Cornelius Flavorfusion TP01070 Training Manual

®

FLAVORFUSION®/

FLAVOROVERLOAD

Training Manual

Publication Number: TP01070

Revision Date: November 16, 2007

Revision: F

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

FLAVORFUSION®/FLAVOROVERLOAD

TRAINING MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

Aurora, Cornelius, FlavorFusion, Focus, Leopard ERV, Nordic, Optifill, Pinnacle, SFV1,

Smart-Pour, Totalflex II, and Vanguard are registered trademarks of IMI Cornelius Inc.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004-2007, All Rights Reserved, IMI Cornelius Inc.

FlavorFusion®/FlavorOverload Training Manual

TABLE OF CONTENTS

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Programming Mode Flashing Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setting Water Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adjusting Syrup/Water Ratio (Brix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setting a Button to Dispense Non-carbonated Water Only . . . . . . . . . . . . . . . . . 5

Setting a Button to Dispense Carbonated Water Only . . . . . . . . . . . . . . . . . . . . 5

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control Box Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valve Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Valve Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Carbonator Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Interface Board and Harness Pin-out Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Point-Point Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ladder Type Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Diagnostics Guide for the Main Control Board (see FIGURE 22) . . . . . . . . . . . . . . 19

© 2004-2007, IMI Cornelius Inc. - i - Publication Number: TP01070

FlavorFusion®/FlavorOverload Training Manual

Publication Number: TP01070 - ii - © 2004-2007, IMI Cornelius Inc.

FlavorFusion®/FlavorOverload Training Manual

PRODUCT OVERVIEW

• Brand density - 16 brands (14 chilled, 2 ambient) plus up to 8 bonus flavors in 30” wide;

• 255 lbs capacity cube ice only hopper;

• Internal cold carbonation with remote pump;

• Total carb/non-carb flexibility on each brand;

• Eye catching merchandising;

• Improved serviceability of agitator motor;

• Bonus flavors programmable for 1-4 second dispense;

• Valve positions programmable without special tools or PDA;

• Front inlet fittings;

• Key lock switch;

• 10” cup clearance;

• 30% more drip tray capacity;

THEORY OF OPERATION

• The FlavorFusion®/FlavorOverload machine is an above counter ice/beverage unit with multi flavor

nozzles and the capability to inject bonus flavors into the finished drink.

• The beverage is cooled via ice melting on an aluminum cold plate. Ice is kept on the cold plate by

means of an opening in the hopper that drops ice onto the surface during agitation of the ice in the

hopper.

• The unit contains a mechanical ice chute and gate mechanism.

• The ice agitation gear motor is removable from the gear box to ease removal of the motor during ser-

vice and lower repair cost.

• The unit has six nozzles for dispensing brand and bonus flavors.

• Each brand nozzle serves four discreet flavors fed by four syrup valves, one plain water, and one carb

water valve. Every position is flexible for use with either carb or non-carb water.

• Each bonus nozzle serves four individual flavors intended for injection into the finished drink. Bonus

nozzles are fed by four syrup valves only. There is no option to dispense water out of the bonus nozzle

without significant plumbing changes.

• Bonus flavors require a separate regulator setting on their BIB pumps (20 psi maximum).

• Brand and bonus flavors are controlled by means of six interface boards (one interface board per noz-

zle). The interface boards are common for each nozzle. Valve positions are configured on the membrane switch. No special tool or PDA is required.

• Valve flow rates are adjustable for 3.0-3.75 oz/sec finished drink dispense rate.

• Unplug the unit or turn off the key switch before attempting any electrical service on the unit, failure to

do this can cause damage to the electrical components!

© 2004-2007, IMI Cornelius Inc. - 1 - Publication Number: TP01070

FlavorFusion® Training Manual

SYSTEM REQUIREMENTS

Dimensions (in): . . . . . . . . 29 x 30 x 39 (l x w x h). Height is measured to top of bin. Lid adds 3 in to

height.

