Page 1

SOPHIA

MULTI-ZONE

INVERTER

SPLIT AIR CONDITIONER

WITH HEAT PUMP

INSTALLATION MANUAL

OUTDOOR UNIT

Models:

CH-18MSPH-230VO

CH-28MSPH-230VO

CH-36MSPH-230VO

CH-48MSPH-230VO

IMPORTANT NOTE:

•

Read this manual carefully before

installing or operating your new air

conditioning unit. Make sure to save

this manual for future reference.

•

This manual only describes the installation of

the outdoor unit. When installing the indoor unit,

refer to the installation manual of the indoor unit.

Page 2

Table of Contents

Installation Manual

1

Accessories

2

Safety Precautions

3

Installation Overview

4

Installation Diagram

5

Specications

....................................................................

.................................................

..........................................

............................................

..............................................................

04

05

06

07

08

6

Outdoor Unit Installation ................................. 09

A. Outdoor Unit Installation Instructions ....... 09

B. Drain Joint Installation ........................................... 11

C. Notes on Drilling the Hole in the Wall ....... 11

D. When Selecting a 24K Indoor Unit ............... 11

Page 3

Refrigerant Piping Connection .................. 12

7

L N

9

Air Evacuation

.......................................................

A. Evacuation Instructions

B. Note on Adding Refrigerant

.................................

......................

20

20

8

Wiring

A. Outdoor Unit Wiring

B. Wiring Figure

................................................................

..........................

..........................................

MC MC

14

14

16

10

Test Run

11

Function of Automatic Wiring/Piping Correction

........................................................................................................................2122

.........

23

Page 3

Page 4

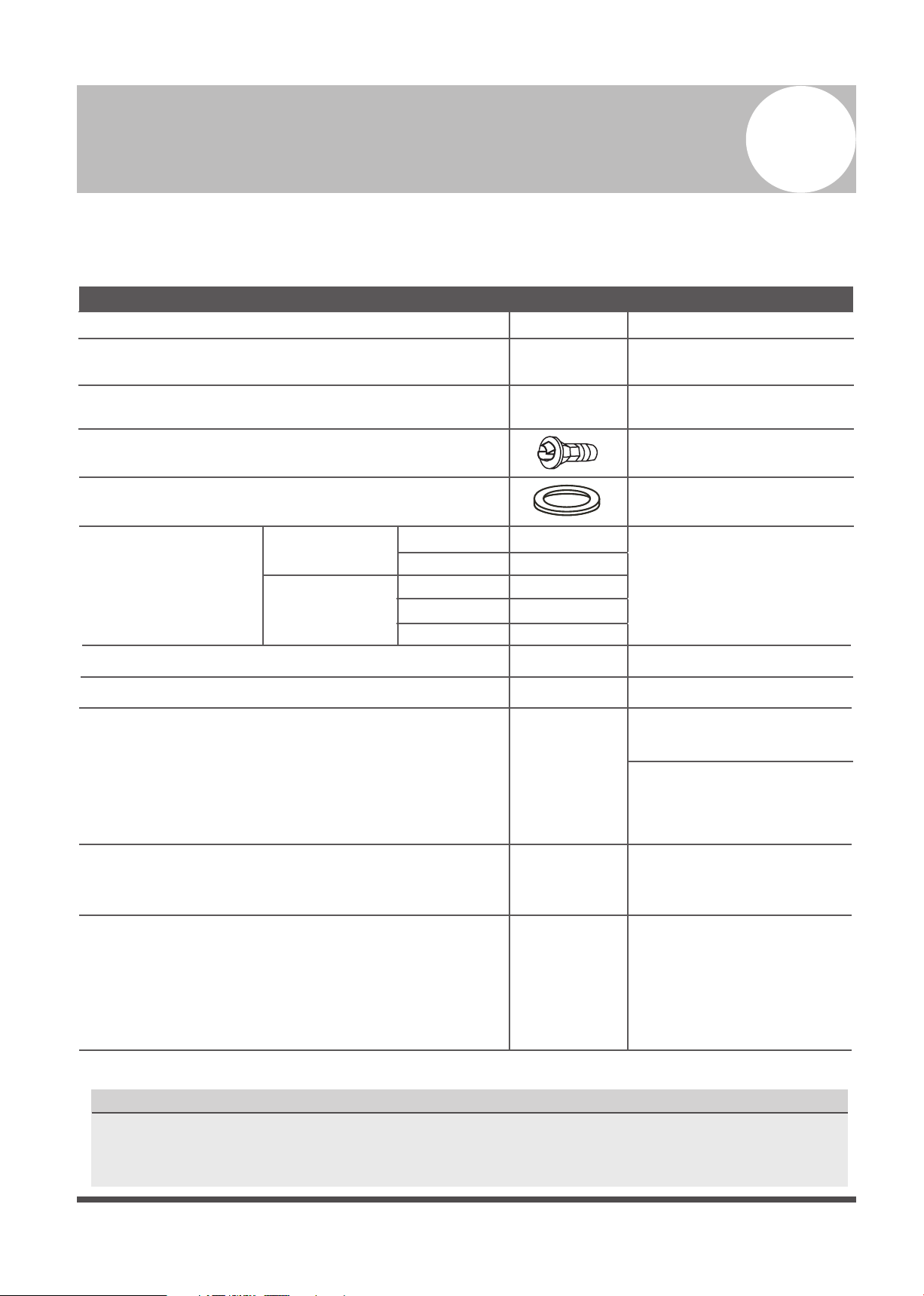

Accessories

1

The air conditioning system comes with the following accessories. Use all of the installation parts and

accessories to install the air conditioner. Improper installation may result in water leakage, electrical

shock, or fire, or cause the equipment to fail.

Name Shape Quantity

Installation plate

1

Plastic expansion sheath

Self-tapping screw AST3.9X25

Drain joint (some models)

Seal ring (some models)

Connecting

pipe

assembly

User’s manual

Installation manual

Transfer connector (packed with the indoor unit

or outdoor unit, depending on the model)

(NOTE: Pipe sizes dier from appliance to appliance.

To meet dierent pipe size requirements, sometimes a

transfer connector must be installed on the outdoor

Magnetic ring

(After installation, hitch this on the connective cable

between the indoor and outdoor units.)

Liquid side

Gas side

unit.)

Ø 6.35

Ø 9.52

Ø 9.52

Ø 12.7

Ø 15.9

5-8

(depending on the models)

5-8

(depending on the models)

1

1

Parts you must purchase

(consult your technician

for the proper size)

1

1

Optional part

(one piece per indoor unit)

Optional part

(1-5 pieces per outdoor unit,

depending on the model)

Optional part

(One piece per cable)

Cord protection rubber ring

(If the cord clamp cannot fasten the cord

because the cord is too small, wrap the cord

protection rubber ring (supplied with the

accessories) around the cord. Then x it with

the cord clamp.)

