Cooper&Hunter CH09SPH115V, CH18SPH230V, CH24SPH230V, CHS30FTXWSV, CH12SPH115V Troubleshooting Guide

...Page 1

SOPHIA

SPLIT AIR CONDITIONER

WITH HEAT PUMP

TROUBLESHOOTING

Page 2

1.1 Indoor Unit Error Display

Operation

lamp

Indoor room temperature sensor T1 open circuit or

short circuit

Evaporator coil temperature sensor T2 open circuit or

short circuit

O

F0

Outdoor ambient temp erature sensor T4 open circuit or

short circuit

Condenser coil temperature sensor T3 open circuit or

short circuit

Compressor discharge t emp er at ur e sensor TP open

circuit or short circuit

High temperature protection of IPM module or

compressor top

7 times

P6

Low pressure protection(Only for 36K)

Timer lamp Display LED STATUS

☆ 1 time

☆ 2 times

☆ 3 times

☆ 4 times

☆ 5 times

☆ 6 times

☆ 7 times

☆ 1 times

☆ 2 times

☆ 3 times

☆ 4 times

☆ 5 times

☆ 6 times

☆ 1 times ☆

X E0 Indoor unit EEPROM parameter er r or

X E1 Indoor / outdoor units com mu nication error

X E2 Zero-crossing signal detection error

X E3 Indoor fan speed has been out of cont rol

X E4

X E5

X EC Refrigerant leakage detection

O F1

O F2

O F3

O F4 Outdoor unit EEPROM parameter error

O F5 Outdoor fan speed has been out of contr ol

Overload current protect io n

P0 IPM malfunction or IG BT over-strong current protection

☆ 2 times ☆

☆ 3 times ☆

☆ 4 times ☆

☆ 5 times ☆

☆ 6 times ☆

☆

*P3

1) In heating mode, when the outdoor temperature is lower than -25℃ for 1 hour, the indoor unit

display error code P3.

2) If the outdoor temperature is higher than -22℃ for 10 minutes and compressor stop for 1 hour or

outdoor temperature is hi gher than -5℃ for 10 minutes, then the unit will return to work.

* Fault Symptom: The display board shows a garbled code or a code that is not an error code found

in the service manual nor a t emp er at ur e r eading.

Trouble shooting:

Use the remote controller. If the unit does not respond to t he r em ot e, the indoor PCB needs to be

replaced; if the unit does respond, then the display board needs to be replaced

☆

O(light) X(off) ☆(flash)

P1 Over voltage or over low voltage protection

P2

P3* Outdoor ambient temperature too low.

P4 Inverter compressor drive error

P5 Indoor units mode conflict (multi-zone ONLY)