Counter Weight (lb): . . . . . 320 (plus ice weight)

Shipping Weight (lb): . . . . 330

Capacity: . . . . . . . . . . . . . 250 lb ice bin capacity (cube ice only)

Indoor installation only

o

40 to 90

Electrical Rating: . . . . . . . . 103-132 Volts

Water supply pressure: . . 50-60 psi at pump

Water volume: . . . . . . . . . 125 gph

CO2: . . . . . . . . . . . . . . . . . 75 psi at carbonator tank

Syrup (brands): . . . . . . . . 60 psi min

Syrup (bonus): . . . . . . . . 20 psi max

F ambient temperature

11 Amps

Syrup supply lines: . . . . . . .375” ID tubing min

NOTE: If water pressure is below 50 psi a water pressure booster is required for still water drinks.

Publication Number: TP01070 - 2 - © 2004-2007, IMI Cornelius Inc.

PROGRAMMING

NOTE: The programming mode is exactly the same for both brand and bonus keypads.

To enter the programming mode, press and hold the two program buttons (see FIGURE 3) at the top of

the keypad for approximately 4 seconds. All keypad LEDs will flash off for approximately 1 second to

indicate the start of the programming mode.

To exit programming mode, press and hold the two program buttons for approximately 4 seconds. All

keypad LEDs will flash off for approximately 1 second, resuming normal operation mode.

