Page 1

EXTEND-A-BUS

A Line of Fieldbus Extenders for DeviceNet

for

User Manual

#TD960801-0MC

Page 2

Trademarks

Contemporary Controls, ARC Control, ARC DETECT and

EXTEND-A-BUS are trademarks or registered trademarks of

Contemporary Control Systems, Inc. ARCNET is a registered

trademark of Datapoint Corporation. Other product names may be

trademarks or registered trademarks of their respective companies.

TD960801-0MC Revised 07-16-02

Copyright

© Copyright April 1999-2002 by Contemporary Control Systems,

Inc. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language or computer language, in any form or

by any means, electronic, mechanical, magnetic, optical, chemical,

manual, or otherwise, without the prior written permission of:

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, Illinois 60515 USA

Tel: +1-630-963-7070

Fax: +1-630-963-0109

E-mail: info@ccontrols.com

WWW: http://www.ccontrols.com

Contemporary Controls Ltd

Sovereign Court Two

University of Warwick Science Park

Sir William Lyons Road

Coventry CV4 7EZ UK

Tel: +44 (0)24 7641 3786

Fax: +44 (0)24 7641 3923

E-mail: info@ccontrols.co.uk

Disclaimer

Contemporary Control Systems, Inc. reserves the right to make

changes in the specifications of the product described within this

manual at any time without notice and without obligation of

Contemporary Control Systems, Inc. to notify any person of such

revision or change.

TD960801-0MC

i

Page 3

Contents

Chapter 1 Introduction......................................................... 1

1.1 Description................................................1

1.2 Features..................................................... 2

1.3 Specifications ............................................ 2

1.4 Port Specifications .................................... 3

1.5 Ordering Information ................................ 4

Chapter 2 Installation........................................................... 5

2.1 Introduction ...............................................5

2.2 Electromagnetic Compliance..................... 5

2.3 Mounting the EXTEND-A-BUS...............6

2.4 Powering the EXTEND-A-BUS ............... 6

2.5 Connecting to the CAN Port ..................... 9

2.6 Connecting to the Backbone Port ............ 12

Chapter 3 Operation .......................................................... 19

3.1 CAN Communications ............................ 19

3.2 Theory of Operation................................ 20

3.3 System Considerations ............................ 23

3.4 LED Indicators........................................ 25

Chapter 4 Service ............................................................... 27

W arranty............................................................. 27

T echnical Support............................................... 28

Warranty Repair ................................................. 28

Non-W arranty Repair .........................................29

Returning Products for Repair............................ 29

Appendices

Appendix A—Permissible Segment Lengths ...... 31

Appendix B—Declaration of Conformity........... 34

TD960801-0MC

ii

Page 4

List of Figures

Figure 2-1 DC Powered........................................................ 7

Figure 2-2 Redundant DC Powered...................................... 8

Figure 2-3 AC Powered........................................................ 8

Figure 2-4 AC Powered with Battery Backup ...................... 9

Figure 2-5 CAN Port Connector Assignments ................... 10

Figure 2-6 Data Rate Switch .............................................. 11

Figure 2-7 Appropriate terminators are required

at the ends of both the coaxial cable backbone

and DeviceNet subnets......................................13

Figure 2-8 A maximum of eight EXTEND-A-BUSes can .....

occupy one coaxial backbone segment before an..

active hub is required ........................................ 14

Figure 2-9 A 62.5/125 µm duplex fiber optic cable is

used on the -FOG model up to a maximum of

1830 meters....................................................... 15

Figure 2-10 By using two AI3-CXS hubs, a

distributed star topology is achieved .................17

TD960801-0MC

iii

Page 5

1 Introduction

1.1 Description

The EXTEND-A-BUS for DeviceNet series of fieldbus

extenders enable the geographic expansion of CAN-based

device networks such as DeviceNet by linking individual

DeviceNet subnets together into a single larger network.

The medium arbitration method used by DeviceNet is intolerant

of excessive signal delay . Since cable length introduces delay ,

DeviceNet networks tend to be distance limited. Repeaters are

ineffective in extending distances since they introduce additional

delay . On the other hand, fieldbus extenders like EXTEND-ABUS solve the problem by segmenting a single DeviceNet

network into manageable subnets.

EXTEND-A-BUS interconnects two physically separated but

similar networks using a different interconnecting medium.

Thus, a pair is required to interconnect two networks (or

subnets) the way two modems are used on leased phone lines.

Utilizing ARCNET as the high-speed deterministic

interconnecting medium, the EXTEND-A-BUS captures

DeviceNet traffic and replicates it to the receiving device. The

receiving device removes DeviceNet data and rebroadcasts the

data to its attached DeviceNet subnet. EXTEND-A-BUS does

not filter out DeviceNet identifiers or MAC addresses, so

DeviceNet messages are rebroadcast unmodified.

Application Information

Each EXTEND-A-BUS creates a DeviceNet subnet and a

minimum of two EXTEND-A-BUSes is required to establish a

network. The data rate on each subnet can be different from the

other subnets. DeviceNet identifiers or MAC ID checks are

replicated on all subnets. EXTEND-A-BUS pairs are best

viewed as an extension cord. Each EXTEND-A-BUS does not

consume a permanent MAC ID and, therefore, is transparent to

the network.

TD960801-0MC

1

Page 6

Extending the Interconnecting Medium or Backbone

The backbone side of the EXTEND-A-BUS must comply with

standard ARCNET cabling rules. Companion AI ARCNET

active hubs are available for extending the backbone cabling up

to 6 km using coaxial cabling and ten active hubs. When using

a fiber optic backbone, a maximum of 4.8 km can be achieved

requiring two active hubs. Hubs are cascaded to reach the

required distance.

