IDC PRO 255

Installation Manual

Release Date: August 05, 2016

Publication Number: 621058578INS

Revision Date: June 20, 2018

Revision: B

Visit the Cornelius web site at

www.cornelius-usa.com for all your Literature needs.

The products, technical information, and instructions contained in this manual are subject to change without notice.

RECYCLE

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible

contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic, and

mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and con

struction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warranty applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident, (6)

alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons

to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating,

cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100% compatible with

the Product) which use voids the entire warranty, (13) Product parts in contact with water or the product dispensed

which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

-

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency Drive

Glendale Heights, IL

Tel: + 1 800-238-3600

Printed in U.S.A.

Correct Disposal of this Product

This marking indicates that this product should not be disposed with other household wastes throughout the EU. To

prevent possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly to

promote the sustainable reuse of material resources. To return your used device, please use the return and collection

systems or contact the retailer where the product was purchased. They can take this product for environmental safe

recycling.

TABLE OF CONTENTS

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Direct Counter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Adjusting the Carbonator CO2 Regulator and Turning on the Water Inlet Supply Line . . . . . . . . . . . 8

Gate Restrictor Plate Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Product to the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water & Syrup Line Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Adding Syrup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mapping Brands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Purging The Syrup Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Syrup Line Cleaning & Sanitizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjusting the Water to Syrup Ratio (BRIX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning Interior Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unit Shutdown/Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Editing the Media Playlist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Updating Software Revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Unit Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Carbonator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SAFETY INSTRUCTIONS

!

DANGER:

!

WARNING:

CAUTION:

!

!

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit

(decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety regulations and/or national and local codes before operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit, be alert to

the potential of personal injury or damage to the unit.

Different Types of Alerts

IDC Pro 255 Installation Manual

Indicates an immediate hazardous situation which, if not avoided, WILL result in serious injury, death or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in serious injury, death, or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury or equipment

damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very

young children or infirm persons without supervision. Young children should be supervised to ensure that

they do not play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

NOTE: The dispenser is not designed for a wash-down environment and MUST NOT be placed in an area

where a water jet could be used.

© 2016-2018, Cornelius Inc. - 1 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

!

WARNING:

!

WARNING:

CAUTION:

!

CAUTION:

!

!

DANGER:

!

WARNING:

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL WIRING

AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD

RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

IF THE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY THE MANUFACTURER, ITS SERVICE

AGENT OR SIMILARLY QUALIFIED PERSONS IN ORDER TO AVOID A HAZARD.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued protection,

observe the following:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the user. Verify

all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may result in

injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must be drained

from the system. A freezing ambient environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

CO2 (CARBON DIOXIDE) WARNING

CO2 displaces oxygen. Strict attention MUST be observed in the prevention of CO2 gas leaks in the entire CO2 and

soft drink system. If a CO

contaminated area before attempting to repair the leak. Personnel exposed to high concentrations of CO

experience tremors which are followed rapidly by loss of consciousness and DEATH.

2 gas leak is suspected, particularly in a small area, IMMEDIATELY ventilate the

2 gas

MOUNTING IN OR ON A COUNTER

When installing the unit in or on a counter top, the counter must be able to support a weight in excess of 1,000 lbs.

(454 kg.) to insure adequate support for the unit. Failure to comply could result in serious injury, death or damage to

the equipment.

NOTE: Many units incorporate the use of additional equipment such as ice makers. When any addition

equipment is used you must check with the equipment manufacturer to determine the additional

weight the counter will need to support to ensure a safe installation.

Publication Number: 621058578INS - 2 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

NOISE LEVEL

This unit emits acoustical noise with an A-weighted sound pressure level no greater than 75dB, as measured in

accordance with ED 60335-2-75.

© 2016-2018, Cornelius Inc. - 3 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

CAUTION:

!

SYSTEM OVERVIEW

The IDC PRO 255 unit solves your ice and beverage service needs in a sanitary, space saving, economical way. It is

designed to be manually filled with ice from any remote ice making source. The unit distributes cubes (up to 1-1/4 inch

in size), Cubelet and compressed (not flaked) ice. Also, the unit includes beverage valves, a cold plate, an internal

carbonator tank and an external pump for the carbonator.

The unit cannot be used with crushed or flaked ice. Use of bagged ice which has frozen into large chunks can void

warranty. The unit agitator is not designed to be an ice crusher. Use of large chunks of ice which “jam up” inside the

hopper will cause failure of the agitator motor and damage to the hopper. If bagged ice is used, it must be carefully

and completely broken into small, cube-sized pieces and left to “temper” or warm up for a minimum of 20 minutes in

room temperature before loading into the unit hopper.

FEATURES

• Brand density - 10 brands on each side, 7 chilled, 3 ambient and up to 8 flavor shots (4 per side) for over

320 drink combinations.

• Large HD promotional display

• 255 lb. capacity ice cube hopper

• Internal cold carbonation with remote pump

• Total carb/mid-carb flexibility on each brand

• Dispenses cubed or chewable soft ice

• UI Touch screen.

