Page 1

www.controltechniques.com

Installation Guide

Unidrive

Regen

Part Number: 0460-0026-02

Issue Number: 2

Page 2

General Information

The manufacturer accepts no liability for any con se quenc es resulting from inappropriate, negligent or incorrect

installation oradjustment of the optional operating parameters of the equipment or from mismatching the variable speed

drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interes ts of a co mm itment to a policy

of continuous development and improv ement, the manufacturer reserves the righ t to change t he specification of the

product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or

mechanical including photocopying, recording or by an information storage or retrieval system, without permission in

writing from the publisher.

Drive software version

This product is s upplied with the latest version of software. If this product is to be used in a n ew or existing system with

other drives, there may be some differences between their software and the software in this product. These differences

may ca use this product to function differently. This may also apply to drives returned from a Control Techniques Service

Centre.

If there is any doubt, contact a Control Techniques Drive Centre.

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manu facturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS ) whi ch is

certified to the International Standard ISO 14001. Further info rmation on the EMS, our Environmental Policy and other

relevant information is available on request, or can be found at www.greendrives.com.

The electronic variable-speed drives manufact ured by Control Techniques have the potential to save energy and

(through increased machine/process efficienc y ) reduce raw material consumption and scrap through out their long

working lifetime. In typical applications, these posit ive environmental effects far outweigh the negative impacts of product

manufacture and end-of-life disposal.

Nevertheless, when theproducts eventually reach the end of theiruseful life, they can very easily be dismantled into their

major component parts for efficient recycling. Many parts snap together and can be separated without the use of tools,

while other parts are secured with conventional screws. V irtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wo oden crates, while smaller

products come in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these

containers can be recycled. Polyethylene, used on the protective film and bags for wrapping p roduct, can be recycled in

the same way. Control Techniques' packaging strategy favours easily-recyclable materials of low environmental impact,

and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

Copyright © October 2002 Control Techniques Drives Limited

Issue Number: 2

Page 3

Contents

1 Introduction....................................................................................................................1

1.1 Principles of operation ...........................................................................................................................1

1.2 Power flow .............................................................................................................................................2

1.3 Advantages of Unidrive operating in Regen mode ................................................................................2

2 Sizing of a Regen system .............................................................................................3

3 Power connections........................................................................................................4

3.1 Overall system layout ............................................................................................................................4

3.2 Non standard configurations ..................................................................................................................7

4 Control circuit connections..........................................................................................8

4.1 Digital/ Analog I/O set-up in Regen mode ............................................................................................8

4.2 Regen inductor thermistors ....................................................................................................................9

5 Components.................................................................................................................10

5.1 Motoring drive ......................................................................................................................................10

5.2 Regen drive .........................................................................................................................................10

5.3 Regen inductor ....................................................................................................................................10

5.4 Softstart resistor ...................................................................................................................................11

5.5 Contactors, MCBs and overload ..........................................................................................................11

5.6 Switching frequency filter .....................................................................................................................12

5.7 RFI filter ...............................................................................................................................................13

5.8 Varistors ...............................................................................................................................................13

5.9 Fusing ..................................................................................................................................................14

6 Important considerations............................................................................................16

6.1 Fundamentals ......................................................................................................................................16

6.2 Unidrive size 3 and 4 ...........................................................................................................................16

6.3 Ventilation ............................................................................................................................................16

6.4 Cable length restrictions ......................................................................................................................17

7 Unidrive Regen EMC information...............................................................................19

7.1 Immunity ..............................................................................................................................................19

7.2 Emission ..............................................................................................................................................19

7.3 Dedicated supplies ..............................................................................................................................19

7.4 Other supplies ......................................................................................................................................19

7.5 Supply voltage notching .......................................................................................................................19

7.6 Supply harmonics ................................................................................................................................19

7.7 Switching frequency emission .............................................................................................................19

7.8 Conducted RF emission ......................................................................................................................19

7.9 Radiatedemission ...............................................................................................................................21

7.10 Wiring guidelines .................................................................................................................................21

7.11 Multi-drive systems ..............................................................................................................................21

8 Parameter descriptions...............................................................................................22

8.1 Menu 15: Sinusoidal rectifier ...............................................................................................................22

9 Commissioning and operation...................................................................................28

9.1 Regen parameter settings ...................................................................................................................28

9.2 Regen drive sequencing ......................................................................................................................28

9.3 Regen drive commissioning .................................................................................................................29

9.4 Motoring drive commissioning .............................................................................................................29

9.5 Trip codes ............................................................................................................................................29

Unidrive Regen Installation

Issue Number: 2

Page 4

Appendix A Unidrive Regen as a Brake Resistor Replacement ............................................. 30

A.1 Introduction .........................................................................................................................................30

A.2 Drive configurations ............................................................................................................................30

A.3 When to use a Regen drive as a brake resistor replacement .............................................................30

A.4 Regen and motoring drive ratings ....................................................................................................... 31

A.5 Power circuit conne ctions and components ....................................................................................... 31

A.6 Control circuit connections .................................................................................................................. 34

A.7 Regen brake drives in operat ion ......................................................................................................... 35

Appendix B Component sizing calculations ............................................................................ 36

B.1 Sizing of MCB for switching frequenc y filter .......................................................................................36

B.2 Resistor sizing for multiple motoring systems .....................................................................................37

B.3 Multiple Unidrive size 5 systems ......................................................................................................... 38

B.4 Thermal / magnetic overload protection for soft start circuit ...............................................................38

Appendix C Long cables ............................................................................................................41

C.1 Exceeding the maximum cable length ................................................................................................ 41

Appendix D Regen kits ............................................................................................................... 43

D.1 Single R egen, single motoring systems .............................................................................................. 43

D.2 Single Regen, multiple motoring and multiple Regen, multiple motoring systems .............................43

Appendix E Unidrive Regen specifications ............................................................................. 44

Appendix F Physical dimensions ............................................................................................. 45

F.1 Regen inductor ................................................................................................................................... 45

F.2 Softstart resistor - type TG series ....................................................................................................... 47

F.3 Switching frequency filter capacitors .................................................................................................. 48

F.4 Switching frequency filter inductor ......................................................................................................51

F.5 Varistors ..............................................................................................................................................53

Unidrive Regen Installation Guide

Issue Number: 2

Page 5

1 Introduction

R

+DC-

Any standard Unidrive canbe configured asanAC Regenerative Unit (hereafterreferredtoas Regen drive).

This Installation guide covers the following:

• Principles andadvantagesofoperation in Regen mode

• Details of additionalcomponentsrequired

• ConfigurationofRegen systems

At least two Unidrives are required to form a complete Regenerative system - one connected to the supply and the second one to the motor. A

Unidrive in Regen mode converts the AC mainssupply to a controlled DC voltage which is fed intoother drive(s)to controla motor.