Page 3

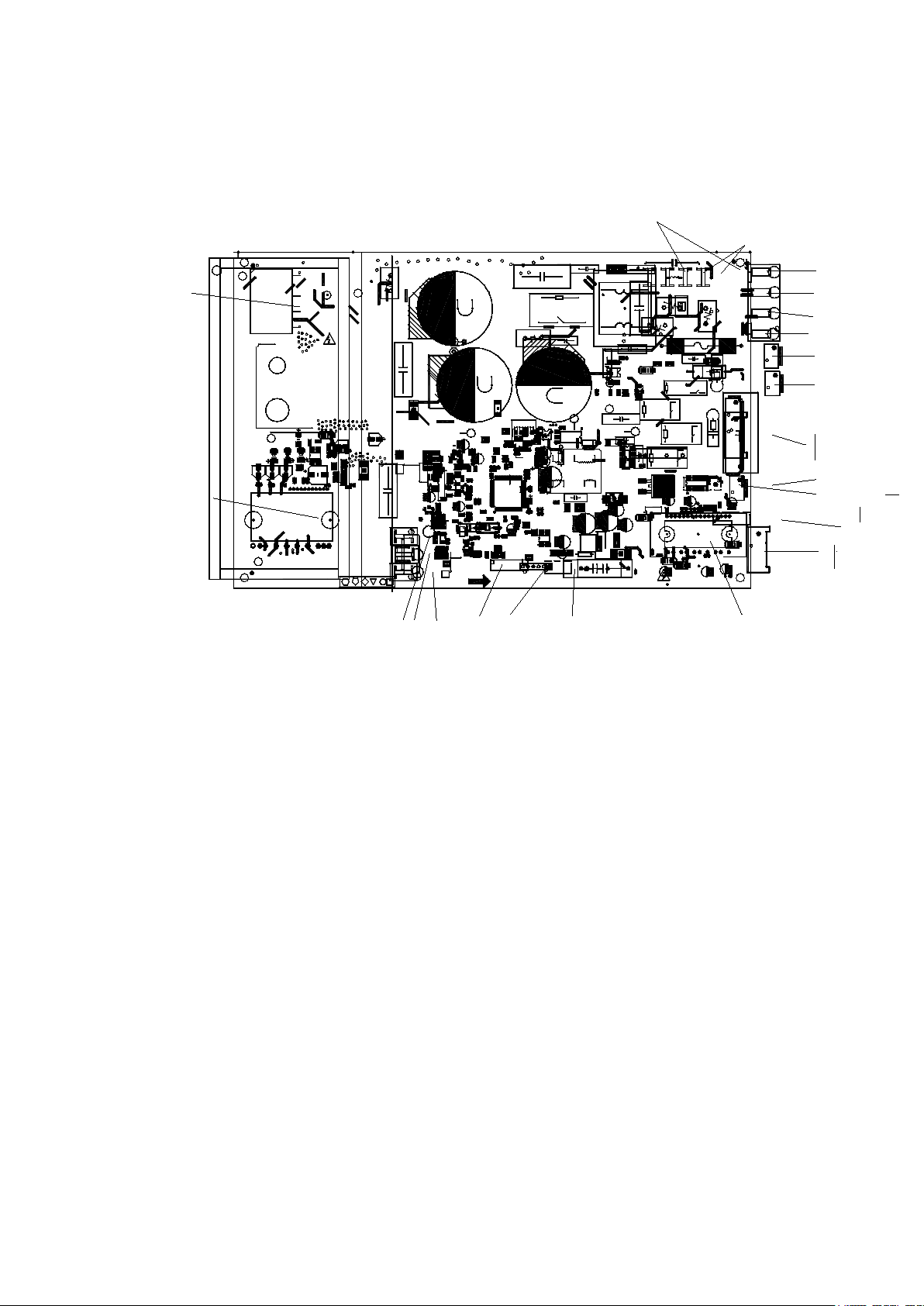

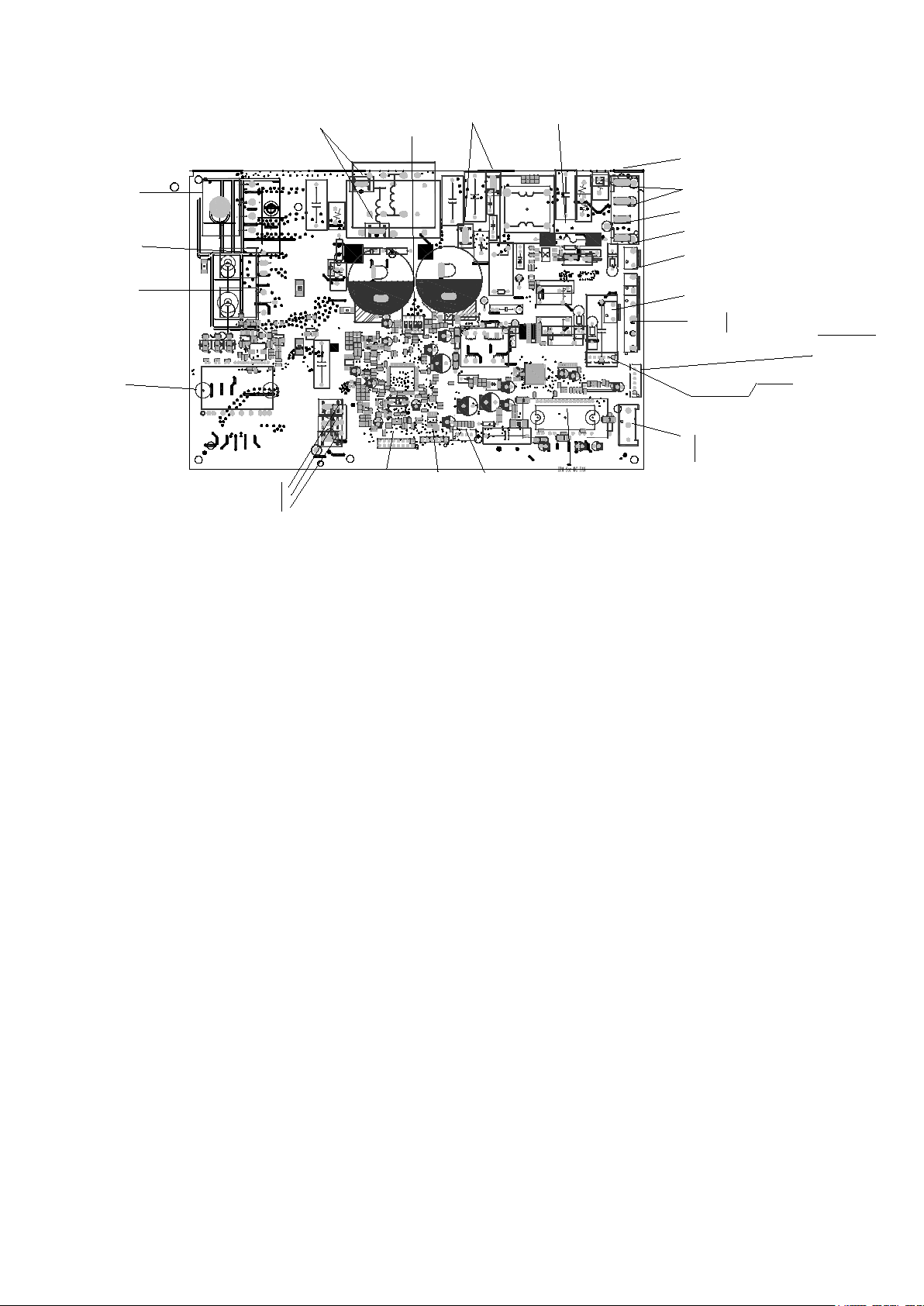

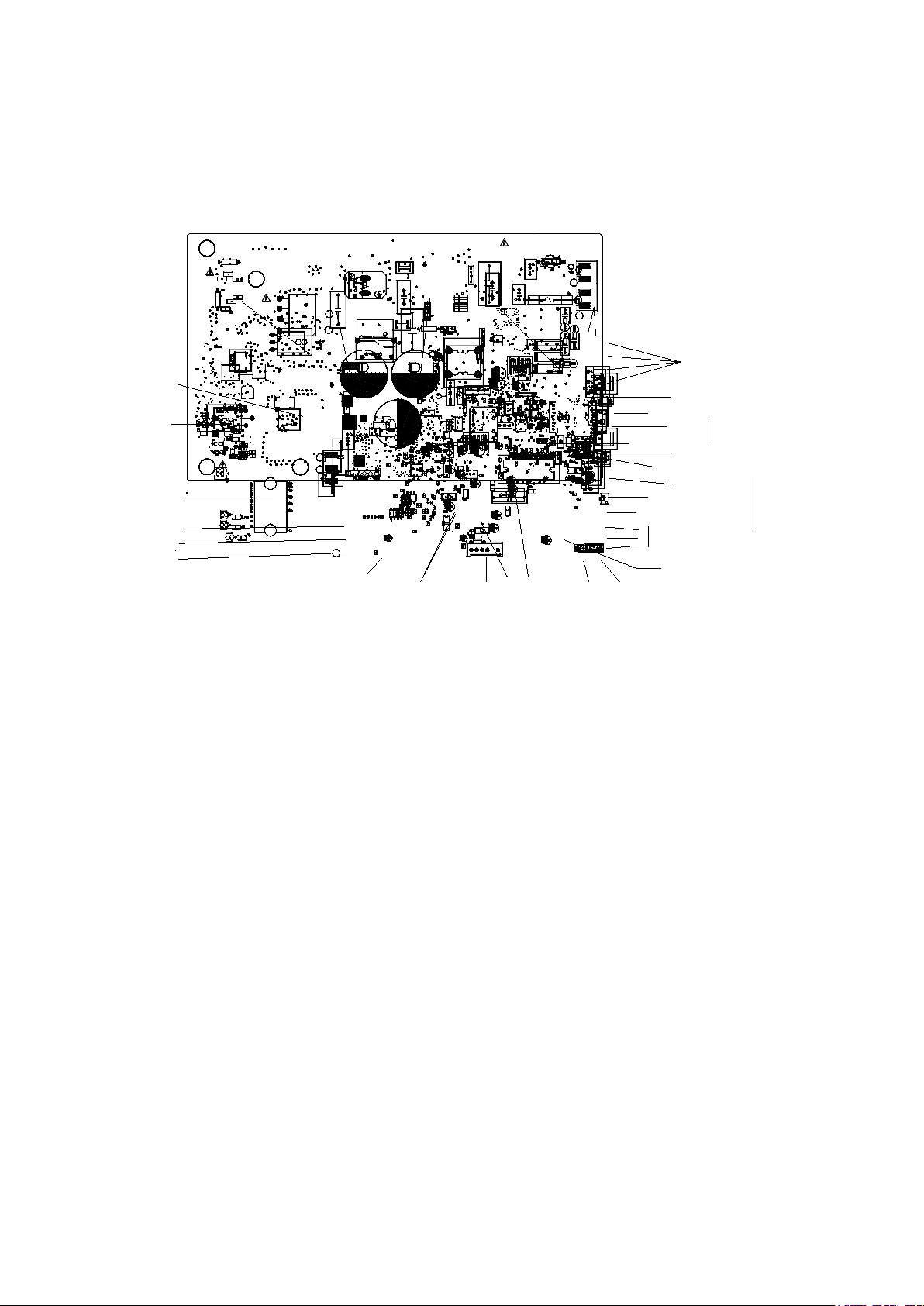

1.2 Outdoor unit error display(TBD)

N

1

17122000019195

1

1

[ 1. 6 ] 20 15-09- 30

US- KFR-35W/BP3N1- (115V+RX62T+41560) .D. 13.WP2- 1

L- IN N- I N

7805

S

HEAT1

4 - WA Y

AC- FAN

HEAT2

Ear t h

DC- F AN

PMV

TESTPORT

BLACK

W

RED

V

BL UE

U

CN4_ 1

CN4_ 2

CN4_ 3CN4 _4

REA CT OR

CAP

T3T4

TP

N

N

N

H

L

CN25

CN31

AC

AC

+

-

BR1

+

E2

CN21

RC1

E304

ZR2

+

-

AC

OUT

IN

~~

RY3A

SJ-S- 112DMG

R191

I C105

CN15

ZR5

ZR4

R628

C618

R118

R123

R122

C324

I C2

R421

R621

D103

C413

C306

C319

I PM301

R176

R175

+

E109

C107

T401

R410

R409

R316

3W-10m¦ ¸¡ À1%

D407

+

+

C110

R623

R602

C624

RY3

R196

D610

C318

C316

C314

C134

+

E605

E303

E208

E206

E302

E300

CN50

R523

R522

R521

R520

R519

R518

R517

R323

R322

R321

R320

R319

R318

R317

I C301

C513

C512

C511

C323

C321

C320

R426

R314

R306

R305

R304

R303

C311

C310

C309

C308

C307

CN28

CN29

CN30

C520

C1

+

E106

C101

D101

C611

R171

D602

I C102

Rdi

D404

D401

CN6

ZR1

RY2

R626

R620

R619

R618

R617

R616

R615

R612

R611

R610

R608

R607

R605

R603

R601

R528

R516

R513

R508

R506

R504

R502

R429

R428

R427

R408

R407

R406

R405

R404

R403

R315

R301

R190

R188

R187

R186

R185

R182

R181

R180

R179

R178

R174

R173

R170

R169

R168

R165

R157

R155

R154

R152

R150

R149

R148

R147

R144

R143

R142

R140

R138

R137

R136

R135

R133

R132

R131

R130

R129

R128

R127

R126

R125

R124

R121

R120

R117

R116

R115

R114

R112

R111

R110

R108

R107

R106

R105

R102

R101

R2

Q101

OSC101

NTC2

+

LED101

I C603

I C602

I C601

I C403

I C401

I C1

+

E602

+

E401

+

E108

+

E107

+

E105

+

E103

+

E102

+

E101

+

E1

+

E3

+

DZ601

DZ304

DZ303

DZ302

DZ301

+

DZ203

+

DZ202

D406

D402

+

D2

+

D1

1

CN50 5

CN7

C615

C614

C612

C606

C605

C601

C509

C508

C507

C506

C505

C504

C503

C412

C410

C409

C408

C405

C404

C403

C402

C401

C322

C312

C305

C303

C302

C274

C273

C272

C271

C133

C132

C131

C130

C129

C128

C127

C126

C125

C124

C123

C121

C120

C119

C118

C116

C115

C114

C113

C112

C111

C106

C105

C104

C103

C102

C16

C11

C10

C7

C6

C5

C4

C3

C2

+

E280

+

E281

+

E282

+

E283

+

E404

+

E407

PTC1

+

E409

D104

R401

R103

C117

R195

R172

+

DZ204

C275

R156

R604

R104

I C101

I C104

RY4

+

E410

+

E405

FUSE1

T20A/25 0VAC

C9A

CN1A

I C404

+

D403

I C103

C613

CN3

CN2

CN1

CN16

+

DZ201

L2L3L4L5

C135

CN17

R21 R23

R158

RY5

21

4

3

3

4

ON

1 2

ON

S W2

RC2

DSA1

I C405

+

CN60

C8

L1

R1

I PM501

C122

Comment

Comment

RY1

CN50 7

R606

3W-10m¦ ¸¡ À1%

R25 3

0. 75¦ ¸/ 1W

R25 4

0. 75¦ ¸/ 1W

connect to compressor heater

when is on, 100-130V AC outpu

connect to 4-way Valve

when is on, 100-130VAC OUTPUT

connect to PFC Capacitor

when is on, 100-130V AC

output

connect to reactor

when is on, 100-130V AC output

connect to

Ground

connect to N-line

(100-130VAC INPUT)

connect to L-line

(100-130VAC INPUT)

connect to indoor unit

communication

U

V

W

10- 230VAC¡ ¯ (r unn i n g)

0VAC (st andby)

conne ct t o DC Mot or

external driver motor

connect to Electric Expansi

pipe temp.sensor& room temp.

sensor&Exaust temp. sensor

6 5 4 3

TP T4

RT

RT

+5VDC

+5VDC

+12V DC pulse wave bet ween ( +1) -G

+12V DC pulse wave bet ween ( +2) -G

+12V DC pulse wave bet ween ( +3) -G

+12V DC pulse wave bet ween ( +4) -G

+12 V DC

+12 V DC

6 5 4 3 2 1

AC fan motor

5

4

3

2

1

low speed

N line

high speed

FAN Starting Capacitor

FAN Starting Capacitor

connect to chassis heater

when is on, 100-130VAC OUTPUT

UV

W

0VAC(standby)

10- 230VAC¡ ¯( runni ng)