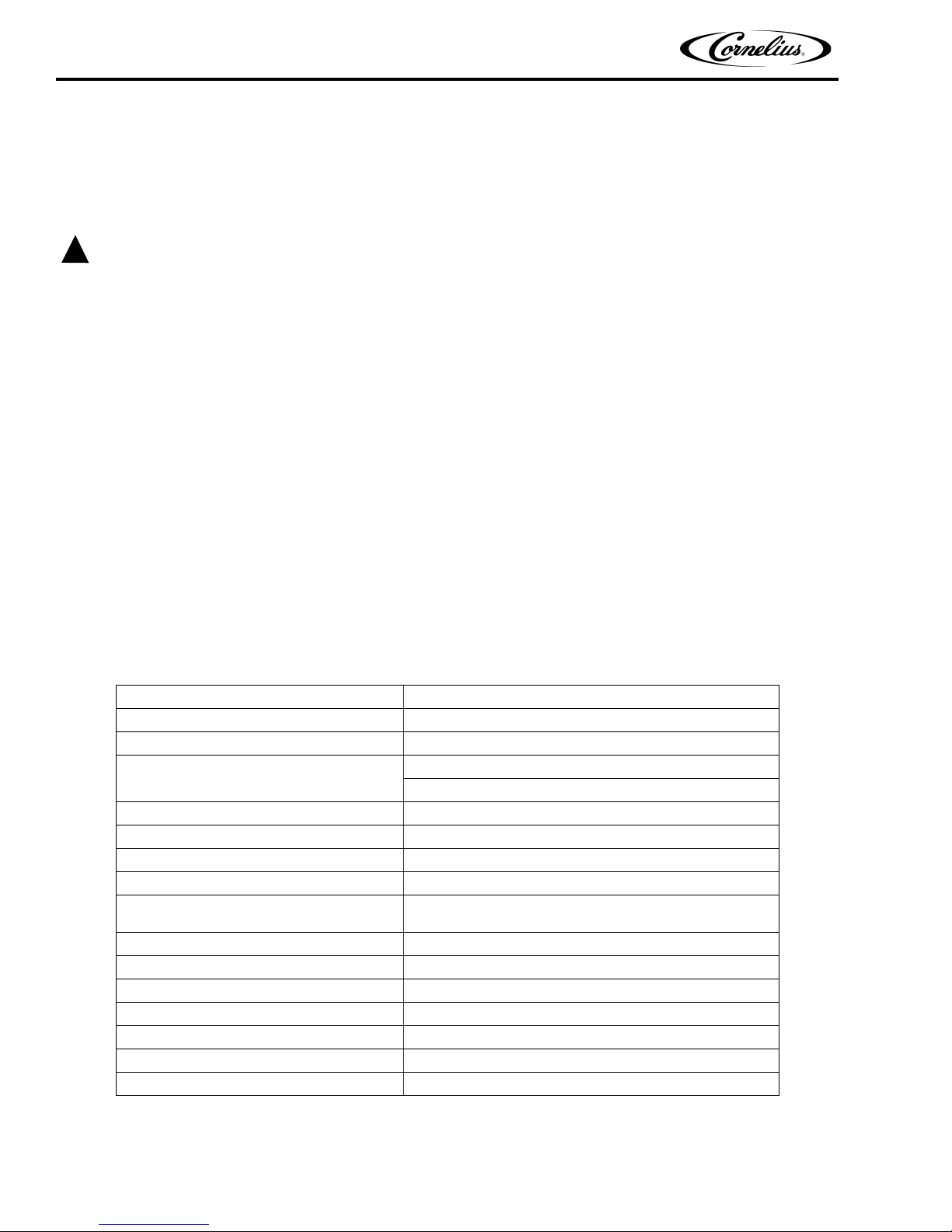

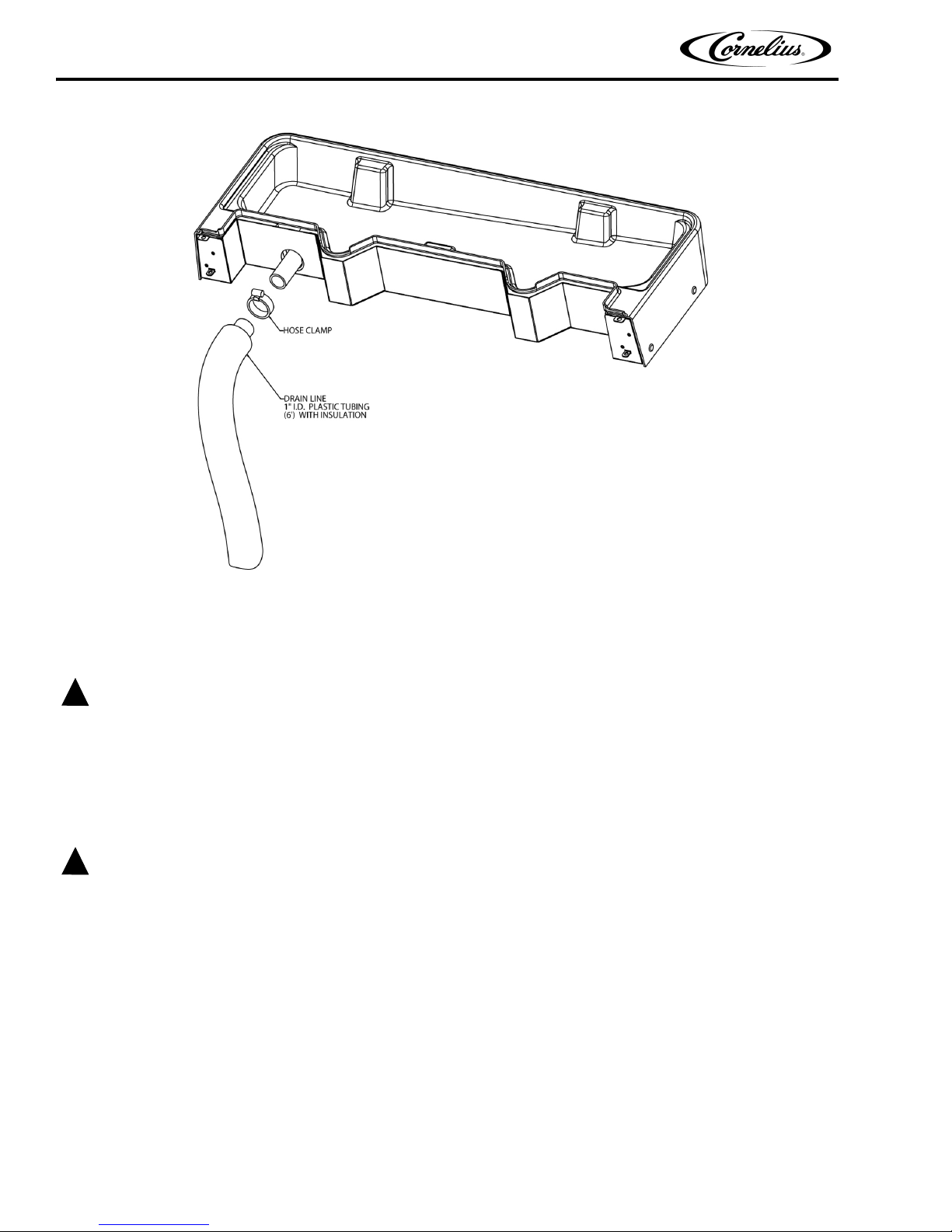

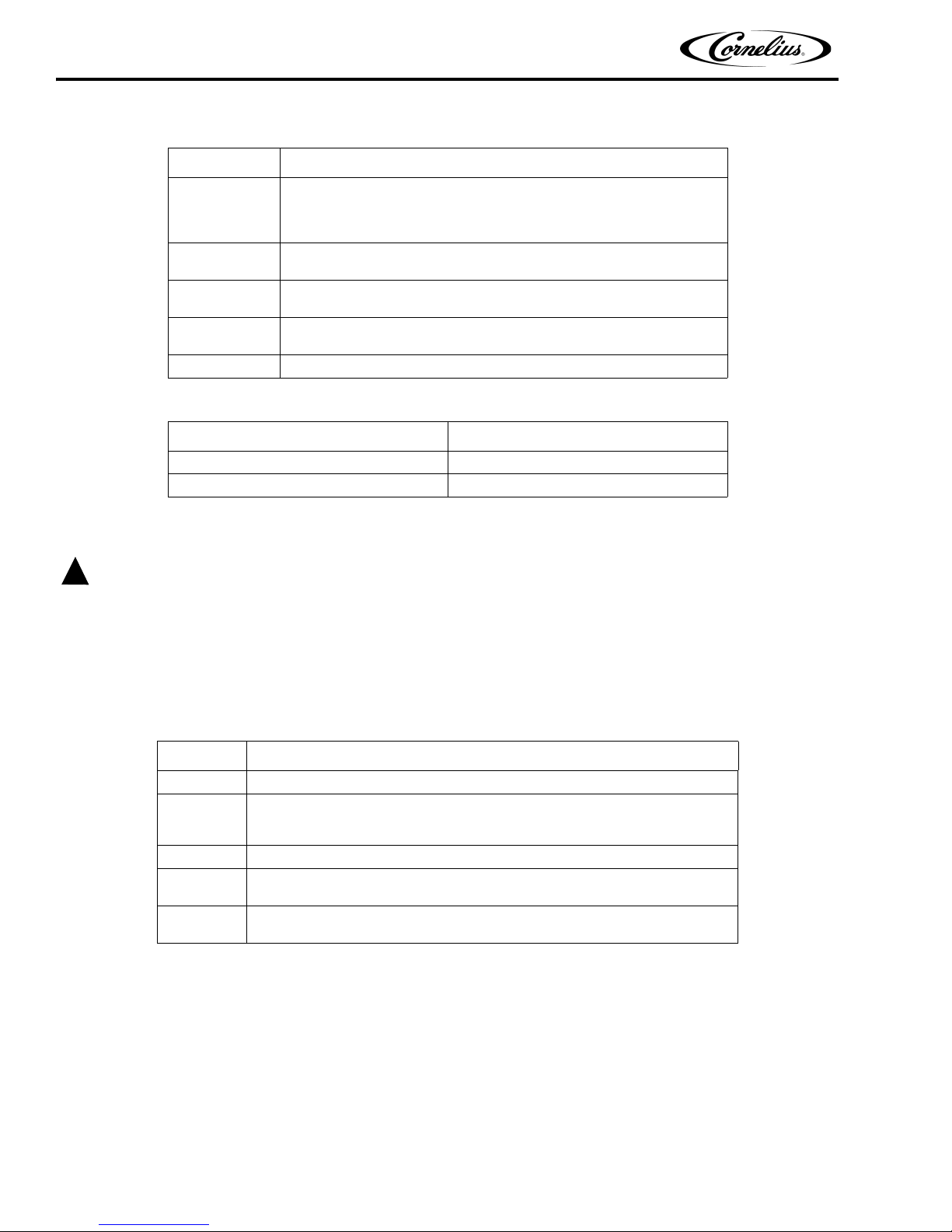

SPECIFICATIONS

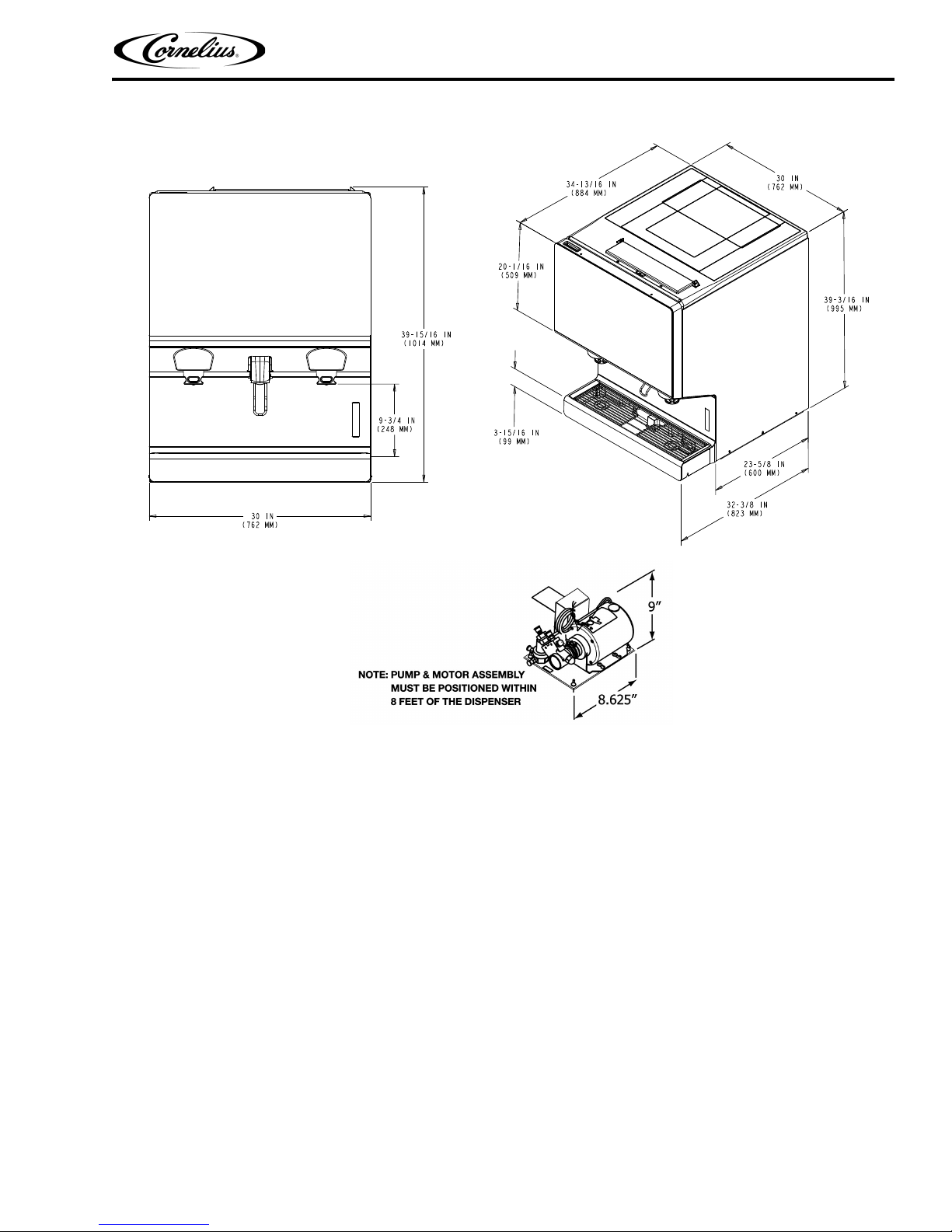

Model IDC Pro 255

Maximum Number of Valves available 36 Total; 20 brands, 8 flavors, 4 Pain & 4 Carb

Built-in Cold Plate Yes

Voltage

Height 39-3/16 in. (.955 m) to top of Adapter lid

Depth 32-3/8 in. (0.823 m)

Width 30 in. (0.762 m)

Screen Dimensions 32 in. Diagonally

2 Operating Pressure

CO

Water Pressure 50-60 psi (345-414 Kpa) at pump

Water Volume Minimum flow rate, 125 gal/hr. (0.473 cubic meters/hr.)

