Page 1

A-2000™ PVC Pipe

ENGINEERED SOLUTIONS

Fittings and Components

1

Page 2

General Notes

1. * Indicates a fabricated part.

2. ** Indicates a molded part with bushing or adaptor.

3. All drawings herein are for illustrative purposes only and

are not intended as true representations of actual parts.

4. This catalog contains the most commonly used

A-2000TM fittings and components. Additional A-2000 parts not

shown may be available from Contech Engineered Solutions LLC

Contact your local Contech Plastic Pipe Specialist about items not

listed.

5. All saddles include templates and stainless steel bands. Adhesives

or gaskets are not included and must be ordered separately.

Joining A-2000 gasketed PVC pipe and fittings

(ASTM D3212)

Lubrication Requirements

(Joints per Gallon)

Pipe Size

(inches)

4 300

6 220

8 100

10 64

12 48

15 25

18 20

21 16

24 11

30 7

36 5

Lubricant

2

Page 3

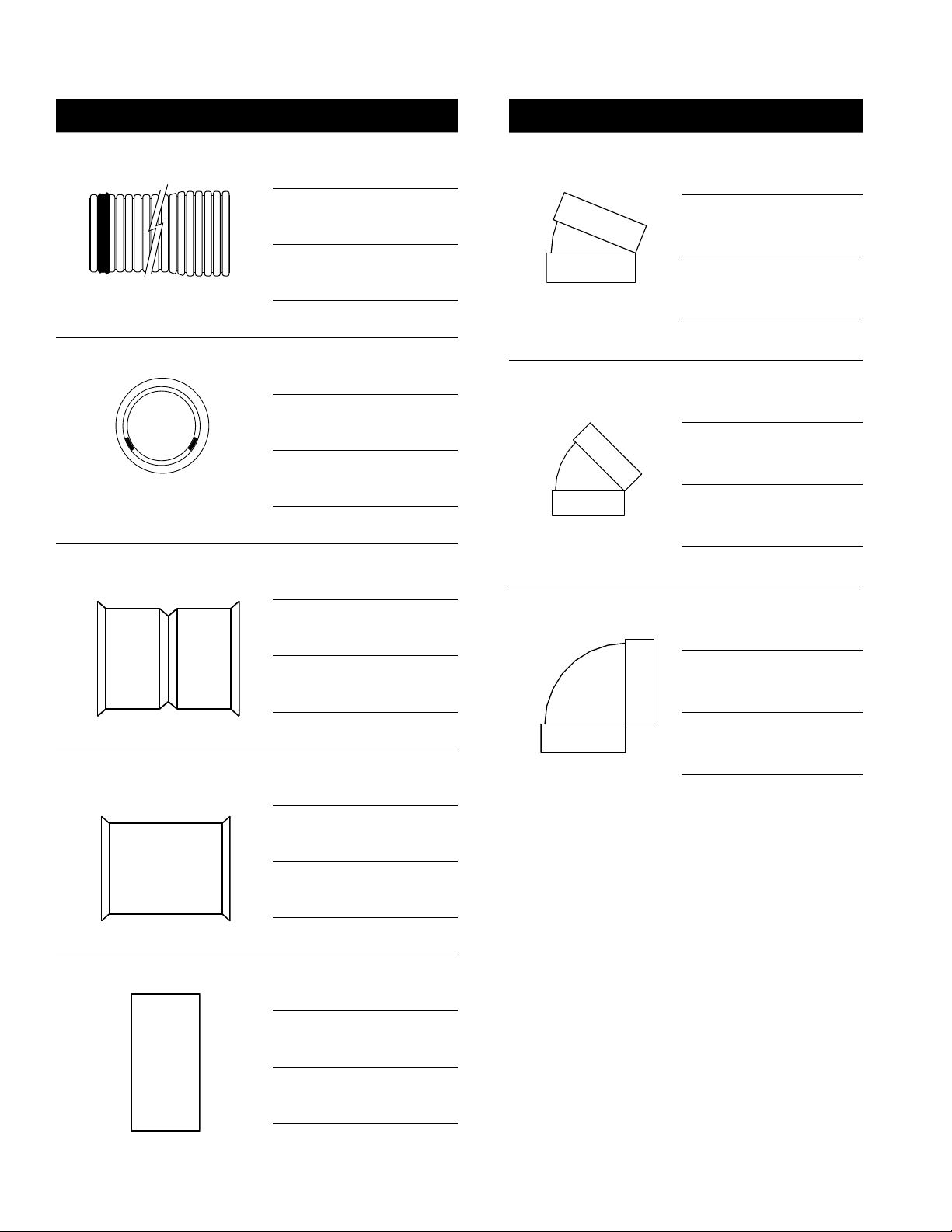

A-2000 Pipe Elbows

Type Available Sizes

Pipe

Perforated Pipe

Same as above. 4” thru 18” pipe is slotted. 21”

through 36” pipe has 3/8” holes.

1/4 Bend

(Bell-Bell)

Loose Coupling

