Page 1

INSTALLATION

AND

MAINTENANCE

TROUBLESHOOTING

Content:

1. Precautions before Performing Inspection or Repair

2. Conrmation

3. Flashing LED of Indoor/Outdoor Unit and Primary Judgement

4. How to Check Simply the Main Part

5. Troubleshooting for Normal Malfunction

Page 2

1. Troubleshooting

1.1 Precautions before Performing Inspection or Repair

Be cautious during installation and maintenance. Do operation following the regulations to avoid electric shock and casualty or even death

due to drop from high attitude.

* Static maintenance is the maintenance during de-energization of the air conditioner.

For static maintenance, make sure that the unit is de-energized and the plug is disconnected.

*dynamic maintenance is the maintenance during energization of the unit.

Before dynamic maintenance, check the electricity and ensure that there is ground wire on the site. Check if there is electricity on the housing and connection copper pipe of the air conditioner with voltage tester. After ensure insulation place and the safety, the maintenance can

be performed.

Take sufcient care to avoid directly touching any of the circuit parts without rst turning off the power.

At times such as when the circuit board is to be replaced, place the circuit board assembly in a vertical position.

Normally,diagnose troubles according to the trouble diagnosis procedure as described below.(Refer to the check points in servicing written

on the wiring diagrams attached to the indoor/outdoor units.)

No. Troubleshooting procedure

1 Conrmation

2 Judgement by Flashing LED of Indoor/Outdoor Unit

3 How to Check Simply the Main Part

NOTE:

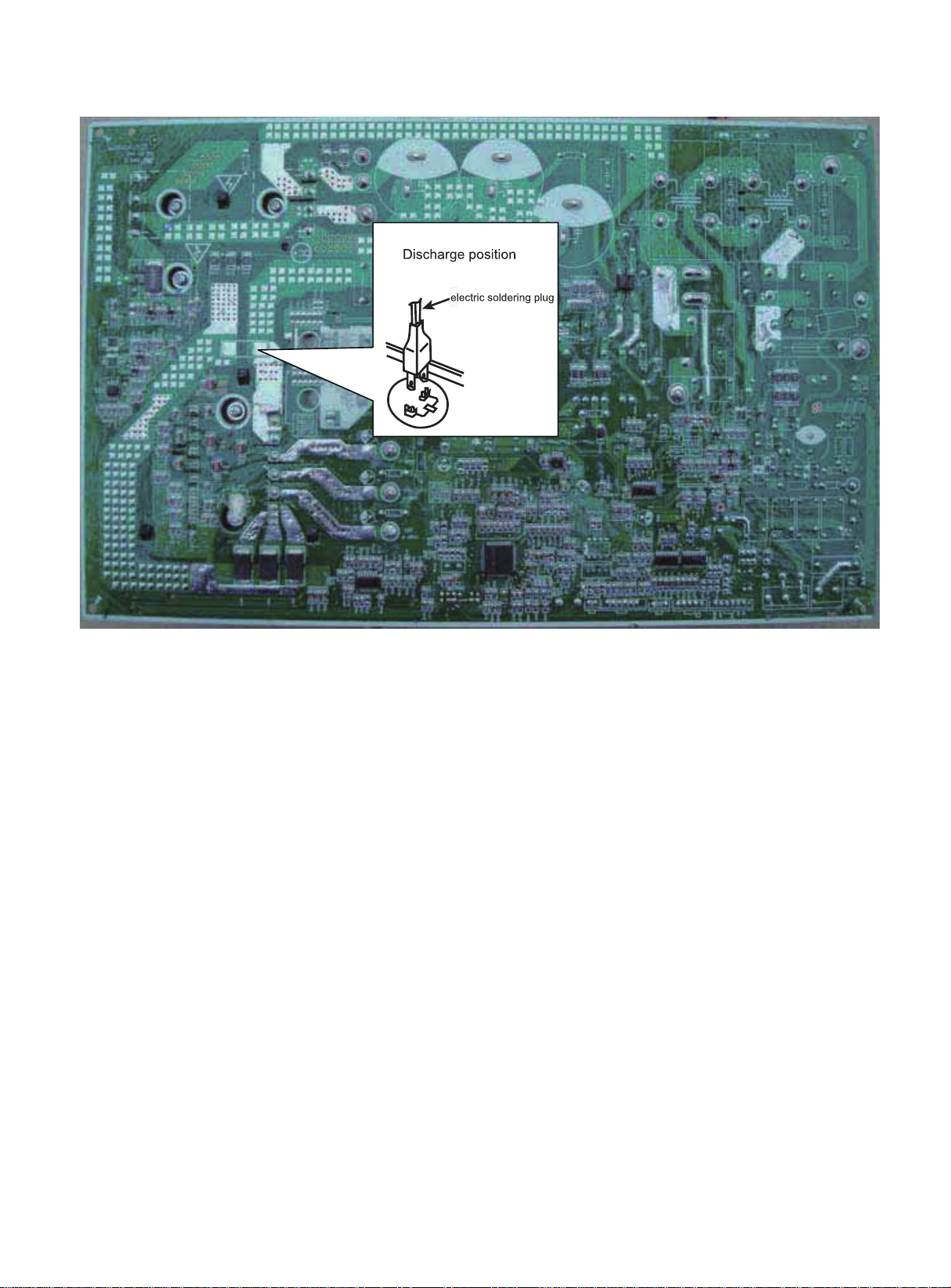

A large-capacity electrolytic capacitor is used in the outdoor unit controller(inverter).Therefore,if the power supply is turned

off,charge(charging voltage DC280V to 380V)remains and discharging takes a lot of time. After turning off the power source,if touching the

charging section before discharging, an electrical shock may be caused. Discharge the electrolytic capacitor completely by using soldering

iron,etc.

Discharging method

(1)remove the inverter cover(Outoor Unit)

(2)As shown below,connect the discharge rescharge resistance(approx.100Ω,20W) or plug of the soldering iron to voltage between + -

terminals of the electrolytic capacitor (test 3*D* and *E* point) on PC Board for 30s ,and then perform discharging

2

Installation and Maintenance

Page 3

2. Conrmation

(1)Conrmation of Power Supply

Conrm that the power breaker operates(ON) normally;

(2)Conrmation of Power Voltage

Conrm that power voltage is AC 208-230 ±10%. If power voltage is not in this range, the unit may not operate normally.

