Coolair MNEFC54, MNBCC54 User Manual

FARM PRODUCTS DIVISION

AMERICAN COOLAIR CORPORATION

PHONE (904) 389-3646 FAX (904) 387-3449

MEMBER OF AMCA

P.O. BOX 2300

JACKSONVILLE, FLORIDA 32203

E-MAIL - agfans@coolair.com

MNBCC54 and MNEFC54

GALVANIZEDWALL FANS

Installation, Operation, and Maintenance Instructions

611/

585/

8

381/

4

701/

4

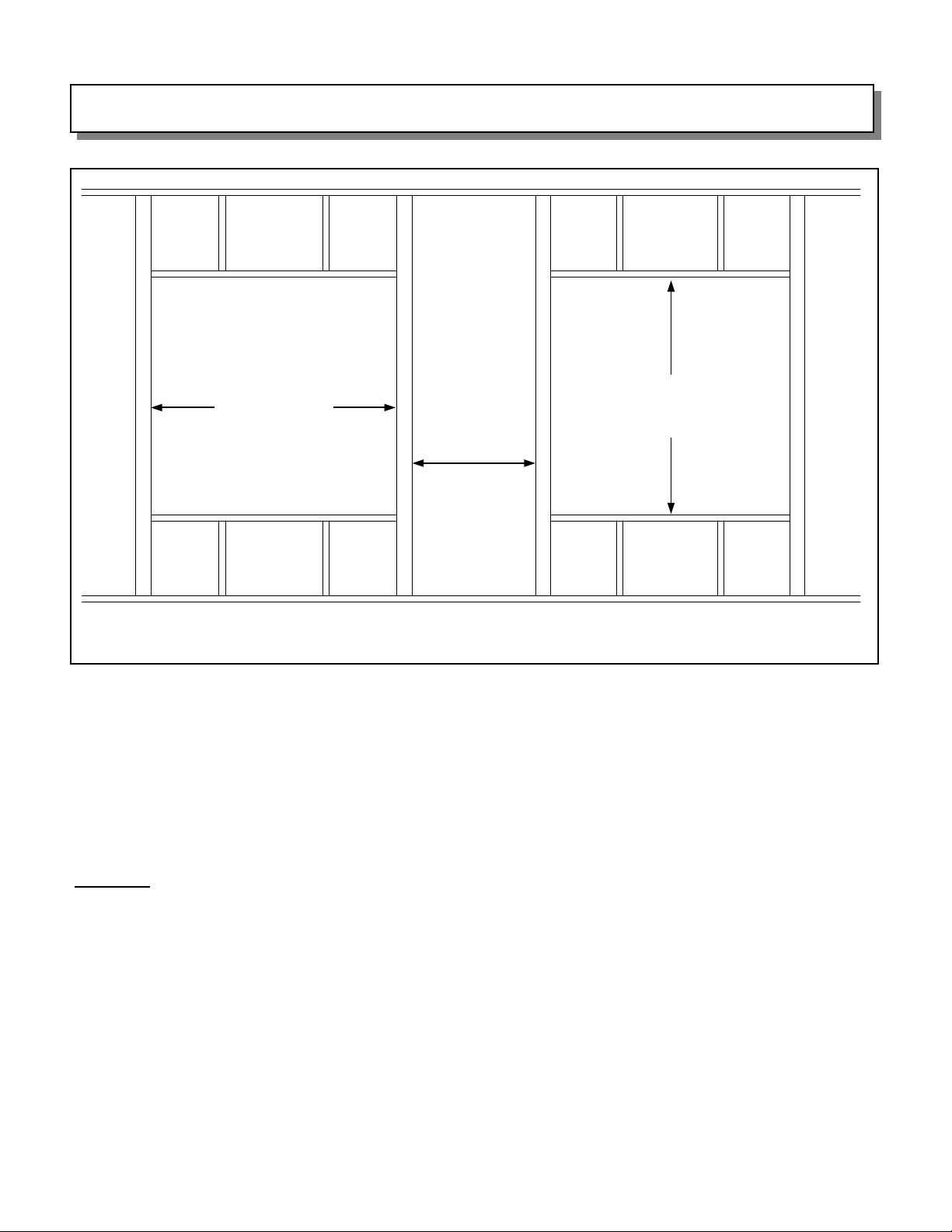

Figure 1 Dimensions in inches.