without Centerstop

Spigot Cap

(inches)

Part Number

4 A2PG041250

6 A2PG061250

8 A2PG081250

10 A2PG101250

12 A2PG121250

15 A2PG151250

18 A2PG181250

21 A2PG211300

24 A2PG241300

30 A2PG301300

36 A2PG361300

4 A2PG041250P

6 A2PG061250P

8 A2PG081250P

10 A2PG101250P

12 A2PG121250P

15 A2PG151250P

18 A2PG181250P

21 A2PG211250P

24 A2PG241300P

30 A2PG301300P

36 A2PG361300P

4 APG04CCS

6 APG06CCS

8 APG08CCS

10 APG10CCS

12 APG12CCS*

15 APG15CCS*

18 APG18CCS*

21 APG21CCS*

24 APG24CCS*

30 APG30CCS*

36 APG36CCS*

4 APG04C

6 APG06C

8 APG08C

10 APG10C

12 APG12C*

15 APG15C*

18 APG18C*

21 APG21C*

24 APG24C*

30 APG30C*

36 APG36C*

4 APG04SC

6 APG06SC

8 APG08SC

10 APG10SC

12 APG12SC*

15 APG15SC*

18 APG18SC*

21 APG21SC*

24 APG24SC*

30 APG30SC*

36 APG36SC*

Type Available Sizes

(inches)

1/16 Bend

(Bell-Bell)

10 APG10L22B*

12 APG12L22B*

15 APG15L22B*

18 APG18L22B*

21 APG21L22B*

24 APG24L22B*

30 APG30L22B*

36 APG36L22B*

1/8 Bend

(Bell-Bell)

10 APG10L45B*

12 APG12L45B*

15 APG15L45B*

18 APG18L45B*

21 APG21L45B*

24 APG24L45B*

30 APG30L45B*

36 APG36L45B*

1/4 Bend

(Bell-Bell)

