Page 1

Combi oven

OES mini easyTouch

Installation manual - Original, ENG

Read instructions before use

Page 2

Page 3

Table of Contents

Table of Contents

1 General 5

1.1 Environmental protection 5

1.2 Identifying your combi oven 6

1.3 Structure of customer documentation 7

1.4 Essential reading relating to safety 8

1.5 About this installation manual 9

2 Design and function 11

2.1 Design and function of the combi oven (6.06/6.10/10.10 mini) 11

2.2 Layout and function of the combi oven (6.10 mini 2in1) 12

2.3 Layout and function of the operating panel 14

3 For your safety 15

3.1 Basic safety code 15

3.2 Intended use of your combi oven 17

3.3 Warning signs on the combi oven (6.06/6.10/10.10 mini) 18

3.4 Warning signs on the combi oven (6.10 mini 2in1) 20

3.5 Hazards and safety precautions when moving the appliance 22

3.6 Hazards and safety precautions when setting up the appliance 23

3.7 Hazards and safety precautions during installation 25

3.8 Hazards and safety precautions when putting the appliance into service 27

3.9 Hazards and safety precautions when removing the appliance from service 30

3.10 Safety devices (6.06/6.10/10.10 mini) 33

3.11 Safety devices (6.10 mini 2in1) 35

3.12 Requirements to be met by personnel, working positions 37

3.13 Personal protective equipment 39

4 Transportation 40

4.1 Safe working when moving the appliance 40

4.2 Conveying the appliance to the installation location 41

5 Setting up the appliance 42

5.1 Safe working when setting up the appliance 42

5.2 Adjacent systems 43

5.3 Requirements for the installation location 44

5.4 Unpacking 48

5.5 Taking the appliance off the pallet 50

5.6 Setting up the appliance on a worktable 51

5.7 Setting up the appliance on a stand 52

5.8 Setting up the appliance on a wheeled stand 53

5.9 Setting up the appliance on the floor (6.10 mini 2in1) 55

5.10 Fitting appliance to the wall 56

5.11 Installing the appliances in a stacking kit 58

5.12 Installing appliances in a wheeled stacking kit 59

6 Installation 60

6.1 Electrical installation 60

6.1.1 Safe working during electrical installation 60

6.1.2 Planning the electrical installation 62

6.1.3 Carrying out the electrical installation 64

Installation manual 3

Page 4

Table of Contents

6.1.4 Converting the electrical supply to a single-phase supply (6.06 mini) 65

6.1.5 Converting the electrical supply to a three-phase supply (6.06/6.10 mini) 66

6.2 Water connection 67

6.2.1 Safe working when making the water connection 67

6.2.2 Water supply 69

6.2.3 Test the water quality 75

6.2.4 Water drain 76

6.3 Installing the ConvoClean system 78

6.3.1 Safe working when installing the ConvoClean system 78

6.3.2 Layout of the fully automatic oven cleaning system 79

6.3.3 Connecting the fully automatic oven cleaning system (6.06/6.10/10.10 mini) 81

6.3.4 Preparing the fully automatic oven cleaning system (6.10 mini 2in1) 82

7 Putting into service 83

7.1 Safe working when putting the appliance into service 83

7.2 Procedure for putting the appliance into service 86

8 Removal from service and disposal 89

8.1 Safe working when removing the appliance from service 89

8.2 Removal from service and disposal 91

9 Technical data and Connection drawing 92

9.1 Technical data 92

9.2 Connection drawing for OES 6.06 mini 96

9.3 Connection drawing for OES 6.10 mini 97

9.4 Connection drawing for OES 10.10 mini 98

9.5 Connection drawing for OES 6.10 mini 2in1 99

10 Checklists and completion of installation 100

10.1 Checklist: moving, setting up and installing the appliance 100

10.2 Checklist: Safety devices and warnings 102

10.3 Checklist: Customer guidance and instruction 103

10.4 Completion of the installation 104

Installation manual 4

Page 5

1 General

1 General

Purpose of this chapter

This chapter shows you how to identify your combi oven and provides guidance on using this manual.

1.1 Environmental protection

Statement of principles

Our customers' expectations, the legal regulations and standards and our company's own reputation

set the quality and service for all our products.

We have an environmental management policy that not only ensures compliance with all environmen‐

tal regulations and laws, but also commits us to continuous improvement of our green credentials.

We have developed a quality and environmental-management system in order to guarantee the con‐

tinued manufacture of high-quality products, and to be sure of meeting our environmental targets.

This system satisfies the requirements of ISO 9001:2008 and ISO 14001:2004.

Environmental protection procedures

We observe the following procedures:

■

Use of residue-free compostable wadding materials

■

Use of RoHS-compliant products

■

REACH chemical law

■

Multiple re-use of cardboard packaging

■

Recommendation and use of bio-degradable cleaning agents

■

Recycling of electronic waste

■

Environmentally friendly disposal of old appliances

Join us in our commitment to protect the environment.

Installation manual 5

Page 6

1 General

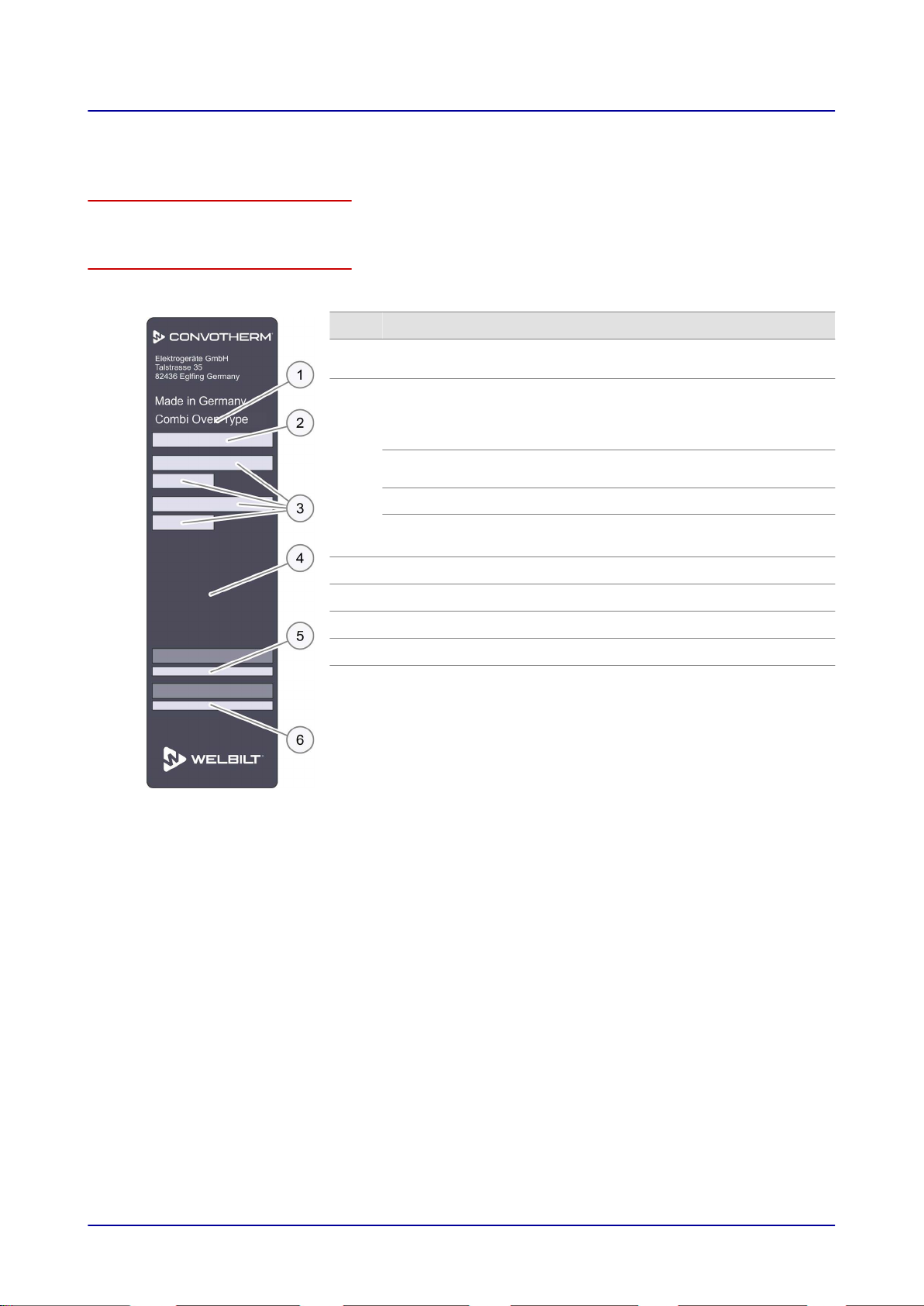

1.2 Identifying your combi oven

Position of type plate

The type plate is located on the left-hand side of the combi oven.

Layout and structure of the type plate

You can use the type plate to identify your appliance. The type plate has the following layout:

Item Name

1

2

3

4

5

6

Name of appliance

Combi Oven

Trade name

Element: Meaning:

OES Electric appliance with water

injection

numbers xx.yy Appliance size

■

mini

■

mini 2in1

Appliance series

Electrical values

Appliance tests

Serial number

Part number

Installation manual 6

Page 7

1 General

1.3 Structure of customer documentation

Contents of customer documentation

The customer documentation for the combi oven includes the following documents:

■

Installation manual (this document)

■

User manual

■

Operating instructions for easyStart mode

■

Help facility included in the software (extracts from the user manual)

Structure of customer documentation

The following table shows the topics and structure of the customer documentation:

Topic Description See

Transportation Moving the combi oven Installation manual

Setting up the appliance■Setup options

■

How to set up the combi oven correctly

Installation

Putting into service How to prepare the combi oven for first-time use

Operation

Cleaning

Servicing

Removal from service How to take the combi oven out of operation Installation manual

Technical data

Dimensional drawings,

connection points

Checklists Installation checklists

■

Electrical connection

■

Water connection

■

Installing the ConvoClean fully automatic oven

cleaning system (optional)

■

Describes the user interface

■

Working procedures and operating steps

■

Cleaning instructions

■

Cleaning programs and cleaning tasks

■

Servicing schedule

■

Minor servicing tasks

■

Shelf options

■

Maximum load

The complete technical specification for the combi

oven

All dimensional drawings and connection points of

the combi oven

(intended for trained

professional staff;

see Requirements to

be met by personnel

User manual

(intended for un‐

trained staff and

trained professional

staff; see Require‐

ments to be met by

personnel)

User manual

Installation manual

Installation manual

)

Installation manual 7

Page 8

1 General

1.4 Essential reading relating to safety

Safety information in the customer documentation

Safety information relating to the combi oven mainly appears in the installation manual and the user

manual.

