Page 1

A-2000™/ D-2000™ PVC Pipe for Storm Sewers and Drainage

Knowledge. Solutions. Service.

Page 2

Selecting Performance Storm Sewers

0

20

40

60

80

100

120

70 80 90 100 110 120 130 140

HDPE

PVC

0

20

40

60

80

100

120

70 80 90 100 110 120 130 140

HDPE

PVC

and Drainage Systems

Drainage systems are required to meet multiple criteria.

The choice of a particular material depends upon a

number of factors; however, the best choice is the one

that yields the best performance over the project life cycle.

Thermoplastic Storm Sewer and Drainage Pipe

In recent years, the use of thermoplastic pipe for

stormwater drainage systems has gained wide

acceptance—based upon performance and economic

advantages when contrasted with more conventional

drainage pipe materials. However, when it comes to

performance, not all thermoplastic storm sewer

pipes are equal. There are distinct differences between

A-2000/D-2000 Polyvinyl Chloride (PVC) drainage pipe

and other drainage pipes that can affect overall pipe

system performance.

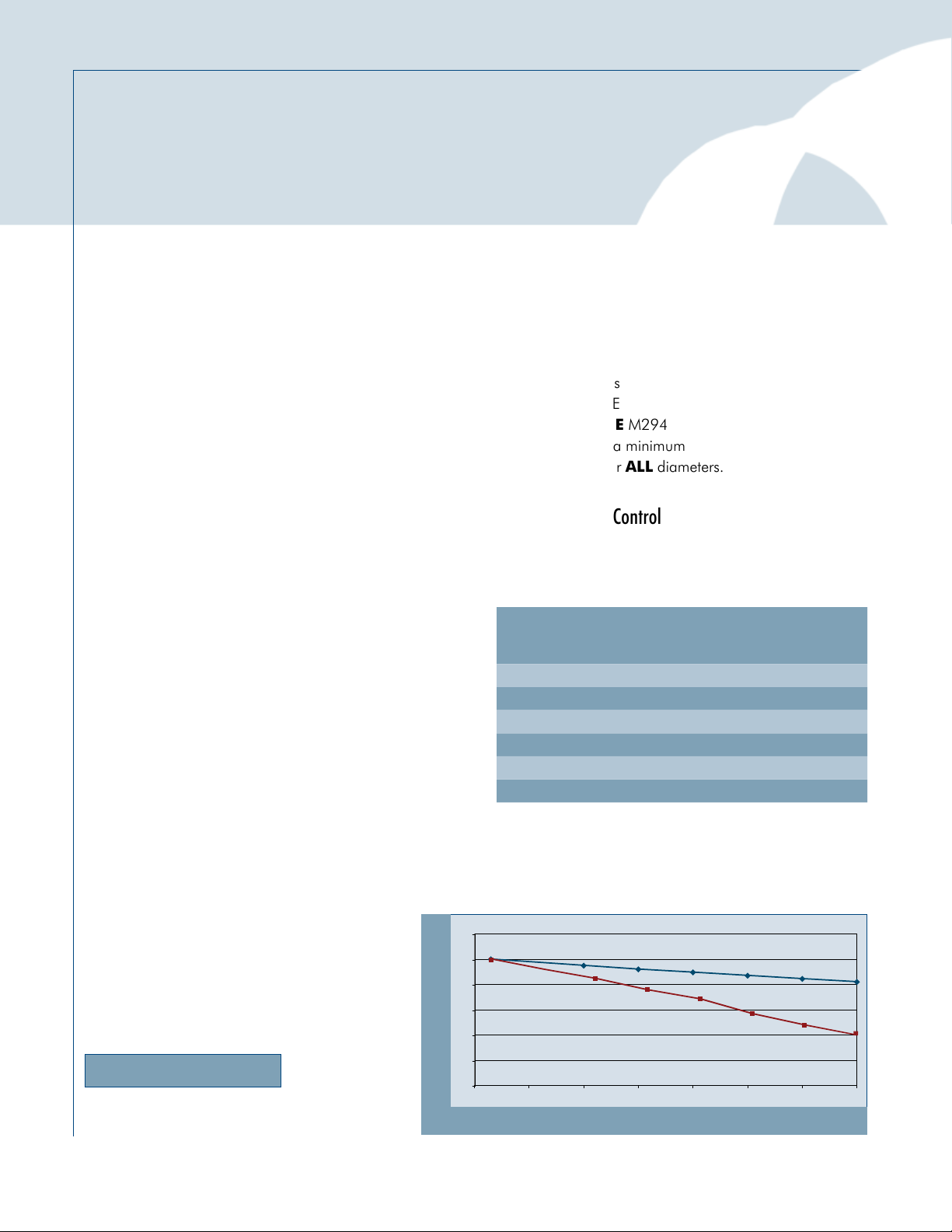

Strength

CONTECH's

PVC compound

provides 6 times

greater long-term

material stiffness as

compared to HDPE

resin. And UNLIKE M294

HDPE pipe, it has a minimum

46 pipe stiffness for ALL diameters.

Better Deflection Control

Minimum Specified Pipe Stiffness (73o)

CONTECH® A-2000 PVC Drainage Pipe:

Available in Diameters 4”-36” and 12.5’, 14’ and

22’ lengths.

Originally developed in the early 1980’s, A-2000 has

built an outstanding performance history that‘s setting the

standard for gravity flow, sanitary sewer applications. The

material advantages offered by PVC—plus the innovative,

double wall design with the unique, patented gasketed

joint system—makes A-2000 and more recently D-2000

the ideal choice for stormwater drainage systems. Now

you can have all of the advantages without the limitations

of AASHTO M294 corrugated HDPE (M294 HDPE pipe)

or reinforced concrete pipe.

18” PVC – HDPE Wall Sections

Compact A-2000 PVC profile is stable and not

subject to local buckling like M294 HDPE pipe.

2

Pipe Diameter PVC

12 46 50

15 46 42

18 46 40

