Page 1

OPERATOR’S MANUAL

AUTOMATED BEVERAGE SYSTEM

This equipment chapter is to be inserted in

the Beverage Systems section of the

Equipment Manual.

MANUFACTURED

EXCLUSIVELY FOR

McDONALD’S

BY

IMI CORNELIUS

ONE CORNELIUS PLACE

ANOKA, MINNESOTA 55303-1562

PHONE (763) 421-6120

1-800-238-3600

FAX (763) 422-3255

®

FOR SERVICE CALL

COKE SMILE

1-800-241-COKE

TABLE OF CONTENTS

WARRANTY............................................................................................................................Page 2

INTRODUCTION.....................................................................................................................Page 4

SAFETY...................................................................................................................................Page 4

PARTS IDENTIFICATION/FUNCTION... ......................... .. .. ......................... .. .. .......................Page 5

OPERATION MODES..............................................................................................................Page 11

FULLY AUTOMATIC OPERATION......................................................................................Page 11

SEMIAUTOMATIC OPERATION.........................................................................................Page 17

MANUAL OPERATION........................................................................................................Page 19

MAJOR SUBSYSTEMS...........................................................................................................Page 23

DAILY START-UP....................................................................................................................Page 39

CLOSING/SANITATION PROCEDURES................................................................................Page 41

MONTHLY CLEANING PROCEDURES................................. .. .. .... .. .................................. .. .. .Page 44

QUARTERLY CLEANING/SANITATION PROCEDURES ............................ .. .. .. .. ...................Page 46

TROUBLESHOOTING.............................................................................................................Page50

WIRING & PNEUMATIC DIAGRAMS........................................... .. .........................................Page 55

Part No. 569000181

November 24, 1997

Revised: January 28, 2001

This manual is for the exclusive use of licensees and employees of McDonald’s Systems, Inc.

© 1999-2001 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Printed In

The United States of America

Page 2

Automated Beverage System

McDonald’s Automatic Beverage System

WARRANTY, DISCLAIMER OF WARRANTY AND LIMITATION OF REMEDY

Products covered by this Warranty include only Automatic beverage Dispenser (“ABS”) manufactures or sold by Cornelius after the date hereof (herein “Products”). THE TERM “PRODUCTS” DOES NOT INCLUDE, AND THIS WARRANTY IN NO EVENT EXTENDS TO,

ITEMS NOT MANUFACTURED OR SOLD BY CORNELIUS, SUCH AS ANY POS SYSTEMS (INCLUDING CABLE CONNECTING THE POS TO THE ABS) AND ANY

RECIRCULATING SYSTEM SUPPLYING CO2 WATER, WATER OR SYRUP TO THE

ABS.

WARRANTY

IMI Cornelius Inc, (Corneluis”) warrants to the original McDonald’ s purch aser with respect to

each product purchased that:

1. For the lesser of (i) one (1) year from the date of installation or (ii) fifteen (15) months

from the date of shipment by Cornelius, all parts comprising such Product (except

Excluded Parts as defined below and the refrigeration system of the precooler) are free

from defects in materials;

2. For the lesser of five (5) years from the date of installation or sixty-three (63) months

from the date of shipment by Cornelius (and subject to the service limitation set forth

below), the parts (except Excluded Parts) comprising the refrigeration system of the precooler of such Product, being only the compressor, eveaporator, condenser, and interconnecting tubing (but not access valves or any otherr part) are free from defects in materials;

and

3. For the lesser of one (1) year from the date of installation or (ii) fifteen (15) months from

the date of shipment by Cornelius that such Product conforms with those industry, government, or professional organizations standards to the extent expressly set forth in written

product information disclosures in Cormelius product literature and documentation;

Provided that the foregoing shall not apply to any warranty claim not made as promptly as possible and in any

event within thirty (30) days after the discovery thereof to the Cornelius Service Department at One Cornelius

Place, Anoka, MN 55303-6234, (612) 421-6120.

For the purposes of the foregoing warraties, “Excluded Parts” include all water filter cartridges, coin mechanisms, light bulbs, fuses, glass diaphragms, seals, o-rings, silicone or rubber parts, parts in contact with water or

the product dispensed and which become inoperative due to scale or chemical change, as well as normal maintenance items.

It is not a defect, and thus these warranties do not apply to, repair, replacement or other service required by or

loss or damage resulting from (i) other that normal and proper use and service conditions with respect to such

Product, (ii) use of the product other that exclusively with soft drinks, soft drink syrup, or iced tea identified in

wring by Cornelius, (iii) improper voltage, (iv) inadequate wiring, (v) abuse, (vi) accident, (vii) alteration, (viii)

risk of transportation, (ix) misuse, (x) neglect, (xi) unauthorized repair, (xii) fire, flood or othere acts of God,

(xiii) improper cleaning, or faliure to follow installation, operating, or maintenance instructions, nor does th ese

Warranties cover normally prescribed maintenance, cleaning, and adjustments.

2

IMI CORNELIUS

ONE CORNELIUS PLACE

ANOKA, MINNESOTA

55303-6234

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Page 3

Automated Beverage System

Disclaimer of Warranty

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABLITY AND FITNESS FOR A PARTICULAR PURPOSE, ALL

OF WHICH OTHER WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED.

Remedy, Limitation of Remedy and Disclaimer of Liability

The remedy for any breach of this Warranty is limited to the repair or replacement or the defect part or the Product in which it is included, at the option of Cornelius. to the extent that, in the judgement of Cornelius, repair or

replacement should be performed through on-site service, such service is included in the Warranty for the lesser

of one (1) year from the date of installation or (ii) fifteen (15) months from the date of shipment by Cornelius,

and even then only to the extent of scheduled straight time labor to repair or replace the defective part. Such service is to be performed by a service agency authorized by Cornelius. Time and rate schedules for labor compensation will be published periodi call y by Co rnel ius . Addi t ional exp enses including, but not limited to travel tim e,

truck charges, overtime charges, material costs, are not the resposiblity of and will not be paid by Cornelius.

neither any part alleged to be defective and covered by this warranty or the product in which it is included shall

be returned to Cornelius without authorization from the Cornelius Service Departm ent. The instructions for

return will be given with any such authorization. All returned parts and/or Products must be shipped prepaid to

Cornelius. Return shipping costs of repaired or replacement parts or Products will be prepaid by Cornelius,

except that as to original purchasers in Alaska or Hawaii, Cornelius will pay shipping cost only to Seattle or San

Fransisco, respectively. Cornelius will not accept collect shipments. Replaced products or parts become prperty

of Cornelius. any product or parts returned to Cornelius under the terms of this Warranty must be accompanied

by a Returned Goods Tag, properly filled out as to unit model number and serial number and detailed explanation

of faliure.

THE SOLE AND EXCLUSIVE REMEDIES FOR BREACH OF ANY OBLIGATION OF CORNELIUS

AND THE SOLE REMEDIES FOR CORNELIUS’ LIABILITY OF ANY KIND (INCLUDING LIABILITY FOR NEGLIGENCE) WITH RESPECT TO THE PRODUCTS AND RELATED SERVICE S

SHALL BE THE REMEDY SET FORTH HEREIN, OR IF NO SUCH REMEDY APPLIES, THEN TO

USE REASONABLE EFFORTS TO PROMPTLY CURE SUCH BREACH.

IN NO EVENT SHALL CORNELIUS’ LIABILITY OF ANY KIND INCLUDE ANY SPECIAL, INDIRECT, PUNITIVE, INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGE, EVEN IF CORNELIUS SHALL HAVE BEEN ADVISED OF THE POSSIBILITY OF SUC H POTENTIAL LOSS OR

DAMAGE.

CORNELIUS CUMULATIVE LIABILITY FOR DAMAGES UNDER OR IN RELATION TO A PRODUCT AND RELATED SERVICES FOR ANY CAUSE WHATSOEVER, AND REGARDLESS OF THE

FORM OF ACTION; WHETHER IN CONTRACT ON IN TORT INCLUDING NEGLIGENCE, SHALL

BE LIMITED TO THE COST OF SUCH PRODUCT.

No alteration or modification of the terms and conditions of this W ar ranty s hall be valid unless expressly agreed

to in writing by Cornelius. Any different, additional, or conflicting terms or conditiond set forth in any order confirmation of other writing are expressly objected to by Cornelius and the terms of this Warranty shall exclusively

govern warranties and remedies with respect to the Products.

IMI CORNELIUS

ONE CORNELIUS PLACE

ANOKA, MINNESOTA

55303-6234

3

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Page 4

Automated Beverage System

INTRODUCTION

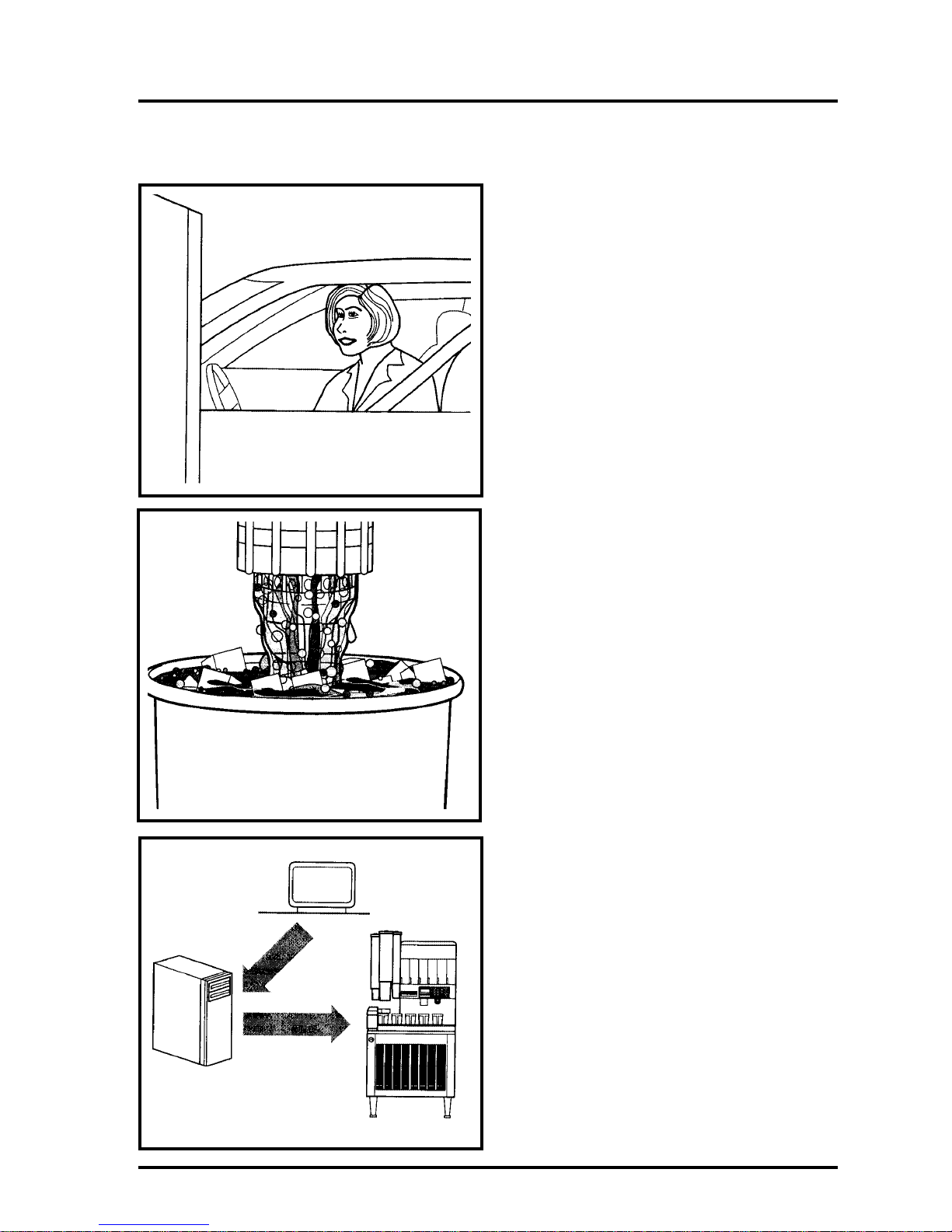

The Automated Beverage System (A.B.S.) is

an automated cold beverage dispenser for

drive-thru applications. When a cold beverage

is ordered from the P.O.S. register, the A.B.S.

will automatically drop the cup, fill it with ice,

and dispense the correct amount and type of

any syrup-based cold beverage. The finished

drink is then moved by the conveyor to the

pick-up station and the drink description is

displayed on the panel.

