Page 1

EF

Advanced User Guide

M’Ax

*

*

**

Compact, high-performance, single-axis servo

amplifier for brushless AC servo motors

Part Number: 0453-0017-04

Issue Number: 4

www.controltechniques.com

Page 2

General information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent

or incorrect installation or adjustment of the optional operating parameters of the equipment or from

mismatching the drive with the motor.

The contents of this guide are believed to be correct at the time of p rinting. In the interes ts of a

commitment to a policyofcontinuous development and improvement, the manufacturer reserves the

right to change the spec ification of the product or its performance, or the contents of the Advanced

User Guide, without notice.

All rights reserved. No p arts of this guide may be reproduced or transmitted in any form or by any

means, electrical or mechanical including photocopy ing, recording or by any information-storage or

retrieval system, without permission in writing from the publisher.

Important...

Servo-amplifier software version

This product is supplied with t he latest version of user-interface and machine-control software. If this

product is to be used with other Control Techniques servo amplifiersin an existing system, there m ay

be some differences between their software and the software in this product. These differences may

cause a difference in f unctions. This may also apply to servo amplifiers returned from a Control

Techniques Service Centre.

If there is any doubt, contact a Control Techniques Drive Centre.

Copyright © J anuary 2003 Control Techniques Drives Ltd

Issue Code: 4

Page 3

Contents

1 Advanced parameters: General information .............................................1

2 Menu 0 Parameters ......................................................................................2

3 Menu 1 Parameters - Speed reference selection ......................................5

4 Menu 2 Parameters - Ramp Selection ......................................................12

5 Menu 3 Parameters - Speed Loop PID gains ...........................................19

6 Menu 4 Parameters - Torque Control .......................................................28

7 Menu 5 Parameters - Motor Control .........................................................34

8 Menu 6 Parameters - Sequencer Functions, AC Supply Loss Modes ...38

9 Menu 7 Parameters - Analog Input Output Settings, Temperature

Monitoring ...................................................................................................42

10 Menu 8 Parameters - Digital Input / Output Settings and Indications ...49

11 Menu 10 Parameters - Status and Diagnostic Information, Trip log,

Braking control ...........................................................................................56

12 Menu 11 Parameters - Scale f actor, Initial displayed parameter, Serial

communications, Drive information .........................................................63

13 Menu 13 Parameters - Pulse Reference Selection & Scaling .................69

M’Ax Advanced User Guide

Issue Number: 4

Page 4

*

1 Advanced parameters: General info rmati on

NOTE

In some cases, the function or range of a parameter are affectedby the settingof anotherparameter; the information in these lists

relate to the defaultcondition of such parameters.

Key

Read-write parameter

RW

RO

{...} Related Menu 0 parameter

[...] Value of a parameter

range of values

ô

default values

ð

~ indicates range of values

Unipolar variable parameter

Uni

Positivevalues only

Bipolarvariable parameter

Bi

Positive and negative values

Text variable parameter

Txt

Alphanumericcode is displayed

Bit parameter

Bit

Two digital states only

Parameters must be copied to the EEPROM (saved) or

R

copied to the flash memory (stored) for a new value to take

effect

A new value is normally copied to the EEPROM (saved) or

copied to the flash memory (stored) at power-down (see

S

parameter 0.50 Parameter transfer function selector in

Chapter8 Menu 0 Parameters)

Protected

P

The parameter cannot be controlled by an external signal

(cannot be a destination parameter)

Maximumspeedof the motor

n

MAX

(defined by the motor via the SLM)

[SLM] Value definedby the motor via the SLM

Read-write (RW) parameter whose default

value is defined by the motor via the SLM

Read-only parameter

Read-only parameter whose value is defined by

themotorviatheSLM

Parameter Information example:

Parameter

number

1.17 Keypad reference

ô

Parameter

description / title

±Pr1.06

Range Default value Units Read only /

ð

0rpmROBiSP0.34

Read write

Unipolar /

Bipolar /

Bit / Txt

R / S / P Equivalent Menu

0 parameter

(where

appropriate)