10 APG10L90B*

12 APG12L90B*

15 APG15L90B*

18 APG18L90B*

21 APG21L90B*

24 APG24L90B*

30 APG30L90B*

36 APG36L90B*

Part Number

4 APG04L22B

6 APG06L22B

8 APG08L22B*

4 APG04L45B

6 APG06L45B

8 APG08L45B

4 APG04L90B

6 APG04L90B

8 APG08L90B

3

Page 4

8 310

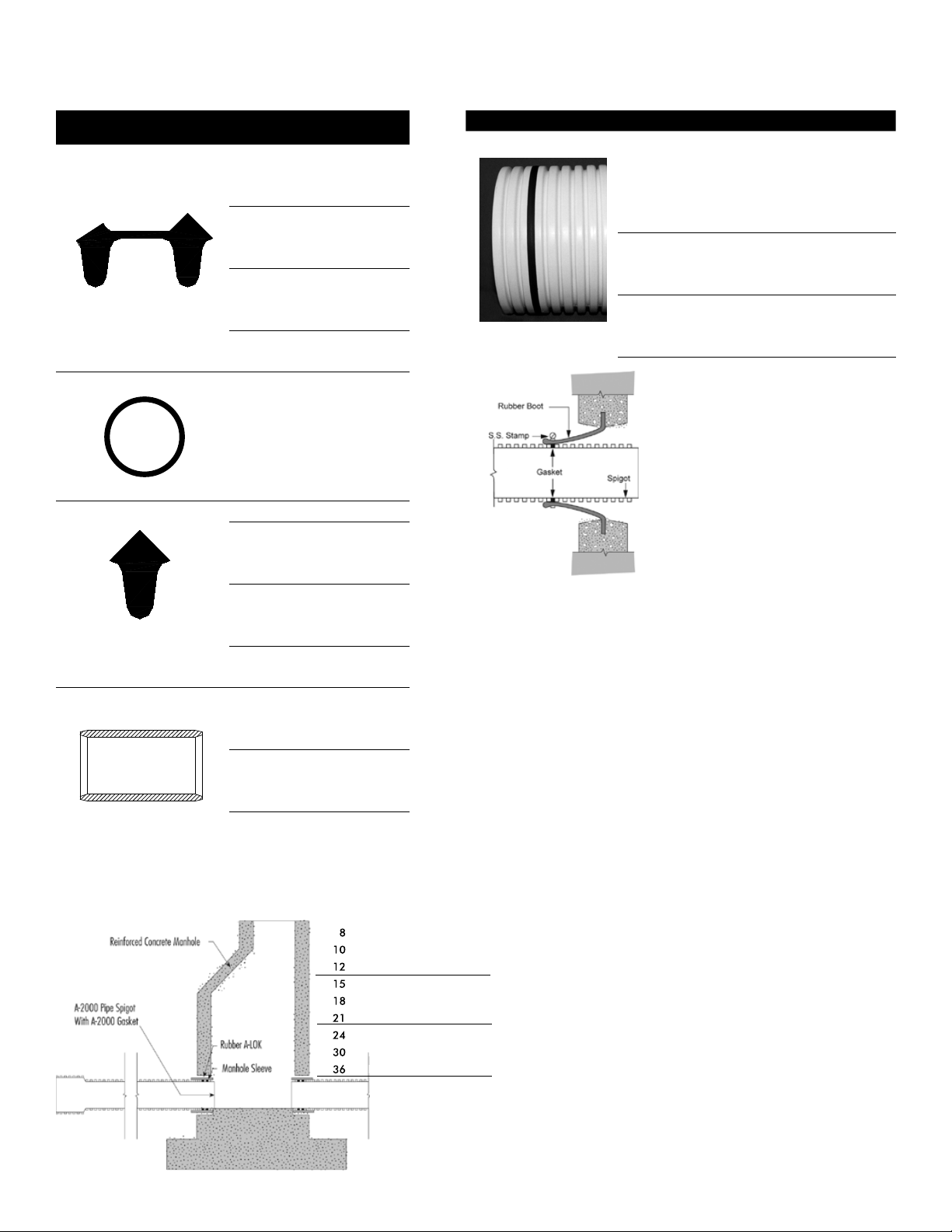

Gaskets and Manhole Connectors

Type Available Sizes

Double Gasket 4 APG04G

O-Ring Gasket 4 PERF APG04GO

For 4” and 6” perforated pipe

Single Gasket 8 PERF APG08GO

For 8” thru 36” perforated and

drainage pipe

Manhole Sleeve for

A-Lok Connection

(inches)

6 APG06G

8 APG08G

10 APG10G

12 APG12G

15 APG15G

18 APG18G

21 APG21G

24 APG24G

30 APG30G

36 APG36G

6 PERF APG06GO

10 PERF APG10GO

12 PERF APG12GO

15 PERF APG15GO

18 PERF APG18GO

21 PERF APG21GO

24 PERF APG24GO

30 PERF APG30GO

36 PERF APG36GO

8 APG08MHC

10 APG10MHC

12 APG12MHC

15 APG15MHC

18 APG18MHC

21 APG21MHC

24 APG24MHC

30 APG30MHC

36 APG36MHC

Part Number

Type Available Sizes (inches) Part Number

Manhole Gasket Diameter

(inches)

4 4.30 APG04G

6 6.42 APG06G

8 8.60 APG08G

10 10.79 APG10G

12 12.80 PFAPG 12 GM

15 15.66 PFAPG 15 GM

18 19.15 PFAPG 18 GM

21 22.59 PFAPG 21 GM

24 25.58 PFAPG 24 GM

30 32.15 PFAPG 30 GM

36 38.74 PFAPG 36 GM

Average Outside

Diameter (inches)

*For 21” diameter and larger pipe, the

boot manufacturers recommend using two

stainless steel clamp assemblies (with two

screws per assembly) per boot. Clamps

should be positioned evenly around the boot

groove with the screws staggered so that the

take-up pressure is equalized. Tighten screws

of the outside clamp in an alternating pattern

to the recommended torque on final screw.

