Unidrive M700

Class leading performance

with onboard real-time Ethernet

0.75 kW - 2.8 MW Heavy Duty (1.0 hp - 4,200 hp)

200 V | 400 V | 575 V | 690 V

Unidrive M

Optimized throughput,

open automation

systems, maximum

ease of use

Led by the results of extensive customer-driven market research,

we have tailored six Unidrive M feature-sets to specic application

needs identied within Industrial Automation. The Unidrive M700

provides class-leading motor control for induction, permanent

magnet and servo applications, plus onboard real-time Ethernet.

Unidrive M700 offers an enhanced upgrade for existing Unidrive

SP users.

For more information on the full Unidrive

M family, please download the Unidrive M:

Drives for Industry brochure.

E171230

2

www.emersonindustrial.com/automation

Unidrive M700 features

Range of multi-language LCD

keypads available with up to 4 lines

of text, for easy set-up and superior

diagnostics

Easy click-in keypad connection

Slot for Smartcard / SD Card Adaptor for

parameter, PLC and motion program storage

Terminal cover for DC bus, braking

terminal and EMC lter

Industry standard dual

port Ethernet switch

supporting IEEE 1588 V2

synchronization

Unidrive M701 - RS485

communications

Single screw

removable cover

3 x System Integration

(SI) module slots for

communications, I/O,

additional feedback

devices and automation/

motion controllers

Power on / Drive

status LED

Aluminum chassis

- allows exible

mounting, with

high performance

extruded heatsink

User-friendly power

connections with

removable terminals*

Pluggable control connections

* Features and their locations vary on some drive sizes

www.emersonindustrial.com/automation

Flexible dual port universal encoder

supporting Incremental, SinCos,

SSI, EnDat, HIPERFACE and Resolver

feedback types

User replaceable fan

Robust cable

management

system providing

grounding point for

shielded control and

power cables

3

Unidrive M700

Class leading induction,

permanent magnet and servo

motor performance with

onboard real-time Ethernet

Unidrive M700 provides high performance motor control and

ultimate control exibility in order to satisfy the requirements of

machine builders and high specication industrial and hoisting

applications. M700 offers an enhanced upgrade for existing

Unidrive SP users.

Unidrive M700 benefits:

Maximize throughput with superior motor control

• High bandwidth motor control algorithm for closed loop

induction, permanent magnet and servo motors - 3,000 Hz

current loop bandwidth and 250 Hz speed loop bandwidth

• Flexible speed and position feedback interface supports a

wide range of feedback technologies from robust resolvers

to high resolution encoders

➪ Up to three encoder channels simultaneously e.g. 1

feedback encoder, 1 reference encoder and 1 simulated

output

➪ Quadrature, SinCos (including absolute), SSI, EnDat

(up to 4 Mb with EnDat 2.2 and 100 m of cable as line

compensation is supported) and resolvers

➪ Simulated encoder output can provide position

reference for CAMs, digital lock and electronic gearbox

applications

Optimize system performance with onboard Advanced

Motion Controller

• M700 incorporates an Advanced Motion Controller capable

of controlling 1.5 axes. The motion functions are carried

out ‘on the drive’ so that system performance is maximized

Design flexible centralized and decentralized control

systems

• Onboard PLC for logic programs

• MCi modules can be added to execute larger programs for

advanced system control capability

• Machine Control Studio is an industry standard IEC61131-3

programming environment for efcient system design and

conguration

• Integrated dual port Ethernet switch provides simple

connectivity using standard connections

• Onboard real-time Ethernet (IEEE 1588 V2) uses RTMoE

(Real-Time Motion over Ethernet) to provide fast

communication and accurate axis synchronization

• Three System Integration (SI) ports are available to t

additional eldbus, position feedback and I/O options

4

www.emersonindustrial.com/automation

Conform to safety standards, maximize uptime and

reduce costs by integrating directly with safety systems

• M700 has an integrated Safe Torque Off (STO) input and

can accommodate an SI-Safety module for safe motion

functions

Powerful and easy field service and upgrade

The M700 is designed to quickly and easily extend the

eld service life of previous generations of products. M701

provides a direct upgrade path from Unidrive SP.

To maximize customer choice, the M700 offers the following 3 variants:

M700 - Ethernet

Onboard real-time Ethernet is included on the standard M700, with 1 x Safe Torque Off (STO) and both analog and digital I/O,

making it an incredibly versatile high performance AC drive.

M701 - Unidrive SP replacement

Designed to match Control Techniques’ highly popular Unidrive SP feature-set. This includes RS485 communications, 1 x STO,

analog and digital I/O, identical control connectors, with Unidrive SP Smartcard parameter sets supported to make upgrading

to Unidrive M as simple as possible.

M702 - Safety Enhanced

The safety enhanced M702 has 2 x STO, onboard real-time Ethernet and digital I/O, where easy integration with modern control

and safety systems is paramount. If analog I/O is required, this can be provided by an SI-I/O option module.