1.2 Features

• Extends the length of DeviceNet networks up to 6 km

• Fully DeviceNet compliant

• Fiber optic or coaxial cabling

• Star, bus or distributed star topology

• Variable data rate up to 500 kbps

• Low voltage AC or DC powered

• Panel-mount enclosure

1.3 Specifications

Electrical

DC AC

Input voltage: 10–36 volts 8–24 volts

Input power: 4 watts 4VA

Input frequency: N/A 47-63 Hz

Power Options

– DC powered

– Redundant powered

– AC powered

– AC powered with battery backup

TD960801-0MC

2

Page 7

Environmental

Operating: 0°C to 60°C

Storage: -40°C to +85°C

Functional

Data latency: 1.2 ms typical per EXTEND-A-BUS pair

Regulatory Compliance

FCC Part 15 Class A

CE Mark

1.4 Port Specifications

CAN Port

Compliance DeviceNet

Volume I, Release 2.0

Data Rate 125 kbps, 250 kbps, 500 kbps select-

able or

Autobaud 125 kbps, 250 kbps, 500 kbps

LEDs CAN status:

Module status/network status

T ransceivers Optically isolated 82C251

Cable DeviceNet Thick

Connectors 5 position Open-pluggable

Maximum segment 125 kbps: 500 meters (1640 ft)

or subnet distance 250 kbps: 250 meters (820 ft)

500 kbps: 100 meters (328 ft)

Maximum number

of nodes per segment 64

Terminating resistor 121 ohms

Backbone Port

Compliance ARCNET

ANSI/ATA 878.1

Data Rate 2.5 Mbps

TD960801-0MC

3

Page 8

LEDs Link status:

Reconfiguration status/activity status

T ransceivers -CXB model: transformer coupled

-FOG model: 850 nm duplex

fiber optic

Cable -CXB model: RG-62/u coaxial

-FOG model: 62.5/125 µm duplex

fiber optic

Connectors -CXB model: BNC

-FOG model: ST

Maximum segment -CXB model: 305 meters (1000 ft)

or subnet distance -FOG model: 1830 meters (6000 ft)

(optical power

budget 10.4dB)

Maximum number -CXB model: 8

of nodes per segment -FOG model: N/A

Terminating resistor -CXB model: 93 ohms

-FOG model: N/A

1.5 Ordering Information

The EXTEND-A-BUS series is available in several

configurations depending upon the application and cable media

supported.

EXTEND-A-BUSes:

EB/DNET-CXB EXTEND-A-BUS with coaxial bus backbone

EB/DNET-FOG EXTEND-A-BUS with fiber optic backbone

Accessories:

AI-XFMR W all-mount transformer 120 VAC (nom)

AI-XFMR-E Wall-mount transformer 240 VAC (nom)

AI-DIN DIN-rail mounting kit

BNC-T BNC “T” connector

BNC-TER 93-ohm BNC terminator

TD960801-0MC

4

Page 9

2 Installation

2.1 Introduction

The EXTEND-A-BUS series is intended to be panel mounted

into an industrial enclosure or into a wiring closet. T wo #8 pan

head screws (not provided) are required for mounting.

Optionally , the bridge can be mounted on a DIN rail by

purchasing a DIN rail mounting kit.

2.2. Electromagnetic Compliance

The EXTEND-A-BUS series complies with Class A radiated

and conducted emissions as defined by FCC part 15 and

EN55022. This equipment is intended for use in non-residential

areas. Refer to the following notices in regard to the location of

the installed equipment.

Note: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own

expense.

W arning

This is a Class A product as defined in EN55022. In a

domestic environment this product may cause radio

interference in which case the user may be required to take

adequate measures.

TD960801-0MC

5

Page 10

The EXTEND-A-BUS has been tested to EN50082 Generic

Immunity Standard–Industrial Environment. This standard

identifies a series of tests requiring the equipment to perform to

a particular level during or after the execution of the tests. The

three classes of performance are defined by CCSI as follows:

Class A - Normal operation, however, occasional

reconfigurations may occur or throughput may be reduced due

to an error recovery algorithm by the ARCNET data link level

protocol.

Class B - Throughput reduced to zero and continuous

reconfigurations occur. Normal operation resumed after

offending signal removed.

Class C - Complete loss of function. Unit resets and normal

operation restored without human intervention.

At no time did the EXTEND-A-BUS fail to return to normal

operation or become unsafe during the execution of these tests.

A copy of the Declaration of Conformity is in the appendix.

2.3 Mounting the EXTEND-A-BUS

The EXTEND-A-BUS is intended for mounting onto a vertical

panel within an industrial control enclosure. T wo #8 screws can

be used for mounting the EXTEND-A-BUS in a vertical

orientation. Refer to the mechanical specifications for details.

T o mount the EXTEND-A-BUS onto a DIN rail, an optional

DIN rail mounting clip (AI-DIN) must be purchased and

installed on the rear of the EXTEND-A-BUS. Once the clip is

mounted to the EXTEND-A-BUS, the EXTEND-A-BUS can be

snapped onto the DIN rail.

2.4 Powering the EXTEND-A-BUS

The EXTEND-A-BUS requires either low voltage AC or DC

power in order to operate. Consult the specifications for power

requirements. Power is provided to a four pin removable keyed

TD960801-0MC

6

Page 11

connector . There are several methods for providing power .

These methods are DC powered, redundant DC powered, AC

powered and AC powered with battery backup.