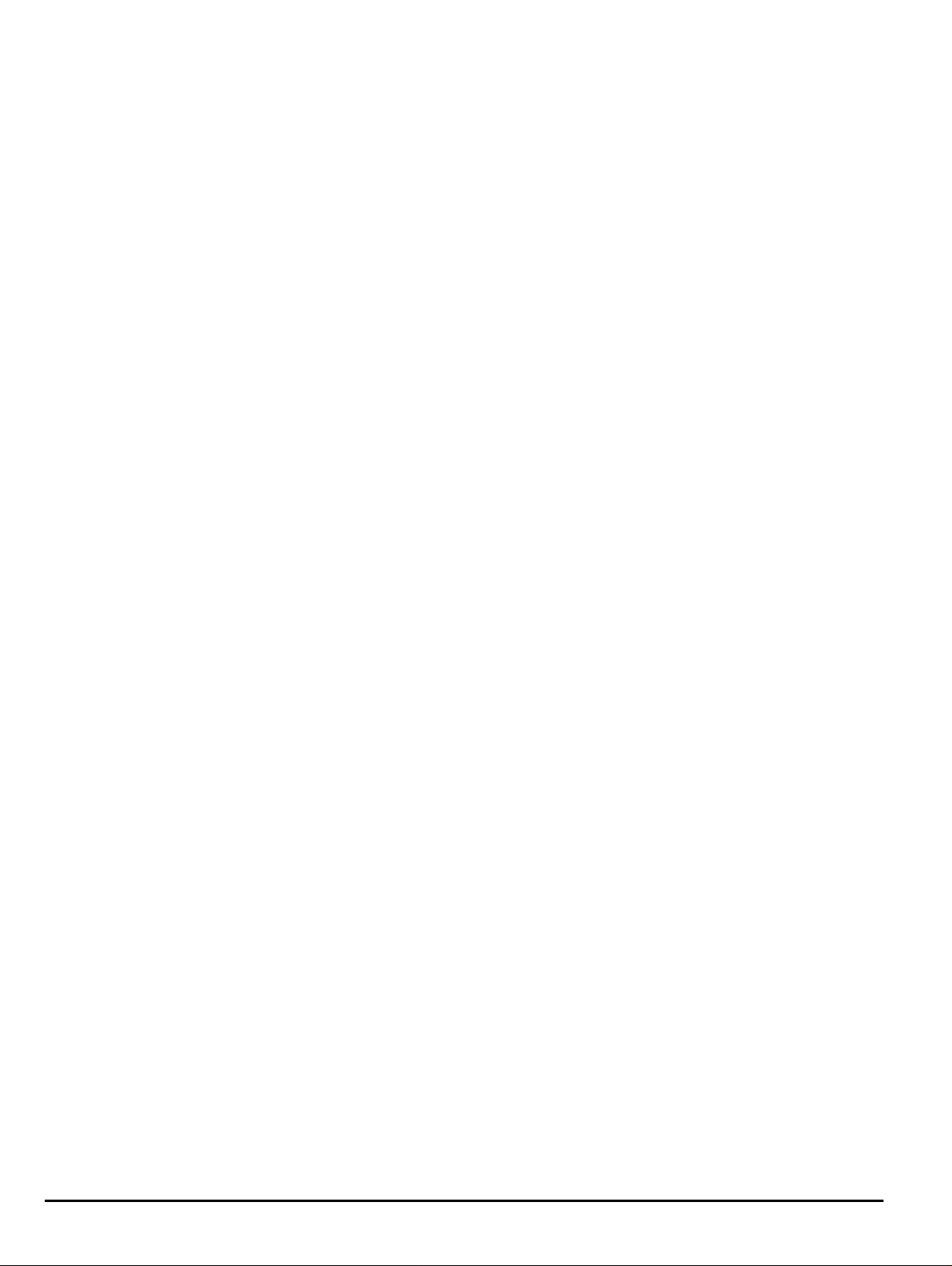

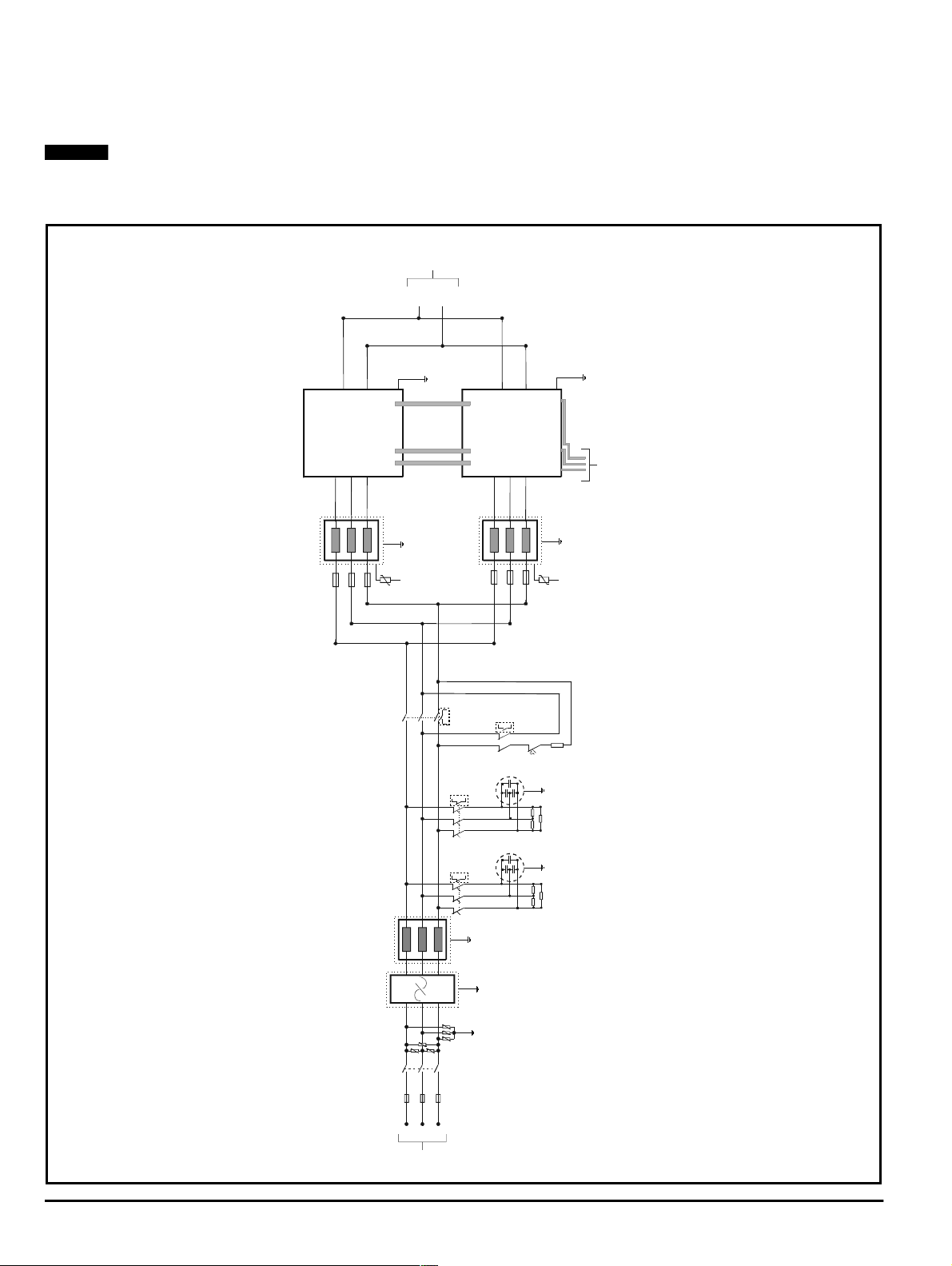

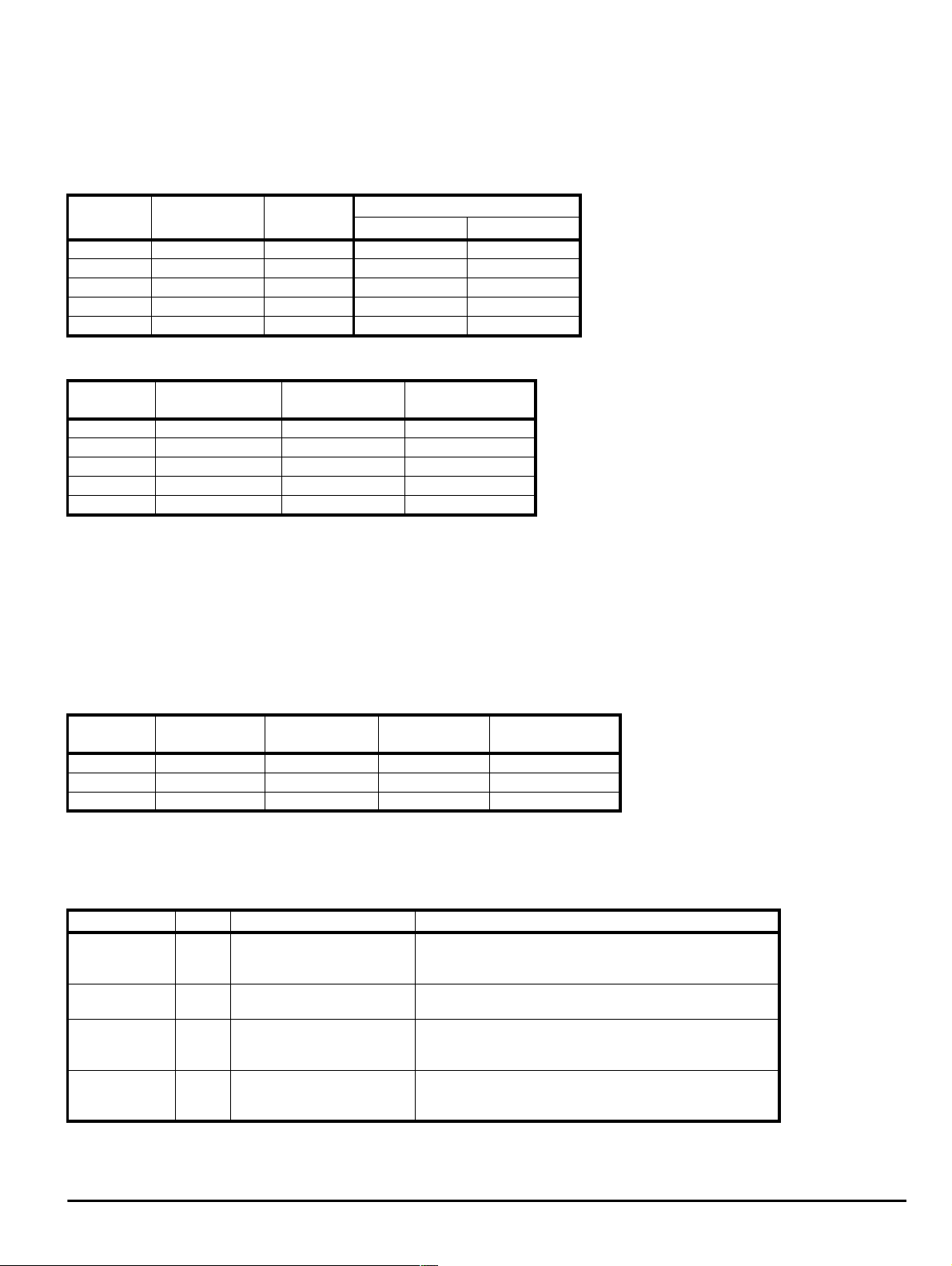

Figure1-1 Regen drivesystem connection

3Phase

Supply

Regen

Inductor

R

Y

B

Additional

Circuitry

U

V

W

egen Drive

AC

DC

+DC

-DC

Motoring Drive

DC

DC

AC

U

V

W

M

1.1 Principles of operation

The inputstage of a non-regenerative AC drive is usually an uncontrolled dioderectifier, therefore power cannot be fed back intothe AC mains

supply.

In the case of a Unidrive operating in Regenerative mode, the IGBT bridge is used as a sinusoidal rectifier, which converts the AC supply to a

controlled DC voltage.This DC voltage canthen be usedtosupply oneormore Unidrives whichcontrolmotors,commonlyknown as motoring drives.

A Regen drive produces a PWM output voltage which has a sinusoidal fundamentalatanamplitude andphase which are almost the same as those

of the AC supply voltage. The differencebetween thedrive PWM linevoltageandthesupplyvoltage occursacross theRegen drive’sinductors.This

voltage has a high frequency component which is blocked by the Regen inductor and a smallsinusoidal component at linefrequency.Asa result,

currents flowing in these inductors are sinusoidal with a small high frequency ripple component.

NOTE

T erminals L1, L2 and L3 and the associated diode rectifier are not connected and are redundant on drives used in a Regen configuration.

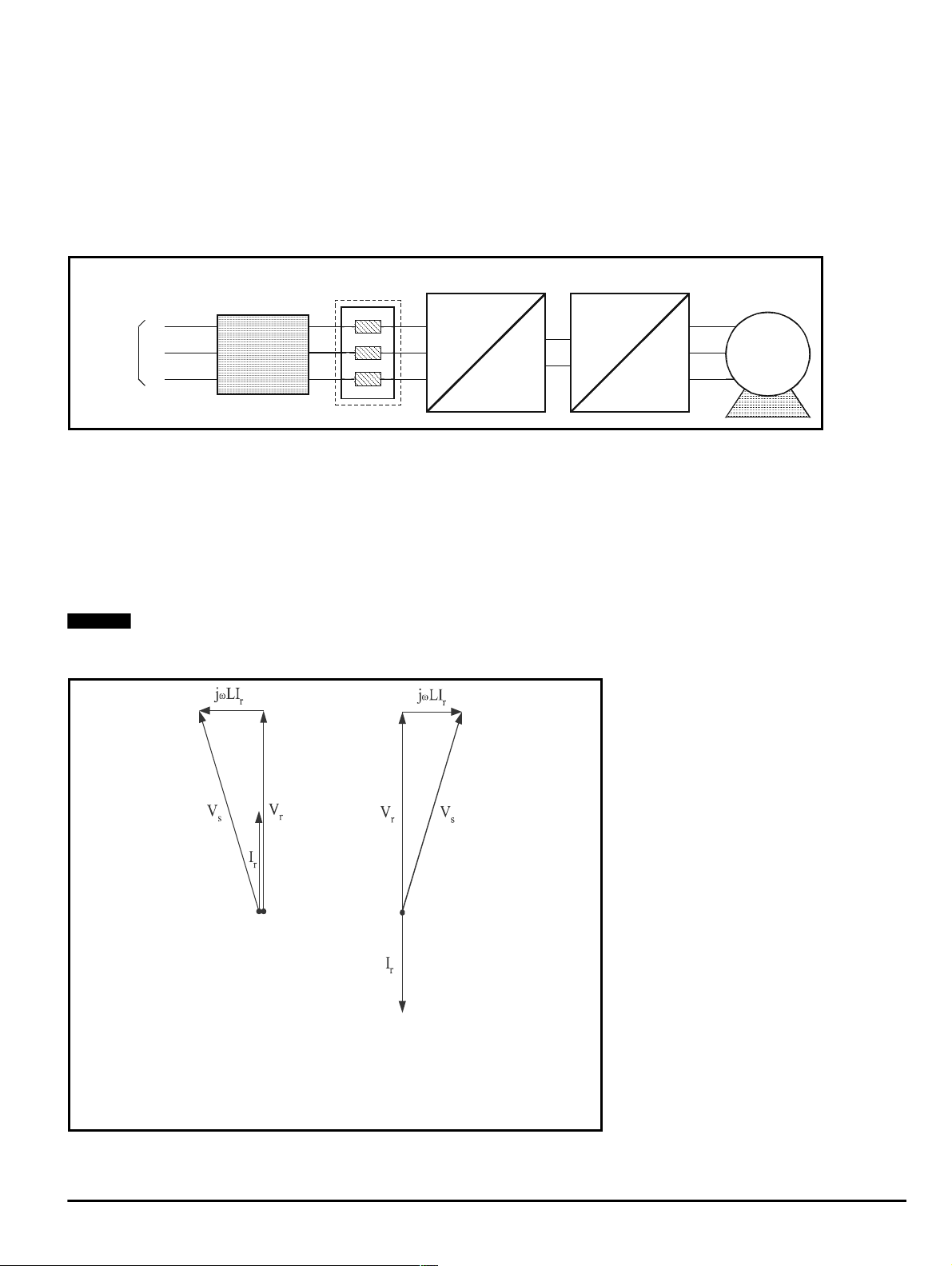

Figure 1-2 Phasor diagram

N

Power flowfrom supply Power flowback to supply

V

s

V

r

jωLI

I

r

Supply Voltage

Voltage at line terminals of Regen drive

Voltage across RegenInductor

r

Current at line terminals of Regen drive

UnidriveRegenInstallation Guide 1

Issue Number: 2 www.controltechniques.com

Page 6

1.2 Power flow

The phasor diagraminFigure 1-2 illustratesthe relationship between the supply voltage and the Regen drivevoltage. The angle betweenthe two

voltage vectorsis approximately 5° at fullload, givingapowerfactor which is nearunity.

The directionofthe power flow can bechanged relative tothesupply voltage, by makingsmall changes to theRegendrive outputvoltage andphase.

A fast transient response is achievedby means of a space vector modulator.

1.3 Advantages of Unidrive operating in Regen mode

The main advantages for an AC Regen system are:

• Energy saving

• The inputcurrent waveformissinusoidal

• The input current has a near unity power factor

• The output voltage for the motor can be higher than the available AC mains voltage

• The Regen drive willsynchronise to any frequency between30and100Hz, provided the supply voltage is between 380V-10% and 480V +10%

• Underconditionsof AC mains instability,a UnidriveRegen system cancontinuetofunction downtoapproximately150Vac supplyvoltage without

any effect on the DC bus voltage and hence on the operation of the motoring drives (increased current will be taken from the AC supply to

compensate up to the currentlimit of the Regendrive)

• The Regen and motoring drives are identical

2 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 7

2 Sizing of a Regen system

Refer to Appendix E Unidrive Regen specifications on page 44, for the specifications of the Unidrive Regen.

The sizing of a Regen system musttake into account the following factors:

•Linevoltage

• Motor rated current, rated voltage and power factor

• Maximum load power and overload conditions

In general, when designing a Regen system, equalRege n and motoring drive rated currents will work correctly. However, care must be taken to

ensurethat under worstcasesupply conditions theRegen drive is able to supply or absorballtherequired power. In multi-drive configurations, the

Regendrive must be of a sufficientsize to supply the netpeakpower demanded by thecombined loadofall the motoring drivesandthe drivelosses.

If the Regendrive is unabletosupply the fullpower required by the motoring drive, theDC busvoltage willdrop and in severe cases may lose

synchronisation with the mains and trip.Ifthe Regen drive is unable to regenerate the full powerfrom the motoring drive intotheDC bus, thenthe

Regen/motoring drive will trip on over-voltage.

The following are twoexamples of how the required ratings of a Regen drive can be calculated.

NOTE

The Regen drive’s current limits are set at 150% and are not adjustable.

In the caseofa 25A,UNI2403 operating in Regen mode from a 400V supply, and a UNI2403driving a 400V rated, 0.85 pf motor:

The rated power of the Regen drive is = √3 x Ratedcurrent x Supply voltage

The motoring drive can supply power = √3 x Rated current x Motor voltage x Powerfactor

When the motoring driveissupplying rated current to themotor, the Regen driveonlyneeds to provide14.7kW, plus drivelosses. The Regen drive

can supply 17.3kW at rated current, which is ample, in this case.