Shipping Weight 545 lb. (247.2 kg)

Counter Weight 440 lb. (199.6 kg)

Ice Storage Weight 255 lbs. (115.7 kg)

Cup Clearance 9-3/4 in. (24.77 cm)

Ambient Operating Temperature 65 to 95° F (18.3 to 35° C)

Table 1.

120 V 60 Hz, single phase; 8.5A. of total unit draw

220 -240V 50 - 60Hz, single phase; 5.5A of total unit draw

More than 80 psig (5.52 bar) feeding carbonator pump (75

psig (5.17 bar) fixed regulator on pump deck)

Publication Number: 621058578INS - 4 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

Figure 1.

© 2016-2018, Cornelius Inc. - 5 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

!

WARNING:

!

WARNING:

INSTALLATION

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit.

ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY

COULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

This equipment must be installed to comply with the International Plumbing Code of the International Code Council

and the Food Code Manual 01 the Food and Drug Administration (FDA). For models installed outside the U.S.A., you

must comply with the applicable Plumbing/Sanitation Code for your area.

Failure to comply could result in serious injury, death or damage to the equipment.

UNIT LOCATION

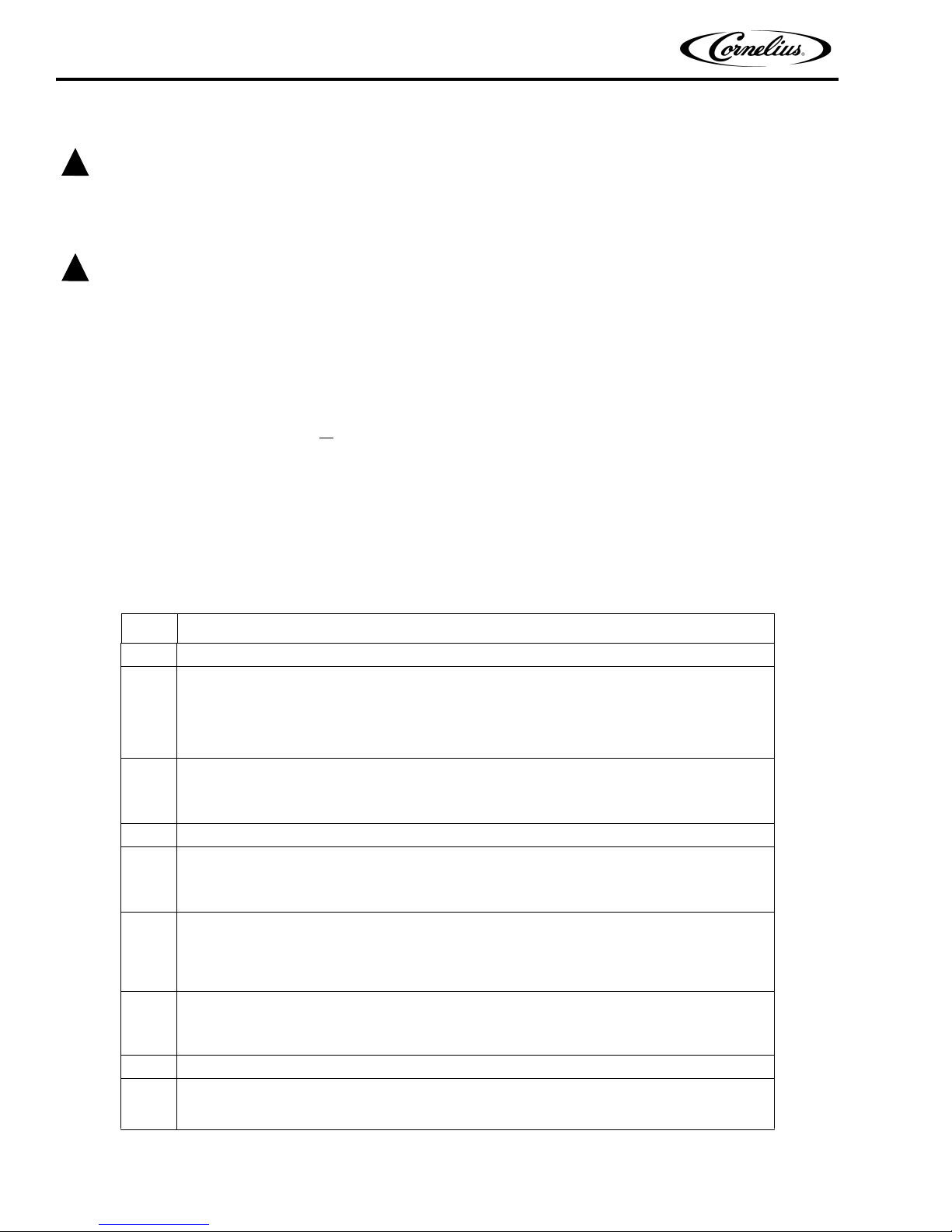

The unit must be sealed to the counter or placed on the included 4” legs (drip tray style unit only). The template

drawing indicates where openings can be cut in the counter. Locate the desired position for the unit, then mark the

outline dimensions on the counter using the template drawing, shown in Figure 2.. Cut the necessary openings in the

counter.

DIRECT COUNTER INSTALLATION

To install the unit on a counter, perform the procedure in Table 2.

Table 2.

Step Action

1 Locate the unit indoors on a level counter top.

When the unit is mounted directly on the counter top, the b

cord are routed through the large opening in the bottom of the unit. See the mounting template

shown in Figure 2. for locating the required clearance openings in the counter.

2

NOTE: Recommended counter opening size 9X12 for utilities and beverage tub-

ing. Opening can be located anywhere within the shaded area.

Apply a continuous bead of NSF International (NSF) silastic sealant (Dow 732 or equal) approximately 1/4-inch inside of the unit outline dimensions and around all openings. Then, position the

3

unit on the counter within the outline dimensions. All excess sealant must be wiped away

immediately.

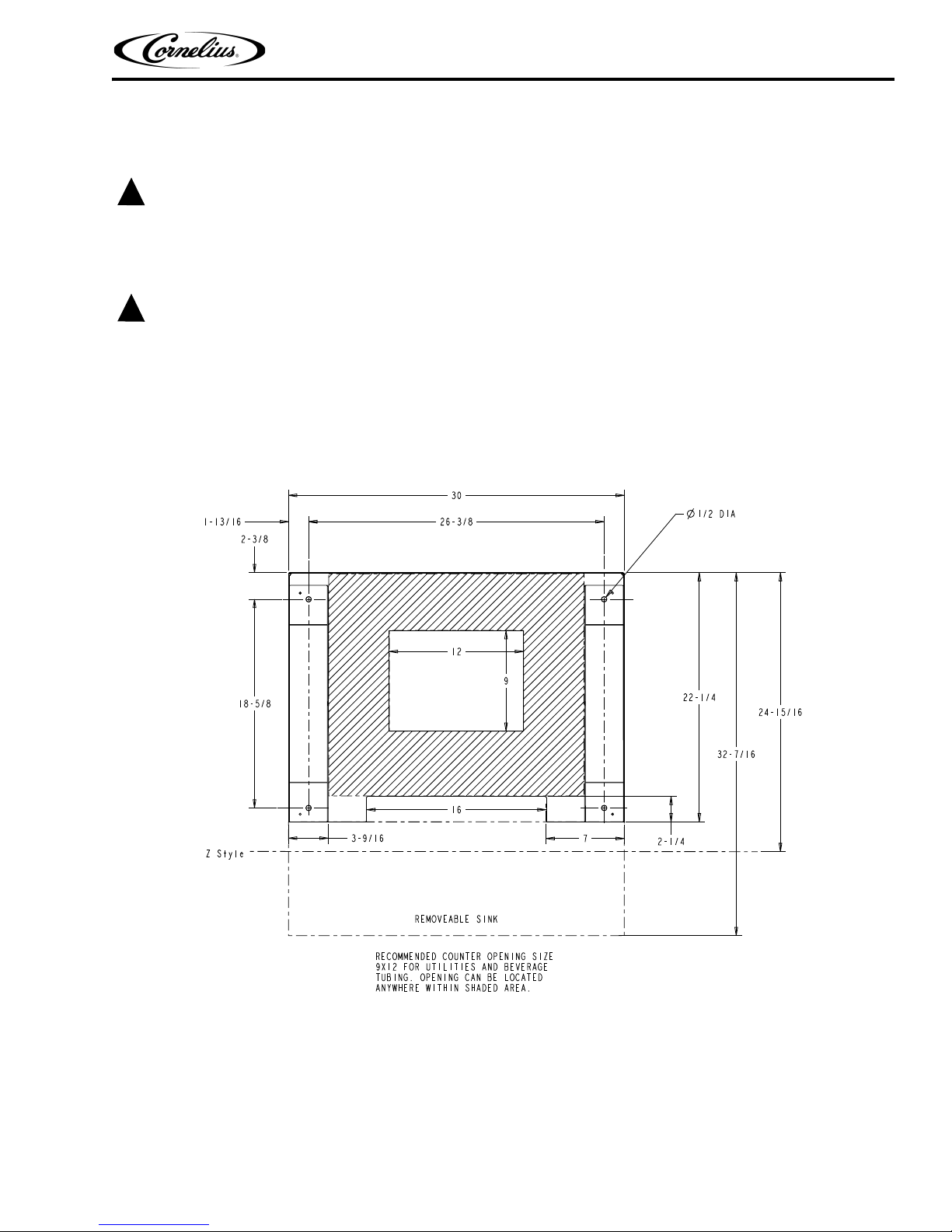

4 Install the drain tube on to the drip tray, as shown in Figure 3..

Route the drain tube to an open drain with the end of the tube above the “flood” level of the drain.

se the tubing, fittings, clamps, and insulation provided with the unit to assemble the drain. The

U

5

completed drain line must pitch continuously downward and contain no “traps” or improper drainage results.