2

587/

21/

8

613/

4

8

MNBCC54L * MNBCCE54L * MNBCC54M

MNBCCE54M * MNEFC54L * MNEFCE54L

MNEFC54M * MNEFCE54M

UNPACKING

Inspect the fan for signs of shipping damage. It is the responsibility of the customer to report any shipping damage

to the freight carrier.

WHAT SHOULD YOU FIND?

Fan, Fan Housing (4 Housing Sheets, 4 Corner Deflectors, and 4 Shutter Latches), Cone (4 Cone Panels and 4

Cone Gussets), Cone Guard, Shutter with 4 Inlet Angles, and Hardware.

FRAME CONSTRUCTION

59 5/8” Width

Spacing

(see below)

Figure 2

The required framed-in opening width for both the MNBCC54 and MNEFC54 is 59 5/8”. The required framed-in

opening height depends on wall thickness:

For 2” thick walls, the height is 59 7/8”.

For 4” thick walls, the height is 60”.

For 6” thick walls, the height is 60 1/4”.

The minimum spacing between fans is 15”. However, to insure optimum fan performance, Coolair recommends a

spacing between fans of at least 30”.

Height

(see below)

CAUTION: To insure proper fan and shutter operation, the frame opening MUST BE SQUARE. To verify this,

measure from the upper right corner of the frame diagonally to the lower left corner. Next, measure from the upper

left corner of the frame diagonally to the lower right corner. These two DIAGONAL MEASUREMENTS MUST BE

EQUAL prior to installing the fan.