• Unidrive M700 and M701 can import Unidrive SP settings

using a Smartcard

• Unidrive M700 and M701 have the same terminal layout as

Unidrive SP

• SI-Applications Plus modules allows Unidrive SP SyPTPro

programs to be recompiled for Unidrive M700

• Unidrive M700 is more compact than Unidrive SP. Fixing

points for existing Unidrive SP installations can be used

with standard mounting brackets or conversion kits

www.emersonindustrial.com/automation

5

Performance control for every motor

Control Techniques’ unique motor control algorithms

combined with the latest microprocessor technology ensure

that Unidrive M drives offer the highest stability and bandwidth

for all industrial motor types. This enables maximum machine

throughput in every application and with every motor, from

standard AC induction motors to dynamic linear motors

and from energy saving permanent magnet motors to high

performance servo motors.

• High bandwidth motor control algorithm for open and

closed loop induction and PM servo motors with up to

3,000 Hz current loop bandwidth and 250 Hz speed loop

bandwidth

Matched servo motors for maximum

performance

Emerson offers two ranges of AC brushless servo motors to

match diverse application needs.

Unimotor fm

Flexible performance AC brushless servo motor

0.72 Nm -136 Nm (408 Nm peak) | 6.37 lb-in - 1,203 lb-in

(3,611 lb-in peak)

Unimotor hd

Compact servo motor for demanding applications

0.72 Nm - 85.0 Nm (255 Nm peak) | 6.37 lb-in - 752 lb-in

(2,256 lb-in peak)

Unimotor hd is a high dynamic servo motor range, designed

for maximum torque density. This AC brushless servo motor

range provides an exceptionally compact, low inertia solution

for applications where rapid acceleration and deceleration is

required.

Electronic nameplates

• All Unimotor servo motors with communication

based encoders come with electronic nameplate data

preloaded. Unidrive M uses this data directly for faster and

more accurate motor matching and commissioning.

Unimotor fm is a exible performance AC brushless servo

motor range optimized for use with Unidrive M. The motors

are available in six frame sizes with various mounting

arrangements, motor lengths and a wide range of feedback

options.

6

www.emersonindustrial.com/automation

Matched drives and motors maximize

performance and energy efficiency

Unidrive M is designed to enhance the energy efciency of

all applications:

• Low power standby mode. In some applications, drives

can sit idle for signicant periods; Unidrive M’s reduced

standby power saves energy

• Easy common DC bus conguration enables braking

energy to be recycled within the drive system,

reducing energy usage and eliminating external supply

components

Motor control options available include:

Control Mode Features

• Unidrive M supports sensorless (open loop) control of

compact high efciency permanent magnet motors

• Active Front End for regenerative AC drive systems

• Dyneo

®

: perfectly synergized permanent magnet motor

and Unidrive M solutions - optimized for performance and

energy saving

• Emerson’s Dyneo

®

Unidrive M and permanent magnet

motor solutions offer exceptional efciency levels across

all operating speeds, especially at lower speeds where the

efciency is much higher than induction motors

• Low losses, up to 98% efcient

Open loop vector or V/Hz induction

motor control

Open loop Rotor Flux Control for

induction motors (RFC-A)

Open loop permanent magnet

motor control (RFC-S)

Closed loop Rotor Flux Control for

induction motors (RFC-A)

Closed loop control of permanent

magnet and servo motors (RFC-S)

Active Front End for power quality

and regeneration

Open loop motor control for induction motors and the easiest conguration. V/Hz can be used for multiple

motor control.

Vector algorithm utilizing closed loop current control to greatly enhance performance for all induction

motor sizes.

Open loop control of compact, high efciency, permanent magnet motors (including the Leroy-Somer

®

Dyneo

LSRPM).

Speed and position control for induction motors, supporting a wide range of feedback devices.

Dynamic control of high efciency and servo permanent magnet motors supporting a wide range of

feedback devices.

Active Front End allows regeneration of energy back onto the power line. The Active Front End also provides

power factor control for power quality management and greatly reduces unwanted power harmonics.