Locate the carbonator pump assembly and connect the po

The cord is connected to the unit’s electrical box and has an electrical connector on the end that plugs

into a receptacle in the junction box at the carbonator pump assembly. Connect inlet water to the

6

pump and the pump outlet to the unit using 3/8-inch food-grade tubing. Disable the pump from operating by switching the switch in the carbonator pump assembly junction box to the OFF position.

Connect the beverage system product

7

NOTE: See the Plumbing Diagram (Figure 9.) or the decal on the lower front of

the unit for the location of syrup and water connections.

8 Clean the hopper interior (see “Cleaning Interior Surfaces” section on page 24).

Connect the unit power cord to a 120 volt, 60 cycl

Volt units, a 3-wire power cord is provided. An appropriate power cord for the particular country

9

may need to be provided by the installer.

tubes as indicated in the Plumbing Diagram, Figure 9..

everage tubes, drain tube and power

wer cord from the dispenser to the pump.

e, 3-wire grounded receptacle. For 220-240

Publication Number: 621058578INS - 6 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

CAUTION:

!

CAUTION:

!

NOTE: Cornelius Inc. recommends that a water shutoff valve and water filter be installed in the plain water

inlet supply line. A Cornelius Water Filter (P/N 313860000) and Quick Disconnect Set (P/N

313867000) are recommended.

Check the minimum flow rate and the maximum pressure of the plain water inlet supply line. MINIMUM FLOW RATE

MUST BE AT LEAST 125-GALLONS PER HOUR. If flow rate is less than 125-gallons per hour, starving of the car

bonator water pump can occur. Starving causes the carbonator

stat on the pump outlet to stop the water pump motor.

INCOMING PLAIN WATER INLET SUPPLY LINE WATER TO PUMP PRESSURE MUST REMAIN A MINIMUM OF

10 psi BELOW THE CARBONATED CO2 OPERATING PRESSURE. (Example: Carbonator CO

sure is 75 psi and the maximum water pressure can be no more t

2 operating pressure) can cause carbonator flooding, malfunction, and leakage through the carbonator relief valve.

CO

If water is exceeding maximum pressure specifications, a Water Pressure Regulator Kit must be installed in the plain

water inlet supply line. If a fitting connector is not available, tap into the plain water supply line with a 3/8 flare saddle

valve.

water pump to overheat, causing the safety thermo-

2 operating pres-

han 65 psi, etc.). Water over pressure (higher than

-

© 2016-2018, Cornelius Inc. - 7 - Publication Number: 621058578INS

Figure 2.

IDC Pro 255 Installation Manual

CAUTION:

!

CAUTION:

!

Figure 3.

ADJUSTING THE CARBONATOR CO2 REGULATOR AND TURNING ON THE WATER

NLET SUPPLY LINE

I

Before connecting the CO2 regulator assembly to a CO2 cylinder, turn the regulator adjusting screw to the left (counterclockwise) until all tension is relieved

1. Open (counterclockwise) the CO

the valve fully to back-seat it. (Back-seating the valve on the CO

shaft).

2. The source CO

Never operate the carbonator pump with the water inlet supply line shutoff valve closed. “Dry running” the water pump

will burn out the pump. A pump damaged in this manner is not covered by the warranty.

3. Open the water inlet supply line shutoff valve.

4. Exercise one of the dispensing valves to exhaust trapped air inside the carbonator tank.

2 regulator must be adjusted to a minimum setting of 80 psi.

from the adjusting screw spring.

2 bulk cylinder valve slightly to allow the lines to slowly fill with gas, then open

2 bulk tank prevents leakage around the valve

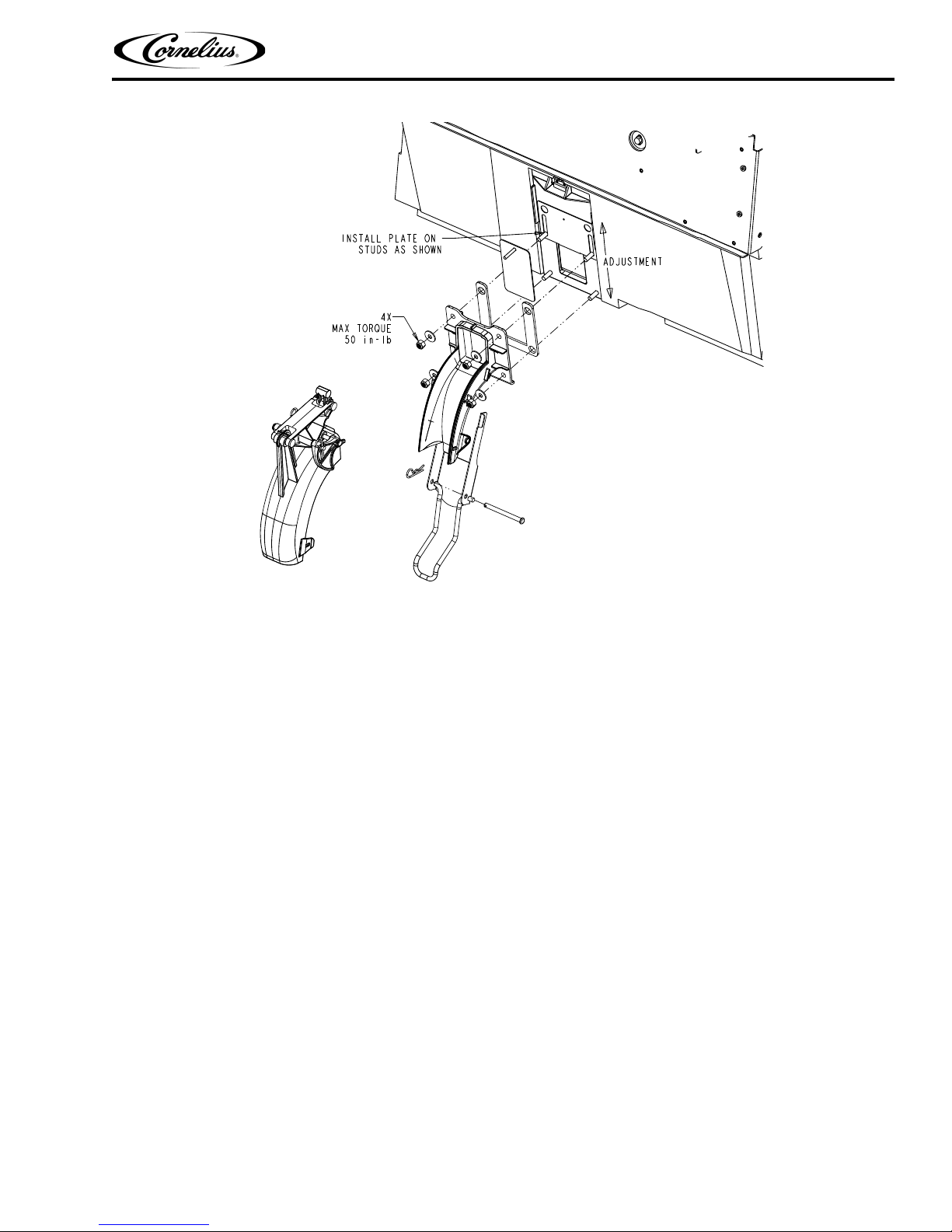

GATE RESTRICTOR PLATE ADJUSTMENT

The rate at which ice is dispensed is adjusted by adjusting the opening of the gate Restrictor plate as illustrated in Figure 4.

To adjust the gate Restrictor plate, loosen the four (4) nuts that hold the ice chute assembly to the hopper. The Restrictor

plate can

the maximum rate of ice dispense is available (approximately 3 oz/sec). Re-tighten the four (4) nuts to set the desired

Restrictor plate opening. DO NOT EXCEED 35 IN-LB of torque.

now be moved up or down. When the Restrictor plate is fully up, the ice gate opening is 2-1/2” in height, and

Publication Number: 621058578INS - 8 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

Figure 4.

CONNECTING PRODUCT TO THE UNIT

Refer to the “Plumbing Diagram” section on page 33 for details of the hook-up.

Any unused lines must remain capped.

NOTE: All inlet connections are clearly marked with a label adjacent to the inlet connections.

Always check for leaks on all connections.