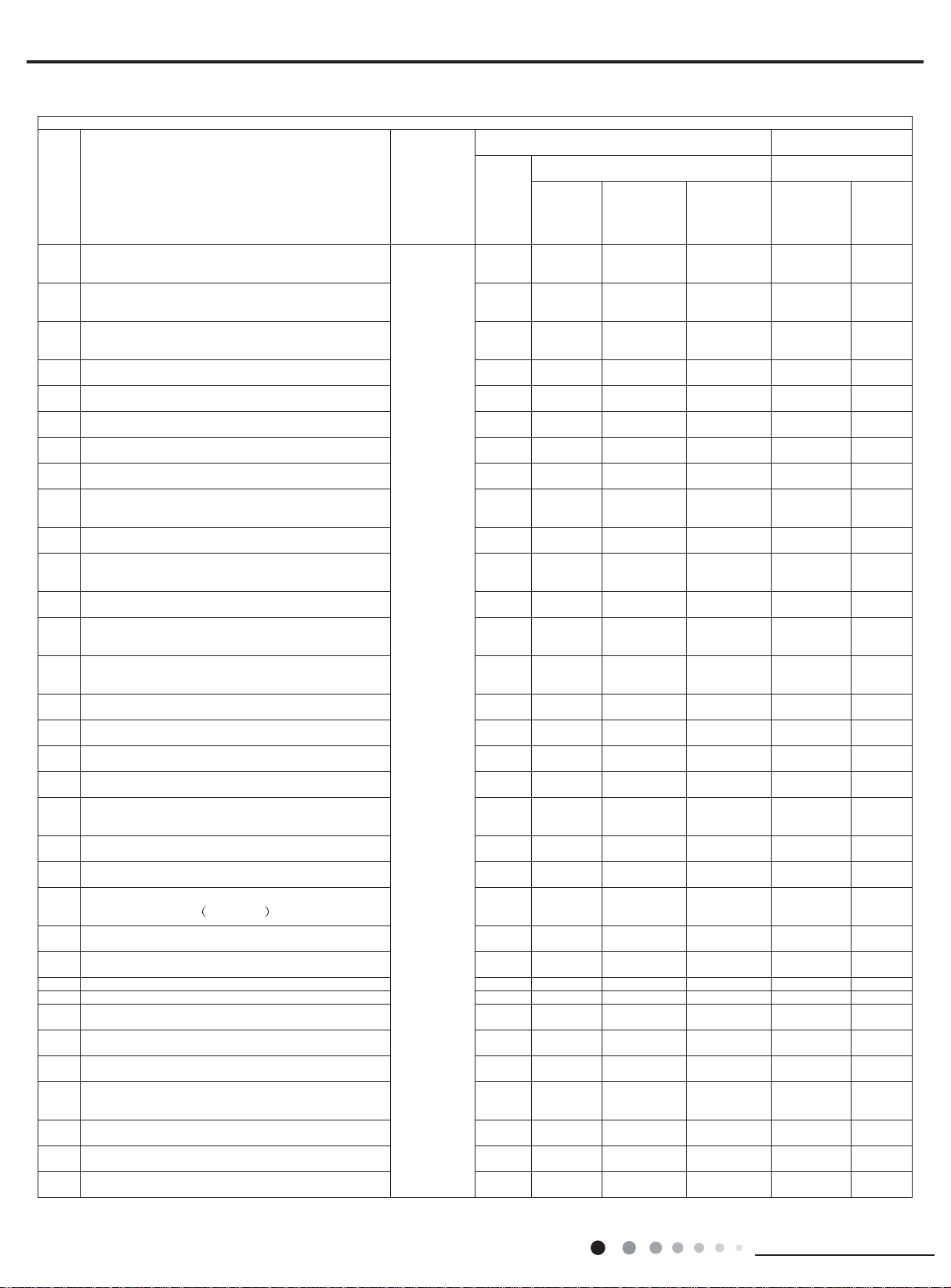

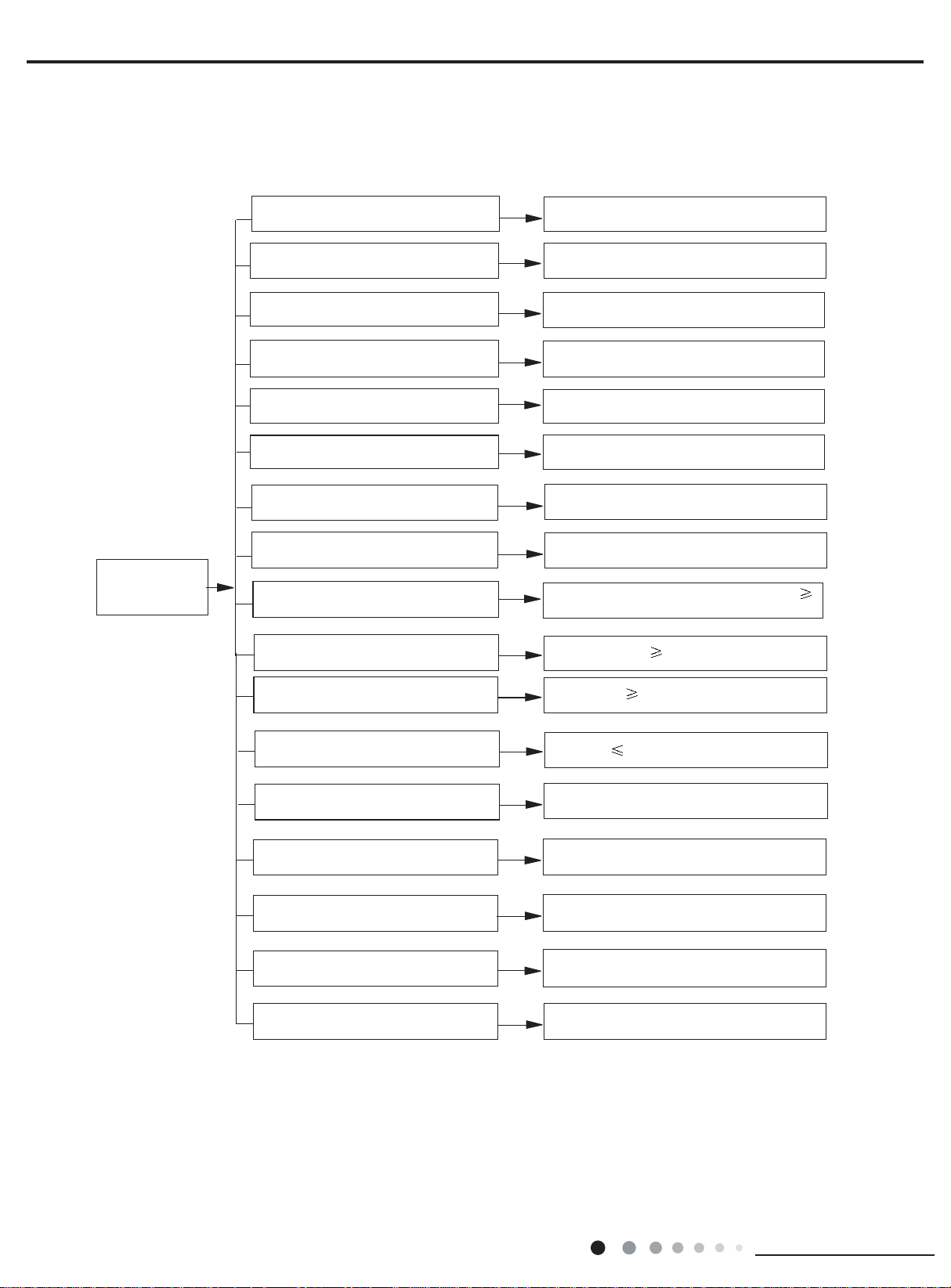

3. Flashing LED of Indoor/Outdoor Unit and Primary Judgement

3

Page 4

(1)Models:09/12K:

Malfunction and Status Display Table

15 times

Display of Malfunction of Indoor Unit

No. Malfunction Name

1 Malfunction of Circuit for zero cross detection U8

2 Malfunction protection for jumper cap C5

3 No feedback from indoor motor H6

Indoor ambient temp sensor has open or short

4

Indoor evaporator temp sensor has open or

5

Liquid valve temp sensor has open or short

6

7

8 Module temp sensor has open or short circuit P7

9

10

11

12

13

14

15

16 Demagnetization protection of compressor HE

17 Malfunction of voltage drop of DC bus bar U3

18 Module temperature protection P8

19

20 Malfunction of charging for capacitor PU

21 High pressure protection for the system E1

22

23

24

25 Overspeed (for commercial air conditioner)

26 Malfunction of

27

28

29

30

31 Thermal overload protection for compressor H3

32 Non-match between indoor and outdoor units LP

33 Malfunction of memory chip

Gas valve temp sensor has open or short

Outdoor ambient temp sensor has open or

Outdoor inlet pipe temp sensor of condenser

has open or circuit (for commercial use)

Outdoor middle pipe temp sensor of condenser

Outdoor outlet pipe of condenser has open or

Outdoor discharge temp sensor has open or

Communication malfunction of indoor and

Malfunction of circuit for detecting phase

Lack of refrigerant or block protection for the

Reset of drive module (for commercial air

AC contactor protection (for commercial air

Temperature drift protection(for commercial air

Sensor connection protection (for commercial

Communication malfunction for drive board(for

has open or short circuit

short circuit (for commercial use)

current of compressor

system (not applicable to residential air

Low pressure protection for the system

Lock of compressor (for commercial air

commercial air conditioner)

circuit

short circuit

circuit

circuit

short circuit

short circuit

outdoor units

conditioner)

reserved

conditioner)

conditioner)

conditioner)

conditioner)

air conditioner)