1 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 5

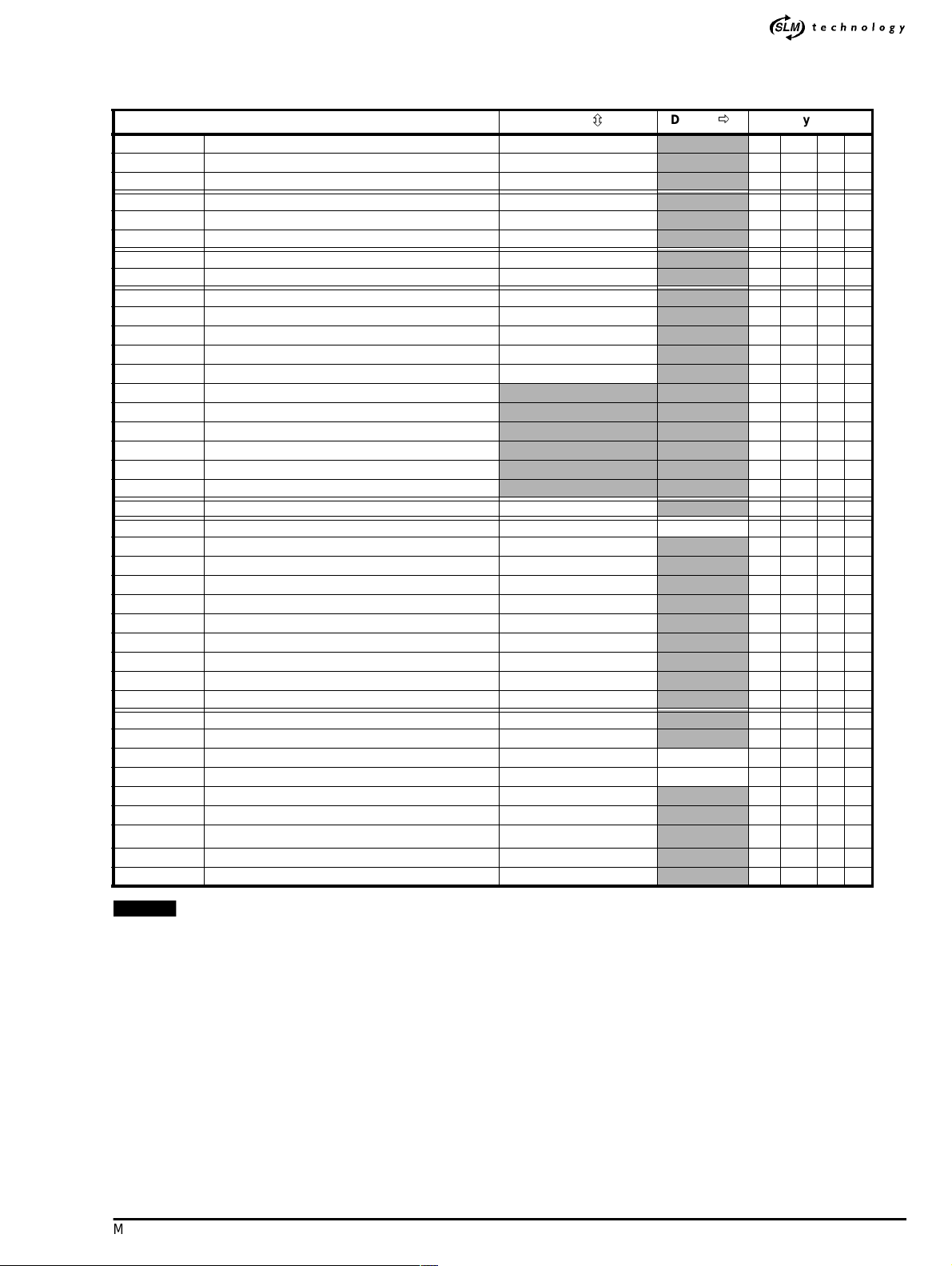

2 Menu 0 Parameters

*

Parameter

0.00 Parameter XX.00 0 ~ 3001

0.01 Hardware enableindicator 0~1

0.02 Reference selectedindicator 1~5

0.03 Valueof selectedreference +

0.04 Final speed reference +

0.05 Speed feedback +

0.06 Reference offset +

0.07 Motor current magnitude 0 ~ Max. overload current of drive

0.08 Maximum reference clamp 0 ~ 7500

0.09 Stiffness angle

0.10 Load inertia

0.11 Inertia units selected

0.12 Speed-loop PID gains selector 0~3 1 RW Uni

0.13 Speed-loop proportional gain Kp1 0.000 ~ 0.3000 [SLM] RW Uni

0.14 Speed-loop integral gain Ki1 0.000 ~ 20.000 [SLM] RW Uni

0.15 Speed-loop derivativegain Kd1 0.0000~ 0.1000 [SLM] RW Uni

0.16 Current-demand filter 1 cut-offfrequency 0 ~ 1200 500Hz RW Uni

0.17 SLM on-line enable 0~1 0 RW Bit

0.18 Symmetrical current limit 0 ~ 300

0.19 Motor-rated current 0 ~ Full load current [SLM] RO Uni

0.20 Drive rated current (FLC) 00.00~ 99.99

0.22 Torque mode selector 0~ 2 0 RW Bit P

0.23 Torque reference +

0.24 Ramp enable 0~1 0 RW Bit

0.25 Acceleration rate 0 ~ 32.000 0.200s/1000rpm RW Uni

0.26 Deceleration rate 0 ~ 32.000 0.200s/1000rpm RW Uni

0.27 Fast ramp select 0~1 0 RW Bit

0.28 Feedback-encoder revolution counter 0 ~ 65535

0.29 Feedback-encoder position 0 ~ 65535

0.30 Reference selector 0~5 1 RW Uni

0.31 Jog selected indicator 0~1

0.32 Jog reference 0 ~ 500 50rpm RW Uni

0.33 Preset reference +

0.34 Keypad reference +

0.35 User security code 0 ~ 255 149 RW Uni S P

0.36 Serial comms. baud rate

0.37 Serial comms. address 0.0 ~ 24.7 1.1 RW Uni P

0.38 Initial parameter displayedselector 00.00 ~ 21.51 0.05 RW Uni P

0.39

0.40

0.41 Drive overload accumulator 0.0 ~ 100.0

0.42

0.43 DC-bus voltage 0 ~ 1000 RO Uni P

0.44 Last trip

0.45 SLM communicationsintegrity 0.0 ~ 100.0

0.46 Programmableparameter 00.00 ~ 21.51

0.47 SLM software version 00.00~ 99.99

0.48 Drive software version 00.00 ~ 99.99

0.49 Security statusindicator 000 ~ 111

0.50 Parameter transferselector 0~4 _AN =0,_SL =4 RW Txt

2

Motor [I

Motor [I

Internal braking-resistor overload

accumulator

t] overload trip indicator

2

t] accumulator

0~1(0=kgm

300,600, 1200, 2400,4800, 9600,

Range(

ô

)Default(

value of [1.06] RO Bi P

value of [1.06] RO Bi P

value of [1.06] RO Bi P

value of [1.06]0RWUni

0.0 ~ 30.0

0.01~600.00kgcm

0.00001~0.06kgm

value of [1.06]1rpmRWBi

value of [1.06] RO Bi

0.0 ~ 100.0

0.0 ~ 100.0

o

2

or

2

2

,1=kgcm2)

200% continuous

motor current

200.00 0~Drive current limit RW Bi

19200

0~1

ð

)

RW Uni R S P

RW Uni

6.0 RW Uni

J

L

[SLM] RO Bit

9600BAUD RW Txt S P

RW Uni

RW Uni

RW

Type

RO Bit P

RO Uni P

RO Uni P

RO Uni P

RO Uni

RO Uni

RO Bit P

RO Bit P

RO Uni

RO Uni P

RO Uni P

RO Txt S P

RO Uni

RO Uni P

RO Uni P

RO Uni

[ ] = value of a parameter [SLM]= value definedby the motor via SLM

M’AxAdvancedUser Guide 2

Issue Number: 4 www.controltechniques.com

Page 6

*

0.50 Parameter tra nsfer selector

ô

Default settings

Version Setting

Use parameter 0.50 to initiate the transfer of parameter values between the RAM, EEPROM (when an option module is fitted), and the flash

memoryin the drive (see Appendix H Storage and Transfer of Parameter Values in the M’Ax User Guide). After changing the setting of

parameter 0.50, perform either of the following,as appropriate:

• While the display is in Edit mode, press at the same time:

•Set10.38at 100 via serial communications.

Terminology

Save Copy main-parametervalues in the RAM to the EEPROM (whenan optionmoduleis fitted)

Retrieve Copy all parametervalues from the EEPROM to the RAM (whenan optionmodule is fitted)

Store Copyparameter values fromthe RAM to the flash memoryin the drive

Restore Copy parameter values from the flash memory to the RAM

Main parameters All parameters other than those that are normally saved or stored at power-down

S-parameters Parameters that are normally saved at power-down(version _AN only)

Notes

At the time of selecting no, boot1 or boot2, all parameter values (including the S-parameters) are copied to the flash memory (store).

All parameters can be stored at any time by setting11.67 Flash update enable at 1. The drive must not be powered-down within 15 seconds.

When S-parameters are not copied, the related values at the destination remain unchanged.

Main parameters can be saved irrespective of the setting of parameter 0.50 (i.e. by setting parameter XX.00 at 1000 and executing the

operation).

See below

AN no

SL boot2

and

ð

RW Txt

Setting Function Usage

At power-down: S-parameter values

no 0

rEAd 1

Prog 2

boot1 3

boot2 4

are copied from the RAM to the

EEPROM (save).

At power up: All parametervalues are

copied from the EEPROM to the RAM

(retrieve).

The main-parameter values in the flash

memoryare immediately copiedto the

RAM (restore).

The main-parameter values in theRAM

are immediately copied to the flash

memory (store).

At power-up: The main-parameter

values in the flashmemory are copied

to the RAM (restore).The valuesof

the S-parameters are ignored.

At power-up: All parameter values

(including the S-parameters) in the

flashmemoryare copiedto the RAM

(restore).

Used only when an option

module is fitted (normally, in

version _AN)

Normally used in version _SL,

but can also be used in version

_AN

3 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 7

S

S

S

0.50

S

K

C

Parameter

S

Prog

set at (2)

Parameter

preset at (save)

XX.00

1000

Flashmemory RAM EEPROM

0.50

Parameter

rEAd

set at (1)

S

Parameter

preset at (0)

0.50

no

*

Parameter set at

S

no , boot1 or boot2

0.50

Parameter

boot1

preset at (3)

S

Parameter

0.50

preset at (4)

boot2

0.50

(0) (3) (4)

S

Parameter

preset at (0)

0.50

boot2

S

Control and

monitoring

ontrol circuits

Parameter

preset at (0)

ey

0.50

no

Parameter values are immediately

copied in the indicated direction

Parameter values are copied in the

indicated direction at the next

power-up

Parameter values are copied in the

indicated direction at power-down

All parameter values are copied,

including the S-parameter values

Main parameter values are copied,

S

(excluding the S-parameter values)

S

Only S-parameter values are copied

M’AxAdvancedUser Guide 4

Issue Number: 4 www.controltechniques.com

Page 8

*

3 Menu 1 P arameters - Speed reference selecti on

Parameter

1.01 {0.03} Value of selected reference +

1.03 Pre-ramp reference +

1.04 {0.06} Reference offset +

1.05 {0.32} Jog reference 0 ~ 500 rpm 50 RW Uni

1.06 {0.08} Maximum referenceclamp

1.11 Reference enabledindicator 0~1

1.12 Reverse selected indicator 0~1

1.13 {0.31} Jog selected indicator 0~1

1.14 {0.30} Referenceselector 0 ~ 5 1 RW Uni P

1.15 Presetreference selector 0 ~ 4 0 RW Uni P

1.17 {0.34} Keypad reference +

1.21 {0.33} Preset reference 1 +

1.22 Presetreference 2 +

1.23 Presetreference 3 +

1.24 Presetreference 4 +

1.36 Analogreference +

1.42 Presetreferences selected indicator 0~1

1.43 Keypadr eference selected indicator 0~1

1.44 Pulse reference selected indicator 0~1

1.45 Preset reference select bit-0 indicator 0~1

1.46 Preset reference select bit-1 indicator 0~1

1.49 {0.02} Referenceselected indicator 1~5

1.50 Preset reference selected indicator 1~4

Range(

ô

)Default(

[1.06] rpm RO Bi P

[1.06] rpm RO Bi P

[1.06] rpm 0 RW Bi

0~n

rpm

MAX

[1.06] rpm RO Bi S P

[1.06] rpm 1 RW Bi

[1.06] rpm 10 RW Bi

[1.06]rpm 100 RW Bi

[1.06] rpm 1000 RW Bi

[1.06] rpm RO Bi

ð

)

[SLM] RW Uni

Type

RO Bit P

RO Bit P

RO Bit P

RO Bit

RO Bit

RO Bit

RO Bit

RO Bit

RO Uni P

RO Uni P

5 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 9

*

M’AxAdvancedUser Guide 6

Issue Number: 4 www.controltechniques.com

Page 10

*

P

R

1

1

1

1

1

P

Figure3-1 Menu 1 software diagram

Preset-reference

selectbit-0 indicator

Preset-reference

selectbit-1 indicator

Preset reference 1

Menu 7

1.45

1.46

1.21

Analog reference

1.36

Preset

reference

1234

0101

0011

1.42

.441.431.42

0

0

0

0

1

1

1

1

reset-references

selected indicator

Keypad-reference

selected indicator

1.43

0

0

1

1

0

0

1

1

ulse-reference

selected indicator

.44

0

1

0

1

0

1

0

1

eference

selector

.14

1.49

1

3

4

4

5

5

5

5

1.49

Reference

selected

Analog

Preset

Keypad

Keypad

Pulse

Pulse

Pulse

Pulse

Menu 7

Reference

selected

indicator

Preset reference 2

Preset reference 3

Preset reference 4

1.22

1.23

1.24

Preset-reference

selected indicator

Preset reference

selector

1.50

1.15

.17

Keypad

reference

13.01

Pulse reference

.04

Reference offset

1.01

Value of selected

reference

7 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 11

1

s

1

R

i

1

DIGITAL I/O

L

3

F

p

1

O

Menu 8

Sequencer

(Menu 6)

*

1.05

Jog reference

1.13

Jog selected

indicator

x(-1)

Reverse

elected

indicator

.06

Maximum

referenceclamp

eedback

encoder

osition

.12

.29

_

3.13

.11

eference

enabled

ndicator

imited

by

13.12

rientation

position

reference

1.03

13.11

13.14

Orientation

13.15

Pre-ramp

reference

Menu 2

Orientation

enable

Orientation

acceptance

window

Orientation

complete

M’AxAdvancedUser Guide 8

Issue Number: 4 www.controltechniques.com

Page 12

*

1.01 Value of selected reference

ô

Indication of the reference being used by the drive is given for systems set-up and fault finding. The value indicated by this parameter is the

sum of input reference and reference offset [1.04].