WATER & SYRUP LINE CONNECTIONS

The standard unit supports the following:

• 1-water line from carbonator pump

• 1-water line for non-carbonated drinks

• 20-Syrup lines

• 8-Flavor Shots

Product Line Connections

To connect the syrup, water and flavor shot lines from the backroom package to the unit, perform the procedure in

Table 3.

NOTE: If lines are to be cut, mark the line numbers above the cut with a marker. If syrup lines are mixed up

hey can be mapped later in the control. Make sure that syrup lines and flavor lines are NOT mixed.

t

© 2016-2018, Cornelius Inc. - 9 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

!

WARNING:

Step Action

1

2

3

4

5 Adjust the CO

Basic Pressure Syrup Valves 75 PSI (5.17 bar)

Basic Pressure Flavor Shot Valves 45 PSI (3.1 bar)

Table 3.

Locate the water, syrup and flavor

inlets are marked S1- S14 included lines labeled, A1-A6 for ambient (non

chilled) syrup and F1 - F8 for flavor lines, CW for Carbonated Water, PW

for plain water

Connect syrup lines 1-14 from the unit to th

backroom package.

Connect the carbonated lines CW from the

Connect carbonator pump to backroom water supply.

Connect the plain water lines PW from the

from the backroom package.

2 regulator for syrup BIB pumps as indicated in Table 4.

Table 4.

Regulator Pressure Settings

lines under the counter. The cold plate

e appropriate lines from the

unit to the carbonator pump.

unit to the appropriate lines

UNIT OPERATION

This unit must be grounded to avoid possible electrical shock to the operator. The unit power cord is equipped with a

three pronged plug. If a three pronged (grounded) outlet is not available use an appropriate method to ground the

unit.

Failure to comply could result in serious injury, death or damage to the equipment.

To initially start up the unit for operation, perform the procedure in Table 5.

Table 5.

Step Action

1 Connect electrical power to the unit.

Locate the switch on the juncti

2

3 Check for water and CO

4

5

water pump will start and fill the carbonator tank with carbonated water. The water

pump stops when the carbonator tank is full.

Dispense Carbonated water drinks until the carbonator pu

time for the carbonator should be about 5-7 seconds.

If the carbonator pump appears to be short-cycling

seconds) refer to the “Troubleshooting” section on page 36.

on box of the carbonator pump and turn it ON. The

2 leaks, and tighten any loose connections.

mp cycles on. The refill

(meaning a refill time of 1-2

Publication Number: 621058578INS - 10 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

1

2

3

4

5

6

7

8

9

0

Enter

<

PREPARING FOR OPERATION

SERVICE MODE

The Service mode is used to perform all of the maintenance and troubleshooting for the unit. There are three menu

levels available depending on the classification of the operator. Figure 5. shows the service mode screen for operators, Figure 6. shows the service mode screen for supervisors and Figure 7. shows the service mode screen for service technicians. To enter the service mode, perform the procedure in Table 6.

Table 6.

Step Action

Display the keypad screen by tapping each

of the video screen starting in the upper

corner

right corner and continuing to tap each corner

in a counterclockwise direction, in the form of a

“C”.

1

NOTE: As each corner is touched, a

small confirmation rectangle

momentarily appears to confirm the touch.

Input the proper password for your access

level (operator, manager or technician) and

press Enter. The Service UI screen is displayed, as shown in Figure 5., Figure 6. or Figure 7., depending on your access level.

NOTE: Each access level has a differ-

2

ent password.Units are shipped

th following preset pass-

wi

words: 1111 (Operator level)

2 (Manager level) 3333 tech-

222

nician level)

Unless customer specific passwords are

configured on a custom basis.

© 2016-2018, Cornelius Inc. - 11 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Figure 5.

Publication Number: 621058578INS - 12 - © 2016-2018, Cornelius Inc.

Figure 6.

Figure 7.

INITIAL SETUP

1

2

3

4

5

6

7

8

9

0

Enter

<

Before operating the unit, perform the initial setup described in the following sections.

Adding Syrup

First, load the images on to the machine:

Table 7.

Step Action

Remove one of the USB cables from the

back of the screen

1

IDC Pro 255 Installation Manual

Install a USB drive which has the appro-

2

priate Brand or flavor images

Enter Service mode using Access Pin

3

“3333”. If not changed by customer settings.

© 2016-2018, Cornelius Inc. - 13 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

UNIT SETUP

SYRUP EDIT

Step Action

4

Select “Unit Setup”

5

Select “Syrup Edit”

Table 7.

Select “Add/Delete Image” at the lower

6

left.

Navigate the USB drive on the LH side

7

to find the images needed.

Publication Number: 621058578INS - 14 - © 2016-2018, Cornelius Inc.

New

Step Action

Select the file names needed and press

8

the right-facing arrow in the center of the

screen

9

Press the “Back” button to return to the main “Syrup Edit” screen

10

Remove the USB drive and replace the USB cable from the back of the screen.

Next, setup The Brand Or Flavor:

IDC Pro 255 Installation Manual

Table 7.

Step Action

In the “Syrup Edit” screen, select the

1

“New” button, the page icon at the bottom with “+” symbol.

Now, the details for this syrup are edit-

2

able on the right side of the screen

Table 8.

© 2016-2018, Cornelius Inc. - 15 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Step Action

Select Name and enter the appropriate

3

name of the syrup

Select Syrup Type to select Brand or

4

Flavor.

Table 8.

Select Water Type to select Carbonated,

5

Plain Water, or Mid-Carbonation (Flavors default to No Water)

Select Ratio and enter the mix ratio for

6

the specific syrup. (follow syrup manufactures specifications)

0

Publication Number: 621058578INS - 16 - © 2016-2018, Cornelius Inc.

SAVE

Step Action

Lastly, press below image on the “+”

sign and all of the loaded images will

7

appear, find the new image that was

loaded for this brand and select it.

Press “Save” on the Syrup edit data

screen.

8

Press “Save” on the syrup edit screen

be

low.

IDC Pro 255 Installation Manual

Table 8.

9

Repeat for any additional flavors or brands needed.

10

Exit the service UI

Mapping Brands

To map the valves to the available brands, perform the procedure in Table 9.

Table 9.

Step Action

Display the keypad screen by tapping each corner of the video screen starting in the upper right

corner and continuing to tap each corner in a

counterclockwise direction, in the form of a “C”.

1

NOTE: As each corner is touched, a

small confirmation rectangle

momentarily appears to confirm

the touch.

© 2016-2018, Cornelius Inc. - 17 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

1

2

3

4

5

6

7

8

9

0

Enter

<

Unit Setup

Brand Mapping

Step Action

Input the password 3333 for your access level

2

(technician) and press Enter.

Table 9.

3 The Service UI screen is displayed.

Press the Unit Setup button as shown above to

4

display the Unit Setup screen.

Press the Brand Mapping button as shown

5

above to open the Brand Mapping screen.

6 Press the Brand or Flavor icon that is to be remapped.

Publication Number: 621058578INS - 18 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

Table 9.

Step Action

The Brand Selection screen opens and you can

7

select the brand to be mapped to the valve location.

8 Repeat Steps 4 & 5 for each location desired.

When all the flavors on the LH are map

9

setup will be identical on the LH and RH side, press the copy to other side button and confirm when prompted.

10 When all the flavors are mapped as desired, press the Save button to save the settings.

ped, press the right button and repeat steps 4 & 5 for the RH side. If the

Purging The Syrup Lines

The purge process is performed as part of the “Syrup Line Cleaning & Sanitizing” section on page 21. It is also used

to ensure no air is in the lines before Brixing. If a BIB container is replaced, the syrup lines need to be purged and

sanitized. To purge the lines, perform the procedure in Table 10.

Step Action

1 Ensure that the water and CO

Display the keypad screen by tapping each corner of the video screen starting in the upper right

corner and continuing to tap each corner in a

counterclockwise direction, in the form of a “C”.

2

NOTE: As each corner is touched, a

2 are turned on. (initial setup only)

small confirmation rectangle

momentarily appears to confirm

the touch.

Table 10.

© 2016-2018, Cornelius Inc. - 19 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

1

2

3

4

5

6

7

8

9

0

Enter

<

Unit Setup

Valve Purge

Step Action

Input the proper password for your access level

3

(technician) and press Enter.

Table 10.

4 The Service UI screen is displayed.

5 Press the Unit Setup button.

The Unit Setup screen is displayed. Press the

6

ve Purge button.

Val

The Valve Purge screen is displayed. Select up to

4 syrup and 2 water at a time, per side, to purge.

7

Valves will stay activated for 12 minutes unless

deactivated.

Publication Number: 621058578INS - 20 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

CAUTION:

!

Quick

Disconnect

Table 10.

Step Action

When the syrup flows and lines are purged, press the same valve again to turn off, or simply select the next

8

valve needed and the first valve selected will stop pouring.

9 Repeat Step 7 until all lines are purged.

When all lines are purged, press the Back button to display

10

Out button.

the Service User Interface screen and select the Log

Syrup Line Cleaning & Sanitizing

Only trained and qualified persons should perform these cleaning and sanitizing procedures.

To sanitize the tubing and BIB connectors, perform the procedure in Table 11.

NOTE: No more than 7 chilled carbonated brands can be mapped per side. Specify the names of chilled vs

bient lines.

am

Table 11.

Step Action

Remove all the quick disconnects from all the

1

BIB containers.

2 Fill a suitable bucket with a soap solution.

Submerge all disconnects in

and then clean them using a nylon bristle

3

brush. (Do not use a wire brush.) Rinse with

clean, potable water.