Malfunction

Type

Malfunction

of

hardware

Display

Nixie

Tube

Operation

F1

F2

b5

b7

F3

A5

F4

A7

F5

E6

U1

F0

E3

LE / / /

P0 / / /

/ / /

LF

/ / /

PF

P9 / / /

PE / /

Pd / / /

P6

EE

Status of LED Lamp

LED

Lamp

for

Blinks

for 17

times

Blinks

for 15

times

Blinks

for 11

times

Blinks

for 6

times

Blinks

once

Blinks

for 3

times

Blinks

for 16

times

LED Lamp

for

Cooling

Blinks

once

Blinks

twice

Blinks for

19 times

Blinks for

22 times

Blinks for

3 times

Blinks for

4 times

Blinks for

5 times

Blinks for

10 times

LED Lamp

Heating

Blinks for

18times

Blinks for

12 times

Blinks for

14 times

Blinks for

20 times

Blinks for

19 times

Blinks for

17 times

Blinks for

3 times

Blinks for

Malfunction of

Outdoor Unit

Status of LED

Lamp

for

Yellow

LED

Lamp

Blinks for

10 times

Blinks for

8 times

Blinks for

16 times

Red

LED

Lamp

Blinks

for 6

times

Blinks

for 5

times

Blinks

for 7

times

Blinks

for 9

times

4

Installation and Maintenance

Page 5

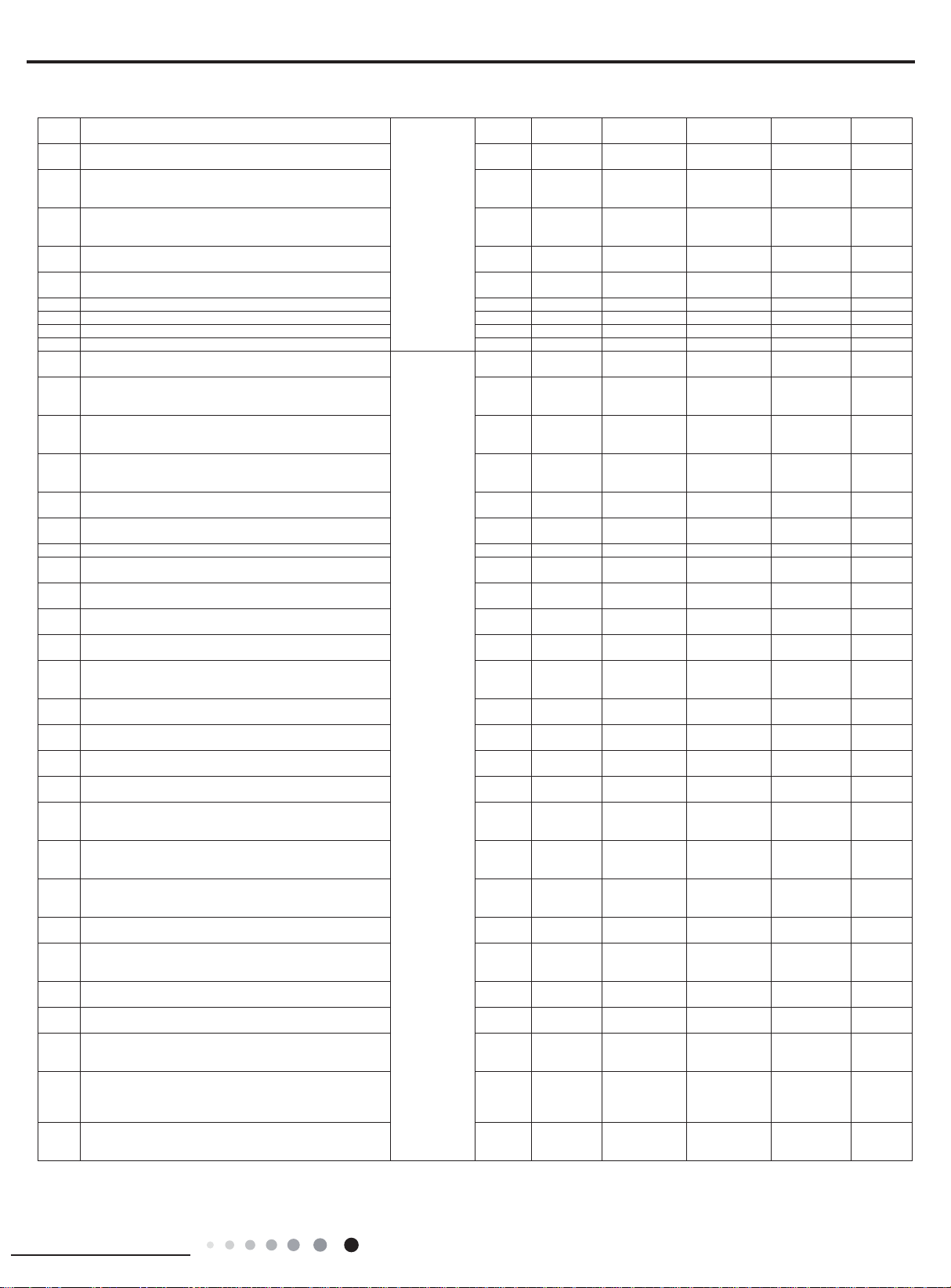

34

Wrong connection of communication wire or

times

35

36

37 Mode conflict E7

38 Refrigerant reclaiming mode Fo

39 Oil return under defrosting or heating H1

40 Nominal cooling or heating (capacity test code) P1 / / /

41 Max. cooling or heating (capacity test code) P2 / / /

42 Middle cooling or heating(capacity test code) P3 / / /

43 Min. cooling or heating(capacity test code) P0 / /

44 Failure of startup of compressor Lc

45

46 Overload protection E8

47 Overcurrent protection for the complete unit E5

48 Overcurrent protection for the complete unit P5

49 Desynchronizing of compressor H7

50 Lack/reverse phase protection of Ld / / /

51 Module current protection (IPM protection) H5

52 Overlow voltage protection for DC bus bar PL

53 Overhigh voltage protection for DC bus bar PH

54 PFC protection HC

55 Overhigh power protection (not for outdoor L9

56 Abnormal reversing of 4-way valve U7

57

58

59

60 Frequency limit/decrease for freeze protection FH

61 Frequency limit/decrease for overload F6

62

63 Oil return in cooling F7

64 Cold air prevention E9

65 Freeze protection E2

66 Reading malfunction of EEPROM

67 Reaching temperature for turning on the unit

68 Frequency limit (power)

69 Malfunction of outdoor fan

malfunction of expansion valve (free match)

Malfunction of current detection for the

Wrong connection of communication wire or

status of detecting malfunction of expansion

High discharge temperature protection of

Frequency limit/decrease for current protection

Frequency limit/decrease for current protection

of the module (phase current)

Frequency limit/decrease for high discharge

Frequency limit/decrease for module

complete unit

valve (free match)

compressor

of the complete unit

temperature

temperature protection

Display is

controlled

by remote

control

dn / / /

U5

dd / / /

Blinks

for 7

times

Blinks

once

E4

F8

En / / /

F9

EU

Blinks

for 4

times

Blinks

for 8

times

Blinks

for 5

times

Blinks

for 20

times

Blinks

for 9

times

Blinks

twice

Blinks for

13 imes

Blinks

once

Blinks for

11 times

Blinks for

20 times

Blinks for

8 times

Blinks for

9 times

Blinks

twice

Blinks for

6 times

Blinks for

6 times

Blinks for

7 times

Blinks

once

Blinks for

11 times

Blinks for

15 times

Blinks for

7 times

Blinks for

5 times

Blinks for

21 times

Blinks for

6 times

Blinks

twice

Blinks for

6 times

Blinks

twice

Blinks for

7 times

Blinks for

6 times

Blinks for

5 times

Blinks for

4 times

Blinks for

12 times

Blinks for

13 times

Blinks for

14 times

Blinks for

9 times

Blinks

once

Blinks

twice

Blinks for

3 times

Blinks for

11 times

Blinks

for 4

times

Blinks

for 3

times

Blinks

for 11

times

Blinks

for 8

times

Blinks

13time

Blinks

for 14

for

s

Installation and Maintenance

5

Page 6

If malfunction occurs,corresponding code will display and the unit will resume normal until protection or

malfunction disappears.

Compressor stars (normal)Yellow indicator blinks for once

Yellow indicator

blinks for twice

Yellow indicator blinks for 3 times

Yellow indicator blinks for 4 times

Yellow indicator blinks for 5 times

Yellow indicator blinks for 6 times

Yellow indicator blinks for 7 times

Yellow indicator blinks for 8 times

Defrosting

Anti-freezing protection (normal

IPM protection

Overcurrent protection

Overload protection

Exhaust protection

Overlod protection of compresoor

(normal display of indoor unit)

display of indoor unit)

Indicator display

of outdoor unit

Red indicator blinks for once

Red indicator blinks for twice

Red indicator blinksfor 3 times

Cooling (dehumidify) or heating current

dropped frequency current.

Exhaust temp. dropped frequency temp.

Tube

temp. dropped frequency temp.

Red indicator blinks for 4 times

Red indicator blinks for 5 times

Red indicator for 6 times

Red indicator blinks for 7 times

Red indicator blinks for 8 times

Green indicator does not blink

T

tube-in

dropped frequency temp.

Outdoor condenser temp. sensor mal.

Outdoor ambient temp. sensor mal.

Outdoor exhaust temp. sensor mal.

Starting at temp. does not reach

Communication is abnormal

6

Installation and Maintenance

Page 7

A

nalysis or processing of some of the malfunction display:

1. Compressor discharge protection

operation;

malfunction of compressor; malfunction of protection relay; malfunction of discharge sensor; outdoor temperature too

high.

Processing method: refer to the malfunction analysis in the above section

2. Low voltage overcurrent protection

Possible reason: Sudden drop of supply voltage.

3. Communic ation malfun ction

Processing method: Check if communic ation signal cable is connected reliably

4. Sensor open or short circuit

Processing

f

lead wire is found.

5. Compressor over load protection

Possible

compresso

Processing

the

6. System malfun ction

Overload

e

temperature of indoor heat exchanger when heating) is too high, protection will beactivated.

Please refer to the malfunction analysis in the previous section for handling method

7. IPM module protection

Processing

power

the malfunction still exists,replace the module.

(2)Models:18/24K:

method: Check whethers ensor is normal, connected with the corre sponding position on the controller and if damage o

reasons: insufficient or too much refrigrant; blockage of capillary an dincrease of su ction temp.; improper running of

r, burning in or stuck of bearing, damage of discharge valve; malfunction of protector.

method: adjust refrige rant amount; replace the capillary; replace the compressor; use univers al meter to check if

.

.

.

protection.When tube temperature(Check the temperature of outdoor heat exchanger when cooling and check th

method:Once the module malfunction happens,if it persists for a long time and can not be self-canceled, cut off the

and turn off the unit,and then re-energize the unit again after about 10 min.After repeating the procedure for sever times, if

.

