Page 1

ENGINEERED SOLUTIONS

ULTRA FLO® & Corrugated Metal Pipe

Handling and Installation Guide for Reline

Page 2

PREFACE

This instruction book is for your crews. Distribute it to help them install Contech® ULTRA FLO® and CMP Liner pipe correctly.

ULTRA FLO is a spiral ribbed steel or aluminum segmental pipe that is inserted (sliplined) into an existing deteriorated pipe or

into a casing pipe or tunnel as a carrier pipe. ULTRA FLO features very low wall friction to provide the greatest water ow and

is the most common metal reline pipe. In addition to ULTRA FLO, other corrugated metal pipe (CMP) products can be used

for liner pipe. These additional CMP products include SmoothCor™, HEL-COR®, MULTI-PLATE®, Aluminum Structural Plate and

Tunnel Liner Plate. You Contech representative can assist in using these guidelines along with other CMP products.

Don’t assume experienced workers know all the answers. Review these instructions with your supervisors and crews. It can

mean a safer and better job for you and your customer.

We recommend holding a preconstruction meeting with your Contech representative and all interested parties to ensure

everyone involved in your project has a high level of understanding on what means and methods will be used to prepare for,

install and grout the new structure(s).

If you have any questions about these instructions, call your Contech Representative.

CONTENTS PAGE

Unloading and Safety Instructions ................................................ 3

Preparation for Sliplining ............................................................. 4

Excavating Insertion Pits ................................................................ 4

ULTRA FLO and CMP Lining Insertion ............................................. 5

Jacking Load and Distance ............................................................ 5

Assembling Gasketed Joint ............................................................ 6

Field Cutting Pipe .......................................................................... 7

Annular Space Grouting ......................................…………………..7

Installation Tips ...................................................…………………..9

Curved Sewers, Repairs, Taps ............................... …………………..9

Dimensions and Handling Weights ................................................9

2

Page 3

TERMS YOU SHOULD KNOW

Alerts you to hazards or unsafe practices that

CAN result in severe personal injury or property

damage.

Messages about procedures or actions that must

SAFETY

INSTRUCTIONS

be followed for safe handling and installation of

ULTRA FLO and CMP Liner Pipe. Failure to follow

these instructions can result in serious injury or

death and/or damage to the pipe.

UNLOADING AND HANDLING

The following equipment is recommended for unloading pipe

or pipe bundles:

• Forklift

• Front-end loader with fork adapters

• Backhoe with fork adapters

• Cranes

• Non-metallic slings

Other unloading methods such as lifting lugs, chains, wire

rope, cinching or hooks in the end of the pipe should not be

used.

SAFETY INSTRUCTIONS

1. Only trained and authorized equipment operators are to

be permitted to unload the trailer.

2. Wear approved safety hat and shoes, gloves and eye

protection.

3. Pipe ends may be sharp. Workers handling pipe

must wear gloves made from cut-resistant materials.

4. Park the truck and trailer on level ground before you start

unloading. It is the responsibility of the consignee to

direct the driver to level ground for parking the truck.

5. Keep all unauthorized persons clear of the area when the

driver releases the binders from the trailer and during

unloading.