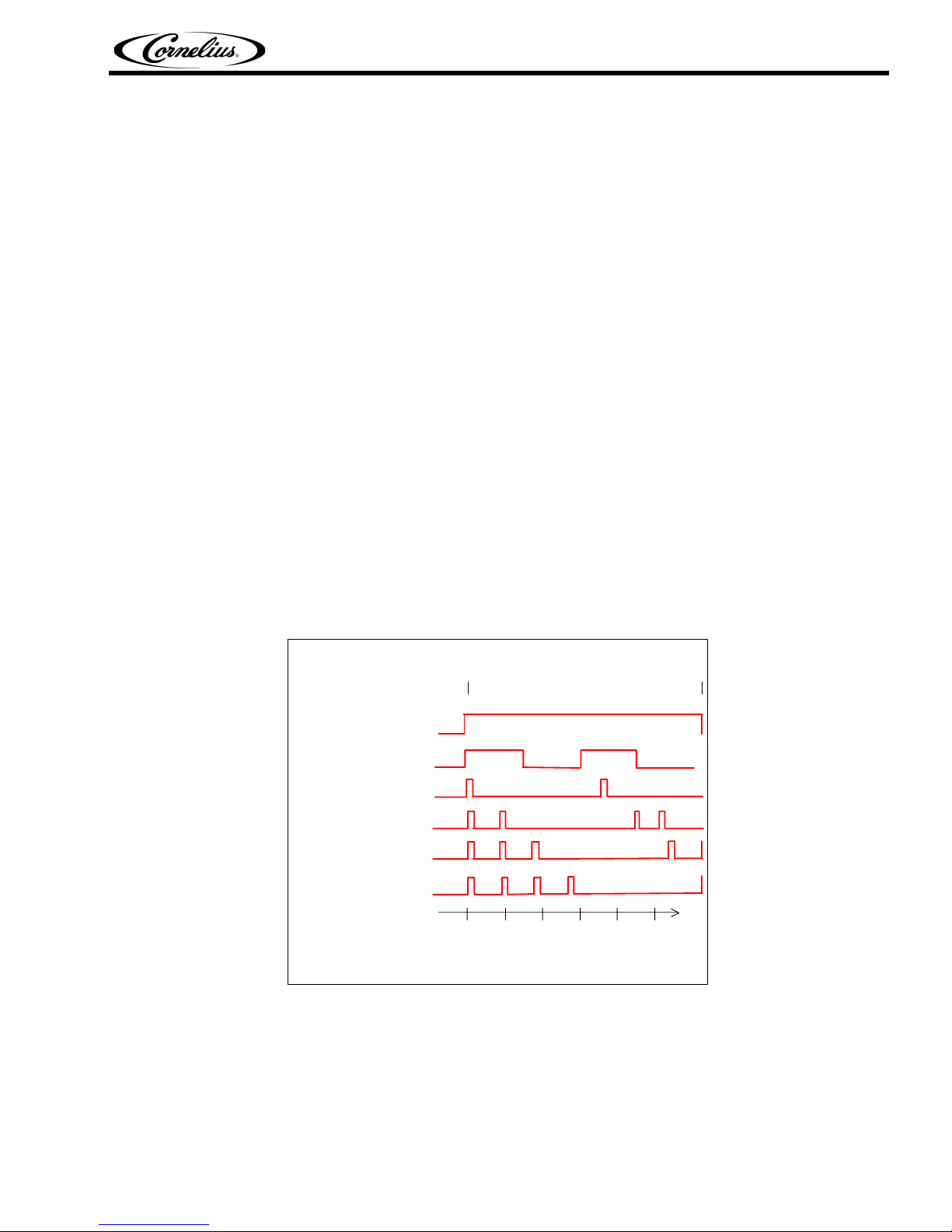

Programming Mode Flashing Sequences

Once in programming mode, each dispense button LED flashes in a sequence cycle according to one (1)

of six (6) dispense types. For Brand Keypads, only dispense types 1 and 2 should be used. For Bonus

Flavor Keypads, dispense types 3 through 6 are used. The six (6) dispense types are described below,

and shown in a timing diagram in FIGURE 1:

• Dispense Type 1, Carbonated water dispense: Solid LED

• Dispense Type 2, Non-carbonated dispense: Flashing LED 1.5 seconds ON, 1.5 seconds OFF

• Dispense Type 3, 1-second flavor shot: LED flashes once for ¼ second, followed by 3 seconds

OFF

• Dispense Type 4, 2-second flavor shot: LED flashes twice for ¼ second ON, ½ second OFF,

followed by 3 seconds OFF

• Dispense Type 5, 3-second flavor shot: LED flashes three (3) times for ¼ second ON, ½ second

OFF, followed by 3 seconds OFF

• Dispense Type 6, 4-second flavor shot: LED flashes four (4) times for ¼ second ON, ½ second

OFF, followed by 3 seconds OFF

Start

proramming

mode

FlavorFusion®/FlavorOverload Training Manual

Exit

programming

mode

1. Carbonated water dispense

2. Non-carbonated dispense

3. 1-second flavor shot

4. 2-second flavor shot

5. 3-second flavor shot

6. 4-second flavor shot

012345

Time

(seconds)

FIGURE 1

NOTE: It is possible to program a flavor shot into a keypad. It is also possible to program a cove

dispense (type 1 or 2) into a flavor shot keypad. Both instances result in an incorrect operation

and should be corrected.