NOTE

When the drive is operating from a pulse reference input and the speed is below100rpm, use the speed feedback parameter [3.02]

for control purposes as parameter 1.01 will display some instability due to the sampling rate at lower speeds.

1.03 Pre-ramp reference

ô

Indication of the final reference being used by the drive is given for systems set-up and fault finding. The value indicated by this parameter is

afterpassing through sequencer control.(Refer to Menu 6)

The range of this parameter is restricted by the value set in parameter 1.06 Maximum referenceclamp.

1.04 Reference offset

ô

This reference is added to the selected reference. It can be used as a trim to finely adjust the main reference being selected.

Adjustment resolution = 1rpm

1.05 Jog reference

ô

Speed reference used for jogging.

The speed is restricted by the value set in parameter 1.06 Maximum referenceclamp.

Adjustment resolution = 1rpm

±Pr1.06

±Pr1.06

±Pr1.06

0~500

ð

ð

ð

ð

0rpmRWBi 0.06

50 rpm RW Uni 0.32

rpm RO Bi P 0.03

rpm RO Bi P

1.06 Maximumreference clamp

ô

Defines drive absolute maximum speed reference.

The range of this parameter is restricted by the mechanical speed limit of the motor (Set by motor manufacturer).

1.11 Reference enabled indicator

1.12 Reference selected indicator

ô

These indicators are controlled by the drive sequencerdefined in Menu6. They indicatetheappropriatereference as commandedby the

drive logic.

0 = Reference disabled

1 = Reference enabled

1.13 Jog selectedindicator

ô

This indicator is controlled by the drive sequencer defined in Menu 6. Thisindicates the appropriate reference as commanded by thedrive

logic.

0 = Jog not selected

1=Jogselected

1.14 Reference selector

0~n

0~1

0~1

max

ð

ð

ð

SLM rpm RW Uni 0.08

RO Bit P

RO Bit P 0.31

ô

Parameter [1.14] selects the speed reference as follows:-

0 = Reference selection by terminal input

1 = Analogreference.

2 = Analogreference.

3 = Preset reference selected.

4 = Keypad reference selected.

5=Pulsereferenceselected

0~5

ð

1 RW Uni P 0.30

9 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 13

*

0: Reference selection by terminal input

The referenceselected dependson the state of bit parameter[1.42]to[1.44]. These bits are for control by digital inputs such that reference

can be selected by external control. If any of the bits are set, the appropriate reference is selected (indicated by parameter [1.49]).Ifmore

than one bit is set the highest numbered will have priority.

1.42 Presetreference

selected indicator

000Analog1

100Preset3

x 1 0 Keypad 4

xx1Pulse5

X = 0 or 1 (don't care condition)

1.43 Keypadreference

selected indicator

1.44 Pulsereference

selected indicator

Reference

selected

1.49 Indication

parameter

1 or 2: Analog Reference

The speed reference is selected from the standard (SL)orhighprecision(AN) analog voltageinput.

3: Preset reference selected

The reference is one of the four preset speeds, refer to parameters [1.15]and[1.21]to[1.24] for further details.

4: Keypad reference selected

The drive is controlled via keypad (Parameter [1.17]or[0.34])

5: Pulse reference selected

F&D/quadrature reference selected.

1.15 Presetreference selector

ô

Parameter [1.15]selects a presetspeedreference as follows:

0 = Presetselectby terminal input

1 = Preset 1 selected [1.21]

2 = Preset 2 selected [1.22]

3 = Preset 3 selected [1.23]

4 = Preset 4 selected [1.24]

0~4

ð

0 RW Uni P

0: Preset selection by terminal input

The preset selected depends on the state of bit parameter [1.45]to[1.46]. These bits are for control by digital inputs such that presets can be

selectedby external control.The preset selected depends on the binary code generated by these bits as follows:

Parameter [1.45] Parameter [1.46] Preset selected [1.50]

00 1

10 2

01 3

11 4

1.17 Keypad reference

ô

Version _AN -[0.34]or[1.17] indicates the valueof the speed referencesetby use of the keypad.

Version _SL -[0.34]or[1.17] is not used.

If this parameter is selected as the frequency reference (i.e. [1.49]=4),itisadjustedbythe'Up'and'Down'keysonlywhenthedisplayisin

the StatusMode. When the drive is notenabled view the keypadreferenceby looking at parameter [0.34]or[1.17] to ensure the correctvalue

is set before enabling the drive.

The value is saved on powerdown such that the keypad frequencyreference does not have to be set up againon power up.

1.21 Presetreference 1

ô

1.22 Presetreference 2

ô

1.23 Presetreference 3

±Pr1.06

±Pr1.06

±Pr1.06

ð

ð

ð

1rpmRWBi 0.33

10 rpm RW Bi

rpm RO Bi S P 0.34

ô

±Pr1.06

ð

100 rpm RW Bi

M’Ax AdvancedUser Guide 10

Issue Number: 4 www.controltechniques.com

Page 14

*

1.24 Presetreference 4

ô

Parameter 1.21 defines the speed reference for preset speed 1.

Parameter 1.22 defines the speed reference for preset speed 2.

Parameter 1.23 defines the speed reference for preset speed 3.

Parameter 1.24 defines the speed reference for preset speed 4.

1.36 Analog refere nc e

ô

Although most parameters can be controlled from analog inputs this parameter is a special case, as, if selected as a speed reference, the

scan rate will be 250µsec.

The range of this parameter is restricted by parameter [1.06].

1.42 Preset references selected indicator

1.43 Keypad reference selected indicator

1.44 Pulse reference selected indicator

ô

These bitsare provided for control by logic inputs (e.g. digital inputs) for external referenceselection.(See parameter 1.14.)

0 = Referencenot selected

1 = Reference selected

1.45 Presetreference selectbit 0 indicator

1.46 Presetreference selectbit 1 indicator

±Pr1.06

±Pr1.06

0~1

ð

ð

ð

1000 rpm RW Bi

rpm RO Bi

RO Bit

ô

These bits are provided for control by logic input (e.g. digital inputs) for external preset reference selection. (See parameter 1.15.)

Preset 1.45 1.46

100

210

301

411

1.49 Reference selected indicator

ô

Indicates the reference currently being selected by parameter 1.14. See parameter 1.14 Reference selectordescription for further details

1 = Analogreference.

2 = Analogreference.

3 = Preset reference selected.

4 = Keypad reference selected.

5=Pulsereferenceselected.

1.50 Presetreference selected indicator

ô

Indicates the preset speed reference currently being selected by parameter 1.15. See parameter 1.15 Preset reference selector description

for further details.

0~1

1~5

0~5

ð

ð

ð

RO Bit

RO Bit P 0.02

RO Uni P

11 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 15

4 Menu 2 P arameters - Ramp Selection

*

Parameter

2.01 Post-ramp reference ±[1.06]

2.02 {0.24} Ramp enable 0~1 0 RW Bit

2.03 Ramp hold enable 0 ~ 1 0 RW Bit

2.04 {0.27} Fast ramp select 0~1 0 RW Bit

2.05 Limit switch ramp enable 0 ~ 1 0 RW Bit

2.06 S-ramp enable 0 ~ 1 0 RW Bit

2.07 S-ramp acceleration limit

2.10 Acceleration rate selector 0~5 0 RW Uni

2.11 {0.25} Acceleration rate 1 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.12 Acceleration rate 2 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.13 Acceleration rate 3 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.14 Acceleration rate 4 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.19 Jog accelerationrate 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.20 Deceleration rate selector 0~5 0 RW Uni

2.21 {0.26} Deceleration rate 1 0~ 32.000 s/1000rpm 0.200 RW Uni

2.22 Deceleration rate 2 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.23 Deceleration rate 3 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.24 Deceleration rate 4 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.25 Forward limit switch deceleration rate 0~ 32.000 s/1000rpm 0.200 RW Uni

2.26 Reverse limit switch deceleration rate 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.29 Jog decelerationrate 0 ~ 32.000 s/1000rpm 0.200 RW Uni

2.32 Acceleration-rate select bit-0 indicator 0~1 0 RO Bit

2.33 Acceleration-rate select bit-1 indicator 0~1 0 RO Bit

2.35 Deceleration-rate select bit-0 indicator 0~1 0 RO Bit

2.36 Deceleration-rate select bit-1 indicator 0~1 0 RO Bit

2.46 Stop-control proportional-gain 1 ~ 200 1 RW Uni

2.47 Stop-control integral-gain 1 ~ 200 10 RW Uni

2.48 Braking-control proportional gain 1 ~ 200 50 RW Uni

2.49 Braking-control integral gain 1 ~ 200 10 RW Uni

Range(

0 ~ 300.000 s

ô

) Default(ð)

