Page 1

HELIX

Operator’s Manual

Release Date: July 13, 2012

Publication Number: 621058497OPR

Revision Date: February12, 2014

Revision: A18

Visit the Cornelius web site at www.cornelius-usa.com

for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

RECYCLE

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation, operation or maintenance of

son(s) working on the equipment have been trained and are skilled in w

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in

ject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius’ Commercial Warrant applicable to this Product and is sub-

this equipment. This manual assumes that the per-

orking with electrical, plumbing, pneumatic,

Cornelius will not be responsible for any repair, replacement or

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

other service required by or loss or damage resulting

“non-authorized” parts (i.e., parts that are not 100%

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius-usa.com

-238-3600

800

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency

Glendale Heights, IL

Tel: + 1 800-238-3600

Drive

Printed in U.S.A.

This document is for reference purposes only. For questions related to this Advance Copy document contact Customer Service, IMI Cornelius, 800-238-3600.

Correct Disposal of this Product

This marking indicates that this product should not be disposed with other household wastes throughout the EU. To

prevent possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly

to promote the sustainable reuse of material resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was purchased. They can take this product for

environmental safe recycling.

Page 3

TABLE OF CONTENTS

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fire Hazard Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fan Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Ventilation Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Defrost Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Appliance Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Helix Machine Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Decommissioning and/or Transporting the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Storage within the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Initial System Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressurizing the CO2/Compressed Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressurizing the Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Initial Unit Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hopper Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unit Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

System Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ingredient Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Blender Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ice Maker Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Sanitation Scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting Sanitation Dates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page 4

Preparing Replacement Product Bags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Blender Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Daily Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unit Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Daily Cleaning Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dispensing a Drink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replacing Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Priming the New Product Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Temperature Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cabinet Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Product Cabinet Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Monthly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Semi-Annual Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Water System Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drain Tube Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Condensation Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Refrigeration System Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overall Mechanical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Auger Bearing Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Unit Level Alarms & Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Sold Outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ingredient Expired Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting - Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting Product Not Cold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 5

Helix Operator’s Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview • Read and follow ALL SAFETY INSTRUCTIONS in this manual and any

warning/caution labels on the unit (decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and

Health Administration) safety regulations and/or national and local codes

before operating this unit.

Recognition

Recognize Safety Alerts

Different Types of Alerts

SAFETY TIPS

This is the safety alert symbol. When you see it in this manual or on the unit, be alert

to the potential of personal injury or damage to the unit.

Indicates an immediate hazardous situation which, if not avoided, WILL result in

serious injury, death or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in

serious injury, death, or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor

or moderate injury or equipment damage.

• Carefully read and follow all safety messages in this manual and safety

signs on the unit.

• Keep safety signs in good condition and replace missing or damaged

items.

• Learn how to operate the unit and how to use the controls properly.

© 2012-2014,Cornelius Inc. All Rights Reserved - 1 - Publication Number: 621058497OPR

Page 6

Helix Operator’s Manual

!

WARNING:

!

WARNING:

CAUTION:

!

CAUTION:

!

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young children or infirm persons

without supervision. Young children should be supervised to ensure that

they do not play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized

modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury.

To ensure continued protection, observe the following:

Disconnect power to the unit before servicing following all lock out/tag out

procedures established by the user. Verify all of the power is off to the unit before

any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment

damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep

this area clean may result in injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all

sanitizing solution must be drained from the system. A freezing ambient environment will cause residual sanitizing solution or water remaining inside the unit to

freeze resulting in damage to internal components.

Publication Number: 621058497OPR - 2 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 7

CO2 (CARBON DIOXIDE) WARNING

!

DANGER:

WARNING:

WARNING:

WARNING:

CO2 displaces oxygen. Strict attention MUST be observed in the prevention of CO2

gas leaks in the entire CO

particularly in a small area, IMMEDIATELY ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentrations of CO

experience tremors which are followed rapidly by loss of consciousness and DEATH.

FIRE HAZARD WARNING

This unit contains a flammable refrigerant. Keep all flammable materials away from

the compressor area. Always be sure to keep the area around the unit clean and

free of clutter. Failure to keep this area clean may result in a fire hazard, injury and/

or equipment damage.

Helix Operator’s Manual

2 and soft drink system. If a CO2 gas leak is suspected,

2 gas

ELECTRICAL WARNING

FAN WARNING

WATER USAGE

This unit contains voltages that may represent a shock hazard. Always avoid

touching metalic terminals and exposed wiring when the covers are off of the unit.

Failure to comply could result in serious injury, death or equipment damage.

This unit contains fans. Caution must be taken to keep hands, etc. from contacting

the rotating blades. Failure to avoid rotating blades could result in injury or equipment damage.

Connect only to the drinking water supply.

© 2012-2014,Cornelius Inc. All Rights Reserved - 3 - Publication Number: 621058497OPR

Page 8

Helix Operator’s Manual

!

WARNING:

!

WARNING:

!

WARNING:

VENTILATION WARNING

DEFROST WARNING

APPLIANCE WARNING

Keep ventilation openings, in the appliance enclosure or in the built-in structure,

clear of obstruction.

Do not use mechanical devices or other means to accelerate the defrosting process

other than those recommended by the manufacturer.

HELIX MACHINE USAGE

Do not use electrical appliances inside the food storage compartments of the

appliance unless they are of the type recommended by the manufacturer.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

This appliance is intended to be used in household and similar applications such as:

• staff kitchen areas in shops, offices and other working environments

• farm houses and by clients in hotels, motels and other residential type

environments

• bed and breakfast type environments

• catering and similar non-retail applications

Publication Number: 621058497OPR - 4 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 9

DECOMMISSIONING AND/OR TRANSPORTING THE UNIT

CAUTION:

!