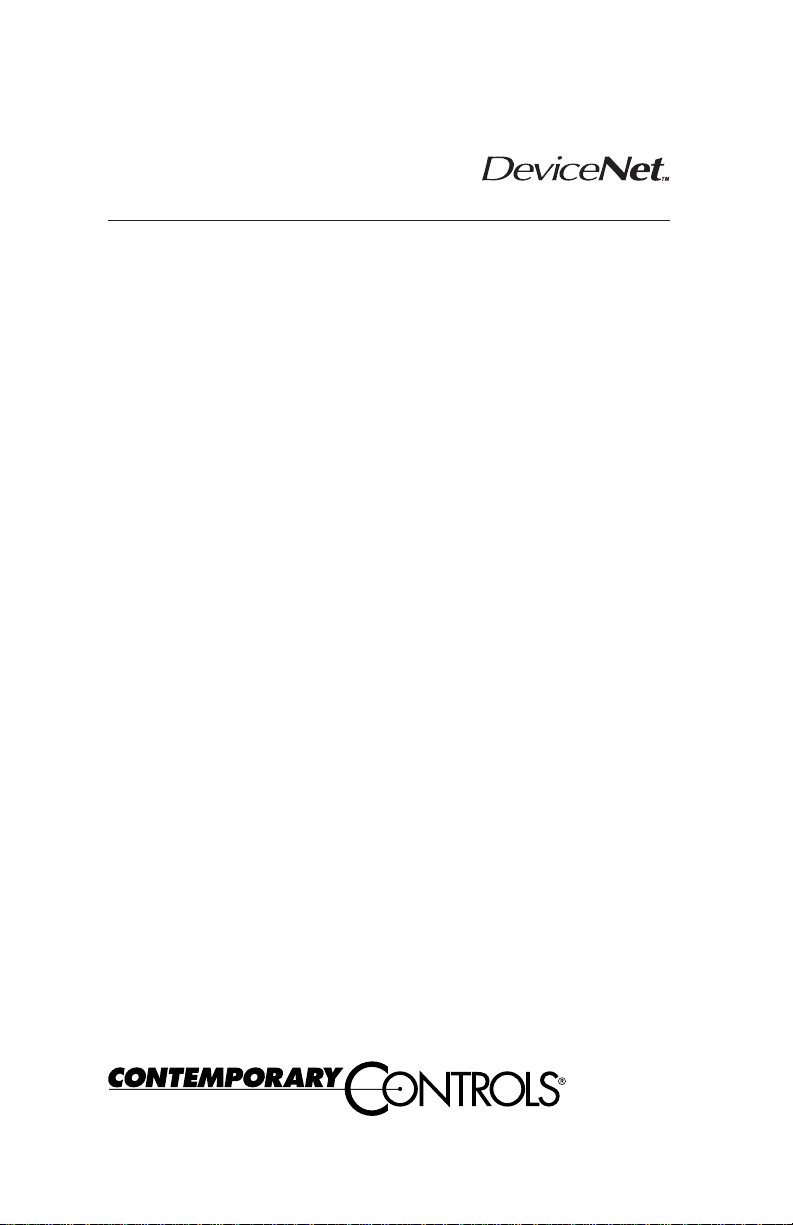

2.4.1 DC Powered

Make connections as shown in Figure 2-1. The EXTEND-ABUS incorporates a DC-DC converter that accepts a wide

voltage range (10–36 VDC) and converts the voltage for

internal use. Input current varies with input voltage so it is

important to size the power conductors accordingly . Input power

to the EXTEND-A-BUS maximizes at 4 watts; therefore, at

10 VDC, the input current is approximately 400 ma. The

ground connection to the EXTEND-A-BUS is connected to

chassis within the EXTEND-A-BUS. The input connections are

reverse voltage protected.

Figure 2-1. DC Power ed

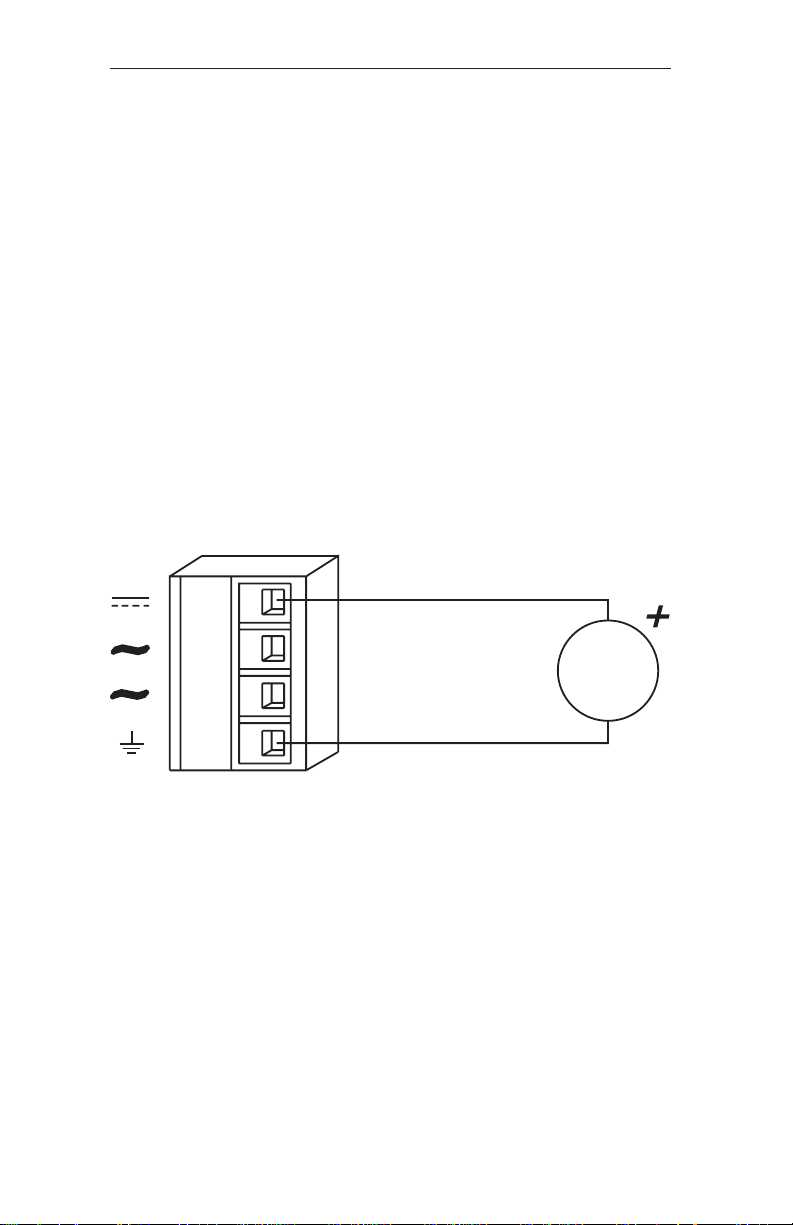

2.4.2 Redundant DC Power ed

Redundant diode isolated DC power inputs are provided on the

EXTEND-A-BUS for those applications in which there is a

concern that the EXTEND-A-BUS remain operational in the

event of a primary power failure. Make connections as shown in

Figure 2-2. Each power supply source must be sized for the full

4-watt load of the EXTEND-A-BUS. Do not assume that input

currents will be balanced from the two supplies.

TD960801-0MC

7

Page 12

Figure 2-2. Redundant DC Powered

2.4.3 AC Powered

If only AC power is available, the EXTEND-A-BUS can be

powered by the secondary of a low voltage transformer whose

primary is connected to the AC mains. The secondary voltage

must be in the range of 8 to 24 VAC, 47–63 Hz with the

capability of delivering up to 4 VA of apparent power. The

secondary of the transformer must not be grounded. For

convenience, two auxiliary power supplies are available:

• AI-XFMR for 120 VAC primary power

• AI-XFMR-E for 240 VAC primary power

Reference Figure 2-3.