Check all screws again to ensure equal

compression of both clamps.

4

A-LOK

Dia. Ring No.

8 310

10 380

12 440

15 525

18 640

21 750

24 855

30 1100

36 1310

Page 5

Wyes

Type Available Sizes

Reducing Inline Wye

with A-2000 Branch

(inches)

Part Number

6x6x4 APG06YB4B

8v8v4 APG086B4B

8x8x6 APG08YB6B*

10x10x4 APG10YB4B*

10x10x6 APG10YB6B*

10x10x8 APG10YB8B*

12x12x4 APG12YB4B*

12x12x6 APG12YB6B*

12x12x8 APG12YB8B*

12x12x10 APG12YB10B*

15x15x4 APG15YB4B*

15x15x6 APG15YB6B*

15x15x8 APG15YB8B*

15x15x10 APG15YB10B*

15x15x12 APG15YB12B*

18x18x4 APG18YB4B*

18x18x6 APG18YB6B*

18x18x8 APG18YB8B*

18x18x10 APG18YB10B*

18x18x12 APG18YB12B*

18x18x15 APG18YB15B*

21x21x4 APG21YB4B*

21x21x6 APG21YB4B*

21x21x8 APG21YB8B*

21x21x10 APG21YB10B*

21x21x12 APG21YB10B*

21x21x15 APG21YB15B*

21x21x18 APG21YB18B*

24x24x4 APG24YB4B*

24x24x6 APG24YB6B*

24x24x8 APG24YB8B*

24x24x10 APG24YB10B*

24x24x12 APG24YB12B*

24x24x15 APG24YB15B*

24x24x18 APG24YB18B*

24x24x21 APG24YB21B*

30x30x4 APG30YB4B*

30x30x6 APG30YB6B*

30x30x8 APG30YB8B*

30x30x10 APG30YB10B*

30x30x12 APG30YB12B*

30x30x15 APG30YB15B*

30x30x18 APG30YB18B*

30x30x21 APG30YB21B*

30x30x24 APG30YB24B*

36x36x4 APG36YB4B*

36x36x6 APG36YB6B*

36x36x8 APG36YB8B*

36x36x10 APG36YB10B*

36x36x12 APG36YB12B*

36x36x15 APG36YB15B*

36x36x18 APG36YB18B*

36x36x21 APG36YB21B*

36x36x24 APG36YB24B*

36x36x30 APG36YB30B*

Type Available Sizes

Non-Reducing Inline Wye

with SDR35 Branch

Reducing Inline Wye

with SDR35 Branch

Non-Reducing Inline Wye

with A-2000 Branch

(inches)

Part Number

4x4x4 APG04YB435__**

6x6x6 APG06YB635__**

6x6x4 APG06YB435__**

8x8x4 APG08YB435__

8x8x6 APG08YB635__

10x10x4 APG10YB435__*

10x10x6 APG10YB635__*

12x12x4 APG12YB435__*

12x12x6 APG12YB635__*

15x15x4 APG15YB435__*

15x15x6 APG15YB635__*

18x18x4 APG18YB435__*

18x18x6 APG18YB635__*

21x21x4 APG21YB435__*

21x21x6 APG21YB635__*

24x24x4 APG24YB435__*

24x24x6 APG24YB635__*

30x30x4 APG30YB435__*

30x30x6 APG30YB635__*

36x36x4 APG36YB435__*

36x36x6 APG36YB635__*

4x4x4 APG04TB4B

6x6x6 APG06TB6B

8x8x8 APG08TB8B

10x10x10 APG10TB10B*

12x12x12 APG12TB12B*

15x15x15 APG15TB15B*

18x18x18 APG18TB18B*

21x21x21 APG21TB21B*

24x24x24 APG24TB24B*

30x30x30 APG30TB30B*

36x36x36 APG36TB36B*

5

Page 6

Tees

Type Available Sizes

Reducing Inline Tee with A-2000 Branch

6

(inches)