CAUTION:

!

Whenever the Signature unit is going to be removed from service and/or transported,

the unit must be completely drained of product and rinsed out to remove residual

product.

When transporting the unit, make sure that the product bowl is removed from the

top of the unit and stored in a safe place for shipment. The unit must be carefully

tied down or stored in such a manner that the unit will not move during shipment.

STORAGE WITHIN THE MACHINE

Do not store explosive substances such as aerosol cans with a flammable propellant in this appliance.

Helix Operator’s Manual

© 2012-2014,Cornelius Inc. All Rights Reserved - 5 - Publication Number: 621058497OPR

Page 10

Helix Operator’s Manual

INTRODUCTION

FEATURES

SYSTEM OVERVIEW

The Helix unit is an automated smoothie machine. It allows blended drinks to be

made easier and faster. All the products are stored in the Helix unit, removing the

need for a back room package while retaining a small, compact footprint.

The Helix unit is designed to be operated by employees or persons with reduced

physical, sensory or mental capabilities, unless they have been given supervision or

instruction concerning the use of the Helix unit in a safe way and they understand

the hazards involved in operating the unit.

With automatically portioned drinks, quality is assured from drink to drink while requiring very little interaction from the user. Witho

to rinse, product and water waste issues are reduced from traditional smoothie

machines.

ut the use of blending pitchers and sinks

• Simple operation (40 sec/drink) and nightly cleaning process

• Provides blended smoothie-type beverages with real fruit

• Blends the drink in the serving cup

• Ability to add whole fruit, fruit juice and purees

• Ability to add dairy components such as cream or yogurt

• Provides refrigerated space for up to 8 products

• Self-rinsing blender/mixer after each use

• Provides refrigerated space for whip cream

• Dispenses products with particulate sizes <1/8 in.

• Two single-serve blend chambers

• Provides cup and lid dispenser

• Simple bag in a tray system for quick bag change outs and cleaning

Publication Number: 621058497OPR - 6 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 11

SPECIFICATIONS

Helix Operator’s Manual

Line Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230VAC, 50 Hz

Max. Current Draw: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Amps

Water Inlet Size:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8 in. (.95 cm) I.D.

Water Supply Pressure . . . . . . . . . . . . . . . . . . . . . . . 0.48-0.83 MPa (70-120 psig)

Drain Outlet Size:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.665 in. (4.23 cm) I.D.

Clearance Requirements: . . . . . . . . . . 12 in. (30.48 cm) top; 2 in. (5.08 cm) back

Equipment Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612 lbs (278 kg)

CO

2/compressed air Tubing Size: . . . . . . . . . . . . . . . . . . . . 1/4 in. (0.635 cm) I.D.

CO

2/compressed air Supply Pressure: . . . . . . . . . . . 0.48-0.83 MPa (70-120 psig)

BIB Tray Size: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 gal. (7.6 liters)

Ice Storage Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 lbs (14.5 kg)

Ice Make Rate:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 lb/day (272 kg/day)

Unit Height: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 in. (190.5 cm)

Unit Width: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 in. (66.04 cm)

Unit Depth:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 in. (86.36 cm)

Ambient Operating Temperature:. . . . . . . . . . . . . . . . . . 55 to 95

o

F (12.8 to 35°C)

A-Weighted Sound Pressure Level (during blender operation) . . . . . . . . . . <70dB

The Helix unit is capable of using syrups with particulate matter up to 1/8” in size.

© 2012-2014,Cornelius Inc. All Rights Reserved - 7 - Publication Number: 621058497OPR

Page 12

Helix Operator’s Manual

Publication Number: 621058497OPR - 8 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 13

OPERATION

!

WARNING:

INITIAL SYSTEM PREPARATION

Pressurizing the CO2/Compressed Air System

The Helix unit is designed to operate on a CO2/compressed air input pressure of

0.48-0.83 MPa (70-120 psig). A shutoff valve must be installed in the line to the

Helix unit. Perform the procedure in Table 1 to pressurize the CO

system.