Figure 2-3. AC Power ed

TD960801-0MC

8

Page 13

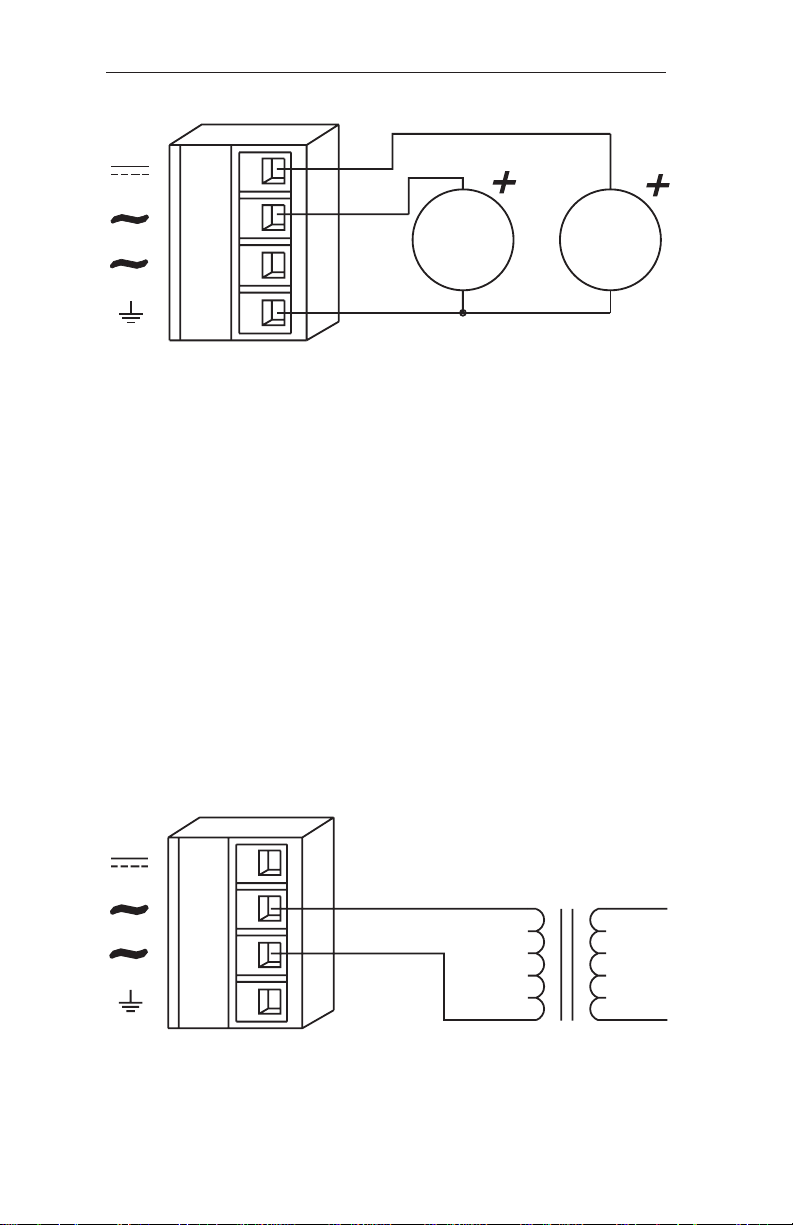

2.4.4 AC Power ed with Battery Backup

The EXTEND-A-BUS can also be powered from both an AC

and DC power source. Usually , the DC source is from a battery

supply which is connected as the DC powered option. Refer to

Figure 2-4. In this application, the EXTEND-A-BUS does not

charge the battery so separate provisions are required for

charging. If the AC source fails, the EXTEND-A-BUS will

operate from the battery source.

Figure 2-4. AC Powered with Battery Backup

2.5 Connecting to the CAN Port

The CAN port complies to the DeviceNet physical layer

specification for an isolated port. Since the port is isolated, bus

power (V+, V–) must be present in order for the port to

function. A bus power sensor has been provided in the

EXTEND-A-BUS to ensure that in the absence of bus power,

the port will not enter the “bus off” state.

2.5.1 CAN Port Assignments

A five position open style male connector has been provided on

the EXTEND-A-BUS for connections. See figure 2-5 for

connector assignments. A mating female connector has been

provided in order to make field connections.

TD960801-0MC

9

Page 14

T erminators are required at the ends of trunk cables. If the

EXTEND-A-BUS is located at the end of a trunk and no

terminator is present, a discrete resistor terminator (121 ohms)

can be connected under the screw terminals for CAN_H and

CAN_L.

Refer to Figure 2-5 for wiring details.

Network C onnector (F emale Contact s)

5 V+ red

4 CAN_H white

3 drain bare

2 CAN_L blue

1 2 3 4 5

Device Connector (Male Contacts)

1 V- black

Figure 2-5. CAN Port Connector Assignments

2.5.2 CAN Port Data Rates

Several data rates can be selected by a rotary switch as shown

in figure 2-6. Switch positions are labeled A, S, 125, 250, 500.

A and S are used to implement autobauding which will be

discussed later. The remaining positions determine a fixed data

rate in units of kbps. Therefore, the lowest rate is 125 kbps and

the highest is 500 kbps. The data rate switch is only read upon

power up; so to change settings, the switch position should be

changed and the power cycled to the EXTEND-A-BUS. A

clockwise rotation increases the data rate setting.

TD960801-0MC

10

Page 15

Figure 2-6. Data Rate Switch

2.5.3 Autobauding

Autobauding is the action of automatically matching the data

rate of the EXTEND-A-BUS to the data rate of a master

controller or scanner in a DeviceNet network. By moving the

Data Rate switch to the A position and powering up the

EXTEND-A-BUS, the EXTEND-A-BUS will attempt to

determine the data rate by observing the traffic on the CAN

port. Therefore, it is important that the CAN port be connected

to the DeviceNet subnet connecting the master controller . All

other EXTEND-A-BUSes should have their Data Rate switch

set to S (slave) position since their data rate will be set by the

master EXTEND-A-BUS (the one connected to the master)

which will broadcast the required data rate to all slaves once the

data rate is determined. Autobauding functions for the three

data rates: 125, 250 and 500 kbps.

TD960801-0MC

11

Page 16

2.6 Connecting to the Backbone Port

The backbone (link) port is ARCNET compliant and, therefore,

complies with the cabling rules for ARCNET networks. For

more information on designing an ARCNET cabling system,

refer to Contemporary Controls’ publication, “ARCNET

Tutorial & Product Guide.”

Either of two transceivers are available on the backbone port.