Conversely, in somecases, a Regen driveofthesame rating asthe motoring drive, may not be able to supply enough power, as the following

example shows:

Example

In the caseofa 156A,UNI4403 operatinginRegenmode, and a UNI4403drivinga 75kW, 400V, 0.95pf motor:

If the motoring drive is supplying 175% maximum current and the Regendrive has its380Vsupply at the lowerlimits of -10%(342Vac), then,atthe

Regencurrent limitof150%:

The Regen drive max. available power is = √3 x 150% x Rated current x Supply voltage

The motoring drive max.poweris = √3 x 175% x Rated currentx Motorvoltage x Power factor

The Regendrive is also required to supplytheRegen and motoring drive losses.However, t his Regen drive is onlycapable of supplying

approximately 138.6kW and therefore a drive of a larger current rating is required.

Due to the effects of increased DC bus capacitance, there is a limit to the number of motoring drives that can be supplied from a Regen drive. This is

true irrespective of the balance of power between the motoring drivesandtheRegen drive.

NOTE

If the system consists of one Regen Unidrive and morethanthree motoringdrives, ControlTechniquesTechnical SupportMUSTbeconsulted about

the design of the system.

N

= 1.73 x 25 x 400

= 17.3kW

= 1.73 x 25 x 400 x 0.85

= 14.7kW

=1.73x1.5x156x342

=138.6kW

=1.73x1.75x156x400x0.95

=179.7kW

N

UnidriveRegenInstallation Guide 3

Issue Number: 2 www.controltechniques.com

Page 8

3 Power connections

The following section covers the power connections required for Unidrive Regen systems. Note that with Unidrive Regen systems there are no AC

supply connectionsmade to L1, L2 or L3 driveterminals.

NOTE

For control circuitconnections refertoChapter 4 Control circuit connectionson page 8.

3.1 Overall system layout

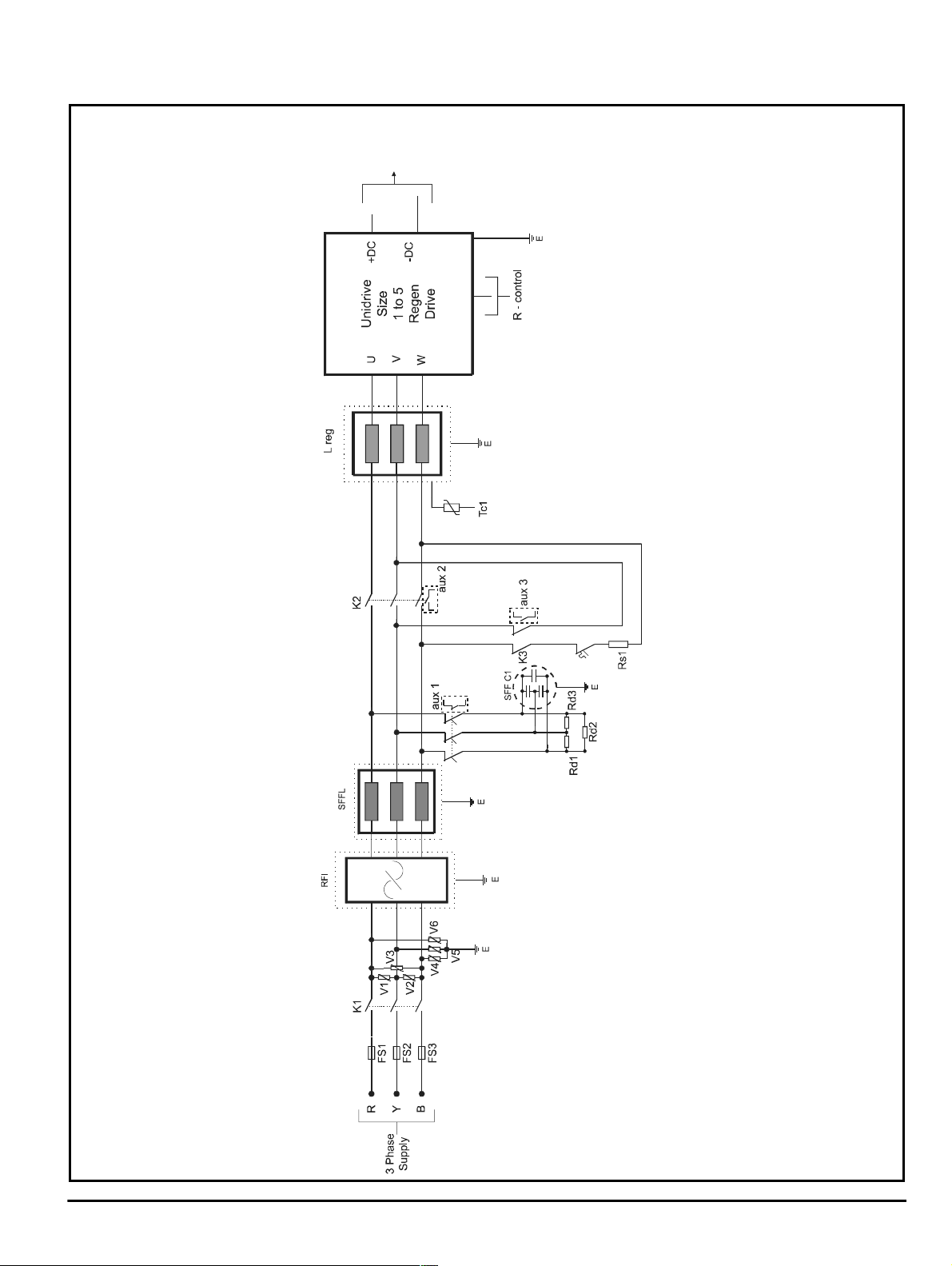

The table below shows the key to the following system layout diagrams.

Table 3-1 KeytoFigure3-1andFigure3-2

V1, V2,V3 Varistor network 550V (linetoline)

V4, V5,V6 Varistor network 680V (linetoground)

N

E Ground connection point

RFI EMC filter

SFFL Switching frequency filter inductor

L regx Regen inductor

Rsx Softstart resistor

R-control Ribboncablestocontrolpod(Unidrivesize5only)

R-parallel Ribboncables between powermodules (Unidrive size5only)

Fsx ACsupply fusing

Fx ACRegenfusing(Unidrivesize5only)

SFF Cx Switching frequency filter capacitor

Rdx Switching frequency filter capacitor discharge resistor

Tcx Thermocouple

K1 Supply contactor

K2 Main contactor

K3 Auxiliary contactor

MCB1x Switching frequency filtercapacitorMCB

aux1x

aux2 Main contactorauxiliaryfor“main contactor closedsignal”

aux3 K3 auxiliary with coil supplyfor K2

Ovld Thermal, Magnetic overload

Switching frequency filter MCB auxiliary through which Regen drive enable is

connected

4 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 9

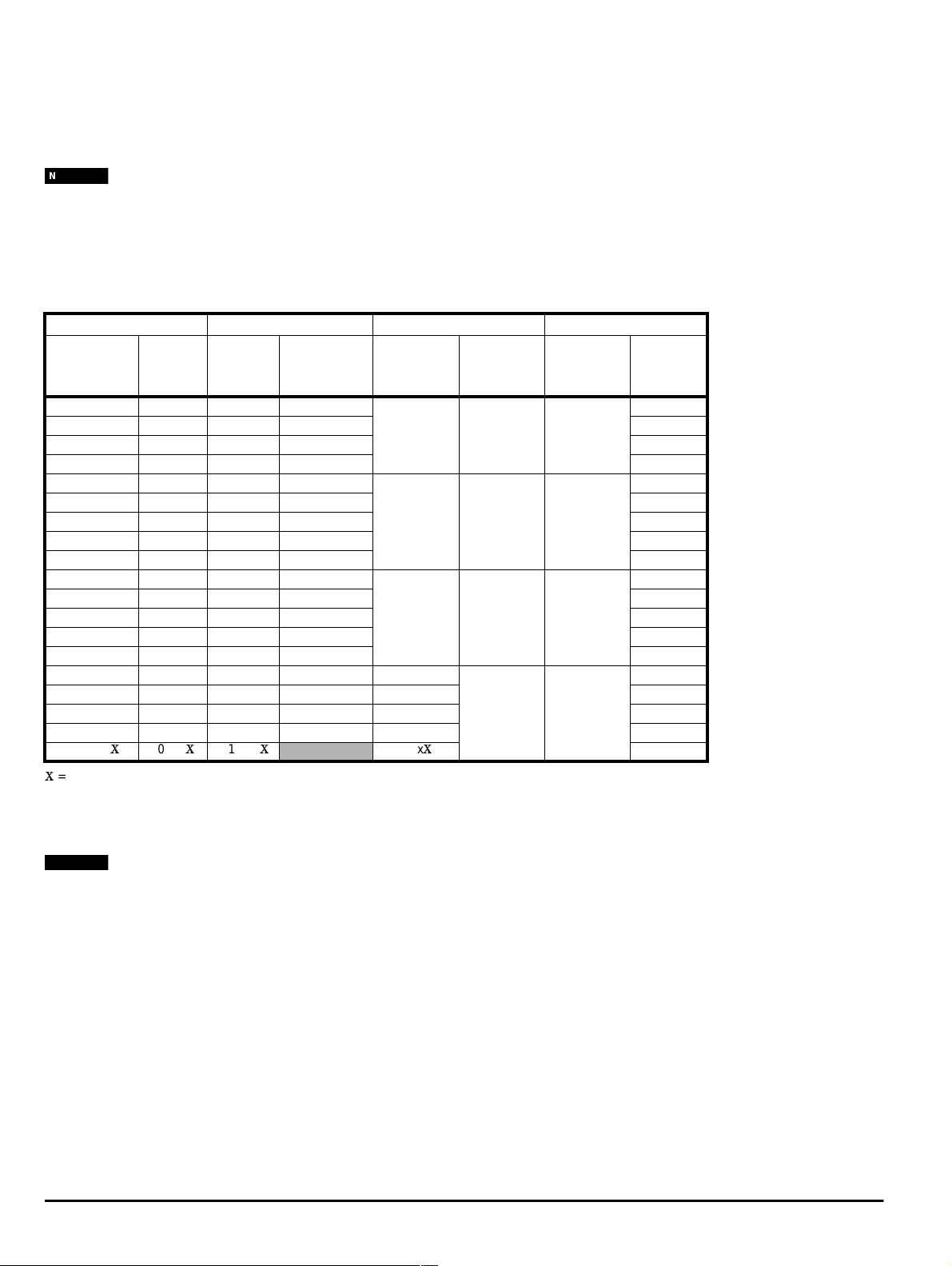

3.1.1 Standard single Regen, single/mul tip le m otoring system

Figure 3-1 Power connections: Single Regen

DC Bus to

Motoring

Drive(s)

Ovld

MCB1

UnidriveRegenInstallation Guide 5

Issue Number: 2 www.controltechniques.com

Page 10

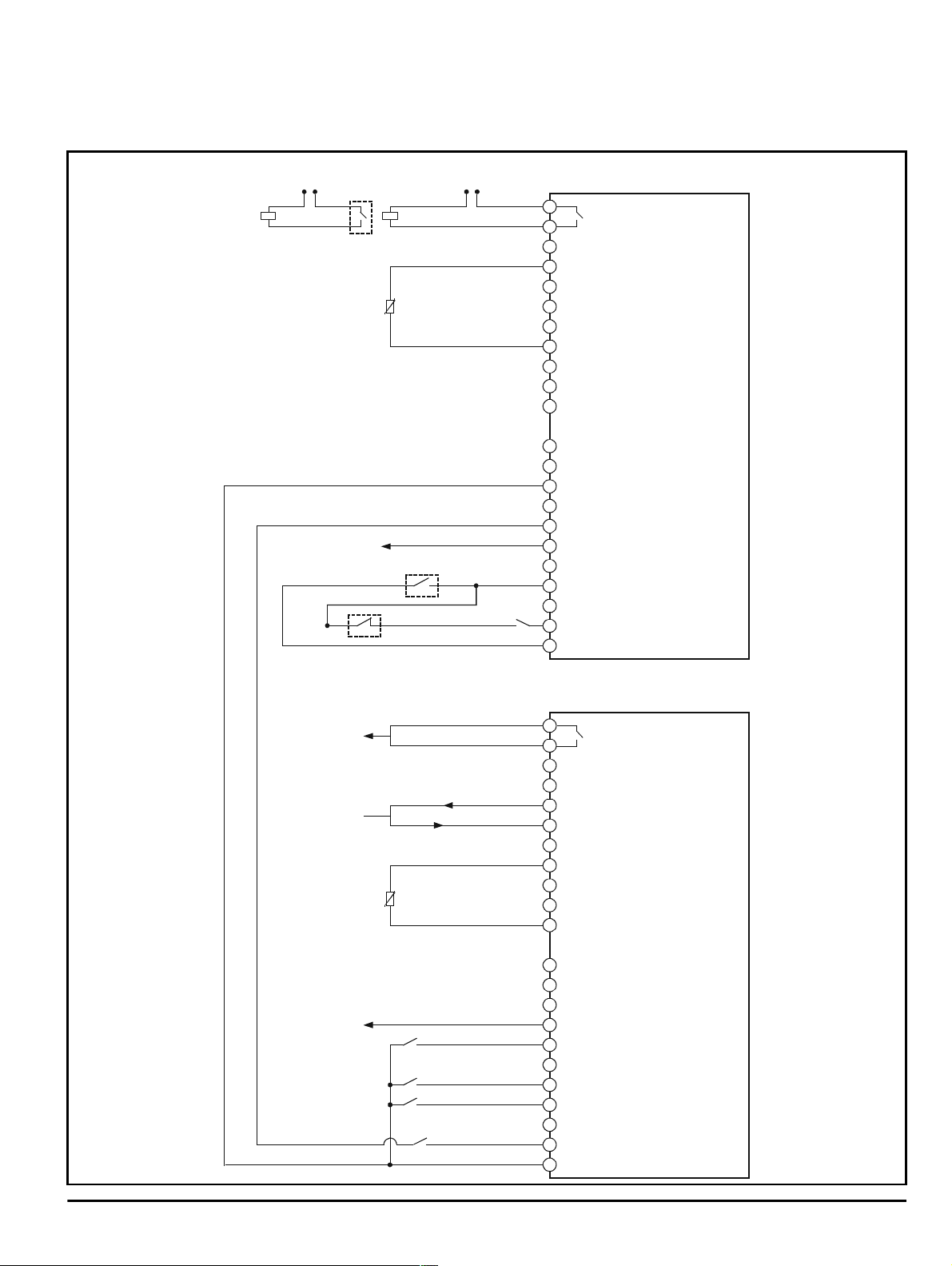

3.1.2 Standard multiple Regen, multiple motoring system

R - control

If the total power requirement istoogreat for one Unidrive size 5 Regen drivetosupply, more than one drive can be used.