Optional Accessories

There are two types of remote controls: wired and wireless.

Select a remote control according to the customer's request and install it in an appropriate place.

To select a suitable remote control, refer to catalogues and technical literature.

Page 4

(on some models)

1

Page 5

Safety Precautions

Failure to observe a warning may result in death. The appliance must be installed in

accordance with national regulations.

Failure to observe a caution may result in injury or equipment damage.

Read safety precautions before installation

Incorrect installation due to ignoring instructions can cause serious damage or injury.

The seriousness of potential damage or injuries is classified as either a WARNING or CAUTION.

WARNING

CAUTION

WARNING

2

• Carefully read the safety precautions before installation.

• In certain functional environments, such as kitchens, server rooms, etc., the use of specially

designed air-conditioning units is highly recommended.

• Only trained and certied technicians should install, repair, and service this air

conditioning unit.

• Improper installation may result in electrical shock, short circuit, leaks, fire, or other damage to

equipment and personal property.

• Strictly follow the installation instructions set forth in this manual.

• Before you install the unit, consider strong winds, typhoons, and earthquakes that might aect

your unit and locate it accordingly. Failure to do so could cause damage to the unit.

• After installation, ensure there are no refrigerant leaks and that the unit is operating properly.

Refrigerant is toxic and flammable and poses a serious health and safety risk.

Note about Fluorinated Gasses

1. This air conditioning unit contains fluorinated gasses. For specific information on the type of gas

and the amount, please refer to the relevant label on the unit itself.

2. Installation, service, maintenance, and repair of this unit must be performed by a certified

technician.

3. Product uninstallation and recycling must be performed by a certified technician.

4. If the system has a leak-detection system installed, it must be checked for leaks at least every 12

months.

5.

When the unit is checked for leaks, proper record-keeping of all checks is strongly recommended.

Page 5

Page 6

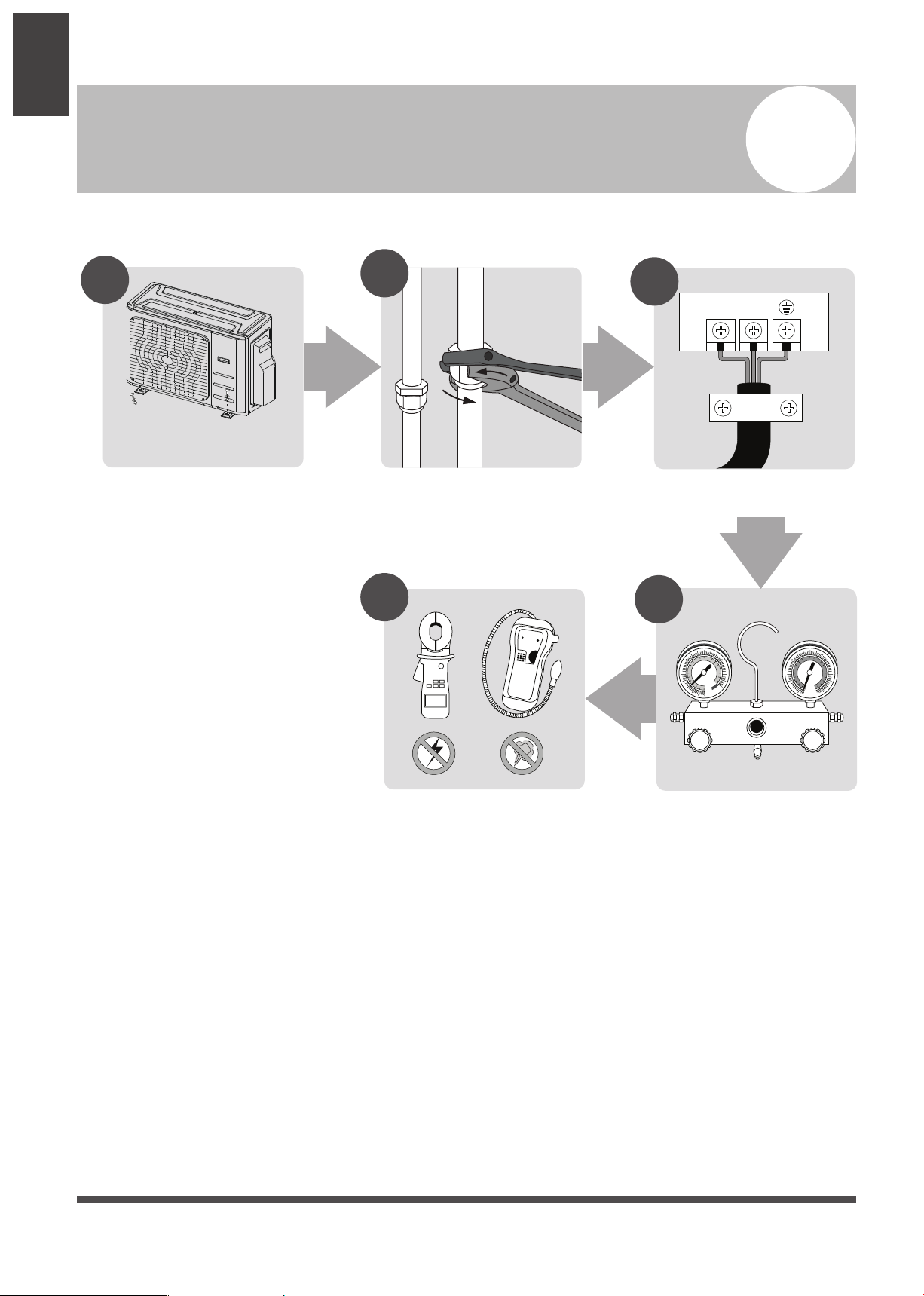

Unit Installation

L N

Overview

Installation Overview

3

INSTALLATION ORDER

1

Install the outdoor unit

(Page 9)

2

Connect the refrigerant pipes

(Page 12)

5

3

Connect the wires

(Page 14)

4

MC MC

Page 6

Perform a test run

(Page 22)

Evacuate the refrigeration

system

(Page 20)