connect to

compressor

connect to PC

communication

EEPROM Programmer

Port

Test Port

bridge

IPM for compressor

IPM for DC FAN

P

For CH-09SPH-115VO, CH-12SPH-115VO, CH-09SPH-230VO, CH-12SPH-230VO

,

Page 4

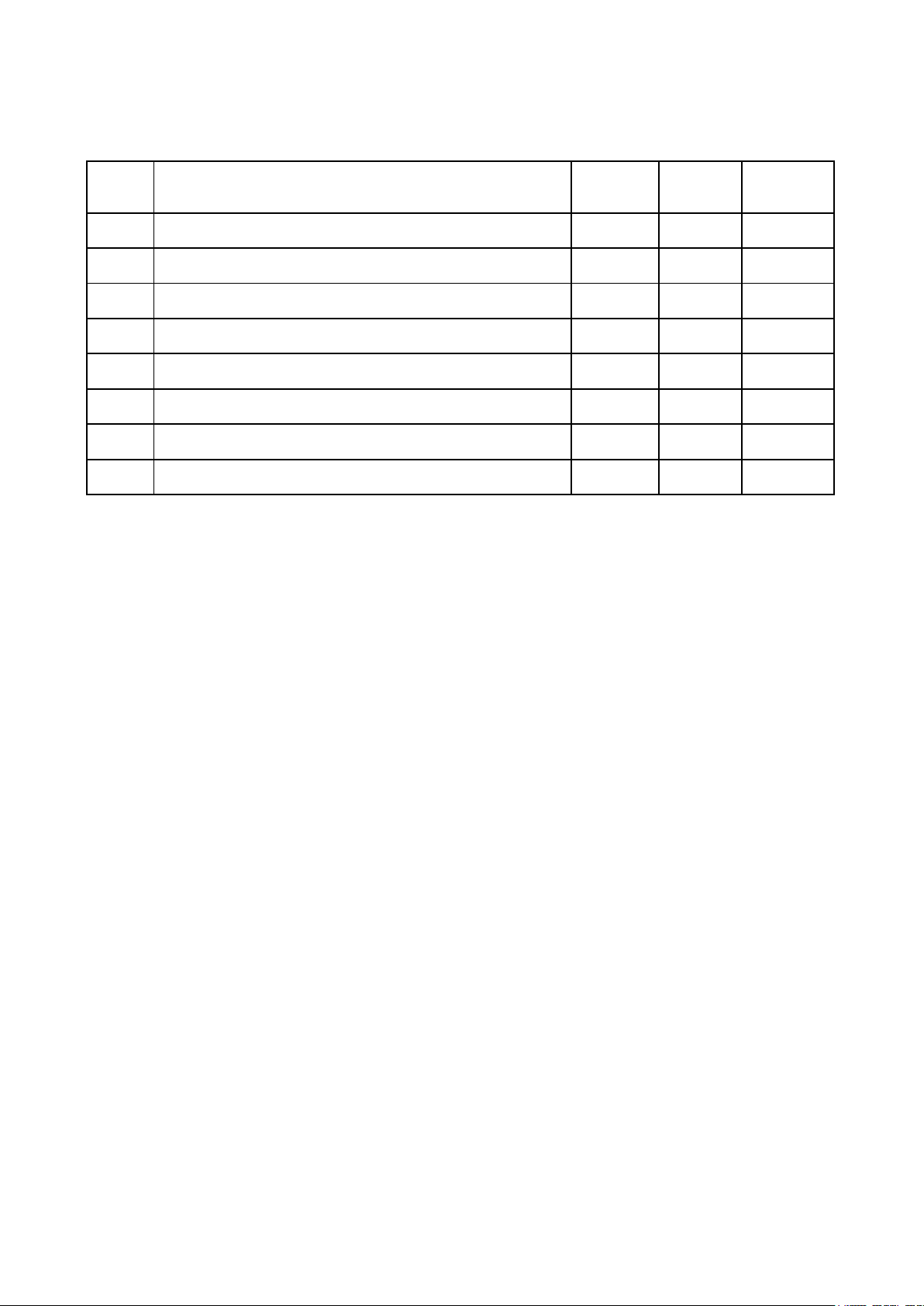

For CH-09SPH-230VO, CH-12SPH-230VO, CH-18SPH-230VO, CH-18SPH-230VO

+

T4

TP

T3

N

L

H

N

N

Rdi

Hav e

Low-Fre

YES

NO

No

U

BLUE

V

RED

W

BLACK

TESTPORT

PMV

DC- FAN

DR_L

DR_N

Ear t h

HEAT2

AC- FAN

4 - WA Y

HEAT1

S

7805

N- I N

L- IN

KFR- 35W/ BP3N1-( RX62T+41560) .D.13. WP2-1

[ 1. 8] 2015- 12- 31

1

1

17122000002718

1

E304

E208

C10

RC3

CN22

ZR4

R696

R69 5

C696

C69 5

ZR5

C9

IPM501

L1

C8

CN60

+

IC405

DAS1

RC2

ON

2

1

ON

4

3

3

4

1

2

SW2

RY5

R158

R23

R21

CN17

CN11

CN10

C135

L5

L4

L3

L2

+

DZ201

L601

CN16

CN1

CN2

CN3

CN3_ 1

C613

IC103

CN50 7

+

D403

IC404

CN1A

FUSE1

T20A/250VAC

E405

E410

RY4

IC104

IC101

R104

R604

R156

C275

DZ204

R172

R195

C117

R103

R40 1

D104

E409

PTC1

CN32

BR1

E407

E404

E283

+

E282

+

E281

+

E280

RY1

D601

Q601

C2

C3

C4

C5

C6

C7

C11

C16

C102

C103

C104

C105

C106

C111

C112

C113

C114

C115

C116

C118

C119

C120

C121

C123

C124

C125

C126

C127

C128

C129

C130

C131

C132

C133

C271

C272

C273

C274

C302

C303

C305

C312

C322

C40 1

C402

C403

C404

C405

C408

C409

C410

C503

C504

C505

C506

C507

C508

C509

C601

C605

C606

C612

C614

C615

CN7

CN9

CN31

CN50 5

D1

D2

D402

D406

DZ202

DZ203

DZ301

DZ302

DZ303

DZ304

DZ601

E1

E2

E101

E102

E103

E105

E107

E108

E401

E602

IC1

I C40 1

IC403

IC601

IC602

IC603

LED101

NTC2

OSC101

Q101

R2

R3

R101

R102

R105

R106

R107

R108

R110

R111

R112

R114

R115

R116

R117

R120

R121

R124

R125

R126

R127

R128

R129

R130

R131

R132

R133

R135

R136

R137

R138

R140

R142

R143

R144

R147

R148

R149

R150

R152

R154

R155

R157

R165

R168

R169

R170

R173

R174

R178

R179

R180

R181

R182

R185

R186

R187

R188

R189

R190

R301

R315

R403

R404

R405

R406

R407

R408

R427

R428

R429

R502

R504

R506

R508

R513

R516

R528

R601

R603

R605

R607

R608

R610

R611

R612

R615

R616

R617

R618

R619

R620

R626

RY2

ZR1

CN6

D40 1

D404

Rdi

IC102

D602

R171

C611

D101

C101

E106

C1

C52 0

ZR3

CN30

CN29

CN28

C307

C308

C309

C310

C311

R303

R304

R305

R306

R314

R426

C320

C321

C323

C511

C512

C513

IC301

R317

R318

R319

R320

R321

R322

R323

R517

R518

R519

R520

R521

R522

R523

CN50

E206

E605

C134

C314

C316

C318

CN25

D610

R196

RY3

C624

R602

R623

C110

C122

D407

R316

3W- 10m| ??¨¤1%

R409

R41 0

R606

3W- 10m1%

T401

C107

E109

R175

R176

I PM301

C319

C306

C413

D103

R621

R421

IC2

C324

R122

R123

R118

C618

R628

CN15

I C105

R191

RY3A

ZR2

RC1

CN21

R1

C41 2

E300

E302

E303

C33 0

C33 1

C33 2

C33 3

C33 4

connect t o t he t er mi nal

208-230V AC

power suppl y

connect to earth

CN60

connect to 4-way valve

when 4-way i s ON, out put 208- 230VAC

connect t o c ompr ess or heat er

power suppl y

CN17

AC fan motor

L low speed

N ground

H high speed

CN21/CN22

exhaust temp. sensor& pipe

temp.sensor& room temp.

sensor

6 5 4 3 2 1

TP T4 T3

RT

RT

+5VDC

RT

+5VDC

+5VDC

connect to Electric Expansion Valve

+12V DC pul se wave bet ween (+1) - GND

+12V DC pul se wave bet ween (+2) - GND

+12V DC pul se wave bet ween (+3) - GND

+12V DC pul se wave bet ween (+4) - GND

+1 2 V DC

+1 2 V DC

6 5 4 3 2 1

connect to indoor unit communication

HEAT2

connect to chassis heater

when is on, 208-230VAC OUTPUT

U

V

W

10- 200VAC¡ ¯ (r unni ng)

0VAC ( st andby)

connect t o t he DC compressor

Test Port

Connect to PC

communication

EEPROM Programmer Port

FUSE1 20A/250VAC

U

V

W

10-200VAC¡ ¯ ( r unni ng)

0VAC ( st andby)

connect t o DC Mot or

External driver motor

slow flicker:standby(

0.5Hz

)

quick flicker:error(

2Hz

)

continuous light: normally running

Connect to reactor

IPM for

compressor

IGBT

FRD

when heater is ON, output 208-230V AC

BR

P

N

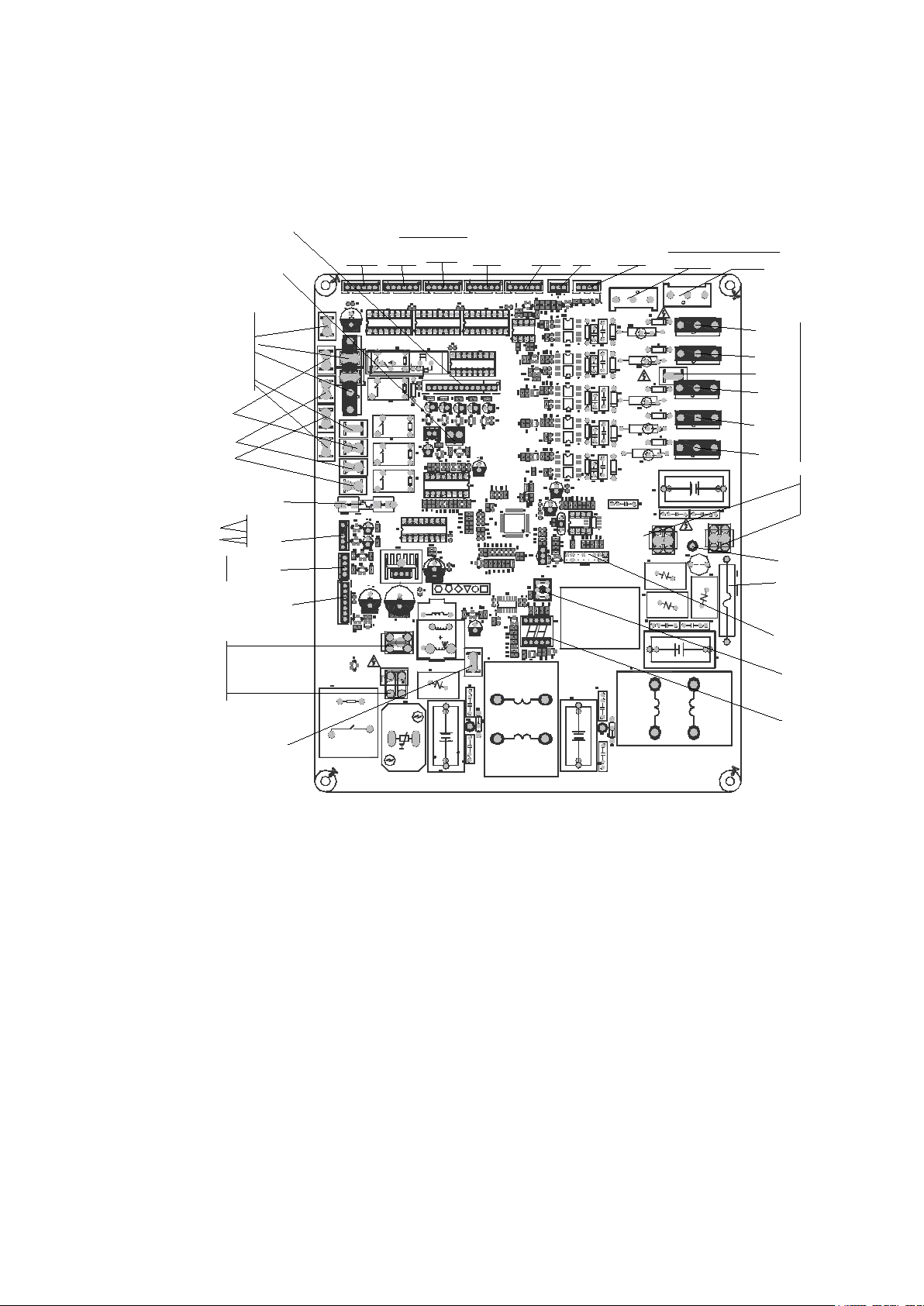

Page 5

Sucti on

Exhaust

+

17122200000309

Hui Qi

Tes tPort

1

1

HEAT

4 - WA Y

W

BL UE

BLACK

RED

V

U

TPT3T4

No

NO

NO

YES

Low-Fre

No

Have

YES

Have

Temp-Pro

Rdi

Ri pm

11

PMV

44

15V17V

[V1. 8] 2015- 01- 16

7815

22

1

34

REACT OR

311 TEST

7805

N- I N

DC- F AN

AC- FAN

L- I N

S

KFR-72W/ BP2- (311+0515+6061HD+PSS30S92F6-AG+6822+HEAT). D. 13.WP2.1

12V 5V

CN3

DSA1

K

A

K

D5

R18

R46

R107A

R515A

R316A

R18A

IC4 03

D4

C21

R54

R55

R68

R69

R56

R90

C14

J4

R16

R52

J5

+

LED1

R78

R142

R141

R155

R154

R153

R152

R151

R150

C3

R108

R107

RC2

RC4

RC1

RC3

C1

FUSE1

65T 250V30A

ZR1

ZR2

CN30

R109

R58

R61

R60

R59

C301

C76

C312

R315

C83

C85

C86

C91

R156

R158

R169

R170

R171

R172

IC34

D11

R157

R159

C310

C306

C308

C311

C307

C309

R110

E305

C302

+

DZ301

Q3

R75

R84

C103

CN28

CN29

CN6- 1

CN6

CN13

CN12

CN2

CN8

CN7

CN22

DR

CN21

DR

R102

J6

PTC1

CN41 4

R127

C105

+

E5

I PM2

C501

C503

C507

C508

C509

C510

C511

C512

C517

+

DZ501

R501

R502

R503

R504

R505

R506

R509

R510

R511

R512

R513

R514

R523

C502

C505

+

DZ502

R515

R522

+

DZ504

C504

R316

~ ~

IN

AC

+

R101

R100

R71

C42

CN20

RY5

CN16

CN18

NTC4

C8

C513

C514

C515

C516

R516

R517

R518

R519

R520

R521

C27

IC7

24LC512

33

49

17

1

IC9

R53

IC1 01

R160

+

E4

+

E3

R83

R82

R81

R80

R79

R50

C47

C20

R322

R321

R320

Q2

IC4 05

+

E10

R120

R167

R166

R32

+

E1

R12

+

LED3

R412

R413

R414

R415

Rdi

Ri pm

R13

CN24

R72

R8

R87

R74

J3

IC17

+

E24

D2

R124

C2

J2

J1

C77

AC AC

+

-

BR1

C13

D3

R7

RY3

RY4

RY2

CN5

R23

R24

R25

R26

R27

C74

C75

RY1

+

E14

C9

C17

C18

C19

C23

C24

C26

C32

C33

C35

C36

C37

C39

C43

C48

C49

C52

C65

C67

C78

C87

C89

C90

C92

C147

C153

C25

CN9

CN23

CN39

+

E17

+

E23

+

E28

IC8

24LC08

IC12

24LC08

IC14

+

LED2

OSC1

R5

R30

R31

R40

R41

R42

R48

R49

R62

R64

R65

R66

R70

R73

R76

R77

R86

R92

R97

R161

R162

R163

R164

R165

R176

R177

R419

X1

C58

+

+

E405

IC4 04

R45

Q1

C15

C22

R21

R22

R28

R29

R33

+

E22

R3

R4

R121

C5

+

E6

R10

C28

C4

CN38

IC10

C79

C80

D7

C6

R148

R63

C506

R507

R508

+

E11

R106

C73

IC21

PC817

IC31

PC817

R175

R178

C409

IC4 02

C403

IC11

+

E402

D401

C401

R403

C411

C40

C50

D403

R401

R405

R406

R404

+

E404

D402

D404

C408

C402

+

E403

R407

R408

C404

C110

+

E409

+

E401

R402

C405

10

9

7

6

5

4

3

1

T401

C406

C407

D13

D14

+

E406

+

E407

+

E408

+

E502

+

E503

+

E504

+

DZ503

CN25

R6

R9

CN60

IC4 06

IC4 07

C7

D1

R1

R137

IC2

PC851

IC1

PC817

R2

R126

R125

R123

R122

R119

R118

R117

R15

R14

C99

C98

C97

C96

C95

C94

C93

C66

D20

R17

CN17

CN10

CN1

C41

R38

C45

C44

R136

R135

R134

R104

D12

D10

C54

+

D8

D9

R57

R20

C242

C243

C244

R89

E2

R67

C84

C10

C11

IC4

C12

C38

R34

R47

R88

IC32

R39

R35

R36

R19

+

DZ6

R37

C46

C51

C53

CN19

+

DZ2

+

E27

IC3

PC817

IC5

PC817

Q8

R43

R44

R85

R91

R93

R95

R96

R99

D15

R51

+

E410

+

E8

C60

C61

E302

E303

E304

C62

VN1

VP1

U

P

VUB

U+

W

V+

V

W+

U-

VVB

VWB

FO

W-

V-

NV

NW

NU

VNC

CIN

I P M1

+

DZ304

+

DZ303

+

DZ302

C314

C316

C318

C30

C34

C31

ZR3

ZR4

C82

L1

R11

R140

CN27

E301

R168

I GBT 1

connect to the DR module

connect to earth

fuse 250V 30A

connect to reactance

290-330VDC standby

210-300VDC running

power supply 208-230V AC connect to the terminal

connect to 4-way val ve

when 4-way is on, output 208-230V AC

AC FAN mot otr

connect to co mpressor heater

when heater is on, output 208-230V AC

1 low speed

2 hign speed

3 ground

external drive mo tor

connect to DC motor

0V AC st andby

10~200V AC

’