The Automated Beverage System has three

modes of operation:

• Automatic Mode

In automatic mode, the customer places an

order at the drive-thru and the A.B.S. automatically produces the order. If extra or no ice

drinks are ordered, they are entered from the

P.O.S. as a “grill order” and the A.B.S.automatically produces the drink as ordered.

• Semiautomatic Mode

While in automatic mode, the operator

resses the desired cup size button, the desired

flavor button and ENTER, then the drink is

dispensed. If extra ice or no ice is required,

the EXTRA ICE or NO ICE button is pressed

after the flavor button has been pressed before

ENTER, then the drink is dispensed.

• Manual Mode

A drink can also be dispensed in manual

mode. Remove the conveyor. Enter the manual mode by pressing the Manual/Auto button.

(Don’t pull cups from A.B.S. Turret damage

may occur to cup tubes.) Locate a sleeve of

cups and remove a cup. Hold the cup under

the ice chute, press EXTRA ICE and ice is

dispensed. Hold the cup under the nozzle,

press and hold the desired flavor button, and

the drink is dispensed. Reinstall the conveyor

and return the A.B.S. unit to normal operation.

SAFETY

T o avoid possible fatal electrical shock or serious injury to the Operator, it is highly recommended that a G.F.I. (ground fault circuit

interrupter) be installed in the electrical power

circuits to the unit.

Always disconnect power before cleaning or

servicing the unit. Do not use metal scrapers,

sharp objects or abrasives on the ice storage

hopper, top cover and the agitator disk, as

damage may result.

Always disconnect CO2 or air pressure to the

unit before cleaning or servicing the grabber

arm or ice chute. A disconnect switch for the

ice gate is located on the control box behind

the cup lid holder panel.

Insure that the unit is in manual mode before

removing or replacing the conveyor assembly

to avoid pinching fingers in the drain area.

The dispenser is very top heavy. To prevent

serious injury, exercise caution when moving

or setting the dispenser in place. The casters

that originally come with the unit should be

removed and replaced with the legs provided

in the installation kit to provide stability.

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

4

Page 5

Automated Beverage System

Illustrated Parts List

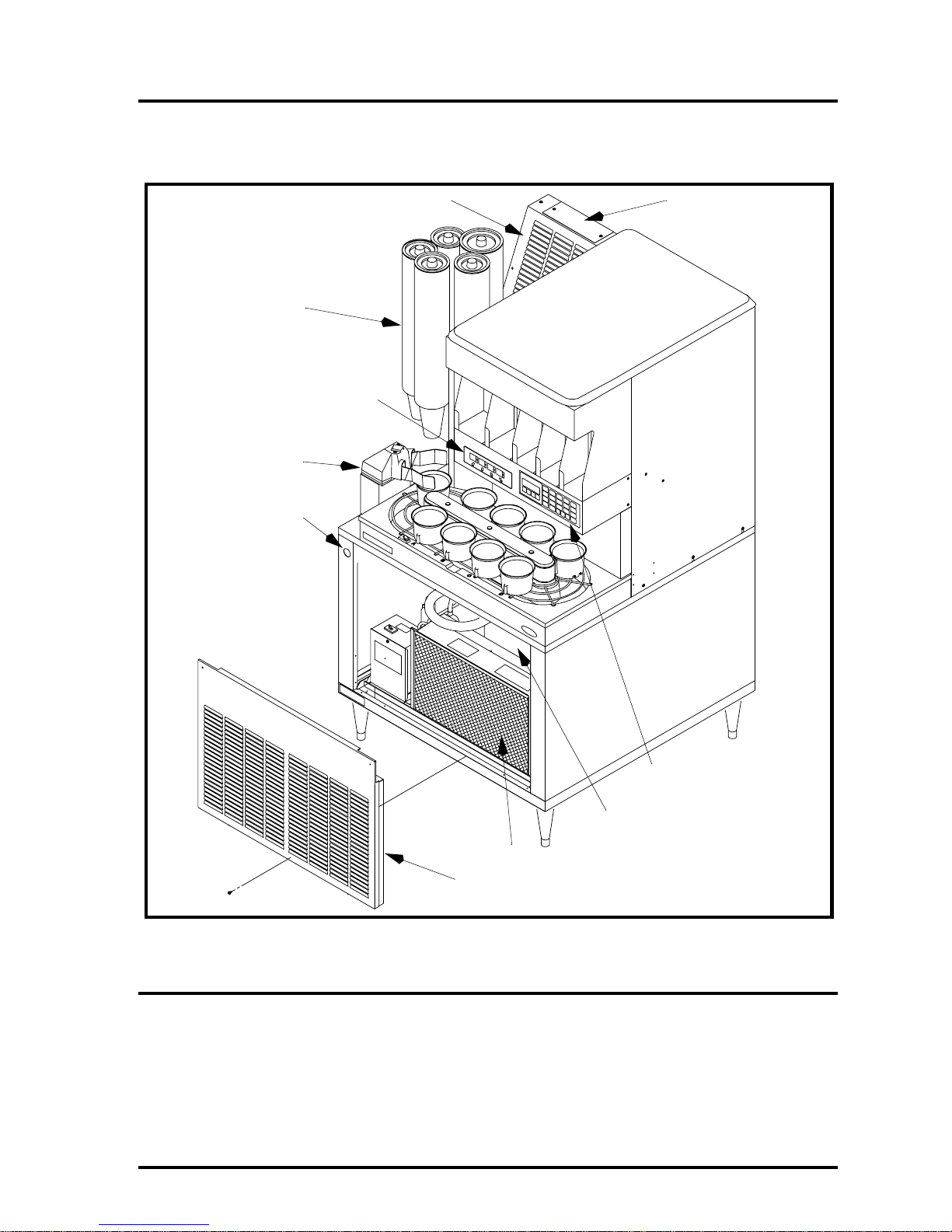

A.B.S. Unit Access

TURRET

FLAVOR DISPLAY

CUP GRABBER

ON/OFF SWITCH

1

2

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1.................... ................560000260.....Ventilation Grill

PRINTED ON RECYCLED PAPER

2.................... ................560000245.....Access Hole Cover

10% Post-Consumer Content

3.................... ................560000291.....Air Filter

40% Pre-Consumer Cont ent

4.................... ................560000289.....Front Panel (Built before Serial No. 56A0019AB102)

...................... ................560002774.....Front Panel (Serial No. 56A0019AB102 and after)

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

CONTROL PANEL

OPTIONAL PRECHILLER

3

4

Assembled Unit Diagram

5

Page 6

Automated Beverage System

Illustrated Parts List

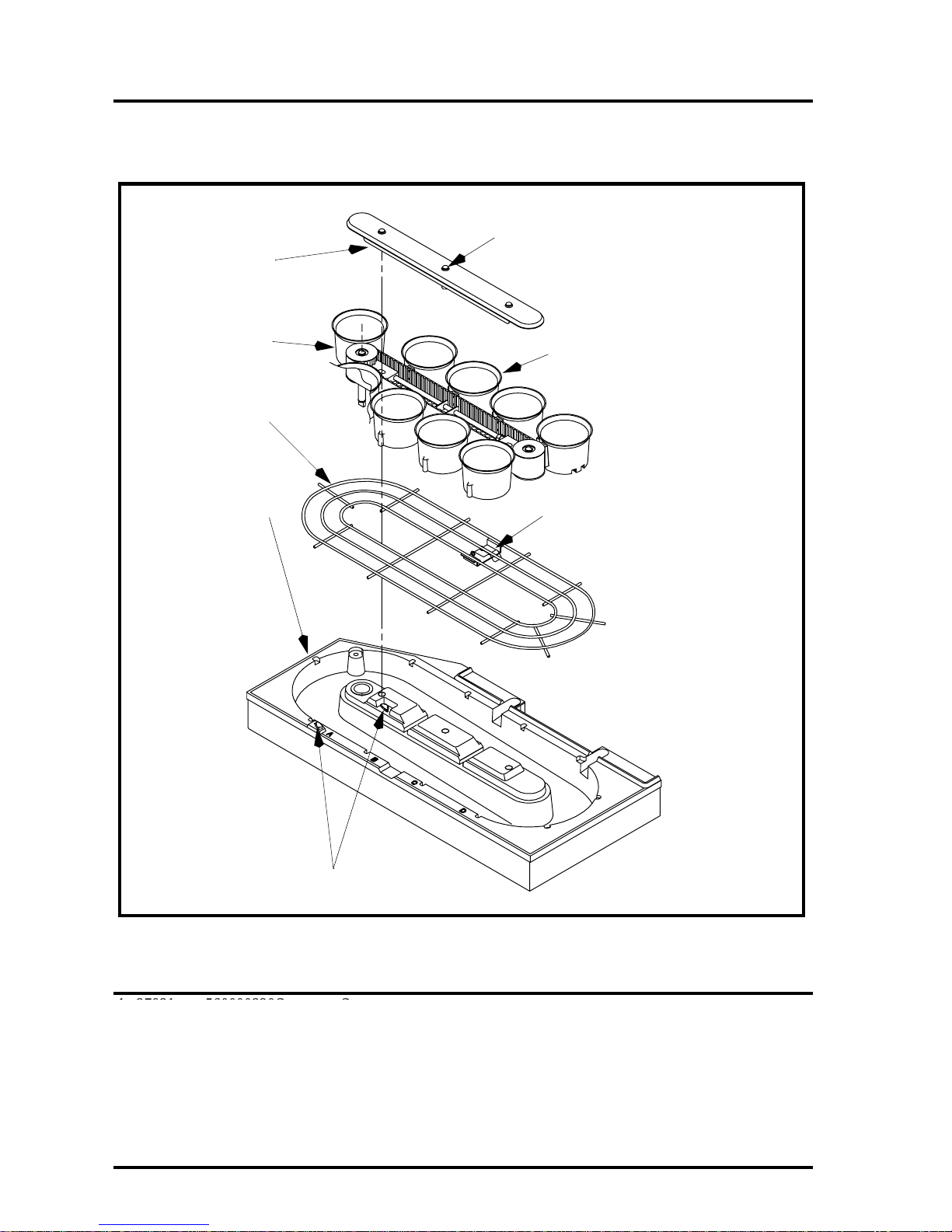

Conveyor Assembly

1

THUMB SCREWS

2

3

4

CUP HOLDER

CUP POSTIONING BRACKET

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1 27921 ...... 560000320Conveyor Cover

1................ 27921...........560000320...... Conveyor Cover

2 ..............27922...................560000325 ..............Conveyor Assembly

2................ 27922...........569000295...... Conveyor Assembly

3 .............. .............................560000315 ..............Cup Rest

3................ .....................560000315...... Cup Rest

4 .............. .............................56 000 030 6..............Drip Tray Assembly