The installation manual contains the safety information for the tasks covered by the manual and which

are performed when moving, setting up and installing the appliance and when putting the appliance

into service and removing the appliance from service.

The user manual contains the safety information for the tasks covered by the manual and which are

performed during cooking, cleaning and servicing work.

The safety information contained in the user manual and installation manual must always be consid‐

ered to be part of the operating instructions. The safety information contained in the user manual and

installation manual must always be observed when performing tasks that go beyond merely operating

the software.

Parts of this document that must be read without fail

If you do not follow the information in this document, you risk potentially fatal injury and property dam‐

age.

To guarantee safety, all people who work with the combi oven must have read and understood the

following parts of this document before starting any work:

■

the chapter 'For your safety', see

■

the sections that describe the activity to be carried out

For your safety on page 15

Danger symbol

Danger symbol Meaning

Warns of potential injuries. Heed all the warning notices that appear af‐

ter this symbol to avoid potential injuries or death.

Form of warning notices

The warning signs are categorized according to the following hazard levels:

Hazard level Consequences Likelihood

Death / serious injury (irreversible) Immediate risk

Death / serious injury (irreversible) Potential risk

Minor injury (reversible) Potential risk

NOTICE Damage to property Potential risk

Installation manual 8

Page 9

1 General

1.5 About this installation manual

Purpose

This installation manual is intended for all people who work with the combi oven, and provides them

with the necessary information for proper and safe working when moving, setting up and installing the

appliance and when putting the appliance into service.

Who should read this manual

This installation manual is aimed at the following groups:

Name of target group Tasks

Equipment mover Conveying within the establishment

Service engineer

Electrical fitter Installing and removing the electrical supply

■

Setting up the appliance

■

Installing and removing the water connection

■

Installing the ConvoClean fully automatic oven cleaning system (option‐

al)

■

Putting the appliance into service and removing the appliance from

service

■

Customer guidance and instruction.

Chapters in the installation manual

The table below lists the chapters in this manual and summarizes their content and purpose:

Contents Purpose

General

Design and function

■

Shows you how to identify your combi oven

■

Provides guidance on using this installation manual

■

Specifies the intended use of the combi oven

■

Explains the functions of the combi oven and shows the position of its

components

For your safety Describes the hazards posed by the combi oven and suitable preven‐

tive measures

It is important that you read this chapter carefully.

Transportation

Setting up the appliance

■

Specifies the basic appliance dimensions

■

Specifies the requirements for the installation position

■

Explains how to convey the appliance to the installation position

■

Explains how to unpack the appliance and specifies the parts sup‐

plied with the appliance

■

Explains how to set up the combi oven

Installation Provides information on installing the:

■

Electrical connection

■

Water connection

■

ConvoClean fully automatic oven cleaning system (optional)

Putting into service Explains the procedure for preparing the appliance for first-time use

Removal from service, dis‐

posal

■

Explains the procedure for taking appliance out of service

■

Contains disposal instructions

Technical data Contains the technical data

Installation manual 9

Page 10

1 General

Contents Purpose

Dimensional drawings and

Contains the dimensional drawings and connection plans.

connection diagrams

Checklists and completion

of installation

■

Contains the checklists for

■

Installation

■

Safety devices and warnings

■

Customer guidance and instruction

■

Contains information on the warranty and explains the completion

procedure using the checklists

Notation for decimal points

A decimal point is always used in order to achieve international standardization.

Installation manual 10

Page 11

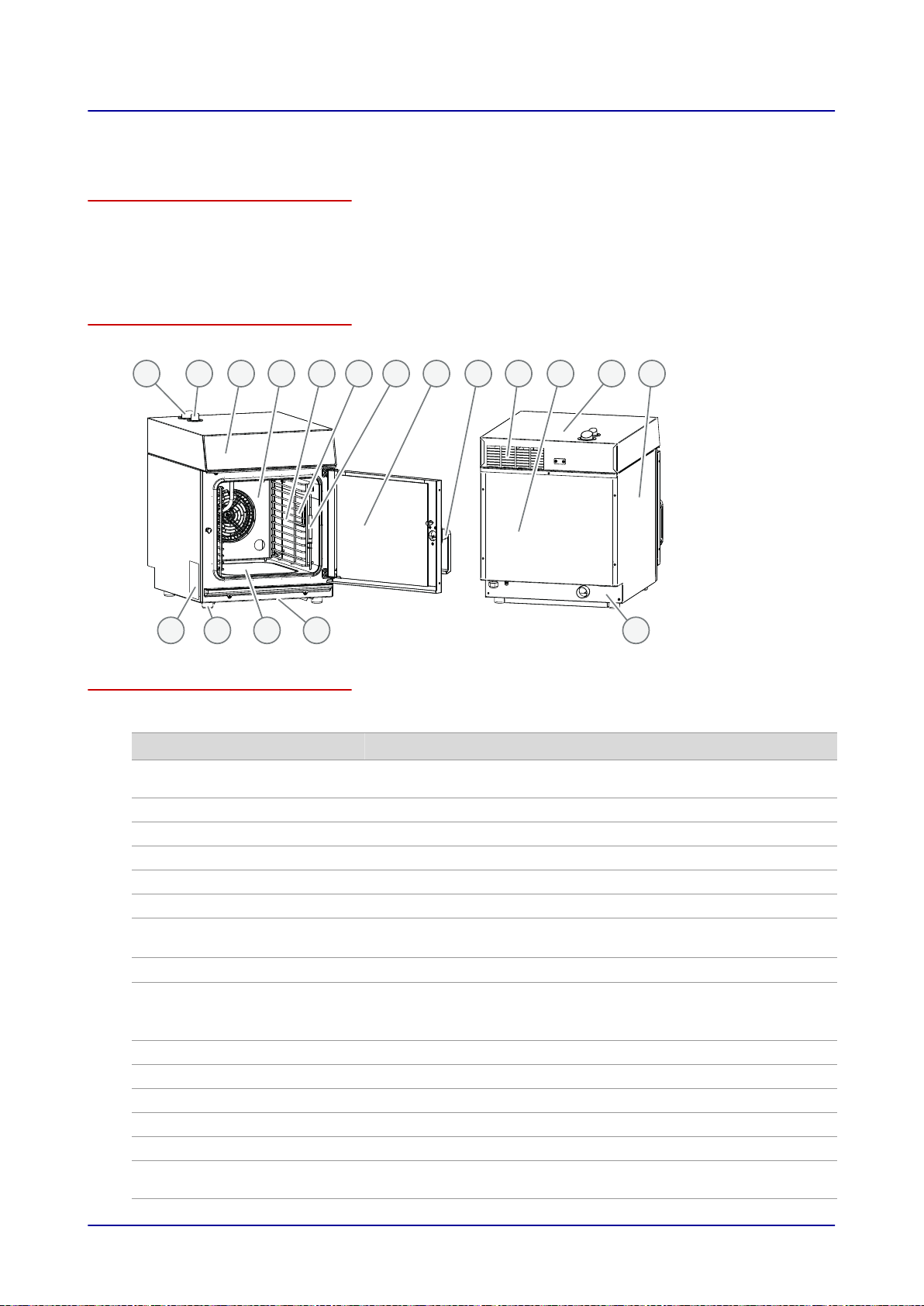

131 32 4 5 6 8 9 1110 127

17 1516 1418

2 Design and function

2 Design and function

Purpose of this chapter

This chapter describes the design and construction of the combi oven and explains its functions.

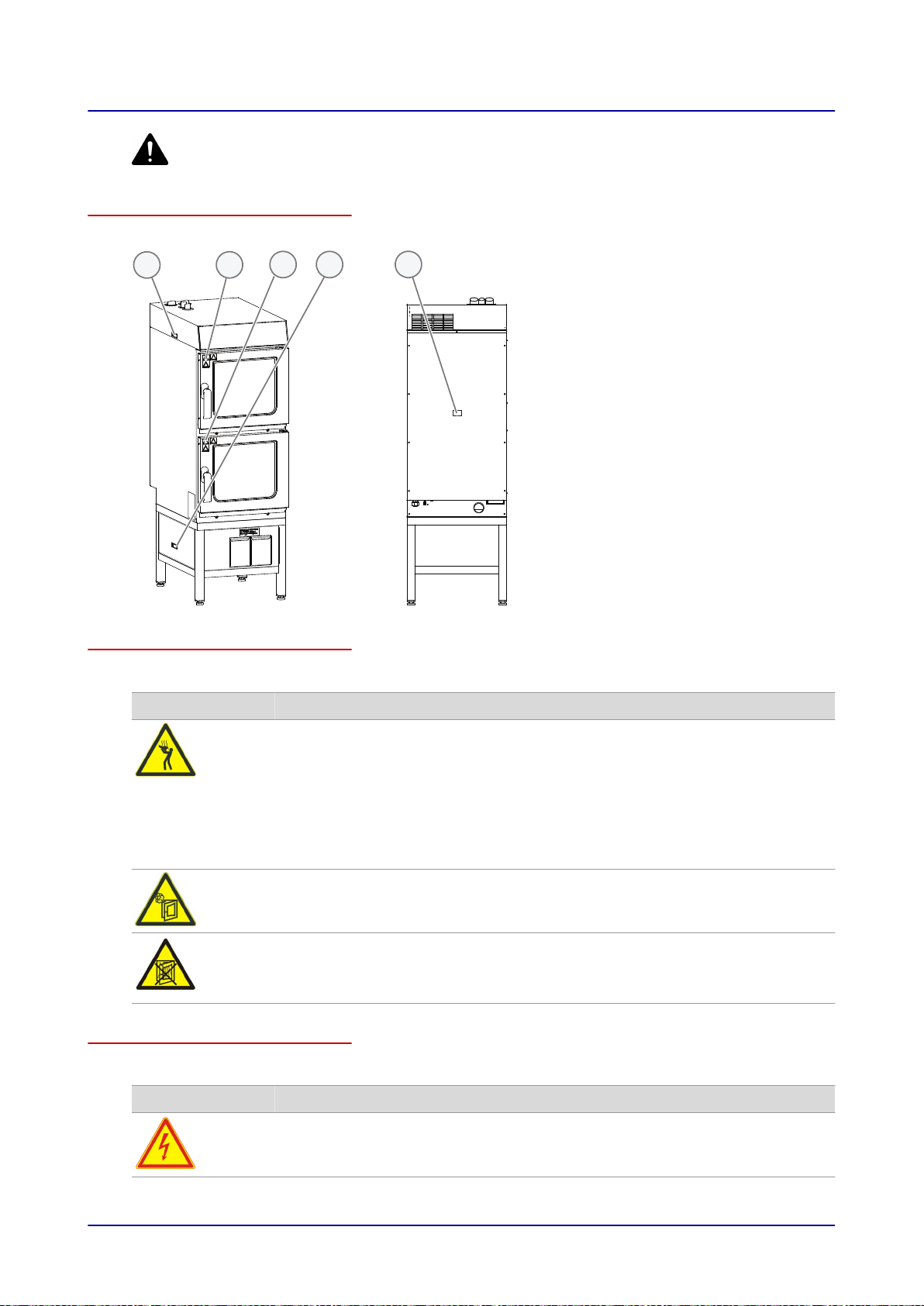

2.1 Design and function of the combi oven (6.06/6.10/10.10 mini)

Layout of the combi oven

The following figure shows the 6.06 mini combi oven (representative of all appliance sizes):