running

U

V

W

connect to electric expansion valve

6 5 4 3 2 1

+

12VDC

+

12VDC

+12V DC pulse wave between( +4)-GND

+12V DC pulse wave between( +3)-GND

+12V DC pulse wave between( +2)-GND

+12V DC pulse wave between( +1)-GND

EEPROM Programmer Port

reserve

test port

Connect to PC

communication

V

U

W

connect to PC communication

test port

LED: status light

(

yellow

)

CN5

/CN4 connect to

chassis

heater

when heater is on, ou tput 208-230V AC

connect to DC motor

0V AC standby

10~200V AC

’

running

bridge

IGBT

fast recovery diode

(FRD)

IPM for compressor

IPM for DC FAN

P

N

For CH-24SPH-230VO,

Page 6

No. Problems

LED

(Green)

IU display

1 standby for normal

O

2 Operation normally

X

3 IPM malfunction or IGBT ov

☆

P0 4 Over voltage or too low voltage prot ection

O

P1

5 EEPROM parameter error

O

E5 6 Inverter compressor drive error

X

P4 7 Inverter compressor drive error

☆

P4

8 Inverter compressor drive error

☆

P4

After power on, LED3(Gre en col or ) and LED2(Red color) will be flash if the unit has some pro blems.

O(light) X(off) ☆(2.5Hz flash)

er-strong current protect ion

3

LED2

(Red)

X

O

X

O

☆

☆

O

☆

Page 7

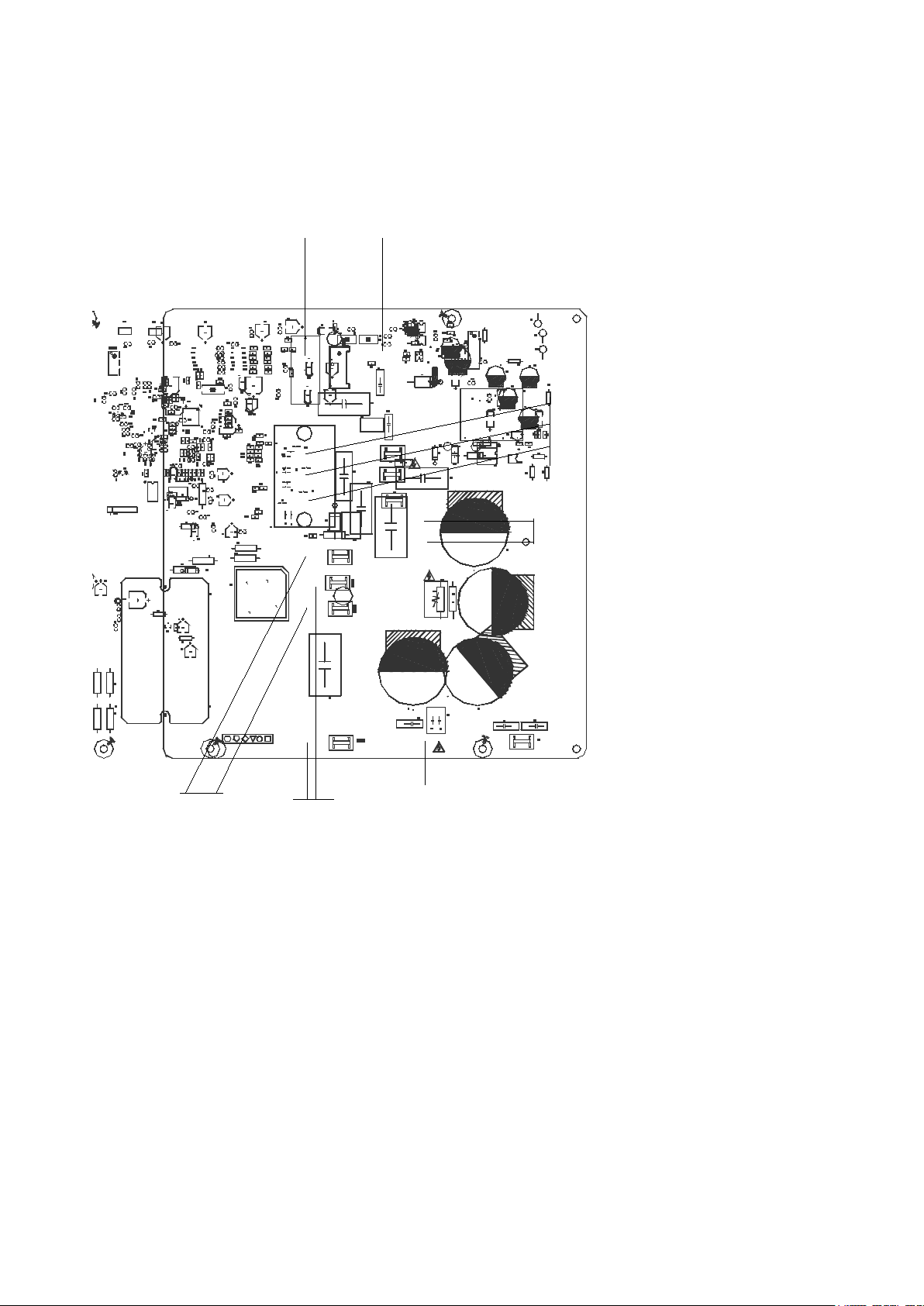

For CH-S30FTXW-SV, CH-S36FTXW-SV,

N

L

SHOW/ SW

EARTH

[ 1. 4]2014. 06. 26

EU- KFR105W/ BP3T5N1- 350S. D. 13. WP1- 1

L - OUT

N- OUT

CONNECT TO INVERTER driver

HI GHL OW

T2B- E

T2B- D

T2B- C

T2B- BT2B- A

TP

T4

T3

S- E

S- D

S- C

S- B

S- A

FAN_OUT

FAN_I N

AB

C

D

E

202302141206

CN19

CN10

N

CN9

S

CN44

HEAT2

CN43

FAN

CN42

C

CN41

C

CN40

HEAT1

CN34

CN33

CN30

CN29

CN28

CN27

CN26

CN22

4 - WAY

CN20

CN18

CN17

CN16

CN14

CompTop

CN12

CN11

CN8

CN6

CN5

CN4

N

CN3

N

CN2

N- I N

CN1

L- I N

CN23

CN7

CN13

P- 1

CN35

N

CN37

FAN-L

CN36

FAN -H

CN21

Electric Expansion

Value B

Electric Expansion

Value E

Electric Expansion

Value D

Electric Expansion

Value C

Electric Expansion

Value A

485

communication

testPort

connect to detector

external drive DC fan

motor input terminal

external drive DC fan

motor ouput terminal

current loop

communication A

current loop

communication B

current loop

communication C

current loop

communication D

current loop

communication E

digital display

Fuse

T30A/250V

connect to high and low

pressure sensor

connect to

trmp. sensor

Fuse 5A/250V

connect to earth

CN23 reserve

digital display button

test report

connect to detector

CN43-5,CN43-1/CN41,CN42

AC fan motor capacitor

connector

CN43-4/CN37 CONNECT TO

AC FAN MOTOR(LOW SPEED)

CN43-3/CN36

AC fan motor low speed

connector

CN43-2/CN35

AV fan motor N phase

current loop

communication C

Signal wire

24VDC Pulse wave

connect to the terminal

connect to the terminal

208-230V AC

power supply

room temp sensor

pipe temp sensor

(3.3V)

(3.3V)

high pressure sensor

low pressure sensor

Connect to the Indoor evap.pipe

out temp. sensor

T2B-A、T2B-B、T2B-C、T2B-D、T2B-E

+12V DC pulse wave between (+1)-GND

+12V DC pulse wave between (+2)-GND

+12V DC pulse wave between (+3)-GND

+12V DC pulse wave between (+4)-GND

+12V DC

+12V DC

6 5 4 3 2 1

when 4-way is ON, output 208-230VAC

connect to the 4-WAY

when heater is ON, output 208-230V AC

connect to compressor heater

CN44 L

CN10 N

CN40 L

CN4 N

CN22 L

CN3 N

connect to exhaust

temp. sensor

connect to the terminal

208-230V AC

external drive DC fan

motor connector

T3

T4

electric

heater1

electric

heater 2

Page 8

202302141237

PFC- L2

[ 1. 6] 20 14. 10. 16

EU-KFR105W/ BP2T3N1- 350( 767). D. 13. MP2-1

PFC- L1

EARTH

+

CN55

T O- MA I N

W

V

U

I P M2

I P M1

I C1 424C08

CN54

L - I N2

N- I N2

OU TF A N( DC)

I C1

CN53

power s uppl y

connect t o t he t er mi nal

208- 230V AC

CN54

CN51CN52

PFC

inductance

terminal

CN58

EATTH

+

210- 300VDC ( Runni ng)

CAPACI TOR Vol t a ge

290- 330VDC ( st andby)

CN55

T O MA I N

CN19

connect to DC fan motor

U

V

W

10- 200VAC ( r unni ng)

0VAC ( s t andby)

connect t o t he compr essor

U

V

W

10- 200VAC ( r unni ng)

0VAC ( s t andby)

IPM board,

Page 9

Error Code

E0/F4

Malfunction decision

Indoor or outdoor PCB main chip does not receive feedback

Supposed causes

Installation mistake

Yes

Replace the indoor/outdoor

main PCB.

Power off,

then restart the

unit 2 minutes later.

your side.

1.3 Diagnosis and Solution

1.3.1 EEPROM parameter error diagnosis and solution(E0/F4)

conditions

from EEPROM chip.