2

/1000rpm

0.031 RW Uni

Type

RO Bi P

M’Ax AdvancedUser Guide 12

Issue Number: 4 www.controltechniques.com

Page 16

*

J

i

d

J

i

1

2

D

1

P

S

D

6

6

Figure4-1 Menu 2 software diagram

Acceleration-rate

select bit-0 indicator

Acceleration-rate

select bit-1 indicator

Acceleration rate1

Acceleration rate2

Acceleration rate3

Acceleration rate4

Deceleration-rate

select bit-0 indicator

Deceleration-rate

select bit-1 indicator

Deceleration rate 1

Deceleration rate 2

2.32

2.33

2.11

2.12

2.13

2.14

2.35

2.36

2.21

2.22

Acceleration

rate

1234

0101

0011

Deceleration

rate

1234

0101

0011

Acceleration

rate selector

2.10

og selected

ndicator

2.19

Jog

acceleration

rate

eceleration

rate selector

2.20

og selected

ndicator

Preset-reference

selected indicator

1.50

1.13

reset-reference

selected indicator

.50

.13

igital input 3

8

Menu 8

equencer

(Menu 6)

DIGITAL I/O

Deceleration rate 3

Deceleration rate 4

Forward limit switch

deceleration rate

Reverse limitswitch

deceleration rate

2.23

2.24

2.25

2.26

.35

.36

Forward

limitswitch

Reverse

limitswitch

.29

Jog

eceleration

rate

2.05

Limit switch

ramp enable

13 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 17

F

s

S

R

e

2

R

S

2

S

a

2

R

B

2

B

2

6.35

6.36

Forward limit

switch

Reverse limit

switch

*

Sequencer

(Menu 6)

2.03

Ramp hold

enable

6.48

6.49

5.05

10.12

10.39

DC-bus level

Controlledstop enable

indicator

DC-bus voltage

Internal

braking-resistor

overload alarm

Internal

braking-resistor

overload

accumulator

amp control

.07

-ramp

cceleration

limit

Ramp controller

ast ramp

2.04

elect

Limitswitch

2.05

ramp enable

top-control

2.46

proportional-gain

Stop-control

2.47

integral-gain

raking-control

.48

proportional gain

raking-control

.49

integral gain

-ramp

.06

S-ramp

enable

Menu 1

Pre-rampspeed

1.03

reference

amp

nable

Sequencer

(Menu 6)

.02

amp enable

over-ride

2.01

Menu 3

Post-ramp

reference

M’Ax AdvancedUser Guide 14

Issue Number: 4 www.controltechniques.com

Page 18

*

2.01 Post-ramp reference

ô

This is the speed reference after the ramps.

The range of this parameter is restricted by the value set in parameter 1.06 Maximum referenceclamp.

2.02 Ramp enable

ô

Set to enable ramps.

0 = Ramp disable

1 = Ramp enable

2.03 Ramp ho ld enable

ô

If thisbitis set the rampwillbe held.IfS-rampis enabled the acceleration willramptowards zero causingthe ramp output to curve towards a

constant speed.

0 = Ramp hold disabled

1 = Ramp hold enabled

2.04 Fast ramp select

ô

This parameter does not affect the acceleration ramp, and the ramp output always rises at the programmed accelerationrate subjectto the

current limits.

±Pr1.06

0~1

0~1

0~1

ð

ð

ð

ð

0 RW Bit 0.24

0 RW Bit

0 RW Bit 0.27

rpm RO Bi P

0 = Fast ramp

When fast ramps are selected the output of the ramp will fall at the programmed deceleration rate (subject to the current limits programmed in

the drive).

1 = Prevention of Braking resistor overload trip

During deceleration, the braking resistoroverload alarm being set will cause a controller to operate,the output of which changesthe ramp

rate.As the controller regulatesthe DC link voltage,themotor decelerationincreases and when the motordeceleration rate reaches the

programmed deceleration rate the controller ceases to operate and the drive continues to decelerate at the programmed rate. Controller

gainscan be adjustedusingparameters 2.48 & 2.49.

Controller

operational

DC Link Voltage

Motor Speed

Programmed

deceleration

rate

t

2.05 Limit switch ramp enable

ô

Setting this parameter enablesthe limit switchramps.

2.06 S-ramp enable

ô

Setting this parameter enables the S-ramp function.S-ramp is disabled during decelerationusingstandard ramp. When the motor is

acceleratedagainafter deceleratingin standard ramp the acceleration ramp used by the S-ramp function is resetto zero.

0 = S-ramp disable

1 = S-ramp enabled

0~1

0~1

ð

ð

0 RW Bit

0 RW Bit

15 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 19

Programmed

ramp rate

S-ramp

acceleration

ramp

2.07 S-ramp acceleration limit

Demand Speed

Acceleration

Actual Speed

*

ô

This parameter defines the maximum rate of change of acceleration/deceleration. The default values have been chosen such that for the

default ramps and maximum speed, the curved parts of the S will be 25% of the original ramp if S-ramp is enabled.

Sincetheramprateisdefinedinsecond

of the S can be determined from:

Enabling S-ramp increases the total ramp time by the period T sincean additional T/2 isaddedtoeachendoftherampinproducingtheS.

ô

The acceleration rate is selected as follows.

When parameter 2.10 is set to 0 the acceleration ramp rate selected depends on the state of bit parameters 2.32 to 2.33. These bits are for

controlby digital inputs such that ramp rates can be selected by external control.The ramp rate selecteddepends on the binarycode

generated by these bits as follows:

Whenparameter 2.10 is set to 5 the appropriate acceleration rate is automatically selecteddependingon thevalueof parameter1.50,andso

an acceleration rate can be programmed to operate with each preset reference. Since the new ramp rate is selected with the new reference,

the acceleration applies towards the selected preset if the motor needs to accelerate to reach the preset.

0.000 ~ 32.000

T = S-ramp rate of change / Ramp rate

2.10 Acceleration rate selector

0~5

0 Ramp rate selection by terminal input

1 ~ 4 Ramp rate definedby paramet er number,i.e.1 = 2.11,2=2.12

5 Ramp rate selection by parameter 1.50

2.33 2.32

002.11

012.12

102.13

112.14

defined by

ð

ð

Ramp

0.031

2

/1000rpm and the S-ramp parameter is defined in second2/1000rpm, the time T for the 'curved' part

0 RW Uni

2

s

/1000rpm

RW Uni

2.11 Acce leration rate 1

ô

ô

Refer to parameter 2.10.

0.000 ~ 32.000

2.12 Acceleration rate 2

2.13 Acceleration rate 3

2.14 Acceleration rate 4

0.000 ~ 32.000

ð

ð

0.200 s/1000rpm RW Uni 0.25

0.200 s/1000rpm RW Uni

M’Ax AdvancedUser Guide 16

Issue Number: 4 www.controltechniques.com

Page 20

*

2.19 Jog acceleration rate

ô

0.000 ~ 32.000

The jog acceleration rate is only usedwhen the drive starts from the inhibit or ready states, or has reached the jog reference from another

stateand the speed is changing because the jog reference is changed.Thisprevents the fast rampsnormally used with jog from beingused

when changing betweenrunning and jogging.

2.20 Deceleration rate selector

ð

0.200 s/1000rpm RW Uni

ô

The deceleration rate is selected as follows.

0 Ramp rate selection by terminal input

1~ 4 Ramp rate definedby parameter number, i.e. 1 = 2.21,2=2.22.

5 Ramp rate selection by parameter1.50

When parameter 2.10 is set to 0 the deceler ation ramp rate selected depends on the state of bit parameters 2.35 to 2.37. These bits are for

control by digital inputssuch that ramp rates can be selected by external control. The ramp rate selected depends on the binary code

generated by these bits as follows:

2.36 2.35 Ramp defined by

00 2.21

01 2.22

10 2.23

11 2.24

When parameter 2.20 is set to 5 the appropriate decelerationrate is automaticallyselected dependingonthevalueof parameter1.50,andso

a deceleration rate can be programmed to operate with each preset reference. Since the new ramp rate is selected with the new referen ce,

the deceleration applies towards the selected preset if the motor needs to decelerate to reach the preset.

2.21 Deceleration rate 1

ô

2.22 Deceleration rate 2

2.23 Deceleration rate 3

2.24 Deceleration rate 4

0~5

0.000 ~ 32.000

ð

ð

0 RW Uni

0.200 s/1000rpm RW Uni 0.26

0.000 ~ 32.000

ô

Refer to parameter 2.20.

2.25 Forward limit switch deceleration rate

2.26 Reverse limit switch deceleration rate

0.000 ~ 32.000

ô

Refer to parameters 6.35 and 6.36 respectively.

2.29 Jog deceleration rate

0.000 ~ 32.000

ô

The jog deceleration rate is only used when the drive is changing speed becausethe jog reference has changed or to stop from the jog

reference. It is not used to go from the jog to the run state.This prevents the fast ramps normallyusedwith jog from being used when

changing between runningand jogging.

ð

ð

ð

0.200 s/1000rpm RW Uni

0.200 s/1000rpm RW Uni

0.200 s/1000rpm RW Uni

17 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 21

2.32 Acceleration-rate select bit-0 indicator

2.33 Acceleration-rate select bit-1 indicator

2.35 Deceleration-rate select bit-0 indicator

2.36 Deceleration-rate select bit-1 indicator

*

ô

These bits are provided for control by logic input terminals for external ramp selection (see parameter 2.10 and 2.20).

2.46 Stop control proportional gain

ô

2.47 Stop control integral gain

ô

Used as a ramp rate controller for controlled stop.