The coaxial bus (-CXB) transceiver requires coaxial cable

allowing a total of eight EXTEND-A-BUS devices to be

connected onto one wiring segment. The fiber optic (-FOG)

transceiver allows for two EXTEND-A-BUSes to be connected

in a point-to-point or link fashion. If star or distributed star

topologies are desired or if the cabling distances must exceed the

basic specifications, ARCNET compliant active hubs are

required. Contemporary Controls provides two series of active

hubs–the MOD HUB series of modular hubs and the AI series

of fix port hubs. Refer to the appendix for more information on

active hubs.

2.6.1 Connecting Coaxial Bus Networks (-CXB)

Coaxial bus backbone ports must be interconnected with

RG-62/u 93-ohm coaxial cable. In a simple two EXTEND-ABUS arrangement, a BNC-Tee (BNC-T) is twisted onto each

BNC backbone port. A length of RG-62/u cable, no shorter

than 6 feet (2 m) nor longer than 1000 feet (305 m) is connected

between the BNC-Tee connectors. At the open end of each

BNC-Tee is connected a 93-ohm terminator (BNC-TER). This

completes the basic connection.

TD960801-0MC

12

Page 17

Figure 2-7. Appropriate terminators are

required at the ends of both the coaxial cable

backbone and DeviceNet subnets.

More than two EXTEND-A-BUSes (but no more than eight)

can be connected to one wiring segment. Insert the desired

number of EXTEND-A-BUSes using BNC-T ee connectors to

the backbone wiring. Make sure that any two EXTEND-ABUSes are separated by at least 6 foot (2 m) of cable and that

the complete cabling segment does not exceed 1000 feet

(305 m).

TD960801-0MC

13

Page 18

Figure 2-8. A maximum of eight EXTEND-A-BUSes can

occupy one coaxial backbone segment before an active hub is

required. Use BNC “Tees” and terminators when making

connections. One of each is included in the -CXB model.

2.6.2 Connecting Fiber Optic Cable (-FOG)

Multimode fiber optic cable is typically available in three sizes,

50/125, 62.5/125, and 100/140. The larger the size, the more

energy that can be launched and, therefore, the greater the

distance. Bayonet style ST connectors, similar in operation to

BNC coaxial cable connectors, are provided for making the

fiber connections.

Fiber optic connections require a duplex cable arrangement.

T wo unidirectional cable paths provide the duplex link. There

are two devices on the EXTEND-A-BUS fiber port. One device,

colored light gray, is the transmitter and the other, dark gray, is

the receiver. Remember that “light goes out of the light (gray).”

T o establish a working link between an EXTEND-A-BUS and

another EXTEND-A-BUS or an EXTEND-A-BUS to a hub, the

transmitter of point A must be connected to a receiver at point

B. Correspondingly the receiver at point A must be connected to

a transmitter at point B. This establishes the duplex link which

is actually two simplex links. Fiber optic cable is available

paired for this purpose. Usually the manufacturers' labeling is

only on one cable of the pair which is handy for identifying

which of the two cables is which. Establish your own protocol

TD960801-0MC

14

Page 19

for connecting cable between hubs and EXTEND-A-BUSes in

the field using the manufacturers' labeling as a guide. However,

remember that to connect point A to point B requires a paired

fiber optic cable and that the light gray connector at one point

must connect to a dark gray connector at the other point.

Figure 2-9. A 62.5/125 µm duplex fiber optic

cable is used on the -FOG model up to a

maximum of 1830 meters.

TD960801-0MC

15

Page 20

2.6.3 Extending the Backbone

The backbone side of the EXTEND-A-BUS must comply with

standard ARCNET cabling rules. Companion AI ARCNET

active hubs are available for extending the backbone cabling up

to 6 km using coaxial cabling and ten active hubs. When using

a fiber optic backbone, a maximum of 4.8 km can be achieved

requiring two active hubs. Hubs can be cascaded to reach the

required distance.

By using active hubs, star and distributed star topologies are

possible. There is, however, a limit to the overall length of the

backbone network. The delay experienced when an EXTENDA-BUS communicates to another EXTEND-A-BUS with each

located at the extreme ends of a network cannot exceed 31 µs.

This delay is due to cable and hub delays. This delay translates

to a maximum of 6 km of coaxial cable or 4.8 km of fiber optic

cable. When making this calculation, only consider the distance

between the two furthest EXTEND-A-BUSes. Also verify the

distance limitations of active hubs being used. Active hubs that

incorporate coaxial star ports (-CXS) allow for 2000 foot

connections between compatible ports but no bussing. When

making a connection to a -CXS port from the EXTEND-ABUS’ -CXB port, make sure that the -CXS port is located at

one end of the segment and that no terminator is used. The

length of a segment connecting a -CXB port cannot exceed

1000 feet (305 m).

TD960801-0MC

16

Page 21

Figure 2-10. By using two AI3-CXS hubs, a distributed star

topology is achieved. Note that the hub-to-hub distance can be

a maximum of 610 m when using coaxial cable and that no

terminators are used at the AI3 ports. However, the cables to

the EXTEND-A-BUSes still cannot exceed 305 m.

TD960801-0MC

17

Page 22

TD960801-0MC

18

Page 23

3 Operation

3.1 CAN Communications

CAN was designed by Bosch and is currently described by ISO

11898. In terms of the Open Systems Interconnection model

(OSI), CAN partially defines the services for layer 1 (physical)

and layer 2 (data link). Other standards such as DeviceNet,

Smart Distributed System and CANopen (collectively called

higher layer protocols) build upon the basic CAN specification

and define additional services of the seven layer OSI model.

Since all of these protocols utilize CAN integrated circuits, they

therefore all comply with the data link layer defined by CAN.

CAN specifies the medium access control (MAC) and physical

layer signaling (PLS) as it applies to layers 1 and 2 of the OSI

model. Medium access control is accomplished using a

technique called non-destructive bit-wise arbitration. As

stations apply their unique identifier to the network, they

observe if their data is being faithfully produced. If it is not, the

station assumes that a higher priority message is being sent

and, therefore, halts transmission and reverts to receiving mode.

The highest priority message gets through and the lower priority

messages are resent at another time. The advantage of this

approach is that collisions on the network do not destroy data

and eventually all stations gain access to the network. The

problem with this approach is that the arbitration is done on a

bit by bit basis requiring all stations to hear one another within

a bit time (actually less than a bit time). At a 500 kbps bit-rate,

this time is less than 2000 ns which does not allow much time

for transceiver and cable delays. The result is that CAN

networks are usually quite short and frequently less than 100

meters in length at higher speeds. T o increase this distance

either the data rate is decreased or additional equipment is

required.

