Page 1

End Sections

ENGINEERED SOLUTIONS

Page 2

Standard End Sections for

corrugated metal pipe, reinforced

concrete pipe and HDPE Pipe

Easily installed, easily maintained culvert end

treatments

Contech

hydraulically superior method of finishing a variety of culvert

materials.

The lightweight, flexible metal construction of Contech End

Sections creates an attractive, durable and erosion-preventing

treatment for all sizes of culvert inlets and outlets. They can

be used with corrugated metal pipe having either annular or

helical corrugations, and both reinforced concrete and plastic

pipes. End sections can be salvaged when lengthening or

relocating the culvert.

Standard End Sections are fabricated from pregalvanized steel.

For added corrosion resistance, aluminum End Sections are

available in smaller sizes. Special End Sections for multiple pipe

installations may be available on a specific inquiry basis.

Better hydraulics

Flow characteristics are greatly improved by the exacting design

of Contech End Sections. Scour and sedimentation conditions

are improved, and headwater depth can be better controlled.

Culverts aligned with the stream flow and finished with Contech

End Sections generally require no additional hydraulic controls.

®

End Sections provide a practical, economical and

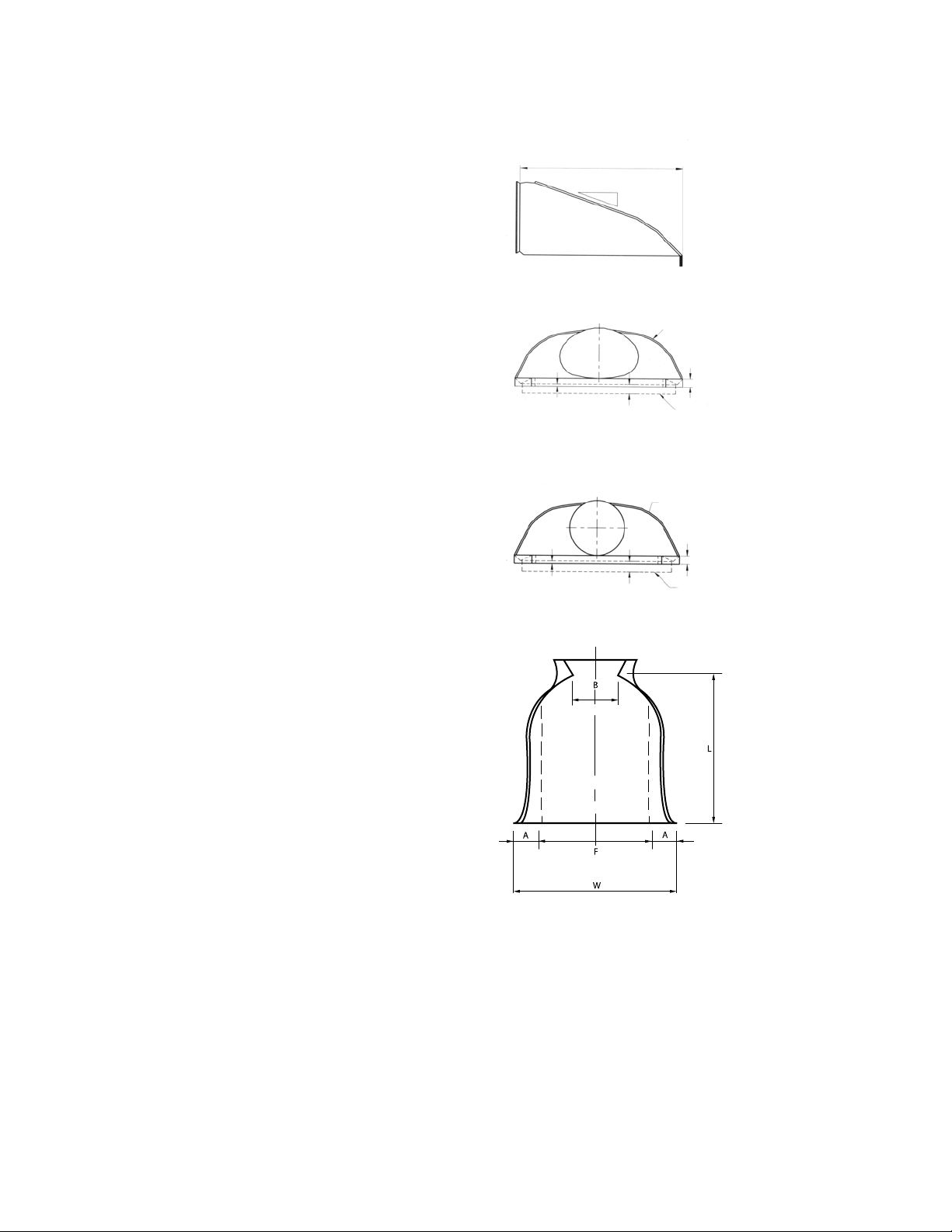

L

Variable Slope

1

Typical Cross Section

2”

8”

Elevation

2”

8”

Elevation

Reinforced Edge

H

Optional Toe

Plate Extension

Reinforced Edge

H

Optional Toe

Plate Extension

Improved appearance

Contech End Sections blend well with the surroundings. The

tapered sides of an End Section merge with slope design to

improve roadside appearance. Unsightly weeds and debris

collection at the culvert end are reduced.

Economical installation

Lightweight equipment and simple crew instructions result

in smooth and easy installation. Contech End Sections are

easily joined to culvert barrels, forming a continuous, onepiece structure. For easiest installation, End Sections should

be installed at the same time as the culvert. Installation is

completed by tamping soil around the End Section.