Page 7

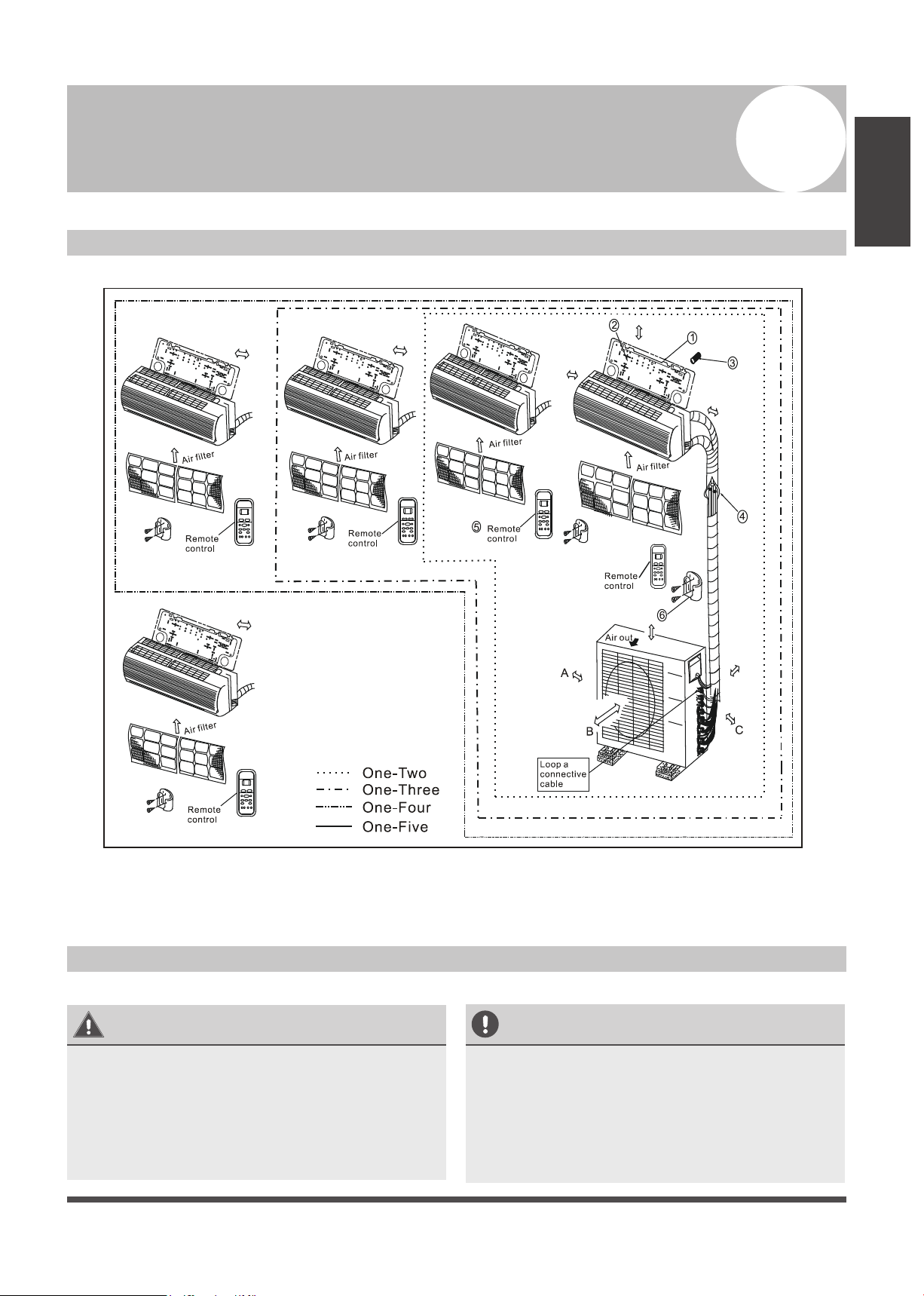

Installation Diagram

Installation Diagram

4

Installation

Diagram

More than 4.7 in (12 см)

More than 4.7 in (12 см)

More than 4.7 in (12 см)

More than 4.7 in

(12 см)

More than

3.9 in (10 см)

More than 78.7 in (200 см)

More than 5.9 in (15 см)

More than 4.7 in

(12 см)

(60 см)

More than 23.6 in

More than

11.8 in (30 см)

More than

23.6 in (60 см)

Safety Precautions

CAUTION

• This illustration is for explanation purposes

only. The actual shape of your air

condtioner may be slightly dierent.

•

Copper lines must be insulated

independently.

Fig. 4.1

CAUTION

• To prevent unnecessary damage to the wall,

use a stud nder to locate studs.

A minimum pipe run of 9.8 ft (3 m) is required

•

to minimize vibration and excessive noise.

•

Two of the A, B, and C directions should be

free from obstructions.