4................ .....................560000306...... Drip Tray Assembly

6

POSITION “A” SENSOR

Conveyor/Cup Rest Assembly Diagram

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Page 7

Automated Beverage System

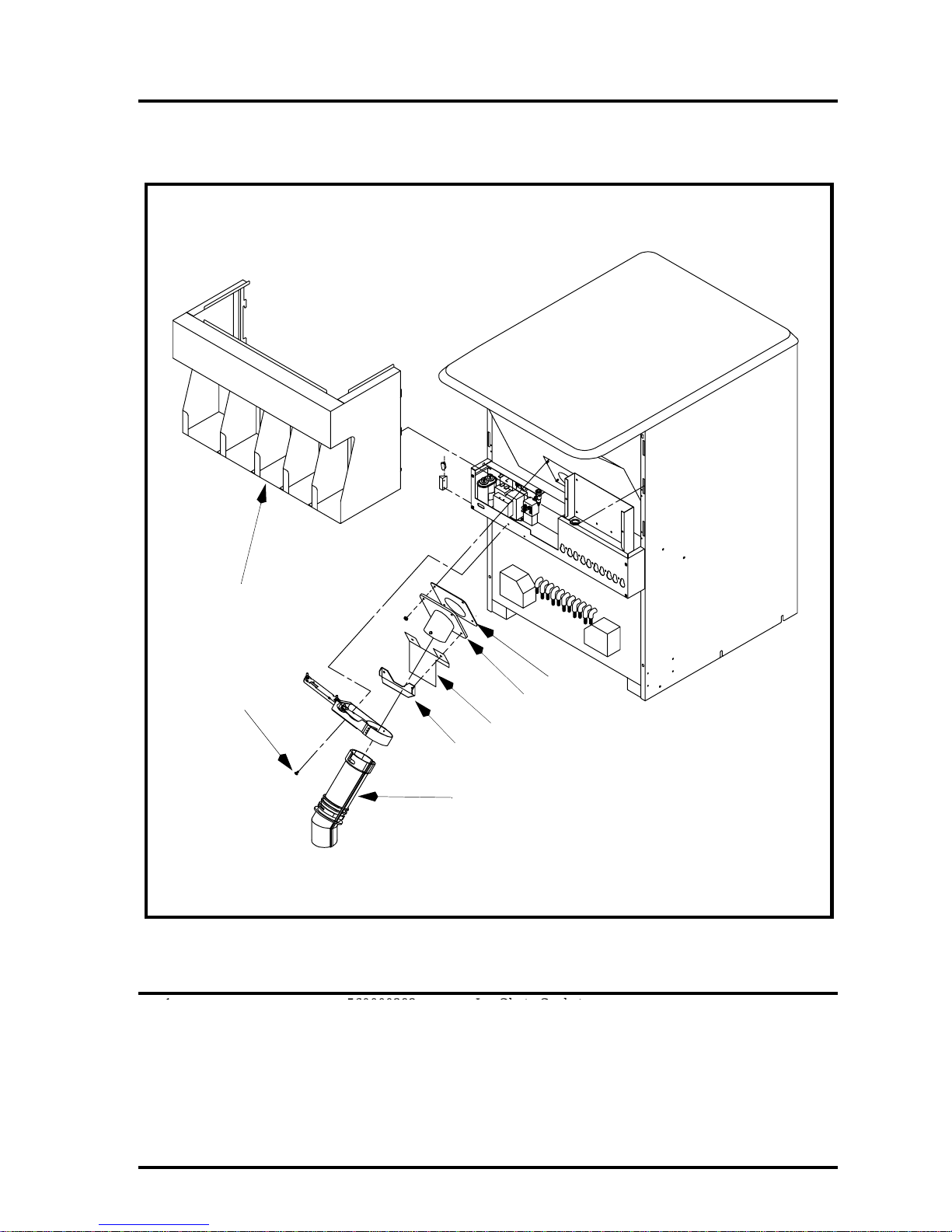

Illustrated Parts List

Ice Chute Assembly

7

1

5

4

3

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1............... ............................560000392 ..............Ice Chute Gasket

1 ................ ...................560000392.....Ice Chute Gasket

2............... ............................560000344 ..............Ice Chute Mounting Plate

2 ................ ...................560000344.....Ice Chute Mounting Plate

3...............27926 ..................560000346 ..............Ice Chute

3 ................ 27926.........560000346.....Ice Chute

4............... ............................560002728 ..............Ice Chute Stiffener

4 ................ ...................560002728.....Ice Chute Stiffener

5............... ............................560000398 ..............Machine Screw, Phillips Truss Head, No. 8 x .5”

5 ................ ...................560000398.....Machine Screw, Phillips Truss Head, No. 8 x .5”

6............... ............................560001548 ..............Ice Chute Shield

6 ................ ...................560001548.....Ice Chute Shield

7............... ............................620014801 ..............Lid Holder Assembly

7 ................ ...................620014801.....Lid Holder Assembly

8...............28076 ..................560001589 ..............Ice Chute Cleaning Brush

8 ................ 28076.........560001589.....Ice Chute Cleaning Brush (Not Shown)

Ice Chute Assembly Components Diagram

2

6

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

7

Page 8

Automated Beverage System

Illustrated Parts List

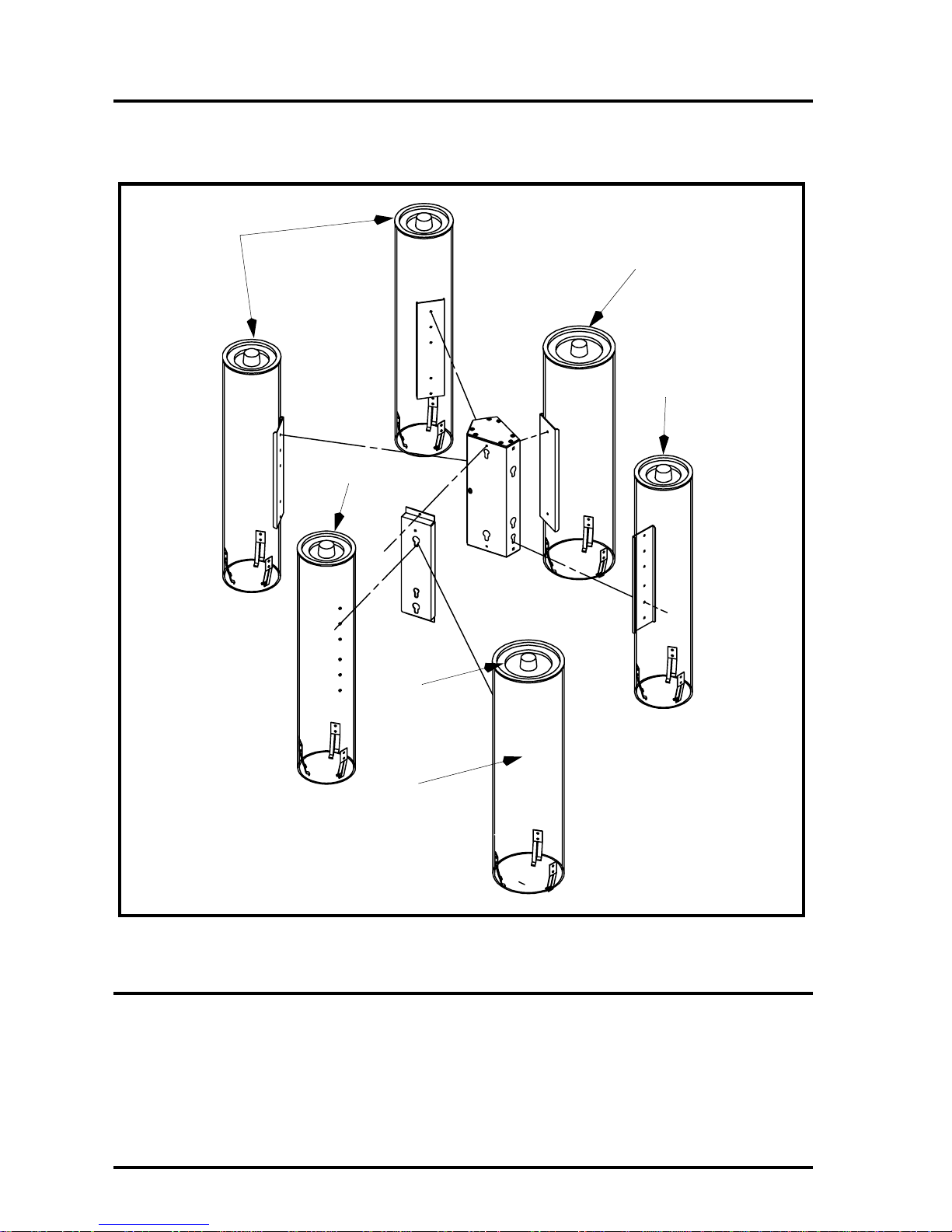

Cup Tube Assembly

2

2

1

2

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1..............27916 ..........560000207 .......5” Cup Tube Cover (32 - 42 oz.)

2..............27915 ..........560000206 .......4” Cup Tube Cover (12 - 21 oz.)

3..............28377 ..........569000199 .......42 Oz. Cup Tube Kit

N/R .........28373 ..........569000172 .......12 Oz. Cup Tube Assembly Kit (Austrailian “Small” size)

N/R .........28374 ..........569000173 .......16 Oz. Cup Tube Assembly Kit (Austrailian “Medium” size, station 3)

N/R .........28375 ..........569000174 .......21 Oz. Cup Tube Assembly Kit (Austrailian “Large” size, station 1)

N/R ......... ....................569000175 .......32 Oz. Cup Tube Assembly Kit

N/R ......... ....................569000159 .......21 Oz. Cup Tube Assembly Kit (Austrailian “Large” size, station 2)

N/R ......... ....................569030035 .......Medium Cup Tube Assembly Kit Station 5, (Australian ABS only)

8

1

3

Cup Tube Components Diagram

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Page 9

Automated Beverage System

Illustrated Parts List

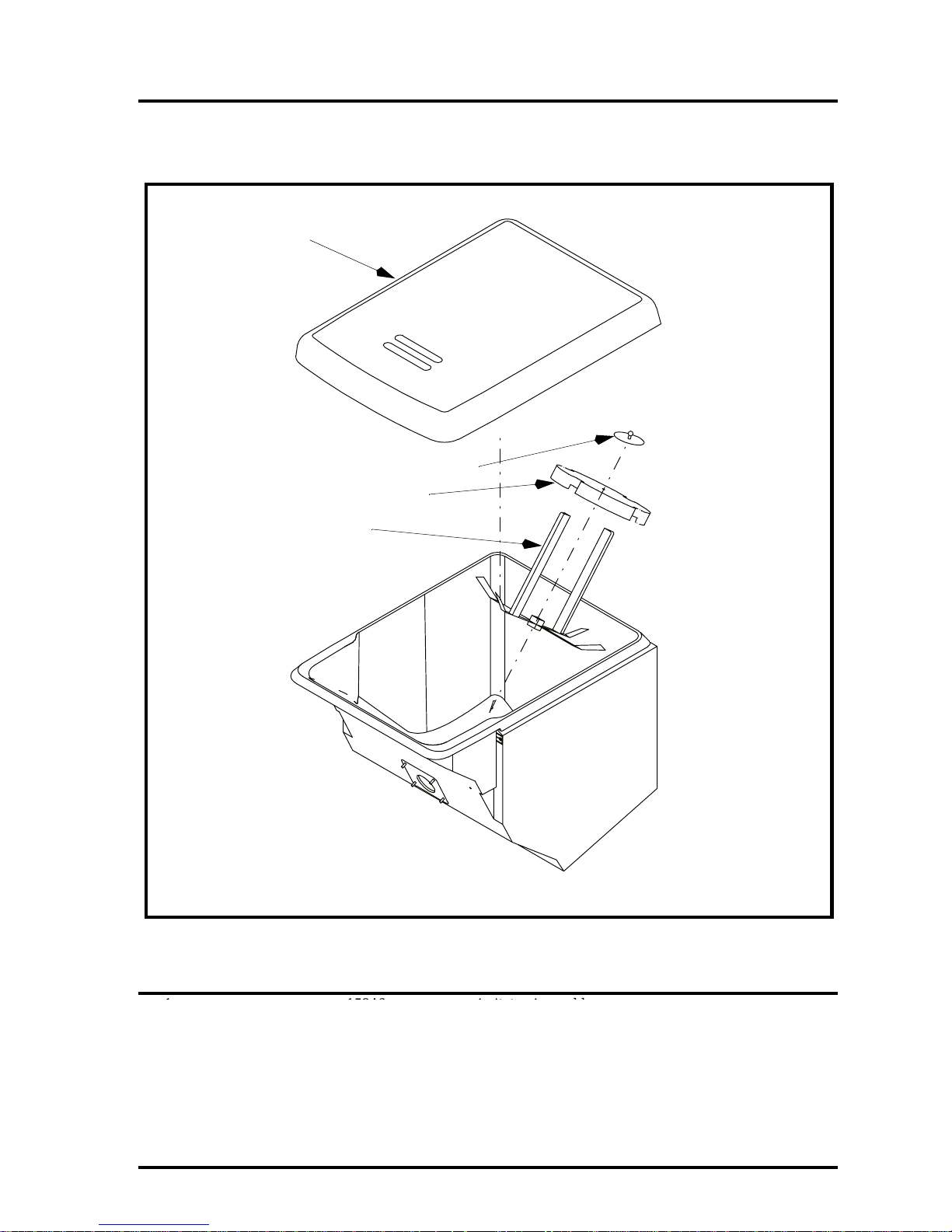

Agitator Assembly

2

4

3

1

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1............... ............................15346 ......................Agitator Assembly

1 ..............15346................................Agitator Assembly

2............... ............................52887 ......................Lid

2 ..............52887................................Lid

3............... ............................53227 ......................Disk

3 ..............53227................................Disk

4............... ............................15087 ......................Agitator Retainer