●

● PCB faulty

Trouble shooting:

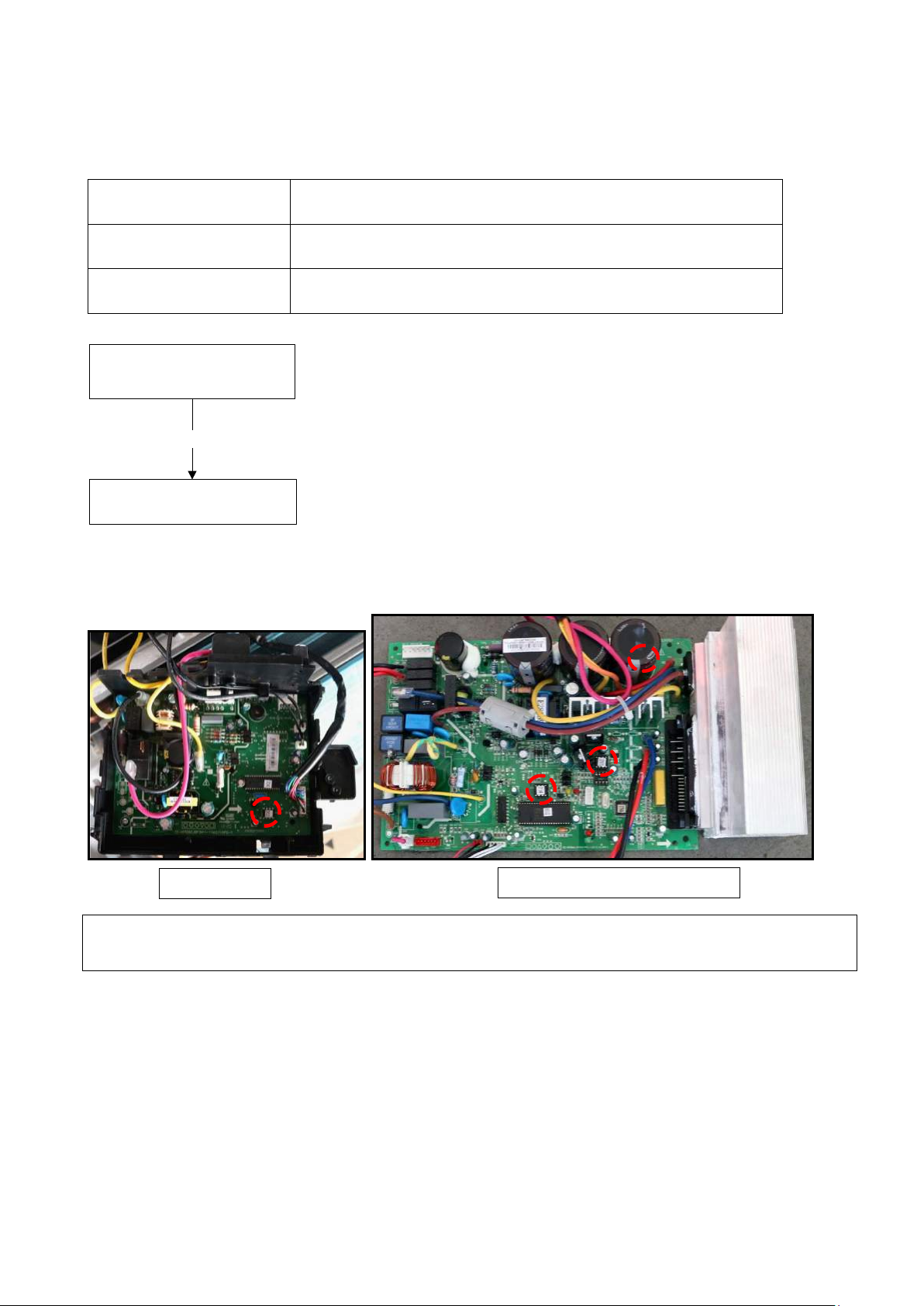

EEPROM: a read-only memory whose contents can be er ased and reprogrammed using a pulsed

voltage. For the location of EEPROM chip, please refer to the below photo s.

Indoor PCB

Note: The two photos above are only for reference, it’s may be not same totally with the one s on

Outdoor PCB

Page 10

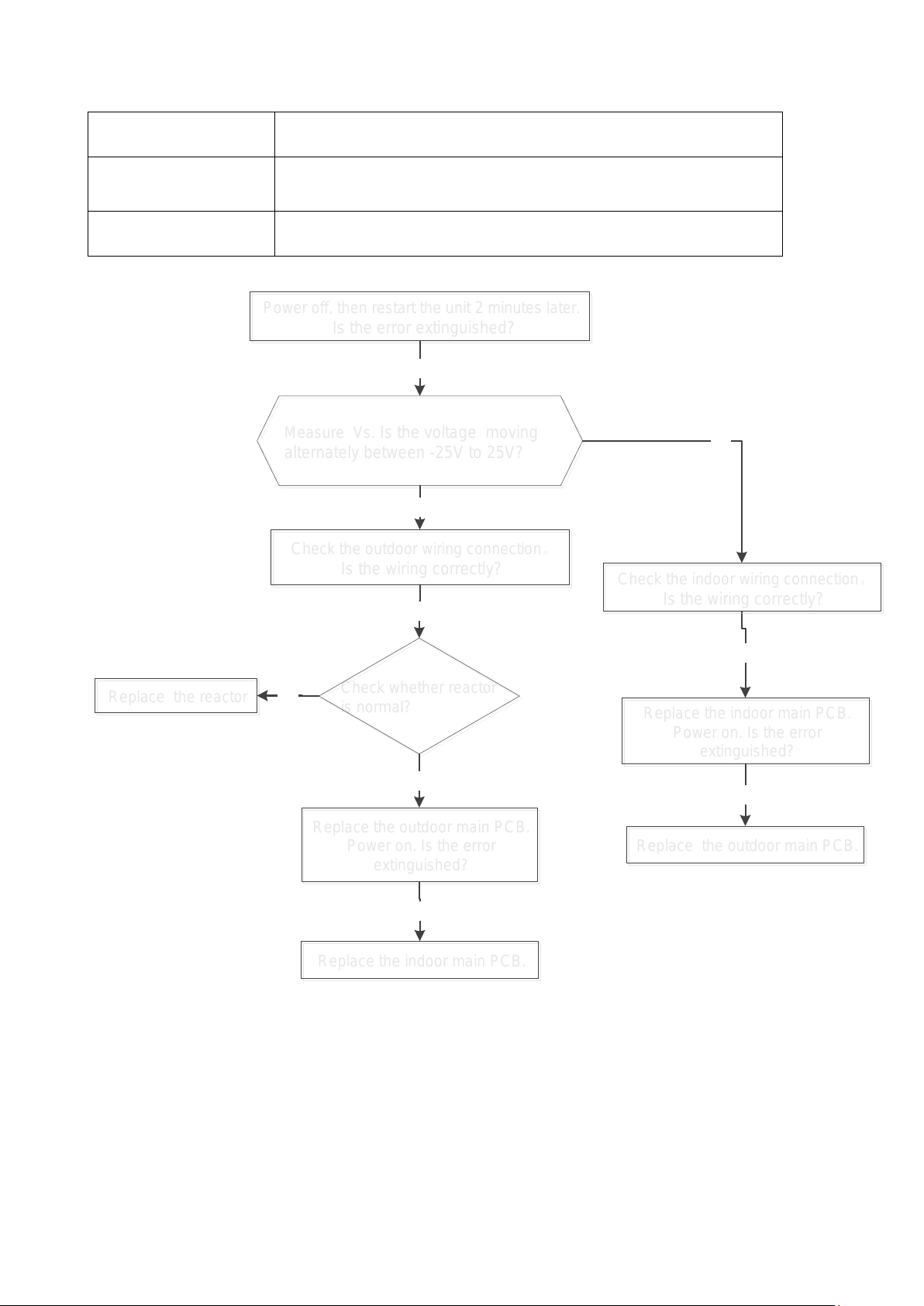

1.3.2 Indoor / outd oor unit’s communi cation diagnosis and s olution(E1)

Error Code

E1

Malfunction decision

Indoor unit does not receive the feedback from outdoor unit

continuously.

Supposed causes

Wiring mistake

Measure Vs

.

Is

the voltage moving

alternately between

-25

V to 25

V

?

Measure Vs

.

Is the voltage moving

alternately between

-25

V to 25

V

?

Yes

Power off,

then restart the unit 2

minutes

later.

Is the error extinguished?

Power off

, then restart the unit

2

minutes

later.

Is the error extinguished?

No

Replace

the outdoor main PCB.

Power on.

Is the error

extinguished?

Replace

the outdoor main PCB.

Power on.

Is the error

extinguished?

Check the outdoor wiring connection

。

Is the wiring

correctly?

Check the outdoor wiring connection。

Is the wiring correctly

?

Replace the indoor main PCB

.

Power on. Is the error

extinguished?

Replace the indoor main PCB

.

Power on

. Is the error

extinguished?

Yes

Replace the outdoor main PCB.

Replace the outdoor main PCB.

No

Replace the indoor main PCB.

Replace the indoor main PCB.

No

Check the indoor wiring connection

。

Is the wiring

correctly?

Check the indoor wiring connection

。

Is the wiring correctly?

Yes

No

Check whether reactor

is normal

?

Check w

hether rea

ctor

is normal?

Yes

Replace

the reactor

Replace

the reactor

No

conditions

Trouble shooting:

during 110 seconds and this condition happens four times

●

● Indoor or outdoor PCB faulty

Page 11

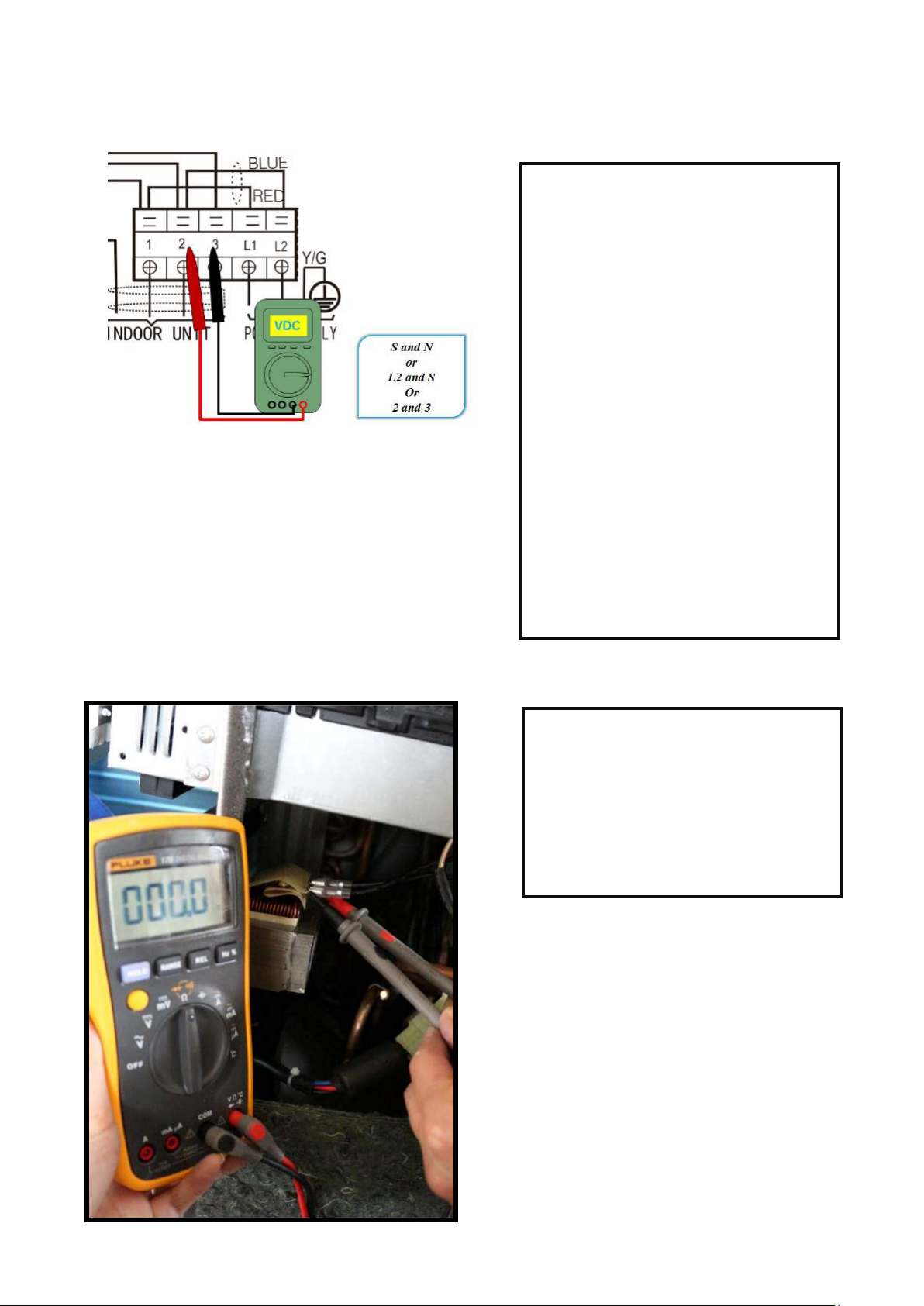

Remark:

Use a multimeter to test t he D C voltage

between 2 port and 3 port of out door

unit. The red pin of mu ltimeter connects

with 2 port while the black pin is for 3

port.

When AC is normal running, the voltage

will move alternately betw een -25V to

25V.