Part Number

6x6x4 APG06TB4B**

8x8x4 APG08TB4B

8x8x6 APG08TB6B

10x10x4 APG10TB4B*

10x10x6 APG10TB6B*

10x10x8 APG10TB8B*

12x12x4 APG12TB4B*

12x12x6 APG12TB6B*

12x12x8 APG12TB8B*

12x12x10 APG12TB10B*

15x15x4 APG15TB4B*

15x15x6 APG15TB6B*

15x15x8 APG15TB8B*

15x15x10 APG15TB10B*

15x15x12 APG15TB12B*

18x18x4 APG18TB4B*

18x18x6 APG18TB6B*

18x18x8 APG18TB8B*

18x18x10 APG18TB10B*

18x18x12 APG18TB12B*

18x18x15 APG18TB15B*

21x21x4 APG24TB4B*

21x21x6 APG24TB6B*

21x21x8 APG24TB8B*

21x21x10 APG24TB10B*

21x21x12 APG24TB12B*

21x21x15 APG24TB15B*

21x21x18 APG24TB18B*

24x24x4 APG24TB4B*

24x24x6 APG24TB6B*

24x24x8 APG24TB8B*

24x24x10 APG24TB10B*

24x24x12 APG24TB12B*

24x24x15 APG24TB15B*

24x24x18 APG24TB18B*

24x24x21 APG24TB21B*

30x30x4 APG30TB4B*

30x30x8 APG30TB6B*

30x30x8 APG30TB8B*

30x30x10 APG30TB10B*

30x30x12 APG30TB12B*

30x30x15 APG30TB15B*

30x30x18 APG30YB18B*

30x30x21 APG30YB21B*

30x30x24 APG30YB24B*

36x36x4 APG36TB4B*

36x36x6 APG36TB6B*

36x36x8 APG36TB8B*

36x36x10 APG36TB10B*

36x36x12 APG36TB12B*

36x36x15 APG36TB15B*

36x36x18 APG36YB18B*

36x36x21 APG36YB21B*

36x36x24 APG36YB24B*

36x36x30 APG36YB30B*

Type Available Sizes

Non-Reducing Inline Tee

with SDR35 Branch

Reducing Inline Tee

with SDR35 Branch

Tee Wye

Non-Reducing Inline Tee

with A-2000 Branch

(inches)

Part Number

4x4x4 APG04TB435**

6x6x6 APG06TB635**

6x6x4 APG06TB435__**

8x8x4 APB08TB435__

8x8x6 APG08TB635__

10x10x4 APG10TB435__*

10x10x6 APG10TB635__*

12x12x4 APG12TB435__*

12x12x6 APG12TB635__*

15x15x4 APG15TB435__*

15x15x6 APG15TB635__*

18x18x4 APG18TB435__*

18x18x6 APG18TB635__*

21x21x4 APG21TB435__*

21x21x6 APG21TB635__*

24x24x4 APG24TB435__*

24x24x6 APG24TB635__*

30x30x4 APG30TB435__*

30x30x6 APG30TB635__**

36x36x4 APG36TB435__*

36x36x6 APG30TB635__*

8x8x4 APG08TY4*

8x8x6 APG08TY6*

10x10x4 APG10TY4*

10x10x6 APG10TY6*

12x12x4 APG12TY4*

12x12x6 APG12TY6*

4x4x4 APG04TB4B

6x6x6 APG06TB6B

8x8x8 APG08TB8B

10x10x10 APG10TB10B*

12x12x12 APG12TB12B*

15x15x15 APG15TB15B*

18x18x18 APG18TB18B*

21x21x21 APG21TB21B*

24x24x24 APG24TB24B*

30x30x30 APG30TB30B*

36x36x36 APG36TB36B*

Page 7

Saddle Wyes Saddle Tees

Type Available Sizes

Smooth Wye

SDR35 Branch

Notes:

1. Saddles are available in 6” thru 18” diameters.

2. Saddles include templates and stainless steel bands. Adhesive or gaskets

are not included and must be ordered separately.