4 ..............15087................................Agitator Retainer

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Ice Bin Components Diagram

9

Page 10

Automated Beverage System

Illustrated Parts List

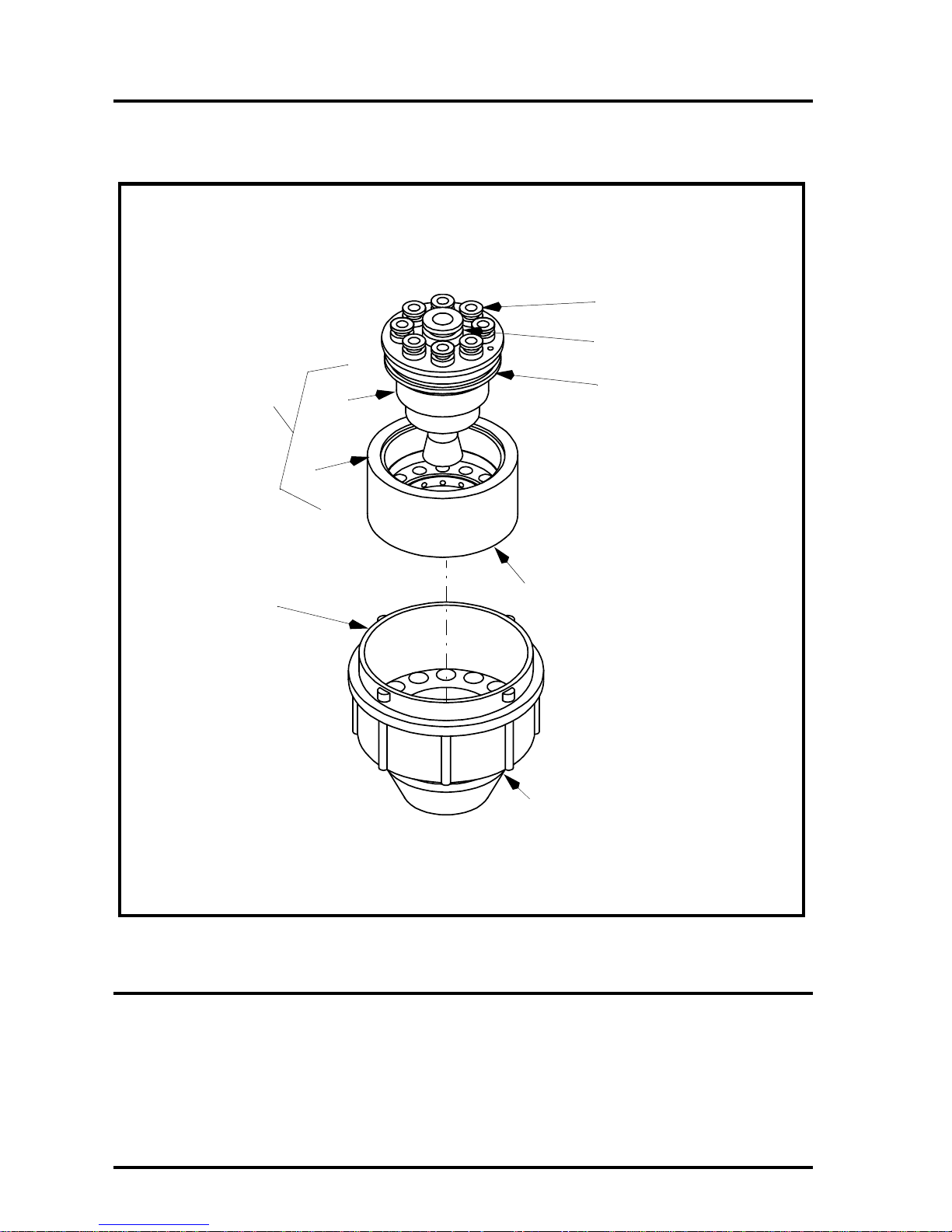

Nozzle Assembly

3

4

2

1

1

2A

2B

DIFFUSER BODY

DIFFUSER RING

5

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1................27940 560001545..........Nozzle

2................27939 560001544..........Diffuser

3................ 110677000..........O-Ring

4................ 180025000..........O-Ring

5................ 560110010..........O-Ring

6................ 325216000..........Nozzle Brush (Not Shown)

10

Nozzle Assembly Components Diagram

© 1999-2001 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Page 11

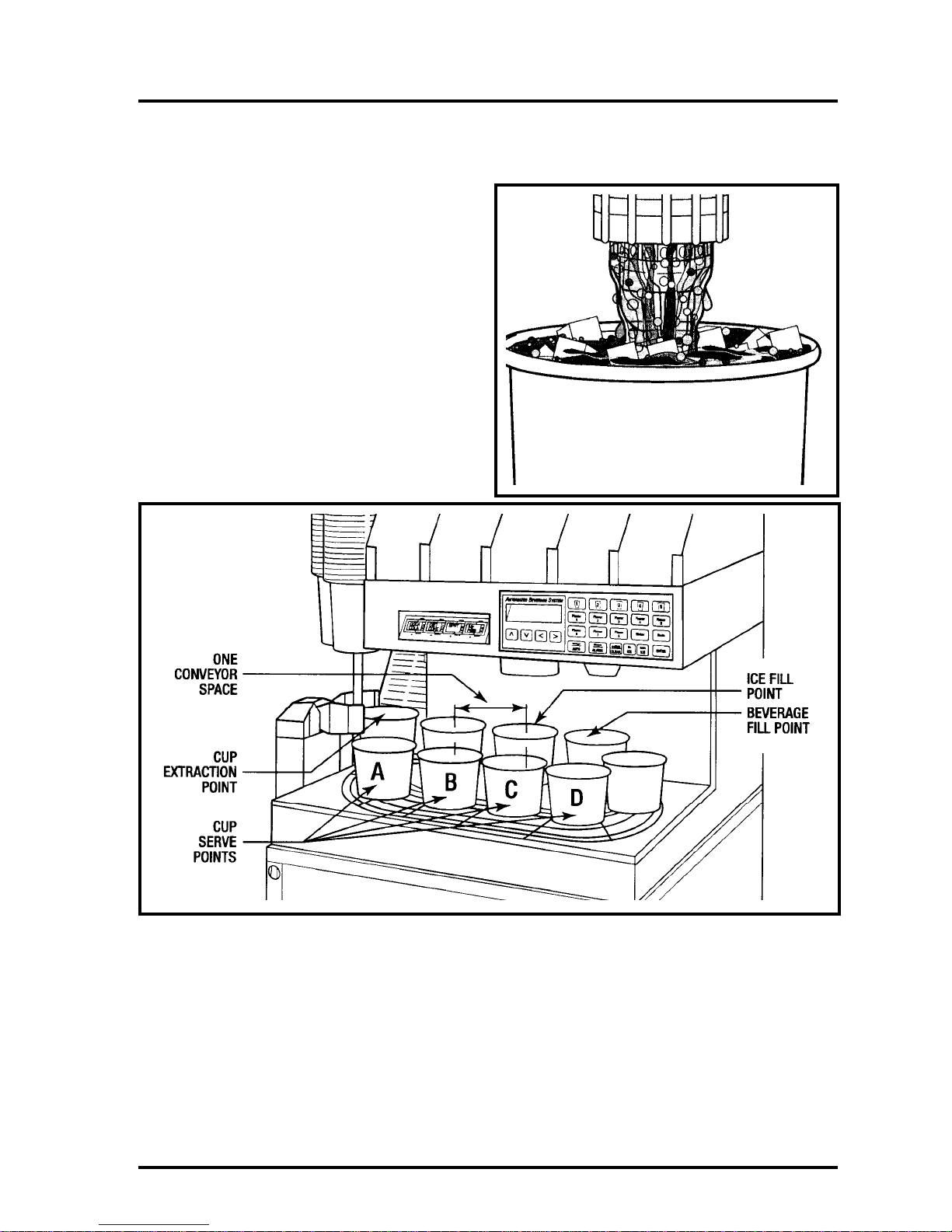

Operational Modes

The A.B.S. has three modes of operation:

• Automatic (Normal Operation)

• Semiautomatic (while in Au to)

•Manual

Automated Beverage System

Fully Automatic Operation

Location Diagram

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

11

Page 12

Automated Beverage System

Automatic Operation

Order Entered On P.O.S.

With the unit in a utomatic mode, the customer

places an order at the Drive-Thru.

Special Ice Drinks

Extra and no ice drinks are entered from the

P.O.S. as a “grill order.” The A.B.S. will automatically produce the drink to the special

order.

P.O.S. Signal To Manager’s Computer

The order is transmitted from the P.O.S. to the

store computer and from there to the A.B.S.

unit.

12

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 13

Automated Beverage System

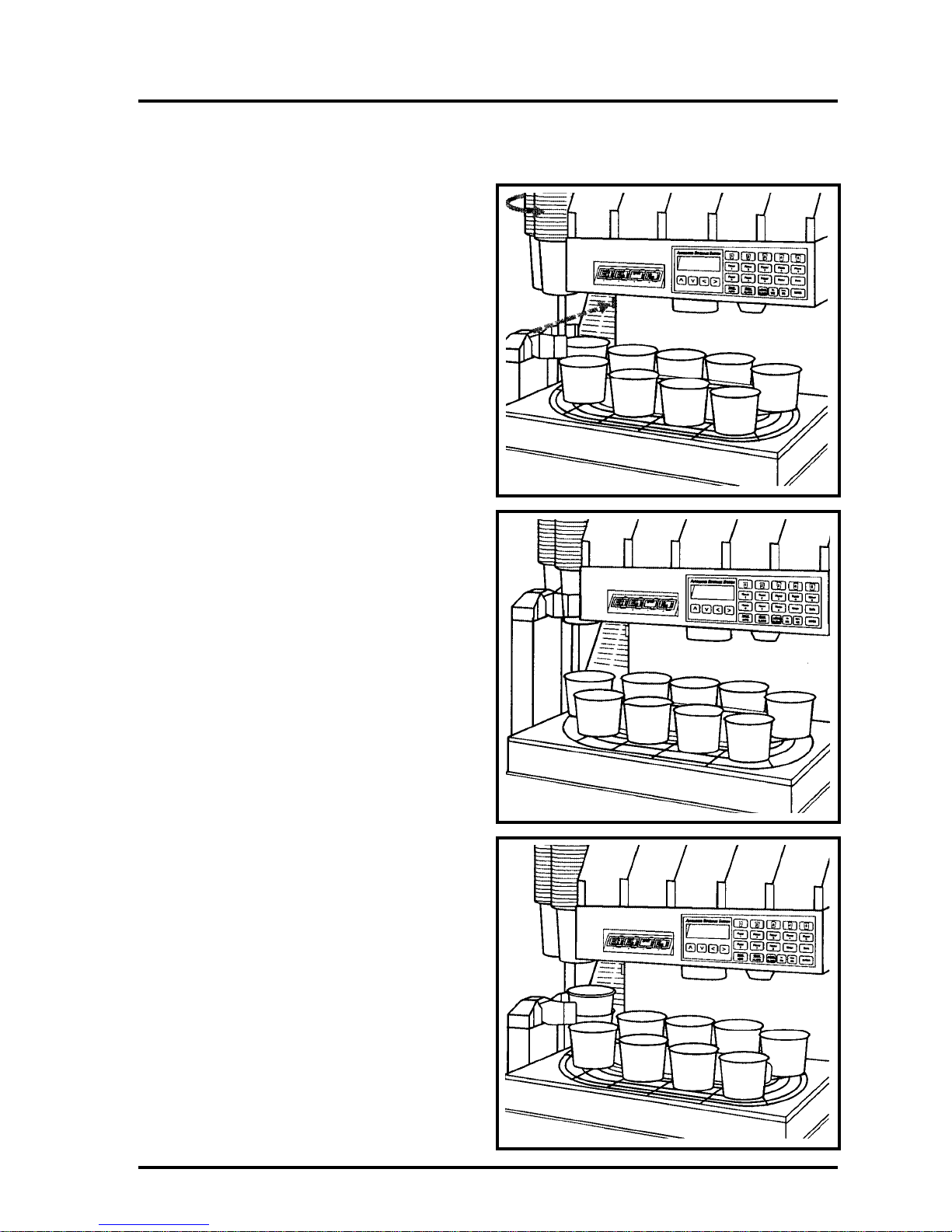

Cup Turret Rotates

After the photo sensor checks for cup too high

condition, the cup turret rotates to move the

proper size cup to the extract position.