Components of the combi ovens and their function

The components of the combi oven have the following function:

No. Name Function

1

Ventilation port External air intake for removing the moisture from the cooking

chamber

2

3

4

5

6

7

Air vent Lets vapour escape

Operating panel Used for operating the combi oven

Suction panel Distributes the heat inside the cooking chamber

Rack Holds standard-sized food containers

Oven light Illuminates the cooking chamber

Core temperature probe

Used for measuring the core temperature

(optional)

8

9

Appliance door Closes the cooking chamber

Door handle

■

Opens and closes the appliance door

■

Venting position for opening the combi oven door safely (with

safety catch option)

10

11

12

13

14

15

Ventilation slots Used for ventilation

Rear wall Covers the wiring compartment of the combi oven

Top box Covers the controller electronics of the combi oven

Outer casing Used for covering the appliance interior

Connecting bracket Used for covering the connection area

Hole between the front

Used for venting air out of appliance

appliance feet

Installation manual 11

Page 12

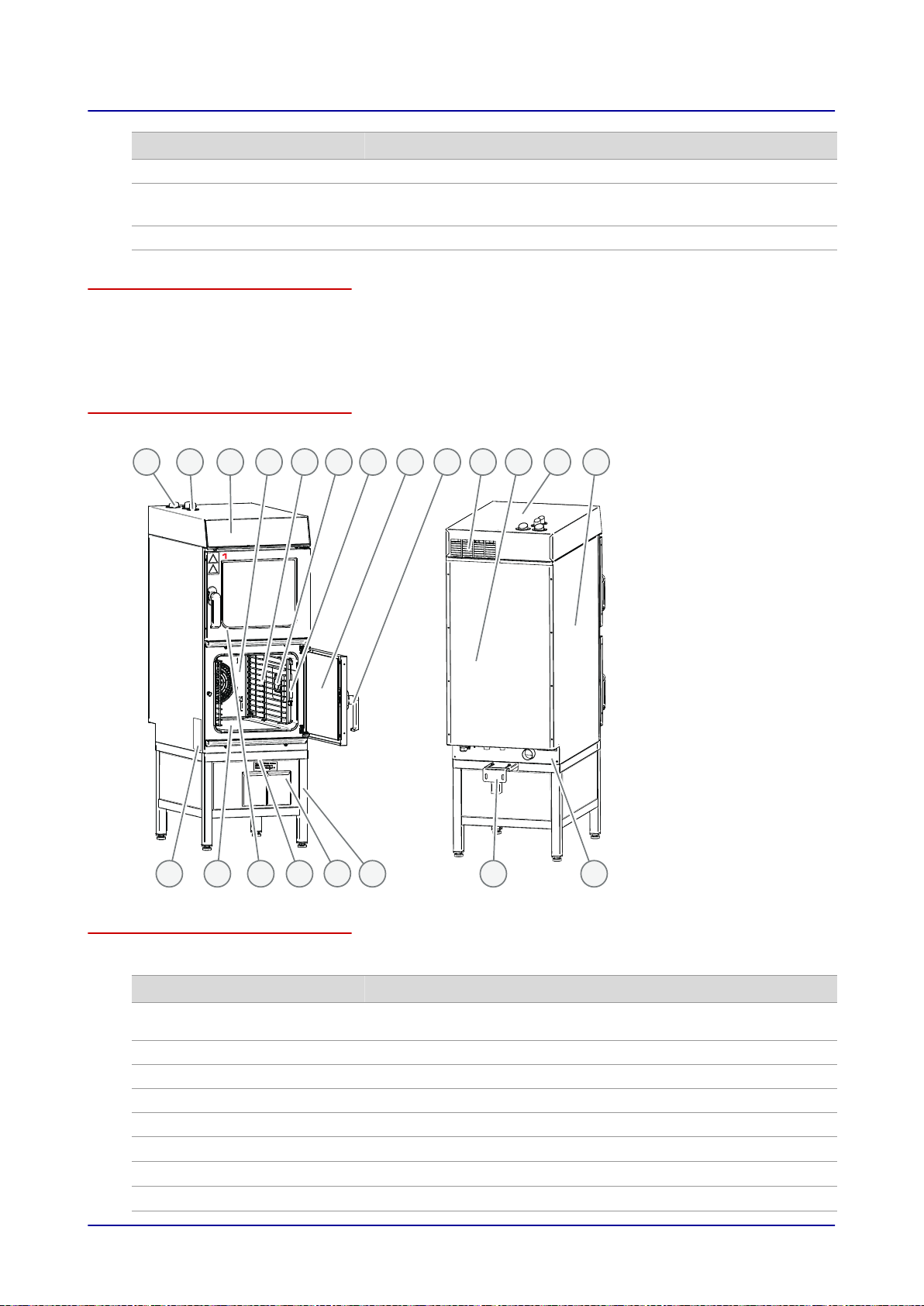

131 32 8 9 1110 127

19 1617 15 14

4 5 6

21

20 18

2 Design and function

No. Name Function

16

17

18

Cooking chamber Contains the food during cooking operation

Appliance feet

■

Used for setting up and adjusting level of appliance

■

Height adjustable on 10.10 mini

Type plate Used for identifying the combi oven

Material

The interior and exterior structure of the combi oven is made of stainless steel.

2.2 Layout and function of the combi oven (6.10 mini 2in1)

Layout of the combi oven

The following diagram shows the combi oven:

Components of the combi ovens and their function

Installation manual 12

The components of the combi oven have the following function:

No. Name Function

1

2 Ventilation ports External air intake for removing the moisture from the cooking

chamber

2

3

4

5

6

7

8

2 air vents Lets vapour escape

Operating panel Used for operating the combi oven

Suction panel Distributes the heat inside the cooking chamber

Rack Holds standard-sized food containers

Oven light Illuminates the cooking chamber

Core temperature probe Used for measuring the core temperature

Appliance door Closes the cooking chamber

Page 13

2 Design and function

No. Name Function

9

10

11

12

13

14

15

16

17

18

19

20

21

Door handle Opens and closes the appliance door

Ventilation slots Used for ventilation

Rear wall Covers the wiring compartment of the combi oven

Top box Covers the controller electronics of the combi oven

Outer casing Used for covering the appliance interior

Connecting bracket Used for covering the connection area

Wall bracket Used to fix the combi oven to a wall

Stand Brings the appliance up to working height

Ventilation slots in the

appliance floor

Cooking chamber 1 Contains the food during cooking operation

Cooking chamber 2 Contains the food during cooking operation

Type plate Used for identifying the combi oven

Cleaning agent drawers Contain the cleaning agent and rinse aid for fully automatic clean‐

Used for venting air out of appliance

ing ConvoClean system

Material

The interior and exterior structure of the combi oven is made of stainless steel.

Installation manual 13

Page 14

2 Design and function

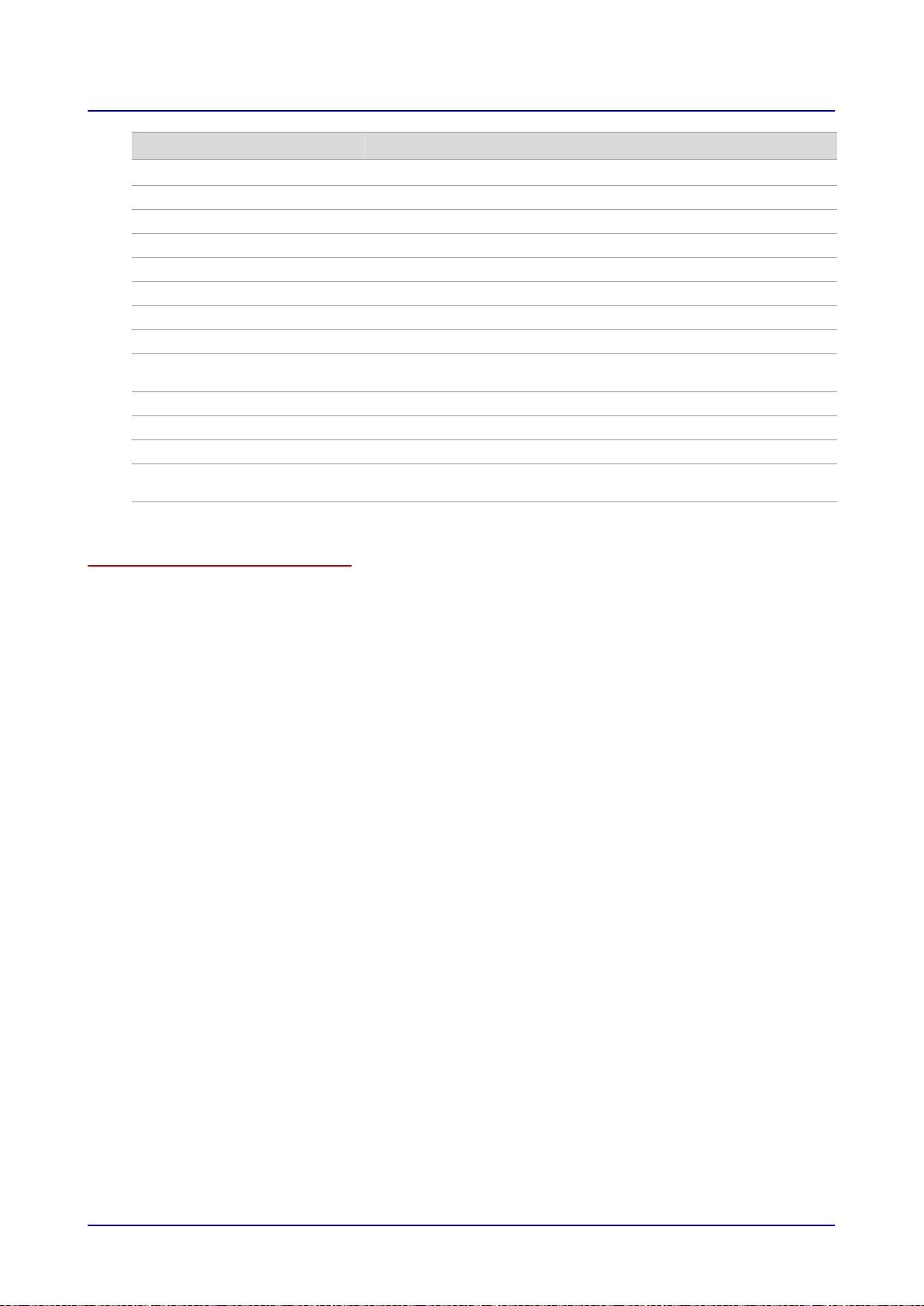

2.3 Layout and function of the operating panel

Layout of the operating panel

The following illustration shows the operating panel:

Layout of the operating panel (6.10 mini 2in1)

The following illustration shows the operating panel:

Elements of the operating panel

The elements of the operating panel have the following function:

No. Name Function

1

2

Main switch Switches the combi oven on and off

Touchscreen Central control of combi oven

■

Appliance operated by touching icons on control panel pages

■

Status displays

Only for 6.10 mini 2in1:

Central control of both cooking chambers of the combi oven

■

Switching from one cooking chamber to the other

3

USB port For connecting external appliances

Installation manual 14

Page 15

3 For your safety

3 For your safety

Purpose of this chapter

This chapter provides you with all the information you need in order to use the combi oven safely with‐

out putting yourself or others at risk.

This is a particularly important chapter that you should read through carefully.

3.1 Basic safety code

Object of this safety code

This safety code aims to ensure that all persons who use the combi oven have a thorough knowledge

of the hazards and safety precautions, and that they follow the warning notices given in the user man‐

ual and on the combi oven. If you do not follow this safety code, you risk potentially fatal injury and

property damage.

Referring to the user manuals included in the customer documentation

Follow the instructions below:

■

Read in full the chapter 'For Your Safety' and the chapters that relate to your work.

■

Always keep to hand the manuals included in the customer documentation for reference.

■

Pass on the user manuals included in the customer documentation with the combi oven if it

changes ownership.

Ground rules for installation

Installation must comply with all national and regional laws and regulations and comply with the local

regulations of the relevant utility companies and local authorities and with other relevant requirements.

Working with the combi oven

Follow the instructions below:

■

Only those persons who satisfy the requirements stipulated in this user manual are permitted to

use the combi oven.

■

Only use the combi oven for the specified use. Never, under any circumstances, use the combi

oven for other purposes that may suggest themselves.

■

Take all the safety precautions specified in this user manual and on the combi oven. In particular,

use the prescribed personal protective equipment.

■

Only stand in the working positions specified.

■

Do not make any changes to the combi oven, e.g. removing parts or fitting un-approved parts. In

particular, you must not disable any safety devices.

Installation manual 15

Page 16

3 For your safety

More on this ...

Related topics

Intended use of your combi oven 17

Warning signs on the combi oven (6.06/6.10/10.10 mini) 18

Warning signs on the combi oven (6.10 mini 2in1) 20

Hazards and safety precautions when moving the appliance 22

Hazards and safety precautions when setting up the appliance 23

Hazards and safety precautions during installation 25

Hazards and safety precautions when putting the appliance into service 27

Hazards and safety precautions when removing the appliance from service 30

Safety devices (6.06/6.10/10.10 mini) 33

Safety devices (6.10 mini 2in1) 35

Requirements to be met by personnel, working positions 37

Personal protective equipment 39

Installation manual 16

Page 17

3 For your safety

3.2 Intended use of your combi oven

Intended use

■

The combi oven is designed and built solely for cooking different foodstuffs in standard-sized food

containers (e.g.

steam (non-pressurized superheated steam) are used for this purpose.

■

The food containers can be made of stainless steel, ceramic, plastic, aluminium, enamelled steel or

glass. Glass food containers must not exhibit any form of damage.

■

The combi oven is intended solely for professional, commercial use.

Restrictions on use

Some materials are not allowed to be heated in the combi oven:

■

NO dry powder or granulated material

■

NO highly flammable substances or objects with a flash point below 270 °C, such

mable oils, fats or plastics

■

NO food in sealed tins or jars

Requirements to be met by personnel

■

The combi oven must only be operated and installed by personnel who satisfy specific require‐

ments. Please refer to 'Requirements to be met by personnel, working positions' on page

the training and qualifications requirements.

■

Personnel must be aware of the risks and regulations associated with handling heavy loads.

Gastronorm containers, standard baking trays). Steam, convection and combi-

as highly flam‐

37 for

Requirements relating to the operating condition of the combi oven

■

The combi oven must only be operated when all safety devices and protective equipment are fitted,

in working order and fixed properly in place.

■

The manufacturer regulations for operating and servicing the combi oven must be observed.

■

The combi oven must not be loaded over the maximum permissible loading weight for the given

model or shelf allowance; see

'Technical Data' on page 92.

Requirements relating to the operating environment of the combi oven

Specified operating environment for the combi oven

■

The ambient temperature lies between

■

NOT a toxic or potentially explosive atmosphere

■

Dry kitchen floor to reduce the risk of accidents

+4 °C and +35 °C

Specified properties of the installation location

■

NO fire alarm, NO sprinkler system directly above the appliance

■

NO flammable materials, gases or liquids above, on, beneath or in the vicinity of the appliance

Mandatory restrictions on use

■

Shelter from rain and wind must be provided if operated outdoors

■

Appliance must NOT be shifted or moved during use

Cleaning requirements

■

Use only cleaning agents that have been approved by the manufacturer.

■

High-pressure cleaners must NOT be used for cleaning.

■

Water jets must NOT be used for cleaning the exterior. The water spray from the recoil hand show‐

er must only be used for cleaning the cooking chamber.

■

The combi oven must NOT be treated with acids or exposed to acid fumes, except for the purpose

of descaling the cooking chamber and the boiler by an authorized service company in accordance

with the manufacturer's instructions.

Installation manual 17

Page 18

1

2

1

3 For your safety

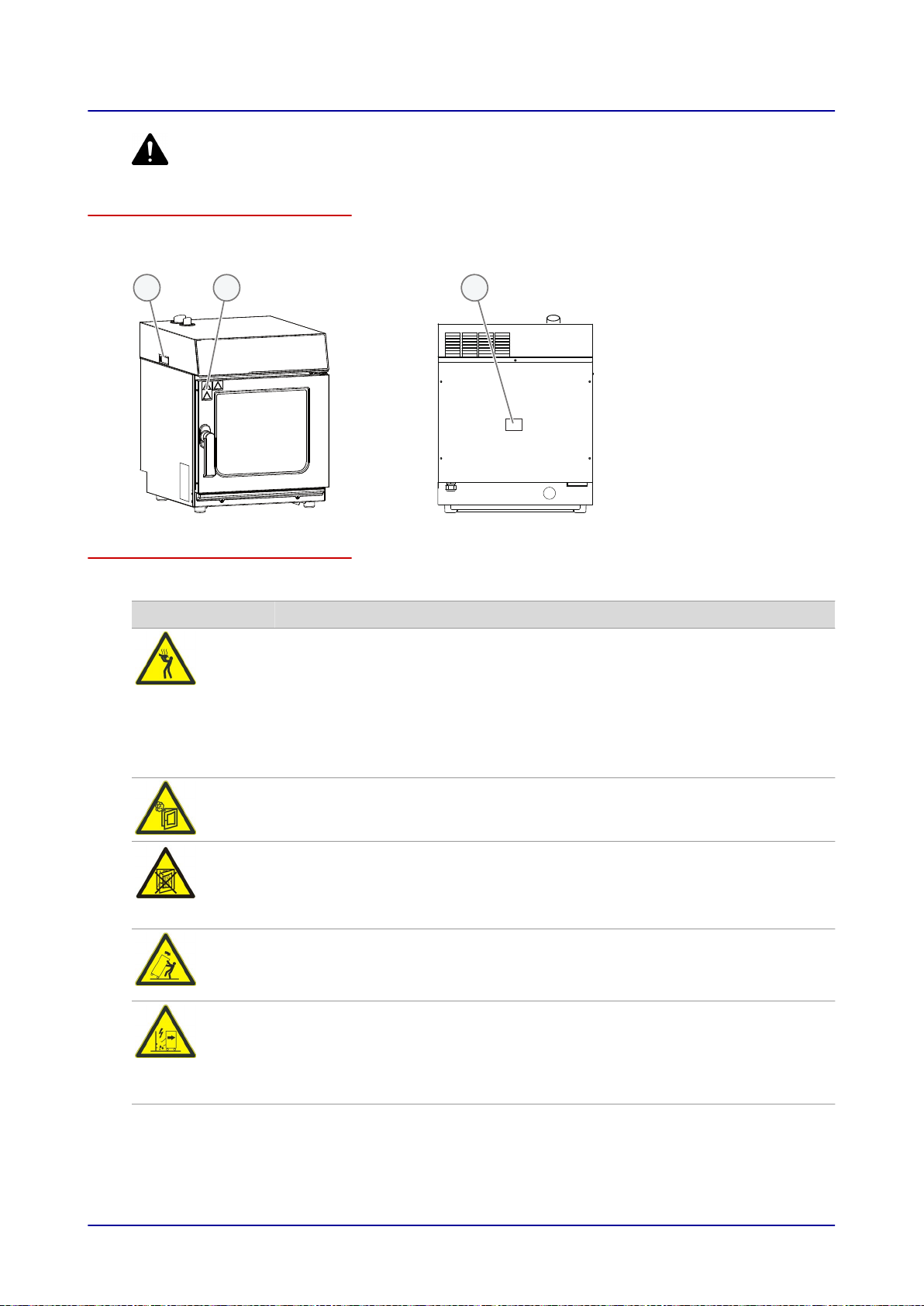

3.3 Warning signs on the combi oven (6.06/6.10/10.10 mini)

Where are the warning signs fitted?