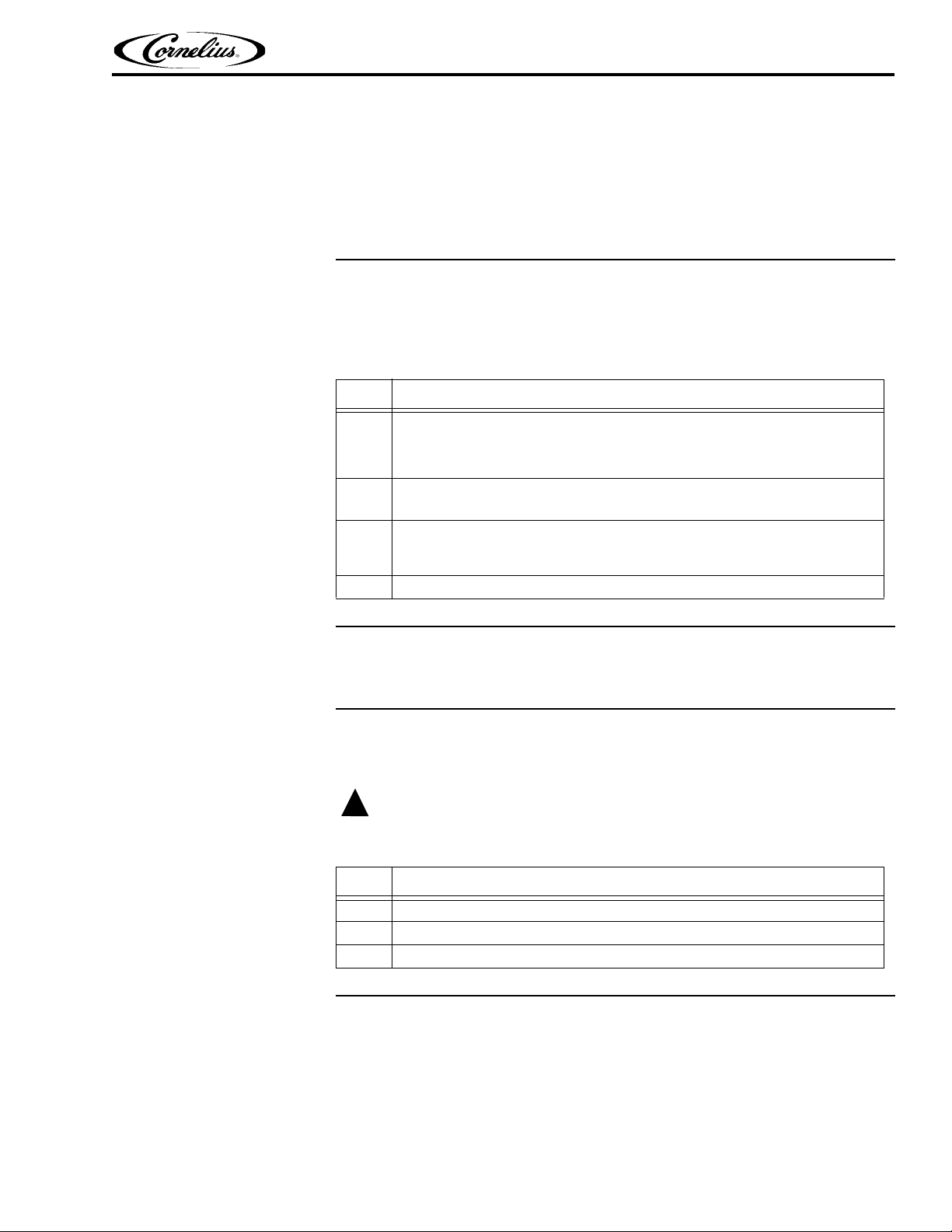

Step Action

1

Open the

with gas. When lines are fully pressurized, listen and check for leaks. Open the

CO2/compressed air cylinder valve all the way until it back-seats itself (this pre-

vents leaks from the valve).

2

Adjust the CO2/compressed air cylinder regulator for the unit to between 0.48-

0.83 MPa (70-120 psig) at the unit.

3

Check for

supply to the unit and listening for leaks. Wait at least 3 minutes and check the

CO2/compressed air cylinder gauge to see if the pressure has dropped.

4 The system is now ready for operation.

CO2/compressed air cylinder valve slightly to allow lines to slowly fill

CO2/compressed air leaks by turning off the CO2/compressed air

Helix Operator’s Manual

2/compressed air

Table 1.

Pressurizing the Water System

The Helix unit is designed to operate with a water inlet pressure of 0.48-0.83 MPa

(70-120 psig)

Perform the procedure in Ta b l e 2 to verify the water connection to the unit.

The unit must only be connected to a clean, potable water supply.

Step Action

1 Turn on the water supply to the unit.

2 Check the system for leaks.

3 The water system is now ready for operation.

Table 2.

© 2012-2014,Cornelius Inc. All Rights Reserved - 9 - Publication Number: 621058497OPR

Page 14

Helix Operator’s Manual

Menu Button

INITIAL UNIT SETUP

Hopper Sanitation

Upon installation, the ice hopper must be sanitized before the unit is started. For ice

hopper sanitizing, perform the procedure in

Tab l e 3 . After initial installation, the sani-

tizing procedure is run through the user interface Reference page number, etc.

Table 3.

Step Action

1 Disconnect power cord from the unit, if connected.

2 Remove the cover from the top of the unit.

3 Unplug the quick disconnect attached to the hopper lid. photo

4

5

6

7

8

9 Spray the lid and clear ice chute with sanitizing solution and let air dry.

10 Reassemble the lid and clear ice chute.

11 Tighten the lid bracket and reattach the quick disconnect.

Use a 1/4” nut driver to loosen hopper lid bracket. Slide the bracket off of the

hopper lid to gain access to the hopper. photo

Spray the inside of the hopper, agitator and the agitator lid with cleaning

solution and wipe them dry with a clean cloth.

Spray the inside of the hopper, agitator and the agitator lid with sanitizing solution and allow the pieces to air dry.

Remove the clear front from the ice chute by lifting it straight up, as

shown in Figure 3.

Spray the lid and clear ice chute with cleaning solution and wipe them

dry with a clean cloth.

Figure 1.

Publication Number: 621058497OPR - 10 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 15

Figure 2.

Helix Operator’s Manual

Figure 3.

© 2012-2014,Cornelius Inc. All Rights Reserved - 11 - Publication Number: 621058497OPR

Page 16

Helix Operator’s Manual

Pull Here

CAUTION:

!

Figure 4.