Automatic Operation

Cup Grabber Rises & Closes

The cup grabber is lifted by a pneumatic cylinder up to the cup. The travel is sensed by the

full travel sensor. If full height is reached, a

pneumatic cylinder closes the grabber arms

against the cup. A sensor detects if cups are

available.

Grabber Lowers & Opens

The cup grabber lowers, pulling the cup from

the cup tube and then the arms open dropping

the cup into the conveyor.

If the grabber should slide off a cup, it would

be detected by the cup sensor.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

13

Page 14

Automated Beverage System

Automatic Operation

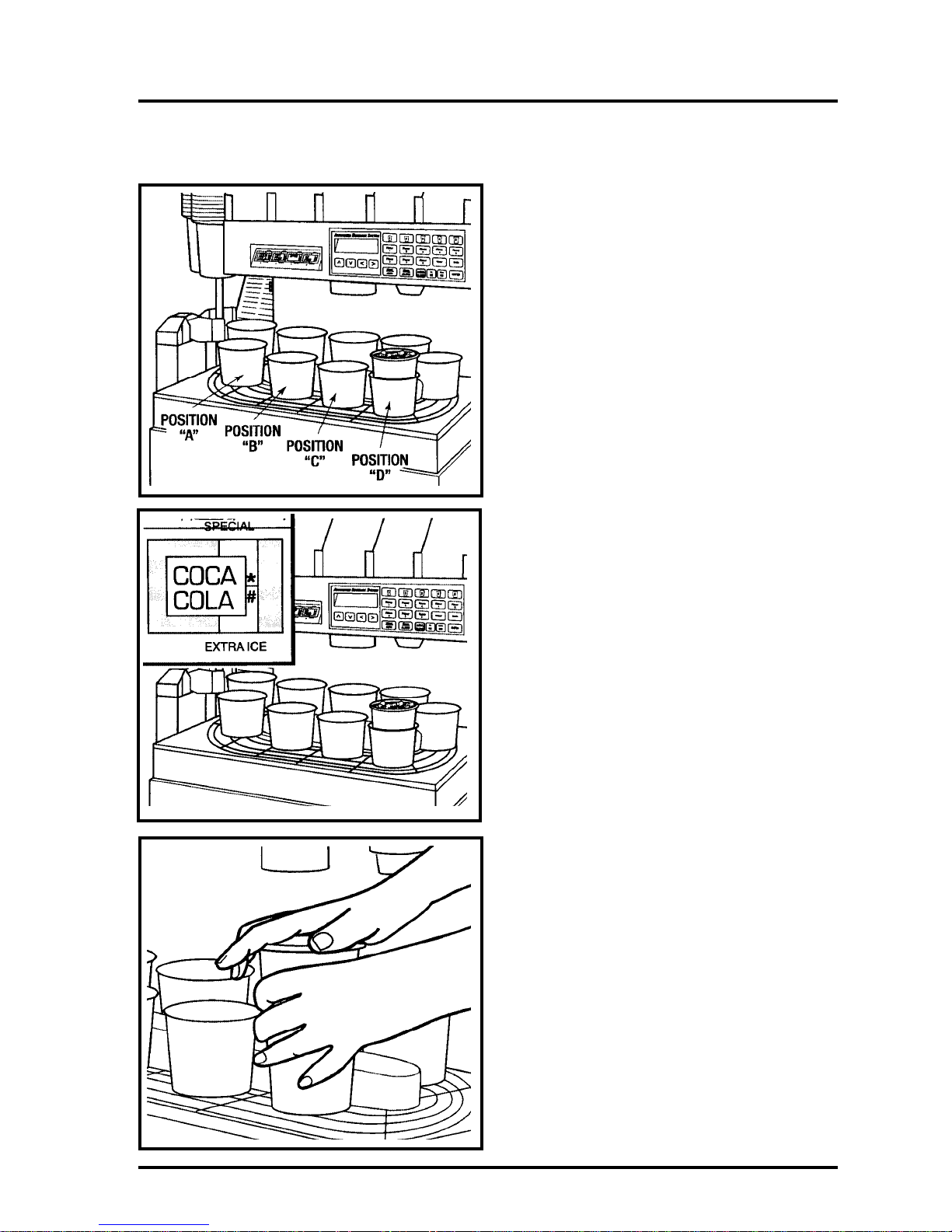

Conveyor Operates

Sensors check for cup too high and a cup in

position “A.” If these are clear, the conveyor

rotates clockwise to move the cup to the ice

chute.

This is based on only one drink being ordered.

If a second drink had been ordered, the conveyor would have moved only one position

and the second cup would have been extracted

and dropped into the conveyor. The two cups

would then be moved clockwise until the first

cup reaches the ice fill port.

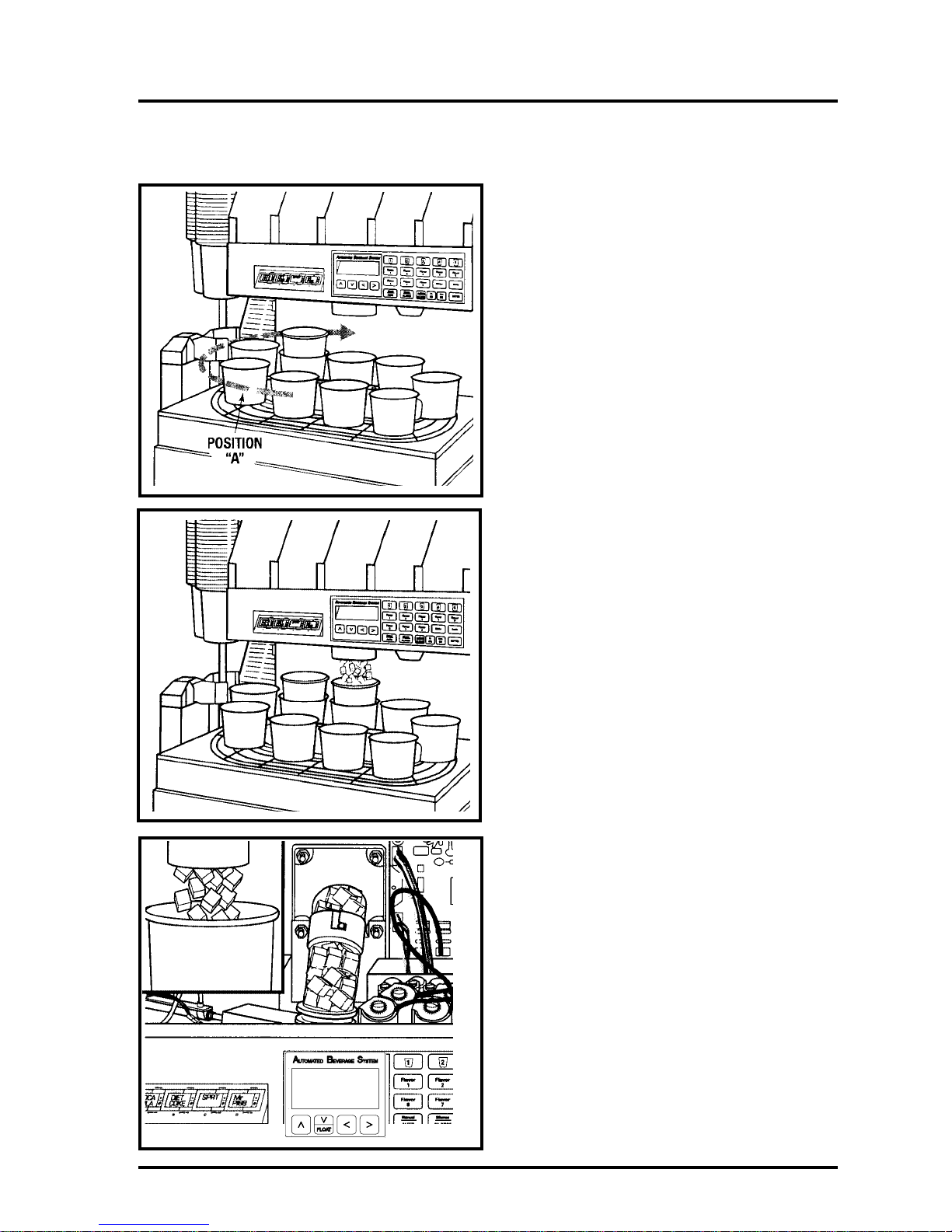

Ice Portion Is Dispensed

The ice gate is opened by a pneumatic cylinder for the time needed to dispense the

selected ice portion. Correct operation is

insured by the ice gate full travel sensor.

14

The agitator continues to operate for the set

refill time to refill the ice chute.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 15

Automated Beverage System

Cup To Dispensing Nozzle

Sensors check for cup too high and a cup in

position A. If these sensors are clear, the conveyor moves the cup to the beverage fill poi nt.

The valve opens to dispense the desired syrup

and water in the desired portions into the cup.

Automatic Operation

Beverage Dispensed

The computer sends the drink portion of the

order to the A.B.S. where the information is

interpreted and the drink is dispensed.

If the drink requires a top-off, the initial portion will be dispensed. After a delay, the balance of the drink will be dispensed.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

15

Page 16

Automated Beverage System

Automatic Operation

Cup Is Moved To Cup Serve Point

Sensors check for cup too high and a cup in

position “A.” If these sensors are clear, the

conveyor moves the cup to cup serve position

“D.”

The display will indicate the flavor of the beverage at cup serve position “D.”

Crew Member Serv es Drink

A crew member caps the drink while still on

the conveyor and serves it with the remainder

of the order.

16

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 17

Automated Beverage System

Semiautomatic Operation (Unit in Automatic)

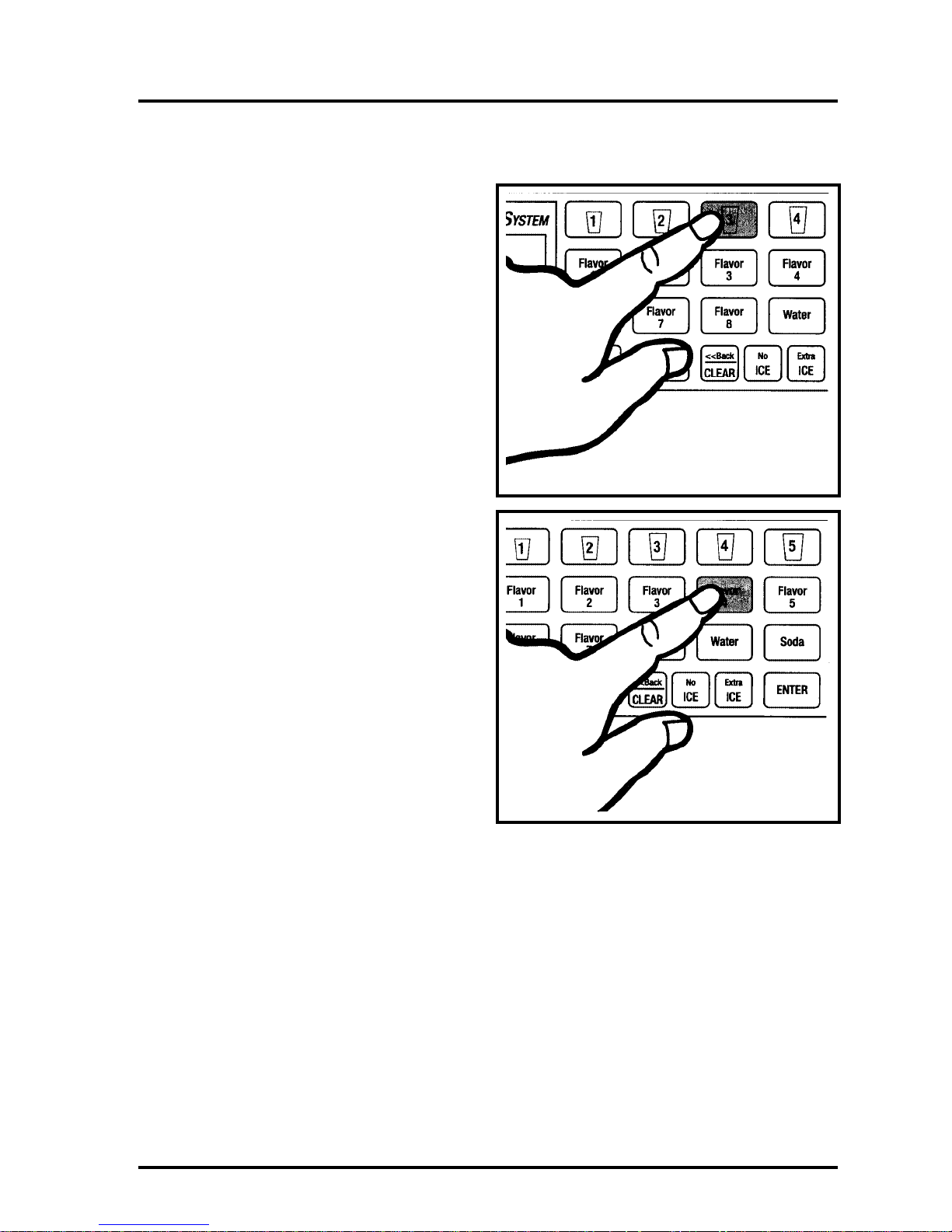

Press Cup Size

While in automatic mode, to dispense a drink

in the semi-automatically, press the desired

cup size button.