24 46 34

30 46 28

36 46 22

Pipe Stiffness Retention vs. Temperature

Percent of Stiffness

Pipe Wall Temperature – Degrees F

ASTM F949

PVC

Corrugated AASHTO

M294

Non reinforced HDPE

Page 3

When compared to other

thermoplastic pipes on the

market, A-2000 stands up to

the test. In fact, it comes out on

top.

When installed in accordance

with ASTM D2321, A-2000 provides

excellent shape control (performance).

Simple surface temperature measurements on

sun-exposed pipe surfaces indicate that under normal

temperatures, black M294 HDPE pipe approaches 140˚F,

while lighter color white pipe reaches temperatures in the

range of 120˚F. The difference between effective pipe

stiffness of PVC and M294 HDPE pipe during construction

on a summer day can result in A-2000 being as much as

3 TIMES STIFFER. This significant stiffness advantage

means A-2000 can be installed with conventional flexible

pipe practice and not experience excessive shape distortions

- lowering installation cost.

Heights of Cover

Based on research done under the National Cooperative

Highway Research Program, AASHTO has revised

its plastic pipe design methods. AASHTO Section 12

designs now include wall profile stability, soil arching

and deflection as design considerations. Unstable wall

profiles will fail due to local buckling rather than by ring

compression or ring buckling. This research demonstrates

that A-2000 profile walls are stable while others, like

those used for M294 HDPE pipe, are not.

When selecting a system based on pipe stiffness,

material strength and structural capability,

A-2000 PVC far exceeds the performance

characteristics of M294 HDPE pipe.

A comparison of cover heights using AASHTO design

methodology and H20 live loading for A-2000 and a major

manufacturer’s M294 HDPE pipe are summarized below.

A-2000 vs. M294 HDPE Heights of Cover

Pipe Type/ Allowable Allowable Min. Min.

Specification Ht. of Cover Structural Compaction Trench

Backfill

PVC A-2000 - ASTM F949 1’-20’ A1A, A1, A3 90% 1.5 X O.D. +12”

A2-4, A2-5

21’-35’ A1A, A1, A3 95% 1.5 X O.D. +12”

AASHTO M294 HDPE 1’-10’ A1A, A1, A3 95% O.D. + 36”

11’-20’ A1A 95% 3.0 x O.D.