Installation and Maintenance

7

Page 8

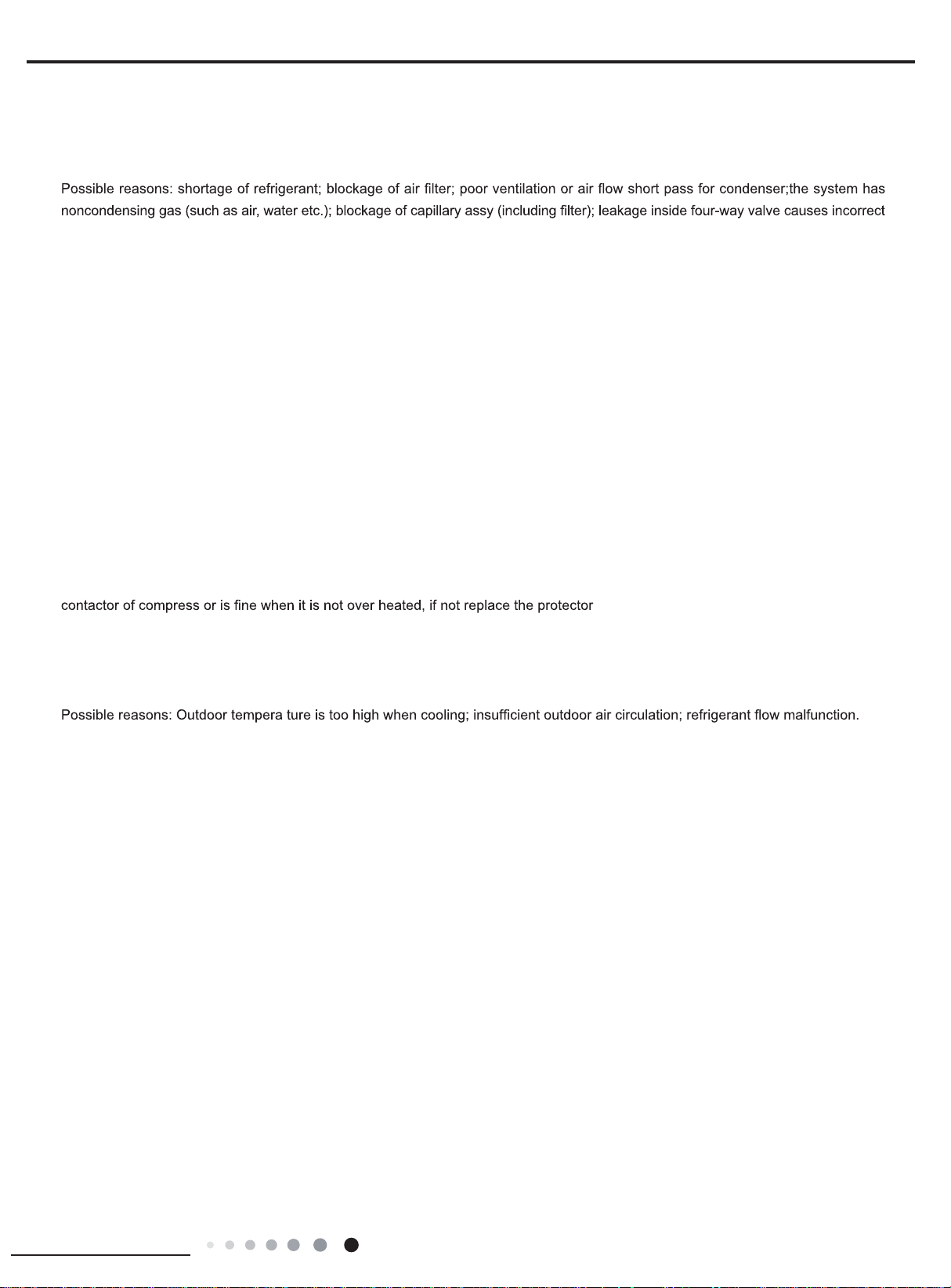

NO.

1

2

3

4

5

6

7

Malfunction

Name

High

pressure

protection of

system

Antifreezing

protection

High

discharge

temperature

protection of

compressor

Overcurrent

protection

Communication

Malfunction

High

temperature

resistant

protection

Internal

motor (fan

motor) do not

operate

Display Method of Indoor Unit

Dual-8

Display

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Code

E1

E2

E4

E5

E6

E8

H6

Operation

Indicator

OFF 3s

and blink

once

OFF 3S

and blink

twice

OFF 3S

and blink 4

times

OFF 3S

and blink 5

times

OFF 3S

and blink 6

times

OFF 3S

and blink 8

times

OFF 3S

and blink

11 times

Cool

Indicator

Heating

Indicator

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated ƿBlink

D5

(D40)D6(D41)

D16

(D42)

D30

(D43)

ƶ ƿ ƿ ƿ

Ƶ ƶ Ƶ ƶ

Ƶ ƶ Ƶ ƿ

ƶ Ƶ ƿ ƶ

ƶ ƶ ƶ ƿ

Ƶ ƶ Ƶ Ƶ

A/C status Possible Causes

During cooling and drying

operation, except indoor

fan operates, all loads stop

operation.

During heating operation, the

complete unit stops.

During cooling and drying

operation, compressor and

outdoor fan stop while indoor

fan operates.

During cooling and drying

operation, compressor and

outdoor fan stop while indoor

fan operates. During heating

operation, all loads stop.

During cooling and drying

operation, compressor and

outdoor fan stop while indoor

fan operates. During heating

operation, all loads stop.

During cooling operation,

compressor stops while indoor

fan motor operates. During

heating operation, the complete

unit stops.

During cooling operation:

compressor will stop while

indoor fan will operate. During

heating operation, the complete

unit stops.

Internal fan motor, external fan

motor, compressor and electric

heater stop operation,guide

louver stops at present location.

Possible reasons:

1. Refrigerant was superabundant;

2. Poor heat exchange (including

and bad radiating environment );

Ambient temperature is too high.

1. Poor air-return in indoor unit;

2. Fan speed is abnormal;

3. Evaporator is dirty.

Please refer to the malfunction

analysis (discharge protection,

overload).

1. Supply voltage is unstable;

2. Supply voltage is too low and

load is too high;

3. Evaporator is dirty.

Refer to the corresponding

malfunction analysis.

Refer to the malfunction analysis

(overload, high temperature

resistant).

1. Bad contact of DC motor

feedback terminal.

2. Bad contact of DC motor

control end.

3. Fan motor is stalling.

4. Motor malfunction.

5. Malfunction of mainboard rev

detecting circuit.

1. No jumper cap insert on

Wireless remote receiver and

button are effective, but can

not dispose the related

command

During cooling and drying

operation, indoor unit operates

while other loads will stop;

during heating operation,

the complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

8

9

10

Malfunction

protection of

jumper cap

Indoor

ambient

temperature

sensor is

open/short

circuited

Overcurrent

protection of

phase

current for

compressor

C5

F1

P5

OFF 3S

and blink

15 times

OFF 3S

and blink

once

OFF 3S

and blink

15 times

ƶ ƿ ƶ ƶ

8

mainboard.

2. Incorrect insert of jumper cap.

3. Jumper cap damaged.

4. Abnormal detecting circuit of

mainboard.

1. Loosening or bad contact of

indoor ambient temp. sensor and

mainboard terminal.

2. Components in mainboard fell

down leads short circuit.

3. Indoor ambient temp. sensor

damaged.(check with sensor

resistance value chart)

4. Mainboard damaged.

Refer to the malfunction

analysis (IPM protection, loss

of synchronism protection and

overcurrent protection of phase

current for compressor.

Installation and Maintenance

Page 9

Malfunction

n

position

y

normal

electrolytic

e

operation.