4 Using a plastic pail, prepare approximately 5 gallons (18.93 l) of sanitizing solution.

Sanitizing fittings must be attached to each BIB disconnect. If the fittings are not availa

empty BIB bags can be cut from the bags and used. These fittings open the disconnects so the sanitizing

5

solution can be drawn through the disconnect.

the soap solution

ble, the fittings from

© 2016-2018, Cornelius Inc. - 21 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Step Action

Place all the BIB disconnects with the sanitizing fittings in place into the pail of sanitizing

ution. Use the “Purging The Syrup Lines”

sol

section on page 19 to purge the lines. Allow

the sanitizer to remain in the lines for 15 minutes.

NOTE: Recommended sanitizing solu-

6

tion: “Dissolve 1 packet [1 oz.

9.5 ml)] of KAY-5 into 2.5 gal-

(2

lons (9.5 L) of warm 80-100° F

6.7-37.8° C) potable water to

(2

ensure 100 ppm of chlorine.”

While the lines are soaking, remove the nozzles and syrup diffusers and clean them in a mild soap solution,

7

rinse them with clean water.

8 Use a spray bottle filled with sanitizing solution to spray the no

9 Reassemble the nozzles and syrup diffusers

Remove the sanitizing fittings from the BIB disconnects a

10

container.

Use the “Purging The Syrup Lines” section on page 19 to purge the lines. Continue until all the sanitizer has

11

been flu

shed from the system and only syrup is flowing.

Table 11.

zzles and diffusers and allow them to air dry.

and replace then on the valves.

nd connect the disconnects to the appropriate BIB

Adjusting the Water to Syrup Ratio (BRIX)

NOTE: During the Brixsssing process, agitate the ice in the bin occasionally to ensure that the cold plate

is at the proper operating temperature.

Water and syrup MUST be cold before checking BRIX.

The unit must be BRIXed initially before the unit is put into operation. To BRIX the unit, perform the procedure in

Table 12.

Table 12.

Step Action

Display the keypad screen by tapping each corner of the video screen starting in the upper

ri

ght corner and continuing to tap each corner

in a counterclockwise direction, in the form of a

“C”.

1

NOTE: As each corner is touched, a

small confirmation rectangle

momentarily appears to confirm

the touch.

Publication Number: 621058578INS - 22 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

1

2

3

4

5

6

7

8

9

0

Enter

<

Unit Setup

Table 12.

Step Action

Input the proper password for your access level

2

(technician) and press Enter.

3 Press the Unit Setup button.

4 Select the Brix setup screen.

All instructions and volumes below are based

on the po

NOTE: When selecting a valve, it will

5

ur rate of 3oz/sec.

activate for a pre-programmed 4

second dispense time.

© 2016-2018, Cornelius Inc. - 23 - Publication Number: 621058578INS

6 Place a Ratio cup under the valve.

7 Select the CW1 button and press Pour

8 If the flow rate is not correct, adj

ust the proper valve to the desired flow. Refer to Figure 8. for valve locations.

to dispense 7.0 oz (210 ml.).

IDC Pro 255 Installation Manual

CAUTION:

!

Water Valves

(White)

Syrup Valves

(Black)

Flavor Shots

(Purple)

(Same layout as opposite side)

Table 12.

Step Action

Turn the flow adjustment valve a 1/4 of a turn at a time and recheck the flow. To increase the flow, turn the knob

9

clockwise. To decrease, turn counter- clockwise.

10 Test the valve and adjust until a consistent ratio is deli

11 Select CW2 and press Pour to dispense 3.0 oz (90 ml.)

12 Perform Steps 8 through 10 for the CW2 valve.

13 Select PW1 and press Pour to dispense 7.0 oz (210 ml.).

14 Perform Steps 8 through 10 for the PW1 valve.

15 Select PW2 and press Pour to dispense 3.0 oz (90 ml.)

16 Perform Steps 8 through 10 for the PW2 valve.

17 Select CW3 and Pour to dispense 7.0 oz (2

18 Perform Steps 8 through 10 for the CW3 valve.

19 Select CW4 and press Pour to dispense 3.0 oz (90 ml.)

20 Perform Steps 8 through 10 for the CW4 valve.

21 Select PW3 and press Pour to dispense 7.0 oz (210 ml.).

22 Perform Steps 8 through 10 for the PW3 valve.

23 Select PW4 and press Pour to dispense 3.0 oz (90 ml.)

24 Perform Steps 8 through 10 for the PW4 valve.

25 Place a graduated cylinder under the valve.

26 Select S1 and press Pour to dispense fol

27 If the rate is not correct, perform Steps 8 through 10 for the S1 valve.

28 Repeat Steps 26 and 27 for S2 through S7 and A1 through A3.

29 Repeat Steps 26 through 27 for S8 through S14 and A4 through A6.

30 When the flow rate process is complete, select the Back button to return to the Uni

31 Press the Back button on the Unit Setup screen to return to the Service UI screen.

32 Press the Log Out button to return to normal operation.

10ml.).

low manufacturer’s specs for proper ratio.

vered two consecutive times.

t Setup screen.

Cleaning Interior Surfaces

As part of the initial cleaning procedures, clean and sanitize the ice hopper by performing the procedure in Table 13.

When pouring liquid into the hopper, do not exceed the rate of 1/2 gallon per minute. Pouring liquid into the hopper

faster than the recommended rate could result in an overflow situation which may result in personal injury or damage

to the equipment.

Publication Number: 621058578INS - 24 - © 2016-2018, Cornelius Inc.

Figure 8.

Step Action

Remove the agitator assembly by unscrewing

1

the

thumbscrew and lifting the agitator assem-

bly out of the hopper.

Using a nylon bristle brush or sponge, clean

the interior of the hopper, top cover and agita-

2

tor assembly with soap solution. Thoroughly

rinse the hopper, cover and agitator surfaces

with clean potable water.

IDC Pro 255 Installation Manual

Table 13.

Reassemble agitator assembly. Take special

3

care to ensure that the thumbscrew is tight.

Using a mechanical spray bottle filled with

sanitizing solution, spray the entire interior

4

and the agitator assembly. Allow them to air

dry.

© 2016-2018, Cornelius Inc. - 25 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Step Action

Open the display panel and remove the ice

5

chute cover from the unit.

Table 13.

With a nylon bristle brush or sponge, clean

the inside of the ice chute, gasket, and cover

6

with soap solution and rinse thoroughly to

remove all traces of detergent.

7 Reassemble the ice chute assembly.

Using a spray bottle filled with sanitizing solu-

8

tion, spray the inside of the ice chute. Allow it

to ai

r dry.

9 Close the display panel.

Publication Number: 621058578INS - 26 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

Shutdown

Button

UNIT SHUTDOWN/RESTART

The unit can be shutdown by entering the service UI at any level and selecting the “shutdown” icon. To shut down or

restart the unit, perform the procedure in Table 14.

Table 14.

Step Action

Display the service screen by tapping each corner of the video screen starting in the upper right

corner and continuing to each corner in a counterclockwise direction, in the form of a “C”.

1

As each corner is touched, a small confirmation rectangle momenta

firm the touch.

rily appears to con-

Select the Shutdown button to display the Shut-

2

down/Restart Screen, as shown.

Press “Restart” to power cycle the screen or

“Shu

3

t down” turn off the screen.

NOTE: The rest of the unit components

are still receiving power.

© 2016-2018, Cornelius Inc. - 27 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

1

2

3

4

5

6

7

8

9

0

Enter

<

Media playlist

EDITING THE MEDIA PLAYLIST

The unit is capable of changing the display video on a preprogrammed schedule. This allows the user to set a specific

time and duration for playing a specific media for breakfast, lunch, dinner or any special media required.

To set the media playlist schedule, perform the procedure in Table 15.

Table 15.

Step Action

1 First, enter the Service Screen at either manager or technician level permissions.

Tap each corner of the video screen starting in the

per right corner and continuing to each corner in a

up

counterclockwise direction, in the form of a “C”.

2

NOTE: As each corner is touched, a small con-

firmation rectangle momentarily

pears to confirm the touch.

ap

Input the proper password for your access level and

3

press Enter. This will take you to the Service UI screen.

This is where you can access the videos (Media Playlist)

To start with changing the playlist, select the “Media

4

Playl

ist” button. This brings you to this screen (only the

default playlist appears initially).

Publication Number: 621058578INS - 28 - © 2016-2018, Cornelius Inc.

Step Action

First, to manipulate the playlist and their schedule. A new

aylist can be added by selecting the second button on

pl

the bottom left (with the + symbol). This will add a new

playlist in addition to the default playlist. The times when

it starts playing and finishes can be adjusted by dragging

the play and stop icon left and right. The corresponding

times appear in the bar shown. So, the “breakfast”

playlist above plays from 7:30 to 9:00am. The default

playlist will fill in the gaps and plays unless any other

playlist is set at that time.

Now, to modify what’s actually in these playlist (or their

5

na

mes), select the pencil on the RH side of the playlist.

The next screen will appear:

IDC Pro 255 Installation Manual

Table 15.

At the top is the name, click on the white box and a

keyboard will appear to allow you to change the name.

Below this are two lists of videos. On the RH side is the

playlist that you are editing. The videos will play, starting

at the top, and repeat, throughout its specified time. To

remove a video from the playlist, select it from the list and

press the ‘X’ on the right side. To add a video that is on

the machine to the playlist, select it from the list on the

left and press the arrow in the center. The position of this

6

video can be changed by using the ‘up’ and ‘down’

arrows on the right.

Static image option: you can add JPEG and PNG file to

the playlist and adjust their duration with the slider on the

media playlist menu.

To add a video from a USB drive, select the “Add/Del

Vid

eos” button in the bottom left. Next screen will pop

up:

© 2016-2018, Cornelius Inc. - 29 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Step Action

All the videos or images currently on the machine are

shown on the right. A USB stick that is connected to any

7

of the (3) available ports will be displayed on the left.

