Continental Refrigerator Undercounter Refrigerators and Freezer User Manual

Operation, Installation and

Instruction Manual

For

Undercounter Refrigerators and Freezers

and

Pizza Preparation Tables

A Division of National Refrigeration & Air Conditioning Products, Inc.

539 Dunksferry Road • Bensalem, PA 19020-5908

215-244-1400 • 1-800-523-7138 • Fax: 215-244-9579

www.continentalrefrigerator.com

REV1004

Operators Manual

Table of Contents Page

Receiving Your New Model ........................................................................................3

General Information And Important Operating Facts ................................................3

Uncrating Your New Model ........................................................................................4

Installation And Location ............................................................................................4

Clearances ..........................................................................................................4

Ventilation ............................................................................................................4

Floor Loads..........................................................................................................6

Installing Legs And Leveling ................................................................................7

Installing Casters And Leveling ..........................................................................8

Installing Condensate Evaporator........................................................................9

Removal Of Doors And Door Adjustment ..........................................................10

Self-Closing Hinge Mechanism Mounting ..........................................................11

Removal And Replacement Of Hinge Mechanism ............................................12

Initial Cleaning Procedure ........................................................................................12

Start-Up Procedure....................................................................................................13

Electrical Connections ........................................................................................13

115 Volt, 60 Hz, 1 Phase Connection ................................................................13

208-230 Volt, 60 Hz, 1 Phase Connection ........................................................14

Special Voltage Connections ..............................................................................14

Start-Up Checklist ..............................................................................................14

Remote Applications ..........................................................................................14

Operation ..................................................................................................................15

Thermometer Calibration ....................................................................................15

Pizza Preparation Table Operation ....................................................................15

Pizza Rail System Switch ..................................................................................15

Pizza Prep Temp Adjustment - Bottom Storage Compartment ..........................15

Pizza Prep Temp Adjustment - Coldwall Rail ....................................................16

Undercounter Refrigerator System And Adjustment ..........................................16

Undercounter Freezer System And Adjustment ................................................16

Defrost Operation ..............................................................................................17

Evaporator Assembly..........................................................................................17

Interior Accessories ..................................................................................................18

Shelving Installation............................................................................................18

Optional Accessories ................................................................................................19

Optional Overhead Or Double-Overhead Shelf..................................................20

Optional Stacking Collar Adapter Kit ..................................................................20

Safety Precautions ....................................................................................................22

Maintenance ..............................................................................................................22

Periodic Cleaning Procedure..............................................................................22

General Preventative Maintenance ....................................................................23

Parts And Service ..............................................................................................23

Troubleshooting And Servicing Guide ......................................................................25

Wiring Diagrams ........................................................................................................28

Warranty ....................................................................................................................31

RECEIVING YOUR NEW MODEL

Congratulations on your recent purchase of Continental Refrigerator superior food

equipment products! When your shipment arrives, please thoroughly examine the

shipping crate for any punctures, dents, or signs of rough handling. It is in your best

interest to partially remove or open the shipping container in order to examine the

model for any concealed damages which may have occurred during shipment. If the

model is damaged, it must be noted on the delivering carrier's delivery slip or bill of

lading (see “filing a damage claim” under warranty section).

GENERAL INFORMA

TION AND IMPORTANT OPERATING FACTS

This manual has been compiled to aid in the installation, operation and maintenance

of your new equipment. Please take the time to read all of the material in order to

become more familiar with your equipment and its operation, and enjoy optimum

performance.

No floor drains or plumbing connections are required since all models are completely

self-defrosting and use an automatic defrost condensate water evaporating system

(see “condensate evaporator pan installation” under installation and location section).

All cabinets must be given sufficient time to reach normal operating temperature

before placing any food inside cabinet or pans (if equipped). For refrigerators,

approximately 1 hour of operation is required to lower the cabinet and pan

temperature to 40°F. During pull-down of open top models, pans should be in

place and top lid should be kept closed. Freezers require approximately

2 hours of operation to lower the cabinet temperature to 0°F (see “operation”

section for further information).