Page 7

Page 8

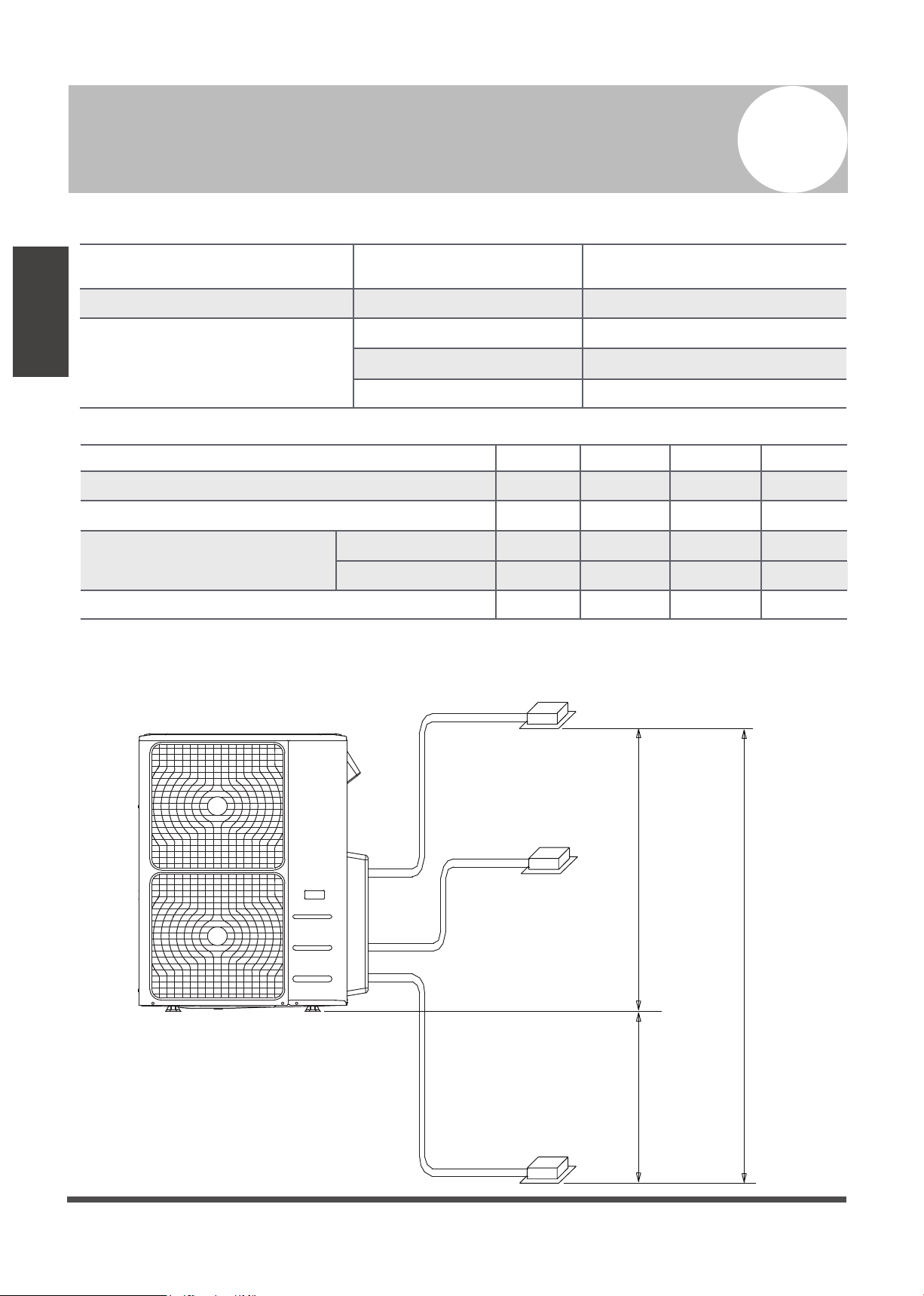

Specications

Table 5.1

5

Specications

Indoor units that can be used in

combination

Compressor stop/start frequency Stop time 3 minutes or more

Power source voltage

Table 5.2

Max. length for all rooms 98.4/30 147.6/45

Max. length for one indoor unit 65.6/20 82/25

Max. height dierent between

indoor and outdoor unit

Max. height dierence between indoor units

When installing multiple indoor units to a single outdoor unit, ensure that the length of the refrigerant

pipe and the drop height between the indoor and outdoor units meet the following requirements:

Outdoor unit

Number of connected

units

Voltage uctuation within ± 10% of rated voltage

Voltage drop during start within ± 15% of rated voltage

Interval unbalance within ± 3% of rated voltage

1 drive 2 1 drive 3

OU higher than IU

OU lower than IU 49/15 49/15

32.8/10 32.8/10

32.8/10 32.8/10

Indoor unit

1-5 units

Unit: ft/m

1 drive 4 1 drive 5

196.8/60 246/75

98.4/30 98.4/30

32.8/10 32.8/10

49/15 49/15

32.8/10 32.8/10

Max. height dierence

Outdoor Unit

Page 8

Indoor unit

49ft (15m)

49ft (15m)

32.8ft (10m)

Indoor unit

Page 9

Outdoor Unit Installation

Outdoor Unit Installation Instructions

Step 1: Select installation location

When choosing a location to install the outdoor

unit, consider the following:

√

Place the outdoor unit as close to the indoor

unit as possible.

√

Ensure that there is enough room for

installation and maintenance.

√

The air inlet and outlet must not be

obstructed or exposed to strong wind.

√

Ensure the location of the unit will not be

subject to snowdrifts, accumulation of leaves,

or other seasonal debris. If possible, provide

an awning for the unit. Ensure the awning

does not obstruct airflow.

√

The installation area must be dry and well

ventilated.

√

There must be enough room to install the

connecting pipes and cables and to access

them for maintenance.

6

√

The area must be free of combustible gases

and chemicals.

√

The pipe length between the outdoor and

indoor units must not exceed the maximum

allowable pipe length.

√

If possible, DO NOT install the unit where it

will be exposed to direct sunlight.

√

If possible, make sure the unit is located far

away from your neighbors’ property so that

the noise from the unit will not disturb them.

√

If the location is exposed to strong winds (for

example, near a seaside), place the unit

against the wall to shelter it from the

wind. If necessary, use an awning

(see Fig. 6.1 & 6.2).

√

Install the indoor and outdoor units, cables,

and wires at least 1 meter from televisions or

radios to prevent static or image distortion.

Depending on the radio waves, a 39.3 in (1 meter)

distance may not be enough to eliminate all

interference.

Outdoor Unit

Installation

Strong wind

Fig. 6.1

Step 2: Install outdoor unit

Fix the outdoor unit with anchor bolts (M10)

>23.6”/60 cm

Fix with bolts

Strong wind

Fig. 6.2

CAUTION

• Be sure to remove any obstacles that

may block air circulation.

• Be sure to refer to Length

Specifications to ensure there is

enough room for installation and

maintenance.

Fig. 6.3

Page 9

Page 10

Split Type Outdoor Unit

(Refer to Fig 6.4, 6.5, 6.6, 6.10, and Table 6.1)

Table 6.1: Length Specications of Split Type

Outdoor Unit (unit: inch/mm)

Outdoor Unit

Installation

W

Fig. 6.4

W

H

Outdoor Unit Dimensions

W x H x D

760 x 590 x 285 (29.9 x 23.2 x 11.2) 20.85 (530) 11.4 (290)

810 x 558 x 310 (31.9 x 22 x 12.2) 21.6 (549) 12.8 (325)

845 x 700 x 320 (33.27 x 27.5 x 12.6) 22 (560) 13.2 (335)

900 x 860 x 315 (35.4 x 33.85 x 12.4) 23.2 (590) 13.1 (333)

945 x 810 x 395 (37.2 x 31.9 x 15.55) 25.2 (640) 15.95 (405)

990 x 965 x 345 (38.98 x 38 x 13.58) 24.58 (624) 14.4 (366)

938 x 1369 x 392 (36.93 x 53.9 x 15.43) 24.96 (634) 15.9 (404)

900 x 1170 x 350 (35.4 x 46 x 13.8) 23.2 (590) 14.88 (378)

800 x 554 x 333 (31.5 x 21.8 x 13.1) 20.24 (514) 13.39 (340)

845 x 702 x 363 (33.27 x 27.6 x 14.3)

946 x 810 x 420 (37.2 x 31.9 x 16.53) 26.5 (673)

946 x 810 x 410 (37.2 x 31.9 x 16.14) 26.5 (673)

952 x 1333 x 410 (37.5 x 52.5 x 16.14) 24.96 (634)

952 x 1333 x 415 (37.5 x 52.5 x 16.14) 24.96 (634)

Mounting Dimensions

Distance A Distance B

21.26 (540)

13.8 (350)

15.87 (403)

15.87 (403)

15.9 (404)

15.9 (404 )

D

H

Fig. 6.5

A

B

Page 10

Fig. 6.6

Page 11

NOTE: The minimum distance between the

outdoor unit and walls described in the

installation guide does not apply to airtight

rooms. Be sure to keep the unit unobstructed

in at least two of the three directions

(M, N, and P) (see Fig. 6.7).