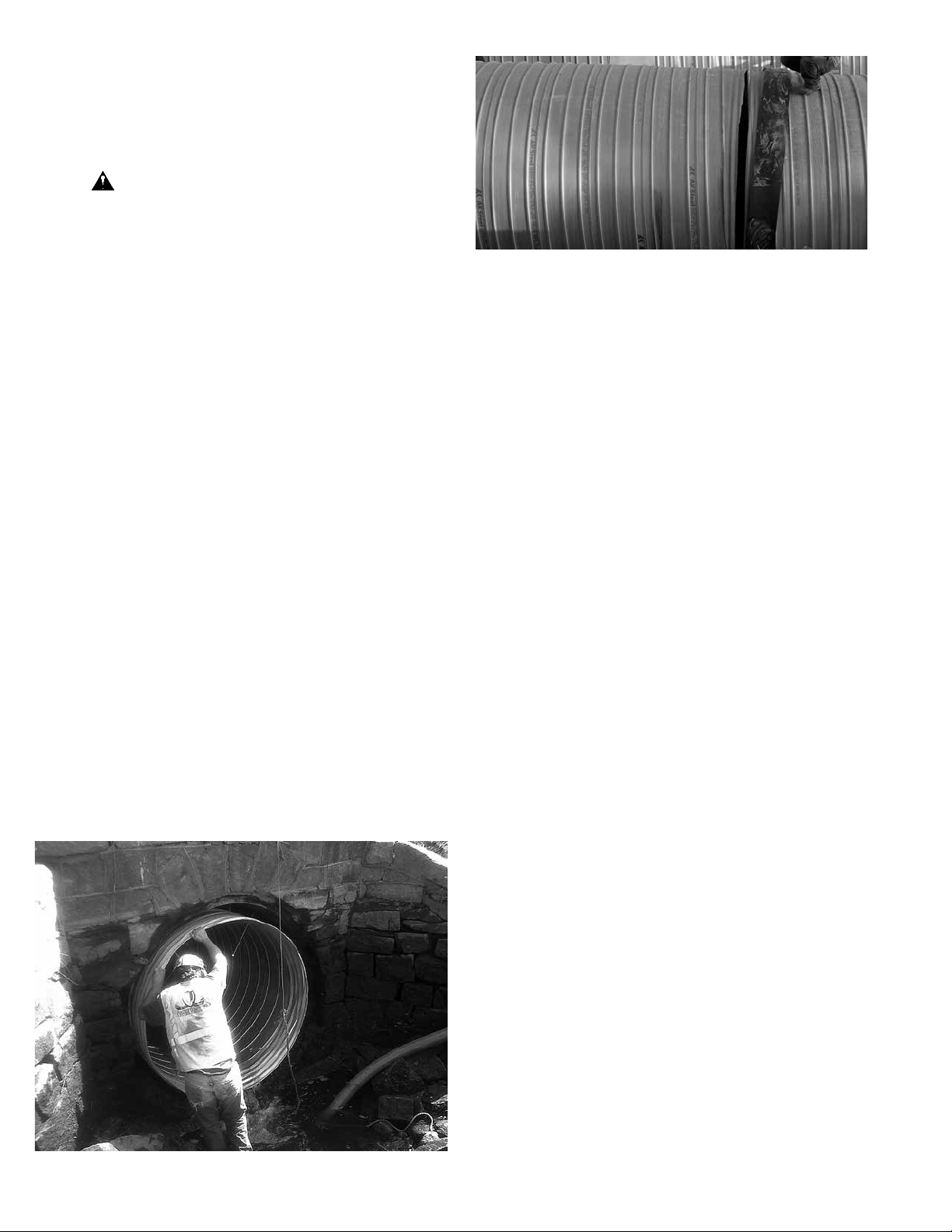

6. Sometimes pipes are bundled together on the

truck with steel straps. Do not cut the steel strapping

around the bundles until the bundles have been

placed on level ground, blocked or secured, and will

not be moved again as a unit. It is recommended

that the steel strapping be cut with appropriate sized

cutting tools. Stand to the side when cutting a strap.

Always be aware that pipe may move, roll or fall

when a strap is cut.

GENERAL

1. Contech recommends the use of non-metallic slings for

all pipe handling requirements.

2. Hooks, chains or wire rope may damage the pipe.

3. Do not push bundles off the trailer or

permit pipe to drop to the ground.

9. Do not stand or ride on the load of pipe

while it is being unloaded. Do not stand beneath or

near the pipe while it is being unloaded.

10. If unloading at multiple drop-off points, secure the

remaining load and pallets between drop off points.

Always unload the top pallets or bundles rst.

11. The contractor shall be responsible for the safety

of his/her employees and agents. Adequate safety

indoctrination is his responsibility and shall be given to

all personnel employed by his rm.

12. Safe practices on construction work as outlined in the

latest edition of the “Manual of Accident Prevention

in Construction,” published by the Associated General

Contractors, shall be used as a guide and observed.

13. The contractor shall comply with all applicable city, state,

and federal safety codes in effect in the area where he is

performing the work. This conformance shall include the

provisions of the current issue of the “OSHA Safety and

Health Standards (29 CFR 1926/1910)” as published by

the U.S. Department of Labor.

7. Do not lift bundles or sections of pipe

by the steel strapping around the bundles.

8. Know the capabilities and rated load capacities of your

lifting equipment. Never exceed them.

3

Page 4

PREPARATION FOR SLIPLINING

Follow all requirements of the project plans and

specications. Prior to sliplining, the following procedures

should be performed to ensure satisfactory results are

obtained.

1.