OneRegensystem can consist of multiple Unidrive size5Regen drives,which can supply multiple Unidrive size5motoring drives, providing thatthe

totalload power doesnot exceed the rating of the Regen drives. See figure3-2for a dual size 5 Regen configuration.

NOTE

High power set-upsshould useUnidrivesize 5. This is the onlymodule whichis designedforparallelRegen operation.

For systemswith more thantwoUnidrive size 5 drives in parallel Regenoperation, contactCTTechnical Support.

Figure 3-2 Power connections: Unidrive size 5 multiple Regen

N

DC

Bus

Common

-DC

+DC

E

+DC

Size 5

Regen

Drive 1

Unidrive

U

V

W-DC

Lreg1

F1F2F3

R-parallel

E

Tc1

K2

SFFL

Lreg2

aux 2

aux 1b

MCB 1b

aux 1a

MCB 1a

E

-DC

+DC

Size 5

Regen

Drive 1

Unidrive

U

V

W

F4

F5

F6

aux 3

K3

Ovld

SFF C2

Rd6

Rd4

SFF C1

Rd3

Rd1

E

E

Tc2

Rs1

E

Rd5

E

Rd2

RFI

V3

V1

V2

K1

FS1

FS2

Y

R

Supply

3Phase

E

V6

V5

E

V4

FS3

B

6 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 11

3.2 Non standard configurations

There are a number of possible options available when designing a Unidrive Regen system depending on the user requirements and the nature of the

AC supply. Non standard systems can be created where favourable supply conditions exist, allowing cost and space savings to be achieved by

reducing the number of components.

3.2.1 Switching frequenc y filter

If the supply to the Regen driveisshared with other equipment, then it is strongly recommendedthat a switching frequency filter be incorporated in

order to avoid the risk of interference or damage to the other equipment.

3.2.2 Supply assessment

The following guidelines should be used when assessing whether or not a switchingfrequency filterisrequired.

Symbols used are:

Nominal drive 100% current rating.

I

Drive

I

Short circuit current of supply at pointofcoupling with other equipment.

SC

Ratedcurrent of supply.

I

Supply

The switching frequency filter may be omitted if the following relation is true:

I

Drive

I

SC

If the short-circuit currentisnot known,thenareasonableestimatecanbe madeifitisassumed that the fault currentof the supply is 20 times the

ratedcurrent.This is very commonly the case wherethe supplyisderived through a distributiontransformer from a higher voltage supply with a high

fault level.

Then:

I

Drive

I

Supply

This second relation is helpful but must be used with care. It is reliable where the Regen drive is supplied through its own cable run from a point close

to the distribution transformer terminals. If theRegen drive shares a long cablerunwith other equipment, thentheeffect of the cableimpedanceon

the faultlevel must be taken into account if a risk of disturbance to the other equipment is to be avoided.

This procedure will normally be applied when assessing a non-dedicated low-voltage supply. It may also be applied to the medium/high voltage

supplywhere the low-voltagesupply is dedicated to the drive.Inthatcase the currents used mustbe referred to the highvoltage side of the

transformer.

3.2.3 RFI filter

Whether or not an RFI filter is required is dependent upon the user requirements and the AC supply network. For further details refer to Chapter

7 Unidrive Regen EMC information on page 19. An RFI filter must not be fitted without a switching frequency filter present in the system.

1

<

140

1

<

7

UnidriveRegenInstallation Guide 7

Issue Number: 2 www.controltechniques.com

Page 12

4 Control circuit connections

All power circuit connections should be made as shown in Chapter 3 Power connections on page4.

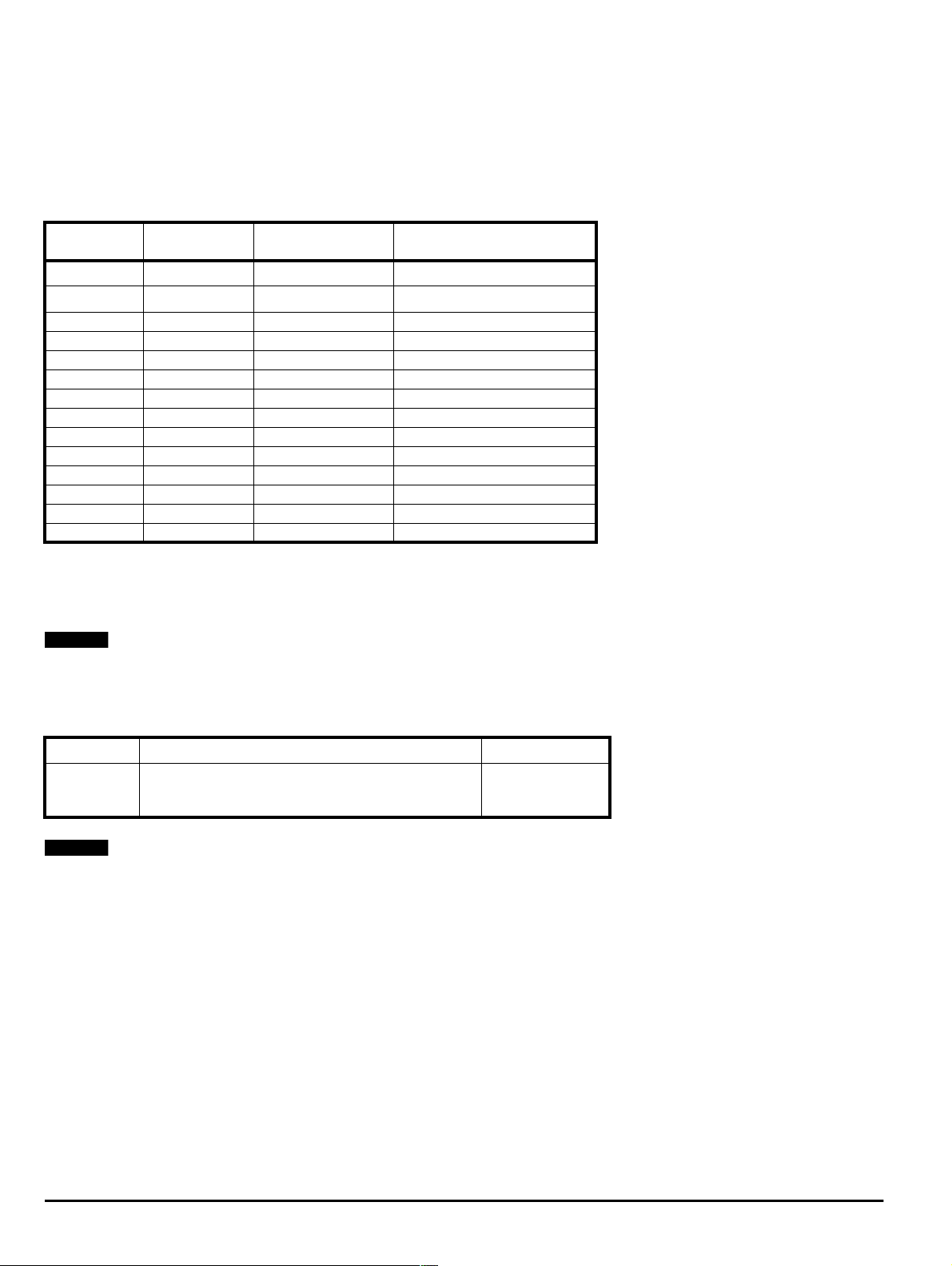

4.1 Digital / Analog I/O set-up in Regen mode

The following table lists the default functions of the analog and digital I/O on a Regen drive. The terminals which are listed as “Fixed” have dedicated

functions for Regen operation. They mustbe connected to perform their allocated functionandcannot be re-programmed.

Table 4-1 Functions of the analog and digital I/O

Terminal No.

1 Drive relay Fixed

2 Drive relay Fixed

5 Analog input1 User-programmable

7 Analog input2 User-programmable

8 Analog input3 User-programmable

9 Analogoutput 1 User-programmable Output- Supply current

10 Analog output 2 User-programmable Output - Supply power

24 Digital output 1 Fixed Not used

25 Digital output 2 Fixed Output - Enable other drive

26 Digital output 3 User-programmable Drivehealthy

27 Digital input 1 User-programmable Input - Reset

28 Digital input 2 Fixed Input - Main contactor closed

29 Digital input 3 User-programmable

30 Enable Fixed Enable

* Pr 8.25 must be setby theuser. See Table 4-2.

Terminal

Description

Fixed or

Programmable

Function in Regen Mode

Output - close auxiliary contactor*

Output - close auxiliary contactor*

Figure 4-1 shows typical control connections for a Regenandmotoring drive. In this example the motoring drive is configured for 4-20mA Speed/

Torque reference and sequencing Mode 4 with Run Forward and Run Reverseinputs.

NOTE

All control connections for theRegen drive mustbe madeas shownin Figure 4-1.

The Regen drive healthy signal can be taken from digital output 3 on terminal 26 (if the Regen drive is disabled, trips, or detects that the mains supply

is lostthis output thenbecomes inactive).

Table 4-2 Configuration of drive relay

Pr8.25 -Relay

NOTE

Unidrive Regenhas beendesignedto operate innegativelogicasdefault.In orderfor thedrive to beconfigured tooperateinpositivelogicalterations

must be madetothecontrol connectionsand parameter settings (contact C.T. TechnicalSupport forthis information).

N

Parameter Description Drive

The Regen drives relay on terminal 1 and 2 has to be

Source

configured toclose theauxiliary contactoronpowerupand

remove the softstart circuit. Set Pr 8.25 to Pr 15.14

Regen drive

N

8 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 13

4.2 Regen inductor thermistors

0

A

A

0

0

D

D

2

D

2

D

2

D

2

D

3

E

3

0

M

0

A

A

A

A

A

1

A

1

0

2

0

2

+

2

0

2

D

2

D

2

D

2

D

2

D

2

D

3

E

3

0

M

Each of the Unidrive 3-phase Regen Inductors has a thermistor fitted; when the system consistsof multipleRegen drivesthethermistorsshould be

connected in series due to there only being a singlethermistorinput on the Regen drive.

Figure 4-1 Control connections - (negative logic configuration)

Externalpower supply

for K2 coil

External power supply

forK3coil

K2

aux3

Tc1

K3

1

2

3

VAnalog

4

10V Out

5

nalog I/P 1+

6

nalog I/P 1-

7

Analog I/P 2

8

Analog I/P 3

9

AnalogO/P 1

10

AnalogO/P 2

11

VAnalog

Relay NO

(Set Pr to

8.25

Pr )

15.14

Regen Drive

21

0V

22

+24V Out

23

V Digital

24

Drive

Healthy

aux2

aux 1x

Output enable

User

enable

25

6

7

8

9

0

1

igitalI/O 1

igitalI/O 2

igitalI/O 3

igitalI/P 1

igitalI/P 2

igitalI/P 3

nable

V Digital

Drive

Healthy

Speed/T orque Ref

4 - 20mA Current

Loop

otor Thermistor

At ZeroSpeed O/P

Reset

Fwd

Rev

User enable

1

2

3

VAnalog

4

10V Out

5

nalog I/P 1+

6

nalog I/P 1-

7

nalog I/P 2

8

nalog I/P 3

9

nalog O/P 1

0

nalog O/P 2

1

VAnalog

1

V

2

24V Out

3

V Digital

4

igitalI/O 1

5

igitalI/O 2

6

igitalI/O 3

7

igitalI/P 1

8

igitalI/P 2

9

igitalI/P 3

0

nable

1

V Digital

Relay NO

otoring Drive

UnidriveRegenInstallation Guide 9

Issue Number: 2 www.controltechniques.com

Page 14

5 Components

The following parts are required to assemble a Unidrive Regen system:

•Motoringdrive

• Regendrive

• Regeninductor

• Softstart resistor

• Contactors,MCBs and overload

• Switching frequency filter (optional)

• RFIfilter (optional)

•Varistors

• Fuses

NOTE

The Regen inductor and softstart resistor duty cycle is very arduous. Therefore, correct component selection is critical. The most sensitive aspects

are line-inductorlinearity, saturation currentand resistor-energypulse rating.Only inductorsandsoftstart resistors as specified in this Installation

Guide should be used.