21’-35’ Not Allowed

3

Page 4

Hydraulic Efficiency

PVC vs. Concrete Pipe

Thermoplastic pipes, with smoother interiors and fewer

joints, reduce resistance to flow and are hydraulically

more efficient than conventional (i.e. RCP) storm drainage

pipe materials. Flow testing conducted in 2002 by the

Utah Water Research Laboratory concluded A-2000 PVC

Pipe, with its inner wall formed over a polished mandrel,

has the lowest wall friction factor (Manning’s “n” = .009)

of any thermoplastic pipe available and offers real

advantages compared to RCP (n = .012- .013). This

added efficiency means A-2000 can be designed as a

smaller and less expensive pipe, with less excavation due

to flatter pipe slopes and less manhole/junction box depth

requirements.

A-2000 PVC pipe has a smooth, glossy

PVC vs. Corrugated HDPE Pipe

Hydraulic tests performed at a major United States

Water Research Laboratory led researchers to conclude

that corrugated M294 HDPE pipe’s “n” factor varied

“depending upon the smoothness of the liners” and “the

bonding of the liner to the corrugations made the pipe

interior somewhat wavy.” Once installed, corrugated

M294 HDPE pipe walls are subject to local buckling

(NCHRP Report 438) and the measured waviness

increases with load. Using the method derived to estimate

the effective Manning’s “n” factor, Manning’s “n” values

of 0.017-0.022 provide a more accurate representation

of M294 HDPE pipe’s hydraulic efficiency when in-service

and under load.

A-2000 PVC pipe, with its engineered, stable profile, is

designed to eliminate local buckling.

interior for uninterrupted flow.

Durability, Service Life

PVC materials used in the manufacture of gravity flow

pipe offer excellent resistance to conventional corrosion

and abrasion. In fact, profile wall PVC pipe has been

shown to have better abrasion resistance than reinforced

concrete pipe in side-by-side laboratory testing at

California State University.

PVC and M294 HDPE pipe do not provide equal

long-term durability performance. Under loading or

localized tensile stress, M294 HDPE pipe is subject to

environmental stress cracking—also known as slow crack

growth.

PVC pipe is not threatened by this type of cracking. When

you consider durability and service life, A-2000 PVC

far exceeds the performance characteristics of M294

HDPE pipe. (See the National Cooperative Highway

Research Program study conducted by Drexel University,

March, 1999: ”HDPE Pipe: Recommended Material

Specifications and Design Requirements”.)

4

Page 5

The Need for Tight Joints

Storm sewers have always presented special needs

for tight jointing systems. Because of their function,

they are subject to rapidly changing flow levels. The

sudden rise and fall of flow levels leaves storm sewers

susceptible to backfill migration into the sewer unless

tight joints are used. This loss of backfill reduces the

soil support of the pipe and causes settlement at the

surface. Where storm sewers are below the existing

water table, water tight joints are needed to prevent

infiltration and maintain storm sewer capacity.

A-2000’s long, 22' lengths and soil/water tight joints

clearly make it the preferred choice with regard to

system tightness. In comparison, RCP has shorter

lengths and more joints. RCP joints are also often

mortared or "mudded in" vs. watertight gasketed

joints, which can lead to future service problems as

cracking at the seams/joints permits water and soil

migration and eventual settlement. And with A-2000

you don’t have to specify special jointing requirements

– watertight gasketed joints are standard with A-2000.

Handling and Installation

A-2000’s easy handling weight and the availability

of up to 22' lay lengths often result in reduced labor

costs and more economical installation. Compared

to heavy-weight and short-length RCP, PVC can be

installed with greater ease and lower cost. And,

contrasted to M294 HDPE pipe, PVC has added

beam strength—which means better line and grade

control, increasing crew efficiency. Plus, PVC requires

less trench width, lowering excavation costs and

speedy installation.