2. The existing sewer line should be inspected to determine

3. Verify and record the location, number and size of all

4. Where the pipe is to be pushed through existing

5. Remove any obstructions in the existing line that will

6. Thoroughly clean the existing line as required (high-

7. Verify adequate clearance for the liner pipe. Measure

Ensure continued space assessment procedures

are followed prior to entry.

the condition of the line and identify problem areas

or obstructions such as displaced joints, crushed

pipe, protruding service laterals, roots, debris, out-ofroundness or inside diameter reductions.

inlets and connections.

manholes, check the alignment and clearance.

prevent insertion of, or cause damage to, the new liner

pipe. Large joint offsets or severely deteriorated pipe may

need to be removed or repaired prior to installing the

pipe. These may be good locations for insertion pits or

point repairs.

pressure water, buckets, reamers or other mechanical

methods). Not cleaning the line thoroughly can result in

excessive jacking/pulling loads or liner pipe hang ups that

can damage the new pipe.

the inside diameter (ID) of the existing pipe at the worst

location and compare the dimension to the liner pipe

outside diameter (OD). Depending on the condition of

the existing pipe and the obstructions present, it may

be desirable to pull a trial liner or mandrel of the same

outside diameter as the liner pipe (outside diameters are

listed on Page 19). The trial liner may be a short section

of ULTRA FLO or CMP pipe and should be attached to

pulling cables at each end. If external bands are used, be

sure there is adequate clearance for the band hardware.

SLIPLINING PROCESS

The best specications allow for creativity on how to go

about the reline process. When designed correctly, a project

will have critical performance requirements and information

within the project documents that will provide limitations,

guidance, and perhaps some suggestions on how to

approach the project.

The information contained herein is intended to introduce

some of the techniques that have been used successfully

in the past, and to provide limited guidance on what

needs to be evaluated when considering a particular reline

project. This information does not represent project specic

recommendations from Contech and cannot be construed as

a complete set of guidelines on how to successfully reline a

drainage structure.

Complete and independent project specic evaluations must

be conducted by a qualied contractor prior to them drawing

any conclusions about how to approach a reline project.

The most common method of slipling with CMP is to place

liner pipe one section at a time through the inlet or outlet

end (for culverts) or through an insertion pit (for closed

systems) and to push or pull the single sections into nal

position. Handling just one section at a time is normally the

most efcient as it minimizes the amount of weight being

pushed or pulled.

4

Page 5

SEGMENTAL SLIPLINING PROCESS FOR CMP

Place the Next Section

New structure

Existing structure

Place the Next Section

Block the Tail End

Place Internal Expanding Band & Gasket

New structure

Existing structure

New structure

Existing structure

Place the Next Section

Block the Tail End

Place Internal Expanding Band & Gasket

Repeat Until All Sections Are Installed

Install Bracing to Prevent Flotation & Displacement During Grouting

New structure

Existing structure

Vertical bracing

Consult your local Contech representative for more detail.

Insert rst section.

Block the rst section

and place the next

section.

Block the tail end

and place internal

expanding band and

gasket.

Repeat until all

sections are installed.

Place bracing to

prevent otation and

displacement during

grouting.

EXCAVATING INSERTION PITS

ULTRA FLO and CMP liner pipe are installed from an excavated insertion pit or other location allowing access to the existing pipe

(i.e. manholes, culvert ends).

When insertion pit locations have not been designated by the engineer or owner, the following conditions should be considered

when selecting locations:

• Changes in line and grade

• Large joint offsets

• Severely deteriorated pipe sections

• Manholes being replaced

• Service laterals

• Pushing and pulling distances

• Accessibility (structures, trafc and existing utilities)

• Soil conditions

It is possible to reduce the number of insertion pits by sliplining in both directions from one location. Depending on the pipe

diameter, the condition of the existing line or casing pipe and compressive/jacking loads, sliplining up to 2,000 feet or more

from a single location is possible. In some cases (tunnels, long runs of large diameter pipe, etc.) it may be desirable to insert

and position individual pipe sections into the existing pipe and then join the sections together to extend the allowable work

distance from one location.

After insertion pit locations have been designated or selected, the required size of the pit should be determined.

ULTRA FLO and helical CMP comes in lengths up to 40 feet. Shorter lengths are available for easier handling. Structural plate

CMP lengths vary by material. The insertion pit length should allow for the longest length of pipe being used, clearance for

joining pipe sections, adequate space for pushing/pulling equipment and trench sheeting or shoring. The width of the insertion

pit should be sufcient to accommodate the new pipe diameter plus provide safe working room for the crew. The depth of the

insertion pit should allow for exposing and removing the existing pipe’s top down to the spring line. The remaining bottom

half of the existing pipe can serve as an open channel to maintain sewage ow. Bypass pumping is generally not required for

segmental sliplining. A clean, level work area between the existing pipe and trench shoring will prevent dirt and debris from

being washed back into the opened pipe.

