit (Tray, Grill & Skirt)

638032765 Drain Tray Assembly

638032729 Grill -- Drain Tray

638032725 Drain Tray Skirt

7 638032822 Ice Chute

8 638038588 Cover -- Dispense Switch, Push Button

9 638038589 Switch Dispense, Push Button

10 638032785 Switch -- Rocker

* 638032818 Wire Harness – Front Cover

* Not Shown

25 638085277

2

1

3

5

FIGURE 18. IMD300--30 AND IMD600--30 CABINET PARTS ASSEMBLY AND PARTS LIST

* Not Shown

11

7 8

6

9

10

ITEM NO. PART NO. DESCRIPTION

1 638032037 Panel -- Left Side

2 638032038 Panel – Top

3 638032036 Panel -- Right Side

4 32030--002 Splash Panel -- Lever Actuated

638032145--006 Splash Panel -- Push Button

5 638032025--001 Front Panel -- Lever Actuated

638032025--002 Front Panel -- Push Button

6 638032050 Drain Try Kit (Tray, Grill & Skirt)

638032043 Drain Tray Assembly

638032044 Grill -- Drain Tray

638032041 Drain Tray Skirt

7 638006529 Cover -- Switch -- Lever Actuated

8 638008315 Switch -- Dispense -- Lever Actuated

9 638031162 Boot -- Switch -- Lever Actuated

10 638009627 Plate -- Dispense -- Lever Actuated

* 638032049 Label “Push & Hold for Ice”

* 638038589 Switch -- Dispense, Push Button

* 638011601 Wire Asm. -- Switch Dispense

(Push Button Actuated)

* 638038588 Cover -- Dispense Switch, Push Button

* 638011643 Cable Asm. -- Lever Actuated

11 638032039 Ice Chute

4

26638085277

7 8 9

6

1

2

3

5

4

10

* Not Shown

FIGURE 19. IMD600--90 CABINET PARTS ASSEMBLY AND PARTS LIST

ITEM

NO.

PART

NO.

DESCRIPTION

1 638032539 Panel -- Left Side

2 638032537 Panel -- Top

3 638032538 Panel -- Right Side

4 638032040--006 Panel Splash Asm. -- Push Button

* 638032541--001 Panel Splash Asm. -- Lever Actuated

5 638032536--002 Front Cover, Push Button

* 638032536--001 Front Panel -- Lever Actuated

6 638032548 Drain Tray Kit (Tray, Grill & Skirt)

638059270 Drain Tray

638058805 Grill -- Drain Tray

638032531 Drain Tray Skirt

638033508 Drain Tray, 8 Valve Drink Front

638033509 Grill -- Drain Tray, 8 Valve Drink Front

638032531--001 Drain Tray Skirt, 8 Valve Drink Front

7 638038588 Cover -- Dispense Switch Push Button

* 638006529 Cover -- Switch, Lever Actuated

8 638038589 Switch -- Dispense --Push Button

9 638011601 Wire Asm. -- Dispense -- Push Button

638008315 Switch -- Dispense, Lever Actuated

638011643 Cable Asm. -- Lever Actuated

638031162 Boot -- Switch, Lever Actuated

638009627 Plate -- Dispense, Lever Actuated

10 638032287 Ice Chute

* 638032136 Window, Ice Chute

* 638083373 Drain Pan Elbow

27 638085277

9

10

8

7

22

23

12

13 14 15

18 19 20 21

2

1

17

16

3 4 6

FIGURE 20. REFRIGERATION AND FRAME ASSEMBLY IMD 300-- 15

638085277

28

REFRIGERATION AND FRAME ASSEMBLY IMD 300 -15 PARTS LIST

ITEM NO. PART NO. DESCRIPTION

1 638000784 Condenser

2 638000872 Shroud--Fan

3 638001007 Fan Blade

4 638003599 Bracket--Fan Mounting

*5 638032843 Water Level Control

6 638000525 Fan Motor (115V)

638010016 Fan Motor (220V/50Hz.)

7 638031108 Dispense Mechanism (115V)

638031108--01 Dispense Mechanism (220V/50Hz.)