The Performance Choice

With the increasing demands on our drainage and

storm sewer systems, products designed and proven

to provide the best performance over the project

life cycle are needed. A-2000 PVC drainage pipe

offers all of the initial cost advantages associated

with thermoplastic pipe when compared with RCP

but without the performance limitations of corrugated

M294 HDPE pipe. There’s no reason to compromise

on performance—Select A-2000 PVC: The Best

Storm Sewer and Drainage Pipe on the Planet.

CONTECH’s A-2000 PVC pipe is

lightweight and easy to handle.

Best Pipe on the Planet

5

Page 6

The New D-2000

Responding to customer demand, CONTECH has introduced its latest solution

for the small diameter drainage market. D-2000 PVC pipe, available in 4”36” diameters, answers the need for a high performance PVC drainage pipe

at a price that is more competitive with corrugated M294 HDPE pipe. D-2000

is manufactured to meet and exceed the minimum pipe stiffness requirements

of AASHTO M304 (vs. ASTM F949 for A-2000), resulting in a lighter weight,

lower cost PVC pipe. Don’t be fooled, D-2000 still offers many performance

advantages over M294 HDPE including:

Higher effective pipe stiffness on warm, sunny days, resulting in superior

•

deflection control and simplified installation procedures.

Cover limits ranging from 12 inches minimum to over 20 feet maximum.

•

Greater beam strength for improved line and grade control.

•

Smoother interior wall for improved hydraulic capacity.

•

Superior short-term and long-term inground joint tightness - where it counts.

•

Improved post installation test results (deflection, air and laser testing).

•

D-2000 Mechanical Properties

INITIAL

Cell Class Minimum Tensile

Strength

12454 7,000 PSI 400,000 PSI

12364 6,000 PSI 440,000 PSI

50 YEAR

Cell Class Minimum Tensile

Strength

12454 3,700 PSI 140,000 PSI 5%

12364 2,600 PSI 158,400 PSI 3.5%

100 YEAR

Cell Class Minimum Tensile

Strength

12454 3,620 PSI 125,600 PSI 5%

Minimum Modulus of

Elasticity

Minimum

Modulus of

Allowable

Long-Term

Elasticity

Minimum

Modulus of

Allowable

Long-Term

Elasticity

Strain

Strain

D-2000 Section Properties

Size

Inside

(in)

Dia. (in)

4 3.95 4.29 0.702 0.106 0.00021 46

6 5.88 6.41 0.876 0.161 0.00070 46

8 7.87 8.59 1.18 0.218 0.00175 46

10 9.84 10.78 1.48 0.394 0.00359 46

12 11.72 12.80 1.80 0.325 0.00603 46

15 14.37 15.66 1.90 0.397 0.00957 38

18 17.61 19.15 1.99 0.516 0.01314 32

24 23.53 25.58 2.68 0.680 0.03195 24

30 29.47 32.15 3.96 0.813 0.08372 19

36 35.48 38.74 4.74 0.992 0.14606 16

* Extreme fiber distance from neutral axis.

Outside

Dia. (in)

Area

(in2/foot)

C* I (in4/

in)

PSI

(min)

6

Page 7

Additional A-2000 Products and

Applications

A-2000 for Roof Drainage Systems

Managing large volumes of stormwater runoff from roof

areas of industrial, commercial and warehouse facilities

is more demanding than for most gravity-fed sewer

systems. Additionally, intense rainfalls, combined with

added building height, can create hydrostatic pressures

within the pipe as well as on the joints and other system

components. To handle these requirements, you need

the higher strength and joint tightness of A-2000 PVC

drainage pipe. CONTECH’s full line of readily-available

adapters and fittings makes connecting downspouts and

laterals simple. Because of the unique gasket and bell

design, there is no field beveling required.

A2™ Liner Pipe for Trenchless Rehabilitation

Renew the performance of your aging underground

infrastructure with A2 Liner Pipe—the proven, trenchless

solution to sliplining existing sewers and culverts. Using

the double wall A-2000 design, CONTECH developed

A2 Liner Pipe for sliplining deteriorating pipelines where

open trenching is not practical or desirable. You can

install A2 Liner Pipe in diameters ranging from 12”-36”

and in lengths from 2.5’ to 20’—speeding installation.

And because of its light weight, you can use smaller, less

expensive equipment for installation—reducing costs.