On all open top refrigerators with salad pans, it is strongly recommended that the top

lid be kept in the closed position when the unit is not in use or between rush periods.

This is extremely important during the summer months and in hot kitchens. Do not

keep the top lid open for prolonged periods of time and never operate open top

models without all pans in place. Please note that sandwich and pizza preparation

tables are not intended for overnight food storage in the open top pans.

Prior to factory shipping, all models are performance run tested for a minimum of

12 hours providing a highly sophisticated temperature analysis recording exclusive

to each individual cabinet. This recording is supplied within this manual packet. A

final leak check, vibration, noise level and visual examination is made by a qualified

quality control team to assure a quality product. The carrier signs to this effect when

he accepts the product for shipping. To insure the maximum in safety and sanitation,

all models are listed under the reexamination service of underwriter's laboratories

and with the national sanitation foundation.

3

UNCRATING YOUR NEW MODEL

The shipping container should remain on your model as protection against

dents or scratches while transporting it to the actual set-up location. Remove

the shipping container only at the last possible moment by following these

simple steps:

1. Using a pry bar, pry off and remove crate end bottom staples.

2. Pry off and remove crate front and rear bottom staples.

3. Slide crate upward and remove it, being careful not to rub against cabinet.

There are up to four (4) bolts securing the cabinet to the wooden skid. The bolts are

located at each end on the underside of the skid. In order to remove these bolts it is

advisable to tilt the cabinet backwards and place wooden blocks at each end in order

to hold it in its tilted position. Using a

3

/4" socket or open end wrench, remove the bolts

and carefully slide the model off of the skid. After skid removal, the cabinet should

never be moved without dollies or rollers to avoid damage to the cabinet bottom or

floor.

Important Note: Do not under any circumstances lay your new model on its front

or sides. Only for a brief period, may you lay the model on its back and only then,

when its properly blocked so as not to crush the louvered venting panel and also

to allow provision for your hands in order to set it in its upright position without

inflicting damage to the cabinet. Do not plug in and operate model for at least

three (3) hours after cabinet is set upright from being on its back as damage

could result to the compressor.

INSTALLATION AND LOCATION

CLEARANCES

Before moving the cabinet to its final point of installation, accurately measure all doorways or passages to assure clearance. If additional clearance is needed, cabinet doors

can be easily removed (see instructions outlined in “removal of doors” section) and, or

hood assembly (when equipped) can be easily removed (see instructions outlined in

“removal of hood” section).

VENTILATION

The final location site of your air-cooled refrigerator or freezer must be able to provide

a large quantity of cool, clean air. The refrigeration system operates most efficiently

and trouble-free with cool, dry air circulation. Avoid locations near heat and moisture

generating equipment such as stoves, ovens, cooking ranges, fryers, dish washers,

steam kettles, etc., and also direct sunlight where temperatures can be in excess of

100°F. Also, do not select a location in an unheated room or area where temperatures

may drop below 55°F. Air supply to the condensing unit is equally important. Restricting

the air supply will place an excessive heat load on the condensing unit and adversely

affect its operating efficiency.