If the outdoor unit has malfunc t io n, the

voltage will move alternately with

positive value.

While if the indoor unit has ma lfunction,

the voltage will be a certain value.

Remark:

Use a multimeter to test the resistance

of the reactor which does not connect

with capacitor.

The normal value should be around

zero ohm. Otherwise, the r eact or m ust

have malfunction.

Page 12

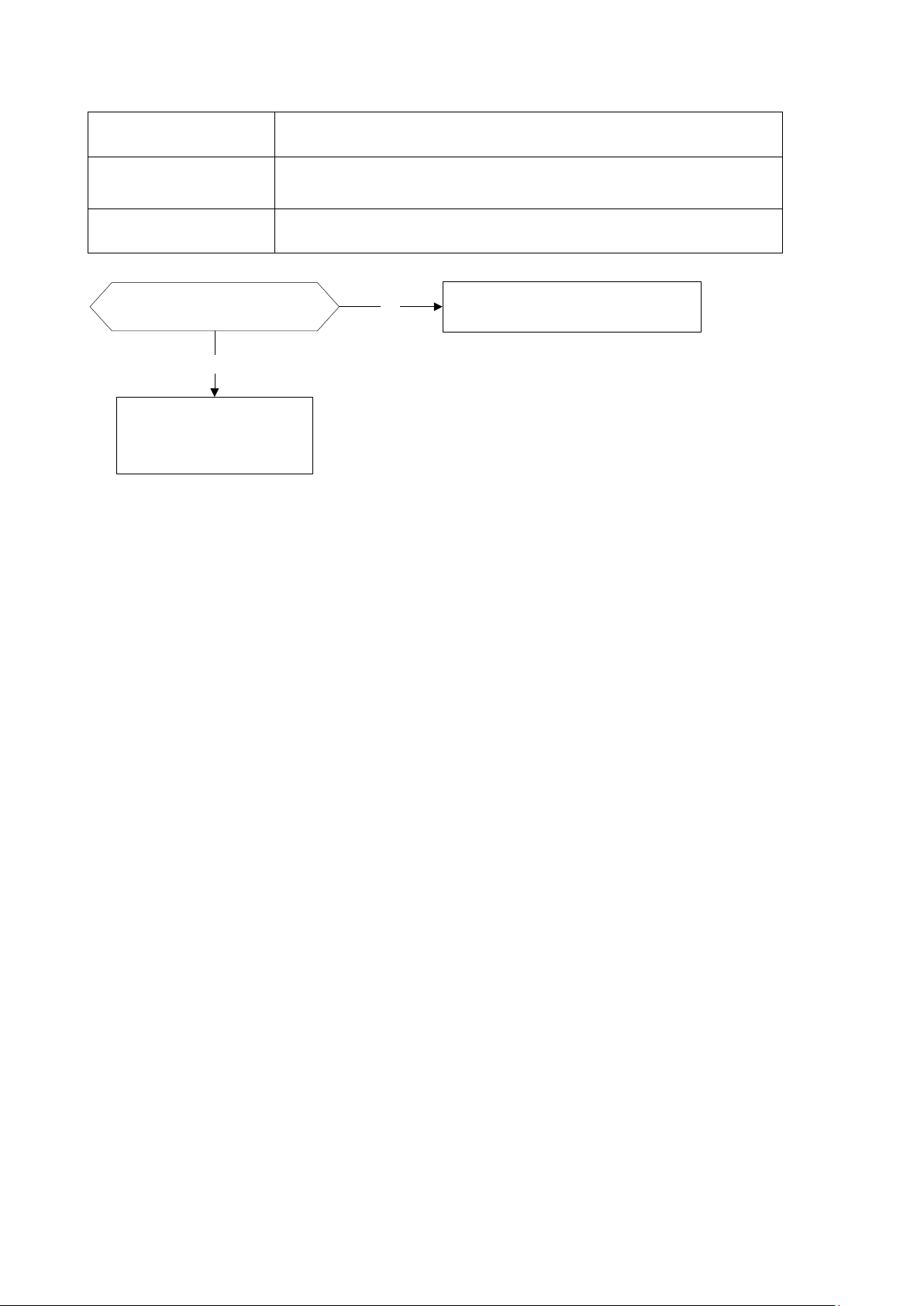

1.3.3 Zero crossi ng detection error diagnos i s and solution (E2)

Error Code

E2

Malfunction decision

When PCB does not receive zero crossing signal feedback for 4

Supposed causes

Connection mistake

Check if the connections and

power supply is normal

?

Correct the connections. Turn on the

unit when the power supply is good.

No

Yes

Indoor main PCB is

defective. Replace indoor

main PCB.

conditions

minutes or the zero crossing signal ti me interval is abnormal.

●

● PCB faulty

Trouble shooting:

Page 13

1.3.4 Fan speed has been out of control diagno sis and solution(E3)

Error Code

E3/F5

Malfunction decision

When indoor fan speed keeps too low (300RPM) for certain time,

Supposed causes

Wiring mistake

PCB faulty

Power off, then restart the

unit 2 minutes later

Shut off the power supply,

Rotate the fan by hand.

The unit operates normally.

Find out the cause and have

it solved

Check the wiring of fan

motor

No

Yes

No

Correct the connections.

No

NoReplace the fan motor

Yes

Yes

Measure the voltage for the

fan motor from the main

PCB refer to the

Appendix 1

Yes

Replace the main PCBNo

conditions

Trouble shooting:

the unit will stop and the LED will display the failure.

●

● Fan ass’y faulty

● Fan motor faulty

●

Page 14

Index 1:

NO.

Color

Signal

Voltage

1

Red

Vs/Vm

280V~380V

2

---

---

---

3

Black

GND

0V

4

White

Vcc

14-17.5V

5

Yellow

Vsp

0~5.6V

6

Blue

FG

14-17.5V

NO.

Color

Signal

Voltage

2

---

---

---

3

Black

GND

0V

4

White

Vcc

14-17.5V

5

Yellow

Vsp

0~5.6V

6

Blue

FG

14-17.5V

1:Indoor or Outdoor DC F an M ot or ( cont r ol chip is in fan motor)

Power on and when the unit is in standby, measure the voltage of pin1-pin3, pin4-pin3 in fan motor

connector. If the value of the voltage is not in the range showing in below table, the PCB must has

problems and need to be replaced.

DC motor voltage input and out put ( voltage: 220-240V~)

DC motor voltage input and out put ( voltage :115V~)

1 Red Vs/Vm 140V~190V

Outdoor DC Fan Motor (control chip is in outdoor PCB)

2.

Power on ,and check if the fan can run normally, if the fan can run normally, the PCB must has

problems and need to be replaced, If the fan can’t run normally, measure the resistanc e of eac h two

pins. If the resistance is not equal to each other, the fan motor must have problems and need to be

replaced, otherwise the PCB must has problems and need to be replaced.

3. Indoor AC Fan Motor

Power on and set the unit running in fan mode at high fan speed. After running for 15 seconds,

measure the voltage of pin1 and pin2. If the value of the voltage is less than 100V(208~240V power

supply)or 50V(115V power supply), t he PC B must has problems and need to be replaced.

Page 15

1.3.5 Open circuit or short circuit of temperature sensor diagnosis a nd solution(E5)

Error Code

E4/E5/F1/F2/F3

Malfunction decision

If the sampling voltage is lower than 0.06V or higher than 4.94V,

Supposed causes

Wiring mistake

PCB faulty

Check the connection

between temperature

sensor and PCB.

Correct the connectionNo

Yes

Replace indoor or outdoor

main PCB

Measure the resistance

value of the sensor

Repalce the sensorNo

Yes

conditions

Trouble shooting:

the LED will display the failure.

●

● Sensor faulty

●

Page 16

1.3.6 Refrigerant Leakag e Detection diagnosis and solution(EC)

Error Code

EC

Malfunction decision

Define the evaporator coil temp.T2 of the com p ressor just starts

<

Supposed causes

T2 sensor faulty

Is there cool air blowing

out from indoor air outlet?

Yes

Yes

Check if T

2 sensor is well

fixed. Correct the installation

or replace T

2 sensor. Does

the problem remain again?

No

Is there any leakage? Especially

the connection parts,

such as the

gas valve and the liquid valve.

No

Shut off the power supply and

turn it on

2 minutes

later.

Is it

still displaying the error code?

Replace indoor PCB.

Yes

Repair the leakage and

recharge the refrigerant.

Yes

Clear the blocking.

Yes

Is there any block ing? (Such as the

capillary or the welded points of the pipes.)

conditions

Trouble shooting:

running as Tcool.

In the beginning 5 minutes after the compressor starts up, if T2

Tcool-2°C(Tcool-35.6°F) does not keep continuous 4

seconds and this situation happens 3 times, the display area

will show “EC” and AC will turn off.

●

● Indoor PCB faulty

● System problems, such as leakage or blocking.

Page 17

1.3.6 Overload current pr ot ec t ion diagnosis and soluti on(F0)

Error Code

F0

Malfunction decision

conditions

An abnormal current rise is detected by checking the specified

current detection circuit.

Supposed causes

Power supply problems.

Compressor malfunction

Check the power supply. Is it

normal?

Check the connections and

wires .Is it well connection?

Stop the unit. Check the power

supply

No

Yes

No

Correct the connections or

replace the wires.

Yes

Replace the outdoor main PCB

Yes

Check the reactor .Is it

normal?

No

Replace the reactor

Is there any blocking?

No

Yes

Clear the blockage

Check the compressor

resistance values refer to the

[

Compressor checking

]. Is it

normal?

Yes

No

Replace the compressor

●

● System blockage

● PCB faulty

● Wiring mistake

●

Trouble shooting:

Page 18

1.3.7 IPM malfunction or IGBT over-strong current protection diagnosis and solution(P0)

Error Code

P0

Malfunction decision

When the voltage signal that IPM send to compressor drive chip

Supposed causes

Wiring mistake

Check if the wiring between main

PCB and compressor . If the wires

and connectors are broken?

Correct the connection or replace

the wires and connectors.

Yes

No

IPM continuity check. Check if the

IPM terminal resistance values are

uniform.

Replace the IPM board or replace the

main PCB if the IPM board and main

PCB are integrated together.

No

Check if the outdoor fan runs

properly or the outdoor unit

ventilation is good.

Yes

No

Please refer to the solution of 【Fan Speed Has Been

Out Of Control】malfunction

Yes

Check if the compressor resistance

values are uniform .

No Replace the compressor.

Yes

Replace the outdoor main PCB if the

main PCB and IPM are separate.

conditions

Trouble shooting:

For 9K~24K:

is abnormal, the display LED will show “P0” and AC will turn off.

●

● IPM malfunction

● Outdoor fan ass’y faulty

● Compressor malfunction

● Outdoor PCB faulty

Page 19

For example:

P-U

P-V

side.

Note: The photos below are only for reference, it’s may be not same totally with the ones on your

Page 20

P-W

N-U

Page 21

N-V

N-W

Page 22

For 30K~36K:

Yes

Check whether the power voltage

is normal

.

Check whether the power voltage

is normal.

Measure whether outdoor terminal

voltage is normal?

Measure whether o

utdoor terminal

voltage is normal?

Restart the unit when the power supply

gets normal

Restart the unit when the power supply

gets normal

No

Yes

No

Reconnect

it

well

Rec

onnect

it

well

Yes

Measure whether

the voltage

between L and N is

normal

?

Measure whether the voltage

between

L

and N

is

normal

?

Yes

Measure whether input voltage of

bridge rectifier

is normal

?

Measure whether input voltage of

bridge rectifier is normal?

No

No

Check the wiring of

power wires well or

correctly

Check the wiring of

power wires well or

correctly

Reconnect it well

Reconnect it well

Check the wiring of L

and N well or correctly

C

heck the wiring of L

and N well or correctly

Rec

onnect

it

well

Reconnect

it

well

Check the wiring of

bridge rectifier well or

correctly

C

heck the wiring of

bridge rectifier well or

correctly

No

Yes

Replace the PFC module(If has)

Replace the PFC module(If has)

No

Measure whether

the voltage

between

P

and N

is

normal

refer to the

Appendix 4?

Measure whether

the voltage

between P and N is normal

refer to the Appendix

4

?