Press Flavor

Press the desired flavor button.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

17

Page 18

Automated Beverage System

Semiautomatic Operation (Unit in Automatic)

Press Special Ice Requirement If

Requested

If extra ice is desired, press the EXTRA ICE

button. If no ice is required, press the NO ICE

button.

If normal ice is desired, no button is pressed.

When Correct, Press Enter

Sequence of pressing the cup size, flavor, and

special ice buttons is not important. At any

time, pressing any button will change the

selection of the drink to be dispensed. When

the correct order is displayed, press ENTER

and the drink will be dispensed.

Any drink entered in this manner will display

an illuminated asterisk in the SPECIAL section of the Drink Position Display identifying

the semiautomatic drink selected at the A.B .S.

panel.

18

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 19

Automated Beverage System

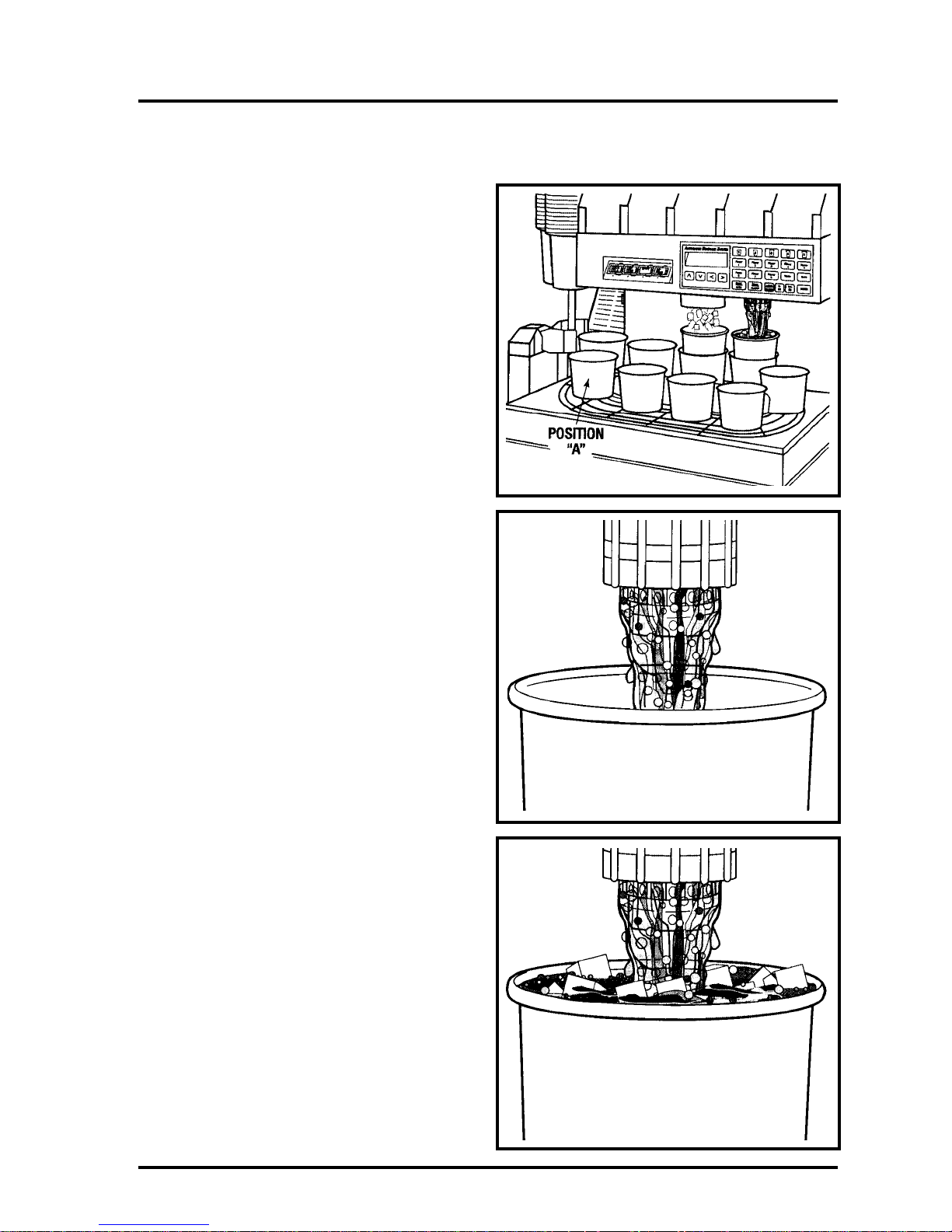

Enter Manual Mode

Enter the manual mode by pressing the Manual/AUTO button.

Manual Operation

Remove The Conveyor

To dispense a drink in the manual mode,

remove the conveyor. This is done by removing the thumb screws holding it in place and

lifting the conveyor up.

Never Remove Cups From Cup Turret

Assembly

Manually pulling cups from the cup tubes can

permanently damage the retainers.

Stock cup sleeves near the unit when in manual mode.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

19

Page 20

Automated Beverage System

Manual Operation

Dispense Ice

Hold the cup under the ic e chute. Dispe nse ice

by pressing the EXTRA ICE button.

Ice Not Dispensed

If there is an issue with CO2, ice may not dispense. In this case, locate a supply of ice near

the unit for manually filling the cups.

Dispense Beverage

Hold the cup under the nozzle. Press and hold

the desired flavor button to dispense the beverage.

20

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 21

Automated Beverage System

Return The A.B.S. To Normal

Operation

Reinstall the cup conveyor by aligning the

drive pin on the left side of the conveyor

assembly so that the conveyor seats properly.

The conveyor drive pin must engage the drive

socket on the gear box. When installing the

conveyor, it may be necessary to move the

conveyor manually to allow the drive pin to

insert into the drive socket.

Tighten the thumb screws on the cover.

Manual Operation

Clear The P.O.S. Order Buffer

If orders are on the screen, the P.O.S. buffer

must be cleared. To clear the P.O.S. buffer , the

A.B.S. unit must be in the MANUAL mode.

Press the UP arrow to highlight the “XXX

ORDERS”.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

21

Page 22

Automated Beverage System

Manual Operation

A confirmation question will appear. Press

ENTER to clear the entire order buffer or

CLEAR to cancel action.

Return To Automatic Mode

Press the Manual/AUTO button to return to

Automatic mode.

22

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 23

Automated Beverage System

Introduction to the A.B.S. Unit

Major Subsystems

Components of the A.B.S.

• Turret

• Cup Lid Rack

• Ice Dispenser

• Control Panel

• Cup Extractor

• Conveyor

• Beverage Dispenser

• Pre-Chiller (Optional)

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

23

Page 24

Automated Beverage System

A.B.S. Unit Major Subsystems

Control Touch Panel

ARROW (CURSOR) DOWN/FLOAT OPTION-Used to move the selection to the down

ARROW (CURSOR) DOWN/FLOAT OPTION-Used to move the selection to the down when in manual mode, used to

when in manual mode, used to add float to ordered drink in Automatic mode.

add float to ordered drink in Automatic mode.

24

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 25

Automated Beverage System

Touch Panel Description

Each button on the Touch Panel is described

in detail in the Touch Panel Diagram on page

24.

Whenever any button is pressed, there is an

audible Beep. If the button is incorrect and

cannot function, there will be a triple Beep

indicating an error.

Display, Touch Panel

A.B.S. Unit Major Subsystems –

Control Touch Panel

The display that is visible through the window

in the Touch Panel is the message center for

the A.B.S. The display examples shown is

only one of the many messages that may be

displayed.

This display shows the status, guides you

through programming, tells you what errors

have occurred, the number of cycles on a

component and other messages.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

25

Page 26

Automated Beverage System

A.B.S. Unit Major Subsystems

Control Panel, Drink Position

Drink Position Display

The Drink Position Display corresponds to

the four drink pickup positions on the conveyor. As a drink moves to position “D” on

the conveyor, the details of the drink are displayed.

26

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 27

Automated Beverage System

A drink that is dispensed from the touch panel

and not from the P.O.S. will be indicated as a

SPECIAL. This will be indicated by the *

being illuminated in the display.

A.B.S. Unit Major Subsystems –

Control Panel, Drink Position

If the drink has the special ice requirements

If the drink has the special ice requirements

EXTRA ICE, the # will be illuminated in the

EXTRA ICE, the # will be illuminated in the

display.

display.

If the drink is a FLOAT drink, F will be illuminated in the display.

ROOT

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

BEER

FL

F

27

Page 28

Automated Beverage System

A.B.S. Unit Major Subsystems

Operation —

Turret, Cup Extractor, & Conveyor

Cup T urret Components – Location Diagram

Cup Turret Components – Location Diagram

Cup Conveyor Components – Location Diagram

Cup Conveyor Components –Location Diagram

28

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 29

Automated Beverage System

A.B.S. unit Major Subsystems Operati on —

Cup Tubes Configuration

The cup tube configuration is 1 – Small; 1 –

Child; 1 – Large; 1 – Medium; 1- XL.

Turret

The cup tube configuration for Australia is 1 –

Small; 2 – Large; 2 – Medium.

The hole mounting pattern is such that the cup

tubes will only mount in one location.

Rotating The Cup Turret

While in the manual mode – press the Cup

Size button corresponding to the cup tube you

wish to install. The turret will rotate until the

correct turret face is forward, allowing easy

mounting of the cup tube. In the standard configuration, the 5th cup size is not being used.

If there are two medium cup tubes, when button #3 is pressed once the first medium turret

cup face is forward, the second time it is

pressed the second medium turret face will

rotate forward.

MD

Other Cup Configuration

The unit can be configured with four or five

cup sizes. If only four cup sizes are needed,

usually two medium cup tubes are used.

The second medium cup tube can be omitted

and an extra large cup substituted. The extra

large cup tube mounting location can be identified by pressing cup size button #5.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

29

Page 30

Automated Beverage System

A.B.S. unit Major Subsystems Operation —

Cup Extractor

Cup Grabber Assembly

The cup grabber consists of two cup grabber

arms actuated by a pneumatic cylinder, an elevating mechanism operated by a pneumatic

cylinder, two guide rods, a Travel sensor and

a Cup Empty sensor. The Cup Too High Sensor is located on the grabber assembly.

Cup Grabber Cycle

When the correct cup is aligned at the cup

grabber, a pneumatic cylinder lifts the cup

grabber to the cup. A sensor detects the full

travel of the grabber during the lift motion. A

signal is sent that the grabber is in position

and then a pneumatic cylinder closes the grabber arms. If the arms close fully indicating

“No Cup,” the control system will attempt to

pull a cup from a second tube of same size cup

if present. If no cup is available a “SOLD

OUT” message will be displayed. If a cup is

available the cup grabber will be lowered and

the cup pulled from the cup tube.

If the grabber arms close on a cup but during

the lowering of the cup it falls incorrectly, a

“CUP JAM” message will be displayed.

When the grabber successfully pulls a cup

from the cup tube and is completely lowered,

the grabber arms will open, dropping the cup

into the conveyor. The conveyor will then

advance and continue to make drinks.

30

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 31

Automated Beverage System

A.B.S. unit Major Subsystems Operati on —

Conveyor

The conveyor contains nine equally spaced

cup holders. Each cup holder contains a

ceramic magnet. A sensor located in the drip

pan at the cup grabber detects the cup holders

and thereby controls the movement of the

conveyor and the position of the cup holders.