23.6”/60 cm above

Notes on Drilling the Hole in the Wall

You must drill a hole in the wall for the

refrigerant piping and the signal cable that will

connect the indoor and outdoor units.

Determine the location of the wall hole

1.

based on the location of the outdoor unit.

Using a 2.5” (65 mm) core drill, drill a hole

2.

in the wall.

11.8”/30 cm on left

M

78”/200 cm in front

N

11.8”/30 cm from back wall

23.6”/60 cm on right

P

Fig. 6.7

Drain Joint Installation

Before bolting the outdoor unit in place, install

the drain joint at the bottom of the unit.

(See Fig. 6.8)

1. Fit the rubber seal on the end of the drain

joint that will connect to the outdoor unit.

2. Insert the drain joint into the hole in the

base pan of the unit.

3. Rotate the drain joint 90° until it clicks in

place facing the front of the unit.

4. Connect a drain hose extension (not

included) to the drain joint to redirect water

from the unit during heating mode.

NOTE: Make sure the water drains to a safe

location where it will not cause water damage

or a slipping hazard.

NOTE: When drilling the wall hole, make

sure to avoid wires, plumbing, and other

sensitive components.

3.

Place the protective wall cu in the hole.

This will protect the edges of the hole and will

help seal it when you nish the installation

process.

When Selecting a 24K Indoor Unit

The 24K indoor unit can only be connected with an

A system. If there are two 24K indoor units, they

can be connected with an A and B system

(see Fig. 6.9).

Table 6.2: Connective pipe size of an A and B

system (unit: inch)

Indoor Unit capacity

(Btu/h)

Liquid Gas

7K/9K/12K 1/4 3/8

12K/18K 1/4 1/2

24K 3/8 5/8

Outdoor Unit

Installation

Base pan hole of

outdoor unit

Seal

Seal

Drain joint

(A) (B)

Fig. 6.8

Fig. 6.9

Page 11

Page 12

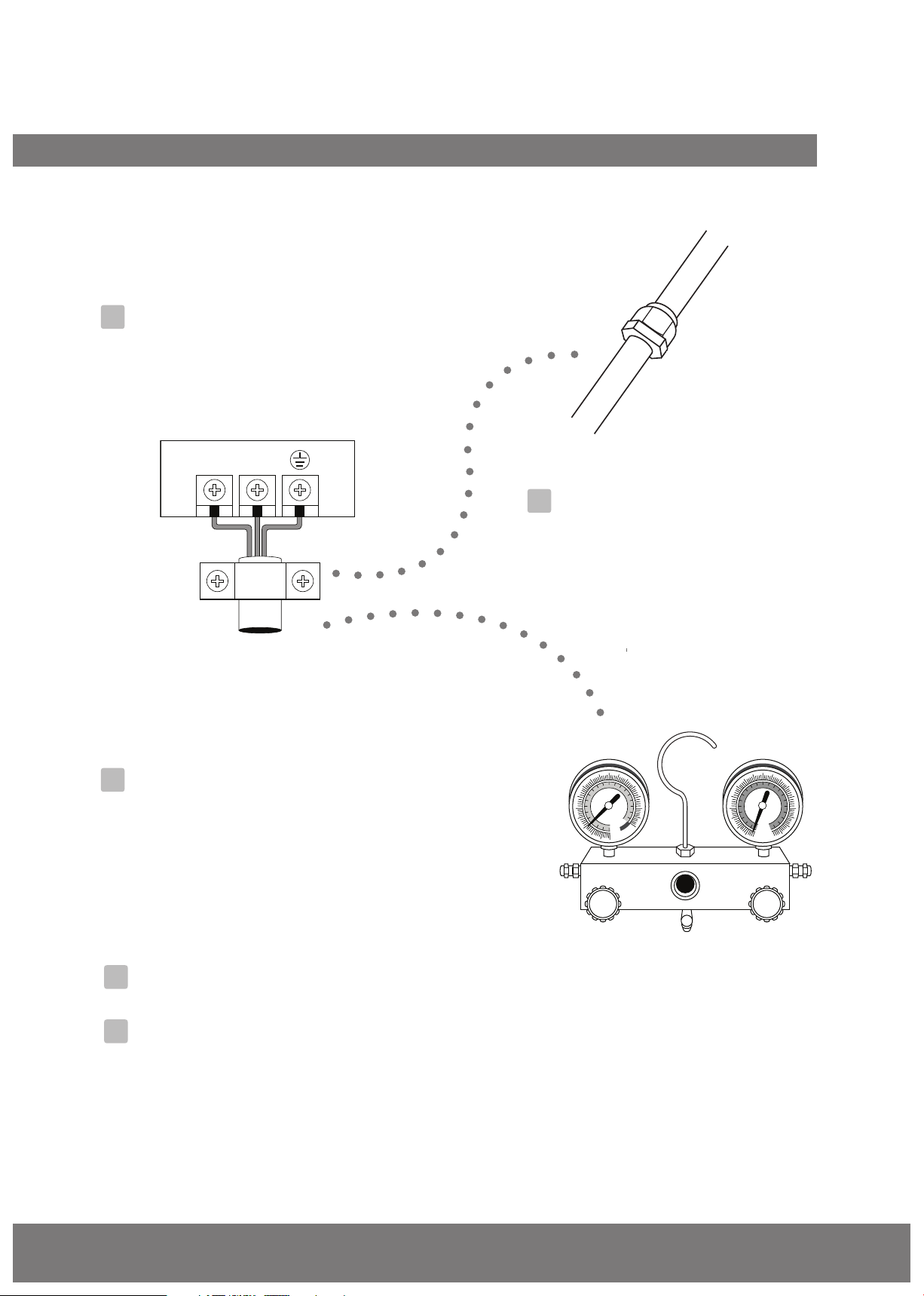

Refrigerant Piping Connection

Point down

7

Safety Precautions

• All eld piping must be completed by a

• When the air conditioner is installed in a small

• When installing the refrigeration system,

Refrigerant Piping

Connection

•

Refrigerant Piping Connection Instructions

WARNING

licensed technician and must comply with

local and national regulations.

room, measures must be taken to prevent the

refrigerant concentration in the room from

exceeding the safety limit in the event of

refrigerant leakage. If the refrigerant leaks

and its concentration exceeds its proper limit,

hazards due to lack of oxygen may result.

ensure that air, dust, moisture, or foreign

substances do not enter the refrigerant circuit.