Duringmains loss,if the DC bus voltagecollapses beyond the level set in parameter6.48 a DC link controller operates, the output of which

changes the ramp rate.Thecontroller can be disabledby setting the detectionlevelin parameter6.48 to 0. As the controller regulates the link

voltage, the motor deceleration increases to keep the DC bus at a maximum level to achieve the fastest possiblecontrolled stop.When the

motorisstopped thecontroller ceases to operate.Controllergains can be adjustedusing parameters 2.46and 2.47.Ifthemainsisre-applied

duringthestop the controller still operates to zerospeed,the mainslossbit6.48 remains set and can only be reset by giving a drive reset.

2.48 Braking-control proportional gain

ô

2.49 Braking-control integralgain

ô

Used as a ramp rate controller for preventing braking resistor overload trip. See parameter 2.04 for more information.

0~1

0~200

0~200

0~200

0~200

ð

ð

ð

ð

ð

0 RO Bit

1 RW Uni

10 RW Uni

50 RW Uni

10 RW Uni

M’Ax AdvancedUser Guide 18

Issue Number: 4 www.controltechniques. com

Page 22

*

5 Menu 3 P arameters - Speed Loop PID gains

Parameter

3.01 {0.04} Finalspeedreference ±[1.06] rpm

3.02 {0.05} Speed feedback ±[1.06] rpm

3.05 Zero-speed threshold 0 ~ 200 rpm 5 RW Uni

3.06 At-speed lower limit 0 ~ [1.06] rpm 5 RW Uni

3.07 At-speed upper limit 0 ~ [1.06] rpm 5 RW Uni

3.08 Over-speed threshold

3.09 Absolute at-speed detect mode select 0 ~ 1 0 RW Bit

3.10 {0.13} Speed-loopproportional gain Kp1 0.0000 ~ 0.3000 [SLM] RW Uni

3.11 {0.14} Speed-loop integral gain Ki1 0.000 ~ 30.000 [SLM] RW Uni

3.12 {0.15} Speed-loop derivative gain Kd1 0.0000 ~ 0.1000 [SLM] RW Uni

3.13 Speed-loop proportional gain Kp2 0.0000 ~ 0.3000 [SLM] RW Uni

3.14 Speed-loop integral gain Ki2 0.000 ~ 30.000 [SLM] RW Uni

3.15 Speed-loopdifferential-feedback gainKd2 0.0000 ~ 0.1000 [SLM] RW Uni

3.16 {0.12} Speed-loop PID gains selector 0 ~ 3 1 RW Uni

3.18 Total inertia

3.19 {0.09} Stiffness angle 0.0 ~ 30.0 ° 6.0 RW Uni

3.20 {0.10} Load inertia

3.22 Hard speed reference ±500.0 rpm 0.0 RW Bi

3.23 Hard speed reference selector 0~1 0 RW Bit

3.25 Feedback-encoder phase offset 0 ~ 65535 REV/65536 [SLM] RO Uni

3.28 {0.28} Feedback-encoder revolution counter 0 ~ 65535 REV

3.29 {0.29} Feedback-encoder position 0~ 65535 REV/65536

3.32 Z marker pulse received indicator 0~1

3.51 High resolution Marker select 0 ~ 1

3.52 Z marker pulse offset 0 ~ 65535 REV/65536

3.53 Shaft-key offset 0 ~ 65535REV/65536 [SLM] RO Uni

3.54 Zero offset ±180 ° 0RWUni

*3.55 Number of encoder lines 0, 100 ~ 8192 and 16384 4096 RW Uni R

3.56 F/D mode select 0~1 0 RW Bit

3.57 Speed-loop PID buffer 1 select 0~1 0 RW Bit

3.58 Speed-loop PID buffer 2 select 0~1 0 RW Bit

3.59 Speed-loop PID buffer 3 select 0~1 0 RW Bit

3.60 Speed-loop proportional gain Kp3 0.0000 ~ 0.3000 [SLM] RW Uni

3.61 Speed-loop integral gain Ki3 0.000 ~ 30.000 [SLM] RW Uni

3.62 Speed-loop derivative gain Kd3 0.0000 ~ 0.1000 [SLM] RW Uni

3.63 Speed-loop PID buffer in use indicator 0~3

3.64 Speed feedback (unfiltered) ±2048

0~n

0.1 ~ 6000.0 kgcm

0.00001 ~ 0.6 kgm

0.1 ~ 6000.0 kgcm

0.00001 ~ 0.6 kgm

Range(

MAX

ô

)Default(

rpm

2

or

2

2

or

2

ð

)

0RWUni

J

t

J

L

Type

RO Bi P

RO Bi P

RO Uni

RW Uni

RO Uni

RO Uni

RO Bit

RW B it

RO Uni

RO Uni

RO Bi

Notes

The measurement units for parameters 3.18 and 3.20 depend on the setting of 5.34 and 5.54.(5.34 = Inertia units and 5.54 = Inertia range.)

Parameter 3.64: sample time = 250µs

Parameter 3.23 canbeusedforsettingafineanalogoffsetortrim;resolution=0.1rpm

See Appendix D Optimisingthe Dynamic Performance in the M’Ax User Guide.

Motor inertia

J

M

(defined by the motor via the SLM,Pr5.33)

J

Load inertia

L

Total inertia = JM+J

J

t

*Parameter 3.55: When this parameteris set to 0, the number of encoder lines= 16384.

A power down and up again is required for a new value to take effect.

L

19 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 23

Figure 5-1 Menu 3 software diagram

f

3

A

3

A

3

O

3

A

a

3

S

1267131

S

M

r

r

Z

S

S

Hard speed

reference

3.22

Hard speed

referenceselector

3.23

Sequencer

(Menu 6)

Menu 2

SLM

Demand

LM PID

buffer 1

LM PID

buffer 2

LM PID

buffer 3

*

Menu 13

Post-ramp

reference

Pulse

reference

2.01

13.01

Encoder simulation

3.55

Number of

encoder lines

3.56

F/D mode

select

onitoring

Speed

3.02

eedback

Feedbackencoder

3.28

evolution

counter

Feedback-

3.29

encoder position

Alignment

Shaft-key offset

3.53

3.01

Final speed

reference

A

A\

B

B\

Z

Z\

Feedback

peed detection and limits

Zero-speed

.05

threshold

t-speed

.06

lowerlimit

t-speed upper

.07

limit

ver-speed

.08

threshold

bsolute

.09

t-speed detect

mode select

Speed detection

indicators

At zero

speed

10.03

indicator

Below set

10.05

speed

indicator

At speed

10.06

indicator

Above set

10.07

speed

indicator

technology

)

SIM ENC

4

Z marker pulse

3.32

eceived indicator

Marker

pulse

ero offset

3.54

M’Ax AdvancedUser Guide 20

Issue Number: 4 www.controltechniques. com

Page 24

*

3.01 Final speed reference

ô

Finalspeed demandatt he input to thespeedregulatorformed by the sumofthe rampoutput and the hard speed reference (ifthehardspeed

reference is enabled). If the drive is disabled this parameter will show 0.0.

3.02 Speed feedback

ô

This is the speed feedback taken from the SLM encoder. This parameter shows the speed feedback used by the speed controller. This

includes quantisation ripplegivenby the counts per revolution (65535)and the samplinginterval of 250µs.

The value seen on the drive display is filtered so that it can be read by the user, however, the actual parameter held within the drive is not

filtered. If this parameter is routed to an analog output the ripple will be present. It should be noted that the quantisation of the speed feedback

does not affect the resolution or accuracy of the speed controller. Use parameter 3.64 for analogoutput purposesfor fast responses.

3.05 Zero-speed threshold

ô

If the speed feedback (parameter 3.02) is at or below the leveldefined by t his parameterin eitherdirectionthe Zero speed flag (parameter

10.03)is1,otherwisetheflagis0.

3.06 At-speed lower limit

ô

Defines the lower threshold for at speed detection. Refer to parameter3.09.

3.07 At-speed upper limit

±Pr1.06

±Pr1.06

0~200

±Pr1.06

ð

ð

ð

ð

5rpmRWUni

5rpmRWUni

rpm RO Bi P 0.04

rpm RO Bi P 0.05

ô

Defines the upper thresholdfor at speed detection. Refer to parameter3.09.

3.08 Over-speed threshold

ô

Defines the speedabove which the drive will trip due to overspeed.

When this parameter is set to a zero the limit is set by parameter 1.06 x1.2.

3.09 Absolute at-speed detect mode select

ô

3.09 = 0 reference window mode. The at speed band is from (reference - lower limit) to (reference+ upper limit).The reference is the pre-

3.09 = 1 absolute window mode. The at speedbandis from the lower limit to the upper limit. The at speedindicator is activewhenthe

3.10 Speed-loop proportional gain. Kp1

ô

3.11 Speed-loop integral gain. Ki1

ô

3.12 Speed-loop derivative gain. Kd1

±Pr1.06

0~n

max

0~1

ramp reference (parameter 1.03). The at speed indicator is active when the following is true:- ([1.03]-3.06)<[3.02]<([1.03]+03.07)

following is true:-3.06 <[3.02]<3.07.

0.0000 ~ 0.3000

0.0000 ~ 30.000

ð

ð

ð

ð

ð

5rpmRWUni

rpm RW Uni

0 RW Bit

SLM RW Uni 0.13

SLM RW Uni 0.14

ô

0.0000 ~ 0.1000

The following diagram shows a generalised representation of the speed controller. The controller includes proportional (Kp) and integral (Ki)

feed-forward terms, and a differential (Kd) feedback term. The drive holds three sets of these gains and either set may be selected for use by

the speed controller with parameter 3.16.