n

,

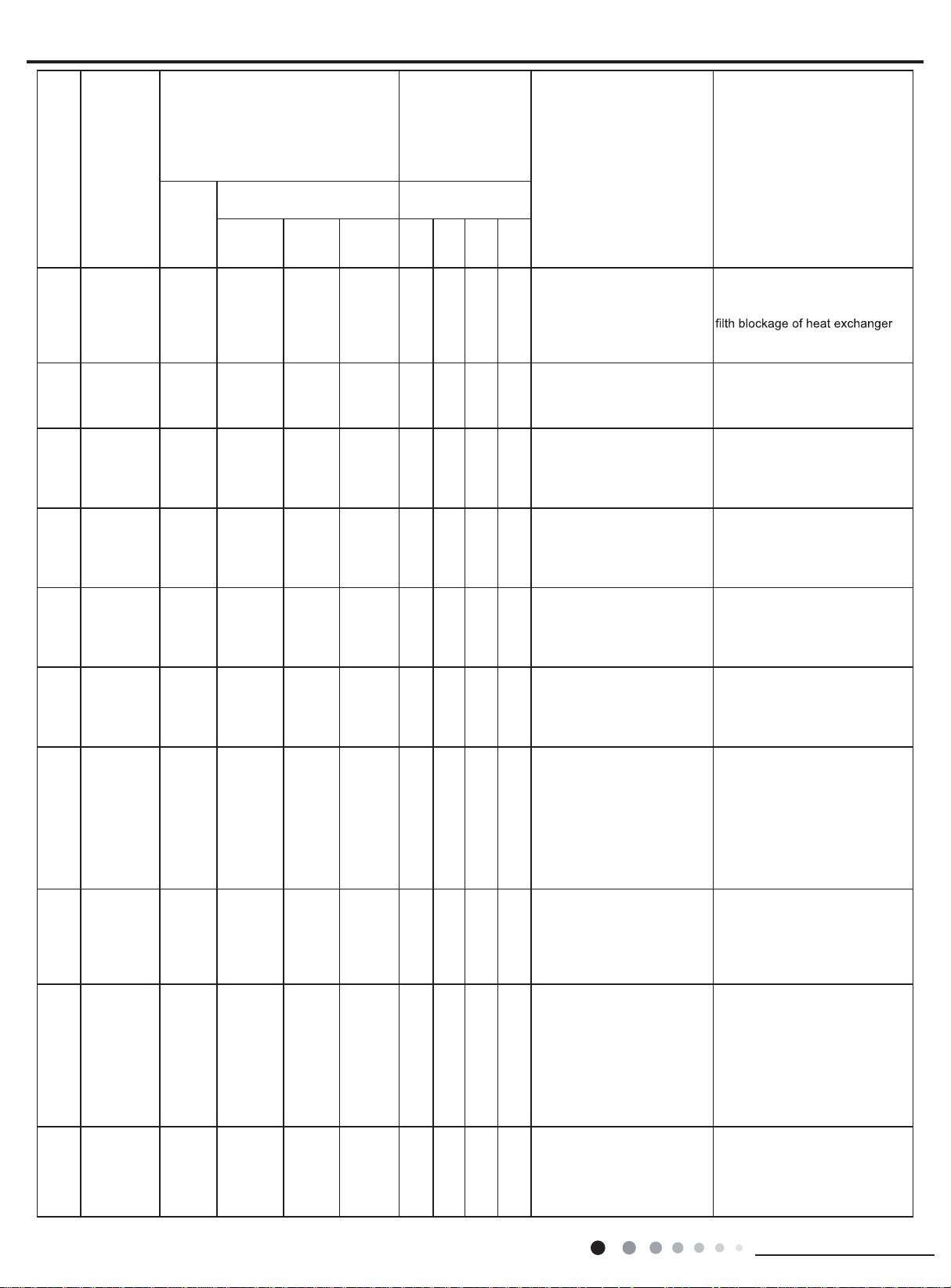

s

NO.

Name

Dual-8

Code

Display

Indoor

evaporator

temperature

11

sensor is

open/short

circuited

Outdoor

ambient

temperature

12

sensor is

open/short

circuited

Outdoor

condenser

temperature

13

sensor is

open/short

circuited

Outdoor

discharge

temperature

14

sensor is

open/short

circuited

Limit/

decrease

frequency

15

due to

overload

Decrease

frequency

16

due to

overcurrent

Decrease

frequency

due to

17

high air

discharge

Voltage for

18

19

DC bus-bar

is too high

Malfunction

of complete

units current

detection

PH

U5

Installation and Maintenance

Display Method of Indoor Unit

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

F2

F3

F4

F5

F6

F8

F9

Cool

Indicator

OFF 3S

and

blink

twice

OFF 3S

and

blink

3 times

OFF 3S

and

blink

4 times

OFF 3S

and

blink

5 times

OFF 3S

and

blink

for 6

times

OFF 3S

and

blink

8 times

OFF 3S

and

blink

9 times

OFF 3S

and

blink

11 times

OFF 3S

and

blink

13 times

Heating

Indicator

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated

D5

(D40)D6(D41)

ƶ ƶ ƿ Ƶ

ƶ ƶ ƿ ƶ

ƿ

D16

(D42)

Blink

D30

(D43)

ƶ ƶ ƿ ƿ

Ƶ ƶ ƿ ƿ

Ƶ Ƶ ƶ Ƶ

Ƶ Ƶ ƶ ƶ

ƶ Ƶ ƶ ƿ

ƶ Ƶ ƿ Ƶ

A/C status Possible Causes

AC stops operation once

reaches the setting

temperature. Cooling, drying:

internal fan motor stops

operation while other loads

stop operation; heating: AC

stop operation

During cooling and drying

operating, compressor stops

while indoor fan operates;

During heating operation, the

complete unit will stop operation

During cooling and drying

operation, compressor stops

while indoor fan will operate;

During heating operation,

the complete unit will stop

operation.

During cooling and drying

operation, compressor will sop

after operating for about 3 mins,

while indoor fan will operate;

During heating operation, the

complete unit will stop after

operating for about 3 mins.

All loads operate normally, while

operation frequency for

compressor is decreased

All loads operate normally, while

operation frequency for

compressor is decreased

All loads operate normally, while

operation frequency for

compressor is decreased

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, the compressor will

stop while indoor fan will operate;

During heating operating,

the complete unit will stop

1. Loosening or bad contact of

Indoor

evaporator temp. sensor and

mainboard terminal.

2. Components on the mainboard

fall

down leads short circuit.

3. Indoor evaporator temp. sensor

damaged.(check temp. sensor

value

chart for testing)

4. Mainboard damaged.

Outdoor temperature sensor

hasnt been connected well or

is damaged. Please check it by

referring to the resistance table for

temperature sensor)

Outdoor temperature sensor

hasnt been connected well or

is damaged. Please check it by

referring to the resistance table for

temperature sensor)

1.Outdoor temperature sensor

hasnt been connected well or is

damaged. Please check it by

referring to the resistance table for

temperature sensor)

2.The head of temperature sensor

hasnt been inserted into the

copper tube

Refer to the malfunction analysis

(overload, high temperature

resistant)

The input supply voltage is too

low;

System pressure is too high and

overload

Overload or temperature is too

high;

Malfunction of electric expansio

valve (EKV)

1. Measure the voltage of

L and N on wiring board (XT), if

the voltage is higher than 265VAC,

turn on the unit after the suppl

voltage is increased to the

range.

2.If the AC input is normal,

measure the voltage of

capacitor C on control panel (AP1),

if its normal, theres malfunction

for the circuit, please replace th

control panel (AP1)

Theres circuit malfunction o

outdoor units control panel AP1

please replace the outdoor unit

control panel AP1.

9

Page 10

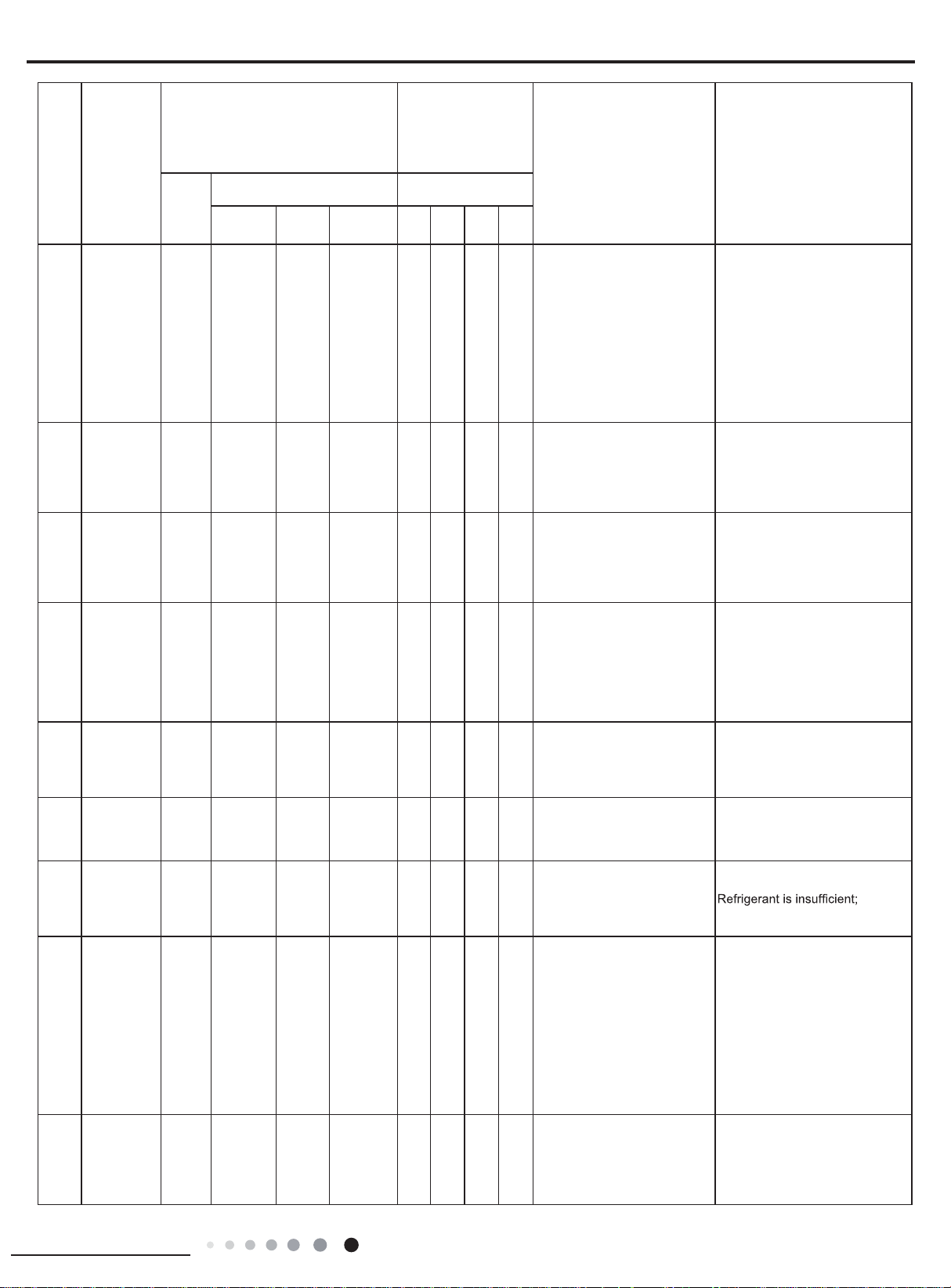

Malfunction

nalysis

NO.