The following figure shows the 6.06 mini combi oven (representative of all appliance sizes).

The warning signs are located in the following positions:

Warnings on the appliance door

The following warning signs (2) are fitted on the appliance door above the door handle:

Warning sign Description

Warning of hot food, hot food containers and hot liquids

There is a risk of burns from hot food and hot food containers if food containers

tip out of the shelf levels or food slips off food containers that are not held level.

This risk is particularly high for shelf levels that lie above the sightline of the

user.

Spillage of hot liquid foods can result in scalds if the upper shelf levels are loa‐

ded with liquids or foods that produce liquid during cooking. Do not use shelf

levels that lie above your sightline for liquid foodstuffs or food that will liquefy

during cooking.

Hot steam and vapour hazard warning

There is a risk of scalding from hot steam and vapour escaping when the appli‐

ance door is opened.

Only for ConvoClean system option

Warning of corrosive cleaning agents injected into oven

There is a risk of chemical burns or irritation to skin, eyes and respiratory sys‐

tem from contact with sprayed cleaning agents and their vapours if the appli‐

ance door is opened during fully automatic cleaning by the ConvoClean

Only for a mobile supporting structure

Tipping or toppling warning for combi oven

There is a risk of the combi oven toppling over if moved. Always take great care

when moving the combi oven.

Only for a mobile supporting structure

Damage or detachment warning for appliance connections

There is a risk of the appliance connections being damaged or detached if the

combi oven is moved. Always ensure there is enough length in the supply ca‐

bles and pipes when moving the combi oven. After moving, always secure the

combi oven against rolling away.

system.

Installation manual 18

Page 19

3 For your safety

Warning signs on the combi oven case

The following warning signs (1) are fitted on the case of the combi oven:

Warning sign Description

High voltage / electric shock hazard warning

There is a risk of electric shock from live parts if the safety cover is opened.

Installation manual 19

Page 20

1

1

2

2

3

3 For your safety

3.4 Warning signs on the combi oven (6.10 mini 2in1)

Where are the warning signs fitted?

The warning signs are located in the following positions on the combi oven:

Warnings on the appliance door

The following warning signs (2) are fitted on the appliance doors above the door handles:

Warning sign Description

Warning of hot food, hot food containers and hot liquids

There is a risk of burns from hot food and hot food containers if food containers

tip out of the shelf levels or food slips off food containers that are not held level.

This risk is particularly high for shelf levels that lie above the sightline of the

user.

Spillage of hot liquid foods can result in scalds if the upper shelf levels are loa‐

ded with liquids or foods that produce liquid during cooking. Do not use shelf

levels that lie above your sightline for liquid foodstuffs or food that will liquefy

during cooking.

Hot steam and vapour hazard warning

There is a risk of scalding from hot steam and vapour escaping when the appli‐

ance door is opened.

Warning of corrosive cleaning agents injected into oven

There is a risk of chemical burns or irritation to skin, eyes and respiratory sys‐

tem from contact with sprayed cleaning agents and their vapours if the appli‐

ance door is opened during fully automatic cleaning by the ConvoClean

system.

Warning signs on the combi oven case

The following warning signs (1) are fitted on the case of the combi oven:

Warning sign Description

High voltage / electric shock hazard warning

There is a risk of electric shock from live parts if the safety cover is opened.

Installation manual 20

Page 21

3 For your safety

Warning signs on the case of the cleaning agent drawers

The following warning sign (3) is mounted on the case of the cleaning agent drawers:

Warning sign Description

High voltage / electric shock hazard warning

There is a risk of electric shock from live parts if the safety cover is opened.

Installation manual 21

Page 22

3 For your safety

3.5 Hazards and safety precautions when moving the appliance

Safety hazard: moving heavy weights

When moving the appliance, be aware of the following hazards and take the specified preventive ac‐

tions:

Danger Where or in what situations

Preventive action Safety device

does the hazard arise?

Risk of injury from over‐

stressing your body

When moving the appliance

■

Use suitable lifting gear

■

Do not exceed safety lim‐

its for lifting and carrying

■

Use lifting straps

■

Wear personal protective

equipment

Safety hazard: mechanical parts of the appliance

When moving the appliance, be aware of the following hazards and take the specified preventive ac‐

tions:

Danger Where or in what situations

Preventive action Safety device

does the hazard arise?

Risk of body parts be‐

ing crushed if the appli‐

ance is dropped

When moving the appliance

■

Use suitable handling

gear

■

Move the appliance slow‐

ly and carefully, and se‐

cure it against tipping

over

■

Make sure center of grav‐

ity is balanced

■

Avoid jolts

Risk of body parts be‐

ing crushed if the appli‐

ance tips over or falls

off

When placing the appliance

down on the supporting sur‐

face

Always observe the re‐

quirements for the support‐

ing surface while setting up

the appliance; see

Require‐

ments for the installation lo‐

cation on page 44

None

None

None

Installation manual 22

Page 23

3 For your safety

3.6 Hazards and safety precautions when setting up the appliance

Safety hazard: moving heavy weights

When setting up the appliance, be aware of the following hazards and take the specified preventive

actions:

Danger Where or in what situations

does the hazard arise?

Risk of injury from over‐

When moving the appliance

stressing your body

Preventive action Safety device

■

Use suitable lifting equip‐

None

ment for placing the ap‐

pliance on the work sur‐

face, on the stand, in the

stacking kit or in the in‐

stallation location (de‐

pendent on appliance

size)

■

Always use the correct

number of persons and

observe the limits speci‐

fied for lifting and carrying

when adjusting the appli‐

ance position

■

Observe the local occu‐

pational safety regula‐

tions

■

Wear personal protective

equipment

For 10.10 mini / 6.10 mini

2in1:

■

Use lifting straps to take

the appliance off the pal‐

let

Installation manual 23

Page 24

3 For your safety

Safety hazard: mechanical parts of the appliance

When setting up the appliance, be aware of the following hazards and take the specified preventive

actions:

Danger Where or in what situations

does the hazard arise?

Risk of body parts be‐

When lifting the appliance

ing crushed if the appli‐

ance is dropped

For 6.06/6.10/10.10

mini:

Risk of crushing due to

loss of appliance stabili‐

ty if the appliance is

mounted on a stand or

in a stacking kit

Risk of body parts be‐

ing crushed if the appli‐

■

When installing the appli‐

ance on the oven stand

■

When fitting the appliances

in the stacking kit

■

When a heavy load is ap‐

plied to the top appliance

alone

When installing the appliance

on the floor

ance tips over or falls

off

Risk of cuts from sharp

edges

When handling sheet-metal

parts

Preventive action Safety device

■

Make sure center of grav‐

None

ity is balanced

■

Avoid jolts

■

Never exert an extra

pressure on the applian‐

ces, e.g. by leaning on

Parking brake

on wheeled

stacking kit

the open appliance door

■

Before fitting the applian‐

ces in a wheeled stacking

kit, secure the stacking kit

by engaging the parking

brake on the wheels

■

Always fit the bottom ap‐

pliance first in the stack‐

ing kit

■

Make sure that the appli‐

ances are seated correct‐

ly in the stacking kit

Always observe the re‐

None

quirements for the support‐

ing surface while setting up

the appliance; see

Require‐

ments for the installation lo‐

cation on page 44

■

Exercise caution when

None

performing these tasks

■

Wear personal protective

equipment as specified in

safety regulations

Installation manual 24

Page 25

3 For your safety

3.7 Hazards and safety precautions during installation

Safety hazard: electrical power

When installing the appliance, be aware of the following hazards and take the specified preventive ac‐

tions:

Danger Where or in what situations

does the hazard arise?

Risk of electric shock

from live parts

Risk of electric shock

from live parts

■

Under covers

■

Under the operating panel

■

On the power supply cable

■

On the appliance and on

adjacent metal parts

■

On the appliance and on

adjacent metallic accesso‐

ries

Risk of electric shock

from incorrect water

connection

■

In the entire work area, as

soon as the water pipe

bursts or starts leaking

Preventive action Safety device

■

Work on the electrical

Covers

system must only be per‐

formed by qualified elec‐

tricians from an author‐

ized service company

■

Professional working

Before removing the cov‐

Covers

ers:

■

Switch off all connections

to the power supply

■

Take protective meas‐

ures at every power

switch to ensure that the

power cannot be switch‐

ed on again

■

If the appliance has previ‐

ously been connected to

the electricity supply, wait

15 minutes to allow the

DC bus capacitors to dis‐

charge

■

Make sure that the appli‐

ance is de-energized

■

Ensure that all electrical

Covers

connections are in perfect

condition and fixed se‐

curely before putting the

appliance into service

■

Before preparing the ap‐

pliance for first-time use,

make sure that the appli‐

Equipotential

bonding sys‐

tem

ance, including all metal‐

lic accessories, is con‐

nected to a equipotential

bonding system.

■

Use a fixed connection

■

Make sure that the water

none

pressure of the water

supply is compatible with

the pressure specified on

the appliance

■

Use suitable pipes and

hoses in accordance with

applicable regulations

(EN 61770 in countries

where European stand‐

ards apply)

Installation manual 25

Page 26

3 For your safety

Safety hazard: mechanical parts of the appliance

When installing the appliance, be aware of the following hazards and take the specified preventive ac‐

tions:

Danger Where or in what situations

Preventive action Safety device

does the hazard arise?

Risk of cuts from sharp

edges

When handling sheet-metal

parts

■

Exercise caution when

performing these tasks

■

Wear personal protective

None

equipment as specified in

safety regulations

Safety hazard: cleaning agent

When installing the appliance, be aware of the following hazards and take the specified preventive ac‐

tions:

Danger Where or in what situations

Preventive action Safety device

does the hazard arise?

Risk of chemical burns

or irritation to skin, eyes

and respiratory system

from contact with clean‐

ing agents and their va‐

pours.

When corrosive cleaning

agents are used

For 6.06/6.10/10.10 mini with

ConvoClean system option:

When fitting the cleaning sys‐

tem

Only use those cleaning

agents specified under

Cleaning agents in the

'Cleaning and Servicing'

chapter of the user manual.

■

Wear personal protective

equipment

■

Observe the labels on the

cleaning agents and the

None

None

relevant safety data‐

sheets

For 6.10 mini 2in1:

When handling the cleaning

agent drawer and rinse aid

drawer

■

Wear personal protective

equipment

■

Close the cleaning agent

drawer and rinse aid

None

drawer carefully without

jolting to avoid any clean‐

ing agent slopping out.