TD960801-0MC

19

Page 24

3.1.1 Repeaters

The usual approach to increasing network distance is to use

repeaters. Repeaters provide signal boost to make up the loss of

signal strength on a long segment. However, the problem with

long CAN segments is usually not lack of signal strength but

excessive signal latency . This latency is due to the propagation

delay introduced by the transceivers and twisted-pair wiring. If

this latency approaches one bit time, the non-destructive bitwise arbitration mechanism fails. Repeaters actually introduce

more delay due to the additional electronics and are not effective

in increasing the overall length of CAN networks. Repeaters

are generally used to increase the effective length of drop cables

from CAN trunk lines. Repeaters operate on the physical layer.

3.1.2 Bridges

Bridges are defined as devices that link two similar networks,

however, bridges can mean different things to dif ferent people so

further clarification is necessary . A local bridge stands by itself

connecting adjacent wiring segments together as in the case of a

repeater. Remote bridging interconnects two physically

separated but similar networks together using a different

interconnecting medium. Therefore, a pair of bridges are

required to interconnect two networks the way two modems are

used on leased phone lines. Sometimes bridges block network

traffic by restricting data only to stations specified in the

transmission that reside on the network controlled by the bridge.

This blocking is difficult to implement in broadcast networks

such as CAN and, therefore, not recommended. Bridges are

ignorant of the higher level protocols sent over CAN since

bridges operate at the data link layer. Therefore, protocols such

as DeviceNet, Smart Distributed System and CANopen are

passed without modification.

3.2 Theory of Operation

The EXTEND-A-BUS is classified as a remote bridge and

contained in a two piece metal enclosure suitable for panel

TD960801-0MC

20

Page 25

mounting into a larger industrial enclosure. As an option, the

EXTEND-A-BUS can be DIN rail mounted by purchasing the

appropriate kit. The EXTEND-A-BUS has two ports, one for

the CAN network and the other for the ARCNET backbone.

The device can be powered from either a low voltage AC or DC

power supply .

3.2.1 CAN Port

One electrically isolated CAN port has been provided capable of

operating to the DeviceNet physical layer specification. This

was done to minimize ground loop problems while providing

isolation to the ARCNET backbone. The port conforms to the

DeviceNet specification for a five position unsealed connector .

One CAN segment, conforming to the electrical restrictions of

the CAN segment, attaches to this port. In a similar method,

additional CAN segments are attached to other EXTEND-ABUS CAN ports. The only restriction is that all CAN

compliant devices on the complete network have unique MAC

IDs.

3.2.2 ARCNET Port

On the coaxial cable model, a BNC connector has been

provided. On the fiber optics model, two ST connectors are

provided-one for transmit (TX) and one for receive (RX). The

coaxial port is of the high impedance type (-CXB) allowing for

up to eight devices on one coaxial cable segment. A BNC

terminator (BNC-TER) and a BNC T ee connector (BNC-T) are

provided to facilitate connections to other bridges on the

ARCNET backbone. The ARCNET port operates at 2.5 Mbps.

Each EXTEND-A-BUS requires a unique ARCNET node ID

which has no meaning to the CAN segments. Node ID’ s are

automatically assigned by the EXTEND-A-BUSes themselves

using an arbitration scheme upon power up.

TD960801-0MC

21

Page 26

3.2.3 Topologies

CAN-based device networks usually operate over a multidrop

topology with provisions for short drops of typically six meters

each. The trunk length depends upon the data rate and at 500

kbps, the maximum length of the trunk is 100 meters.

Conceptually , the multidrop topology is easy to understand and

appears easy to implement and for many applications this is

true. However, for some machines or processes, the star or

distributed star topology would reduce wiring especially when

devices are clustered in all directions from the main control

panel. By incorporating bridges, the multidrop topology is

maintained since the ARCNET side of the bridges are bused;

however, since each CAN segment attached to a bridge can

comply with the maximum capabilities of the CAN segment, a

system is created with a long ARCNET trunk of 1000 feet and

eight long CAN “drop” segments of 330 feet each. If a true star

topology or longer distances are desired, each EXTEND-ABUS can be connected to a companion AI series active hub.

For distributed star topologies, multiple AI series active hubs

can be cascaded up to the ARCNET limit of four miles when

using coaxial cable. With increased distances comes increased

signal latency and potential real time performance degradation

of the network.

3.2.4 Power Requirements

Either low voltage AC or DC power will power the EXTENDA-BUS. A DC-DC converter accepts the input power and

converts it to +5 volts DC for use by the EXTEND-A-BUS.

The AC power must come from a floating secondary in the

range of 8 to 24 volts AC. The DC power source must be in the

range of 10 to 36 VDC. Power connections are derived from a

four position unsealed connector. The CAN port must still be

powered from the network itself since the EXTEND-A-BUS

does not serve as a network power supply; however, the

EXTEND-A-BUS can be powered from the 24 volt network

power supply .

TD960801-0MC

22

Page 27

3.2.5 EXTEND-A-BUS Engine

A high speed 32 Mhz 80C188 microprocessor provides the

computing power for the EXTEND-A-BUS. The ARCNET

port consists of a 20020 controller chip and coaxial bus or fiber

optic transceiver . The CAN port consists of a Intel 82527 CAN

controller and isolated 82C251 transceiver. The CAN port is

capable of generating interrupts at a high speed since the

EXTEND-A-BUS must listen to all CAN traffic. Back to back

CAN data frames can generate an interrupt every 94 µs at 500

kbps. The ARCNET buffers will also generate interrupts

making low latency interrupt handling a priority for the

EXTEND-A-BUS. Included in the engine is a 128Kx8 FLASH

ROM and 128Kx8 SRAM. An internal serial port is used to

update the firmware.

3.3 System Considerations

There are some design considerations when implementing a

remote bridging system.

By its very nature of storing and forwarding messages, the

EXTEND-A-BUS system introduces additional signal latency

which may disturb DeviceNet systems with tight timing

constraints. With the DeviceNet protocol, there has been little

evidence of any timing problems. However, the potential exists

for a system to erroneously signal a failed response to an action

when short cabling delays are assumed. On systems with very

fast DeviceNet scanners while operating at low data rates and

lightly load systems, the possibility exists for the master to issue

a comment to a slave and fail to wait for the slave’ s response

before issuing another command assuming a failed response.

This is especially true for devices that support long fragmented

messages. The solution is to increase the interscan time to

either 5 to 10 ms in order to allow sufficient time for response.