A-2000 Perforated Pipe for Subdrainage Systems

CONTECH A-2000 offers several critical features

and benefits that make it the performance choice for

subsurface drainage systems:

• 46 psi pipe stiffness for structural stability and improved

deflection control.

• Glossy smooth interior for improved hydraulic capacity.

• PVC rigidity that provides essential beam strength for

improved line and grade control during installation.

• Positive-gasketed jointing system.

Standard perforations for 4”-18” diameters are slots,

while perforations for pipe sizes 21”-36” are circular 3/8”

diameter (.375”) holes. Fully perforated A-2000 is also

available for even greater open area.

Perforation Dimensions

Pipe Size

(in)

10 2.187L x 0.031W 8.83 1.98

12 1.687L x 0.051W 1.03 2.00

15 1.250L x 0.051W 1.38 2.00

18 2.250L x 0.051W 1.38 2.00

21 0.375 Diameter 1.60 3.30

24 0.375 Diameter 1.90 2.70

30 0.375 Diameter 2.32 2.20

36 0.375 Diameter 2.61 2.00

Slot Dimension/Hole

Size (in) (min)

4 1.062L x 0.031W 0.42 1.90

6 1.375L x 0.031W 0.52 1.98

8 1.750L x 0.031W 0.69 1.90

Centers

(in)

Perforation Open

Area (in2/LF)

7

Page 8

A-2000 Specifications

RECYCLED

PAPER

Constant Stiffness Thermoplastic Pipe

1.0 PIPE: Polyvinyl Chloride (PVC) storm sewer/drain

pipe and fittings shall be manufactured and tested in

accordance with ASTM F949.

2.0 MATERIAL AND DESIGN: The structural design of

thermoplastic pipes shall be in accordance with AASHTO

Section 12 titled: “Buried Structures and Tunnel Liners.”

To ensure long-term design strength properties, PVC pipe

shall be manufactured from 12454 cell class material per

ASTM D1784. Pipe and fittings shall have a minimum

pipe stiffness of 46 lbs./in./in., when tested in accordance

with ASTM D2412.

CONTECH Construction Products Inc. provides site solutions

for the civil engineering industry. CONTECH’s portfolio

includes bridges, drainage, retaining walls, sanitary sewer,

stormwater, erosion control and soil stabilization products.

3.0 JOINTING SYSTEM: Joints shall be an integral

bell-gasketed joint. When the joint is assembled, it shall

prevent misalignment of adjacent pipes and form either

a soil tight joint (2 psi hydrostatic test per AASHTO

Standard Specification for Highway Bridges, Section

26.4.2.4) or a watertight joint (10.8 psi test per ASTM

D3212 titled: “Standard Specification for Joints for Drain

and Sewer Plastic Pipes using Flexible Elastomeric Seals’)

as required.

4.0 HYDRAULICS CAPACITY: The PVC Pipe covered in

this section shall provide a Manning’s “n” value of .009.

5.0 INSTALLATION: Thermoplastic pipe and fittings

shall be installed in strict accordance with ASTM D2321

or AASHTO Section 30.

For more information, call one of CONTECH’s Regional Offices

located in the following cities:

Ohio (Corporate Office) 513-645-7000

California (Long Beach) 562-733-0733

Colorado (Denver) 720-587-2700

Florida (Tampa) 727-544-8811

Georgia (Atlanta) 770-409-0814

Maine (Scarborough) 207-885-9830

Maryland (Baltimore) 410-740-8490

Oregon (Portland) 503-258-3180

Texas (Dallas) 972-590-2000

Visit our web site: www.contech-cpi.com

800.338.1122

NOTHING IN THIS CATALOG SHOULD BE CONSTRUED AS AN EXPRESSED WARRANTY

OR AN IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE. SEE THE CONTECH STANDARD CONDITION OF SALES (VIEWABLE AT

WWW.CONTECH-CPI.COM/COS) FOR MORE INFORMATION.

REV-9 6M 1/10 MC

©2010 CONTECH CONSTRUCTION PRODUCTS, INC.

All rights reserved. Printed in USA.

Loading...

Loading...