3.16 = 1, gains Kp1,Ki1 and Kd2 are used

3.16 = 2, gains Kp2,Ki2 and Kd2 are used

3.16 = 3, gains Kp3,Ki3 and Kd3 are used

ð

SLM RW Uni 0.15

21 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 25

*

r

Parameter 3.16 may be changed whenthe drive is enabledor disabled.Itisnecessaryto updatethe SLM with the required PID set by setting

PID buffer update bit i.e. Pr 11.67 to 1. Any of the available 3 buffers can be selected "on the fly".

Speed

reference

(wr*)

Kp

+

-

Ki

1

s

+

Torque

+

+

Speed

feedback

(wr)

eference

(Te*)

+

s

Kd

Proportional gain (Kp)

If Kp has a valueand Ki is set to zerothecontroller will only have a proportional term, and there must be a speed error to produce a torque

reference. Therefore as the motorload increases there willbe a difference between the referenceand actualspeeds. This effect,called

regulation, depends on the level of the proportional gain, the higher the gain the smaller the speed error for a given load. If the proportional

gain is too high then the closed-loop stability limit is reached.

Integral gain (Ki)

The integral gain is provided to prevent speed regulation. The error is accumulated over a period of time and usedto produce the necessary

torque demand without any speed error. Increasing the integral gain reduces the time taken for the speed to reach the correct level and

increases the stiffness of the system, i.e. it reduces the positional displacement produced by applying a load torque to the motor.

Unfortunately increasing the integral gain also reduces the system damping giving overshoot after a transient. For a given integral gain the

damping can be improvedby increasi ng the proportional gain.A compromisemustbe reachedwherethesystemresponse, stiffness and

damping are all adequate for the application. The integral term is implemented in the form of Σ(Ki x error), and so the integral gain can be

changed when the controller is active without causing large torque demand transients.

Differential gain ( Kd)

The differential gain is provided in the feedback of the speed controller to give additional damping. The differential term is implemented in a

way that does not introduce excessive noise normally associated withthistype of function. Increasingthedifferential term reducesthe

overshoot producedby under-damping, however, for most applications the proportional and integralgains alone are sufficient.

To analysethe performance of the speed controllerit may be represented as an s-domain model as shown below.

w*(s)

(rs

Kp

+

Ke

-1

)

_

Ki 1/s

+

+

+

+

s

Kd

Kc Kt L(s)

Ke

w(s)

(rs

-1

)

Where:

Kc is the conversionbetweentorque reference and torque producingcurrent. A value of unity at the inputto this block gives a torque

producing currentequivalent to the full scale current of the drive. The drive automatically compensates the torque producingcurrent for flux

variations in field weakening, and so Kc can be assumed to have a constantvalue. Drive rated currentis equivalent to 0.5 x full scale (see

Menu 4 for details of current scaling), and so

Kc = Drive rated current / 0.5

Kt is the torqueconstant of the motor (i.e. torquein Nm peramp of torque producingcurrent).

L(s) is the transfer function of the load.

The s-domainsystemabovemay be used to determine the performance of systems with a relatively low bandwidth. However, the real drive

systemalsoincludes non-idealdelaysdue t o the torque controller response, and speed measurementand controldelays. These delays,

which can be approximated with a simple unity gain transport delay (T

) as shown below, should be taken into accountfor moreaccurate

delay

results.

M’Ax AdvancedUser Guide 22

Issue Number: 4 www.controltechniques. com

Page 26

*

w*(s+)

Kp+Ki/s

_

1+Kds

Speed measurement

delay

+

Kc.Kt

_

Torque reference

calculation delay

L(s)

T

delay

T orque controller delay

62.5µs47.5µs600µs 710µs

Calculating Kp, Ki, Kd for M'Ax

(Set-up method based on Compliance angle)

Compliance angle basedset-up required following parameters.

Description M’Ax Parameter Symbol

Motor rated current 5.07

Symmetrical current limit (%) 4.07

Motor torqueconstant 5.32

Motor Inertia 5.33

Load Inertia 3.20

Stiffness Angle 3.19 α

T otal inertia 3.18 J

I

M(rated)

I

limit

K

t

J

m

J

L

w(s)

T

delay

Calculate the following:

NOTE

I

has to be stated in percent of motor rated current (as in parameter 4.07)

limit

I

limit

------------

100

4

-- -

π

I

×=

M rated()

×=

K

c

=

K

b

K

oKcKt

Then,theseequations shouldyieldcorrectvalues for thegains.

22.5

------- ----

K

==

i

α

K

2

p

for no over shoot. If drive is used with position loop then use Kd= 0 for minimumfollowing error.

Use K

d

1

---

K

d

2

JK

×

----- ----------- ----=

K

×

bKo

------- ----------- ----------- --- -=

K

× K

bKo

90

----- ----------- -----------

π K

×α×

b

i

J

×

i

To give an example:

Description Symbol Value Units

Motor rated current

Symmetrical current limit (%)

Motor torqueconstant

Motor Inertia

Load Inertia

I

M(rated)

I

limit

K

J

m

J

L

t

9.5 A

200 %

1.6

0.00076

0.00224

Nm/A

Stiffness Angle α 6 °

Total inertia J

J

m+JL

Kgm

Kgm

Kgm

RMS

2

2

2

23 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 27

200

------- -- -

K

c

K

b

K

o

9.5× 19==

100

4

-- -

const==

π

19 1.6× 30.4==

J 0.00076 0.00224+ 0.003==

α 6=

Therefore:

22.5

------- ----

K

i

3.75==

6

*

K

K

0.003 3.75×

2

------ ----------- ----------- ---- - 0.034==

p

d

4

-- -

30.4×

π

1

0.003

-- -

------ ----------- ----------- ---------- - 0.0023==

2

4

---

30.4 3.75××

π

3.13 Speed-loop proportional gain. Kp2

ô

0.0000 ~ 0.3000

ð

SLM RW Uni

3.14 Speed-loop integral gain. Ki2

ô

0.0000 ~ 30.000

ð

SLM RW Uni

3.15 Speed-loop derivative gain.Kd2

ô

0.0000 ~ 0.1000

ð

SLM RW Uni

Refer to above text.

3.16 Speed-loop PID gain selector

ô

0~3

ð

1 RW Uni 0.12

The drive holds threegainbuffers, any buffercan be selected for use by the speed controller with parameter 3.16.

0 = Terminal input control

1 = PID buffer 1 is selected

2 = PID buffer 2 is selected

3 = PID buffer 3 is selected

Summary of effected parameters when switching P.I.D buffers

K

Pr 3.16

KIKDK

P

Current demand filter cut off

C

1 3.10 3.11 3.12 4.07 4.12

2 3.13 3.14 3.15 4.24 4.23

3 3.60 3.61 3.62 4.28 4.27

3.18 Total inertia

ô

0.1 ~ 6000.0

0.00001 ~ 0.6

ð

Kgcm

Kgm

2

RO Uni 0.11

2

T otal inertia driven by the motor is the sum of: Load Inertia + Motor Inertia.

This is requiredto calculate the PID gains.

3.19 Stiffness angle

ô

0.0 ~ 30.0

ð

6.0

o

RW Uni 0.09

The stiffness angle is the required angulardisplacementwhent he drivedelivers a torque producing current equivalentto the drive rated

M’Ax AdvancedUser Guide 24

Issue Number: 4 www.controltechniques. com

Page 28

*

current (parameter 11.32) with no field weakening.

Zero

Load

100% Motor rated current

Stiffness angle

3.20 Load inertia

ô

The load inertia should be calculated and entered into 3.20 so t hat the totalinertia can be calculated. Before enteringthe load inertia value

into parameter 3.20, check the range statusin parameters5.34 and 5.54.

Example:

ô

ô

The hard speed reference is a referencevalue which does not pass through the ramp system (Menu 2). It is added to the normal post ramp

speed reference. The maximum of this input is limited to 500 rpm.

ô

This parameter display’s the flux alignmentvalueof the motor.

0.1 ~ 6000.0

0.00001 ~ 0.6

5.34 =0=kgm

=1=kgcm

5.54 = 0 = Ranges are shown for 3.18 and 3.20

= 1 = Ranges are divided by 10

Load inertia = 42kgcm

When 5.34 =1and5.54 =0,3.20 =42.0

When 5.34 =1and5.54 =1,3.20 =4.20

3.22 Hard speed referen ce

3.23 Hard speed referen ce selector

3.25 Feedback encoder phase offset

2

2

±500

0~1

0 ~ 65535

ð

2

ð

ð

ð

J

ML

0.0 rpm RW Bi

1 RW Bit

SLM REV RW Uni

Kgcm

Kgm

2

RW Uni 0.10

2

3.28 Feedback encoder revolution counter

ô

When the encoderrotates by more than one revolution,the revolutionsin parameter 3.28 incrementor decrement in the form of a sixteen bit

roll-over counter. Resets to zeroon power down.

3.29 Feedback encoder position

ô

This parameter gives the encoderposition counted from the point when the drive was powered up. On powerup, SLM uses single cycle SinCos output to find absolute shaft position.