20 Defrosting H1

Name

Dual-8

Code

Display

Display Method of Indoor Unit

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

Cool

Indicator

Heating

Indicator

OFF 3S

and blink

once

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated

D5

(D40)D6(D41)

ƿ

D16

(D42)

Blink

A/C status Possible Causes

D30

(D43)

Defrosting will occur in heating

mode. Compressor will operate

while indoor fan will stop

operation.

Its the normal state

21

22

23

24

25

26

27

28

29

Static

dedusting

protection

Overload

protection for

compressor

System is

abnormal

IPM

protection

PFC

protection

Desynchronizing of

compressor

Decrease

frequency

due to high

temperature

resistant

during

heating

operation

Failure startup

Malfunction

of phase

current

detection

circuit for

compressor

H2

H3

H4

H5

HC

H7

H0

LC

U1

OFF 3S

and blink

twice

OFF 3S

and blink

3 times

OFF 3S

and blink

4 times

OFF 3S

and blink

5 times

OFF 3S

and blink

6 times

OFF 3S

and blink

7 times

OFF 3S

and blink

10 times

OFF 3S

and blink

11 times

OFF 3S

and blink

13 times

ƶ ƿ ƿ ƶ

Ƶ ƶ Ƶ Ƶ

ƶ ƿ ƶ Ƶ

ƶ Ƶ ƿ ƿ

ƶ ƿ Ƶ ƿ

Ƶ ƶ ƿ ƿ

ƶ ƿ ƶ ƿ

ƶ ƿ Ƶ ƶ

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

All loads operate normally, while

operation frequency for

compressor is decreased

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

/

1. Wiring terminal OVC-COMP

is loosened. In normal state, the

resistance for this terminal should

be less than 1ohm.

2.Refer to the malfunction a

( discharge protection, overload)

Refer to the malfunction analysis

(overload, high temperature

resistant)

Refer to the malfunction

analysis (IPM protection, loss

of synchronism protection and

overcurrent protection of phase

current for compressor.

Refer to the malfunction analysis

Refer to the malfunction

analysis (IPM protection, loss

of synchronism protection and

overcurrent protection of phase

current for compressor.

Refer to the malfunction analysis

(overload, high temperature

resistant)

Refer to the malfunction analysis

Replace outdoor control panel AP1

10

Installation and Maintenance

Page 11

NO.

capacitor C on control panel (AP1),

30

31

32

33

34

35

Malfunction

Name

EEPROM

malfunction

Charging

malfunction

of capacitor

Malfunction

of module

temperature

sensor circuit

Module high

temperature

protection

Malfunction

of voltage

dropping for

DC bus-bar

Voltage of

DC bus-bar

is too low

Display Method of Indoor Unit

Dual-8

Display

Indicator Display (during blinking,

ON 0.5s and OFF 0.5s)

Code

Operation

Indicator

EE

PU

P7

P8

U3

PL

Cool

Indicator

Heating

Indicator

OFF 3S

and blink

15 times

OFF 3S

and blink

17 times

OFF 3S

and blink

18 times

OFF 3S

and blink

19 times

OFF 3S

and blink

20 times

OFF 3S

and blink

21 times

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated

D5

(D40)D6(D41)

D16

(D42)

ƿ

Blink

D30

(D43)

ƶ ƶ ƶ Ƶ

ƶ Ƶ ƶ Ƶ

ƶ ƶ Ƶ ƿ

Ƶ ƶ ƿ Ƶ

ƶ Ƶ Ƶ Ƶ

ƶ Ƶ Ƶ ƶ

A/C status Possible Causes

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

During cooling operation,

compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

Replace outdoor control panel

AP1

Refer to the part three—charging

malfunction analysis of capacitor

Replace outdoor control panel

AP1

After the complete unit is deenergized for 20mins, check

whether the thermal grease on

IPM Module of outdoor control

whether the radiator is inserted

tightly. If its no use, please replace

control panel AP1.

Supply voltage is unstable

1. Measure the voltage of position

L and N on wiring board (XT), if

the voltage is higher than 150VAC,

turn on the unit after the supply

voltage is increased to the normal

range.

2.If the AC input is normal,

measure the voltage of electrolytic

36

37

38

39

Limit/

decrease

frequency

due to high

temperature

of module

The four-way

valve is

abnormal

Zerocrossing

malfunction

of outdoor

unit

Limit/

decrease

frequency

due to

antifreezing

EU

U7

U9

FH

Ƶ Ƶ Ƶ ƿ

Ƶ ƶ ƿ ƶ

Ƶ Ƶ ƿ ƶ

Ƶ Ƶ Ƶ ƶ

All loads operate normally, while

operation frequency for

compressor is decreased

If this malfunction occurs during

heating operation, the complete

unit will stop operation.

During cooling operation,

compressor will stop while

indoor fan will operate; during

heating,the complete unit will

stop operation.

All loads operate normally, while

operation frequency for

compressor is decreased

if its normal, theres malfunction

for the circuit, please replace the

control panel (AP1)

Discharging after the complete

unit is de-energized for 20mins,

check whether the thermal grease

on

IPM Module of outdoor control

whether the radiator is inserted

tightly.

If its no use, please replace control

panel AP1.

1.Supply voltage is lower than

AC175V;

2.Wiring terminal 4V is loosened

or broken;

3.4V is damaged, please replace

4V.

Replace outdoor control panel

AP1

Poor air-return in indoor unit or fan

speed is too low

Installation and Maintenance

11

Page 12

4. How to Check Simply the Main Part

s

Indoor unit:

(1)Temperature sensor malfunction

Start

Is the wiring

terminal between temperature

sensor and the controller loosened or

poorly contacted?

yes

Insert the temperature

sensor tightly

no

no

Is there short circuit due to tri-pover

of the pa rts?

no

no

Is the temperature

sensor normal acc o rding to the

Resistance Table?

yes

no

M alfunction is

eliminated.

yes

Make the parts upright

Malfunction is

eliminated.

no

Replace it with a

temperature sensor

of the same model

Malfunction is

removed.

yes

ye

12

Replace the c ontroller with

one of the same model

End

yes

Installation and Maintenance

Page 13

(2)Indoor fan does not operate (H6)

s

Start

Pull the blade by

hand under

de-energization

status

Whether the

blade can operate

smoothly

Yes

Check whether the

wiring terminal between

indoor fan and main

board is loose

No

Energize and restart upthe

unit, test whether the voltage beween motor

terminal 1 and 2 is 280~310VDC

Yes

No

No

Yes

No

No

No

Adjust the motor and

blade assembly to let

the motor can operate

smoothly

Is malfunction

eliminated

Reinsert the wiring

terminal of indoor fan

Is malfunction

eliminated

It's the malfunction of

main board. Replace

the main board with

the same model

Is malfunction

eliminated

Yes

Ye

Yes

Installation and Maintenance

Test whether the voltage bewween motor

terminal 2 and 3 is 15VDC

Yes

Test whether there's voltage signal

beween motor terminal 2 and 4

Yes

It's the malfunction

of motor. Replace

the motor.

No

No

No

No

It's the malfunction of

main board. Replace

the main board with

the same model

Is malfunction

eliminated

It's the malfunction of

main board. Replace

the main board with

the same model

Is malfunction

eliminated

End

Yes

Yes

13

Page 14

(3)Jumper cap malfunction (C5)

C5 is dis played

on the unit.

Is there jumper cap on the

controller?

Yes

Is the jumper cap inserted

incorrectly or improperly?

No

Replace the jumper

cap

No

No Yes

No

Yes

Install a matching

Re-insert the jumper

jumper cap.

Is the

malfunction

eliminated?

cap

Is the

malfunction

eliminated?

14

Is the

malfunction

eliminated?

No

The mainboard is

defined abnormal;

replace it

End

Yes

Yes

Installation and Maintenance

Page 15

(4) Communication malfunction (E6)

Is there incorrect match

between the main board and the

display panel or between the indoor

and outdoor boards?

Poor contact of any line

may lead to communication

malfuntion.

Is there

incorrect connection?

Note:

1.Before replacing mainboard of indoor unit, make sure the mainboard for replacement is qualied. The following testes shall be done:

a.Check if protective tube FUSE 1 has open circuit. If so, replace it with a protective tube of the same model.

b.Energize the unit and check if buzzer is sound. If not, the mainboard of indoor unit can’t be used.

c.Energize the unit with display and check if all icons are displayed after energization and if the display is normal. If not, the main board can’t

be used.