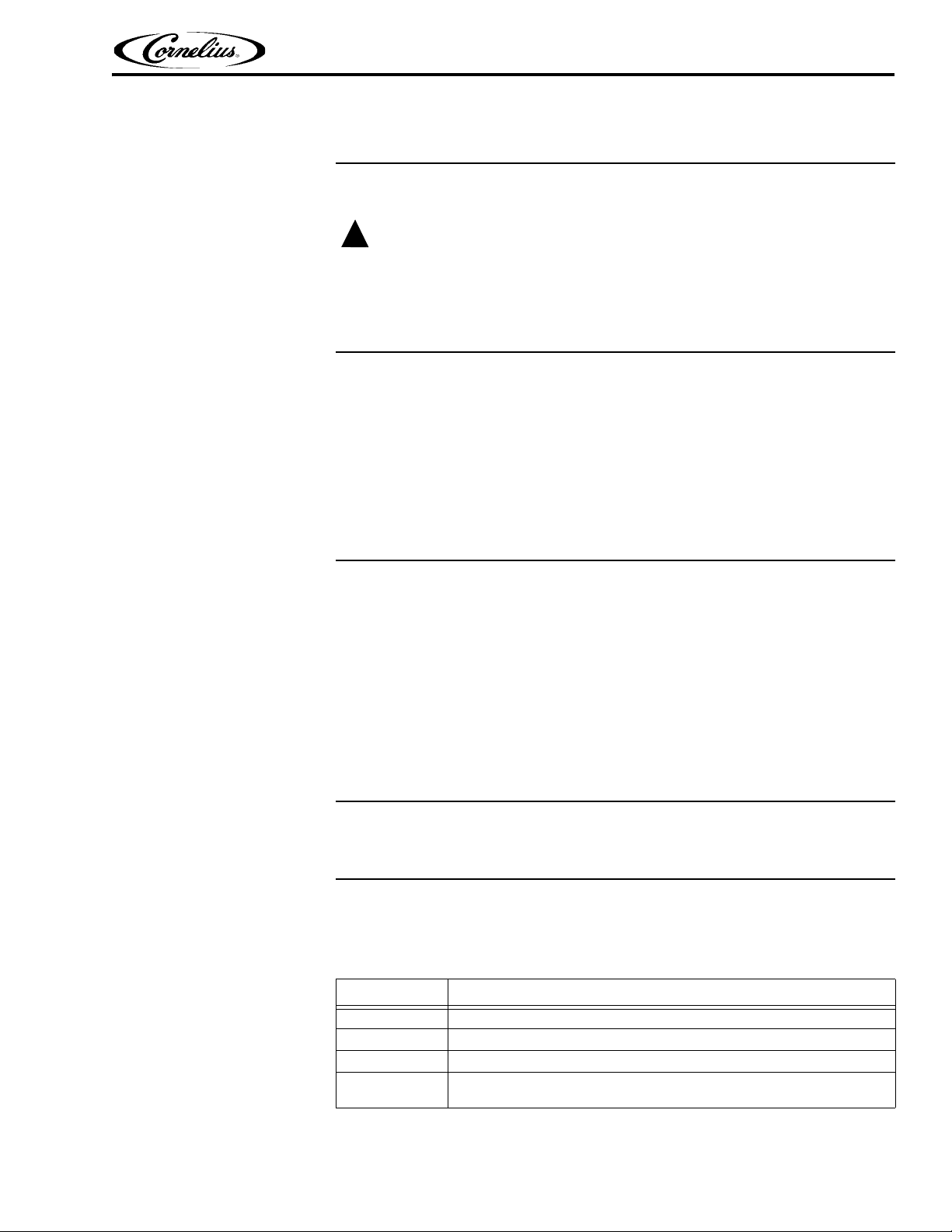

Unit Startup

To start the unit, open the control panel by grabbing the lower right-hand corner

and opening it. (See

If the supply cord is damaged, it must be replaced by a special cord or assembly

available from the manufacturer or its service agent.

Turn on the power switch located behind the control panel, as shown in Figure 6.

Figure 5.)

Figure 5.

Publication Number: 621058497OPR - 12 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 17

Power Switch

System Sanitation

Helix Operator’s Manual

Figure 6.

The system now displays the Home Screen, shown in Figure 1.

Before initially placing product into the cabinet, the unit must be sanitized to ensure

there is no contamination of the product when it is placed in the unit.

The unit should be cleaned on a weekly basis (minimum) using the Sanitation Menu.

The menu is accessed from the Menu Screen. The following list of supplies are

needed for this operation:

• Clean Cloths

• Ru

b

ber gloves

• Spray bottle with cleaning solution

• Spray bottle with sanitizer solution

• 3 5-gallon buckets

• Sanitation funnel

• Sanitation spyder

• Ice collection tray

To sanitize the system, perform the procedure in Ta b l e 4 .

Table 4.

Step Action

1

2

3

NOTE: During initial set up, all ingredie

From the Home Screen, press the Menu button in the upper left hand

corner as shown in Figure 1.

In the Menu Screen, press the Sanitize button in the top center of the

screen, as shown in Figure 7. This opens the Sanitize menu. Follow

the instructions displayed on the left side of the screen.

Select the weekly product tab and press the Play button, as shown in

Figure 8. The sanitization program steps through the rest of the procedure providing step-by-step instructions.

nt lin

es and blenders must be sani-

tized. When selected, the ingredient image turns grey.

© 2012-2014,Cornelius Inc. All Rights Reserved - 13 - Publication Number: 621058497OPR

Page 18

Sanitize Button

Helix Operator’s Manual

Figure 7.

Figure 8.

Ingredient Sanitation

The ingredient sanitation is automatically started after selecting the weekly product tab.

To sanitize the ingredients, perform the procedure in Ta b l e 5 .

Step Action

1 Wash and sanitize hands or use clean rubber gloves.

2 Select the Sanitization Selection screen, shown in Figure 7 on page 14.

3 Select the weekly product tab to sanitize ALL ingredient trays and lines.

4

Publication Number: 621058497OPR - 14 - © 2012-2014, Cornelius Inc. All Rights Reserved

Press the Play button to start the sanitation process. Follow the steps

shown on the screen to complete the sanitation process.