Contamination in the system may cause poor

operating capacity, high pressure in the

refrigeration cycle, explosion, or injury.

Ventilate the area immediately if there is

refrigerant leakage during the installation.

Leaked refrigerant gas is both toxic and

flammable. Ensure there is no refrigerant

leakage after completing the installation work.

CAUTION

DO NOT deform pipe while cutting. Be extra

careful not to damage, dent, or deform the pipe

while cutting. This will drastically reduce the

heating efficiency of the unit.

1. Make sure the pipe is cut at a perfect

Step 2: Remove burrs

Burrs can aect the air-tight seal of the refrigerant

piping connection. They must be completely

removed.

1. Hold the pipe at a downward angle to

2. Using a reamer or deburring tool, remove

90° angle. Refer to Fig. 7.1 for examples of

bad cuts.

90°

Oblique

Rough

Warped

Fig. 7.1

prevent burrs from falling into the pipe.

all burrs from the cut section of the pipe.

Pipe

Reamer

CAUTION

• The branching pipe must be installed

horizontally. An angle of more than 10° may

cause malfunction.

• DO NOT install the connecting pipe until both

the indoor unit and the outdoor unit have

been installed.

• Insulate the gas and liquid piping to

prevent water leakage.

Step1: Cut pipes

When preparing refrigerant pipes, take extra

care to cut and flare them properly. This will

ensure efficient operation and minimize the

need for future maintenance.

1. Measure the distance between the indoor

and outdoor units.

2. Using a pipe cutter, cut the pipe a little

longer than the measured distance.

Page 12

Fig. 7.2

Step 3: Flare pipe ends

Proper flaring is essential to achieve an airtight seal.

1. After removing burrs from the cut pipe, seal

the ends with PVC tape to prevent foreign

materials from entering the pipe.

2. Sheath the pipe with insulating material.

3. Place flare nuts on both ends of the pipe.

Make sure they are facing in the right

direction because you can’t put them on

or change their direction after aring

(see Fig. 7.3).

Flare nut

Copper pipe

Fig. 7.3

Page 13

4. Remove the PVC tape from the ends of the

pipe when you're ready to perform the aring

work.

5. Clamp the are form on the end of the pipe. The

end of the pipe must extend beyond the flare

form.

Flare form

NOTE: Use both a spanner and a torque wrench

when connecting or disconnecting pipes to/from

the unit.

Fig. 7.4

Pipe

6. Place the aring tool onto the form.

7. Turn the handle of the flaring tool

clockwise until the pipe is fully flared. Flare

the pipe in accordance with the dimensions

shown in table 7.1.

Table 7.1: PIPING EXTENSION BEYOND FLARE

FORM

Pipe

gauge

Ø 6.4

Ø 9.5

Ø 12.7

Ø 15.9

Ø 19.1

Ø 22

Tightening

torque

14.2-17.2 N.m

(144-176 kgf.cm)

32.7-39.9 N.m

(333-407 kgf.cm)

49.5-60.3 N.m

(504-616 kgf.cm)

61.8-75.4 N.m

(630-770 kgf.cm)

97.2-118.6 N.m

(990-1210 kgf.cm)

109.5-133.7 N.m

(1117-1364 kgf.cm)

Flare dimension (A)

(Unit: in/mm)

Min. Max.

0.3/8.3 0.3/8.3

0.48/12.4 0.48/12.4

0.6/15.4 0.6/15.8

0.7/18.6 0.74/19

0.9/22.9 0.91/23.3

1.06/27 1.07/27.3

Flare shape

°

4

±

90

45

°

±

A

R0.4~0.8

Fig. 7.5

2

8. Remove the flaring tool and flare form,

then inspect the end of the pipe for cracks

and even flaring.

Step 4: Connect pipes

Connect the copper pipes to the indoor unit first,

then connect them to the outdoor unit. First connect

the low-pressure pipe, then the high-pressure pipe.

1. When connecting the flare nuts, apply a thin

coat of refrigeration oil to the flared ends of

the pipes.

2. Align the center of the two pipes that you will

connect.

Indoor unit tubing

Fig. 7.6

Flare nut

Pipe

3. Tighten the flare nut as tightly as possible

by hand.

4. Using a spanner, grip the nut on the unit

tubing.

5. While firmly gripping the nut, use a torque

wrench to tighten the flare nut according to

the torque values in table 7.1.

Fig. 7.7

CAUTION

• Be sure to wrap insulation around the piping.

Direct contact with the bare piping may result

in burns or frostbite.

• Make sure the pipe is properly connected.

Over tightening may damage the bell mouth

and under tightening may lead to leakage.

NOTE ON MINIMUM BEND RADIUS

Carefully bend the tubing in the middle

according to the diagram below. DO NOT bend

the tubing more than 90° or more than 3 times.

Bend the pipe with your thumb

min. radius 10 cm (3.9”)

Fig. 7.8

6. After connecting the copper pipes to the

indoor unit, wrap the power cable, signal

cable, and piping together with binding

tape.

NOTE: When bundling these items together,

do not intertwine or cross the signal

cable with any other wiring.

7. Thread this pipeline through the wall and

connect it to the outdoor unit.

8. Insulate all the piping, including the valves

of the outdoor unit.

9. Open the stop valves of the outdoor unit to

start the flow of the refrigerant between

the indoor and outdoor units.

CAUTION

After completing the installation work, make sure

there is no refrigerant leak. If there is, ventilate

the area immediately and evacuate the system

(refer to the Air Evacuation section of this

manual).

Refrigerant Piping

Connection

Page 13

Page 14

Wiring

8

Wiring

Safety Precautions

WARNING

• Be sure to disconnect the power supply

before working on the unit.

• All electrical wiring must be done

according to local and national regulations.

• Electrical wiring must be done by a

qualied technician. Improper connections

may cause electrical malfunction, injury,

and fire.

• An independent circuit and single outlet

must be used for this unit. DO NOT plug

another appliance or charger into the

same outlet. If the electrical circuit capacity

is not enough or there is a defect in the

electrical work, it can lead to shock, re,

and unit and property damage.

• Connect the power cable to the terminals

and fasten it with a clamp. An insecure

connection may cause a re.

• Make sure that all wiring is done correctly

and the control board cover is properly

installed. Failure to do so can cause

overheating at the connection points, fire,

and electrical shock.

• Ensure that the main supply connection is

made through a switch that disconnects

all poles, with a contact gap of a least

0.118 in (3 mm).

• DO NOT modify the length of the power

cord or use an extension cord.

Follow these instructions to prevent distortion

when the compressor starts:

• The unit must be connected to the main

outlet. Normally, the power supply must

have a low output impedance of 32 ohms.