Another solution is to increase the data rate on all devices to

500 kbps. Still another solution is to move problem devices to

the local segment (the same segment as the scanner) in order to

eliminate delays due to the EXTEND-A-BUSes.

TD960801-0MC

23

Page 28

Within a CAN segment, at least one device must acknowledge

the valid receipt of another device’ s transmission. That

acknowledgment, however, does not extend beyond an

EXTEND-A-BUS. Even though a successful transmission

occurred on a CAN segment, that transmission must be

replicated on all other CAN segments generating additional

acknowledgments. Therefore, it is possible that a replicated

transmission on one CAN segment may fail due to a cabling

problem resulting in no acknowledgment while all other CAN

segments view the transmission successful. However, the

DeviceNet protocol does not rely upon the CAN data link

acknowledgment as sole indication of a successful transmission.

Additional error checking has been incorporated in the upper

layer DeviceNet protocol.

Single nodes can operate on an individual CAN segment with

remote bridging. Since each EXTEND-A-BUS has one internal

CAN chip, this CAN chip acknowledges the single node’ s

message. Without remote bridges, a single node will fail to hear

an acknowledgment and will continuously retry.

The DeviceNet protocol supports autobauding which is possible

for the EXTEND-A-BUS to implement. One EXTEND-A-BUS

acts as a master for all other bridges on the network functioning

as slaves. The master EXTEND-A-BUS must be connected to

the CAN segment connected to the master controller. As the

master controller transmits data, the master EXTEND-A-BUS

determines the data rate and informs all other EXTEND-ABUSes the required data rate over the ARCNET connection.

Once the data rates are determined, traffic is sent between the

bridges functioning as one long extension cord. The EXTENDA-BUS data rates can be manually set by way of a switch and

there is no inherent reason why individual CAN segments

cannot be set to different data rates.

Using the same extension cord analogy , it would appear that a

remote bridging system must be powered before or at the same

time as the slave devices or master controller in order that all

devices can execute initialization routines such as duplicate

TD960801-0MC

24

Page 29

MAC ID tests as in the case of DeviceNet. However, if a

remote bridge loses power while all other devices remain

powered, the failure mode should be no different than cutting the

cable in the middle of a CAN segment. When power is restored

to the remote bridges, the restart sequence should be the same as

if the maintenance person reconnected a disconnected cable.

CAN networks are usually configured in a bus or multidrop

topology while ARCNET can be configured as a bus, star or

distributed star topology . Therefore CAN implementations can

take advantage of the more flexible ARCNET cabling options.

Do not cascade EXTEND-A-BUSes beyond two since the delay

stackup could be excessive. Instead connect all EXTEND-ABUSes in a star topology using a hub thereby reducing data

latency to that of two EXTEND-A-BUSes.

Implementing fiber optics over any reasonable distance with

CAN is difficult due to the increased delays caused by the

additional circuitry . However, fiber optic ARCNET solutions

are readily available. Therefore, the benefits of fiber optics can

be gained simply by adding remote bridges. Note that the

propagation delay of fiber optic cable (5 ns/m) is 25% more

than that of coaxial cable. This is important when calculating

ARCNET delay margin and was considered when setting the 4.8

km fiber optic limit.

3.4

LED Indicators

One CAN Status LED and one LINK Status LED are provided

in order to convey information regarding their respective ports.

When LEDs flash, they will flash approximately at a rate of 0.5

seconds on and 0.5 seconds off.

3.4.1 CAN Status LED

A dual color LED (red/green) is used to identify status of the

CAN port. After a power-on sequence, the LED indications are

as follows:

TD960801-0MC

25

Page 30

RED—The EXTEND-A-BUS has detected an internal problem

with the CAN port requiring service.

Flashing RED—The CAN port does not have sufficient voltage

on its V+ and V– lines to power the optically isolated port.

GREEN—The CAN port is receiving data.

Flashing GREEN—The CAN port is commissioned, however,

no CAN data has been received in over a second.

3.4.2 LINK Status LED

A dual color LED (yel/green) is used to identify status of the

ARCNET (backbone) port. After a power-on sequence, the

LED indications are as follows:

YELLOW—Continuous network configuration occurring or no

other EXTEND-A-BUS nodes found.

Flashing YELLOW—One or more network reconfigurations

detected on an operating network.

GREEN—Data is being received from the network.

Flashing GREEN—Network is operational, however, no data is

being received from the network in the last second.

3.4.3 Power-on LED Sequence

The CAN Status and LINK Status LEDs are sequenced upon

power-up to verify the integrity of the LEDs. The sequence is

as follows:

CAN status off and Link status off

CAN status GREEN for 0.25 seconds

CAN status RED for 0.25 seconds

LINK status GREEN for 0.25 seconds

LINK status YELLOW for 0.25 seconds

After the power-on sequence, both LEDs assume their normal

operation.

TD960801-0MC

26

Page 31

4 Service

Warranty

Contemporary Controls (CC) warrants its product to the

original purchaser for one year from the product’ s shipping

date. If a CC product fails to operate in compliance with its

specification during this period, CC will, at its option, repair or

replace the product at no charge. The customer is, however,

responsible for shipping the product; CC assumes no

responsibility for the product until it is received. This warranty

does not cover repair of products that have been damaged by

abuse, accident, disaster, misuse, or incorrect installation.

CC’s limited warranty covers products only as delivered. User

modification may void the warranty if the product is damaged

during installation of the modifications, in which case this

warranty does not cover repair or replacement.

This warranty in no way warrants suitability of the product for

any specific application.

IN NO EVENT WILL CC BE LIABLE FOR ANY

DAMAGES INCLUDING LOST PROFITS, LOST

SAVINGS, OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF THE

USE OR INABILITY TO USE THE PRODUCT EVEN IF CC

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES, OR FOR ANY CLAIM BY ANY PARTY

OTHER THAN THE PURCHASER.

THE ABOVE WARRANTY IS IN LIEU OF ANY AND ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED OR

STATUTORY, INCLUDING THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR USE, TITLE AND NONINFRINGEMENT.

TD960801-0MC

27

Page 32

Repair or replacement as provided above shall be the

purchaser’s sole and exclusive remedy and CC’ s exclusive

liability for any breach of warranty .

Technical Support

Contemporary Controls (U.S.A.) will provide technical support

on its products by calling 1-630-963-7070 each weekday

(except holidays) between 8:00 a.m. and 5:00 p.m. Central time.

Contemporary Controls Ltd (U.K.) will provide technical

support on its products by calling +44 (0)24 7641 3786 each

weekday (except holidays) between 8:00 a.m. and 5:00 p.m.