5.1 Motoring drive

Unidrive in Open Loop,Closed Loop or Servomode. Any software version.

This controlsthemotor by convertingthe DC bus voltagetoa variable voltage, variable frequency supply. Power flowis betweenthe DC bus and the

motor. TherearenoACsupply connections.

5.2 Regen drive

Unidrive in Regen mode. (Must be software version 2.10.04 or higher).

The Regen drive converts the AC supply to a regulated DC voltage. It also provides bi-directional power flow and sinusoidal input currents.

5.3 Regen inductor

The Regen inductor supports the difference between the PWM voltage from the Regen drive and sinusoidal voltage from the supply.

NOTE

Regen inductors are special parts. Under no circumstances must a part be used other than those listed in Table 5-1.

Table 5-1 3-phase Regen inductors

Drive Model

N

N

Rated

power

kW A rms mH

UNI 1405 4 9.5 6.3 1 4401-0001

UNI 2401 5.5 12 5.0 1 4401-0002

UNI 2402 7.5 16 3.75 1 4401-0003

UNI 2403 11 25 2.4 1 4401-0004

UNI 3401 15 34 1.76 1 4401-0005

UNI 3402 18.5 40 1.5 1 4401-0006

UNI 3403 22 46 1.3 1 4401-0007

UNI 3404 30 60 1.0 1 4401-0008

UNI 3405 37 70 0.78 1 4401-0009

UNI 4401 45 96 0.63 1 4401-0010

UNI 4402 55 124 0.48 1 4401-0011

UNI 4403 75 156 0.38 1 4401-0012

UNI 4404 90 180 0.33 1 4401-0013

UNI 4405 110 202 0.30 1 4401-0014

UNI 5401 160 300 0.24 1 4401-0015

Rated

current

Inductance

Number

requiredper

Regen drive

CT

part number

10 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 15

5.4 Softstart resistor

The start-up circuit limits the amountofcurrent flowing intothe DCbusoftheRegen driveandinto the motoring drives.

5.4.1 Single systems

The softstart resistor for singleRegen applications mustbeasspecifiedin the following table. Energyrating andoverload are non-standard and both

are important.

Table 5-2 Single Regen, single motoring, Unidrive size 1 to 5

Drive

size

1 1 150 1270-3157 150

2 1 150 1270-3157 150

3 1 48 1270-2483 48

4 2 24 1270-2483 48

5 2 24 1270-2483 48

Table 5-3 Softstart resistor data

Drive size Resistors Rms current

1 1270-3157 0.4 5

2 1270-3157 0.4 5

3 1270-2483 0.5 15

4 1270-2483 x 2 0.6 32

5 1270-2483 x 2 1.2 32

The above figures havebeencalculatedassumingapeak supply voltage of480Vac +10%.Refer alsoto AppendixBComponent Sizing Calculations.

Number of

parallel resistors

5.4.2 Multiple systems

In nonstandardcases,e.g. multiple motoring, multipleRegen systems, thesoft-start resistor sizeand ratingmust be recalculated due to thecharging

characteristics changing. For the method of calculating the new resistor size and rating, refer to Appendix B Component sizing calculations on

page 36.

5.4.3 Protection

Protection for the softstart circuit is provided using a thermal overload to protect against a high impedance short circuit, and a separate magnetic

overload to protectagainst a directshort circuit.For multiplesystems the softstartresistorsizemustberecalculated resulting in resizing of the

thermalmagnetic overload required. Refer to Appendix B Component sizing calculations on page 36.

Table 5-4 Thermal magnetic overload

Drivesize Rated CurrentARated Voltage

1 & 2 0.3 480 1 4133-0117

3 1 480 1 4133-0217

4 & 5 2 480 1 4133-0277

Totalvalue Resistors

Ω CT part number Value Ω

Charging current

Vac

A

Number of

Poles

A

CT part number

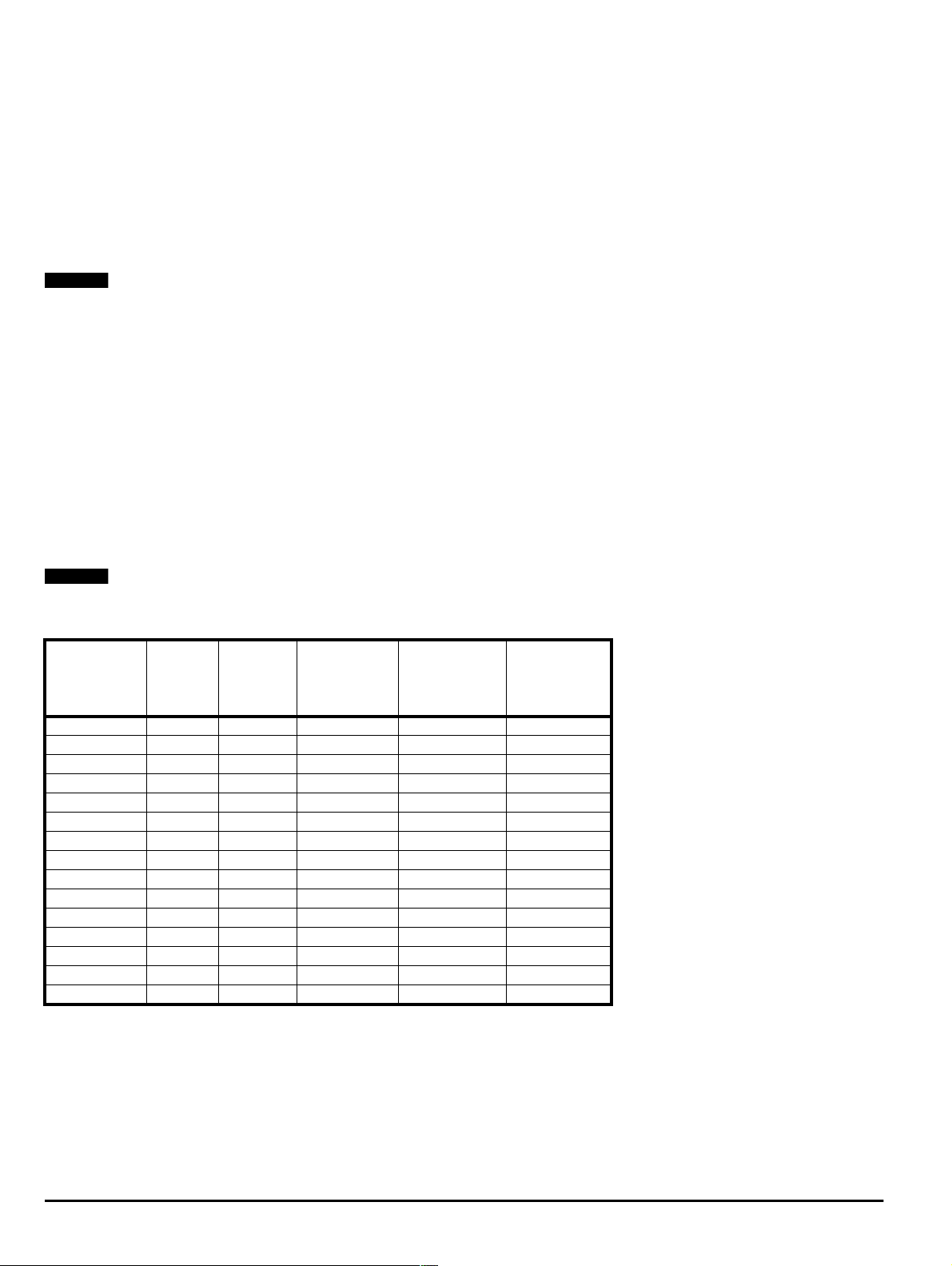

5.5 Contactors, MCBs and overload

Contactors and MCBs are required as follows:

Table 5-5 Contactors and MCBs

Function Ref Description Specification

3 pole NO + auxiliary NO

Main contactor K2

Auxiliary

contactor

Switching

frequency filter

MCB

Thermal

magnetic

overload

MCB 1x is fitted between the switching frequency filter capacitors and the AC supply. The MCB should have an auxiliary which the enable for the

Regen and motoring drive is connected through. This will act as a safe guard and prevent the system running with a fault on the switching frequency

filter. Also refertoAppendix B Component sizing calculations on page36.

contact. Coil voltage selected

to suit available supply.

K3 2 pole NC + auxiliary NO

MCB

3 pole + auxiliary NC

1x

Ovld Single pole

UnidriveRegenInstallationGuide 11

Issue Number: 2 www.controltechniques.com

Current ratingequal to totalcurrentrequirement.

Voltage rating equaltoAC mains supplyvoltage.

Coil mustnotexceed 240Vac5A resistiveload.

Installation category 1.

Currentrating sized to rms currentof switchingfrequency filter

capacitors andchargingcurrent at powerup.

(Refer to Table 5-6).

Sized to thesoftstart resistortoprotect thermally and

magnetically.(Refer to Appendix B Componentsizing

calculations on page 36).

Page 16

5.6 Switching frequency filter

The AC input terminals of a Regen drive produce a PWM output voltage, which has a sinusoidal component at line frequency, plus significant

harmonics at the switching frequency and its multiples.

This filter prevents switching frequency harmonic currents gettingbackinto the supply. If the filter is notfitted, the presence of currents in the kHz

regioncould cause supply problemsordisturbance to otherequipment.

NOTE

The switching frequencyfilter inductors needtobe rated to the totalcurrent requirement.

The followinginductorsarestandard 3-phase inductors(ratedatdrive ratedcurrentfora singleRegensystem or rated at total currentrequirementfor

multiple Regensystem), they carry only 50/60Hzcurrentwith a negligible amountof highfrequency current.

The capacitors specified below are suitable for operation at any switching frequency. These capacitors are sized for operation at 3kHz however

operation above 3kHz is possible with the capacitors being more effective.

Table 5-6 Switching frequency filter

N

Drive 3-phase inductor 3-phase capacitor MCB rating

Rated

Model

UNI 1405 9.5 3.160 4401-0162

UNI 2401 12 2.500 4401-0163 31

UNI 2402 16 1.875 4401-0164 36

UNI 2403 25 1.200 4401-0165 45

UNI 3401 34 0.880 4401-0166

UNI 3402 40 0.750 4401-0167 115

UNI 3403 46 0.650 4401-0168 124

UNI 3404 60 0.500 4401-0169 142

UNI 3405 70 0.390 4401-0170 160

UNI 4401 96 0.315 4401-0171

UNI 4402 124 0.240 4401-0172 262

UNI 4403 156 0.190 4401-0173 325

UNI 4404 180 0.165 4401-0174 348

UNI 4405 202 0.135 4401-0175 385

UNI 5401 300 0.100 4401-0176 80 (x1)

UNI 5402 600 0.050 4401-0177 80 (x2) 580

UNI 5403 900 0.034 4401-0178 80 (x3) 580

UNI 5404 1200 0.025 4401-0179 80 (x4) 580

UNI 540

current

AmH µFAA

X

300 x

Lfilt

X

0.100 /

CT part

number

X

Cfilt

5.7 1610 - 5752 2.1

24 1665 - 2244 15

48 1665 - 2484 25

80 (xX)580

CT part

number

1665 - 2804

rms

current

35 per

capacitor

Peak

current

28

106

252

580

X

= number of size 5 drives

5.6.1 Protection

An MCB shouldbefitted between the AC supplyand the capacitor.This is to protect thewiring betweenthecapacitorandthemainbus bar.

NOTE

For multiple Regen systems, refertoAppendix B Component sizing calculations on page 36 for sizing of the MCB.

N

12 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 17

5.7 RFI filter

E

In common withconventional drives, significantground currentsaregeneratedby the capacitance of the motorto ground, themotor cablesto ground,

and the drivepower circuits to t heir heatsinks.The RFIfilter willprovide a relatively shortr eturn path for ground currents back to the drivespower

circuit.