Note: The conveyor will not operate if there is

a cup or any obstruction in the cup holder at

Cup Serve

Point “A.”

Conveyor

Cup Rest

The cup rest must be installed with the oval

rails up and with the “Cup Positioning

Bracket” must be at the rear of the drip tray.

Drive Seal

Check to see drive seal is installed properly.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

31

Page 32

Automated Beverage System

A.B.S. unit Major Subsystems Operation —

Conveyor

Cup Positioning Bracket

The cup positioning bracket, located on the

cup rest, contains a spring that is positioned so

it touches the cup in the cup holder as the cup

moves past the spring. This moves the cup to

the rear (based on the direction of movement)

of the cup holder. This insures that all cups

will be in the same position for dispensing

regardless of its size.

Cup In Position “A”

Part of the conveyor assembly is the cup in

position “A” sensor. This senses if a cup is in

the last conveyor position to prevent full cups

from traveling into the grabber mechanism.

Reinstall Conveyor

Align the drive pin on the left side of the conveyor assembly so that the conveyor seats

properly . The conveyor drive pin must engage

the drive socket on the gear box. When installing the conveyor, it m ay be necessary to move

the conveyor manually to allow the drive pin

to insert into the drive socket.

Tighten the thumb screws on the cover.

32

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 33

Automated Beverage System

A.B.S. unit Major Subsystems Operation —

Ice Gate Description

The ice gate is a pneumatically operated

“gate” that is controlled by the Beverage

Interface Board. The time the gate is open is

very precise and determines the portion of ice

dispensed. The gate opens and closes under

pneumatic pressure. The gas is controlled by

solenoids.

Ice Dispenser

Ice Dispensing Cycle

The ice gate opens; the agitator turns to refill

the ice chute and to maintain ice on the coldplate; the ice gate closes; the agitator continues to fill the ice chute fr the set period of

time.

Low Ice – Refill Soon

The LOW ICE – REFILL SOON condition is

sensed by the A.B.S. through a temperature

sensor located in the ice bin.

The LOW ICE – REFILL SOON alarm

sounds when the bin has about 40 drinks left

in its capacity . It wil l resound with every tenth

drink made, until refilled.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

33

Page 34

Automated Beverage System

A.B.S. unit Major Subsystems Operation —

Ice Dispenser

Auto-Agitate

Ice from the bin is used for the coldplate.

If the A.B.S. unit is idle for a period (pro-

grammed during setup), the agitator will agitate for a preset period to maintain ice on the

coldplate.

The ice bin has a sensor that detects a low ice

condition and displays a warning.

Ice Chute

The ice chute directs the ice into the cup. It

can be removed for cleaning or replacement.

Access to the ice chute is obtained by removing the cup lid rack.

34

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 35

Automated Beverage System

A.B.S. Unit Major Subsystems Operation —

Ice Chute Removal & Replac eme nt

1.With the unit in manual mode, remove the

cup lid rack.

Ice Dispenser

2.WARNING: Shut off the manual ice gate

switch.

3.Slide the gate out of the chute.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

35

Page 36

Automated Beverage System

A.B.S. Unit Major Subsystems Operation —

Ice Dispenser

4.Pull the ice chute release mechanism out

and turn the chute clockwise 1”.

5. Holding the ice chute release mechanism,

rotate the ice chute clockwise and pull down.

Drop the ice chute down through the ice gate

frame and replace it. To reinstall ice chute,

follow procedures in reverse order.

6. Return the A.B.S. unit to normal operation.

36

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 37

Automated Beverage System

A.B.S. Unit Major Subsystems Operation —

Valve Description

The dispensing valve is located behind the

touch panel and is made up of five blocks,

each containing two solenoids, two flow controls, and two shutoffs. The blocks are permanently manifolded together to supply a single

outlet nozzle. (The top view is depicted.)

Beverage Dispenser

Beverage Dispensing

The valve opens to dispense the desired syrup

and water in the desired portions into the cup.

If foaming is an issue, the service agent can

program a top-off. The initial portion will be

dispensed. After a delay, the balance of the

drink will be dispensed.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

37

Page 38

Automated Beverage System

A.B.S. Unit Major Subsystems Operation —

Pre-Chiller

Optional Pre-Chiller

An optional pre-chiller must be installed if

carbon-ated water and plain water are not

chilled in a backroom package.

38

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 39

Automated Beverage System

Fill Ice Bin

Remove the ice bin lid and fill with ice cubes

to the top of the bin. Do not overfill. The bin

cover must be able to rest securely on the top

of the bin.

Daliy Start-Up Procedures —

Fill Ice Bin

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

39

Page 40

Automated Beverage System

Daliy Start-Up Procedures —

Filling Cup Tubes

Rotating The Cup Turret

Place the unit in the manual mode – press the

Cup Size button corresponding to the cup tube

you wish to fill. The turret will rotate until the

correct turret face is forward, allowing easy

filling of the cup tube.

Filling Cup Tubes

Remove top cup tube cover and hold under

the cup tube to catch cups and prevent them

from falling through.

Return top cup tube cover.

Do not over fill the cup tubes. Damage may

result to the cup tubes or may result in cup

jams.

When all tubes have been filled, return to

automatic mode by pressing the Manual/Auto

button.

40

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 41

Automated Beverage System

Daily Cleaning/ Sani ti zing Tasks

At close, the following tasks should be performed:

• Put in manual mode (do not shut off main

power).

• Remove and clean the conveyor, and cup rest.

• Clean drip tray and exterior surfaces.

• Pou r warm (NOT HOT) water do wn the drip

tray drain.

• Reinstall cup rest and conveyor.

• Remove and clean the valve nozzle and diffuser.

• Wipe down and clean the A.B.S. unit with sanitizing solution.

Closing/Sanitation Procedures

Remove Conveyor & Cup Rest

Remove the conveyor by removing the 3

thumb screws holding it in place. Remove the

cup rest by lifting it up and removing it. W ash

the conveyor, conveyor cover, and the cup

rest in warm soapy water then rinse with clean

potable water.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

41

Page 42

Automated Beverage System

Closing/Sanitation Procedures

Clean Drip Tray & Exterior Surfaces

Clean drip tray and all exterior surfaces with

warm soapy solution and rinse with clean

potable water.

Pour warm (NOT HOT) water down the drip

tray drain to flush drain line.

Inspect drive seal after cleaning to check for

proper installation.

Reinstall Cup Rest

The cup rest must be installed with the oval

rails up and the “Cup Positioning Bracket”

must be at the rear of the drip tray.

The cup positioning bracket, located on the

cup rest, contains a spring that is positioned so

it touches the cup in the cup holder as the cup

moves past the spring. This moves the cup to

the rear (based on the direction of movement)

of the cup holder. This insures that all cups

will be in the same position regardless of its

size.

Reinstall Conveyor

Align the drive pin on the left side of the conveyor assembly so that the conveyor seats

properly . The conveyor drive pin must engage

the drive socket on the gear box. When installing the conveyor, it m ay be necessary to move

the conveyor manually to allow the drive pin

to insert into the drive socket.

42

Tighten the thumb screws on the cover.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 43

Automated Beverage System

Clean Nozzle & Diffuser

• Remove the nozzle by twisting clockwise. Then

pull the diffuser straight down. Separate the diffuser. Clean the beverage nozzle and diffuser

using nozzle brush and rinse with carbonated

water.

• Reinstall diffuser nozzle

Closing/Sanitation Procedures

Wipe Down A.B.S. Unit

At the end of closing shift, the crew should

wipe down the exterior of the unit with a sanitizing solution.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

43

Page 44

Automated Beverage System

Monthly Cleaning/Sa nitation Procedures

Cleaning Conveyor Thru-Beam (Last Position) Sensor

The thru-beam (Position “A”) sensor requires cleaning. If not clean, the sensor may work

intermittently.

With the conveyor off, wet a clean napkin with carb water and carefully wipe the lens of the

thru-beam sensor emitter and the receiver.

(Note: Don’t use cleaning towel on sensor, it may leave film on sensor lens.)

Monthly Cleaning/Sanitation of Ice Bin

WARNING: DO NOT USE SHARP OBJECTS, METAL DEVICES OR ABRASIVES ON THE ICE

HOPPER, TOP COVER, ICE CHUTE OR AGITATOR DISC AS IRREPARABLE DAMAGE MAY

RESULT. DO NOT USE SOLVENT OR OTHER CLEANING AGENTS AS THEY MAY ATTACK

THE PLASTIC MATERIAL.

Soapy Solution:

Sanitizing Solution:

water. Preparing the sanitizing solution at this ratio will create a solution of 200 PPM chlorine.

1. Turn ABS unit power switch OFF. The switch is located on the lower left-hand side of the ABS unit

front panel.

2. Remove top cover and set aside.

3. Remove all ice from the hopper and discard. If necessary, pour clean, potable water slowly into the

hopper to assist in melting the ice.

4. After all the ice is removed inspect the cold plate areas and drains as follows:

A. Remove the splash panel and the plastic cold plate access cover.

Use a mixture of mild detergent and warm (100oF) potable water.

Use 1/2 ounce of non-s cented household bleach in one gallon of potable

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

44

Page 45

Automated Beverage System

Monthly Cleaning/Sanitation Procedures

B. Locate and remove any debris from the drain trough and cold plate. Make sure the drain holes

are not clogged.

C. Reinstall the cold plate access cover and splash panel.

5. Remove the agitator retainer and the ice agitator assembly.

6. Using a long handled nylon bristle brush, clean the interior of the hopper, top cover, agitator,

agitator cover and cold plate with warm, soapy solution. The cold plate is to be cleaned by

reaching through the ice openi ng into the hop per botto m with the long handle brush. Be certai n to

clean the entire surface area of the cold plate including all the corners. Thoroughly rinse the

hopper, top cover, agitator, agitat or cover and the cold plate with clean potable water.Automated

Beverage System

7. Using a long handle nylo n bristle brush, clean the interior of the ice chute with the warm, soapy

solution. Access to the to the ice chute can be gained via the inter ior of the hopper and the ice

chute outlet on the front of the ABS unit. Thoroughly rinse the ice chute with clean, potable water.

8. Reinstall the agitator assembly.

9. Using a mechanical spray bottle filled with sanitizi ng solution, spray the entire interi or of the ice

bin, ice chute and ice agitator assembly. Allow to air dry.

10. Turn the ABS unit power switch ON.

11. Return the ABS unit to AUTO mode.

45

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 46

Automated Beverage System

Quarterly Cleaning/Sanitation Procedures

UARTERLY SANITATION OF POST-MIX SYRUP SYSTEM

Q

IMPORTANT: Only qualified Service Personnel should perform the sanitizing procedure on

the post-mix syrup systems.

The post-mix syrup systems should be sanitized every 90 days using a non-scented household

liquid bleach containing a 5.25% sodium hypochlorite concentration. Proceed as follows to

sanitize the post-mix syrup systems.

1. Disconnect syrup supplies from the syrup systems.

2. Rinse the quick disconnects (syrup tank systems) or bag-in-box connectors (syrup bag-in-box

systems) in warm, potable water.

STEP 1: WASH THE SYRUP SYSTEMS

WARNING: To avoid possible personal injury or property damage, do not attempt

to remove the syrup tank cover until CO

pressure has been released from the

2

3. Using a clean syrup tank (syrup tank system) or a five gallon container (bag-in-box system),

o

prepare a full tank or c ontainer of liquid dishwash er detergent by using 70

o

C) potable water and 5 oz.(15 ml) of liquid dish washer detergent to one gallon of potable

(38

water.Stir detergent solution to thoroughly mix the solution.

4. Syrup Tank Systems

A. Observe and n ote CO

regulator to 60 to 80 PS I. Pr essur ize t he syr up tank , that conta ins the deterg ent s olutio n

CO

2

to 60 to 80 PSI.

B. Connect the pressurized (60 to 80 PSI) detergent solution tank into one of the syrup systems.

5. Bag-In- Box Syrup Systems

A. Install the bag valves, cut from empty bag-in-box syrup containers, on the end of syrup

container’s syrup outlet tube connectors.

B. Place syrup outlet tube, with bag valve on end, into container of detergent solution.

.

pressure setting on t he syrup tan k’s CO2 regulator, then re-adjust the

2

.