Installation manual 26

Page 27

3 For your safety

3.8 Hazards and safety precautions when putting the appliance into service

Safety hazard: electrical power

When preparing the appliance for first-time use, be aware of the following hazards and take the speci‐

fied preventive actions:

Danger Where or in what situations

does the hazard arise?

Risk of electric shock

from live parts

Risk of electric shock

from live parts

■

Under covers

■

Under the operating panel

■

On the power supply cable

■

On the appliance and on

adjacent metal parts

■

On the appliance and on

adjacent metallic accesso‐

ries

Preventive action Safety device

■

Work on the electrical

Covers

system must only be per‐

formed by qualified elec‐

tricians from an author‐

ized service company

■

Professional working

Before removing the cov‐

Covers

ers:

■

Switch off all connections

to the power supply

■

Take protective meas‐

ures at every power

switch to ensure that the

power cannot be switch‐

ed on again

■

If the appliance has previ‐

ously been connected to

the electricity supply, wait

15 minutes to allow the

DC bus capacitors to dis‐

charge

■

Make sure that the appli‐

ance is de-energized

■

Ensure that all electrical

Covers

connections are in perfect

condition and fixed se‐

curely before putting the

appliance into service

■

Before preparing the ap‐

pliance for first-time use,

make sure that the appli‐

Equipotential

bonding sys‐

tem

ance, including all metal‐

lic accessories, is con‐

nected to a equipotential

bonding system.

Installation manual 27

Page 28

3 For your safety

Safety hazard: moving appliances supported on a wheeled platform

Danger Where or in what situations

does the hazard arise?

All specified hazards While appliances are being

moved on a wheeled platform

Risk of crushing of

body parts

Pinch point hazard for

hands and feet

Risk of scalding from

hot wastewater

Risk of scalding from

hot liquid food

Risk of electric shock

from live parts

Risk of skin and eye ir‐

ritation from contact

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

with cleaning products

Risk of tripping from ex‐

posed cables and pipes

Risk of falling on wet

floor caused by waste‐

water

Risk of falling on wet

floor caused by clean‐

ing fluids

While cleaning behind appli‐

ances when pulled forward

■

While cleaning behind ap‐

pliances when pulled for‐

ward

■

In front of the appliances

■

While cleaning behind ap‐

pliances when pulled for‐

ward

■

In front of the appliances

Preventive action Safety device

■

Before moving applian‐

ces with a fixed wastewa‐

Retaining de‐

vice

ter connection, discon‐

nect the drain pipe

■

Disconnect the appliance

from the electrical supply

before moving it

■

Before moving (for in‐

stance to clean the case

of the combi ovens or to

clean the floor), check

whether the retaining de‐

vice which restricts the

radius of movement of

the platform plus appli‐

ance is connected.

■

When moving the appli‐

ance, take care not to

wheel over the electrical

supply cables or the wa‐

ter pipes

■

Watch out for the con‐

None

necting cables and pipes.

■

Use at least two people

to move it

■

Keep the appliance doors

None

closed

■

Let the appliance

None

cool down

■

Wipe up immediately any

water spillages

■

Wear protective clothing

■

Always remove any food

None

from the appliances be‐

fore moving them

■

Watch out for connected

None

electrical cables and wa‐

ter pipes

■

Make sure that the con‐

None

necting lines and pipes

are long enough

■

Keep cleaning-fluid canis‐

ters closed when moving

the base

■

Exercise caution when

None

performing this action

■

Wipe up immediately any

None

water spillages

■

Make sure that the con‐

necting lines and pipes

are long enough

■

Keep the cleaning-fluid

None

canisters closed when

moving appliances

Installation manual 28

Page 29

3 For your safety

Additional safety hazards when putting the appliance into service

When preparing the appliance for first-time use, read and follow the safety information given in this

chapter and also the following topics in the chapter 'For your safety' in the user manual:

■

Hazards and safety precautions during operation

■

Hazards and safety precautions during cleaning

■

Personal protective equipment

Installation manual 29

Page 30

3 For your safety

3.9 Hazards and safety precautions when removing the appliance from service

Safety hazard: electrical power

When taking the appliance out of service, be aware of the following hazards and take the specified

preventive actions:

Danger Where or in what situations

Preventive action Safety device

does the hazard arise?

Risk of electric shock

from live parts

■

Under covers

■

Under the operating panel

■

Work on the electrical

system must only be per‐

formed by qualified elec‐

tricians from an author‐

ized customer service

company

■

Professional working

Before removing the cov‐

ers:

■

Switch off all connections

to the power supply

■

Take protective meas‐

ures at every power

switch to ensure that the

power cannot be switch‐

ed on again

■

Wait 15

minutes to allow

the DC bus capacitors to

discharge

■

Make sure that the appli‐

ance is de-energized

Safety hazard: moving heavy weights

When taking the appliance out of service, be aware of the following hazards and take the specified

preventive actions:

Covers

Danger Where or in what situations

does the hazard arise?

Risk of injury from over‐

When moving the appliance

stressing your body

Installation manual 30

Preventive action Safety device

■

Use suitable lifting gear

■

Do not exceed safety lim‐

None

its for lifting and carrying

■

Use lifting straps

■

Wear personal protective

equipment

Page 31

3 For your safety

Safety hazard: moving appliances supported on a wheeled platform

Danger Where or in what situations

does the hazard arise?

All specified hazards While appliances are being

moved on a wheeled platform

Risk of crushing of

body parts

Pinch point hazard for

hands and feet

Risk of scalding from

hot wastewater

Risk of scalding from

hot liquid food

Risk of electric shock

from live parts

Risk of skin and eye ir‐

ritation from contact

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

While appliances are being

moved on a wheeled platform

with cleaning products

Risk of tripping from ex‐

posed cables and pipes

Risk of falling on wet

floor caused by waste‐

water

Risk of falling on wet

floor caused by clean‐

ing fluids

While cleaning behind appli‐

ances when pulled forward

■

While cleaning behind ap‐

pliances when pulled for‐

ward

■

In front of the appliances

■

While cleaning behind ap‐

pliances when pulled for‐

ward

■

In front of the appliances

Preventive action Safety device

■

Disconnect the appliance

from the electrical supply

Retaining de‐

vice

before moving it

■

Before moving applian‐

ces with a fixed wastewa‐

ter connection, discon‐

nect the drain pipe

■

Before moving (e.g. to

access the back of the

appliance), check that the

retaining device is con‐

nected. This device re‐

stricts the range of move‐

ment of the platform sup‐

porting the appliance.

■

When moving the appli‐

ance, take care not to

wheel over the electrical

supply cables or the wa‐

ter pipes

■

Watch out for the con‐

None

necting cables and pipes.

■

Use at least two people

to move it

Keep the appliance doors

None

closed

■

Let the appliance

None

cool down

■

Wipe up immediately any

water spillages

■

Wear personal protective

clothing

Always remove any food

None

from the appliances before

moving them

Watch out for connected

None

electrical cables and water

pipes.

■

Make sure that the con‐

None

necting lines and pipes

are long enough

■

Keep cleaning-fluid canis‐

ters closed when moving

the base

Exercise caution when per‐

None

forming this action

■

Wipe up immediately any

None

water spillages

■

Make sure that the con‐

necting lines and pipes

are long enough

Keep the cleaning-fluid

None

canisters closed when

moving appliances

Installation manual 31

Page 32

3 For your safety

Safety hazard: mechanical parts of the appliance

When taking the appliance out of service, be aware of the following hazards and take the specified

preventive actions:

Danger Where or in what situations

For 6.10 mini 2in1:

Risk of body parts be‐

ing crushed if the appli‐

ance is dropped

For 6.06/6.10/10.10

mini:

Risk of crushing due to

loss of appliance stabili‐

ty if the appliance is

mounted in a stand or

in a stacking kit

Risk of cuts from sharp

edges

Safety hazard: cleaning agent

does the hazard arise?

When lifting the appliance

■

When removing the appli‐

ance from the stand

■

When removing the appli‐

ances from the stacking kit

■

When a heavy load is ap‐

plied to the top appliance

alone

When handling sheet-metal

parts

Preventive action Safety device

■

Make sure center of grav‐

None

ity is balanced

■

Avoid jolts

■

Never exert an extra

pressure on the applian‐

ces, e.g. by leaning on

Parking brake

on wheeled

stacking kit

the open appliance door

■

Before removing the ap‐

pliances from a wheeled

stacking kit, secure the

stacking kit by engaging

the parking brake on the

wheels

■

Always remove the top

appliance first from the

stacking kit

■

Exercise caution when

None

performing these tasks

■

Wear personal protective

equipment as specified in

safety regulations

Danger Where or in what situations

does the hazard arise?

Risk of chemical burns

or irritation to skin, eyes

and respiratory system

from contact with clean‐

■

When removing the clean‐

ing system

■

When disposing of the ap‐

pliance

ing agents and their va‐

pours.