8 638032744 Storage Bin Asmb.

9 638032770 Ice Level Control (115V)

638032770--002 Ice Level Control (220V/50 Hz.)

10 638032776 Electrical Box Asm. (115V)

638032776--002 Electrical Box Asm. (220V/50 Hz.)

*11 638031763--002 Drain Receptacle Asm.

Front End Assembly (115V)

Front End Assembly (208V)

Front End Assembly (220V)

13 638032739 Compressor 1/3hp R--134a (115V)

638032845 Compressor 1/3hp R--134a (220V/50 Hz.)

* 638004393 Drier

*14 638030732 Overload 115V

638032845--001 Overload 220V

*15 638030733 Relay 115V

638032845--002 Relay 220V

*16 638030734 Start Capacitor 115V

638032845--003 Start Capacitor 220V

17 638032714 Air Filter

18 638032762 Water Valve (115V)

638032762--002 Water valve (208V/220V)

19 638032777 Valve--Needle 1/4 X 1/4 Female Pipe

20 638032778 1/4 Hose Barb X 1/4 MPT

21 638007373 Connector--1/4 MFL X 1/4 FPT, Brass

22 638032815 Water Dispense Tube

23 638006070 Tube -- Vinyl

* Not Shown

NOTE: Start components are supplied with the compressor

29 638085277

9

8

11

7

10

6

2

1

3 4

5

FIGURE 21. REFRIGERATION AND FRAME ASSEMBLY IMD 300-- 30 AND IMD 600-- 30

638085277

10

30

REFRIGERATION AND FRAME ASSEMBLY IMD 300--30 AND IMD 600--30 P ARTS LIST

n

ITEM NO. PART NO. DESCRIPTION

1 638004204 Condenser -- (Air Cooled)

638036383 Condenser -- IMD 300 (Water Cooled)

638036272 Condenser -- IMD 600 (Water Cooled)

2 638004285 Shroud -- Fan

3 638004387 Fan Blade

4 638004391 Bracket--Fan Mounting

* 638004643--04 Water Level Control

5 638008646 Fan Motor (115V)

638036225--03 Fan Motor (208V 60 Hz.)

638008886--001 Fan Motor (220V 50 Hz.)

* 638008943 Exhaust Fan (Water Cooled Units)

* 638033058 Mounting Bracket, Exhaust Fan

6 638011307 Conduit Asm. Compressor (300--30)

638011308 Conduit Asm. Compressor (600--30)

7 638031108 Dispense Mechanism (115V)

638031496--001 Dispense Mechanism (208V 60 Hz.)

638031108--01 Dispense Mechanism (220V 50 Hz.)

8 638031110--01 Storage Bin 300--30

638031110 Storage Bin 600--30

9 638031494--001 Ice Level Control (115V)

638031494--002 Ice Level Control (220V 50Hz.)

* 638031763--002 Drain Receptacle Asm.

10 Front End Asm. 300 -- 30 (115V)

Front End Asm.301 -- 30 (208V 60Hz.)

Front End Asm. 302-30 (220V 50Hz.)

Front End Asm. 600 -- 30 (115V)

Front End Asm. 601 -- 30(208V 60 Hz.)

Front End Asm. 602 -- 30(220V 50 Hz.)

*

* 638009755 Pressure Switch (Water Cooled)

638090021 Valve, Water Regulating (Water Cooled)

300--30 301--30 302--30 600--30 601--30 602--30 Descriptio

11 631500016 631500017 631500018 631500020 631500019 Compressor kit

* Not Shown

Note: Compressor start components are included with compressor kits shown above.