4

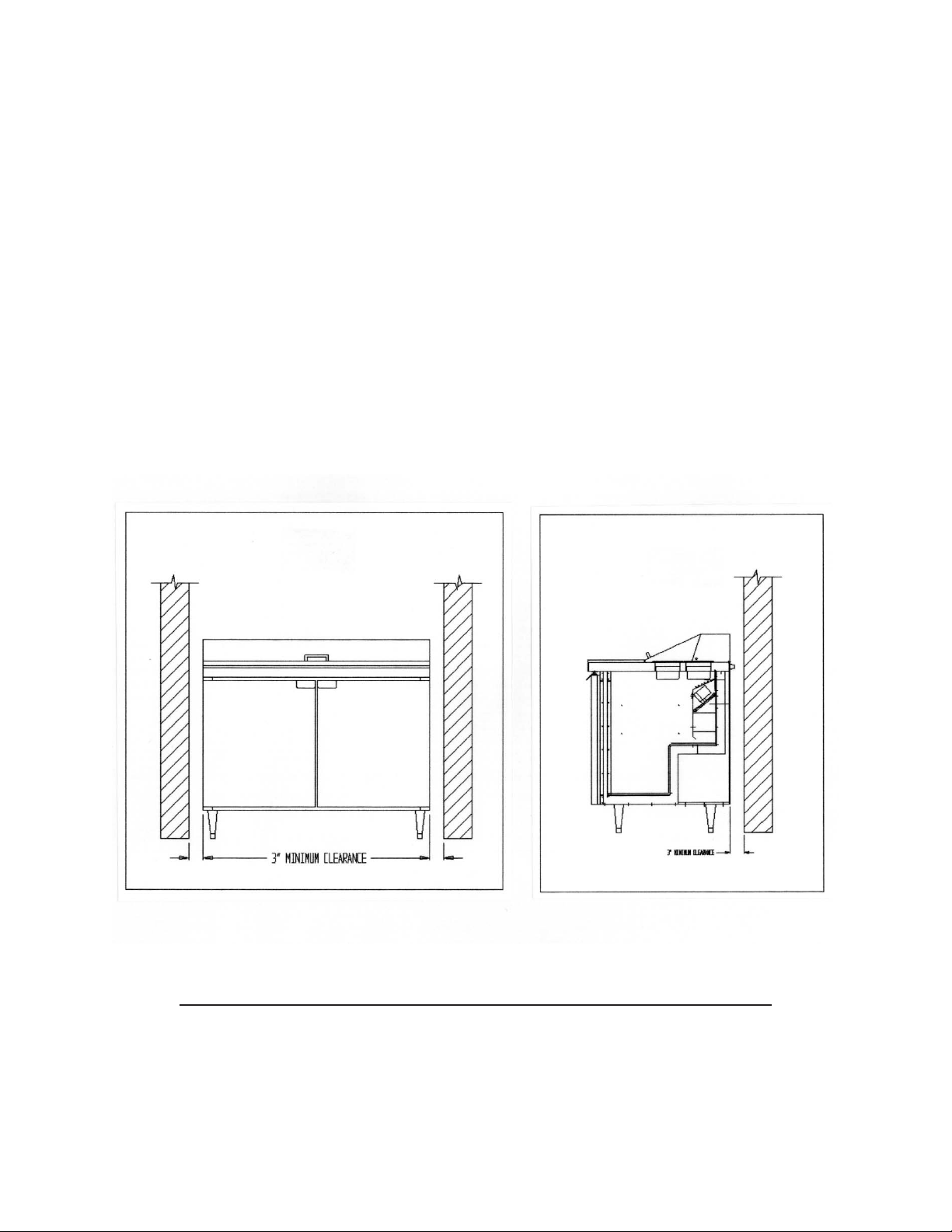

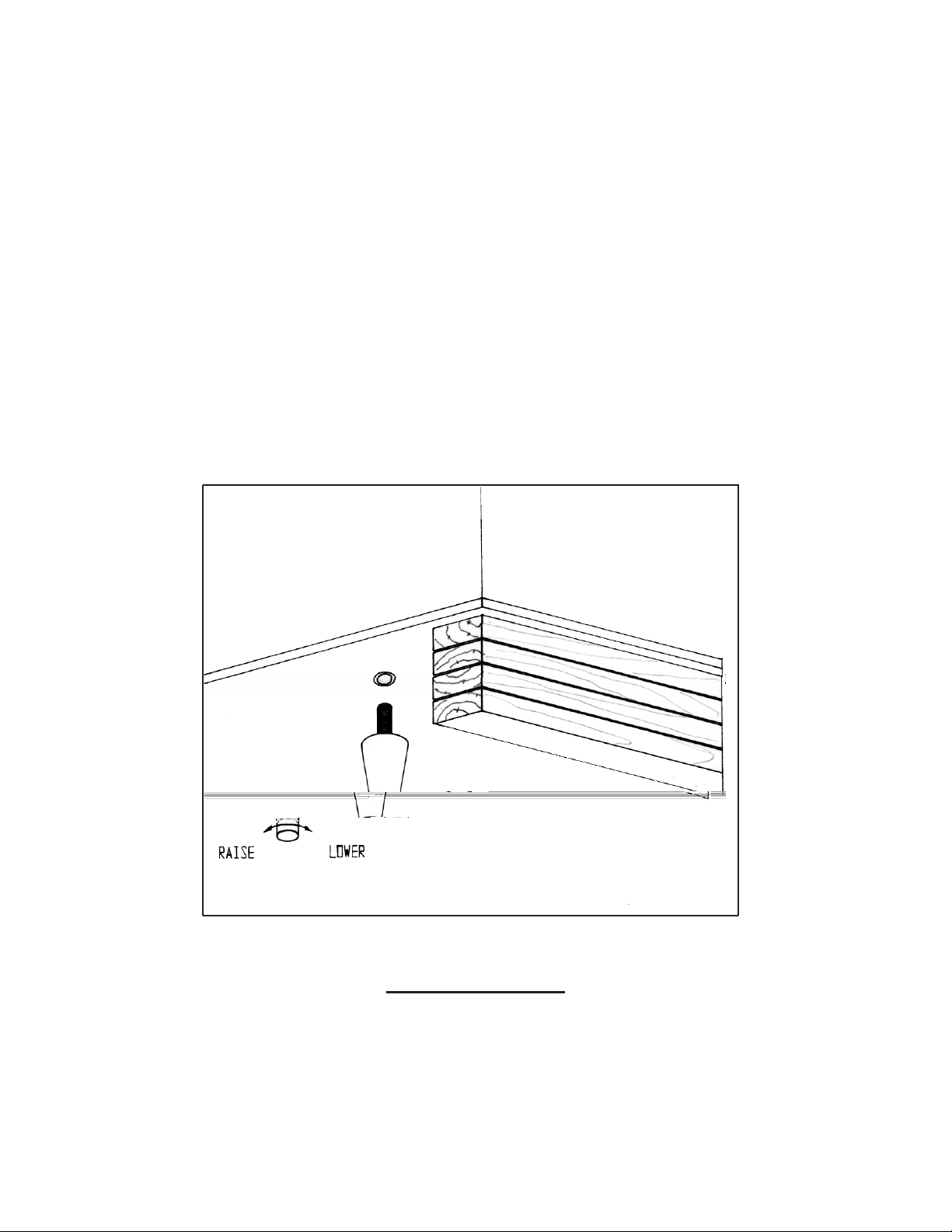

Important Note: To assure maximum operating efficiency, your new “SW” series

model should be located where an unrestricted air supply can circulate underneath

and behind the cabinet. For optimum performance, the cabinet must be installed on

legs or casters (see “installing legs or installing casters” later in this section) and a minimum of 3" on each side and rear of the cabinet must be provided (see figure 1a). Your