F (21o C) to 100o F

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

46

Page 47

Automated Beverage System

Quarterly Cleaning/Sanitation Procedures

QUARTERLY CLEANING/SANITATION PROCEDURES

6. Flush the syrup system and dispensing valve as follows:

A. Place a waste container under the dispensing valve.

B. Place the ABS unit in the TEST/VALVE TEST mode and press each flavor button until all th e

syrup is expelled and water fills the tubing.

C. Continue to ac tiva t e each di sp ensi n g va lv e i n cy cle s (ON for 15 seco nd s, OFF, then ON for 15

seconds). Repeat ON and OFF cycles for 15 cycles.

7. Connect the detergent solution to any rema ining syrup systems a nd flush syrup out of the syru p

systems as instructed in Step 6 above.

8. Remove the detergent solution source from the syrup system.

STEP 2: FLUSH THE SYRUP SYSTEMS

9. Syrup Tank Systems.

A. Connect a syrup tank fill ed with potable water press urized at 60 to 80 PSI , into one of the

syrup systems.

10. Bag-In-Box Syrup System.

A. Fill a five gallon container with potable water.

B. Place syrup outlet tube, with bag valve on end, into container of potable water.

11. Flush the detergent solution out of the syrup system and dispensing valve as follows:

A. Place a waste container under the dispensing valve.

B. Place the ABS unit in the TEST/VALVE TEST mode and press each flavor button until all th e

detergent solution is expel led and water fills the tubin g. Activate the dispe nsing valve for one

minute to purge all detergent solution and flush out the syrup system.

C. Continue to ac tiva t e each di sp ensi n g va lv e i n cy cle s (ON for 15 seco nd s, OFF, then ON for 15

seconds). Repeat ON and OFF cycles for 15 cycles.

47

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 48

Automated Beverage System

Quarterly Cleaning/Sanitation Procedures

12. Connect the potable water source to any remaining syrup systems and flush the detergent solution

out of the syrup systems as instructed in Step 11 above.Automated Beverage System

13. Remove the potable water source from the syrup system.

STEP 3: SANITIZE THE SYRUP SYSTEMS

14. Using a clean syrup tank (syrup tank system) or a five gallon container (bag-in-box system),

o

prepare sanitizing solution using 70

non-scented househ old liquid ble ach that cont ains a 5.25% sod ium hypoch lorite concen tration to

one gallon of potabl e w ater. This mixture

solution to thoroughly mix .

F (21o C) to 100o F (38o C) potable water and 5 oz.(15 ml) of

must not

exceed 200 PPM of ch lori ne. Sti r the sa ni tiz in g

15. Syrup Tank Systems

A. Connect the pressurized (60 to 80 PSI) sanitized solution tank into one of the syrup systems

16. Bag-In-Box Syrup System

A. Place all syrup outlet tubes, with bag valves on, into the container of sanitizing solution.

17. Sanitize the syrup system and dispensing valve as follows:

A. Place a waste container under the dispensing valve.

B. Place the ABS unit in the TEST/VALVE TEST mode and press each flavor button until all th e

water is expelled and s anitize r fil ls the tubing. Acti vate the disp ensin g val ve for one mi nute t o

purge all water out of and install sanitizing solution into the syrup system and dispensing

valve.

C. Continue to activate each dispensing valve in cycles (ON for 15 seconds, OFF, then ON for 15

seconds). Repeat ON and OFF cycles for 15 cycles.

18. Repeat Steps 15, 16 and 17 to flush water out of and in stall sanitizing soluti on in the remaining

syrup systems and dispensing valve.

19. Remove sanitizing solution source from the system.

.

.

20. Allo w the sanitizin g solution to remain in t he syrup syste ms for not less than TEN MINUTES and

no more than FIFTEEN MINUTES (MAX) contact time.

STEP 4: WATER FLUSH THE SYRUP SYSTEMS

WARNING: Flush sanitizing solution from the syrup systems as instructed. Residual

sanitizing solution left in the syrup systems could create a health hazard.

21. Fill the sy rup tank (syr up tank syst em) or a five gal lon conta iner (bag- in-box syst em) with pot able

water.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

48

Page 49

Automated Beverage System

Quarterly Cleaning/Sanitation Procedures

22. Syrup Tank Systems.

A. Con nec t a syr up ta nk filled wi th po tabl e wat er and pr ess ur ized at 60 to 80 P SI, into one of th e

syrup systems.

23. Bag-In-Box Syrup System

A. Place all syrup outlet tubes, with bag valves on, into a container of potable water.

24. Flush the sanitizing solution from the syrup system and the dispensing valve as follows:

A. Place a waste container under dispensing valve.

B. Place the ABS unit in the TEST/VALVE TEST mode and press each flavor button until all th e

sanitizer is expel led a nd wate r fil ls the tubing. Activ ate the disp ensin g valve for one mi nute t o

purge all the sanitizing solution out of the syrup system and the dispensing valve.

C. Continue to ac tiva t e each di sp ensi n g va lv e i n cy cle s (ON for 15 seco nd s, OFF, then ON for 15

seconds). Repeat ON and OFF cycles for 15 cycles.

25. Repeat Steps 22, 23 and 24 to flush saniti zing solution out of the re maining syrup system s and

dispensing valve.

26. Remove the potable water source from the syrup system.

.

STEP 5: PURGE THE WATER OUT OF THE SYRUP SYSTEMS TO RESTORE UNIT OPERATION

27. Syrup Tank Systems.

A. Noting syrup tanks CO

CO

regulator to the observed pressure setting.

2

B. Connect the tanks containing the syrup into the syrup systems.

28. Bag-In-Box Syrup System

A. Remove all bag valves from syrup outlet tubes.

B. Connect bag-in-box syrup containers into the syrup systems.

29. Place a w aste conta iner under the dispe nsing va lve. dispen se from al l dispe nsing va lve to permi t

the syrup to purge all the potable water from the syrup systems and the dispensing valves.

Continue to dispe nse from th e dispe nsing val ves until only the s yrup is dispensed from th e syrup

systems and valve.

30. Dispose of waste sanitizing solution in a sanitary sewer, not in a storm drain, then thoroughly rinse

the inside and outside of the container that was used for sanitizing solution to remove all sanitizing

solution residue.

regulator pressure setting observed in Step 4 preceding, re-adjust

2

.

49

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 50

Automated Beverage System

Troubleshooting

Important: Only qualified personnel should

service internal components or electrical wiring of the A.B.S. unit.

A.B.S. unit Service

The A.B.S. Unit is serviced by an authourized

Coca-Cola Service Agent.

Call 1-800-241-COKE.

50

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 51

If the A.B.S. unit fails to operate properly,

check to see that there is power to the unit.

Automated Beverage System

Troubleshooting

Check the ice bin for ice.

If the A.B.S. unit does not dispense, check the

Troubleshooting chart on pages 54 - 56.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

51

Page 52

Automated Beverage System

Handling Alarms & Errors — Alarm & Warning Messages

Alarm & Warning Messages

When an alarm occurs, press the Silence/Alarm button to silence the alarm. Read the display

to determine the problem so that the appropriate corrective action can be taken.

LEFT and RIGHT arrow are used to scroll the alarm list and the number of unresolved warnings and alarms are displayed with direction cues to scroll.

Listed below are all of the Alarm and Warning messages that may appear on the display

screen.

Message Explanation Corrective Action

(X) CUP OUT A T ST ATION (Y) The cup tube for size (X) is empty at

station (Y).

CLEAR SYRUP SOLD OUT The clear syrup (Sprite) is sold out

(empty B.I.B.).

Refill the empty cup tube with

the correct cup size and then

press ENTER to continue dispensing.

Connect a new syrup supply and

the A.B.S. unit will continue.

Sensor must be installed and connected to the A.B.S. system for this

warning to occur.

LOW ICE – REFILL SOON Ice level in the ice bin is too low. Refill the ice bin with ice. Press

CLEAR CUP JAM Cup(s) jammed in the conveyor at

the cup extraction position and the

conveyor and turret are unable to

operate.

NO CUP EXTRACTED The gripper did not or could not

extract a cup from the cup tube.

TURRET STALLED Cup(s) jammed in the conveyor at

the cup extraction position and the

conveyor and turret are unable to

operate.

CONVEYOR STALLED Cup(s) jammed in the conveyor at

the cup extraction position and the

conveyor and turret are unable to

operate

AIR OR CO

LOW OR OUT CO2 supply is low or empty or air

2

compressor not operating.

If the ENTER button is pressed

before the syrup supply is

replenished, automatic operation will resume but only the cup

and ice will be dispensed for this

flavor.

ENTER.

Remove all cups from the conveyor cup holders at the Extract

Position before pressing the

ENTER button. Another cup will

be extracted and dispensing will

continue.

Check cup supply at the extract

station and make sure the cups

are not stuck. Make sure the

gripper pads are not damaged.

Remove all cups from the conveyor cup holders at the Extract

Position before pressing the

ENTER button. Another cup will

be extracted and dispensing will

continue.

Remove all cups from the conveyor cup holders at the Extract

Position before pressing the

ENTER button. Another cup will

be extracted and dispensing will

continue.

Change CO2 cylinder pr have

bulk tank refilled. Check cause

not opera t ing and repair.

52

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 53

Automated Beverage System

Troubleshooting –Trouble/Probable Cause Chart

Problem Probable Cause Corrective Action

Blown fuse or cicuit breaker A. Short circuit in wiring

Call for service.

B. Defective agitator motor.

Gate does not open. Agitator does

not turn.

Gate does not open or is sluggi sh.

Agitator turns.

Slushy ice. Water in ice bin. A. Blocked drain.

Beverages do not dispense. A. No 24 volt power to the valve.

Beverages too sweet A. Carbonator not working.

Beverages not sweet enough. A. Empty B.I.B. cont ainer.

Beverages not cold. A. No ice in hopper.

Ice does not dispense from gate

assembly.

A. No power or CO

A. Defective gate cylinder.

B. Excessive pressure against gate

slide.

B. Unit not level.

C. Poor ice quality due to water

quality or icemaker problems.

Improper use of flaked ice.

B. No CO

B. No CO2 pressure in carbonator.

C. Valve ratio requires adjusting.

B. Valve ratio requires adjusting.

B. Drains plugged and water stand-

ing on coldplate

A. Agitator not moving.

B. Defective gate cylinder.

pressure.

2

. Plug in unit.

2

Call for service

Replace CO

Call for service.

Call for service.

Call for service.

Clean ice bin and flush drain

with warm water.

Call for service.

Call for service.

Call for service.

Plug in unit

Replace CO2.

Call for service.

Call for service.

Call for service.

Call for service.

Replace

Call for service.

Fill ice bin.

Clean ice bin and flush drain

with warm water.

Call for service.

Call for service.

Call for service.

.

2

A.B.S. will not enter auto mode. A. Cup jam detected, possibly from

Conveyor will not operate. A. Cup rest upside down.

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

C. CO2 supply disconnected or

depleted.

D. Agitator motor defective or wired

incorrectly.

wrong cup in tube and setting too

low.

B. Cup jam detected, possibly from

wrong cup in tube and setting too

low.

C. Convey or assembly not properly

installed.

Replace CO2.

Call for service.

Clear cup jam.

Check cup size.

Reset.

Call for service.

Call for service.

Remove cup.

Refill with correct size cups.

Reset.

Reinstall conveyor.

53

Page 54

Automated Beverage System

Troubleshooting – Trouble/Probable Cause Chart

Trouble Probable Cause Corrective Action

Not enough ice in the cup. A. Ice bin empty.

Fill ice bin.

B. Defective gate cylinder.

C. CO2 supply disconnected or

depleted.

D. Agitator motor defective or wired

incorrectly.

Ice will not dispense. A. Ice bin empty.

B. Defective gate cylinder.

C. CO2 supply disconnected or

depleted.

D. Agitator motor defective or wired

incorrectly.

Drinks too foamy. A. Carobonator pressure too high.

Normal operating rang e should be

80 - 100 P.S.I.

Won’t pour drinks. A. Cup tubes empty. Refill cup tubes with correct

Call for service.

Reconnect CO2.

Replace CO2 cylinder.

Call for refill (bulk)

Call for service

Call for service.

Fill ice bin.

Call for service.

Reconnect CO2.

Replace CO2 cylinder.

Call for refill (bulk)

Call for service

Call for service.

Call for service.

cups.

54

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Page 55

Automated Beverage System

Wiring Diagram

WIRING DIAGRAM 115V

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

WIRING DIAGRAM 230V

55

Page 56

Automated Beverage System

Pneumatic Schematic

56

© 1999 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Loading...

Loading...