3.32 Z marker pulse received indicator

ô

The encoder has a marker channel and this is used to correct the absolute position with in a revolution after power-Up. After passing through

the marker this bit is set and zero offset parameter [3.54]is updatedwith the differencebetween 0 of encoderposition[3.29] and marker. This

is due to error on initial angle calculation usingsinglecyclesin-cos.

3.51 High resoluti on marker select

ô

CT-coder has a marker channel and this is used to correct the absolute position within a revolution after power-up. After passing through the

marker, if this bit is set to 1 then zero offset parameter 3.54 isupdatedusing12 Bit accuracywithoutinterpolation, otherwiseupdatedusing16

Bit accuracywith interpolation.

0 ~ 65535

0 ~ 65535

0~1

0or1

ð

ð

ð

ð

REV RO Uni 0.28

REV RO Uni 0.29

RO Bit

RW Bit

25 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 29

3.52 Z marker pulse offset

*

ô

Difference in between the encodermarkerand 0 positionat parameter 3.29. On power up, SLM uses single cycleSin-Cos output to find

absolute shaft position. This measurementhas a maximum of ±3° error.After passingthroughMarker pulse this offset is calculated.

3.53 Shaft key offset

ô

This is offset in between SLM marker pulse and shaft key, set by motor manufacturer.

3.54 Zero offset

ô

User specified marker offset for encoder simulation.

3.55 Number of simulated encoder lines

ô

Range selectable from 100 lines per revolution to 8192 lines per revolution

Set this parameter to 0 enables16384pulses per revolution

When modified, in order for the new value to take effect,a power-down and up again is required.

3.56 F/D mode select

ô

0 = Quadrature A & B diff erential outputs (IncludingMarker pulses)

1 = Frequency & Directional differential outputs (Including Marker pulses)

0 ~ 65535

0 ~ 65535

0~180

0, 100 ~ 8192

selectable

& 16384

0~1

ð

ð

ð

ð

ð

SLM REV RO Uni

0

4096 RW Uni R

0 RW Bit

REV RO Uni

o

RW Uni

3.57 Speed-loop PID Buffer 1 select

3.58 Speed-loop PID Buffer 2 select

3.59 Speed-loop PID Buffer 3 select

ô

Allows the user to select which gain buffer is required. Buffer selection:

Pr3.57 Pr3.58 Pr3.59 Gain Buffer selected, Pr3.16

1xx 1

01x 2

001 3

x = don't care conditions

3.60 Speedloopproportionalgain.Kp3

ô

3.61 Speed loop integral gain. Ki3

ô

3.62 Speedloopderivativegain.Kd3

ô

Refer to parameters 3.10, 3.11, 3.12

0~1

0.0000 ~ 0.3000

0.0000 ~ 30.000

0.0000 ~ 0.1000

ð

ð

ð

ð

0 RW Bit

SLM RW Uni

SLM RW Uni

SLM RW Uni

3.63 SpeedloopPIDbufferinuseindicator

ô

Used to indicate which PID buffer currently in use.

0~3

ð

RO Uni

M’Ax AdvancedUser Guide 26

Issue Number: 4 www.controltechniques. com

Page 30

*

3.64 Speed feedback unfiltered

ô

The speed feedback in counts / 250µs taken from the SLM encoder.T his is usedas sourceforanalogoutput. This can be used by a PLC for

instantaneous speed measurements.

±2048

ð

RO Bi

27 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 31

6 Menu 4 Parameters - To rq ue Control

*

Parameter

Range(

4.01 {0.07} Motor current magnitude

4.03 Torque demand

±200.0%I

4.04 Current demand 0 ~ 620

4.07 {0.18} Symmetrical current limit Kc1

4.08 Torque reference

4.09 Torque-referenceoffset

0 ~ 300.0%I

±200.0%I

±200.0%I

0~I

ô

) Default(ð)

A

OL

A

T

M

LIM

LIM

200.0 RW Uni

0.0 RW Bi

0.0 RW Bi

Type

RO Uni P

RO Bi P

RO Uni P

4.10 Torque-referenceoffset enable 0~1 0 RW Bit

4.11 Torque mode selector 0~2 0 RW Uni

4.12 {0.16} Current-demand filter1 cut-offfrequency 0 ~ 1200Hz 500 RW Uni

4.15 Motor- thermal time-constant

[SLM] RO Uni

4.23 Current-demand filter 2 cut-off frequency 0 ~ 1200Hz 500 RW Uni

4.24 Symmetrical current limit Kc2

0 ~ 300.0%I

M

4.26 Torque-compensation gain 0 ~ 5000 rads/s

200.0 RW Uni

RW Uni

4.27 Current-demand filter 3 cut-off frequency 0 ~ 1200Hz 500 RW Uni

4.28 Symmetrical current limit Kc3

0 ~ 300.0%I

M

200.0 RW Uni

4.51 Reserved for internal system purposes

4.52 Motorthermal-overloadtrip level

4.53

Symmetrical current limit after motor thermaloverload trip

0 ~ 125%I

0 ~ 300%I

M

M

110 RW Uni

105 RW Uni

4.54 Thermal-overload time to trip 0 ~ 200s 10 RW Uni

4.55 SLM overheat thresholdparameter 0 ~ 100°C85RWUni

4.56 Motoroverload alarm level 0 ~ 100 70 RW Uni

4.57 Motoroverload alarm 0 ~ 1

RO Uni

4.58 ‘U’ phase current loop offset correction 0 ~ 65535 0 RW Uni

4.59 ‘V’ phase current loop offset correction 0 ~ 65535 0 RW Uni

Notes

Parameters 4.52, 4.53, 4.54: see section F.2 Adjustingthe threshold for the motor thermal-overload alarmin the M’Ax User Guide.

Parameter 4.04: the range 0 ~ 620 represents 0 ~ 200% FLC

Full-load current (continuous-current rating of the

FLC

drive)

I

Maximum overload current from the drive [2 x FLC]

OL

Rated continuous motor-current (defined by the motor

I

M

via the SLM)

Maximum torque-producing current (derived from

I

T

[FLC x kT])

Value of the current limit that is obtained from the

I

LIM

setting of 4.07 Symmetrical current limit

LT Triplevelof the drive thermal-overload accumulator

n

Maximum speed of the motor (defined by the motor via

MAX

the SLM)

J

Motorinertia (definedby the motor via the SLM)

M

M’Ax AdvancedUser Guide 28

Issue Number: 4 www.controltechniques. com

Page 32

*

4

M

m

T

d

S

T

c

1

i

M

d

4

M

r

t

1

Figure6-1 Menu 4 software diagram

SLM overheat

threshold

Motor overload alarm

level

Motor overload alarm

'U'phasecurrentloop

offset correction

'V' phase current loop

offset correction

Torque compensation

gain

Torque mode

selector

4.55

4.56

4.57

4.58

4.59

4.26

4.11

4.12

4.23

4.27

Current-demand

filter 1 cut-off

frequency

Current-demand

filter 2 cut-off

frequency

Current-demand

filter 3 cut-off

frequency

Menu 3

Symmetrical current

4.07

limit Kc1

Symmetrical current

4.24

limit Kc2

Symmetrical current

4.28

limit Kc3

4.15

5.07

1.32

−

thermal

Motor

ime-constant

otor

−

ated current

Drive rated

current

SLM

Current

demand

Speed demand

Torque

reference

4.08

Torquereference

offset enable

4.10

4.09

Torque

reference offset

Menu 5

Motor current

Menu 3

)

orque

4.03

emand

RMS current calculation

technology

orque

ompensation

2

Motor [I t] overload

trip

ndicator

caling

otor overload

etection

0.17

.01

otor current

agnitude

.04

Current

demand

Menu 5

29 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 33

4.01 Motorcurrent magnitude

*

ô

This parameter is the r.m.s. current from each output phase of the drive.

4.03 Torque demand

ô

The torquedemand is derived from the torquereference and offset. The units of the torque demandare% of allowed maximumtorque to the

motor (Based on Symmetrical currentlimit).

100% rated torque= 100% rated currentof the motor.

4.04 Current demand

ô

The Currentdemandis read from SLM. The units of the current demand are % of rated drive current.

620 = 200% rated drive current

4.07 Symmetrical current limit Kc1

ô

Symmetrical current limit is used to scale the maximum motor current. This is used to scale the currentscalingfrom SLM. After changingthis

parameter SLM-PIDupdate is necessary to use new settings. Refer to P.I.D gain calculation sectionin Menu 3.

4.08 Torque-reference

ô

This is the parameter for main torque reference. The units are % of maximum motor rated torque based on symmetrical current limit with a

resolution of 0.1%. If connectedto an analog input on the drive this parameteris updated every 250µs.

0~I

OL

±0 ~ 200

0~620

0~300

±200

ð

ð

ð

ð

ð

200.0

0.0

AROUni P0.07

%ITA

%I

%I

M

LIM

RO Bi P

RO Uni P

RW Uni 0.18

RW Bi

4.09 Torque-reference offset

ô

This parameter is for an offset to be addedto the main torque reference.The torqueoffset is updated every 1ms when connectedto an

analoginput, and so parameter 4.08 should be used for fast updating if required.

4.10 Torque-reference offset enable

ô

The torque offset is added to the torque reference when parameter 4.10 is set to one.

0 = Torque reference offset disable

1 = Torque reference offset enable

4.11 Torque mode selector

ô

0=Speedcontrolmode

The torque demand is equal to the speed loop output.