© 2004-2007, IMI Cornelius Inc. - 3 - Publication Number: TP01070

FlavorFusion® Training Manual

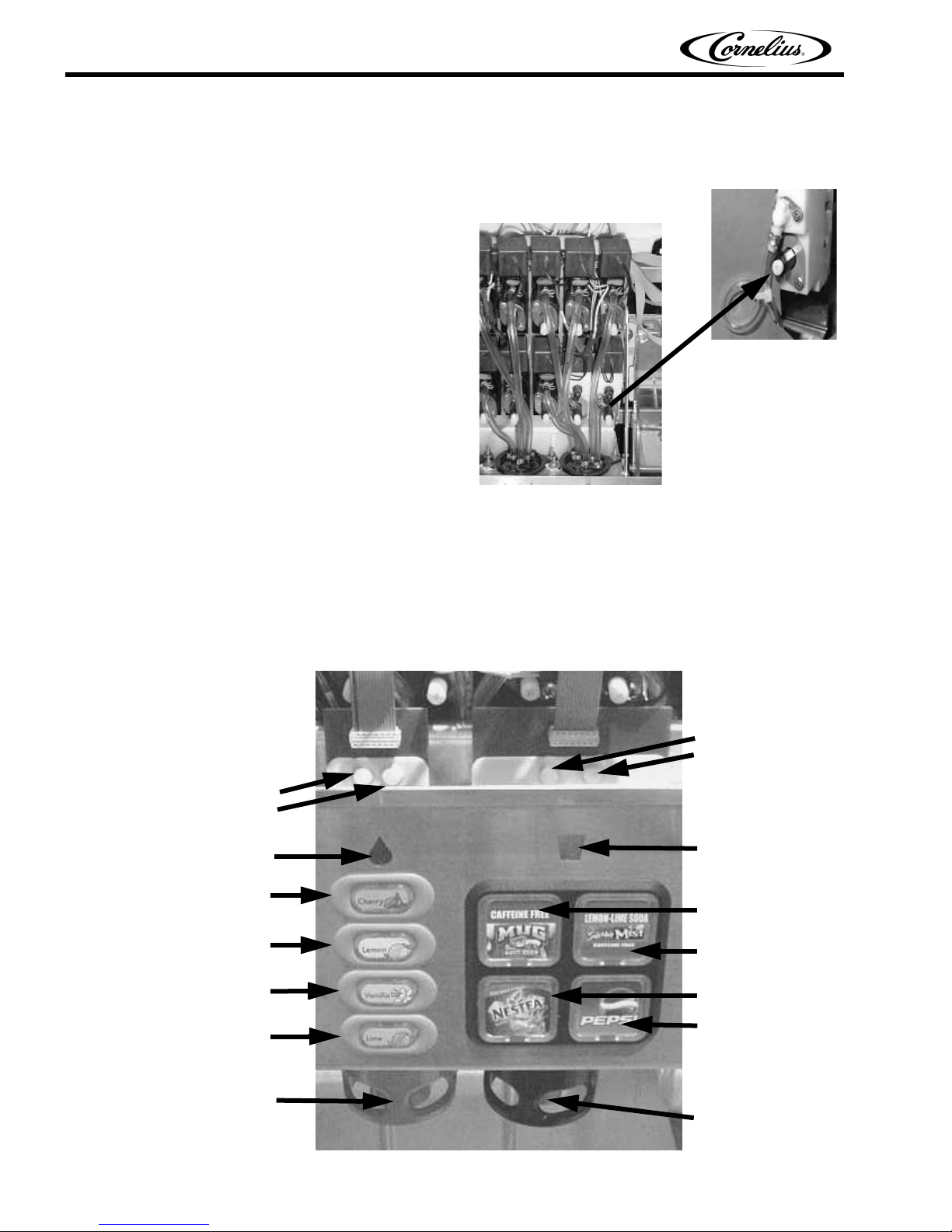

Setting Water Flow Rate

Setting the water flow rate will require a timed dispense. To accomplish this, the following procedure

should be followed:

1. Enter programming mode for the valve

block by simultaneously pressing and

holding both programming buttons for 4

seconds (see FIGURE 3). The LED’s for

flavors 1-4 should flash off and then back

on. The drink icon should turn off.

2. Set the valve block to a 4 second pour

mode by simultaneously pressing and

holding Flavor 1 and Flavor 4 buttons until

the flash pattern for all four buttons

changes.

3. Place an empty ratio cup under the

appropriate nozzle and press the left

program button for a 4 second dispense of

carbonated water. There should be

approximately 10 oz. dispensed.

4. If necessary, adjust the water flow control

(see FIGURE 2), empty ratio cup, and

repeat step 3. Otherwise empty ratio cup

and repeat step 3 using the right program

button for plain water.

5. Exit 4 second pour mode by simultaneously pressing and holding Flavor 1 and Flavor 4

buttons until the flash pattern for all for buttons changes.

6. Exit programming mode by simultaneously pressing and holding both programming buttons

for 4 seconds.

Flow Adjuster Detail

(Water)

FIGURE 2. Valve with Flow Adjusters

(see plumbing diagram for plumbing and valve

configuration)

Bonus Flavor

Programming

Buttons

(Left

and Right)

Bonus Flavor Icon

Bonus Flavor Button 1

Bonus Flavor Button 2

Bonus Flavor Button 3

Bonus Flavor Button 4

Bonus Flavor Nozzle

Brand Flavor

Programming

Buttons

(Left and

Right)

Drink Icon

Brand Flavor Button 1

Brand Flavor Button 2

Brand Flavor Button 3

Brand Flavor Button 4

Brand Flavor Nozzle

Publication Number: TP01070 - 4 - © 2004-2007, IMI Cornelius Inc.

Loading...

Loading...