Click on the name of the drive and, subsequently,

through any folders to find the videos to be added.

These videos can be transferred to the machine by

selecting them and pressing the arrow button in the

center. Any videos that were added are now available

8

to the playlist by pressing the ‘Back’ button. File can

also be copied from the machine to USB drive by

selecting the files on the RH side and pressing the left

facing arrow.

Table 15.

Important Note: Please press save on the Playlist Edit screen and again on the Media Playlist screen when

9

making any changes.

To export sales information, return to

10

back of the door. Select “Marketing Data” and again select “Export Data”. The data will be exported directly to the

the main service UI. Insert a USB drive in an available USB slot on the

USB.

Publication Number: 621058578INS - 30 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

Update

Software

UPDATING SOFTWARE REVISIONS

The unit can be updated as new versions of software become available, they may be installed on the unit by performing the procedure in Table 16.

Table 16.

Step Action

1 Enter Service mode, as described in “Service Mode” section on page 11.

2 Open the display panel.

On the back of the display, unplug the USB con-

3

nection to the ADA panel and plug in the USB stick

ith the software update loaded on it.

w

4 Press the Update Software button.

The Update Software screen is displayed. Press

5

the Launch Software Updater button.

© 2016-2018, Cornelius Inc. - 31 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Step Action

The Software Updater screen is displayed. Press

6

the Update Software button.

7 The second Update Software screen is displayed.

Table 16.

Select the software version to be installed by selecting from the list on the left side of the screen. If the list on the

8

left side of the screen is empty, press the Scan button. This reads the software updates contained on the USB

stick. When the proper version is highlighted, press the Install Software button on the right side of the screen.

When the update is complete, press the Back button to revert to the previous screen, then

9

Refresh button to restart the Screen.

10 Unplug the USB stick from the connecto

r and reinstall the ADA cable.

press the Restart/

11 Close the display panel.

Publication Number: 621058578INS - 32 - © 2016-2018, Cornelius Inc.

PLUMBING DIAGRAM

IDC Pro 255 Installation Manual

S - Syrup Line.

F - Flavor Line.

A - Ambient Line.

© 2016-2018, Cornelius Inc. - 33 - Publication Number: 621058578INS

Figure 9.

IDC Pro 255 Installation Manual

Carb

Tank

Carb

Motor

J3

Progate Switch

Agitator/Carb/Heater

Control PCB

#620314825-100

Agitator

L1

L2

Heater

L1

Ballast

L1

L2

Carb Motor

EARTH

Agitator Heater

620058352-002

L1

L2

XFMR

L1_IN

L2_IN

Line In

J4

Probes

620313664

Prox Switchat Ice Chute

#620314527

620057808-400

Valve PCB (MFV)

Left Nozzle

J3 J2

J4

J1

Water

Solenoid

Brand 1

Solenoids

Brand 2

Solenoids

Flavor

Solenoid

4 Max

8 Max

4 Max

2 Max

J18

RS-485 Comms

J16

DC In

USB-A

ADA Keypad Assy

Touchscreen

User Interface

J19

620057808-400

Valve PCB (MFV)

Right Nozzle

J3 J2

J4

J1

Water

Solenoid

Brand 1

Solenoids

Brand 2

Solenoids

Flavor

Solenoid

4 Max

8 Max

4 Max

2 Max

J18

RS-485 Comms

J16

DC In

J19

Address

Switch

(OFF-OFF)

Address

Switch

(ON-ON)

USB-A

USB-B

USB-B

30VDC Power Supply

240W

#620057649-005

(Upper)

L

N

PE

Remote

Master

Local

Master

J13

+V

+V

24/12VDC

To RightMFV Bd

From 30V

Supply (Upper)

J10

J11

J10

J11

E-Box

30VDC Power Supply

240W

#620057649-005

(Lower)

L

N

PE

+V

+V

To LeftMFV Bd

#4345

( ViewInside E-Box )

IEC60320-C13 PowerCord Family

620062568-005

USB-B

J13

USB-A

USB-B

24/12VDC Power Supply

250W

#620057649-001

L

N

PE

V1

V2

To U.I.Breakers

RTN

ON

ON

3A Breaker

620058545-003

From 30V

Supply (Lower)

3A Breaker

620058545-003

Valve Panel

A2

A1

A3

S1

S2 S4 S6

PW2

90

PW1

210

F3

F1

F4

F2

S3 S5 S7

CW1

210

A5

A4 A6

S8

S10 S12 S14

PW4

90

PW3

210

F7

F5

F8

F6

S9 S11 S13

CW3

210

LEFT BANK

RIGHT BANK

Right

Nozzle

Downlight

Left

Nozzle

Downlight

-V

-V

-V

-V

5A Breaker(12V)

620058545-002

4A Breaker (24V)

620058545-001

From 24/12V

Supply

To U.I.

620061906

From 24/12V

Supply

Term Block

18-7876-000

620062108

620057864-003

620057864-003

Part of

620062290

Part of

620062290

620058991-401

620058991-402 620058990-402

620058990-401

620058989-411620058989-401

620058989-410620058989-402

620057826-009

620057826-013

620057826-013

+24

+12

COM

1H

1.5H

2H

2.5H

3H

10

MIN

30

MIN

0.5S

1S

1.5S

2S

2.5S

3S

3.5S

4S

4.5S

5S

ON

TIMES

OFF

TIMES

Carbonator Tank Probes:

White Wire Top

Black Wire Bottom

Red secured to tank body

CW2

90

CW4

90

Part of

620062290

Part of

620062290

Part of

620062290

J14J15

12V Out

J17

LED

J14J15

12V Out

J17

LED

Flavor 1(5)– Red-Blk

Flavor 2(6)– Wht-Blk

Flavor 3(7)– Grn-Blk

Flavor 4(8)– Blu-Blk

BANK 1:

Syrup 1(8) – Red-Blk

Syrup 2(9) – Wht-Blk

Syrup 3(10)– Grn-Blk

Syrup 4(11)– Blu-Blk

Syrup 5(12)– Ylw-Blk

Syrup 6(13) – Brn-Blk

Syrup 7(14) – Org-Blk

Ambient 1(4)– Red-Wht

BANK 2:

Ambient 2(5) – Red-Blk

Ambient 3(6) – Wht-Blk

Carb Water1(3) – Red-Blk

Carb Water2(4) – Wht-Blk

Plain Water1(3) – Grn-Blk

Plain Water2(4)– Blu-Blk

Wire ColorScheme

(Numbers inparentheses are

for rightside nozzle)

ON

TIME

OFF

TIME

N

L

PE

620059241-005

620316455

L2

YEL

BRN

RED

WH/BRN

Run Capacitor

#560002379

#620314913

Agitator_EARTH

J2

J1

GRN/YEL

GRN

BLU

RED

620316445

BRN

BRN

EARTH_IN

Agitator

Settings

Location

See note

620316456

620061888

(includes Gnd)

#620408124

Default shown:

1Hr Off, 4sec On

BLK

YLW

YLW/RED

BLK/YEL

BLU

BRN

WHT

BLK

620059241-004

620316457

J9

Lid Switch

Prox Switchat Bin Lid

#620314527

620059497-001

BLK

Agitator

Motor

Blacknot connectedhere

L2_Agitator

J5

620313664

WIRING DIAGRAM

Publication Number: 621058578INS - 34 - © 2016-2018, Cornelius Inc.

Figure 10. 115V premium unit wiring

N

L

PE

620057808-400

Valve PCB (MFV)

Left Nozzle

J3 J2

J4

J1

Water

Solenoid

Brand 1

Solenoids

Brand 2

Solenoids

Flavor

Solenoid

4 Max

8 Max

4 Max

2 Max

J18

RS-485 Comms

J16

DC In

USB-A

ADA Keypad Assy

Touchscreen

User Interface

J19

620057808-400

Valve PCB (MFV)

Right Nozzle

J3 J2

J4

J1

Water

Solenoid

Brand 1

Solenoids

Brand 2

Solenoids

Flavor

Solenoid

4 Max

8 Max

4 Max

2 Max

J18

RS-485 Comms

J16

DC In

J19

Address

Switch

(OFF-OFF)

Address

Switch

(ON-ON)

USB-A

USB-B

USB-B

Remote

Master

Local

Master

J13

24/12VDC

Flavor 1(5) – Red-Blk

Flavor 2(6)– Wht-Blk

Flavor 3(7) – Grn-Blk

Flavor 4(8) – Blu-Blk

BANK 1:

Syrup 1 (8)– Red-Blk

Syrup 2 (9)– Wht-Blk

Syrup 3 (10)– Grn-Blk

Syrup 4 (11)– Blu-Blk

Syrup 5 (12)– Ylw-Blk

Syrup 6 (13)– Brn-Blk

Syrup 7 (14)– Org-Blk

Ambient 1(4)– Red-Blk

BANK 2:

Ambient 2 (5)– Red-Blk

Ambient 3 (6)– Wht-Blk

Carb Water 1(3)– Red-Blk

Carb Water 2(4)– Wht-Blk

Plain Water 1(3)– Grn-Blk

Plain Water 2(4)– Blu-Blk

From 30V

Supply (Upper)

J10

J11

J10

J11

E-Box

USB-B

J13

USB-A

USB-B

ON

ON

3A Breaker

620058545-003

From 30V

Supply (Lower)

3A Breaker

620058545-003

Valve Panel

A2

A1

A3

S1

S2 S4 S6

PW2

90

PW1

210

F2

F1

F4

F3

S3 S5 S7

CW1

210

A4

A5 A6

S8

S10 S12 S14

PW4

90

PW3

210

F6

F5

F8

F7

S9 S11 S13

CW3

210

LEFT BANK

RIGHT BANK

Right

Nozzle

Downlight

Left

Nozzle

Downlight

5A Breaker (12V)

620058545-002

4A Breaker (24V)

620058545-001

From 24/12V

Supply

To U.I.