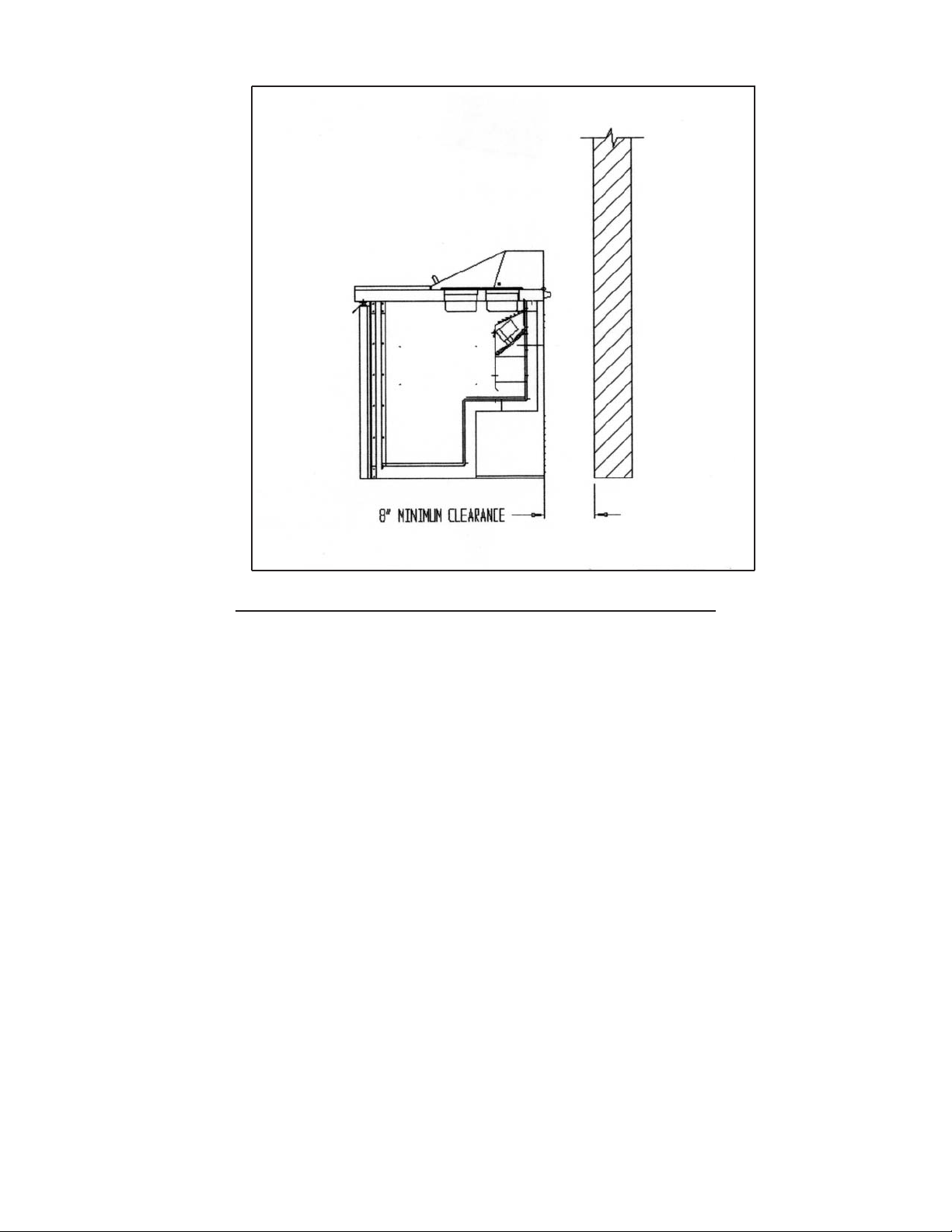

model has been designed to operate sufficiently without legs or casters and directly on

the floor as long as a minimum clearance of 8" is provided from the rear venting louvers and the rear wall (see figure 1b). Cabinet side clearance is not required when

mounting your model directly on the floor without legs or casters. If

necessary, special venting or air supply ducts must be installed by the installer if

any of the above conditions cannot be achieved. Do not at any time obstruct the

grill area in the rear of the cabinet in any way, and never place or store anything

inside of the cabinet machine compartment. These rules are essential for maximum

cooling capacity and long life of refrigeration parts.

5

FIGURE 1a

MINIMUM CLEARANCE DIMENSIONS FOR OPTIMUM CONDITIONS

FIGURE 1b

MINIMUM CLEARANCE DIMENSIONS WITHOUT LEGS

FLOOR LOADS

The floor at the final location site must be level, free of vibration and strong enough

to support the total combined weights of your new model plus the maximum product

load which might be placed into it. A fully loaded reach-in model may reach 2,000 3,000 pounds. To estimate the possible product load weight, assume that each cubic

foot of storage space weighs approximately 35 pounds. Multiply 35 pounds by the

amount of cubic feet in the cabinet and obtain the product load weight. For example,

a 20 cubic foot refrigerator can hold approximately 700 pounds of product (35 x 20)

and assuming the refrigerator itself weighs 300 pounds, the total combined weight

of cabinet and product is approximately 1000 pounds. Therefore, the floor in this

example must be capable of supporting up to 1000 pounds.