5

Page 6

ULTRA FLO AND CMP LINING INSERTION

After the existing line has been properly prepared for liner

pipe insertion and the insertion pit(s) have been excavated,

liner insertion (installation) can begin. ULTRA FLO or CMP liner

pipe can be either pushed or pulled through the existing line.

External skids are recommended to protect the liner pipe

from abrasion during the insertion process. Factory attached

metal skids are available through Contech as an option.

Suitable skids can also be developed and installed at the

jobsite by the installer.

Pushing Method

1. Bands connecting pipe segments may be either internal

or external. External bands must be assembled outside of

the host pipe. Be sure there is adequate clearance in the

annulus between the liner and the host pipe.

2. Internal bands can be assembled after the segment is

positioned in the host pipe. After grouting the internal

band can be removed or re-used.

3. If internal bands are used, the ULTRA FLO or CMP liner

pipe will have annular re-rolled ends that will accept a

corrugated band. If the liner pipes are match-marked

position them correctly, otherwise either end can be

inserted as the leading end. Guide rails will help the

liner pipe ride over small joint misalignments and other

small obstructions and inconsistencies in the existing

pipe. If liner passage is questionable, a steel cable can

be threaded through the liner pipe during installation

and attached to the leading edge. This allows the liner

pipe to be retracted (pulled backward) if the liner pipe

gets caught on an obstruction. A pushing ring should

be used in the tail end to evenly distribute the load from

the pushing equipment. The pushing ring can be a short,

sacricial piece of liner pipe or a timber frame.

Pulling Method

The pulling method is similar to the pushing method. A steel

cable is threaded through the existing pipe and attached to

a pulling ring or plate positioned against the far end of the

liner pipe or to the skid rails or pulling hardware that can be

attached to the pipe segments. Pulling hardware must be

positioned at or near the invert.

The pipe pushing/pulling loads should be monitored.

Excessive force can “telescope” pipe joints and/or buckle the

liner pipe. On some installations, small diameter (1” to 2”)

plastic pipe can be installed as runner rails.

The cable is attached to a winch assembly to facilitate pulling

the liner through the existing pipe section. After each pull,

the steel cable is disconnected from the pulling ring and

threaded through the next liner pipe section to be joined.

After the pulling ring is reconnected to the cable, the process

is repeated.

4. See the “Assembling Gasketed Joints”

section for more information on joining

pipe sections.

5. Bulkheads should be formed to seal the

annular space between the liner pipe and

the existing pipe at each culvert end, all

manhole and insertion pit entries and

exits as required. If the entire annular

space between bulkheads is to be lled

with grout, then bulkheads should

be constructed to provide adequate

resistance to grouting pressures and

to provide appropriate vent and

drainage tubes. When service and lateral

connections are to be connected, it may

be desirable to complete downstream

bulkheads for the line segment after

connections have been reinstated to

provide an outlet for sewage/drainage

between the pipes.

Table 1 – Jacking Loads and Pushing Distances

Steel ULTRA FLO Aluminum ULTRA FLO

Dia.

Jacking

(in)

Load

(lbs)

18 3,220 860 2,140 1,610 640 1,610

21 3,660 820 2,030 1,830 610 1,520

24 4,070 810 2,030 2,940 650 1,630

30 4,950 790 1,970 4,380 580 1,460

36 5,090 550 1,370 7,800 670 1,690

42 4,950 330 830 8,510 650 1,630

48 4,750 280 700 9,050 600 1,500

54 5,090 270 670 9,540 560 1,400

60 5,510 260 660 10,040 540 1,350

66 10,260 440 1,110 10,110 490 1,230

72 10,180 400 1,010 10,520 460 1,160

78 10,290 380 950 11,030 450 1,120

84 14,650 500 1,260 11,480 440 1,100

90 14,840 470 1,180 --- --- ---

96 14,020 420 1,050 --- --- ---

102 14,420 410 1,030 --- --- ---

1

Based on Sliding Coefcient of 0.25

2

Based on Sliding Coefcient of 0.10

Safe

Allowable

Jacking

Distance

(ft)

Allowable

1

Distance

Jacking

(ft)

Jacking

2

Safe

Load

(lbs)

Allowable

Jacking

Distance 1

(ft)

Allowable

Jacking

Distance

2

(ft)

6

Page 7

ASSEMBLING GASKETED JOINTS

ULTRA FLO and CMP liner pipe gaskets are tted on the

annular re-rolled end of the pipe. Follow these steps:

Internal Bands

External Bands

1. Conrm that there is enough clearance for the pipe with

the band and clamp to pass through the host pipe.