Low maintenance

Contech End Sections reduce maintenance expense because

their tapered design promotes easier mowing

and snow removal. There is no obstruction to hamper

weed cutting.

Notes for all End Section:

1. All three-piece bodies to have 12-gage sides and 10-gage center panels.

Multiple panel bodies to have lap seams which are to be tightly joined by

galvanized rivets or bolts.

2. For 60” through 84” sizes, reinforced edges are supplemented with stiffener

angles. The angles are attached by galvanized nuts and bolts. For the 66” and

72” equivalent round pipe-arch sizes, reinforced edges are supplemented by

angles. The angles are attached by galvanized nuts and bolts.

3. Angle reinforcements are placed under the center panel seams on the 66” and

72” equivalent round pipe-arch sizes.

4. Toe plate is available as an accessory, when specified on the order, and will be

same gage as the End Section.

5. Stiffener angles, angle reinforcement, and toe plates are the same base metal

as end section body.

6. End sections with 6:1 and 4:1 slopes are available in 12” through 24”

diameters.

7. Actual dimensions may vary slightly.

Page 3

Table 1

End Sections for Round Pipe (2-2/3” x 1/2”, 3” x 1” and 5” x 1”)

Pipe

Diameter

Inches

Gage

A (Min.)

(Inches)

Approximate Dimensions, Inches

B (Max.)

(Inches)

H (Min.)

(Inches)

12 16 5 7 6 22 21 44 2-1/4

15 16 6 8 6 28 26 52 2-1/4

18 16 7 10 6 34 31 58 2-1/8

21 16 8 12 6 40 36 66 2-1/8

24 16 9 13 6 46 41 72 2-1/8

30 14 11 16 8 55 51 88 2-1/8

36 14 13 19 9 70 60 105 2

42 12 15 25 10 82 69 122 2-1/8

48 12 17 29 12 88 78 131 2

54 12 17 33 12 100 84 143 2

60 12/10 17 36 12 112 87 157 1-/78

66 12/10 17 39 12 118 87 162 1-5/8

72 12/10 17 44 12 120 87 169 1-1/2

78 12/10 17 48 12 130 87 178 1-3/8

84 12/10 17 52 12 136 87 184 1-1/3

Note: Larger sizes available in some locations.

(7)

F (Min.)

(Inches)

L(+/-2”)

(Inches)

W

(Max. Width)

(Inches)

Approx.

Slope

Table 2

Span/

Rise

Equiv. Round

(Inches)

End Sections for Pipe-Arch (2-2/3” x 1/2”)

Approximate Dimensions, Inches

Gage A (Min.)

(Inches)

B (Max.)

(Inches)

H (Min.)

(Inches)

(7)

F (Min.)