2.The mainboard for replacement shall has the same model with the original mainboard, so do the jumper cap.

3.The wiring and assembly methods shall also be the same with that of the original mainboard when replacing the mainboard.

Installation and Maintenance

15

Page 16

(1) Capacity charging malfunction (outdoor unit malfunction) (AP1 below is control board of outdoor

Outdoor unit:

unit)

Main detection point:

● Detect if the voltage of L and N terminal of wiring board is between 210AC-240AC by alternating voltage meter;

● Is reactor (L) well connected? Is connection wire loosened or pull-out? Is reactor (L) damaged

"

Malfunction diagnosis process:

Turn on the unit

and wait 1 minute

Use DC voltmeter

to measure the

voltage on the two

ends of electrolytic

capacitor

Voltage higher than 200V?

N

Measure the AC voltage between

L and N on wiring board

terminal

XT(power supply)

Voltage within

210VAC~250VAC?

Y

Shut down the power and wait 20 mi

use DC voltmeter to measure the voltage

on the two ends of capacitor (test3), until

the voltage is lower than 20V

Check the

connection of reactor

(L in the Electrical

Wiring Diagram)

nutes; or

Y

N

Fault with the voltage

testing circuit on

control panel AP1

Shut down the power

and repair the power

supply to restore the

range

210VAC~250VAC

Replace the control

panel AP1

power on and

restart the unit

N

If the fault is

eliminated?

Y

16

If the wiring of

is normal?

reactor L

Y

Replace the control

panel AP1

End

Connect the reactor

Laccording to Elec-

N

trical Wiring Diagram correctly

Re-energize and

turn on the unit

N

If the fault is

eliminated?

Y

Installation and Maintenance

Page 17

(2) IPM protection, desynchronizing malfunction, phase current of compressor is overcurrent (AP1 below is control

board of outdoor unit)

Main detection point:

If control board AP1 and compressor COMP is well connected? If they are loosened? If the connection sequence is correct?

Is voltage input in the normal range (Test the voltage between L, N of wiring board XT by DC voltage meter)?

If coil resistance of compressor is normal? Is compressor coil insulating to copper pipe well?

If the work load of unit is heavy? If radiating of unit is well?

If the refrigerant charging is appropriate?

Malfunction diagnosis process:

Installation and Maintenance

17

Page 18

Energize and

p

A

switch on

IPM protection

occurs after the

machine has run for

eriod of time?

a

Please confirm:

1. If the indoor and

outdoor heat

exchangers are

dirty? If they are

obstructed by other

objects which affect

the heat exchange

of indoor and

outdoor unit.

2. If the indoor and

outdoor fans are

working normally?

3. If the environment

temperature is too

high, resulting in

that the system

pressure is too high

and exceeds the

permissible range?

4. If the charge

volume of

refrigerant is too

much, resulting in

that the system

pressure is too

high?

5. Other conditions

resulting in that the

system pressure

becomes too high.

Refer to the

Electrical Wiring

Diagram and check

if the connection

between AP1 and

COMP is loose and if

the connection order

is correct.

Use AC voltmeter

to measure the

voltage between

Y N

terminal L and N

on the wiring

board XT)

Voltage between

Y

the two ends of celectrolytic

capacitor is

higher than

250V

Stop the unit and

disconnect the power

supply. Then, check

the connection of

capacitor C2

according to Electrical

Wiring Diagram.

Remove the wires

on the two ends of

capacitor C2. Then,

use capacitance

meter to measure

the capacitor C2.

Verify as per the

Parameters Sheet.

If capacitor

C2 is failed?

N

If there is any

abnormality

described above?

Y

N

between the two ends of

capacitor C2, until the

voltage is lower than 20V

control panel AP1

If the voltage

between terminal L

and N on wiring

board XT is within

210VAC~250VAC?

Restart the unit. Before

protection occurs,

use DC voltmeter to

measure the voltage

between the two

ends of electrolytic

capacitor on control

panel AP1

The connection

of capacitor C2

is loose.

Stop the unit and

disconnect the power

supply. Wait 20 minutes,

or use DC voltmeter to

measure the voltage

Replace the capacitor

C2. Then, energize

and start the unit.

Replace the

Take corrective actions

according to Technical

Y

Service Manual, and

then energize and start

the unit.

Replace the

control panel AP1

Check the supply

voltage and

restore it to

210VAC~250VAC

N

Y

N

If the unit can

work

normally?

Reconnect the

capacitor C2 according

to Electrical Wiring

Diagram. Then,

Restart the

unit.

If the unit can

work normallv?

If the unit can

work normally?

N

If the unit can

work normally?

N

Y

Y

Y

Y

18

If the connection

between AP1 and

COMP is unsecure

or the connection

order is wrong?

Use ohmmeter to

measure the resistance

between the three

terminals on compressor

COMP, and compare the

measurements with the

compressor resistance on

Service Manual.

Use ohmmeter to

measure the resistance

between the two

terminals of compressor

COMP and copper tube.

Connect the control panel

P1 and compressor

Y

COMP correctly according

to the Electrical Wiring

Diagram. Then, energize

and start the unit.

If the

resistance is

normal?

Resistance higher

than 500MΩ?

Replace the

control panel

N

AP1

Replace the

compressor

COMP

N

If the unit can

work

normally?

END

Y

Installation and Maintenance

Page 19

(3) Diagnosis for anti-high temperature, overload protection (AP1 below is control board of outdoor unit)

Main detection point:

● If the outdoor ambient temperature is in normal range;

● If the indoor and outdoor fan is running normal;

● If the radiating environment of indoor and outdoor unit is well.

Malfunction diagnosis process:

Anti-high temperature,

overload protection

If the outdoor ambient temperature is

higher than 53 ºC?

Normal protection, please use

Y

it after improve the outdoor

ambient temperature

N

After the unit de-

energized for 20min

If the radiating of outdoor

and indoor unit is well?

N

If the indoor and outdoor

fan work well?

Y

Improve the

Y

N

radiating

environment of

unit

1. Check if fan terminal

OFAN is connected well

2. Test if resistance value

of any two terminals is less

than 1k with ohmic meter

Replace fan

Replace

capacitor C1

control board

AP1

Installation and Maintenance

Replace

outdoor fan

End

19

Page 20

(4) Diagnosis for failure start up malfunction (AP1 below is control board of outdoor unit)

Main detection point:

● If the compressor wiring is correct?

● If the stop time of compressor is enough?

● If the compressor is damaged?

● If the refrigerant charging is too much?

Malfunction diagnosis process:

Energize the unit

and start it

If the stop time of compressor

is more than 3min?

Y

If the stop time is not enough and the

N

high and low pressure of system is not

balance , please start it after 3min

If the compressor wire COMP(UVW) is

well connected and connection sequence

is correct

Y

If the refrigerant charging is

too much?

Y

Charge the

refrigerant according

to service manual

Does the unit start

up normally?

N

Replace control board AP1

Improve the connection situation

of control board AP1 and

N

compressor COMP, connect it

with wiring diagram

Does the unit start

N

up normally?

Y

20

If malfunction is

removed?

N

Replace the

compressor

End

Installation and Maintenance

Page 21

(5) Diagnosis for compressor synchronism (AP1 below is control board of outdoor unit)

Main detection point:

● If the system pressure is over-high?

● If the work voltage is over-low?

Malfunction diagnosis process:

Synchronism after

energize the unit

N

and start it

Synchronism

occurred during

operation

If the stop time of

compressor is more than

If the outdoor fan works

normally?

N

3min

Y

Y

N

If the compressor wire COMP(UVW) is well

connected, the connection sequence

forwards to clockwise direction?

Connect

wire well

Y

Replace

control board

AP1

Y

Remove

malfunction?

N

Replace

compressor

If the radiating of unit is

well?

N

If the input voltage of unit

is normal?

Y

If the refrigerant is too

much?

N

Replace

control board

AP1

Y

N

Y

Remove

malfunction?

End

N

Y

Check if the fan

terminal OFAN is

connected well

Improve the radiating

of unit (clean heat

exchanger and

increase ventilation)

Start to run until the

power resume normal

voltage

Charge the

refrigerant with

service manual

Replace fan

capacitor C1

Replace

outdoor fan

Installation and Maintenance

Replace

compressor

End

21

Page 22

(6) Diagnosis for overload and discharge malfunction (AP1 below is control board of outdoor unit)

Main detection point:

● If the electron expansion valve is connected well? Is the expansion valve damaged

?

● If the refrigerant is leakage?

● If the overload protector is damaged?

Malfunction diagnosis process:

After the unit

de-energized

for 20min

N

Replace

overload

protector SAT

If the overload protector SAT

is well connected?

Y

Under ambient temperature, test the

resistance of overload protector with ohmic

Y

If the wiring terminal FA of electron

expansion is well connected?

Y

The resistance value of

first 4 l ead foot an d th e

fif th lead foot is similar,

less than 100

Replace EKV

coil of electron

expansion valve

N

Connect wire

N

well with wiring

diagram

22

Remove

malfunction?

N

Check refrigerant, if there is

leakage, please refer to

specification

Remove

malfunction?