Table 5-7 RFI filter data

CT Model

Number

UNI1405 480 4 10

UNI2401 to 2402 480 7.5 16

UNI2403 480 11 25

UNI3401 to 3403 480 22 50 Book End 100 4200-6116

UNI3404 480 30 63 B ook End 100 4200-6117

UNI3405 480 37 100 Book End 100 4200-6106

UNI4401 to 4402 480 55 150 Book End 100 4200-6107

UNI4403 to 4404 480 90 180 Book End 100 4200-6111

UNI4405 480 110 220 BookEnd 100 4200-6112

UNI5401 480 160 300 BookEnd 100 4200-6115

Volts

Vac kW A m

Maximum

power

Filter

current

rating

Mounting style

Book End 100 4200-6105

Footprint or Book End 100 4200-6104

Book End 100 4200-6109

Footprint or Book End 100 4200-6108

Book End 100 4200-6114

Footprint or Book End 100 4200-6113

Motor

cable

length

CT part

number

Do not use an RFI filter without the specified switching frequency filter, as failure of the RFI filter will occur, due to the switching currents.

CAUTION

5.8 Varistors

AC line voltage transients can typically be caused by the switching of large items of plant, or by lightning strikes on another part of the supply system.

If thesetransientsare not suppressed, they cancause damagetotheinsulation of the Regen inputinductors,orto the Unidrive Regen drive

electronics.

Table 5-8 Varistors

Configuration

Line to line 1 to 5 550 400 Z500NS 3 2482-1501

Line to ground 1 to 5 680 450 Z680LNS 3 2482-0680

NOTE

Seven varistors are requiredwhen operating with an IT supplyas shown in Figure3-1 on page 5, Figure 3-2 on page 6 and Figure A-2 on page 32.

N

Drive

size

Varistor

voltage

Vac J

5.8.1 Configuration

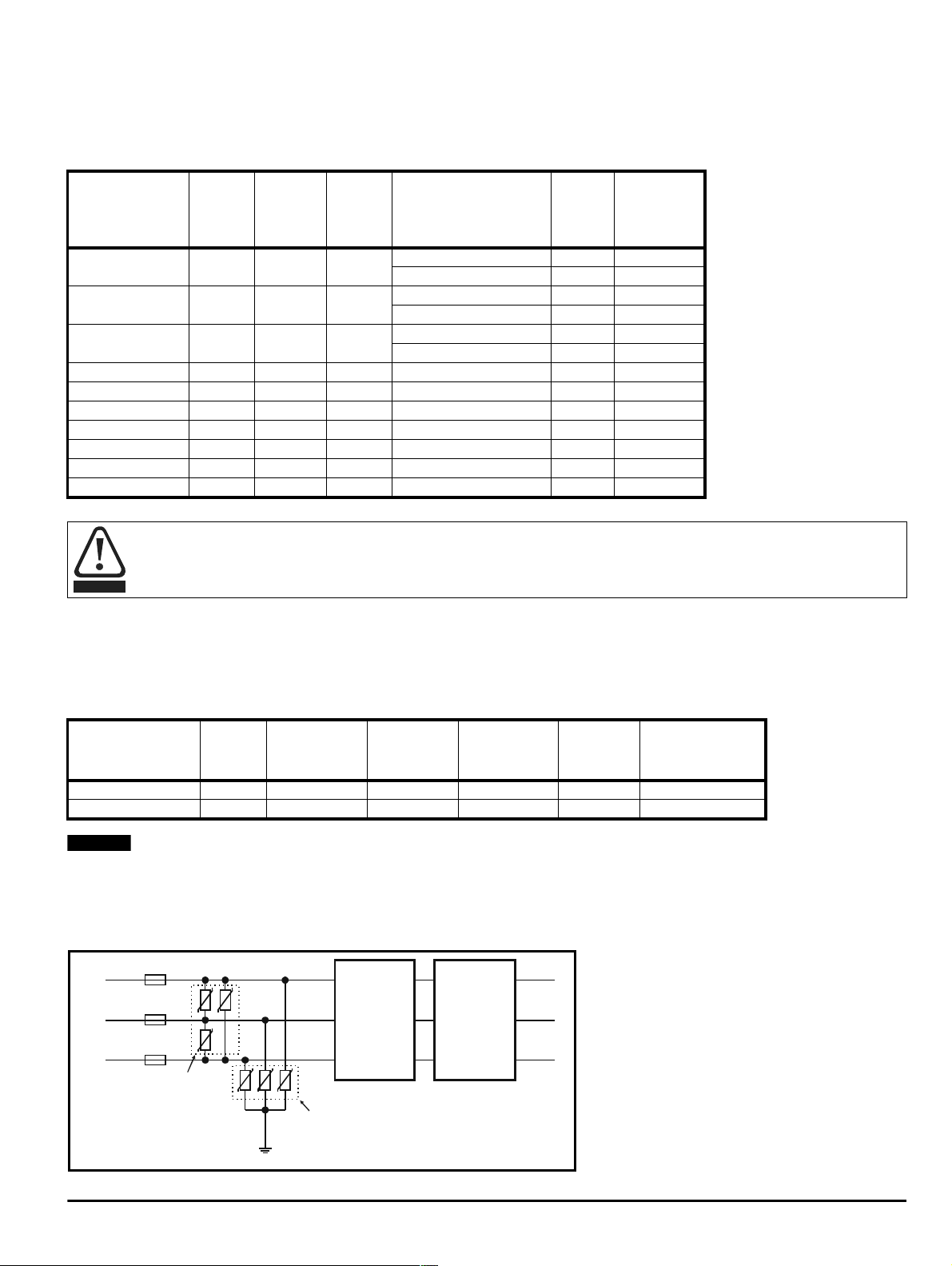

Varistors should be fitted after the supply fuses, as shown in Figure 5-1:

Figure 5-1 Fitting of Varistors

Fuses Varistors

R

Y

B

550Vac

varistors

680Vac

varistors

RFI

Filter

Varistor

energy

Type number Quantity CT part number

Switching

Frequency

Filter

UnidriveRegenInstallationGuide 13

Issue Number: 2 www.controltechniques.com

Page 18

5.9 Fusing

RegenInductor

+DC-DC+DC-DCUVW

RegenDriveMotoringDrive

DCBusFusing

RegenInductor+DC-DC

+DC-D

C

+DC-DCUVW

RegenDriveM

o

D

M

o

D

Fusing for the Regen systemis requiredinorder to protectthefollowing:

• Supply transformer

• Supply cables

• Regeninductor

• Regendrive

•Motoringdrive

In the event of failure, the fusing will prevent fire by limiting the amount of energy allowed into the Regen and motoring drive units. The AC supply

fusingshouldberatedtotheRegensystem’scontinuousratedcurrent.TheRegenACfusingwhenusedwitheachmultiplesize5Regendrive

should be ratedtothe 450Acontinuousrated currentof the drive. The +

motoring driveratedcurrent and >

750Vdc.

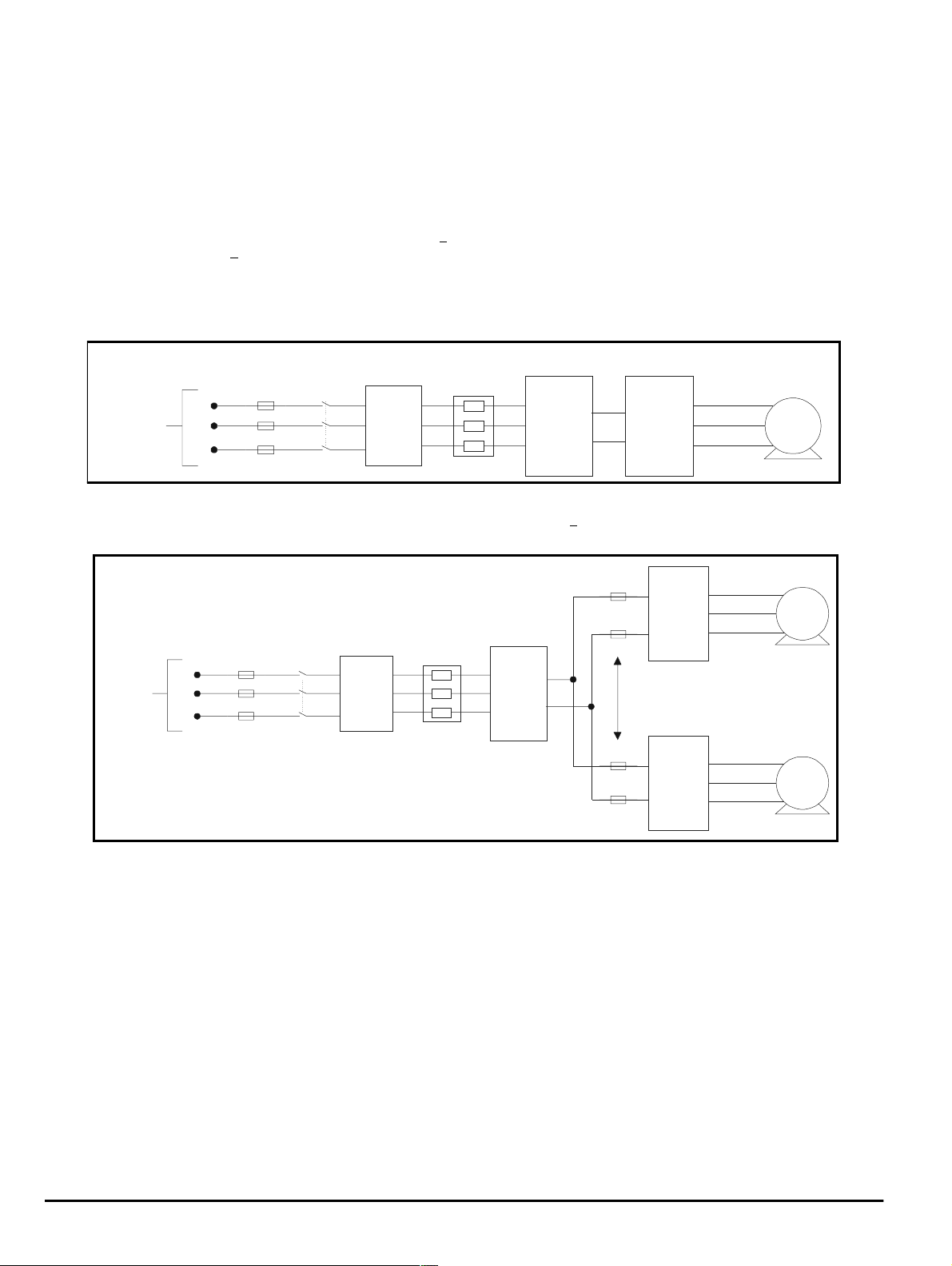

5.9.1 Standard systems

FusingforastandardRegen system,single Regen plussingle motoring drive (both drives of the same rating)should consistofACsupply fusingas

shown below:

Figure 5-2 Fusing: Standard systems

DCbusfusingwhenusedwithmultiplemotoringdrivesshouldberatedto2x

3 Phase

Supply

AC

Supply

Fusing

R

Y

B

Main

Contactor

Additional

Circuitry

U

V

W

M

5.9.2 Multiple size 1 to 4 motoring drives

When a Regensystem consists of multiplesize 1 to 4 motoringdrives, AC supplyfusing and +DCbusfusingshouldbefittedasshownbelow:

Figure 5-3 Fusing: Multiple size 1 to 4 motoringdrives Regen system

toring

rive

U

3Phase

Supply

V

AC

Supply

R

Fusing

Y

Main

Contactor

Additional

Circuitry

W

B

toring

rive

U

V

W

M

M

14 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 19

5.9.3 Multiple size 5 Regen

M

DCBusFusingRegenACFusin

g

+DC-DCUVW+DC-DCUV

W

MotoringDriveMotoringDriv

e

When a Regensystem consists of multiple size 5 Regen andmotoring drives, AC supplyfusing and -DC bus fusing should be fitted as shownbelow:

Figure 5-4 Fusing: Multiple size 5 Regen system

3 Phase

Supply

Regen

Inductor

AC

Supply

R

Fusing

Y

Main

Contactor

Additional

Circuitry

Regen

Drive

U

+DC

V

W

-DC

B

Regen

Drive

U

+DC

V

-DC

W

Regen

Inductor

Output

Sharing

Choke

Output

Sharing

Choke

UnidriveRegenInstallationGuide 15

Issue Number: 2 www.controltechniques.com

Page 20

6 Important considerations

6.1 Fundamentals

6.1.1 You must

• UseRegen inductors of the correct type and value,as specified.

• Usea start-up resistor of the correcttype and value,asspecified.

• Connect the Regendrive outputenable signal to the enableinput on the motoring drive(s).

• Use a switching frequency filter if an RFI filter is present or the AC supply is not dedicated solely to the Regendrive.

• Fitfuses where specified,andensure they are of thecorrect rating.

• Ensure that the cubicle is correctly sized andventilated, taking into accountthelosses generated by all of thecircuit components.

6.1.2 You must not

• Connect a circuitofanytype between a Regenandmotoring drive’s DC bus.

• Attempt to use a Unidrive size 1-4 Regen in parallel configuration (only Unidrive size 5 Regen can be used in parallel configuration).

6.2 Unidrivesize3and4

If a Unidrive size 3 or 4 of anyothervariantexcept the Regenvariant istobe usedin a Regen system,aninternalmodificationisrequiredtoboth the

Regen and motoring drive(s).

Damage to the drive(s) will result if this modification is not carried out.

CAUTION

NOTE

Modification of the drive must only be carried out by CT authorised personnel. If any details are required,contact C.T. Technicalsupport.