Replace the bridge rectifier

Replace the

bridge rectifier

No

Check whether

bridge

rectifier is normal

Check whether

bridge

rectifier is normal

Check the wiring of reactor

or

inductance

Check the wiring of reactor

or inductance

Reconnect the wiring

Reconnect the wiring No

Check whether reactor or

inductance is normal

Check whether reactor or

inductance is normal

Yes

Replace reactor

or

inductance

Replace reactor or

inductance

No

Check whether the connecting

wire

between main board and the

IPM board is connected tightly

Check whether the connecting

wire

between main board and the

IPM board is connected tightly

Reconnect it well

Reconnect it well

No

Check if the outdoor unit

ventilation is good

Check if the outdoor unit

ventilation is good

Yes

Make the outdoor unit ventilate well

Make the outdoor unit ventilate well

Check whether the refrigerant system is ok

Check whether the refrigerant system is ok

No

Check if the outdoor fan runs

properly

Check if the outdoor fan runs

properly

please refer to the solution of [fan speed

has been out of control malfunction] .

Find out the cause and have it solved.

please refer to the solution of [fan speed

has been out of control malfunction]

.

Find out the cause and have it solved.

No

Yes

No

Yes

Yes

Check the compress is

normal

Check the compress is

normal

Yes

Replace the compressor

Replace the compressor

No

Replace

IPM board

Replace

IPM

board

Replace the outdoor main PCB

Replace the outdoor main PCB

No

Check whether the connecting

wire of the compressor is

connected correctly or tightly

Check whether the connecting

wire

of the compressor is

connected correctly or tightly

Reconnect

it well

Reconnect

it well

No

Yes

Yes

At first test the resis tance bet ween e ver y two por ts of U, V, W of IPM and P, N. If an y result of them is 0 or

close to 0, the IPM is defective. Otherwise, please follow the procedure below:

Page 23

Page 24

1.3.8 Over vol t age or t oo low voltage protection diagnosis and solution(P1 )

Error Code

P1

Malfunction decision

conditions

An abnormal voltage rise or drop is detected by checking the

specified voltage detection circuit.

Supposed causes

Power supply problems.

PCB faulty

Check the power supply

Check the connections and

wires

Stop the unit

No

Yes

No

Correct the connections or

replace the wires.

Yes

Replace the reactor

Yes

No

Replace the IPM board

Check the voltage between P

and N

Check the reactor

Yes

No

Replace outdoor main PCB

P

N

●

● System leakage or block

●

Trouble shooting:

Remark:

Measure the DC voltage

between P and N port . The

normal value should be

around 310V.

Page 25

1.3.9 High temperature protection of IPM module or compressor top diagnosis and

Error Code

P2

Malfunction decision

conditions

If the sampling voltage is not 5V, the LED will display the failure.

Supposed causes

Installation mistake

PCB faulty

Yes

Tighten the screws and apply

silicon grease.

Tighten the screws and apply

silicon grease.

Replace the outdoor control PCB.

Replace the outdoor control PCB.

No

Check if the Fastening screws

on the PCB and IPM radiator

are fixed tightly.

Check if the air flow system

of indoor and outdoor units

are obstructed?

Clear up the air inlet and outlet or the heat

exchanger of indoor and outdoor units.

Yes

No

Yes

Yes

Turn off the power supply and turn

it on 10 minutes later.

Check if the temperature

of compressor Top

Is

more than 90

℃?

No

Check if the refrigerant

system

is normal?

Repair the refrigerant

system .

Replace the outdoor control PCB.

Yes

Check if all the connection, especially

the connection of OLP (Over Load

Protector) sensor is good.

Correct the connection.No

Measure the resistance

between the two ports of

the OLP. Is it zero?

Yes

Replace the OLP.No

Replace the outdoor control PCB.Yes

No

solution(P2)

●

● Power supply problems.

● System leakage or block

●

Trouble shooting:

For 18K,24K,

For other models,

Page 26

1.3.10 Inverter compressor drive error diagnosis and solution(P4)

Error Code

P4

Malfunction decision

An abnormal inverter compressor drive is detected by a special

and so on.

Supposed causes

Wiring mistake

Outdoor PCB faulty

Check if the wiring between main

PCB and compressor connected

well

?

Correct the connection or

replace the wires and

connectors.

No

Check if the IPM installed correctly.

Correct the installation

,

tighten the screws and

apply silicon grease

.

No

IPM continuity check

.

Check if the

IPM terminal resistance values are

uniform.

Yes

Replace the IPM board or replace

the main PCB if the IPM board and

main PCB are integrated together.

No

Check if the outdoor fan runs

properly or the outdoor unit

ventilation is good.

Yes

No

Please refer to the solution of 【

Fan

Speed Has Been Out Of Control

】

malfunction

Yes

Check if the compressor resistance

values are uniform .

No

Replace the compressor

.

Yes

Replace the outdoor main PCB if the

main PCB and IPM are separate

.

Check the reactor or

Inductance

.

Is it normal

?

No

Replace the reactor

or

Inductance

Yes

Yes

conditions

Trouble shooting:

For 9K~24K:

detection circuit, including commun ication signal detection,

voltage detection, compressor rotation speed signal detection

●

● IPM malfunction

● Outdoor fan ass’y faulty

● Compressor malfunction

●

IPM continuity check

Turn off the power, let the large capacity electrolytic capacitors discharge completely, and dismount the IPM. Use a

digital tester to measure the resistance between P and UVWN; UVW and N.

Page 27

Digital tester

Normal resistance value

Digital tester

Normal resistance value

(+)Red

(-)Black

(+)Red

(-)Black

P

N

U

U

V

V

W

W

(+)Red

Yes

Check whether the power voltage

is normal

.

Check whether the power voltage

is normal.

Measure whether outdoor terminal

voltage is normal?

Measure whether outdoor terminal

voltage is normal?

Restart the unit when the power supply

gets normal

Restart the unit when the power supply

gets normal

No

Yes

No

Reconnect it well

Rec

onnect

it

well

Yes

Measure whether

the voltage

between L and N is normal?

Measure whether the voltage

between L and N is

normal

?

Yes

Measure whether input voltage of

bridge rectifier

is normal

?

Measure whether input voltage of

bridge rectifier is normal?

No

No

Check the wiring of

power wires well or

correctly

Check the wiring of

power wires well or

correctly

Reconnect it well

Reconnect it well

Check the wiring of L

and N well or correctly

Check the wiring of L

and N well or correctly

Reconnect it well

Rec

onnect it

well

Check the wiring of

bridge rectifier well or

correctly

Check the wiring of

bridge rectifier well or

correctly

No

Yes

Replace the PFC module

(If has

)

Replace the PFC module(If has

)

No

Measure whether

the voltage

between P and N is normal

refer to the

Appendix 4

?

Measure whether the voltage

between P and N is normal

refer to the Appendix 4

?

Replace the bridge rectifier

Replace the bridge rectifierNo

Check whether bridge

rectifier

is normal

Check whether bridge

rectifier

is normal

Check the wiring of reactor

or inductance

Check the wiring of reactor

or inductance

Reconnect the wiring

Reconnect

the wiring

No

Check whether reactor or

inductance

is normal

Check whether reactor or

inductance is normal

Yes

Replace r

eactor or

inductance

Replace r

eactor or

inductance

No

Check whether the connecting

wire between main board and the

IPM board

is connected tightly

Check whether the connecting

wire between main board and the

IPM board

is connected tightly

Reconnect

it well

Reconnect

it well

No

Check if the outdoor unit

ventilation is good

Check if the outdoor unit

ventilation is good

Yes

Make the outdoor unit ventilate well

M

ake the outdoor unit ventilate well

Check whether the refrigerant system is ok

Check whether the refrigerant system is ok

No

Check if the outdoor fan runs

properly

Check if the outdoor fan runs

properly

please refer to the solution of [fan speed

has been out of control malfunction]

.

Find out the cause and have it solved.

please refer to the solution of [fan speed

has been out of control malfunction] .

Find out the cause and have it solved.

No

Yes

No

Yes

Yes

Check the compress is

normal

Check the compress is

normal

Yes

Replace the compressor

Replace the compressorNo

Replace IPM board

Replace IPM board

Replace the outdoor main PCB

Replace the outdoor main PCB

No

Check whether the connecting

wire of the compressor is

connected correctly or tightly

Check whether the connecting

wire of the compressor is

connected correctly or tightly

Reconnect it well

Reconnect it well

No

Yes

Yes

∞

(Several MΩ)

N

∞

(Several MΩ)

For 30K~36K:

At first test the resistance between every two ports of U, V, W of IPM and P, N. If any result of them is 0 or

close to 0, the IPM is defective. Otherwise, please follow the procedure below:

Page 28

Error Code

P6

Malfunction decision

When the pressure of system reach a certain value, the low

normal ,the protection code will disappear.

Supposed causes

Wiring mistake

System problems.

Whether the wiring

between the low pressure

protector and main control

board is connected well or

correctly

Whether the wiring

between the low pressure

protector and main control

board is connected well or

correctly

Method: Disconnect the

plug. Measure the

resistance of the low

pressure protecto

r. If the

protector is normal the value

is o

Method: Disconnect the

plug. Measure the

resistance of the low

pressure protector. If the

protector is normal the value

is o

Yes

Yes

Connect it well

Connect it well

Replace outdoor main board

Replace outdoor main board

No

Replace low pressure protector

Replace low pressure protector

No

Whether the low

pressure protector

is broken

Whether the low

pressure protector

is broken

Check whether the outdoor

ambient temperature is too

low

Check whether the outdoor

ambient temperature is too

low

No

Stop the unit

Stop the unit

Yes

Open fully valve core of high

pressure valve

Open fully valve core of high

pressure valve

No

Check whether valve core of

high pressure valve is

opened

Check whether valve core of

high pressure valve is

opened

Check if the indoor fan runs

properly in cooling mode

Check if the indoor fan runs

properly in cooling mode

please refer to the solution of [fan

speed has been out of control

malfunction]. Find out the cause and

have it solved

.

please refer to the solution of [fan

speed has been out of control

malfunction]. Find out the cause and

have it solved.

No

Yes

Yes

No

Check whether the

refrigerant system is ok

Check whether the

refrigerant system is ok

Refrigerant is not enough add the

refrigerant

Refrigerant is not enough add the

refrigerant

No

1.3.11 Low pressure protection diagnosi s and solution(P6)

conditions

Trouble shooting:

pressure protector will switch off. After the pressure resume to

●

● Pressure protector faulty

● Fan motor faulty

● PCB faulty

●

Page 29

Main parts check

1. Temper atur e sensor checking

Disconnect the temperature sensor from PCB, measure the resistance value with a tester.

Temperature sensors.

Room temp.(T1) sensor,

Indoor coil temp.(T2) sensor,

Outdoor coil temp.(T3) sensor,

Outdoor ambient temp.(T4) sensor,

Compressor discharge temp.(TP) sensor.

Measure the resistance value of each winding by using the multi-meter.