1or2 =Torquecontrol

The torque demand is given by the sum of the torque reference and the torque offset, if enabled. The speed is not limited in any way,

however, the drive will trip at the over speed threshold if runaway occurs.To activate a parameterchange,a save and power down is

necessary.

4.12 Current demand filter 1 cut-off frequency

ô

A first order filter, with specified bandwidth by this parameteris providedon the currentdemand to reduce acoustic noiseand vibration

produced in an application. The filter introduces a lag in the speed loop, and so the speed loop gains may need to be reduced to maintain

stability as the filter time constantis increased. Alternative bandwidth can be selected depending on the valueof the speed controller gain

selector[3.16].

[3.16] = 1 parameter [4.12]isused

[3.16] = 2 parameter [4.23]isused

[3.16] = 3 parameter [4.27]isused

±200

0~1

0~2

0 ~ 1200

ð

ð

ð

ð

0

0 RW Bit

0 RW Uni

500 Hz RW Uni 0.16

%I

LIM

RW Bi

M’Ax AdvancedUser Guide 30

Issue Number: 4 www.controltechniques. com

Page 34

*

4.15 Motor-thermal time-constant

ôð

The motor is modelled thermally in a way that is equivalent to the electrical circuit shown below.

=RC

2

I

C

The temperature of the motor as a percentage of maximum temperature, with a constant current magnitude of I, after time t is given by

Temp =[I2/(Motor rated current x Motor overload threshold)2](1 - e-t/τ)x100%

Thisassumes thatthemaximum allowedmotor temperatureisproduced with 110%rated currentand that τ is the thermaltime constant of the

point in the motor that reaches it maximum allowed temperature first. τ is defined by SLM (indicated by parameter [4.15]) and Motor overload

threshold is defined in parameter [4.52]. When the estimated temperature reaches Motor overload threshold the drive limits the current to

current scaling set by the parameter [4.53]. The time for a tripor reductionof currentlimit from coldwith constant motor currentis given by:

=-(Par 4.15)xln(1 -((4.52/100)xPar 5.07/ Par 4.01)2)

T

trip

The thermal model accumulator is set to zero at power-up and accumulates the temperature of the motor whilst the drive remains poweredup.

4.23 Current-demand filter 2 cut-off frequency

ô

Refer to parameter 4.12.

0 ~ 1200

ð

SLM RO Uni 0.16

R

Temp

500 Hz RW Uni

4.24 Symmetrical current limit Kc2

ô

Refer to parameter 4.07 and P.I.D calculation section in Menu3.

4.26 Torque-compensation gain

ô

Not available in current software version.

4.27 Current-demand filter 3 cut-off frequency

ô

Refer to parameter 4.12.

4.28 Symmetrical current limit Kc3

ô

Refer to parameter 4.07 and P.I.D calculation section in Menu3.

4.51 Reserved for internal system purposes

For drive’s internal system purposes only.

4.52 Motor thermal-overload trip level

0~300

0 ~ 5000

0 ~ 1200

0~300

ð

ð

ð

ð

200.0

500 Hz RW Uni

200.00

%I

Rads/s RW Uni

%I

M

M

RW Uni

RW Uni

ô

See parameter 4.15.Toactivateanewvalueasaveandpowerdownisnecessary.

0~125

ð

110

%I

M

RW Uni

31 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 35

4.53 Symmetrical current limit after motor thermal-overload trip

*

ô

0~300

ð

105

%I

M

RW Uni

The Motor overload warningbit10.17is set if integrator value is greater than Motor overload warning threshold 4.52. Also the output current

2

scaling is switched to parameter4.53 (Current scalingduring I

I2t trip threshold

2

I

t Warningthreshold

Accumulator value

Standard current Scaling , ,

Current scaling

Current Scaling During I t Trip24.53

2

SLM I t Trip Bit 13 Status

2

I tWarning Bit Status

When the I

2

t threshold goes above the limit set in parameter 4.52, the SLM alters its current scalingto limit the motor current in a default

4.52

4.56

10.58

4.07 4.24 4.28

4.57

1

0

1

0

t limit).

Time

Time

state.

If a controller wants to use this as a warning bit, the threshold [4.52] can be adjustedtoa requiredlevel(i.e. 75% insteadof 110%).Changing

2

the I

t thresholdin [4.52] will not limit the currentscalingafter the motor thermal overload alarm is set.In this case the controllershould take

the necessaryaction to protect the motor,i.e. reduce acceleration or stop.

The drive will operate,when the motor thermaloverload alarm is set, until thethermaloverl oad timeto trip parameter value [4.54]has been

exceeded.

Typical Example:

Parameter Value

4.15 Motor – thermal time-constant 89

4.07 Symmetrical currentlimitKc1 150

4.24 Symmetrical currentlimitKc2 200

4.28 Symmetrical currentlimitKc3 175

Process cycletime 11.5s

Gainsequencing using all three PID-gains buffers

1. Set 4.53 Symmetrical current limit after motor thermal-overload alarm at 200 (the largest of the symmetrical current limit values).

2. Set 4.54 Thermal-overload time to trip at 12 (process cycle time, rounded-up to nearest integer).

3. Calculate the following:

t

c

t

c

4.15[]– In 1

89– In 1

æö

×=

ç÷

èø

æö

105

× 28.7 s()==

------ ----- -

–

ç÷

èø

200

105

------- ------------

–

4.53[]

2

2

2

2

4. Calculate the following:

t

DtC

4.54[]– 28.7 12– 16.7 s()===

5. Calculate the following:

t–D4.15[]⁄

4.52[]4.53[]1e

4.52[]200[]1e

–×=

16.7–()89⁄

–× 82.7==

(%)

6. Enter the calculated value into4.52.

7. Performthefollowing, as appropriate:

M’Ax AdvancedUser Guide 32

Issue Number: 4 www.controltechniques. com

Page 36

*

Version _AN

Initiatethe save operationby settingparameterXX.00 at 1000.

Execute the operationby performing either of the following:

• While the displayis in Edit mode, press at thesame time:

and

• Set parameter 10.38 at 100 (via serial communications)

Version _SL

Version _AN (if required)

Ensurethe driveis disabledby checking that the Hardware enable contact is open or that parameter 6.15 is set at 0, then perform either

of the following:

• Initiatethe store operation by setting parameter 0.50 at 2 (Prog). Execute the operation by setting parameter 10.38 at 100.

• Set 11.67 Flash update enable at 1.

4.54 Thermal overload time to trip

ô

This is a secondary motor overloadprotection.The user can set Current scaling duringI

the motion controller reduces torque demand in order to protect the motor. This secondary protection tripsthe drive on motor overload

(I2t.AC) if Motor overloadwarning bit (10.17)is continuously set more than Motor overloadtimelimit.

4.55 SLM overheat threshold parameter

ô

The value set in this parameteris the trip thresholdlevelfor the SLM thermistor.Once this level has been exceeded, the drive will trip ‘Oht3’.

4.56 Motor overload alarm level

ô

4.57 Motor overload alarm

ô

This bit parameter is set if the motor overload accumulator [10.58] rises above the motor overload alarm level set in parameter 4.56,

otherwise cleared.

4.58 ‘U’ phase current loop offset correction

4.59 ‘V’ phase current loop offsetcorrection

ô

These parameters areto compensate for t he current loop and power stage offsets, which end up as speed ripple on the demandedspeed.

These parameters arerelayedto the SLM on power-up and are onlyrequired for high performance applications.

Please contact T echnical Support for further assistance in using these parameters.

0~200

0~100

0~100

0~1

0 ~ 65535

ð

ð

ð

ð

ð

10 s RW Uni

2

t limit (4.53)to standard current scaling (4.07)and

85 °CRWUni

70 RW Uni

RO Bit

0 RW Uni

33 M’Ax Advanced User Guide

www.controltechniques.com Issue Number: 4

Page 37

7 Menu 5 Parameters - Motor Control

*

Parameter

5.05 {0.43} DC-bus voltage 0 ~ 1000 V

5.07 {0.19} Motor- rated current 0~ FLC A [SLM] RO Uni

5.08 Motor- rated speed 0 ~ 7500rpm [SLM] RO Uni

5.09 Motor- rated voltage

5.11 Motor - number of poles 0 ~ 255 [SLM] RO Uni

5.12 Flux alignment test enable 0~1 0 RW Bit

5.32 Motortorque-constant 0.00 ~ 500.00Nm/A [SLM] RO Uni

5.33 Motorinertia

5.34 {0.11} Inertia units selected 0~1 [SLM] RO Bit

5.52 Reserved for internal system purposes

5.53 Reserved for internal system purposes

5.54 Inertia range select 0~1 1 RW Bit

Notes

The settings of parameter 5.34 are as follows:

0 kgm

1 kgcm

The settings of parameter 5.54 are as follows:

0 Ranges are as shown for 3.18 and 3.20

1 Ranges are divided by 10

Full-load current

FLC

(continuous-currentrating of thedrive)

2

2

0.1 ~ 6000.0 kgcm

0.00001 ~ 0.6 kgm

Range(

0~V

ô

) Default(ð)

S

2

or

2

[SLM] RO Uni

[SLM] RO Uni

RO Uni P

Type

V

AC supply voltage

S

M’Ax Advanced User Guide 34

Issue Number: 4 www.controltechniques. com

Page 38

*

P

M

Figure7-1 Menu 5 software diagram

Phase advance

Current

demand

[MO]

SLM

5.05

DC-bus voltage

Menu 4

Sine-wave