2. Lubricate gaskets and outside of pipe. Gaskets tend to

get stiff in cold weather.

3. Remove any foreign matter that might be lodged

between the pipe and the band.

4. Position gaskets around and into the rst annular

corrugation of the pipe end.

5. Snap the gasket several times to seat into the

corrugation.

6. Lubricate the inside of the band.

7. Check the bars on the band clamp for position and align

as needed.

8. Use seam sealant tape at the band laps

9. Align band clamps and position band laps. Band

corrugation should be located in the second annular

corrugation next to the gasket. Hand-tighten bolts.

10. While tightening the bolts, adjust the band by tapping to

seat the band in corrugations.

11. Torque bolts between 25’ and 30’-pounds and inspect for

adequate seating of the band in the corrugations.

1. After two liner

pipe segments

are positioned

check the spacing

between the

rst annular

corrugation on

either side of the

joint.

2. Clean the

corrugations and

remove any foreign matter.

3. Place a at gasket evenly across the joint. Mastic or spray

adhesive may be used to tack the gasket in place.

4. Lubricate the overlap section of the band.

5. Locate the corrugations and position the internal band

over the pipe joint.

6. Turn the bolts to expand the band. Tap the band to make

necessary adjustments and seat the corrugations.

7. If any gaps are detected, plug with oakum, silicone

sealant or similar material.

8. After grouting the internal bands may be removed and

reused. Be sure to clean all surfaces and threads before

reusing. Inspect gaskets for reuse. Plan on having extra

gaskets as some may be damaged beyond reuse during

grouting and removal of the band.

FIELD CUTTING PIPE

If ULTRA FLO or CMP liner pipe is eld cut, the annular re-

rolled ends may be removed. Bands and gaskets may not seal

the joints to keep uid grout in place. All voids under the

band will have to be plugged prior to grouting. Field cutting

should only be done at the end of pipe runs.

1. The recommended cutting tool is a chop saw and

abrasive saw blade. Refer to the Operating Instructions

from the saw manufacturer for additional information.

2. Blade thickness should be no less than 1/8” thick and is

recommended to be made of 2-ply material that is used

to cut steel pipe (see gure 1).

3. Use the leading edge of the blade to cut into the ribs of

the pipe.

4. Bury the blade as much as possible into the pipe as you

proceed.

5. The alternative cutting tool is a handheld reciprocating

saw with bi-metal blade suited for cutting steel.

Always use safety glasses when cutting ULTRA FLO

and CMP pipe and use protective gloves in case

sharp edges are exposed.

Figure 1

7

Page 8

BRACING & BLOCKING THE NEW PIPE

Flotation

Bracing and blocking isn’t always the best option but it is

often the quickest and lowest risk way to get the structure

grouted. Quick is a relative term here, since multiple grout

stages and balanced, controlled grout placement are usually

required. The notable exception is when a foaming agent is

used to lighten the uid unit weight of the grout, in which

case the dead weight of the new pipe and perhaps sand bags

in the invert can offset the buoyancy forces.

Another possible alternative to full bracing and blocking is

to oat the new structure to the crown of the existing. This

can be done with little hydraulic impact on lengthy structures

because the grades at the inlet and outlet ends can be

transitioned with appropriate blocking/bracing while most of

the structure can be allowed to oat. When this technique

is used, care must be taken to keep the joints sealed and to

control the shape of the new structure against the buoyant

loads by strutting the inside (as opposed to running a brace

through the top of the structure. Floating to the crown of the

old structure might also be a good option when an increase

in elevation of the overall invert grade line of the structure

doesn’t negatively impact the hydraulic performance.

When project plans and specications require the liner pipe

to be positioned on the invert of the existing pipe, otation

of the liner pipe resulting from grouting operations should be

addressed. Depending on the type of grout and the grouting

method being used, it may be necessary to perform one or

more of the following to offset buoyant forces on the pipe:

1. Fill the liner pipe with water, partially or fully, depending

on the grout density and grout lift thickness. For

monolithic grouting, the liner pipe should be full of

water, and the grout density must be lower than that of

the pipe when full of water.

2. Stage grout with a suitable lift thickness, depending on

grout density.

3. Attach blocking or spacers to the pipe exterior with

strapping.

4. Use internal jacks that pass through a liner grout port (12

o’clock position) to offset buoyant forces.