Table 5.

Page 19

Table 5.

Step Action

Sanitization Preparation: Prepare three, 5-gallon buckets for the cleaning process as follows:

Bucket #1: Fill the bucket with cleaning solution (100 ppm, Kay-5

5

cleaner/sanitizer) mixed as directed on the package.

Bucket #2: Fill the bucket with 5 gallons of clean hot water (100° F. - 38°

C).

Bucket #3: Fill the bucket with sanitizer solution (100 ppm, Kay-5

cleaner/sanitizer) mixed as directed on the package.

Helix Operator’s Manual

Blender Sanitation

Figure 9.

The Blender Sanitization screen is accessed from the Sanitize screen. It will automatically follow the ingredient sanitation process.

To sanitize the blenders, perform the procedure in Ta b l e 6 .

Table 6.

Step Action

1 Wash and sanitize hands or use clean rubber gloves.

2

3

4

Ingredient sanitation is now complete, press Play to start blender sanitization.

Remove the cleaning hose from its storage space under the left-front

side of the unit, inside the product compartment, as shown in Figure 11.

Sanitation Preparation: Prepare three, 5-gallon buckets for the cleaning process as follows:

Bucket #1: Fill the bucket with cleaning solution (100 ppm, Kay-5 cleaner/

sanitizer) mixed as directed on the package..

Bucket #2: Fill the bucket with five gallons of clean hot water (100° F. - 38° C).

Bucket #3: Fill the bucket with sanitizer solution (100 ppm, Kay-5 cleaner/

sanitizer) mixed as directed on the package.

© 2012-2014,Cornelius Inc. All Rights Reserved - 15 - Publication Number: 621058497OPR

Page 20

Helix Operator’s Manual

Table 6.

Step Action

5

Press the Play button to start the process. Follow the steps shown on

the screen to complete the sanitation process.

Ice Maker Sanitation

Figure 10.

Figure 11.

The Ice Maker Sanitization screen is accessed from the Sanitize screen.

To sanitize the ice maker, perform the procedure in Tab l e 7 .

Table 7

Step Action

1 Wash and sanitize hands or use clean rubber gloves.

2 Select the Ice Maker Sanitization tab, shown in Figure 12.

Publication Number: 621058497OPR - 16 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 21

Table 7

Step Action

3

4

5

Remove the cleaning hose from its storage space under the left-front

side of the unit, inside the product compartment, as shown in Figure 11.

Sanitation Preparation: Prepare three, 5-gallon buckets for the cleaning

process as follows:

Bucket #1: Fill the bucket with sanitizer solution (100 ppm, Kay-5

cleaner/sanitizer) mixed as directed on the package.

Bucket #2: Fill the bucket with five gallons of clean hot water (100° F. 38° C).

Bucket #3: Fill the bucket with sanitizer solution (100 ppm, Kay-5

cleaner/sanitizer) mixed as directed on the package.

Press the Play button to start the process. Follow the steps shown on

the screen to complete the ice maker sanitation process.

Helix Operator’s Manual

Figure 12.

Sanitation Scheduler

The Helix software contains a Sanitation Scheduler that allows the user to set up an

automated schedule for sanitizing the unit.

Pressing the Sani Scheduler button shows the current sanitation schedule settings.

Setting Sanitation Dates

The Sanitization Schedule allows each ingredient and blender to be scheduled for

sanitization individually. This menu can be accessed from the Menu Screen in the

second row, as shown in

set to sanitize at least once a week. This menu requires a minimum of manager or supervisor permission to access it. It can also be accessed by service

tec

© 2012-2014,Cornelius Inc. All Rights Reserved - 17 - Publication Number: 621058497OPR

hnici

ans.

Figure 13. All ingredient lines and blenders should be

Page 22

Sani Schedule

Button

Helix Operator’s Manual

Figure 13.

To set the Sanitization Scheduler, perform the procedure in Tabl e 8 .

Table 8.

Step Action

1 Select ingredients/blenders to schedule and then press the Play button.

2 Select the frequency of sanitation (Weekly or none.)

3 If applicable, choose the day that sanitation will take place. (See Figure 14.)

4 Choose the time of day for sanitation. (See Figure 14.)

5

Press the “Set” button (check mark) to save the settings. The arrows can

be pressed to restore the defaults and the “X” can be pressed to cancel

the changes.

Figure 14.

Publication Number: 621058497OPR - 18 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 23

Preparing Replacement Product Bags

!

WARNING:

Syrup bags must not be connected or prepared until all ingredient lines have

been sanitized and the unit has been pre-chilled to operating temperature (3240° F). Refer to the System Sanitation section on page 13.

The Ingredient Status Screen is used to prepare the bags. The Ingredient Status

Screen shows the location for each syrup bag in the cabinet. The level indicators

show the amount of product in each bag. To prepare the system after replacing a

product bag, perform the procedure in Tab l e 9 .

Step Action

1

2

3

4 Follow the on-screen instructions to finish preparing the bags in the unit.

NOTE: The bag should engage the fitting on the back wall. If product is leak-

From the Main Screen, select the Ingredient Status Screen (Figure 15)

by pressing the Menu button, shown in Figure 1 on page 10.

Place each bag/tray in its appropriate location, making sure that the bag

connector is fully seated onto the stem in the back of the cabinet.

Select all ingredients that have been replaced and press the Play button

(See Figure 16 and Figure 17).

ing out, the connection did not seal and the bag should be reinserted.

Helix Operator’s Manual

Table 9.