Preventive action Safety device

■

Wear personal protective

None

equipment

■

Observe the labels on the

cleaning agents and the

relevant safety data‐

sheets

Installation manual 32

Page 33

1 2 3 4

3 For your safety

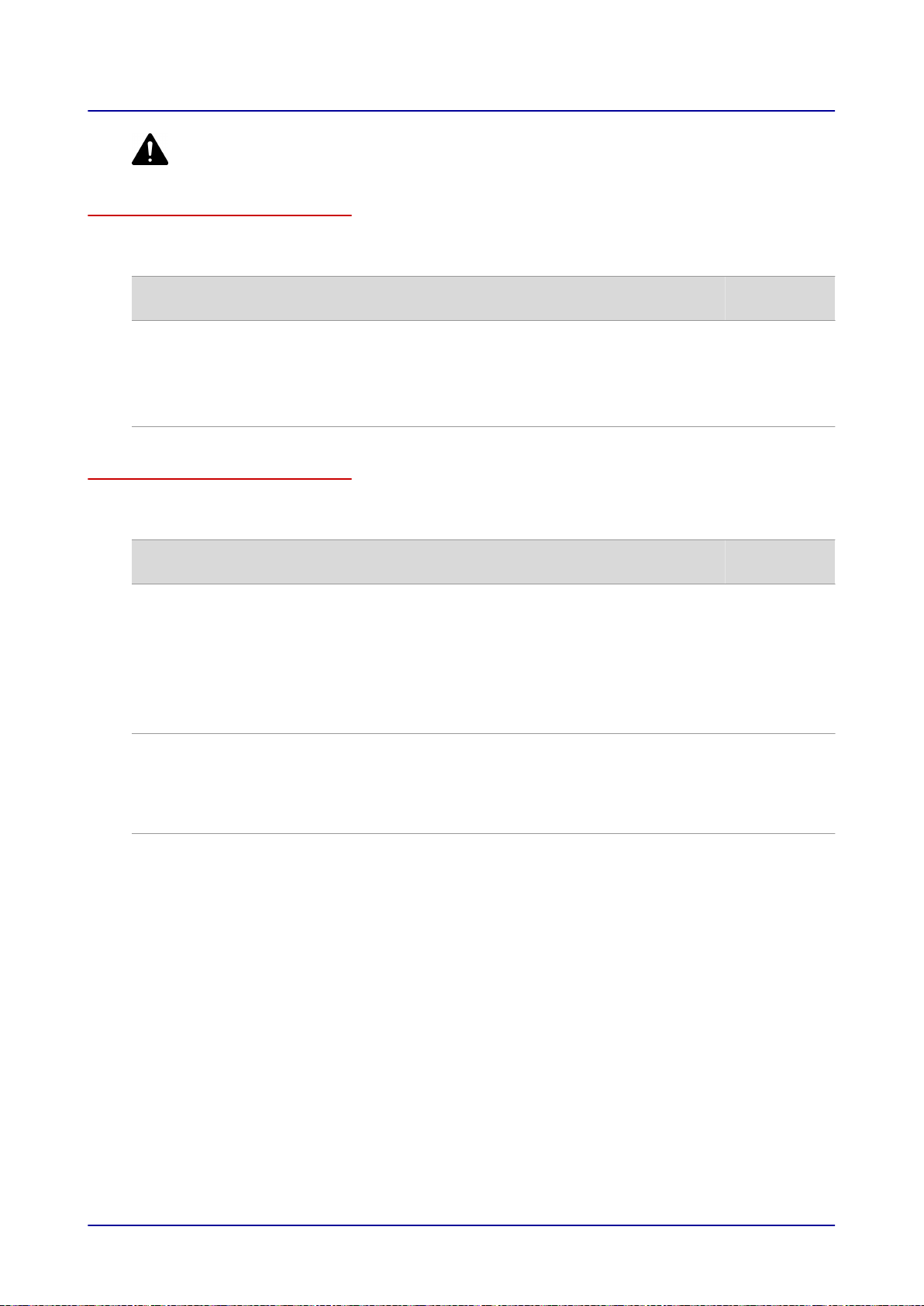

3.10 Safety devices (6.06/6.10/10.10 mini)

Meaning

The combi oven has a number of safety devices to protect the user from hazards. It is absolutely es‐

sential that all safety devices are fitted, secured correctly and in working order when operating the

combi oven.

Position

The following figure shows the location of the safety devices on a 6.06 mini combi oven with the safety

catch option (representative of all appliance sizes):

Functions

The following table enumerates all the safety devices on the combi oven, explains their function and

describes the check procedure:

No. Safety device Function Check

1

Covers can only be re‐

moved using a tool

■

Prevents live parts from be‐

ing touched accidentally

■

Prevents access to the mov‐

ing fan from the wiring com‐

partment

2

Appliance door Protects the user and outside

environment from hot steam

For the safety catch op‐

tion:

Appliance door with

magnetic switch

Magnetic door switch (electri‐

cal door sensor):

■

When the appliance door is

opened, the switch stops:

■

rotation of the fan wheel

(comes to a stop after a

few seconds)

■

operation of the heating el‐

ement

■

Distribution of the cleaning

agent by the fully automat‐

ic oven cleaning system

(for ConvoClean system

option)

■

Prompt to close the appli‐

ance door

Check that the covers are in

place

Check regularly for scratches,

cracks, indentations etc. and

replace door if any are found

Check magnetic door switch

at low temperature

Action:

■

Open the appliance door

fully

■

Press Start

Result:

Motor must not start up

Installation manual 33

Page 34

3 For your safety

No. Safety device Function Check

3

4

5

(no

picture)

6

(no

picture)

7 (installed

by

customer)

8

(no

picture)

For the safety catch op‐

tion:

On-latch position of ap‐

pliance door

Suction panel in cook‐

ing chamber; can only

be removed using a

tool

for ConvoClean system

option:

Automatic safety rins‐

ing after power failure

in case cleaning agent

left in combi oven

For ConvoClean sys‐

tem option:

Spray-guard

Disconnector

When installing on a

wheeled supporting

structure:

Retaining device

Prevents scalding of user's

face and hands from escaping

steam

Prevents access to the moving

fan and ensures good heat dis‐

tribution

Re-starts fully automatic clean‐

ing (ConvoClean system) in a

defined state after power fail‐

ure

Stops the cleaning agent being

injected during fully automatic

cleaning (ConvoClean system)

when the appliance door is

opened

Prompt to close the appliance

door

■

Installed by the customer

close to the appliance; easily

visible and accessible, 3pole action, minimum contact

separation 3 mm.

■

Used to disconnect the appli‐

ance from the power supply

during cleaning, repair and

servicing work and in a haz‐

ardous situation

Restricts the range of move‐

ment of the assembly (support‐

ing structure plus appliance) at

the customer's site.

When appliance is at low tem‐

perature, check door positions

as described in '

Opening and

closing the appliance door

safely' in the user manual

See

'Removing and fitting the suc‐

tion panel' in the user manual

for further details.

Test is a software function

Test is a software function

Action:

■

Trip the disconnector

■

Check at the -X10 terminal

strip on the appliance that

none of the three phases

carry a live voltage

Check that the retaining de‐

vice is connected

Installation manual 34

Page 35

3

1

2

3 For your safety

3.11 Safety devices (6.10 mini 2in1)

Meaning

The combi oven has a number of safety devices to protect the user from hazards. It is absolutely es‐

sential that all safety devices are fitted, secured correctly and in working order when operating the

combi oven.

Position

The following diagram shows the location of the safety devices:

Functions

The following table enumerates all the safety devices on the combi oven, explains their function and

describes the check procedure:

No. Safety device Function Check

1

Covers can only be re‐

moved using a tool

■

Prevents live parts from be‐

ing touched accidentally

■

Prevents access to the mov‐

Check that the covers are in

place

ing fan from the wiring com‐

partment

2

Appliance door Protects the user and outside

environment from hot steam

Check regularly for scratches,

cracks, indentations etc. and

replace door if any are found

3

4

(no

picture)

Suction panel in cook‐

ing chamber; can only

be removed using a

tool

Automatic safety rins‐

ing after power failure

in case cleaning agent

left in combi oven

Prevents access to the moving

fan and ensures good heat dis‐

tribution

Re-starts fully automatic clean‐

ing (ConvoClean system) in a

defined state after power fail‐

ure

See

'Removing and fitting the suc‐

tion panel'

in the user manual

for further details.

Test is a software function

Installation manual 35

Page 36

3 For your safety

No. Safety device Function Check

5

(no

picture)

6

(no

picture)

7 (installed

by

customer)

Spray-guard Stops the cleaning agent being

injected during fully automatic

cleaning (ConvoClean system)

when the appliance door is

opened

Prompt to close the appliance

door

Block on simultaneous

cooking and cleaning

Prevents cooking being per‐

formed in one cooking cham‐

ber while the other is being

cleaned

Disconnector

■

Installed by the customer

close to the appliance; easily

visible and accessible, 3pole action, minimum contact

separation 3 mm.

■

Used to disconnect the appli‐

ance from the power supply

during cleaning, repair and

servicing work and in a haz‐

ardous situation

Test is a software function

Test is a software function

Action:

■

Trip the disconnector

■

Check at the -X10 terminal

strip on the appliance that

none of the three phases

carry a live voltage

Installation manual 36

Page 37

3 For your safety

3.12 Requirements to be met by personnel, working positions

Requirements to be met by personnel

The table shows the skills required to perform the specified roles. One person may perform more than

one role depending on need and organization of work, provided this person has the skills required for

the role concerned.

Role Skills required Tasks

Owner of the com‐

bi oven

or

owner's member

of staff who is re‐

sponsible for the

appliance and for

the operating per‐

sonnel

Equipment mover

Service engineer

Electrical fitter

Plumber

Start-up engineer

(Service engineer)

Knows the regulations associated with

handling heavy loads

■

Trained in the use of a pallet truck

and forklift truck

■

Knows the regulations associated

with handling heavy loads

■

Is an employee of an authorized serv‐

ice company

■

Has relevant technical training

■

Is trained in the particular appliance

■

Knows the regulations associated

with handling heavy loads

■

Can assess whether the electrical,

water supplies and the wastewater

system have been connected correct‐

ly.

■

Is an employee of an authorized serv‐

ice company

■

Has relevant professional training

■

Is a qualified electrician

■

Is an employee of an authorized serv‐

ice company

■

Has relevant professional training

■

Is an employee of an authorized serv‐

ice company who has overall respon‐

sibility for preparing the combi oven

for first-time use

■

Has relevant technical training

■

Is trained in the particular appliance

■

Knows the regulations associated

with handling heavy loads

■

Can assess whether the electrical,

water supplies and the wastewater

system have been connected correct‐

ly.

■

As the representative for the entire

team of operating personnel, is

made aware of all safety-related

functions and devices of the combi

oven by the start-up engineer

■

As the representative for the entire

team of operating personnel, is in‐

structed by the start-up engineer

on how to operate the appliance

■

Provides assistance as instructed

with conveying the appliance with‐

in the establishment and setting up

the appliance.

Conveying within the establishment

■

Setting up the appliance

■

Installation of the fully automatic

oven cleaning system (for Convo‐

Clean system option)

■

Putting the appliance into service

■

Removing the appliance from serv‐

ice

■

Connecting the appliance to the

building's electrical supply

■

Disconnecting the electrical con‐

nection

■

Connecting the appliance to the

building's water supply

■

Disconnecting the water connec‐

tion

■

Connecting the appliance to the

building's drain connection

■

Disconnecting the drain connection

■

Instructing the owner and/or mem‐

ber of staff with relevant responsi‐

bility

■

Checking the work procedures and

status values against the check‐

lists

Installation manual 37

Page 38

3 For your safety

Working positions when installing the appliance and putting the appliance into service

The working position for personnel installing the appliance and putting the appliance into service is the

entire appliance area.