HOW TO DETERMINE BUOYANT LOADS

DURING STAGED GROUTING

It is absolutely necessary to keep stray rocks out of the

pump. Always use a screen on the pump hopper to sift out

any larger aggregate that could inadvertently be mixed in

the grout. The transport truck that delivers grout was likely

carrying normal concrete as its prior load. A couple of 1-½”

stones can clog a 2” grout line resulting in signicant back

pressure which can result in a sudden ‘blow out’ of the reline

structure (see gure 4).

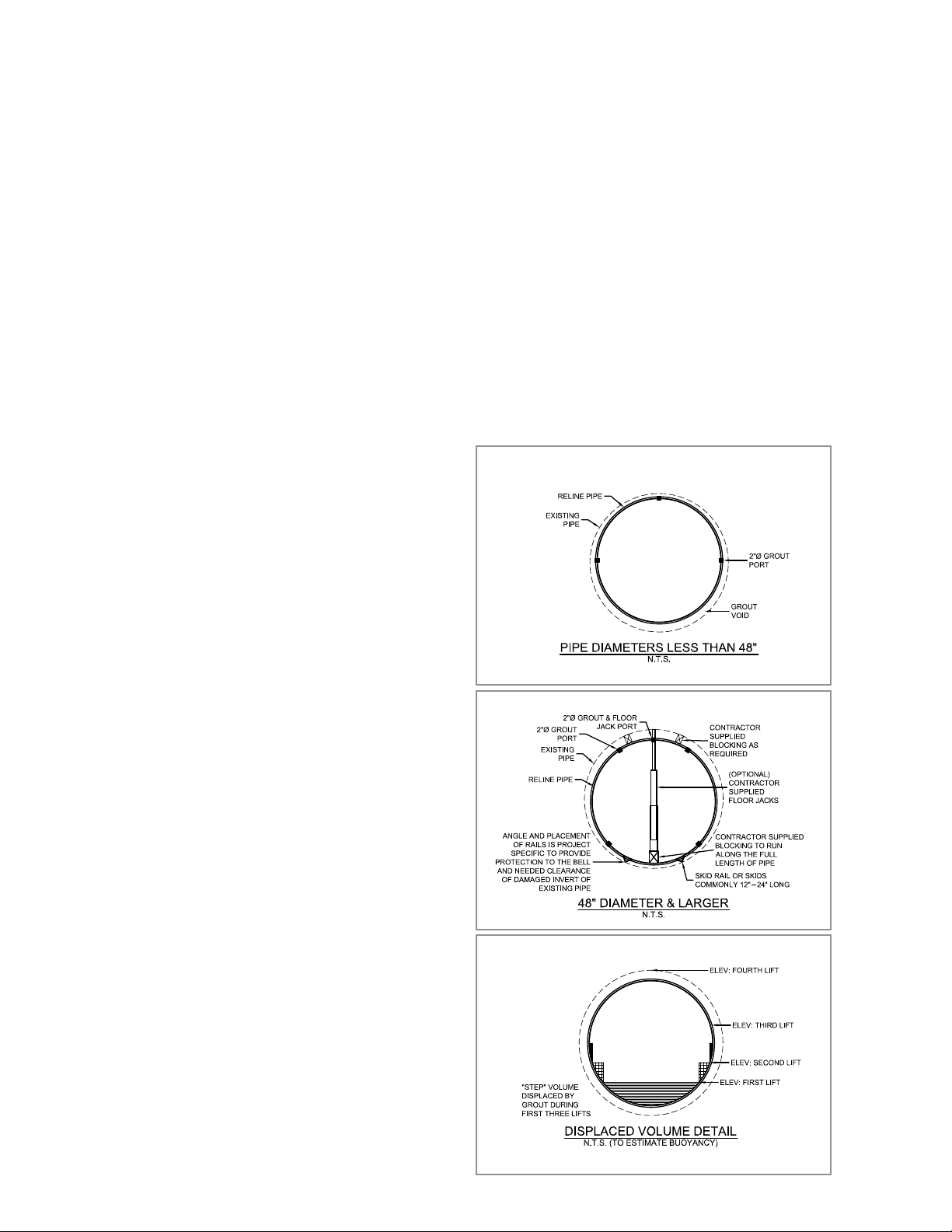

A reasonable yet conservative approach is to make a vertical

projection from the new structure at the lowest point where

a particular depth of uid grout touches the structure to

the top of the uid lift, or to the springline for any lift that

tops the springline. The spring line is the elevation at which

maximum span occurs. For round pipe, it is at ½ way up the

pipe. On a structural plate pipe arch or underpass the spring

line can be approximated as the ‘B dimension’ from the

NCSPA handbook. This volume of ‘displaced’ uid (the area

resulting from the projection described herein) times the uid

unit weight of grout is the resulting upward buoyant force

that must be resisted. To analyze each lift, consider the prior

lift to have solidied. The shop drawings by Contech normally

show this information. On a single radius arch less than 180°,

there are no buoyant forces. However, lateral uid pressures

must be considered with arches.