Page 30

Appendix 1 Temperature Sensor Resistance Value Table for T1,T2,T3,T4 (°C--K)

°C

°F

K Ohm

°C

°F

K Ohm

°C

°F

K Ohm

°C

°F

K Ohm

-20 -4 115.266 20 68 12.6431 60 140 2.35774 100 212 0.62973

-19 -2 108.146 21 70 12.0561 61 142 2.27249 101 214 0.61148

-18 0 101.517 22 72 11.5 62 144 2.19073 102 216 0.59386

-17 1 96.3423 23 73 10.9731 63 145 2.11241 103 217 0.57683

-16 3 89.5865 24 75 10.4736 64 147 2.03732 104 219 0.56038

-15 5 84.219 25 77 10 65 149 1.96532 105 221 0.54448

-14 7 79.311 26 79 9.55074 66 151 1.89627 106 223 0.52912

-13 9 74.536 27 81 9.12445 67 153 1.83003 107 225 0.51426

-12 10 70.1698 28 82 8.71983 68 154 1.76647 108 226 0.49989

-11 12 66.0898 29 84 8.33566 69 156 1.70547 109 228 0.486

-10 14 62.2756 30 86 7.97078 70 158 1.64691 110 230 0.47256

-9 16 58.7079 31 88 7.62411 71 160 1.59068 111 232 0.45957

-8 18 56.3694 32 90 7.29464 72 162 1.53668 112 234 0.44699

-7 19 52.2438 33 91 6.98142 73 163 1.48481 113 235 0.43482

-6 21 49.3161 34 93 6.68355 74 165 1.43498 114 237 0.42304

-5 23 46.5725 35 95 6.40021 75 167 1.38703 115 239 0.41164

-4 25 44 36 97 6.13059 76 169 1.34105 116 241 0.4006

-3 27 41.5878 37 99 5.87359 77 171 1.29078 117 243 0.38991

-2 28 39.8239 38 100 5.62961 78 172 1.25423 118 244 0.37956

-1 30 37.1988 39 102 5.39689 79 174 1.2133 119 246 0.36954

0 32 35.2024 40 104 5.17519 80 176 1.17393 120 248 0.35982

1 34 33.3269 41 106 4.96392 81 178 1.13604 121 250 0.35042

2 36 31.5635 42 108 4.76253 82 180 1.09958 122 252 0.3413

3 37 29.9058 43 109 4.5705 83 181 1.06448 123 253 0.33246

4 39 28.3459 44 111 4.38736 84 183 1.03069 124 255 0.3239

5 41 26.8778 45 113 4.21263 85 185 0.99815 125 257 0.31559

6 43 25.4954 46 115 4.04589 86 187 0.96681 126 259 0.30754

7 45 24.1932 47 117 3.88673 87 189 0.93662 127 261 0.29974

8 46 22.5662 48 118 3.73476 88 190 0.90753 128 262 0.29216

9 48 21.8094 49 120 3.58962 89 192 0.8795 129 264 0.28482

10 50 20.7184 50 122 3.45097 90 194 0.85248 130 266 0.2777

11 52 19.6891 51 124 3.31847 91 196 0.82643 131 268 0.27078

12 54 18.7177 52 126 3.19183 92 198 0.80132 132 270 0.26408

13 55 17.8005 53 127 3.07075 93 199 0.77709 133 271 0.25757

14 57 16.9341 54 129 2.95896 94 201 0.75373 134 273 0.25125

15 59 16.1156 55 131 2.84421 95 203 0.73119 135 275 0.24512

16 61 15.3418 56 133 2.73823 96 205 0.70944 136 277 0.23916

17 63 14.6181 57 135 2.63682 97 207 0.68844 137 279 0.23338

18 64 13.918 58 136 2.53973 98 208 0.66818 138 280 0.22776

19 66 13.2631 59 138 2.44677 99 210 0.64862 139 282 0.22231

Page 31

Appendix 2 Temperature Sensor Resistance Value Table for TP (°C --K)

°C

°F

K Ohm

°C

°F

K Ohm

°C

°F

K Ohm

°C

°F

K Ohm

-20 -4 542.7 20 68 68.66 60 140 13.59 100 212 3.702

-19 -2 511.9 21 70 65.62 61 142 13.11 101 214 3.595

-18 0 483 22 72 62.73 62 144 12.65 102 216 3.492

-17 1 455.9 23 73 59.98 63 145 12.21 103 217 3.392

-16 3 430.5 24 75 57.37 64 147 11.79 104 219 3.296

-15 5 406.7 25 77 54.89 65 149 11.38 105 221 3.203

-14 7 384.3 26 79 52.53 66 151 10.99 106 223 3.113

-13 9 363.3 27 81 50.28 67 153 10.61 107 225 3.025

-12 10 343.6 28 82 48.14 68 154 10.25 108 226 2.941

-11 12 325.1 29 84 46.11 69 156 9.902 109 228 2.86

-10 14 307.7 30 86 44.17 70 158 9.569 110 230 2.781

-9 16 291.3 31 88 42.33 71 160 9.248 111 232 2.704

-8 18 275.9 32 90 40.57 72 162 8.94 112 234 2.63

-7 19 261.4 33 91 38.89 73 163 8.643 113 235 2.559

-6 21 247.8 34 93 37.3 74 165 8.358 114 237 2.489

-5 23 234.9 35 95 35.78 75 167 8.084 115 239 2.422

-4 25 222.8 36 97 34.32 76 169 7.82 116 241 2.357

-3 27 211.4 37 99 32.94 77 171 7.566 117 243 2.294

-2 28 200.7 38 100 31.62 78 172 7.321 118 244 2.233

-1 30 190.5 39 102 30.36 79 174 7.086 119 246 2.174

0 32 180.9 40 104 29.15 80 176 6.859 120 248 2.117

1 34 171.9 41 106 28 81 178 6.641 121 250 2.061

2 36 163.3 42 108 26.9 82 180 6.43 122 252 2.007

3 37 155.2 43 109 25.86 83 181 6.228 123 253 1.955

4 39 147.6 44 111 24.85 84 183 6.033 124 255 1.905

5 41 140.4 45 113 23.89 85 185 5.844 125 257 1.856

6 43 133.5 46 115 22.89 86 187 5.663 126 259 1.808

7 45 127.1 47 117 22.1 87 189 5.488 127 261 1.762

8 46 121 48 118 21.26 88 190 5.32 128 262 1.717

9 48 115.2 49 120 20.46 89 192 5.157 129 264 1.674

10 50 109.8 50 122 19.69 90 194 5 130 266 1.632

11 52 104.6 51 124 18.96 91 196 4.849

12 54 99.69 52 126 18.26 92 198 4.703

13 55 95.05 53 127 17.58 93 199 4.562

14 57 90.66 54 129 16.94 94 201 4.426

15 59 86.49 55 131 16.32 95 203 4.294

16 61 82.54 56 133 15.73 96 205 4.167

17 63 78.79 57 135 15.16 97 207 4.045

18 64 75.24 58 136 14.62 98 208 3.927

19 66 71.86 59 138 14.09 99 210 3.812

Page 32

Appendix 3:

-5

23

21

69.8

51

123.8

82

179.6

113

235.4

-4

24.8

22

71.6

52

125.6

83

181.4

114

237.2

-3

26.6

23

73.4

53

127.4

84

183.2

115

239

-2

28.4

24

75.2

54

129.2

85

185

116

240.8

-1

30.2

25

77

55

131

86

186.8

117

242.6

0

32

25.5

77.9

56

132.8

87

188.6

118

244.4

0.5

32.9

26

78.8

57

134.6

88

190.4

119

246.2 1 33.8

27

80.6

58

136.4

89

192.2

120

248

1.5

34.7

28

82.4

59

138.2

90

194

121

249.8

2

35.6

29

84.2

60

140

91

195.8

122

251.6

2.5

36.5

30

86

61

141.8

92

197.6

123

253.4

3

37.4

31

87.8

62

143.6

93

199.4

124

255.2

3.5

38.3

32

89.6

63

145.4

94

201.2

125

257 4 39.2

33

91.4

64

147.2

95

203

126

258.8

4.5

40.1

34

93.2

65

149

96

204.8

127

260.6

5

41

35

95

66

150.8

97

206.6

128

262.4 6 42.8

36

96.8

67

152.6

98

208.4

129

264.2

7

44.6

37

98.6

68

154.4

99

210.2

130

266

8

46.4

38

100.4

69

156.2

100

212

131

267.8 9 48.2

39

102.2

70

158

101

213.8

132

269.6

10

50

40

104

71

159.8

102

215.6

133

271.4

11

51.8

41

105.8

72

161.6

103

217.4

134

273.2

12

53.6

42

107.6

73

163.4

104

219.2

135

275

13

55.4

43

109.4

74

165.2

105

221

136

276.8

14

57.2

44

111.2

75

167

106

222.8

137

278.6

15

59

45

113

76

168.8

107

224.6

138

280.4

16

60.8

46

114.8

77

170.6

108

226.4

139

282.2

17

62.6

47

116.6

78

172.4

109

228.2

140

284

18

64.4

48

118.4

79

174.2

110

230

141

285.8

19

66.2

49

120.2

80

176

111

231.8

142

287.6

20

68

50

122

81

177.8

112

233.6

143

289.4

9ΔT(℃)

ΔT(℉) =

5

°C °F °C °F °C °F °C °F °C °F

Page 33

Normal voltage of P and N

208-240V(1-phase,3-phase)

380-420V(3-phase)

In standby

around 310VDC

around 530VDC

In operation

With partial

module

>200VDC

>310VDC

>370VDC

>450VDC

Appendix 4

1.

With passive

PFC module

active PFC

With fully active

PFC module

/

Page 34

2. Compressor checking

Position

Resistance Value

ASN98D22UFZ

ASM135D23UFZ

ATF235D22UMT

ATF250D22UMT

Blue - Red

Blue - Black

Red - Blue

Measure the resistance value of each winding by using the tester.

1.57Ω

1.75 Ω

0.75 Ω

0.75 Ω

Page 35

3. Fan Motor

Model

YKT-32-6-

202L

YKT-32-6-

3L

YKT-48-6-

206

YKT-63-6-

200L

Brand

Tongde

Welling

Welling

Welling

Black –

Main

Ω

86

213

152

88.5

Blue –

AUX

Ω

64

156

142

138

Measure the resistance value of each winding by using the tester.

Red

Black

Page 36

4. Pressure On Service Port

ODT

IDT

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

BAR

70/59

8.2

7.8

8.1

8.6

10.1

BAR

75/63

8.6

8.3

8.7

9.1

10.7

BAR

80/67

9.3

8.9

9.1

9.6

11.2

ODT

IDT

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

PSI

70/59

119

113

117

125

147

PSI

75/63

124

120

126

132

155

PSI

80/67

135

129

132

140

162

ODT

IDT

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

MPA

70/59

0.82

0.78

0.81

0.86

1.01

MPA

75/63

0.86

0.83

0.87

0.91

1.07

MPA

80/67

0.93

0.89

0.91

0.96

1.12

75 (23.89

85 (29.44

95 (35

105 (40.56

115 (46.11

70/59

75/63

80/67

Cooling chart:

°F(°C)

°F(°C)

°F(°C)

12,0

10,0

8,0

6,0

4,0

2,0

0,0

)

)

)

)

)

Page 37

Heating Chart:

(°C)

ODT

IDT

(13.89/11.67)

(8.33/6.11)

(2.78/0.56)

(-2.78/-5)

(-8.33/-10.56)

BAR

55

30.3

28.5

25.3

22.8

20.8

BAR

65

32.5

30.0

26.6

25.4

23.3

BAR

75

33.8

31.5

27.8

26.3

24.9

(°C)

ODT

IDT

(13.89/11.67)

(8.33/6.11)

(2.78/0.56)

2.78/-5)

(-8.33/-10.56)

PSI

55

439

413

367

330

302

PSI

65

471

435

386

368

339

PSI

75

489

457

403

381

362

ODT

IDT

(13.89/11.67)

(8.33/6.11)

(2.78/0.56)

2.78/-5)

(-8.33/-10.56)

MPA

55

3.03

2.85

2.53

2.28

2.08

MPA

65

3.25

3.00

2.66

2.54

2.33

MPA

75

3.38

3.15

2.78

2.63

2.49

No.

Parts name

Procedures

Remarks

57/53

47/43

37/33

27/23

17/13

55

65

75

°F

°F

°F

(°C)

40,0

35,0

30,0

57/53

57/53

57/53

47/43

47/43

47/43

37/33

37/33

37/33

27/23

27/23 (-

27/23 (-

17/13

17/13

17/13

25,0

20,0

15,0

10,0

5,0

0,0

(13.89/11.67)

(8.33/6.11)

(2.78/0.56)

(-2.78/-5)

(-8.33/-10.56)

2. Disassembly Instructions

Note: This part is for reference, the photos may have sli ght di f f er ence with your machine.

2.1 Indoor unit

Page 38

1

Front panel

How to remove the front pane l.

1) Pull the below side of

①1 screw

②

⑤

the panel toward you and

remove screw of the cover.

2) Release the connector of

the display ass’y.

3) Release the two clips and

then remove the panel.

4) Remove the fi lter and the

horizontal louver.

5) Remove the three screws

and then remove the panel

ass’y.

Page 39

2

Electrical

parts

How to remove the electric al

②

③

④

⑤

parts.

1) Remove the front

panel from procedure 1.

2) Pull out the room temp.

sensor (T1). Remove the two

screws for the ground

connection.

3) Remove the fixing screw.

4) Pull out the coil temp.

sensor.

5) From the side direction,

open the electronic control box

cover fixing by clips. Pull out

the fan motor connector and

swing motor connector. Then

remove the electronic con trol

box.

Loading...

Loading...