Saddle Wye

A-2000 Branch

Notes:

1. Saddles are available in 6” thru 36” diameters.

2. All saddles include templates and stainless steel bands. Adhesive or

gaskets are not included and must be ordered separately.

(inches)

6x4 APX06Y435B__**

8x4 APX08Y435B__**

8x6 APX08Y635B__**

10x4 APX10Y435B__**

10x6 APX10Y635B__**

12x4 APX12Y435B__**

12x6 APX12Y635B__**

15x4 APX15Y435B__**

15x6 APX15Y635B__**

18x4 APX18Y435B__**

18x6 APX18Y635B__**

Note:

1. __ must be filled in to indicate type

of branch joint.

G = Gasketed

S = Solvent Weld

6x4 APX06Y4**

8x4 APX08Y4**

8x6 APX08Y6

10x4 APX10Y4**

10x6 APX10Y6

12x4 APX12Y4**

12x6 APX12Y6**

15x4 APX15Y4**

15x6 APX15Y6**

18x4 APX18Y4**

18x6 APX18Y6**

Part Number

Type Available Sizes

Saddle Tee

SDR35 Branch

Notes:

1. Saddles are available in 6” thru

36” diameters.

2. Saddles include templates and

stainless steel bands. Adhesive

or gaskets are not included and

must be ordered separately.

Saddle Tee

A-2000 Branch

Notes:

1. Saddles are available in 6” thru 36” diameters.

2. All saddles include templates and stainless steel bands. Adhesive or

gaskets are not included and must be ordered separately.

(inches)

6x4 APX06T435B__

8x4 APX08T435B__**

8x6 APX08T635B__**

10x4 APX10T435B__**

10x6 APX10T635B__**

12x4 APX12T435B__**

12x6 APX12T635B__**

15x4 APX15T435B__**

15x6 APX15T635B__**

18x4 APX18T435B__**

18x6 APX18T635B__**

21x4 APX215435B__**

21x6 APX21T635B__**

24x4 APX24T435B__**

24x6 APX245635B__**

30x4 APX30T435B__**

30x6 APX30T635B__**

36x4 APX36T435B__**

36x6 APX36T635B__**

Note:

1. __ must be filled in to indicate type

of branch joint.

G = Gasketed

S = Solvent Weld

6x4 APX06T4B**

8x4 APX08T4B**

8x6 APX08T6B

10x4 APX10T4B**

10x6 APX10T6B

12x4 APX12T4B**

12x6 APX12T6B**

15x4 APX15T4B**

15x6 APX15T6B**

15x8 APX15T8B*

18x4 APX18T4B**

18x6 APX18T6B**

21x4 APX21T4B**

21x6 APX21T6B**

24x4 APX24T4B**

24x6 APX24T6B**

30x4 APX30T4B**

30x6 APX30T6B**

36x4 APX36T4B**

36x6 APX36T6B**

Part Number

Saddle Adhesive Caulking CPSC

Tubes (SIKAFLEX 221)

(RAPIDSEAL 365)

7

Page 8

Adaptors Coupling/Caps

Type Available Sizes Part

(inches) Number

A-2000 4 APG0435S*

Bell/SDR35 Spigot 6 APG0635S*

Adaptor 8 APG0835S*

10 APG1035S*

12 APG1235S*

15 APG1535S*

18 APG1835S*

21 APG2135S*

24 APG2435S*

30 APG3035S*

A-2000

36 APG3635S*

Bell

A-2000 4 APB0435BS*

Bell/SDR35 Bell 6 APB0635BS*

Adaptor

A-2000

Bell

A-2000 4 APG04DWV*

Bell/DWV Bell 6 APG06DWV*

Adaptor

SDR 35

Spigot

SDR 35

Solvent Weld

Bell

Type Available Sizes Part

(inches) Number

Cleanout and Cap 4 APG04CLN**

6 APG06CLN**

Threaded Cleanout

A-2000 Bell

Repair Coupling 4 004FCA

(Fernco Type 1056) 6 006FCA

8 008FCA

10 010FCA

12 012FCA

15 015FCA

18 018FCA

21 021FCA

24 024FCA

Note: 12” and larger Fernco couplings

30 030FCA

are not inventoried and are available

36 036FCA

on special order.