6

INSTALLING LEGS AND LEVELING

Your new “SW” series model is supplied with adjustable type legs for leveling

purposes. Each SW27, SW48, SW60 and SW72 model has four leg mounting

holes on its case bottom. Legs are packed in the accessory carton from which

they must be removed and installed on the cabinet case bottom (see figure 2).

In order to install the legs, carefully tip the cabinet rearward adding four (4) 2"

wood blocks underneath and simply screw the threaded leg studs into the case

bottom front leg holes. Repeat this procedure by tilting the cabinet in the opposite

direction and install the remaining legs. Make sure the legs are tightened extremely

well or the entire model will sway or rock with each opening or closing of the doors,

possibly causing damage to the case bottom. This procedure should be performed

close to the final installation site and allow access to the rear of the cabinet for

condensate evaporator installation (see “condensate evaporator installation” under

installation and location section).

To assure your cabinet is level, all legs are equipped with bullet-type leveling bolts.

These bolts can be turned by hand or by wrench, clockwise or counterclockwise to

level the cabinet.

7

FIGURE 2

LEG INSTALLATION

Important Note: It is extremely important that your new model is perfectly

level for proper operation. If it is not level, the following adverse conditions will

become apparent:

1. The door(s) will not be properly aligned and consequently will not provide

a good seal.

2. You model will run excessively due to improper door seal(s).

3. An excessive amount of ice will accumulate inside the cabinet, around the

door opening(s) and especially on the finned evaporator coil. If allowed to

continue, ice will eventually block the coil and the model will fail. This will

result in the loss of all food stored within the cabinet.

4. Defrost water will fail to drain properly and will overflow the evaporator coil

drain pan and into the cabinet of both refrigerator and freezer models.