www.emersonindustrial.com/automation

7

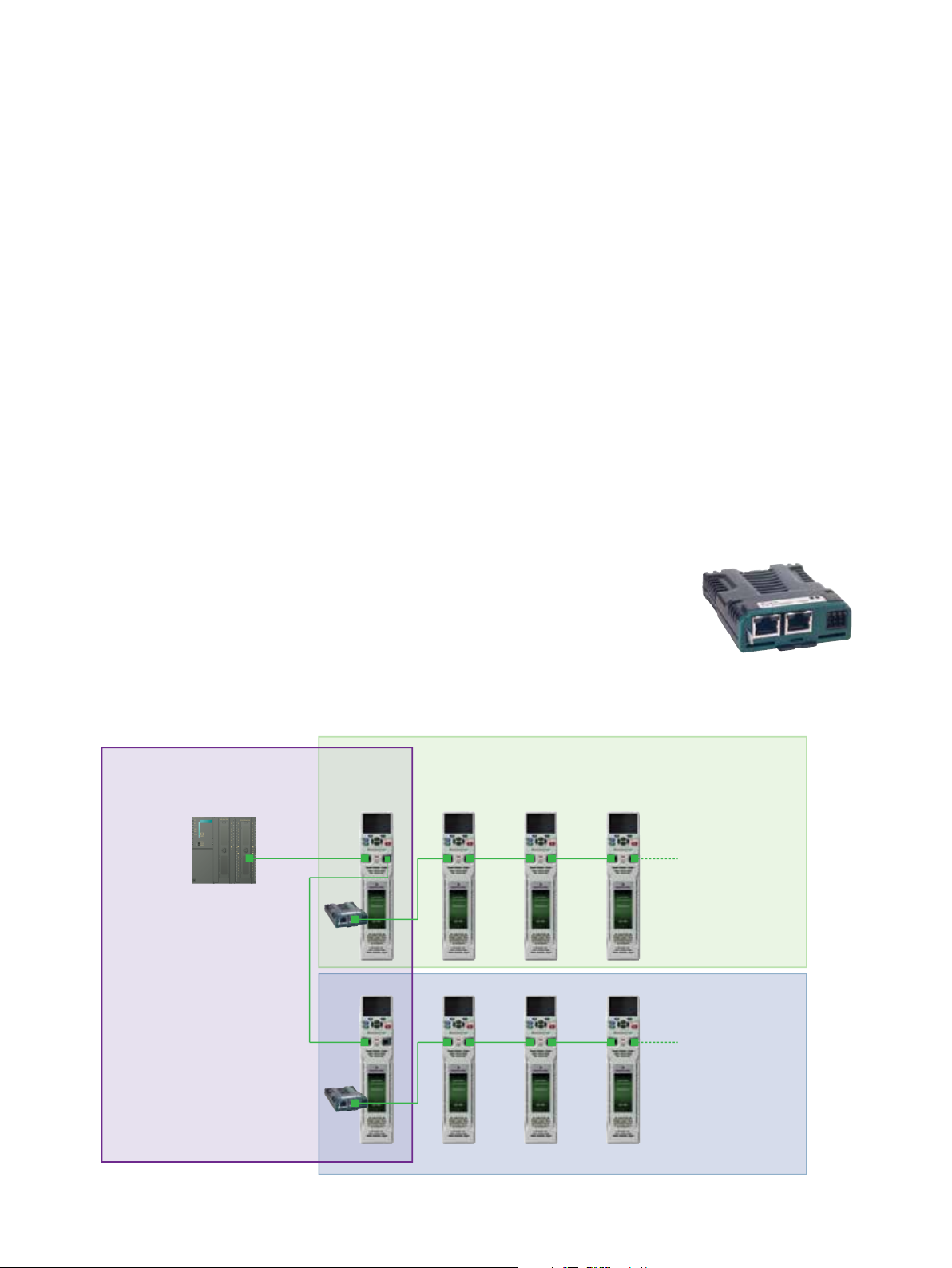

Machine controllers: MCi200,

SF

CPU314C-2 DP

BF

DC5V

FRCE

RUN

STOP

PUSH

RUN

STOP

MRES

0

1

2

3

4

5

6

7

IN IN OUT

DI+2 DI+0

DI+1

D0+0

D0+1

DI8xDC24V

AI5/A02x12Bit

DI16/D016xDC24V

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

MCi210 and SI-Applications Plus

Second processor for PLC programs and

Save costs and streamline machine design

multi-axis control

MCi modules add a powerful processor to Unidrive M700

which can execute comprehensive application programs to

extend system and machine control capability. As a result of the

highly exible plug-in option module format, system design is

streamlined by removing the need for PLCs and other external

components. Programs are fast and easy to develop thanks to

the user-friendly Machine Control Studio software which uses

industry standard IEC 61131-3 programming languages to

build highly exible and productive systems. MCi programs can

access and manage Unidrive M’s embedded Advanced Motion

Controller across a wide range of networks to provide perfectly

synchronized multi-axis machine performance and throughput.

• MCi modules can eliminate the need for external PLCs and

motion controllers

• Plug-in option modules powered from the drive’s internal

power supply mean less wiring and less physical space is

required

• Simple integration with external components such as I/O,

HMIs and other networked drives can be achieved using

Unidrive M’s integrated standard Ethernet ports (with

RTMoE or standard protocols), or eldbuses supported

by SI option modules

(EtherCAT, PROFINET,

PROFIBUS, CANopen)

• MCi210 has two

additional Ethernet ports

with an internal switch

Segregated network control

Network 1 Network 2

System

Controller

Machine 1

MCi

Controller

Network 3

Machine 2

MCi

Controller

8

www.emersonindustrial.com/automation

Loading...

Loading...