(Inches)

L(+/-2”)

(Inches)

W

(Max. Width)

(Inches)

(6)

Approx.

(6)

Slope

6

17”x13” 15 16 5 9 6 28 20 52 2-1/8

21”x15” 18 16 6 11 6 34 24 58 2

24”x18” 21 16 7 12 6 40 28 58 2-1/8

28”x20” 24 16 7 16 6 46 32 66 2

35”x24” 30 14 9 16 6 58 39 72 1-7/8

42”x29” 36 14 11 18 7 73 46 88 1-7/8

49”x33” 42 12 12 21 9 82 53 105 1-3/4

57”x38” 48 12 16 26 12 88 62 122 1-7/8

64”x43” 54 12 17 30 12 100 69 131 1-7/8

71”x47” 60 12 17 36 12 112 77 143 1-7/8

77”x52” 66 12 17 36 12 124 77 157 1-5/8

83”x57” 72 12 17 44 12 130 77 162 1-1/2

Table 3

End Sections for Pipe-Arch (3” x 1” and 5” x 1”)

Approximate Dimensions, Inches

Span/

Rise

Equiv. Round

(Inches)

Gage A (Min.)

(Inches)

B (Max.)

(Inches)

H (Min.)

(Inches)

53”x41” 48 12 17 26 12 88 63 130 1-3/4

60”x46” 54 12 17 36 12 100 70 142 1-7/8

66”x51” 60 12 17 36 12 112 77 156 1-3/4

73”x55” 66 12 17 36 12 124 77 168 1-1/2

81”x59” 72 12 17 44 12 136 77 179 1-5/8

87”x63” 78 12 17 44 12 136 77 186 1-1/2

95”x67” 84 12 17 44 12 160 87 210 1-1/2

103”X71” 90 12 17 44 12 172 87 222 1-1/3

112”x75” 96 12 17 44 12 172 87 226 1-1/4

(7)

F (Min.)

(Inches)

L(+/-2”)

(Inches)

W

(Max. Width)

(Inches)

Approx.

Slope

6

(6)

Page 4

Contech End Sections attach to corrugated metal pipe,

reinforced concrete and plastic pipe.

End Of Pipe

End Of Pipe

Pipe To

Which End

Section Is

Attached

Flat Strap

Connector

Type 1

Note: The Type 3 connection is not illustrated. This connection is a one-foot length of pipe attached to the end section.

Strap Bolt

1/2”

Threaded

Rod

Type 2

1/2”

Threaded

Rod

Contech End Section

End Section on

Round CSP

End Sections are

available for CSP

Pipe Arch

Dimple

Band Collar

Bolted To End

Section With

3/8” Bolts

Type 5

Contech End Sections

are often used on

concrete pipe. They

can be used on both

the bell and spigot

end.

Low-slope End Sections—

Contech manufactures 4:1

and 6:1 low-slope End

Sections for corrugated

metal pipe. This photo

shows the optional fieldattached safety bars.

Contech Engineered Solutions provides site solutions for the civil

engineering industry. Contech’s portfolio includes bridges, drainage,

retaining walls, sanitary sewer, stormwater, erosion control, soil

stabilization and wastewater treatment products.

For more information, call one of Contech’s Regional Offices

located in the following cities:

Ohio (Corporate Office) 513-645-7000

California (Long Beach) 562-733-0733

Colorado (Denver) 720-587-2700

Florida (Tampa) 727-544-8811

Georgia (Atlanta) 770-409-0814

Maine (Scarborough) 207-885-9830

Maryland (Baltimore) 410-740-8490

Oregon (Portland) 503-258-3180

Texas (Dallas) 972-590-2000

Visit our web site: www.ContechES.com

800-338-1122

NOTHING IN THIS CATALOG SHOULD BE CONSTRUED AS

AN EXPRESSED WARRANTY OR AN IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

SEE THE CONTECH STANDARD CONDITIONS OF SALE (VIEWABLE

AT WWW.CONTECHES.COM/COS) FOR MORE INFORMATION.

BRO-ENDS 05/12 PDF MC

ENGINEERED SOLUTIONS

©2012 Contech Engineered Solutions LLC

All rights reserved. Printed in USA.

Loading...

Loading...