PAGE 2

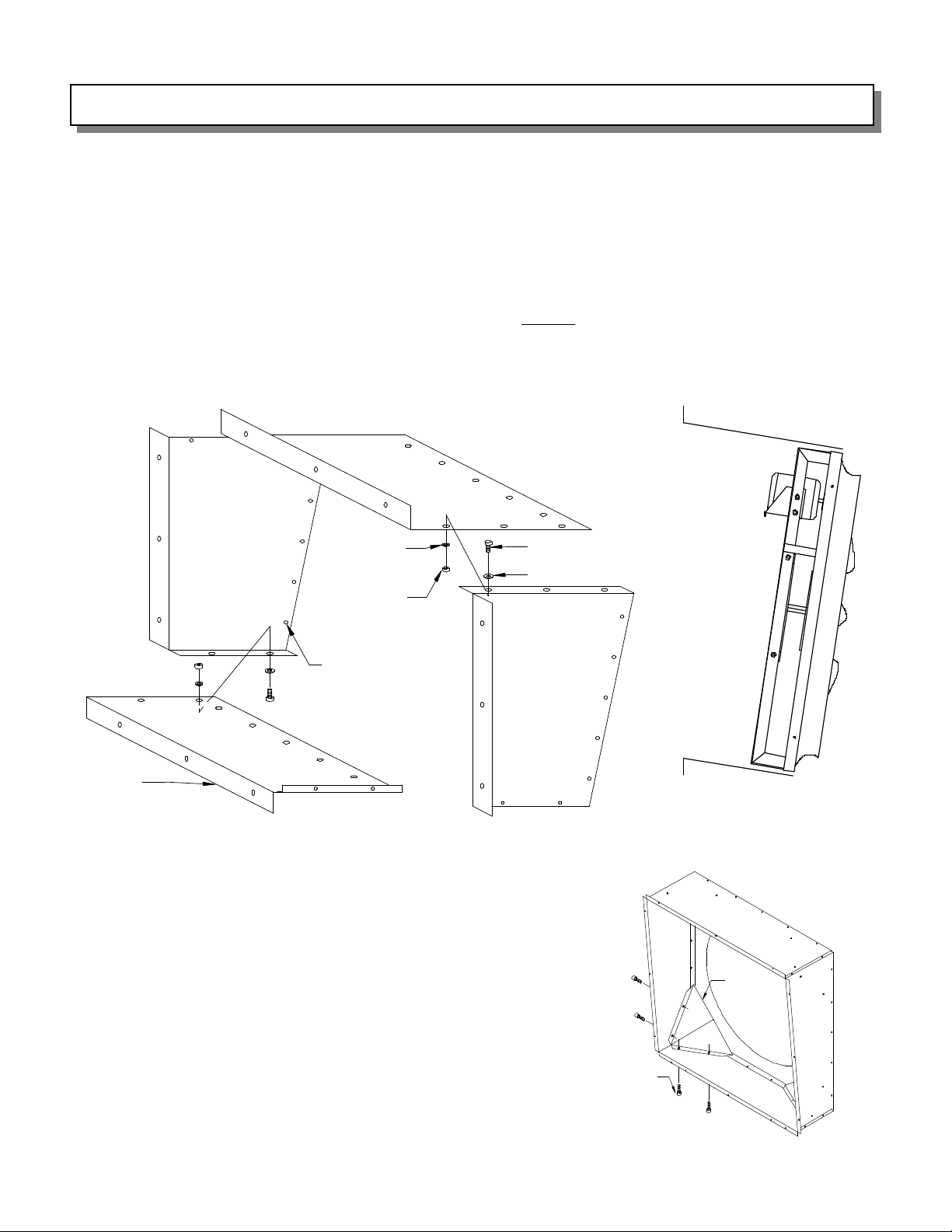

FAN & HOUSING ASSEMBLY

For assembly and maintenance instructions for the fan and motor, see Form 220-40 included with the fan.

If the fan and housing are factory assembled, skip to Page 4 — Fan Mounting & Installation. For the

proper mounting of the motor bracket to the fan frame, disregard Figure 1 on Form 220-40 and install the motor

bracket towards the top of the fan — see Figure 4. Make sure the motor is mounted on top of the motor bracket.

There are 4 wall housing sheets -- the two that are the same size are the side sheets. The smaller rectangular sheet

is the bottom. The larger rectangular sheet is the top. Assemble the bottom and one side sheet together using 1/4"

hardware as shown in Figure 3. Then, place the fan on the bottom housing sheet aligning the holes in the fan

flanges with the fan mounting holes in the wall housing sheets. Caution: for proper shutter clearance, the fan must

be mounted in the housing with the motor at the top of the housing as shown in Figure 4. Now, assemble the

remaining housing sheets around the fan using 1/4" nuts and bolts for the housing assembly and for mounting the

fan panel to the housing. When assembling the wall housing, do not tighten any hardware until all bolts are in place.

Top

Sheet

(Left) Side

Sheet

¼” Lock

Washer

¼” Nut

Fan

Mounting

Holes

Bottom

Sheet

Housing

Mounting

Flange

Figure 3 — Housing Assembly

CORNER DEFLECTOR INSTALLATION: For proper fan

operation, the corner deflectors must be fastened to the fan.

There are two sizes of these triangular deflectors — the longer

deflectors will be installed in the top two corners where the fan

panel meets the housing, and the shorter deflectors will be

installed in the bottom two corners.

First, place the deflector inside the housing such that the two

shorter sides (with the flanges and mounting holes) are against

the housing, and the longer side is against the fan panel. The

holes in the deflectors should align with the holes in the housing.

If the holes are not aligned, check that you are using the correct

length deflector in the proper corner. Fasten each deflector

using four of the ¼” x ¾” self-tapping screws provided. The

screws must be fastened from the outside of the housing through

the housing and then through the deflector. See Figure 5.

¼” x ¾” Bolt

¼” Flat Washer

(Right) Side

Sheet

Figure 4 — Side view of

the fan assembled in the

housing

Corner

Deflector

¼” x ¾” Self-

Tap Screws

Figure 5

PAGE 3

Loading...

Loading...