31 638085277

3

4 5 6

7

9

1

2

8

FIGURE 22. REFRIGERATION AND FRAME ASSEMBLY IMD 600-- 90

638085277

32

REFRIGERATION AND FRAME ASSEMBLY IMD 600--90 PART LIST

ITEM NO. PART NO. DESCRIPTION

1 638036273 Condenser, Air Cooled

638036272 Condenser, Water Cooled

2 638090635 Shroud, Condenser

3 638090630 Front End Asm. (115V)

638090630--001 Front End Asm. (208V 60 Hz)

638090630--002 Front End Asm. (220V 50 Hz)

4 638090236 Fan Motor (115V)

90236--001 Fan Motor (208V 60 Hz)

90236--002 Fan Motor (220V 50 Hz)

5 638090009 Bracket, Fan Motor

6 638096723 Fan Blade

7 638032545 Water Level Control Asm.

8 638090625 Electrical Box Assembly (115V)

638090625--002 Electrical Box Assembly (208V/220V)

* 638090021

* 638009755 Pressure Switch (Water Cooled Only)

* 638008943 Fan Exhaust (115V Water Cooled Only)

* 08943--002 Fan Exhaust (208V 60 Hz Water Cooled Only)

* 08943--002 Fan Exhaust (220V 50 Hz Water Cooled Only)

* 638031832 Bracket Exhaust Fan (Water Cooled Only)

* 31763--002 Drain Receptacle Assembly

Valve, Water Regulating (Water Cooled Only)

600-- 90 601-- 90 602-- 90 DESCRIPTION

9 638090221 638090241 638090231 Compressor

* 638090222 638090242 638090238 Start Relay

* 638090224 638090244 638090244 Comp. Start Cap.

* 638090223 638090243 Comp. Run Cap.

90221--001 Overload

638004393 638004393 638004393 Drier

* Not Shown

Note: Compressor start components must be ordered separately (excluding overload)

33 638085277

3

2

1

5

6

4

7

FIGURE 23. WATER CONTROL ASSEMBLY AND PARTS LIST PART NO.

04643-04 IMD 300-30 AND IMD 600-30

ITEM

PART NO. DESRIPTION

NO.

1 638030822 Resevoir Assembly

Resevoir

Cover

O-Ring

Wing Nut

2 638030823 Hardware, Water Level Control

Valve Body

Cotter Pin

Cap

Spacer

Plunger, Rubber

Washer, Fiber

Nut

Sleeve

Nut, Compression

3 638030819 Float and Stem Assembly (Service)

Magnet and Bracket Assembly

Float

4 638008483-01 Reed Switch (300-30, 600-30)

5 638004717 Bracket, Water Level

6 638008097 Clamp, Reed Switch

7 638007002-01 Screw, No. 6-32 By 1/4 BHMS

638085277

34

2

3

1

4

5

FIGURE 24. WATER CONTROL ASSEMBLY AND PARTS LIST PART NO. 32843 IMD 300--15

32545 IMD 600-90

ITEM

PART NO. DESRIPTION

NO.

1 638030825 Resevoir Assembly

Resevoir

Cover

O-Ring

Wing Nut

2 638030824 Hardware, Water Level Control

Valve Body

Cotter Pin

Cap

Spacer

Plunger, Rubber

Washer, Fiber

Nut

Sleeve

Nut, Compression

3 638030821 Float and Stem Assembly

Magnet and Bracket Assembly

Float

4 638008483-06 Reed Switch (300-15)

638008483-03 Reed Switch (600-90)

5 638032515 Bracket, Water Level

35 638085277

GROUND

8

2

3

4

6

NO TAG

13

1

7

9

10

11

12

5

FIGURE 25. TOP VIEW ICE LEVEL CONTROL ASSEMBLY

PART NO. 32770 IMD 300-15 AND 32770-002 IMD 302--5

4

24

14

23

22

17

16

15

21

FIGURE 26. SIDE VIEW ICE LEVEL CONTROL ASSEMBLY

PART NO. 32770 IMD 300-15 AND 32770-002 IMD 302--5

638085277

1819

20

36

ICE LEVEL CONTROL ASSEMBLY PARTS LIST FOR PART NO

32770 IMD 300--15 AND 32770--002 IMD302--15

ITEM

PART NO. DESRIPTION

NO.