• No other equipment should be connected

to the same power circuit.

• The unit’s power information can be found

on the rating sticker on the product.

Outdoor Unit Wiring

WARNING

Before performing any electrical or wiring work,

turn o the main power to the system.

1. Prepare the cable for connection

A. First choose the right cable size. Be sure to

use H07RN-F cables.

Table 8.1: Minimum Cross-Sectional Area

of Power and Signal Cables North America

Rated Current of

Appliance (A)

≤ 7 18

AWG

CAUTION

• Connect the outdoor wires before

connecting the indoor wires.

• Make sure to ground the unit. The

grounding wire should be away from gas

pipes, water pipes, lightning rods,

telephone wires, or other grounding wires.

Improper grounding may cause electrical

shock.

• DO NOT connect the unit with the power

source until all wiring and piping is

completed.

• Make sure that you do not cross your

electrical wiring with your signal wiring, as

this can cause distortion and interference.

Page 14

7 - 13 16

13 - 18 14

18 - 25 12

25 - 30 10

Page 15

Table 8.2: Other Regions

Rated Current of

Appliance (A)

Nominal Cross-Sectional

Area (mm²)

≤ 6 0.75

6 - 10 1

10 - 16 1.5

16 - 25 2.5

25 - 32 4

32 - 45 6

B. Using wire strippers, strip the rubber jacket

from both ends of the signal cable to reveal

about 5.9 in (15 cm) of the wires inside.

C. Strip the insulation from the ends of the

wires.

D. Using a wire crimper, crimp u-lugs on the

ends of the wires.

5. Insulate unused wires with electrical tape.

Keep them away from any electrical or metal

parts.

6. Reinstall the cover of the electric control box.

NOTE: While connecting the wires, please

strictly follow the wiring diagram (found inside

the electrical box cover).

2. Remove the electric cover of the outdoor unit.

If there is no cover on the outdoor unit,

disassemble the bolts from the maintenance

board and remove the protection board

(see Fig. 8.1).

Cover

Screw

Wiring

Fig. 8.1

3. Connect the u-lugs to the terminals.

Match the wire colors/labels with the labels on

the terminal block, then rmly screw the u-lug

of each wire to its corresponding terminal.

4. Clamp down the cable with the designated

cable clamp.

Page 15

Page 16

Wiring Figure

CAUTION

Connect the connective cables to the terminals as identied with their respective matched

numbers on the terminal block of the indoor and outdoor units. For example, see the following US

models: Terminal L1(A) on the outdoor unit must connect with terminal L1 on the indoor unit.

NOTE: If the client wants to perform the wiring himself, refer to the following gures.

Run the main power cord through the lower line-outlet of the cord clamp.

One-two models:

Wiring

Page 16

Model A

Model B Model C Model D

Model E Model F Model G

Magnetic ring (not supplied, optional part)

(Used to hitch to the connective cable of the indoor

and outdoor units after installation.)

Page 17

NOTE: If the client wants to perform the wiring himself, refer to the following gures.

One-three models:

Model D Model E Model F

One-four models:

Model A

Model G

Model B

Model C

Wiring

Model A Model B

Model C Model D

Page 17

Page 18

Wiring

Model G

One-ve models:

Model E

Model F

Page 18

Model A Model B

Model C Model D

Page 19

Model E

Model F

Model G

CAUTION

After the conrmation of the above conditions, prepare the wiring as follows:

• Never fail to delegate an individual power circuit specically for the air conditioner. For the

method of wiring, use the circuit diagram posted on the inside of the control cover as a guide.

• The screws which fastens the wiring in the casing of electrical ttings are liable to come loose

from vibrations to which the unit will be subjected during the course of transportation. Check to

make sure they are all tightly fastened. (If they are loose, the wires could burn out.)

• Specication of power source.

• Conrm that the electrical capacity is sucient.

• See that the starting voltage is maintained at more than 90 percent of the rated voltage

marked on the name plate.

• Conrm that the cable thickness is as specied in the power source specication.

Wiring

• Always install an earth leakage circuit breaker in a wet or moist area.

• The following could be caused by a voltage drop: The vibration of a magnetic switch (which will

damage the contact point), the breakage of a fuse, or the disturbance of the normal function of

the overload.

• The means for disconnection from a power supply must be incorporated in the xed wiring

and have an air gap contact separation of at least 0.12 in (3 mm) in each active (phase) conductor.

• Before terminals are accessed, all supply circuits must be disconnected.

Page 19

Page 20

Air Evacuation

V

9

Safety Precautions

CAUTION

• Use a vacuum pump with a gauge reading

lower than -0.1 MPa and an air discharge

capacity above 40 L/min.

• The outdoor unit does not need vacuuming.

DO NOT open the outdoor unit’s gas and

liquid stop valves.

• Ensure that the compound meter reads

-0.1 MPa or below after 2 hours. If after 3

hours of operation the gauge reading is

still above -0.1 MPa, check if there is a gas leak

or water inside the pipe. If there is no leakage,

perform another evacuation for 1 or 2 hours.

• DO NOT use refrigerant gas to evacuate the

system.

Evacuation Instructions

Before using the manifold gauge or vacuum

pump, read their operation manuals to familiarize

yourself with how to use them properly.

Low-pressure valve

1. Connect the charge hose of the manifold

gauge to the service port on the outdoor unit’s

low-pressure valve.

2. Connect another charge hose from the

manifold gauge to the vacuum pump.

3. Open the low-pressure side of the manifold

gauge. Keep the low-pressure side closed.

4. Turn on the vacuum pump to evacuate the system.

5. Run the vacuum for at least 15 minutes, or until

the compound meter reads -76 cmHG (-1x105 Pa).

6. Close the low-pressure side of the manifold

gauge and turn o the vacuum pump.

7. Wait 5 minutes, then check that there has

been no change in the system pressure.

Manifold gauge

Compound gauge

-76 cmHg

Charge hose

Low-pressure valve

Fig. 9.1

Pressure gauge

High-pressure valve

Charge hose

Vacuum pump

NOTE: If there is no change in the system pressure,

unscrew the cap from the packed valve (highpressure valve). If there is a change in the system

pressure, there may be a gas leak.

8. Insert a hexagonal wrench into the packed valve

(high-pressure valve) and open the valve by

turning the wrench counterclockwise a 1/4 turn.

Listen for gas to exit the system, then

close the valve after 5 seconds.

Flare nut

Cap

alve body

Valve stem

Fig. 9.2

9. Watch the Pressure Gauge for one minute to

make sure that there is no change in pressure.

The pressure gauge should read slightly higher

than atmospheric pressure.

10.Remove the charge hose from the service port.