N

Replace

control board

AP1

End

Y

Installation and Maintenance

Page 23

(7) PFC (correction for power factor) malfunction (outdoor unit malfunction) (AP1 below is control board of outdoor

unit

)

Main detection point:

● Check if reactor (L) of outdoor unit and PFC capacity are damaged.

Malfunction diagnosis process:

Start

Check the

connection wire

of reactor (L) of

outdoor unit and

PFC capacity

Replace

If there is damaged

short circuit

N

Remove PFC capacity

and test resistance of

two terminals

If the resistance

value is 0

N

Cut the terminal of reactor,

test the resistance

between two terminals of

reactor with ohmic meter

Y

Y

Capacity is

circuit and

replace it

wire with circuit

short

connection

diagram

N

Re-energize

the unit and

start it

N

If the malfunction is

removed?

If the malfunction is

removed?

Y

If there is damaged

short circuit

control board

Installation and Maintenance

N

Replace

AP1

End

Y

Replace the

reactor

Re-

energize

the unit and

start it

N

If the malfunction is

removed?

Y

Y

23

Page 24

(8) Communication malfunction (AP1 below is control board of outdoor unit)

Main detection point:

● Check if the connection wire and the built-in wiring of indoor and outdoor unit is connected well and no damaged

● If the communication circuit of indoor mainboard is damaged? If the communication circuit of outdoor mainboard (AP1) is damaged

Malfunction diagnosis process:

Start

;

If the unit is operation

Y

normal before malfunction

N

Check connection

wire of indoor and

outdoor unit with

circuit diagram

Check built-

in wiring of

indoor and

outdoor unit

Y

N

Malfunction of

circuit is

detected with

control board

AP1 voltage

If the malfunction

is removed?

Y

N

If the wiring is

damaged?

N

Check communication

circuit of outdoor unit

Connection

correct?

N

Check connection

wire of indoor and

outdoor unit with

circuit diagram

If the malfunction

is removed?

Problem of

communication

circuit

N

Y

Replace outdoor

mainboard AP11

If the

malfunction is

removed?

Replace indoor

N

board

24

Y

Y

End

Y

Installation and Maintenance

Page 25

5. Troubleshooting for Normal Malfunction

1. Air Conditioner can't Be Started Up

Possible Causes Discriminating Method (Air conditioner Status) Troubleshooting

Conrm whether it's due to power failure. If yes,

No power supply, or poor

connection for power plug

Wrong wire connection between

indoor unit and outdoor unit,

or poor connection for wiring

terminals

Electric leakage for air conditioner

Model selection for air switch is

improper

Malfunction of remote controller

2. Poor Cooling (heating) for Air Conditioner

Possible Causes Discriminating Method (Air conditioner Status) Troubleshooting

Set temperature is improper Observe the set temperature on remote controller Adjust the set temperature

Rotation speed of the IDU fan

motor is set too low

Filter of indoor unit is blocked Check the lter to see it's blocked Clean the lter

Installation position for indoor unit

and outdoor unit is improper

Refrigerant is leaking

Malfunction of 4-way valve Blow cold wind during heating Replace the 4-way valve

Malfunction of capillary

Flow volume of valve is

insufcient

Malfunction of horizontal louver Horizontal louver can’t swing

Malfunction of the IDU fan motor The IDU fan motor can’t operate

Malfunction of the ODU fan motor The ODU fan motor can't operate

Malfunction of compressor Compressor can't operate

After energization, operation indicator isn’t bright

and the buzzer can't give out sound

Under normal power supply circumstances,

operation indicator isn't bright after energization

After energization, room circuit breaker trips off at

once

After energization, air switch trips off Select proper air switch

After energization, operation indicator is bright,

while no display on remote controller or buttons

have no action.

Small wind blow Set the fan speed at high or medium

Check whether the installation postion is proper

according to installation requirement for air

conditioner

Discharged air temperature during cooling is

higher than normal discharged wind temperature;

Discharged air temperature during heating is

lower than normal discharged wind temperature;

Unit's pressure is much lower than regulated

range

Discharged air temperature during cooling is

higher than normal discharged wind temperature;

Discharged air temperature during heating is

lower than normal discharged wind temperature;

Unit't pressure is much lower than regulated

range. If refrigerant isn’t leaking, part of capillary

is blocked

The pressure of valves is much lower than that

stated in the specication

wait for power recovery. If not, check power

supply circuit and make sure the power plug is

connected well.

Check the circuit according to circuit diagram

and connect wires correctly. Make sure all

wiring terminals are connected rmly

Make sure the air conditioner is grounded

reliably

Make sure wires of air conditioner is connected

correctly

Check the wiring inside air conditioner. Check

whether the insulation layer of power cord is

damaged; if yes, place the power cord.

Replace batteries for remote controller

Repair or replace remote controller

Adjust the installation position, and install the

rainproof and sunproof for outdoor unit

Find out the leakage causes and deal with it.

Add refrigerant.

Replace the capillary

Open the valve completely

Refer to point 3 of maintenance method for

details

Refer to troubleshooting for H6 for maintenance

method in details

Refer to point 4 of maintenance method for

details

Refer to point 5 of maintenance method for

details

3. Horizontal louver can't Swing

Possible Causes Discriminating Method (Air conditioner Status) Troubleshooting

Wrong wire connection, or poor

connection

Stepping motor is damaged Stepping motor can't operate Repair or replace stepping motor

Main board is damaged

Installation and Maintenance

Check the wiring status according to circuit

diagram

Others are all normal, while horizontal louver

can't operate

Connect wires according to wiring diagram to

make sure all wiring terminals are connected

rmly

Replace the main board with the same model

25

Page 26

4. ODU Fan Motor can't Operate

Possible causes

Wrong wire connection, or poor

connection

Capacity of the ODU fan motor is

damaged

Power voltage is a little low or

high

Motor of outdoor unit is damaged

5. Compressor can't Operate

Possible causes

Wrong wire connection, or poor

connection

Capacity of compressor is

damaged

Power voltage is a little low or

high

Coil of compressor is burnt out

Cylinder of compressor is blocked Compressor can't operate Repair or replace compressor

Discriminating method (air conditioner status) Troubleshooting

Check the wiring status according to circuit

diagram

Measure the capacity of fan capacitor with an

universal meter and nd that the capacity is out of

the deviation range indicated on the nameplate of

fan capacitor.

Use universal meter to measure the power supply

voltage. The voltage is a little high or low

When unit is on, cooling/heating performance

is bad and ODU compressor generates a lot of

noise and heat.

Discriminating method (air conditioner status) Troubleshooting

Check the wiring status according to circuit

diagram

Measure the capacity of fan capacitor with an

universal meter and nd that the capacity is out of

the deviation range indicated on the nameplate of

fan capacitor.

Use universal meter to measure the power supply

voltage. The voltage is a little high or low

Use universal meter to measure the resistance

between compressor terminals and it's 0

Connect wires according to wiring diagram to

make sure all wiring terminals are connected

rmly

Replace the capacity of fan

Suggest to equip with voltage regulator

Change compressor oil and refrigerant. If no

better, replace the compressor with a new one

Connect wires according to wiring diagram to

make sure all wiring terminals are connected

rmly

Replace the compressor capacitor

Suggest to equip with voltage regulator

Repair or replace compressor

6. Air Conditioner is leaking

Possible causes

Drain pipe is blocked Water leaking from indoor unit

Drain pipe is broken Water leaking from drain pipe Replace drain pipe

Wrapping is not tight

7. Abnormal Sound and Vibration

Possible causes Discriminating method (air conditioner status) Troubleshooting

When turn on or turn off the unit,

the panel and other parts will

expand and there's abnormal

sound

When turn on or turn off the unit,

there's abnormal sound due

to ow of refrigerant inside air

conditioner

Foreign objects inside the indoor

unit or there're parts touching

together inside the indoor unit

Foreign objects inside the outdoor

unit or there're parts touching

together inside the outdoor unit

Short circuit inside the magnetic

coil

Abnormal shake of compressor Outdoor unit gives out abnormal sound

Abnormal sound inside the

compressor

Discriminating method (air conditioner status) Troubleshooting

Eliminate the foreign objects inside the drain

pipe

Water leaking from the pipe connection place of

indoor unit

There's the sound of "PAPA"

Water-running sound can be heard

There's abnormal sound fro indoor unit

There's abnormal sound fro outdoor unit

During heating, the way valve has abnormal

electromagnetic sound

Abnormal sound inside the compressor

Wrap it again and bundle it tightly

Normal phenomenon. Abnormal sound will

disappear after a few minutes.

Normal phenomenon. Abnormal sound will

disappear after a few minutes.

Remove foreign objects. Adjust all parts'

position of indoor unit, tighten screws and stick

damping plaster between connected parts

Remove foreign objects. Adjust all parts'

position of outdoor unit, tighten screws and

stick damping plaster between connected parts

Replace magnetic coil

Adjust the support foot mat of compressor,

tighten the bolts

If add too much refrigerant during maintenance,

please reduce refrigerant properly. Replace

compressor for other circumstances.

26

Installation and Maintenance

Page 27

www.cooperandhunter.us

Loading...

Loading...