United Kingdom time. If you have a problem outside these

hours, leave a voice-mail message in the CC after hours

mailbox after calling our main phone number. You can also fax

your request by calling 1-630-963-0109 (U.S.) or +44 (0)24

7641 3923 (U.K.), or contact us via e-mail at

info@ccontrols.com or info@ccontrols.co.uk. You can visit our

web site at www.ccontrols.com. When contacting us, please

leave a detailed description of the problem. We will contact you

by phone the next business day or in the manner your

instructions indicate. W e will attempt to resolve the problem

over the phone. If unresolvable, the customer will be given an

RMA number in order that the product may be returned to CC

for repair.

W arranty Repair

Products under warranty that were not subjected to misuse or

abuse will be repaired at no charge to the customer . The

customer, however, pays for shipping the product back to CC

while CC pays for the return shipment to the customer . CC

normally ships ground. International shipments may take

longer. If the product has been determined to be misused or

abused, CC will provide the customer with a quotation for

repair . No work will be done without customer approval.

TD960801-0MC

28

Page 33

Non-Warranty Repair

CC provides a repair service for all its products. Repair

charges are based upon a fixed fee basis depending upon the

complexity of the product. Therefore, Customer Service can

provide a quotation on the repair cost at the time a Returned

Material Authorization (RMA) is requested. Customers pay the

cost of shipping the defective product to CC and will be

invoiced for the return shipment to their facility . No repair will

be performed without customer approval. If a product is

determined to be unrepairable, the customer will be asked if the

product can be replaced with a refurbished product (assuming

one is available). Under no circumstances will CC replace a

defective product without customer approval. Allow ten

working days for repairs.

Returning Products for Repair

T o schedule service for a product, please call CC Customer

Service support directly at 1-630-963-7070 (U.S.) or +44 (0)24

7641 3786 (U.K.). Have the product model and serial number

available, along with a description of the problem. A

Customer Service representative will record the appropriate

information and issue, via fax, an RMA number—a code

number by which we track the product while it is being

processed. Once you have received the RMA number, follow

the instructions of the Customer Service support representative

and return the product to us, freight prepaid, with the RMA

number clearly marked on the exterior of the package. If

possible, reuse the original shipping containers and packaging.

In any event, be sure you follow good ESD-control practices

when handling the product, and ensure that antistatic bags and

packing materials with adequate padding and shock-absorbing

properties are used. CC is not responsible for any damage

incurred from improper packaging. Shipments should be

insured for your protection.

TD960801-0MC

29

Page 34

Ship the product, freight prepaid, to the location from which it

was purchased:

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, IL 60515

U.S.A.

Contemporary Controls Ltd

Sovereign Court Two

University of W arwick Science Park

Sir William Lyons Rd.

Conventry CV4 7EZ

U.K.

TD960801-0MC

30

Page 35

Appendices

Appendix A—Permissible Segment Lengths

A segment is defined as any portion of the complete ARCNET

cabling system isolated by one or more hub ports. On a hubless

or bus system, the complete ARCNET cabling system consists

of only one segment with several nodes; however, a system with

hubs has potentially many segments. An ARCNET node is

defined as a device with an active ARCNET controller chip

requiring an ARCNET device address. Active and passive hubs

do not utilize ARCNET addresses and, therefore, are not nodes.

Each segment generally supports one or more nodes, but in the

case of hub-to-hub connections there is the possibility that no

node exists on that segment.

The permissible cable length of a segment depends upon the

transceiver used and the type of cable installed. T able A-1

provides guidance on determining the constraints on cabling

distances as well as the number of nodes allowed per bus

segment.

The maximum segment distances are based upon nominal cable

attenuation figures and worst case transceiver power budgets.

Assumptions are noted.

When approaching the maximum limits, a link loss budget

calculation is recommended.

When calculating the maximum number of nodes on a bus

segment, do not count the hub ports that terminate the bus

segments nodes.

Do consider the maximum length of the bus segment to include

the cable attached to the hub ports.

The -CXB transceiver requires a minimum distance between

nodes. Adhere to this minimum since unreliable operation can

occur .

TD960801-0MC

31

Page 36

Appendix A (continued)

Permissible Cable Lengths and Nodes Per Segment

Trans ceiver Description Cabl e Connectors

-CXS coaxial star RG-62/u BNC

-CXB coaxial bus RG-62/u BNC

-FOG duplex fiber optic 50/125 ST

-FOG duplex fiber optic 62.5/125 ST

-FOG duplex fiber optic 100/140 ST

1

This represents the minimum distance between any two nodes or

between a node and a hub.

2

May require a jumper change on the EXTEND-A-BUS to achieve this

distance.

Table A-1. Permissible Cable Length

and Nodes Per Segment

TD960801-0MC

32

Page 37

(2.5 Mbps)

Cable Length Max Nodes

Min Max Bus Segment Notes

0 2000 ft/610 m N/A 5.5 dB/1000 ft max

6 ft/2 m11000 ft/305 m 8 5.5 dB/1000 ft max

0 3000 ft/915 m N/A 4.3 dB/km max

0 6000 ft/1825 m N/A 4.3 dB/km max

2

0

9000 ft/2740 m N/A 4.0 dB/km max

TD960801-0MC

33

Page 38

Appendix B—Declaration of Conformity

Applied Council Directives:

Electromagnetic Compatibility Directive, 89/336/EEC Council

Directive as amended by Council Directive 92/31/EEC &

Council Directive 93/68/EEC

Standard to which Conformity is Declared

EN 55022:1995 CISPR22: 1993, Class A, Limits and Methods

of Measurement of Radio Disturbance Characteristics of

Information T echnology Equipment

EN 50082-2:1995, Electromagnetic Compatibility - Generic

Immunity Standard, Part 2: Industrial Environment

Manufacturer:

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, IL 60515 USA

Authorized Representative:

Contemporary Controls Ltd

Sovereign Court T wo

University of W arwick Science Park

Sir William Lyons Road

Coventry CV4 7EZ

UNITED KINGDOM

TD960801-0MC

34

Page 39

T ype of Equipment:

Industrial network extender

Model Directive

EMC

EB/DNET-CXB Yes

EB/DNET-FOG Yes

T echnical File TD960801-0F A

I, the undersigned, hereby declare that the product(s) specified

above conforms to the listed directives and standards.

George M. Thomas, President April 6, 1999

TD960801-0MC

35

Loading...

Loading...