11. Using a hexagonal wrench, fully open both the

high-pressure and high-pressure valves.

OPEN VALVE STEMS GENTLY

When opening valve stems, turn the hexagonal

wrench until it hits against the stopper. DO NOT

try to force the valve to open further.

12.Tighten the valve caps by hand, then tighten

them using the proper tool.

13.If the outdoor unit uses all vacuum valves,

and the vacuum position is at the main

valve, the system is not connected with the

indoor unit and must be tightened with a

screw nut. Check the gas leakage before

operation to prevent leakage.

Fig. 9.3

Air Evacuation

Page 20

Page 21

Note on Adding Refrigerant

CAUTION

• Refrigerant charging must be performed after wiring, vacuuming, and the leak test.

• DO NOT exceed the maximum allowable quantity of refrigerant or overcharge the system.

Doing so may damage or impact the unit’s function.

• Charging with unsuitable substances may cause explosions or accidents. Ensure that the

appropriate refrigerant is used.

•

Refrigerant containers must be opened slowly. Always use protective gear when charging the system.

• DO NOT mix refrigerant types.

N=2 (one-twin models), N=3 (one-three models), N=4 (one-four models), N=5 (one-ve models).

Some systems require additional charging depending on pipe lengths. The standard pipe length varies

according to local regulations. For example, in North America, the standard pipe length is 7.5 m (25 ft)

In other areas, the standard pipe length is 5 m (16 ft). The additional refrigerant to be charged can be

calculated using the following formula:

ADDITIONAL REFRIGERANT PER PIPE LENGTH

Connective Pipe

Length

Pre-charge pipe length (ft/m)

(standard pipe length x N)

More than (standard

pipe length x N) ft/m

Air Purging

Method

Vacuum pump

Vacuum pump

(Total pipe length - standard pipe length x N) x 15 g/m

(Total pipe length - standard pipe length x N) x 0.16 oZ/ft

Safety And Leakage Check

Electrical safety check

Perform the electric safety check after

completing installation:

1. Insulated resistance

The insulated resistance must be more

than 2 MΩ.

2. Grounding work

Air Evacuation

After nishing the grounding work, measure

the grounding resistance by visual detection

and with a grounding resistance tester. Make

sure the grounding resistance is less than 4 Ω.

3. Electrical leakage check (performed during

test running)

During test operation after installation is

nished, the service man can use the

electroprobe and multimeter to perform

the electrical leakage check. Turn o the

unit immediately if there is leakage.

Look for a solution to the problem until

the unit operates properly.

Additional Refrigerant (

Liquid Side: Ø 6.35 (Ø 1/4”)

Gas leak check

1. Soapy water method:

To check for leakage in the connecting points

of the piping, use a soft brush to apply soapy

water or a liquid neutral detergent to the

indoor or outdoor unit connections. If bubbles

come out, there is leakage.

2. Leak detector

Use the leak detector to check for leakage.

NOTE: The illustration is for explanation purposes

only. The actual order of A, B, C, D and E on the

machine may be slightly dierent from the unit

you purchased. The actual shape shape prevails.

Outdoor unit

check point

R410A:)

N/A

Liquid Side: Ø 9.52 (Ø 3/8”)

(Total pipe length - standard pipe length x N) x 30 g/m

(Total pipe length - standard pipe length x N) x 0.32 oZ/ft

Indoor unit

check point

Page 21

Fig. 9.4

A, B, C, and D are points on a one-four type.

A, B, C, D, and E are points on a one-ve type.

Page 22

Test Run

10

Before Test Run

A test run must be performed after the entire

system has been completely installed. Confirm

the following points before performing the test:

a) The indoor and outdoor units are properly

installed.

b) Piping and wiring are properly connected.

c) No obstacles are near the inlet and outlet of

the unit that might cause poor performance

or product malfunction.

d) The refrigeration system does not leak.

e) The drainage system is unimpeded and

draining to a safe location.

f) The heating insulation is properly installed.

g) The grounding wires are properly connected.

h) The length of the piping and the added

refrigerant stow capacity have been recorded.

i) The power voltage is the correct voltage for

the air conditioner.

F. Check that the drainage system is

unimpeded and draining smoothly.

G. Make sure there is no vibration or

abnormal noise during operation.

5. For the outdoor unit:

A. Check to see if the refrigeration system is

leaking.

B. Make sure there is no vibration or

abnormal noise during operation.

C. Make sure the wind, noise, and water

generated by the unit do not disturb your

neighbors or pose a safety hazard.

NOTE: If the unit malfunctions or does not

operate according to your expectations, please

refer to the Troubleshooting section of the

User's manual before calling customer service.

CAUTION

Failure to perform the test run may result in unit

damage, property damage, or personal injury.

Test Run Instructions

1. Open both the liquid and gas stop valves.

2. Turn on the main power switch and allow the

unit to warm up.

3. Set the air conditioner to COOL mode.

4. For the indoor unit:

A. Ensure the remote control and its buttons

work properly.

B. Ensure the louvers move properly and can

be changed using the remote control.

C. Double check to see if the room

temperature is being registered correctly.

D. Ensure the indicators on the remote control

and the display panel on the indoor unit

work properly.

E. Ensure the manual buttons on the indoor

unit works properly.

Test Run

Page 22

Page 23

Function of Automatic Wiring/Piping Correction

11

Automatic Wiring/Piping Correction Function

The new product is able to automatically correct a wiring/piping error. Press the "check switch" on the

outdoor unit PCB board for 5 seconds until the LED display shows "CE." This means the function is

working. Approximately 5-10 minutes after the switch is pressed, "CE" will disappear, the wiring/piping

error will be corrected, and the wiring/piping will be properly connected.

Check switch

LED display

Correct

Terminal

block

Liquid/

gas pipe

Outdoor unit

Incorrect wiring

B

A

Indoor unit B

B

A

Indoor unit A

Automatic

Correction Function

How to Activate This Function

1. Check that the outside temperature is above 41° F (5° C).

(This fuction does not work when the outside temperature is not above 41° F (5° C))

2. Check that the stop valves on the liquid and gas pipes are open.

3. Turn on the breaker and wait at least 2 minutes.

4. Press the check switch on the outdoor PCB board until the LED display shows "CE."

Outdoor unit

Incorrect wiring

Outdoor unit

Terminal

block

Liquid/

gas pipe

Terminal

block

Liquid/

gas pipe

B

A

Indoor unit B

B

A

Indoor unit A

B

A

Indoor unit B

B

A

Indoor unit A

Page 23

Page 24

The design and specications are subject to change without prior notice for product

improvement. Consult with the sales agency or manufacturer for details.

www.cooperandhunter.us

Loading...

Loading...