1 638032760 Gear Motor-Dispense (115V)

638032760-002 Gear Motor-Dispense (220V 50HZ)

2 638032759 Spacer, Eyelet

3 638007051-08 Screw, No. 10-32 By 5/8-In. Long BHMS

4 638007204-06 Nut, No. 10-32 Keps, Stainless Steel

5 638032748 Cable, Gear Motor

6 638003924 Switch

7 638032745 Switch Bracket

8 638007002-12 Screw, No. 6-32 By 1-In. Long

9 638007341-10 Strain Relief

10 638032771 Cable-Ice Level Control

11 638007009-02 Screw, No. 6 By 3/8-In. Long

12 638004001 Cover-Switch

13 638007026-16 Screw, No. 8-32 By 1 1/2-In. Long

14 638032747 Rod, Actuator

15 638032750 Ice Level Plate

16 638032754 Spacer

17 638032713 Push-On Ring, 1-In. Dia.

18 638007301-18 Washer, Plain Flat

19 638007088-03 Screw, 1/4-20 By 1/2-In. Long

20 638032719 Agitator Arm

21 638032718 Upper Agitator Plate

22 638032761 Agitator Shaft

23 638007345-07 Roll Pin, .125 Dia. By 3/4-In. Long

24 638036645 Gasket-Strip, 4 pieces at 10 3/8-In. Long

37 638085277

2

1

21

8

20

24

FIGURE 27. TOP VIEW ICE LEVEL CONTROL ASSEMBLY IMD 300-30 AND

IMD 600-30PART NO. 31494-001 (115V) PART NO. 31494-002 (208V/220V)

6

5

25

7

3

9

12

17

10

11

4

16

22

14 15

13

19

23

18

FIGURE 28. SIDE VIEW ICE LEVEL CONTROL ASSEMBLY IMD 300-30 AND

IMD 600-30PART NO. 31494-001 (115V) PART NO. 31494-002 (208V/220V)

638085277

38

ICE LEVEL CONTROL ASSEMBLY PARTS LIST IMD300--30 AND IMD600--30

PART NUO 31494--001 (115V) PART NO. 31494--002 (208V/220V)

ITEM

PART NO. DESRIPTION

NO.

1 31075 Top, Cover, Outside

2 638031493-001 Dispense Motor Assembly (115V)

638031493-002 Dispense Motor Assembly (208V/220V)

3 31077 Switch Mounting Bracket

4 31011 Switch, Bracket

5 638031156 Ice Level Switch

6 11396 Bin Control Cable

7 638007308-01 Washer, Fibre

8 638007009-10 Screw, No. 6-32 By 1 1/4-In. Long

9 31010 Rod, Actuator

10 31014 Spring, Return

11 638007337-02 E-Ring

12 31146 Motor Mounting Bracket

13 638031150 Diaphram

14 638031147 Ice Level Plate

15 31100-06 Rivnut Fastener

16 638031076 Top Cover, Inside

17 638007264-02 Nut Tinnerman, Twin

18 638031078 Agitator Arm

19 638007088-03 Screw, 1/4-20 By 1/2-In. Long

20 638007002-03 Screw, No. 6-32 By 3/8-In. Long

21 638001026 Strain Relief

22 638007069-02 Screw, No. 10-32 By 1 1/4-In. Long

23 638007301-18 Washer

24 07051-07 Screw, No. 10-32 By 3/8-In. Long

25 638031159 Upper Agitator Arm

* 638011620-001 Main Power Cable

39 638085277

1

2 20

3

19

6 7 8

5

11

11

12

11 12

10

11

9

10

11

13

11

14

15

14

11

13

FIGURE 29. TOP VIEW ICE LEVEL CONTROL ASSEMBLY IMD 600-90

PART NO. 31892

16

17

18

19

6

7

8

20

2

24

23

26

27

28

25

29

8

30