Figure 2

Figure 3

To determine grout quantities, geometric properties of the

existing structure need to be known or estimated in addition

to consideration given to the slope of the new and old

structures, and the use of intermittent bulkheads that are

occasionally used between the inlet and outlet bulkheads.

8

Figure 4

Page 9

Placement

MAXIMUM PRESSURE

There are many acceptable grouting methods, and they

usually fall under two general categories: monolithic grouting

and stage grouting.

Diameters less than 48 inches

Monolithic grouting (in one step) involves lling the entire

annular space with one lift. Grout is injected, under low

pressure, from the upstream end of the pipe run from

manhole to manhole, or from an insertion pit to manhole.

The grout moves down the annulus in a wave-like fashion

pushing any ground water ahead of the grout (see gure 2).

Diameters equal to or greater than 48 inches

Staged grouting involves placement of the grout in lifts and

when done properly can eliminate liner otation. The liner

pipe is grouted into a cradle in the rst stage. After the rst

lift of grout has cured, the remaining lift(s) of grout is placed.

Since the liner pipe is in a cradle after the rst lift, and further

deformation is limited, it may be possible to increase grout

injection pressures, if needed, to ensure complete grouting of

the annular space. Factory installed grout ports are optional

and can simplify the grouting process (see gure 3).

Other grout placement methods include grouting from the

surface through drilled holes and slick-line grouting from

a tube, within the annulus, that is retracted while grout is

pumped through it.

For all placement methods, the annular space should be

uniformly and completely lled on both sides of the liner

simultaneously. Unbalanced or uneven grouting can affect

liner shape, line and grade (see gure 5).

ANNULAR SPACE GROUTING

Most sliplining installations require the annular space

between the existing (host) pipe and the liner pipe to be

grouted. Grouting of the annular space xes the position

of the new liner pipe, provides uniform support, increases

allowable external hydrostatic pressure on the liner pipe

and inhibits further failure of the host pipe. Introducing the

grout into the annulus is accomplished by gravity ow or by

pumping. Properly controlled grouting is essential to prevent

liner pipe otation, deformation or even collapse.

Host pipe

Bulkhead

Vent pipe

CMP liner pipe

The recommended maximum grouting pressure for ULTRA FLO

and CMP is 5 psi. However, site conditions and pipe stiffness

may allow slightly higher pressure. Appropriate gages should

be used to monitor external pressures on the liner pipe. See

Table 2 for more detail.

Table 2 – ULTRA FLO Grouting Pressure

Steel – Max PSI

Recommended*

Liner

Diameter

Round 5%

Deection

(in)

18 5

21 5

24 5

30 5

36 5

42 5

48 5

54 5

60 5 3 5 3

66 5 3 4 3

72 4 3 3 2

78 3 2 2 2

84 4 2 2 1

90 3 2 --- ---

96 2 2 --- ---

102 2 1 --- ---

1

Contact your local Contech representative for more information about

recommended grout pressure and grout procedures.

2

Grout pressure limited to 5 psi maximum for practical, safe installation

considerations. Higher grouting pressures may be possible and tolerable,

depending upon the type of joint system used and other site-specic

installation considerations.

* Includes a Factor of Safety (FS) = 3.0 for installed ULTRA FLO liner pipe that

is perfectly round or a FS = 2.0 for liner pipe with 5% deection.

2

2

2

2

2

2

2

2

Bulkhead designs should provide adequate venting and

draining tubes. Hydrostatic head pressure resulting from the

slope and/or diameter of the pipe, elevation change between

the gage and the pipe, elevation difference between grout

pump and the nozzle, etc. should be considered in addition

to the grouting pressure on the gage. The hydrostatic head

pressure combined with the pressure on the gage should not

exceed the recommended maximum pressure. Contact your

local Contech Sales Engineer for more information.

2

5

2

5

2

5

2

5

2

5

2

5

2

5

5 5

Typical Grouting Procedures

Aluminum – Max PSI

1

Recommended*

Round 5%

Deection

2

5

2

5

2

5

2

5

2

5

2

5

2

5

2

1

2

5

2

5

2

5

2

5

2

5

2

5

2

5

5

Figure 5

Grout port - 1

It is absolutely necessary to

keep stray rocks out of the

pump. Always use a screen

on the pump hopper to sift

out any larger aggregate that

could inadvertently be mixed in

the grout. The transport truck

that delivers grout was likely

carrying normal concrete as its

prior load. A couple of 1-½”

stones can clog a 2” grout line

resulting in signicant back

pressure which can result in a

sudden ‘blow out’ of the reline

st

lift

structure.