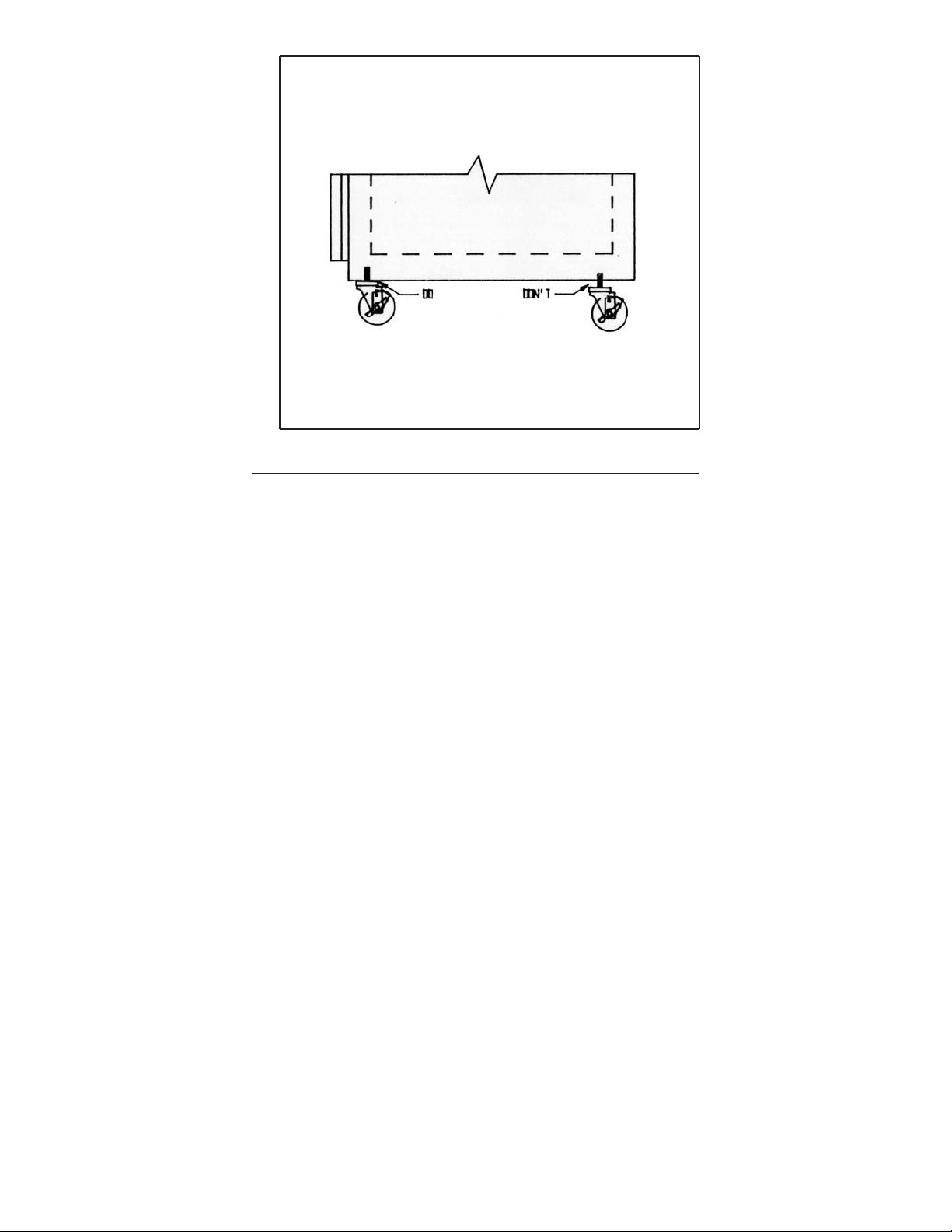

INSTALLING CASTERS AND LEVELING

Your new “CRB” and “CPT” series models are supplied with non-adjustable casters.

To install casters on your new model, follow the steps above for “installing legs” to

install the casters, making sure again that the casters are tightened extremely well

(see figure 3). If the casters are not installed tightly, the cabinet will sway or rock

with each opening or closing of the doors, possibly causing damage to the case

bottom.

To assure that your cabinet is level, caster cups must be installed under the casters

which need leveling. Caster cups are not provided with your new model but can be

purchased at most hardware or furniture stores. Do not attempt to level casters

by unscrewing them from the case bottom as this will cause damage to the

cabinet bottom and leg hole threads, voiding all warranties.