Figure 15.

© 2012-2014,Cornelius Inc. All Rights Reserved - 19 - Publication Number: 621058497OPR

Page 24

Helix Operator’s Manual

Figure 16.

Figure 17.

Calibration

To begin normal operation, the unit must be calibrated for all ingredients. These procedures can be done by a manager or service technician. Refer to the installation

man

ual (P/N 621058497INS) for calibration instructions.

Publication Number: 621058497OPR - 20 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 25

Blender Operation

CAUTION:

!

DAILY OPERATION

Helix Operator’s Manual

No separate process is required to prepare the blenders for operation. The blenders

should be test operated to ensure they are working correctly before the unit is operated.

Do not run blenders dry. Use a cup of plain water for testing.

From the Home Menu, select a drink and drink size to be poured. This pours a drink

and moves a blender up in preparation to blend. Once the blender shield has moved

up, a drink can be put in the cup holder to blend.

Once the unit is installed, it should be left on and the Main Screen is displayed.

Each day, wash all external surfaces with a mild detergent solution and rinse with clean,

po

table water. Dry all external surfaces with a clean, soft, dry cloth. Remove the cup rest

and wash it with the same detergent solution. Dry the cup rest thoroughly and replace it.

Unit Cleaning

Daily Cleaning Menu

The unit should be cleaned on a daily basis using the Daily Cleaning Menu. The

menu is accessed from the Menu Screen. The following list of supplies are needed

for this operation:

• Clean Cloths

• Rubber gloves

• Spray bottle with cleaning solution

• Spray bottle with sanitizer solution

• 2 clear cups and 2 red cups (supplied)

To complete daily cleaning, perform the procedure in the Unit Cleaning section.

There is a daily cleaning menu that is accessed from the Main menu by pressing the

Sanitize button.

To initiate the daily cleaning process, perform the procedure in Table 10.

Table 10.

Step Action

1 Wash and sanitize hands or use clean rubber gloves.

2 From the Main menu, press the Sanitize button.

3 Press the Menu button to access the Daily Clean screen, shown in Figure 18.

4

Press the Play button to start the process. Follow the steps shown on

the screen to complete the cleaning process.

© 2012-2014,Cornelius Inc. All Rights Reserved - 21 - Publication Number: 621058497OPR

Page 26

Helix Operator’s Manual

CAUTION:

!

Table 10.

Step Action

Supplies needed are as follows:

Clean cloth

5

Spray bottle with cleaning solution

Spray bottle with sanitizer solution

2 medium size cups with cleaning solution

2 medium size cups with sanitizer solution

Dispensing a Drink

Figure 18.

Never use abrasive or chlorine-based cleansers on the unit.

If there is a system malfunction, refer to Unit Startup section on page 12 and reset

the switch.

To dispense a drink, perform the steps in Ta b l e 1 1 .

Table 11.

Step Action

1

2

3

4

5

Place the desired size cup into the cup stand under the dispense nozzle, as shown in Figure 19.

Match the drink size to the cup selected by pressing the correct size on

the touch screen.

Select the desired flavor from the Main Screen, shown in Figure 20.

When the button is pressed, the syrup and ice dispense.

When the unit is done dispensing, place it in the designated blender, as

shown in Figure 21. (Screen indicates which blender to use.)

Press the Blend button (lower right or left corner of the screen) and wait

for the blend cycle to finish. Blender will stop and lift blade.

Publication Number: 621058497OPR - 22 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 27

Helix Operator’s Manual

Table 11.

Step Action

6

7 Press the Rinse button to automatically rinse the blender chamber.

8 Blender shield will rise when the unit is done rinsing.

When th

blender.

e blender guard raises, immediately remove the cup from the

NOTE: If the rinse button is not pressed within 60 seconds after blending a

drink, the unit automatically lowers the shield and performs a rinse

cycle on the blender. This can be disabled by a manager level or

above in the settings menu.

Figure 19.

Figure 20.

© 2012-2014,Cornelius Inc. All Rights Reserved - 23 - Publication Number: 621058497OPR

Page 28

Helix Operator’s Manual

Figure 21.

Publication Number: 621058497OPR - 24 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 29

!

WARNING:

!

WARNING:

REPLACING SUPPLIES

Helix Operator’s Manual

MAINTENANCE

Never use a water jet (power washer) to clean the exterior of the unit.

Do not store explosive substances, such as aerosol cans with a flammable

propellant in this unit.

The Helix unit is capable of using syrups with particulate matter up to 1/8” in size.

To replace a product bag, perform the procedure in Table 12.

Table 12.

Step Action

1 Open the product door, shown in Figure 22.

2

3

4

5

Remove the tray containing the empty product bag, shown in Figure 23.

Make sure to close the cabinet door after removing the tray.

Remove the bag from the tray by pulling the BIB connector up and

unsnapping it from the tray.

Replace the product bag in the tray and snap the BIB connection into

the tray.

Place the tray into the appropriate shelf and make sure the BIB connection is snug on the nozzle, as shown in Figure 24. Make sure the cabinet door is completely closed.

Figure 22.

© 2012-2014,Cornelius Inc. All Rights Reserved - 25 - Publication Number: 621058497OPR

Page 30

BIB

Connection

Helix Operator’s Manual

Figure 23.

Priming the New Product Bag

Figure 24.

Whenever a product bag is replaced, the bag must be primed.

To prime a product bag, perform the procedure in Tabl e 1 3 .

Table 13.