9

Page 10

INSTALLATION TIPS

1. For curved sewers or severely misaligned sewers, using

short ULTRA FLO or CMP liner pipe sections may reduce

pushing or pulling forces and prevent hang ups. For large

diameter sewers or tunnels, individual pipe lengths can

be pulled through the line and joined within the line

when necessary. When pulling individual pipe lengths,

care should be taken to prevent damage to the re-rolled

ends or alignment tabs.

2. When the annular space between the liner pipe and the

exiting pipe is to be lled with grout, estimating the

required grout volume before grout placement begins

may be helpful. The estimate may include grout volume

requirements for lling voids or sink holes outside the

existing (host) pipe. Slope of the new structure must be

taken into account when estimating volumes, buoyancy

forces and bulkhead location.

REPAIRS

1. Should damage to the pipe occur at any point

during installation, the Engineer should be contacted

immediately.

2. For smaller abrasions or exposed steel after eld cutting

apply zinc-rich paint or cold galvanizing compound.

3. Contact your local Contech Sales Engineer if you have

any questions or concerns and for recommendations.

TAPS AND LATERALS

1. ULTRA FLO and CMP liner pipe can be supplied with

standard prefabricated saddle stubs, ttings or

components per job plans once prefabrication drawings

are reviewed by Contech Engineering and approved by

the Engineer. Overall clearance needs to be considered

while choosing the appropriate details.

2. Consult the Engineer and your Contech Sales Engineer

for further assistance.

Table 3 – ULTRA FLO Pipe Dimensions*

Pipe Diameter

(in)

18 20.28 15 5

21 23.28 18 6

24 26.28 20 9

30 32.28 25 15

36 38.28 37 23

42 42.28 59 26

48 50.28 67 30

54 56.32 75 34

60 62.38 83 37

66 68.44 92 41

72 74.50 100 45

78 80.56 108 49

84 86.62 116 52

90 92.68 125 ---

96 98.74 133 ---

102 104.80 140 ---

* Based on AASHTO M36 Specications.

Custom diameters available upon request.

Max

O.D. (in)

Steel Approx.

Weight

(lbs/ft)

Aluminum

Approx. Weight

(lbs/ft)

10

Page 11

Support

My Primary Contech Contact:

Phone:

________________________________________________________________________ Email: ———————————————

My Customer Solutions Coordinator (CSC) is:

Phone:

——————————————————————————————————————————————————————

Project Site Address:

——————————————————————————————————————————————————————————

——————————————————————————————————————————————————————————

————————————————————————————————————————————————

________________________________________________________________________________________

______________________________________ Email: ———————————————

Notes:

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

11

Page 12

ENGINEERED SOLUTIONS

• Drawings and specications are available at www.ContechES.com.

• Site-specic design support is available from our engineers.

Contech Engineered Solutions provides site solutions for the civil engineering industry. Contech’s portfolio includes

bridges, drainage, retaining walls, sanitary sewer, stormwater, erosion control, soil stabilization and wastewater

products. For information on other Contech offerings, visit www.ContechES.com or call 800-338-1122.

NOTHING IN THIS CATALOG SHOULD BE CONSTRUED AS A WARRANTY. APPLICATIONS SUGGESTED HEREIN ARE DESCRIBED ONLY TO HELP READERS MAKE THEIR OWN EVALUATIONS AND

DECISIONS, AND ARE NEITHER GUARANTEES NOR WARRANTIES OF SUITABILITY FOR ANY APPLICATION. CONTECH MAKES NO WARRANTY WHATSOEVER, EXPRESS OR IMPLIED, RELATED

TO THE APPLICATIONS, MATERIALS, COATINGS, OR PRODUCTS DISCUSSED HEREIN. ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND ALL IMPLIED WARRANTIES OF FITNESS FOR ANY

PARTICULAR PURPOSE ARE DISCLAIMED BY CONTECH. SEE CONTECH’S CONDITIONS OF SALE (AVAILABLE AT WWW.CONTECHES.COM/COS) FOR MORE INFORMATION.

CMP Liner Pipe Installation Guide 8/17 PDF

© 2017 Contech Engineered Solutions LLC, a QUIKRETE Company

800-338-1122 | www.ContechES.com

Loading...

Loading...