8

FIGURE 3

CASTERS MUST BE TIGHT T

O CABINET BOTTOM

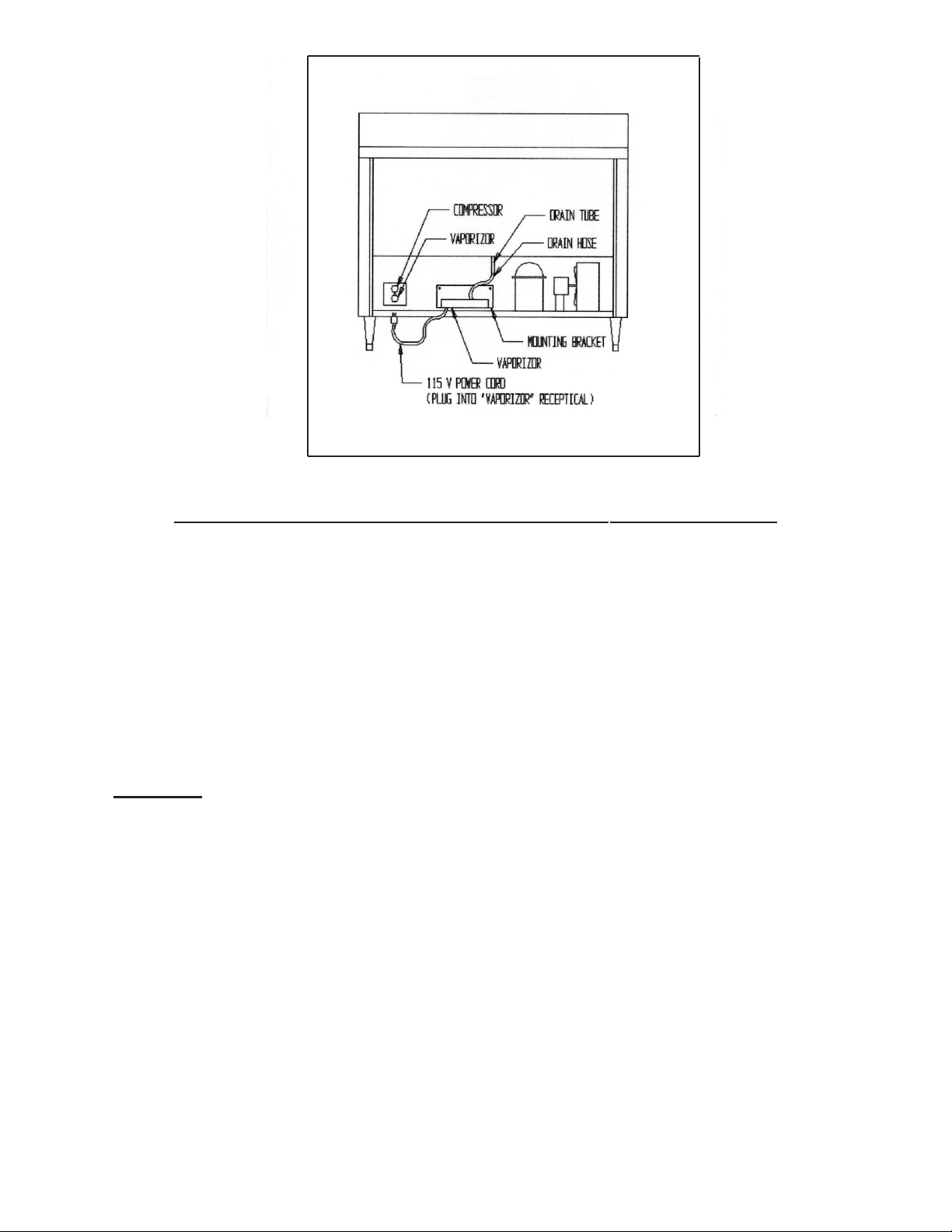

INSTALLING CONDENSATE EVAPORATOR

No floor drains or plumbing connections are required since all models use an

automatic condensate water evaporating system. All models utilize a unique

hot air condensate water evaporating system which is completely self-contained

and no further assembly or maintenance is required. In some adverse conditions

such as high ambient temperature, high humidity, extremely heavy usage, frequent

loading for prolonged periods of time, and heavy pan loading, an optional electric

condensate evaporator pan may be purchased as an accessory. An electric

condensate evaporator pan is also supplied with all remote models. To install the

condensate pan, remove all rear cabinet cover screws and install the mounting

bracket on the case rear next to and behind the compressor as shown in figure 4.

Slide the condensate pan onto the bracket, install the drain tube into the pan

making sure it is not blocked or kinked, and plug the ten foot power cord into the

receptacle labeled “vaporizer” located on the compressor compartment electrical

box.

Important Note: It is extremely important to be sure that the condensate pan is

plugged into its correct receptacle labeled “vaporizer” and that the condensing

unit is plugged into its correct receptacle labeled “condensing unit”.

9

FIGURE 4

OPTIONAL

ELECTRIC CONDENSATE EVAPORA

TOR INSTALLATION

REMOVAL OF DOORS AND DOOR ADJUSTMENT

During installation, it may become necessary to remove the cabinet doors to facilitate

passage through narrow doorways or hallways. To remove a door, swing the door to

the open-door position (90°) and remove the two screws marked “a” (figure 5) while

carefully holding the door open. Care must be taken to hold the door fully open during

the screw removal since the top hinge is spring loaded and may snap towards the door

when the screws are removed. After removing both screws, carefully lift the door

straight upward to avoid bending the bottom hinge pin. To reinstall the door, reverse

the above procedure.

Caution: The top hinge is spring loaded and may snap towards the door when

the mounting screws are removed. Be sure to hold door fully open before

removing mounting screws.

All doors have been aligned at the factory, however vibration during transportation

may cause doors to shift and realignment may be necessary. If the door(s) require

realignment, proceed as follows:

1. Swing the door to the open-door position and loosen but do not remove

the screws marked “A” on both top and bottom hinges (see figure 5).

2. Relocate the door to its required position by hand or by tapping on the

door edges with a hammer and a block of wood.

3. Securely tighten all screws “A”.

10

Loading...

Loading...