N

6.3 Ventilation

When designing a RegenSystem, considerations must be made fortheadditionalventilation requirements due to the introduction of the Regen and

Switching Frequency filter inductors.

The inductors have normal operating temperatures of approx. 150°C depending upon the ambient and the motor cable lengths. Care must

be taken so that this does not create a fire risk.

CAUTION

A Regen System can operateinanambient temperaturerange of 0°C to 50°C (32°F to 122°F) forUnidrivesizes 1 to 5. An output currentderating

must be applied with ambient temperatures between 40°C and 50°C. For derating figuresseetheUnidriveSize1to5UserGuide.

Ventilation for both the Regen and motoring drives in the system should be as specified in the UnidriveSize1to 5 User Guide.Providedthe

maximum cablelengthsin Table 6-3 onpage 18 havenotbeen exceeded, natural airflowventilationthrough theRegen and switching frequencyfilter

inductors is adequate. In special conditions, where themaximum cablelength (refer to Table6-3 on page 18) has been exceeded, forcedcooling

should be introducedf or the Regen Inductora s specif ied in Appendix C Long cableson page 41.

When sizingthe cubicle(s)for the Regen systemconsiderations mustbe madeforthe systems losses.

System Losses Documented In...

RFI Filter

Regen drive

Motoring drive

Control Module, Unidrive size 5

PowerModule, Unidrive size 5

UnidriveSize1to5UserGuide

16 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 21

Table 6-1 3-phase Regeninductor

Drive size

UNI 1405 9.5 6.3 1 4401-0001 125

UNI 2401 12 5.0 1 4401-0002 146

UNI 2402 16 3.75 1 4401-0003 175

UNI 2403 25 2.4 1 4401-0004 210

UNI 3401 34 1.76 1 4401-0005 285

UNI 3402 40 1.5 1 4401-0006 310

UNI 3403 46 1.3 1 4401-0007 320

UNI 3404 60 1.0 1 4401-0008 345

UNI 3405 70 0.78 1 4401-0009 415

UNI 4401 96 0.63 1 4401-0010 515

UNI 4402 124 0.48 1 4401-0011 585

UNI 4403 156 0.38 1 4401-0012 645

UNI 4404 180 0.33 1 4401-0013 775

UNI 4405 220 0.30 1 4401-0014 845

UNI 5401 300 0.24 1 4401-0015 1760

Table 6-2 3-phase switching frequency filter inductor

Drive size

UNI 1405 9.5 3.160 1 4401-0162 28

UNI 2401 12 2.500 1 4401-0163 35

UNI 2402 16 1.875 1 4401-0164 37

UNI 2403 25 1.200 1 4401-0165 40

UNI 3401 34 0.880 1 4401-0166 52

UNI 3402 40 0.750 1 4401-0167 60

UNI 3403 46 0.650 1 4401-0168 60

UNI 3404 60 0.500 1 4401-0169 80

UNI 3405 70 0.390 1 4401-0170 90

UNI 4401 96 0.315 1 4401-0171 100

UNI 4402 124 0.240 1 4401-0172 110

UNI 4403 156 0.190 1 4401-0173 130

UNI 4404 180 0.165 1 4401-0174 170

UNI 4405 220 0.135 1 4401-0175 180

UNI 5401 300 0.100 1 4401-0176 220

UNI 5402 600 0.050 1 4401-0177 400

UNI 5403 900 0.034 1 4401-0178 530

UNI 5404 1200 0.025 1 4401-0179 700

Rated current Inductance

A rms mH W

Rated current Inductance

A rms mH W

No perRegen

Drive

No perRegen

Drive

CT

part number

CT

part number

Total

losses

Total

losses

6.4 Cable length restrictions

There are 3 significant cable lengths which must be taken into account when designing a Regen system. Refer to Figure 6-1 on page 18.

6.4.1 AC supply conne ction

A is the AC cable length between the Regen inductor and the Regen drives terminals.

In general, no specialprecautions are necessary for the AC supplywiring in respect to the Regendrive. However the voltage in the wiring between

the Regen inductor and the Regen drive terminals is a source of radio frequency emission. To minimise emissions, these cables should be kept as

shortas possible. Ideally, the inductors should be mounted closetothedrive terminals.

If it is necessary to use a cable longerthan 5m, a screened cable should be used with the screen grounded as shown inFigure 6-1 on page 18.

6.4.2 DC bus connection

B is the DC bus connection between the Regen and motoring drive, the + DC bus connections between the drives should be treated as a single two

core cableandnott wo individualcable / bus bar lengths.

The DC poweroutput from theUnidrive which is used as the inputstage to the motoring drive(s) carries a common-mode high frequency voltage

comparable withtheoutput voltage from a standard drive. Allprecautionsrecommended for motor cablesmust also be appliedtoallcables

connected to this DC circuit.

UnidriveRegenInstallationGuide 17

Issue Number: 2 www.controltechniques.com

Page 22

If it is necessary to use a cable longer than 5m, a screenedcable should beusedwith the screengrounded as showninFigure 6-1.

RBYE

E

6.4.3 Motor connection

C is the AC cable length between the motoring drive and the motor.

Figure 6-1 Calculating the cable length of the Regen system

B

Regen

Drive

L1L2L3 WVU

E E

A C

Regen

Inductor

-DC

+DC

E

E

E

Motoring

L1L2L3 WVU

Motor

Drive

+DC

-DC

E

6.4.4 Maximum cable l eng th

The sum total length of the DC bus and motor cables (B and C in Figure 6-1)must not exceedthe values showninthetable below:

Table6-3 Cablelengths

Regen drive size

14 50

25.5-11 100

3 15 - 37 200

445-110 200

5 132 200 per Regen drive

Power rating Maximum cable length

kW m

If the cablelength in the abovetable is exceeded, additi onal components are required. Referto Appendix C Longcables on page 41.

18 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 23

7 Unidrive Regen EMC information

7.1 Immunity

Theimmunityof theindividual drivemodulesisnot affected byoperationin the regenerativemode.See driveEMC data sheets forfurtherinformation.

This Guide recommendstheuse of varistors between the incoming AC supply lines. These are strongly recommendedtoprotect thedrive from

surgescaused by lightning activityand/ or mains supply switching operations.

Since the regenerative input stage must remain synchronised to the supply, there is a limit to the permitted rate of change of supply frequency. If rates

of change exceeding 100Hz/s are expected then C.T .Technical Support should be consulted. This would only arise under exceptional circumstances

e.g. where the power system is suppliedfrom an individual generator.

7.2 Emission

Emissionoccurs over a wide range of frequencies.The effects are dividedinto three maincategories:

• Low frequency effects, such as supply harmonics and notching

• High frequency emission below30MHz where emissio n is predominantly by conduction

• High frequency emission above 30MHzwhere emissionis predominantly by radiation

7.3 Dedicated supplies

The natureofthe mains supplyhasanimportant effectontheEMCarrangements.For a dedicated supply, i.e. one whichhasnoother electrical

equipment fed from the secondary of its distribution transformer, normally neither an RFI filter or a switching frequency filter are required. Refer to

section3.2.2 Supply assessment on page 7.

7.4 Other supplies

Wherever otherequipment shares the samelowvoltagesupply, i.e. 400Vac, careful considerationmust be giventothelikelyneedforboth switching

frequency and RFI filters, as explained in section 7.7 Switching frequency emission and section 7.8 Conducted RF emission .

7.5 Supply voltage notching

Because of the use of input inductors and an active rectifier the drive causes no notching - but see section 7.7 Switching frequency emission for

adviceon switchi ng frequency emission.

7.6 Supply harmonics

When operated from a balanced sinusoidal three-phase supply, the regenerative Unidrive generates minimal harmonic current.

Imbalance between phase voltages willcausethe drive to generate some harmonic current. Existingvoltageharmonicsonthepower system will

cause some harmonic current to flow from the supply into the drive. Note that this latter effect is not an emission, but it may be difficult to distinguish

between incoming andoutgoingharmoniccurrent in a site measurementunlessaccuratephase angledata is availablefor theharmonics.No general

rule can be givenforthese effects, but the generated harmonic current levelswill always be smallcomparedwiththose causedby a conventional

drive with rectifier input.

7.7 Switching frequency emission

The Regendrive uses a PWM technique to generate a sinusoidalinput voltagephase-locked to the mainssupply. The input current theref ore

contains no harmonics of the supply unless thesupply itself contains harmonics or is unbalanced. It doeshowever contain current at the switching

frequency and itsharmonics,modulatedbythe supply frequency. For example, witha 3kHzswitching frequencyand50Hz supplyfrequency there is

current at 2.95, 3.15,5.95, 6.05kHzetc. The switching frequency is not related to that of the supply, so the emission will not be a true harmonic - it is

sometimes referred to as an “interharmonic”. The possible effect of this current is similartothat of a high-orderharmonic, and it spreads throughthe

powersystemina manner depending on theassociatedimpedances.T he internal impedance oftheRegen driveis dominatedby the seriesinductors

at the input.The voltage produced at switching frequency at the supply point is therefore determined bythepotentialdivideraction of the series

inductors and the supply impedance; section3.2.2 Supply assessment on page 7 gives guidelines to help in assessing whether a switching-

frequency filter is required. In case of doubt,unless the driveoperatesfromadedicated supply not shared with otherloads, it is strongly

recommended that the filterbefitted.

Failure to fit a switching frequencyfilter may result in damage to other equipment, e.g. fluorescentlight fittings, powerfactor correction

capacitors and RFI filters.

CAUTION

7.8 Conducted RF emission

Radiofrequency emission in the frequency rangefrom 150kHz to 30MHzismainly conducted out of the equipment through electrical wiring. It is

essentia l for compliance withall emissionstandards,except forIEC61800-3second environment, that the recommendedRFI f ilter and a shielded

(screened) motor cable are used.Most types of cablecan be used providedit has an overall screen. For example, the screenformed by the

armouring of steel wired armoured cable is acceptable. The capacitance of the cable forms a load on the drive and should be kept to a minimum.

UnidriveRegenInstallationGuide 19

Issue Number: 2 www.controltechniques.com

Page 24

When an RFI filter is used the switching frequency filter discussed above must also be used. Failure to observe this may result in the RFI

filter becoming ineffective and being damaged.

CAUTION

When used with the recommended filters, the Regendrive systemcomplies with the requirements for conductedemissionin thefollowingstandards:

Table 7-1 Requirements for conducted emission

Motor cable length (m)

1.5 I

100 I

Key to

table

I

1 The first environment is one where the low voltage supply network also supplies domestic premises

2 Restricted distribution means thatdrives areavailableonly to installers withEMCcompetence

For installation in the “second environment”, i.e.where the low voltage supply network doesnot supply domestic premises, no filterisrequiredin

ordertomeetIEC61800-3 (EN61800-3):1996.

Standard Description

EN50081-2

EN61800-3

IEC1800-3

Generic emission standard

for the industrial

environment

Productstandard for

adjustable speed power

drive systems

Switching frequency (kHz)

3

Frequency

range

0.15 - 0.5MHz

0.5 -30MHz

Inputcurrent >25A:Requirements for thefirstenvironment

Inputcurrent<25A: Requirements forthe firstenvironment

Limits Application

79dBµV quasi peak

66dBµVaverage

73dBµV quasi peak

60dBµVaverage

Unrestricted distribution

distribution

AC supply lines

1

:

2

: Restricted

Operation without a filter is a practical cost-effective possibility in an industrial installation where existing levels of electrical noise are likely

to be high, andany electronic equipment in operation has been designed for such an environment. Thereis somerisk of disturbance to

otherequipment,and inthis case theuser andsupplierof the drive systemmust jointlytakeresponsibilityfor correctingany problemwhich

CAUTION

occurs.

7.8.1 Recommended RFI filters

These are the same filters as recommended for standard (non-regenerative) operation:

Table 7-2 Recommended filters

Drive

UNI 1405

UNI 2401 - 2402 4200-6109

UNI 2403 4200-6114

UNI 3401 - 3403 4200-6116

UNI 3404 4200-6117

UNI 3405 4200-6106

UNI 4401 - 4402 4200-6107

UNI 4403 - 4404 4200-6111

UNI 4405 4200-6112

UNI 5401 4200-6115

Motor cable

length m

100

RFI filter:

C.T.part number

4200-6105

7.8.2 Related produc t standards

The conducted emission levelsspecifiedin EN50081-2areequivalent to the levelsrequiredby thefollowingproduct specific standar ds:

Table 7-3 Conducted emission from 150kHz to 30MHz

Generic standard Product standard

EN50081-2

EN55011 Class A Group 1

CISPR 11 Class A Group 1

EN55022 Class A

CISPR 22 Class A

Industrial, scientific and medical

equipment

Informationtechnology

equipment

20 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 25

7.9 Radiated emission

Radio frequency emission in the frequency range from 30MHz to 1GHz is mainly radiated directly from the equipment and from the wiring in its

immediate vicinity. Operation in regenerative mode does not alter the radiated emission behaviour, and the EMC data sheet for the individual

Unidrives used should be consulted for further information.

NOTE

Theoretically the use of two drives physically close together can cause an increase in emission level of 3dB compared with a single drive, although

thisisusuallynot observed in practice. All Unidriveshavesufficient margin in respect of thegenericstandardfor theindustrialenvironment EN500812 to allow forthis increase.