Step Action

1

2 Place an empty cup in the cup holder, as shown in Figure 19 on page 23.

3 Press the Ingredient Status button on the Menu Screen, shown in Figure 25.

4

5 Press the Home button to return to the Main Screen

When the new bag has been placed in the tray, press the Menu button

on the Home Screen, shown in Figure 1 on page 10.

Select the bag that was replaced and then press the Arrow button and

follow the steps shown on the screen to complete the priming process.(See Figure 26.)

Publication Number: 621058497OPR - 26 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 31

Ingredient

Status

Button

Figure 25.

Helix Operator’s Manual

Figure 26.

TEMPERATURE MONITORING

Temperatures in the product cabinet is monitored by the system. This allows the

operator to ensure that all products are acceptable to dispense and consume. See

Figure 27 for the Temperature screen.

© 2012-2014,Cornelius Inc. All Rights Reserved - 27 - Publication Number: 621058497OPR

Page 32

Helix Operator’s Manual

Cabinet Temperature

DATE AND TIME

Figure 27.

The cabinet temperature should remain between 38 and 40º F (0.56 – 2.22º C).

When the cabinet reaches a temperature of 41º F (5º C) or higher, a red warning

symbol appears. This means that the product cabinet is now above the recommended storage temperature.

If the cabinet temperature has a yellow warning symbol, make sure the cabinet door

is

comp

letely closed and allow a short time for the temperature to cool down.

If the cabinet temperature has a red warning symbol, dispose of all product and contact a manager.

The Date and Time menu allows a person to set the date and time for the real time

clock display on the Main screen, shown in

Use the up and down arrows to set the Hour, Minute, AM/PM, Month, Day and Year.

To sa

ve the settings press the check mark, or to cancel changes press the “X”.

Figure 28.

Publication Number: 621058497OPR - 28 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 33

Figure 28.

CAUTION:

!

Helix Operator’s Manual

DAILY MAINTENANCE

WEEKLY MAINTENANCE

Preventive maintenance can increase the trouble-free life of the unit. Failure to perform preventive maintenance could void your equipment warranty.

On a daily basis, clean all external surfaces with a mild soap solution and rinse with

clean

applicable) and wash with a mild soap solution. Dry the tray thoroughly and replace it.

Do not use chlorine-based solutions on stainless steel surfaces

The following procedures should be performed on a weekly basis:

ater. Dry all external surfaces with a clean soft cloth. Remove the drip tray (if

w

• Weekly product sanitation

• Product cabinet inspection

System Sanitation

Perform the procedure in the System Sanitation section on page 13. The unit requires

sanitation at least once a week. More frequent sanitation may be required by local code.

© 2012-2014,Cornelius Inc. All Rights Reserved - 29 - Publication Number: 621058497OPR

Page 34

Helix Operator’s Manual

Product Cabinet Inspection

Open the product cabinet and pull out the bottom two product trays. Check for any

spilled product. Use cleaning solution and a clean cloth to remove any spilled product.

MONTHLY MAINTENANCE

The following procedures should be performed on a monthly basis.

• All weekly maintenance tasks

• Condenser cleaning (ice maker and product cabinet)

• Water feed reservoir inspection

• Ingredient sanitation

• Ice Maker sanitation

Condenser Cleaning

The condensers should be cleaned at least once a month (more often in harsh environments). To clean the condensers, use a soft brush, vacuum cleaner or blow out

t

he condenser from the inside using compressed air.

SEMI-ANNUAL MAINTENANCE

The following procedures should be performed on a semi-annual basis.

• All weekly and monthly maintenance tasks

• Inspect and service water system

• Inspect tubing

• Check for condensation

• Check safety circuits

• Check for vibration/noise

• Inspect upper bearings on auger assembly

Water System Inspection

Check for water leaks in all of the tubing connections, water fittings and the lower ice

maker water seal.

Publication Number: 621058497OPR - 30 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 35

Drain Tube Inspection

Check the drain tubes for clogs and aged tubing. If tubes are stained or brittle, replace

them with new tubing.

Condensation Inspection

Check for signs of condensation. Clean the area where necessary and replace insulation in the proper locations.

Refrigeration System Inspection

Visually inspect the refrigeration system for signs of wear or leaks. Call service if

repairs are needed.

Helix Operator’s Manual

Overall Mechanical Inspection

Check unit for any unusual noise or rattles. Tighten any loose screws if necessary.

Auger Bearing Inspection

Check white upper auger bearings for wear. If bearings are less than 1/16” thickness,

replace the bearing. Refer to

Figure 29.

Figure 29.

© 2012-2014,Cornelius Inc. All Rights Reserved - 31 - Publication Number: 621058497OPR

Page 36

Helix Operator’s Manual

ALARMS

The Alarms menu has two different screens. The Active Errors screen, shown in Figure 30, allows users to see what alarms are currently affecting the unit. The log file,

shown in Figure 31, provides a history of the unit’s performance and is intended for

service technicians. To access the Alarm St

the Menu screen.

at

us screen, press the Alarms button on

Figure 30.

Figure 31.

Publication Number: 621058497OPR - 32 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 37

Unit Level Alarms &

Warnings

Sold Outs

Ingredient Expired

Warning

Helix Operator’s Manual

Alarms activated on the unit display on the main screen. Underneath the word “Main”,

the words “see alarms” flashes. This indicates that the alarm should be checked and

resolved before operating the unit.

Cabinet Ingredients Sold Out - The display shows a sold out condition for ingredients as a red warning symbol to indicate that t

using this ingredient are disabled on the Main screen.

Water Sold Out - If water is not present, a red warning symbol illuminates. Any recipe using water cannot be dispensed. Also

and the ice maker will not run. Management should be notified immediately.