620061906

From 24/12V

Supply

Term Block

18-7876-000

620062108

620057864-003

620058991-401

620058991-402 620058990-402

620058990-401

620058989-411620058989-401

620058989-410620058989-402

620057826-009

620057826-013

620057826-013

Carbonator Tank Probes:

White Wire Top

Black Wire Bottom

Red secured to tank body

CW2

90

CW4

90

Part of

620062290

Part of

620062290

J14J15

12V Out

J17

LED

J14J15

12V Out

J17

LED

Wire Color Scheme

(Numbers in parenthesesare

for right sidenozzle)

Carb

Tank

Carb

Motor

J3

Progate Switch

Agitator/Carb/Heater

Control PCB

#620314825-100

Agitator

L1

L2

Heater

L1

Ballast

L1

L2

Carb Motor

EARTH

Agitator Heater

620058352-003

L1

L2

XFMR

L1_IN

L2_IN

Line In

J4

Probes

620313664

Prox Switch atIce Chute

#620314527

30VDC Power Supply

240W

#620057649-005

(Upper)

L

N

PE

+V

+V

L

N

PE

+V

+V

#4345

( View InsideE-Box )

24/12VDC Power Supply

250W

#620057649-001

L

N

PE

V1

V2

To U.I. Breakers

RTN

-V

-V

-V

-V

620313664

+24

+12

COM

J9

Lid Switch

Part of

620062290

620059241-004

620059241-005

620316455

L2

YEL

BRN

RED

BRN

Run Capacitor

#620314324

3.5uF 440VAC

#620717110

AgitatorEARTH

J2

J1

GRN/YEL

GRN

Agitator

Motor

BLU

RED

620323735

BRN

BRN

EARTH_IN

See note

620316456

IEC60320-C13 Power CordFamily

620062568-00x

#620408153

1H

1.5H

2H

2.5H

3H

10

MIN

30

MIN

0.5S

1S

1.5S

2S

2.5S

3S

3.5S

4S

4.5S

5S

ON

TIMES

OFF

TIMES

ON

TIME

OFF

TIME

Agitator

Settings

Location

Default shown:

1Hr Off, 4sec On

To Left MFVBd

Part of

620062290

30VDC Power Supply

240W

#620057649-005

(Lower)

To Right MFVBd

Part of

620062290

YLW

BLK

BLK/YEL

YLW/RED

620061888

(includes Gnd)

BLU

BRN

WHT

BLK

Prox Switch atBin Lid

#620314527

620316457

620059497-001

J5

L2_Agitator

620057864-003

IDC Pro 255 Installation Manual

© 2016-2018, Cornelius Inc. - 35 - Publication Number: 621058578INS

Figure 11. 230V premium unit wiring

IDC Pro 255 Installation Manual

!

WARNING:

!

WARNING:

TROUBLESHOOTING

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit.

ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY

COULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

If repairs are to be made to a product system, remove quick disconnects from the applicable product tank, then relieve

the system pressure before proceeding. If repairs are to be made to the CO

supply, then relieve the system pressure before proceeding. If repairs are to be made to the refrigeration system,

CO

2

make sure electrical power is disconnected from the unit.

Should your unit fail to operate properly, check that there is power to the unit and that the hopper contains ice. If the

unit does not dispense, check the following chart under the appropriate symptoms to aid in locating the defect.

UNIT TROUBLESHOOTING

Table 17

Symptom Cause Remedy

system, stop dispensing, shut off the

2

Blown fuse or circuit breaker

Agitator does not turn

Ice dispenses continuously

Slushy ice or water in hopper

Beverage does not dispense

Beverage is too sweet

A. Short circuit in electrical wiring

B. Inoperable agitator motor (shorted motor)

A. No power

B. Improperly installed upper ice chute

assembly (Reed switch is not being acti

vated)

C. Inoperable reed switch

D. Electrical board driver circuit is defective

E. Gear motor has open circuit

F. Reed switch is not activated, improper

assembly of upper ice chute to lower chute

G. Broken wire in the 2-wire harness leading

to the reed switch

H. Bad connection at main control board.

A. Ice gate mechanism is stuck in open posi-

tion

B. Stuck or bent ice lever (does not allow gate

to close and open reed switch)

A. Blocked drains in cold plate

B. Poor ice quality due to water quality or ice

maker problems

A. No 24VAC to valves

B. No CO2 pressure

A. Valve BRIX requires adjustment

B. Carbonator is not operating

C. No CO2 in carbonator

D. City water pressure supply low or inconsis-

tent

-

A. Repair wiring

B. Replace gear motor

A. Restore power or plug in unit

B. Check the upper ice chute assembly for

proper assembly and operation

C. Replace reed switch

D. Replace main control board

E. Replace gear motor

F. Check to make sure tongue of upper chute

engages into the back of the lower chute,

ensure upper chute engages outside the

lower chute, and snap front of chute into

place

G. Repair of replace 2-wire harness

H. Repair connection or replace 2-wire har-

ness

A. Inspect gasket for proper position. Examine

gate plate to see if it slides freely behind

the lower ice chute.

B. Examine ice dispense lever to see if it is

bent.

A. Remove access covers in cold plate cover

& inspect/clean drains

B. Correct water quality or repair ice maker

A. Restore 24 VAC to valves

B. Restore CO2 pressure

A. Adjust valve BRIX

B. Repair carbonator

C. Restore CO2 pressure in carbonator

D. Booster pump must be used if dynamic

water pressure drops below 40 psig.

Publication Number: 621058578INS - 36 - © 2016-2018, Cornelius Inc.

IDC Pro 255 Installation Manual

Table 17

Symptom Cause Remedy

Unit will not dispense carbonated drinks. Dispenses

syrup only.

Unit will not dispense carbonated drinks. Spurts CO2

and syrup only.

Carbonated drinks are flat

(low on carbonation)

Low water pressure

A. CO2 pressure in carbonator tank is too

high.

B. Water valve will not open

A. Carbonator tank is empty, because tank

was emptied while power was applied to

unit. 5 minute time-out of carbonator pump/

motor occurred and carbonator pump is

locked off.

B. Note that this can occur while the water fil-

ter system is serviced or water supply is

shutoff. If drinks are drawn from the unit

while water pressure is shutoff, the carbonator pump starts and runs continuously,

then shuts off on the 5 minute timeout.

A. Unit is out of CO2

B. Carbonator tank is 100% filled because the

city water pressure exceeds the carbonator

tank CO

A. Could be caused by excessively long runs

(over 40 ft.) of 3/8” water supply line.

B. Low water pressure

C. Plugged water filter

D. Water booster bladder has burst

2 pressure regulator setting.

A. Check CO2 pressure regulator setting. 75

psig recommended. Relieve pressure from

carbonator tank.

B. Check electrical connection to water valve.

Check resistance of coil (should be 9

ohms). Check for voltage at coil when

brand button is depressed.

A. Unplug the unit and reconnect the unit.

Main control board will reset, ice agitation

will occur, and carbonator tank will refill to

normal level.

B. 1) low water pressure switch deactivates

carbonator pump, 2) after 5 minutes reset

and retry carbonator pump. If water supply

is restored, the 5 minute timeout will not

occur. Repeat reset a second time, but on a

third time, then lockout carbonator pump,

which will generate a service call.

A. Replace CO2 cylinder

B. CO2 setting for the carbonator tank is 75

psig, max water pressure is 60 psig. If nec

essary, install a water pressure regulating

valve.

A. Increase line size to 1/2”

B. Add water pressure booster pump

C. Change water filter

D. Replace water booster tank/bladder

-

CARBONATOR TROUBLESHOOTING

Symptom Cause Remedy

A. Power cord for the carbonator pump motor

Carbonator pump does not

start to fill tank

Power cord is connected

but carbonator pump does

not run

Carbonator pump is short

cycling with every drink

drawn

is not connected

A. Carbonator pump motor is disabled

B. Probes were dry, unit was powered up,

water was not turned on, and carbonator

did not fill

C. Water service was interrupted for more

than 5 minutes

A. Lower liquid level probe reads “dry” while

upper probe reads “wet”

Table 18

A. Carbonator pump is powered off the main

control board inside the electrical box of the

unit. Check that the umbilical cord is connected from the unit to the pump motor terminal box.

A. Check the enable/disable switch on the car-

bonator pump terminal box and enable it, if

necessary.

B. This results in a 5 minute timeout. Unplug-

ging the unit and plugging it in will reset the

unit and start the carbonator pump

C. Unplugging the unit and plugging it in will

reset the unit and start the carbonator

pump

A. Check color of leads going to probes. Black

should go to bottom probe and white to top

probe. Reverse if incorrect.

© 2016-2018, Cornelius Inc. - 37 - Publication Number: 621058578INS

IDC Pro 255 Installation Manual

Symptom Cause Remedy

Table 18

Carbonator tank overfills,

overflows through relief

valve, and pump shuts off

after 5 minutes.

A. Poor electrical connections between car-

bonator tank and main control board.

B. Broken wires between carbonator tank and

main control board.

C. Defective liquid level probes.

A. Check connections at carbonator tank and

at connector J4 on the main control board

B. Replace wire harness.

C. Replace both liquid level probes.

NOTE: Contact your local syrup or beverage equipment distributor for additional information and trouble-

shooting of beverage system.

Publication Number: 621058578INS - 38 - © 2016-2018, Cornelius Inc.

Cornelius Inc.

www.cornelius-usa.com

Loading...

Loading...