Installation manual 38

Page 39

3 For your safety

3.13 Personal protective equipment

Moving and setting up the appliance

When moving and setting up the combi oven, wear the following personal protective equipment:

Activity Materials used Personal protective equipment

■

Conveying within the establish‐

ment

■

For 6.06/6.10/10.10 mini: Setting

up the appliance on a worktable,

stand or in a stacking kit

■

For 6.10 mini 2in1: Setting up the

appliance in the installation loca‐

tion

Installation, putting into service and removal from service

Activity Materials used Personal protective equipment

Installing and removing (from serv‐

ice) the

■

Electrical connection

■

Water connection

■

Drain connection

Additionally for ConvoClean system

option:

Fitting and removing the fully auto‐

matic oven cleaning system

■

Putting the appliance into service

■

Instructing the user

Dismantling the appliance (removal

from service)

■

Lifting straps

■

Suitable lifting gear

Tools and equipment

depend on the task

Tools and equipment

depend on the task

Tools and equipment

depend on the task

■

Lifting straps

■

Suitable lifting gear

■

Forklift truck or pallet

truck

■

Protective gloves

■

Safety boots

■

Hard hat (e.g. when heavy loads

are being lifted, working over‐

head,...)

Work wear and personal protective

equipment depending on the job

that needs doing as specified in na‐

tional regulations

Items of protection equipment, de‐

pending on cleaning agent being

used:

■

Breathing mask

■

Safety goggles

■

Protective gloves

■

Protective clothing/apron

The EC safety datasheet for the rel‐

evant cleaning agent contains a

more precise specification of these

items. An up-to-date copy can be

obtained from the manufacturer.

Refer to the label on the cleaning

agent concerned.

Work wear as specified in countryspecific standards and directives

(BGR 111 in Germany) for kitchen

work, in particular:

■

Protective clothing

■

Heat protective gloves (compliant

with EN 407 in European Union)

■

Safety boots

■

Protective gloves

■

Safety boots

■

Hard hat (e.g. when heavy loads

are being lifted, working over‐

head,...)

Installation manual 39

Page 40

4 Transportation

4 Transportation

Purpose of this chapter

This chapter provides information on how to move your appliance.

This chapter is intended for the user, as well as for installation technicians and authorized customer

service staff.

4.1 Safe working when moving the appliance

For your safety

Before starting work, familiarize yourself with the hazards described in Hazards and safety precautions

when moving the appliance

Eligibility of personnel for moving the appliance

Personnel eligible for moving the appliance:

■

Only personnel who are trained in the use of a pallet truck and fork-lift truck for handling purposes

are permitted to move the appliance.

■

Personnel must be aware of the regulations relating to handling heavy loads.

on page 22.

Personal protective equipment

Wear the personal protective equipment specified in the section 'Personal protective equipment' on

page

39 of the 'For your safety' chapter for the relevant tasks.

Moving heavy loads

Risk of injury from lifting incorrectly

When lifting the appliance, the weight of the appliance may lead to injuries, especially in the area of

the torso.

Use a fork-lift truck/pallet truck or suitable lifting gear to move the appliance.

When lifting the appliance, use enough people for the weight of the appliance (guide value: 15 to

55 kg max., depending on age and gender). Observe the local occupational safety regulations.

Wear personal protective equipment.

Unsuitable supporting surface

Risk of crushing if the appliance tips over or falls off

Body parts can be crushed if the appliance tips over or falls off.

Make sure that the appliance is never placed on an unsuitable supporting surface.

Installation manual 40

Page 41

4 Transportation

4.2 Conveying the appliance to the installation location

Space required for conveying the appliance

Make sure that there is enough width and height along the entire route used for conveying the appli‐

ance to ensure it can get through to its installation location.

The table below shows the required minimum door size to allow the combi oven to be brought to its

intended location:

Minimum door opening 6.06 mini 6.10 mini 10.10 mini 6.10 mini 2in1

Width [mm] 580 580 580 800

Height [mm] 830 830 1065 1750

Load bearing capability for conveying the appliance

Provide moving equipment that is rated capable of carrying the load.

Refer to the weight of the appliances including packaging to determine the minimum working load limit

of handling equipment; see 'Dimensions and weights'.

Moving the appliance to the installation location

Please observe the following points when conveying the appliance:

■

Always move the appliance on a pallet.

■

Always move the appliance in an upright position.

■

Move the appliance slowly and carefully, and secure it against tipping over.

Make sure that you do not knock against things with the appliance.

Avoid moving appliance along uneven routes or up or down steep slopes.

The following diagram illustrates how to move the appliance using a forklift truck:

Installation manual 41

Page 42

5 Setting up the appliance

5 Setting up the appliance

Purpose of this chapter

This chapter provides information on how to set up your appliance.

This chapter is intended for the user, as well as for installation technicians and authorized customer

service staff.

5.1 Safe working when setting up the appliance

For your safety

Before starting work, familiarize yourself with the hazards described in Hazards and safety precautions

when setting up the appliance

Eligibility of personnel for setting up the appliance

Personnel eligible for setting up the appliance:

■

Only skilled personnel from an authorized customer service office are permitted to set up the appli‐

ance.

on page 23.

Regulations for setting up the appliance

Local and national standards and regulations relating to workplaces in catering kitchens must be ob‐

served.

The rules and regulations of the regional authorities and supply companies that apply to the installa‐

tion site concerned must be observed.

Personal protective equipment

Wear the personal protective equipment specified in the section 'Personal protective equipment' on

page 39

Moving heavy loads

Risk of injury from lifting incorrectly

When lifting the appliance, the weight of the appliance may lead to injuries, especially in the area of

the torso.

of the 'For your safety' chapter for the relevant tasks.

Use suitable lifting equipment for placing the appliance on the work surface, on the stand, in the

stacking kit or in the installation location (for 6.10 mini 2in1).

To shift the appliance into the correct position, lift the appliance using enough people for the weight

of the appliance (guide value: 15 to 55 kg max., depending on age and gender). Observe the local

occupational safety regulations.

Use lifting straps to take the appliance off the pallet.

Wear personal protective equipment.

Unsuitable supporting surface

Risk of crushing if the appliance tips over or falls off

Body parts can be crushed if the appliance tips over or falls off.

Make sure that the appliance is never placed on an unsuitable supporting surface.

Installation manual 42

Page 43

5 Setting up the appliance

5.2 Adjacent systems

Dealing with the discharged air

During operation, the combi oven generates heat and moisture, which mainly escape upwards into the

surrounding air as hot vapour from the air vent. It is not permitted to connect air ventilation pipes di‐

rectly to the air vent of the combi oven.

The manufacturer recommends using a fume extractor hood or ceiling-fitted ventilation equipment to

extract the discharged air from the room in which the combi oven is operating.

In order to avoid the risk of fire or other damage to the building such as corrosion, mould growth

and/or reduced stability, there must be a sufficiently large distance between the top of the appliance

and the ceiling.

■

For guidance on the minimum vertical clearance, see 'Requirements for the installation location' on

page 44.

■

Type of air-vent system

■

the nature of the ceiling in the installation location

It is a fundamental requirement that the combi oven is always set up, installed and operated in accord‐

ance with national and local standards and regulations (in the latest version).

In addition, please observe the following regulations:

■

VDI Directive 2052 'Ventilation equipment for kitchens'

■

Guidance from the local building authority for fume extraction systems

This distance depends on the following factors:

Installation manual 43

Page 44

5 Setting up the appliance

5.3 Requirements for the installation location

Meaning

This section contains information to help you choose a suitable installation location for the appliance.

Inspect the intended installation location carefully to ensure it is suitable before bringing the appliance

there and starting the installation.

Rules for setting up the appliance safely (6.06/6.10/10.10 mini)

To prevent hazards that arise from the installation site and environment of the appliances, the follow‐

ing rules must be observed:

■

It must be possible to comply with the operating conditions. For operating conditions, see

ments relating to the operating environment of the combi oven on page 17.

■

There is a risk of fire from the heat emitted from hot surfaces. Therefore there must not be any

flammable materials, gases or liquids above, on, beneath or in the vicinity of the appliance. When

choosing where to install the appliance it is essential to remember this requirement together with

the information in the topic 'Adjacent systems' on page 43 and the minimum space required for the

appliance.

■

Heat sources in the vicinity must lie at a minimum distance of 500 mm.

■

Deep-fat fryers or appliances that use hot, uncovered fat that are located in the vicinity must lie at a

minimum distance of 1.00 m. The appliance must be installed so that there is absolutely no possi‐

bility that liquid from the appliance or liquid coming from cooking processes can reach deep-fat fry‐

ers or appliances that use hot, uncovered fat. An appliance fixed on a wall bracket must not be in‐

stalled above a deep-fat fryer, an appliance that uses hot, uncovered fat or an electrical appliance.

■

Do not install the appliance directly under a fire alarm or sprinkler system. Fire alarm installations

and sprinkler systems must be set up to handle the level of steam and vapour expected to escape

from the appliance.

■

It must be possible to set up the supporting structure for the appliance (work surface, stand or

stacking kit) in the installation position so that it cannot tip over or slide about. The subfloor must

satisfy relevant requirements.

■

The structure supporting the appliance (stand or stacking kit) must be fixed so that it cannot tip

over when subject to a one-sided load - e.g. appliance door is open.

■

For appliances on a wheeled supporting structure, a retaining device must be connected to limit the

range of movement of the assembly (supporting structure plus appliance) at the customer's site.

The maximum distance that the supporting structure plus appliance can be pulled out is 0.5 m.

The lengths of the supply cables and pipes must accommodate the range of movement allowed by

the retaining device. When moving the assembly, never strain or wheel over the supply cables and

pipes.

■

It must be possible to lock the wheels on the supporting structure

■

With the equipment currently fitted in this model, the appliance must not be used in environments in

which the appliance might be subject to strong vibrations or jolting (e.g. on vehicles or on ships).

■

Vibrations must be avoided when using wheeled oven stands or wheeled stacking kits.

Require‐

Installation manual 44

Page 45

5 Setting up the appliance

Rules for setting up the appliance safely (6.10 mini 2in1)

To prevent hazards that arise from the installation site and environment of the appliances, the follow‐

ing rules must be observed:

■

It must be possible to comply with the operating conditions. For operating conditions, see

ments relating to the operating environment of the combi oven on page 17.

■

There is a risk of fire from the heat emitted from hot surfaces. Therefore there must not be any

flammable materials, gases or liquids above, on, beneath or in the vicinity of the appliance. When

choosing where to install the appliance it is essential to remember this requirement together with

the information in the topic 'Adjacent systems' on page 43 and the minimum space required for the

appliance.

■

Heat sources in the vicinity must lie at a minimum distance of 500 mm.

■

Deep-fat fryers or appliances that use hot, uncovered fat that are located in the vicinity must lie at a