CO

2/compressed air Sold Out - If CO2/compressed air is not present, drinks and ice

cannot be dispensed. Management should be notified immediately.

he BIB container is empty. Any drinks

, the blending chambers cannot be washed

Ingredient Warning - An ingredient expiration warning is triggered 24 hours (1 day)

before the product use by date. Expiration date of the product is based on the time

value entered into the recipe. The expiration date is reset when a new product BIB is

connected in the BIB rack.

© 2012-2014,Cornelius Inc. All Rights Reserved - 33 - Publication Number: 621058497OPR

Page 38

Helix Operator’s Manual

TROUBLESHOOTING

TROUBLESHOOTING - CONTROLS

Problem Probable Cause Remedy

A. Unit unplugged / cable disconnected

B. No power to branch circuit.

No activity at all

Front panel LEDs indicate

unit on but no motor activity/will not respond

No condenser fan or com-

pressor

No condenser fan but com-

pressor runs

No compressor but con-

denser fan runs

Product Bowl blades do not

turn

Product does not dispense

C. Keypad bad or disconnected.

D. Control Board bad.

A. Software detected error condition

B. 24VAC missing

C. Bad or missing cable connection

D. Control Board bad

A. Software detected error condition

B. Bad contactor or connections

A. Bad connections

B. Bad condenser fan

C. Bad contactor

A. Bad connections

B. Bad start relay

C. Bad capacitor(s)

D. Bad compressor

E. Bad contactor

A. Blades uncoupled from drive

B. Bad / missing connections to hopper

motor

C. Control Board bad

D. Bad Product Bowl motor

A. Motor does not turn

B. Bad connections to dispense switch

C. Dispense switch bad or mis-located

D. Control Board bad

A. Make sure unit is plugged in and cord is

connected in E-box

B. Make sure fuse is good/installed or

breaker is switched to “ON”.

C. Check for proper connection/replace

keypad

D. Replace Control Board

A. See error table .

B. Check that faceplate is in proper

mounted position and adjust as needed

Check for excessive refrigeration pressure and correct

Check connections and transformer in

E-box and correct

C. Connect or replace cable.

D. Replace Control Board

A. See error table document

B. Check connections, contactor and

transformer in E-box and correct

A. Check connections at contactor and fan

and correct

B. Replace

C. Replace

A. Check connections at contactor, capac-

itors, start relay and compressor and

correct

B. Replace

C. Replace

D. Replace

E. Replace

A. Check that hopper product viscosity is

within limits & correct as necessary

B. Check connections & correct as neces-

sary

C. Replace Control Board

D. Replace motor

A. See next section

B. Check connections / correct as needed

C. Adjust/replace as needed

D. Replace board

Publication Number: 621058497OPR - 34 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 39

Helix Operator’s Manual

Motor does not turn at all

A. Face plate not in proper position or

missing

B. Product frozen solid

C. Software detected error condition

D. Bad connections.

E. Faceplate switch bad or mis-located

F. Control Board bad

A. Verify face plate is secure and in proper

position for unit operation

B. Clean out barrel and check that viscos-

ity settings are correct for current prod-

uct

C. See error table document

D. Check connections between E-Box,

control board and correct as needed.

E. Adjust or replace faceplate

F. Replace

TROUBLESHOOTING PRODUCT NOT COLD

Problem Probable Cause Remedy

A. Barrel not in Freeze or Refrigerate

mode.

B. No voltage to compressor.

Compressor not Running

Compressor Running but not

Cooling

Restricted Air Flow

Fan Motor not operating

properly

Liquid Line Valves not oper-

ating

No/Low Refrigerant A. Leak. A. Repair and weigh in new charge.

Thermistors/Reed Switches

C. Bad start components.

D. Compressor’s thermal overload protec-

tor “open”.

E. Open or shorted compressor windings.

F. Bad Control Board.

A. Low refrigerant.

B. Restricted condenser/filter.

C. Condenser fan motor/blade defective.

D. Liquid Line valves not operating.

E. Defective compressor.

A. Dirty filter.

B. Dirty condenser.

C. Damaged fins.

D. Not enough “clearance” around unit.

A. Bad connection

B. Bad motor

C. Cracked or bent fan blade

A. Miswired.

B. Defective coil.

C. Valve mechanically bad.

D. Defective control board or transformer.

A. Bad connection.

AF. Bad sensor.

AG. Sensor out of position.

AH. Defective control board.

A. Select Freeze or Refrigerate.

B. Check power at contactor L2 - L3, T2 -

T3.

C. Check components and wiring.

D. Check resistance of compressor wind-

ings and check incoming line voltage.

E. Check resistance of compressor wind-

ings.

F. Troubleshoot, replace if necessary.

A. Repair leak and weigh in new charge.

B. Clean or repair.

C. Repair or replace.

D. Check cables and connections to con-

trol board and repair or replace.

E. Repair or replace.

A. Clean or replace filter.

B. Clean condenser.

C. Repair/replace if necessary.

D. Ensure proper spacing around unit.

A. Check/connect

B. Replace motor

C. Replace fan blade

A. Correct wiring.

B. Replace coil.

C. Replace valve.

D. Check and replace.

A. Correct wiring.

B. Replace sensor.

C. Reposition sensor and clip.

D. Re p l ace.

© 2012-2014,Cornelius Inc. All Rights Reserved - 35 - Publication Number: 621058497OPR

Page 40

Helix Operator’s Manual

Publication Number: 621058497OPR - 36 - © 2012-2014, Cornelius Inc. All Rights Reserved

Page 41

Page 42

Cornelius Inc.

www.cornelius-usa.com

Loading...

Loading...