N

7.10 Wiring guidelines

The wiring guidelines provided for the individual drives alsoapply to regenerative operation,except thattheswitchingfrequency filter must be

interposed between the input drive and the RFI filter. The same principles apply, the most important aspect being that the input connections to the RFI

filtershould be carefully segregatedfromthe power wiring of the drives which carriesa relatively high “noise”voltage.

7.11 Multi-drive systems

It is common for regenerative drive systems to be constructed using numbers of drives with a single input stage, or other more complex

arrangements.I t is generallynotpossibleto laydownspecificEMCrequirements for suchsystems, sincethey are too largeforstandardisedtests to

be carriedout. In many cases the environmentcorresponds to the “secondenvironment” as described in IEC61800-3, in which case no specific limit

to conducted emission is required.National legisla tion such asthe European UnionEMCDirectivedoes not usuallyrequire thatcomplex installations

meet specific standards, but onlythat they meettheessential protectionrequirements, i.e.not to cause or sufferfrom electromagnetic interference.

Where the environment is known to include equipment which is sensitive to electromagnetic disturbance, or the low voltage supply network is shared

withdomestic dwellings,then precautions should be takento minimiseconductedradio frequency emission by the useofafilter at the systempower

input. For current up to 300A the Control Techniques filters listed previously are suitable.

For currents exceeding300Aup to 2400A suitable filters are available from thefollowing manufacturers:

Siemens B84143.A250.S(range up to 2500A)

Schaffner FN3359-300-99 (range up to 2400A)

These filters may not give strict conformity with EN50081-2, but in conjunction with the relevant EMC installation guidelines they will reduce emission

to sufficiently low levels to minimise the risk of disturbance.

UnidriveRegenInstallationGuide 21

Issue Number: 2 www.controltechniques.com

Page 26

8 Parameter descriptions

Key to parameter codes:

ô

ð

RW Read/Write

RO Read Only

Bit Two stateonlyparameter,0or1.

Bi Bipolar - can have positive and negative values.

Uni Unipolar - can have positive values only.

Txt Parameter value is represented on the display with strings of Text.

P ParameterisProtectedfrom beingcontrolledbyprogrammable inputs

Notethatthe equivalent Menu 0 parameter appears in the box preceding the parameterdescription.

8.1 Menu 15: S inusoidal rectifier

A Unidrive can be used as a sinusoidal input current powerunit to supplyoneormore Unidrives via their DC buses. When this mode is selected as

the drive type, menu 15 appears. This menu is used to set up the Unidrive. At the same time, menu 0 defaults to showing Pr 15.01 to Pr 15.13asPr

0.11 to Pr 0.28.

Range of values

Default value

and functions.

15.01

ô

This parameter gives the rms phasecurrent fromthesupply. Thesinusoidal rectifier controls the currentsothatthe fundamental current and voltage

are in phase at the power terminals of the drive. There is a small phase shift across the input inductors, and so the current magnitude and the real

component ofcurrentare approximatelyequal.Ifpower isflowing intothesinusoidalrectifierthe currentmagnitudeisnegative,andif poweris flowing

out (back into the supply) the current magnitude is positive.

15.02

ô

When the sinusoidal rectifier unit is active the supply voltage is given by this parameter. If the unit is not active this parameter shows zero.

0.11 Supply current magnitude

± Maximum drive current

0.12 Supply voltage

0to528

ð

ð

AROBi P

Vac RO Uni P

15.03 0.13 Supply power

± Drive max. current x 5.09 x √3/1000

ô

T otalsupply power of the drive is calculated from the product of the line voltage and current which is equivalent to 15.01 x 15.02x √3. Note that as the

powerfactor is approximately unity the powerisequal to the volt-amperes. The power shownis that flowing out of the drive, hence whenpower is

flowing from the supplytotheRegen drivePr 15.03 is negative, and when power is flowing from the Regen drive back into the supply Pr 15.03 is

positive.

ð

kW RO Bi

15.04 0.14 DC bus voltage

ô

Voltage at the DC output of the drive.

15.05

ô

When the sinusoidal rectifier unit is active this parameter givesthesupply frequency. P ositive values indicate positivephase sequence andnegative

values indicatenegative phasesequ ence. If the unit is not active this parameter shows zero.

0to830

0.15 Supply frequency

±100

ð

ð

Vdc RO Uni P

Hz RO Bi P

22 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 27

15.06

0.16 Input inductance

ô

At power-up this parameter is zero. Each time the unit is enabled the supply inductance is measured and displayed by this parameter. The value

given includes the supply inductance and the inductors inserted at the supply to the sinusoidal rectifier unit. The value given is only approximate, but

willgiveanindication as to whether the input inductance is correct for the sinusoidal rectifier unitsize.

15.07

ô

The sinusoidal rectifier unit will attempt to hold the DC bus at the level specified by this parameter. The higher the bus voltage the better the

performanceof the unit as there willbemorevoltage availabletocontrol theinput current. The bus voltage must always be higher than thepeakof

the line to line supply voltage if the unit is to operate correctly. T he voltagecanbeset to a levelupto800V,but this only leaves 30Vheadroom below

the over-voltage trip level.Thereforeit is bestto use the defaultvalue of700Vunless the supplyvoltageissuch that itmustberaised above thislevel.

Supply voltage

15.08

ô

This parameter sets the PWM frequency and also determines the sample frequency for loops.

The sampling frequency of the control system is based on the switching frequencies as follows:

Current control

DC bus voltage control and synchronisation with the supply

0.001 to 100

ð

0.17 DC bus voltage set-point

0to800

Minimum

Vac

380 650 700 800

415 680 700 800

480 780 780 800

Vdc

700 Vdc RW Uni

ð

0.18 Switching frequency

0 to 4: [3, 4.5, 6, 9, 12]

Switching frequency

kHz

3 3

4.5 4.5

66

94.5

12 6

Switching frequency

kHz

3 3

4.5 2.25

63

92.25

12 3

0:[3kHz] kHz RW Txt P

ð

mH RO Uni P

Recommended

Vdc

Control frequency

kHz

Control frequency

kHz

Maximum

Vdc

15.09

ô

Setting this parameter to 1 modifies the IGBT switching pattern so as to reduce the number of switching events. This has the following effects:

• Slightly reduced power loss in the Regen drive.

• Increased acoustic noisefrom input inductors.

0.19 High stability space vector modulation

0~1

0 RW Bit

ð

UnidriveRegenInstallationGuide 23

Issue Number: 2 www.controltechniques.com

Page 28

15.10

0.20 Quasi-square operation select

0.21

0.22

0~1

Sinusoidal rectifier synch ronising

0~1

Sinusoidal rectifier synch ronised

0~1

ô

The rate at which the DC bus voltage can be reduced by the drive depends on the headroom between the bus voltage and the supply voltage. If

quasi-square mode is selected this headroom can be effectively increased at some points within a supply cycle. This can give better performance,

particularly when the supply voltage is high or the bus voltage set-point is low.

15.11

ô

When the drive is enableditmustdetect thephase and frequencyof the mains. During this period this bit is set.Oncesynchronisationhas been

completed successfully this bit is cleared. If the supply is very severely distorted or a phase is missing the drive will repeatedly attempt to synchronise

untilitisdisabled or synchronisation is completed.

15.12

ô

Whenthedrive has beenenabled andsuccessfully synchronisedthis bit willbeset to 1. If the drive isdisabled,theunit tripsordetects thatthemains

is lost,this bit will besetto0.

0 RW Bit

ð

ð

ð

RO Bit

RO Bit

15.13 0.23 Sinusoidal rectifier phase loss

ô

If a supply phase is not presentthesinusoidalrectifier unit will not synchronisewhenitisenabled.However,if a phase is lost after synchronisation

one of thefollowing will occur:

• Lightly loaded: the unit will continue to operate normally.

• Medium load: the unit will continue to operate, but the phase loss bit is set.

• Heavyload: the unit will detect mainsloss,disable itselfandattempt to re-synchronise.

0~1

ð

RO Bit

15.14

ô

When the Regen drive has powered up through the soft start resistor and the DC bus voltage stabilised this bit will change from 0 to 1. This bit must

be routed to a digital output terminal which is used to energise the soft start contactor coil.

15.15

ô

When the close contactor output goes active the soft-start contactor should operate and short out the soft-start resistor. This bit should be set as the

destinat ion parameter foradigital inputconnected to anauxiliarycontacton the soft start contactor. If this inputbecomes inactive whenbit Pr 15.14 is

set then after a 100ms (approx.) delay the drive will inhibit so as to protect the soft-start circuit.

0.24

0.25

Close soft start contactor

0~1

ð

Soft start contactor is closed

0~1

ð

RO Bit

RO Bit

15.16 0.26 Enable motor drive

ô

When theunit has been enabledandsuccessfully synchronisedt his bit willbesetto1. If the Regendrive isdisabled,theunit trips or detects that the

mainsislost, this bitwill set to 0.

This bit should be routed to a digital output and used to enable the motoring drive(s) connected to the DC bus of theRegendrive.

0~1

ð

RO Bit

24 Unidrive Regen Installation Guide

www.controltechniques.com Issue Number: 2

Page 29

15.17

0.27

Line synchronisation trip enable

0.28

0~1

Line synchronisation status

0~5

ô

When the drive is enabled and the main contactor is closed it will try and synchronise the line supply. If this bit is 0 then the drive will continue to try

and synchronise to thelinecontinuallyuntil disabled, even if it does notsynchronisesuccessfully. If this bitis setto a 1 and the drive hasnot

successfully synchronised after trying for 30 seconds then the drive will trip ‘LI.SYNC’.

15.18

ô

This parameter is the linesupply synchronisation status. It is intendedtogivesome diagnostic information ifthe drivef ails to synchronisetothe

supply. If no attempt to synchronise to the supply has been made sincethedrive was switched on, if the driveissynchronised to the supply and

running, or if it has been running then this parameter will show ‘SYNC’. If the drive can not synchronise to the supply then this parameter will show the

reason why synchronisation failed. If the drive does fail to synchronise to the supply the most likely reasons are that the supply is very distorted, or

there are large voltage notches / spikes on the supply.

0SYNCSuccessfullysynchronised to linesupply

1PhDetFailed to correctly detect the phasing of the supply

2FrLoLine frequency too low

3FrHiLine frequency too high

4PLLOIOver current during final synchronisation of PLL to supply

5PLLPhPhasing error duringfinal synchronisation of PLL to supply

0 RO Bit

ð

ð

RO Txt P

15.19 Current control proportional gain

ô

0to30,000

110 RW Uni

ð

15.20 Current control integral gain

N

0to30,000

DR

xRand320xIDRx R (where R is the supply resistance of one phase) should be used.

DR

ô

NOTE

These parameters are only available when the software version is 3.01.07 or higher

When the drive is operated as a Regen drive it uses a DC bus voltage controller with inner current controllers as shown below:

The gainsof thevoltageandcurrent controllersaffect the stability of theRegen drive control system and incorrect gainsettings can result in overvoltage or over-current trips. (The gain of the voltage controller is set by Pr 15.21). In most applications the default gainsgiven for the current

conditions will be suitable, however, it may be necessary forthe user to change these if the inductance or resistance of the supply plus theRegen

inductors variessignificantly fromtheexpected values.

The mostcriticalparameterfor stabilityis the current controllerproportionalgainand the required valuefor this isdependentonthe Regendriveinput

inductance. If the inductanceof the supply is a significant proportion of the recommendedRegeninductor (i.e.>60mH/I

rated current), then the proportional gain may need to be increased. The supply inductance is likely to be negligible compared to the Regen inductor

value with small drives, but is likely to be significant with larger drives. The proportional gain should be adjusted so that

Pr 15.19 = 1800 x Total input L x I

The current controller integral gain is notso critical, and ina majority of casesthedefault valueis suitable. However, if it is necessary to adjustthis

parameter a value between 80 x I

Even whenthegains are set correctly there will be a transient change of DC busvoltage when there is a change in the loadon any drive connected

to the Regendrive. If thepower flow fromthe supplyis increased(i.e. more poweris taken fromthesupply or less power isfed backinto the supply)

the DC bus voltage will fall, but the minimum level will be limited to just below the peak rectified level of the supply provided the maximum rating of the

1,000 RW Uni

ð

.whereIDRis the drive

DR

UnidriveRegenInstallationGuide 25

Issue Number: 2 www.controltechniques.com

Page 30

driveisnot exceeded.I f the powerflowfrom the supplyis reduced (i.e. lesspower istaken from the supplyor morepower is fed backinto thesupply)

the DC bus voltage will rise. During a rapid transient the bus will rise and then fall as shown below:

The exampleshown is for a very rapidload change where the torquereferenceof the motoring drive has been changedinstantly fromonevalue to

another. In most applications where the motoring drive is operating under speed control the speed controller may only require a limited rate of change

of torque demand, reducing the rate of change of power flow, and also reducing the size of the transient voltage. If the set point voltage (Pr 15.07)

plus the transient rise exceed the over-voltage trip level (830V for a medium voltage drive) the Regen drive will trip.