Shear Stop for 4 004CRP*

Repair Coupling 6 006CRP*

8 008CRP*

10 010CRP*

12 012CRP*

15 015CRP*

18 P18CRP*

Mechanical 4 04MP

Plug 6 06MP

Stainless Steel

Straps

A-2000

Bell

A-2000 Bell 4 APG04AD35BG*

Adaptor (to SDR35 6 APG06AD35BG*

Gasketed Bell)

A-2000

Bell

Bell Converter 4 APS04BC35BG*

(Converts A-2000 6 APS06BC35BG*

Bell to SDR35

Gasketed Bell)

A-2000

8

Spigot

Solvent

Weld

DWV Bell

SDR 35

Bell

SDR 35

Bell

Page 9

Bushings

Type Available Sizes Part

(inches) Number

Bushing 6 x 4 APG06BU4

8 x 4 APG08BU4**

8 x 6 APG08BU6

10 x 4 APG10BU4*

10 x 6 APG10BU6*

10 x 8 APG10BU8*

12 x 4 APG12BU4*

12 x 6 APG12BU6*

12 x 8 APG12BU8*

12 x 10 APG12BU10*

15 x 4 APG15BU4*

15 x 6 APG15BU6*

15 x 8 APG15BU8*

15 x 10 APG15BU10*

15 x 12 APG15BU12*

18 x 4 APG18BU4*

18 x 6 APG18BU6*

18 x 8 APG18BU8*

18 x 10 APG18BU10*

18 x 12 APG18BU12*

18 x 15 APG18BU15*

21 x 4 APG21BU4*

21 x 6 APG21BU6*

21 x 8 APG21BU8*

21 x 10 APG21BU10*

21 x 12 APG21BU12*

21 x 15 APG21BU15*

21 x 18 APG21BU18*

24 x 4 APG24BU4*

24 x 6 APG24BU6*

24 x 8 APG24BU8*

24 x 10 APG24BU10*

24 x 12 APG24BU12*

24 x 15 APG24BU15*

24 x 18 APG24BU18*

24 x 21 APG24BU21*

30 x 4 APG30BU4*

30 x 6 APG30BU6*

30 x 8 APG30BU8*

30 x 10 APG30BU10*

30 x 12 APG30BU12*

30 x 15 APG30BU15*

30 x 18 APG30BU18*

30 x 21 APG24BU21*

30 X 24 APG30BU24*

36 x 4 APG36BU4*

36 x 6 APG36BU6*

36 x 8 APG36BU8*

36 x 10 APG36BU10*

36 x 12 APG36BU12*

36 x 15 APG36BU15*

36 x 18 APG36BU18*

36 x 21 APG36BU21*

36 x 24 APG36BU24*

36 x 30 APG36BU30*

(Spigot x Bell)

Type Available Sizes Part

(inches) Number

Bushed Reducer 6 x 4 APG06BR4**

(Bell/Bell) 8 x 4 APG08BR4**

8 x 6 APG08BR6**

10 x 4 APG10BR4*

10 x 6 APG10BR6*

10 x 8 APG10BR8*

12 x 4 APG12BR4*

12 x 6 APG12BR6*

12 x 8 APG12BR8*

12 x 10 APG12BR10*

15 x 4 APG15BR4*

15 x 6 APG15BR6*

15 x 8 APG15BR8*

15 x 10 APG15BR10*

15 x 12 APG15BR12*

18 x 4 APG18BR4*

18 x 6 APG18BR6*

18 x 8 APG18BR8*

18 x 10 APG18BR10*

18 x 12 APG18BR12*

18 x 15 APG18BR15*

21 x 4 APG21BR4*

21 x 6 APG21BR6*

21 x 8 APG21BR8*

21 x 10 APG21BR10*

21 x 12 APG21BR12*

21 x 15 APG21BR15*

21 x 18 APG21BR18*

24 x 4 APG24BR4*

24 x 6 APG24BR6*

24 x 8 APG24BR8*

24 x 10 APG24BR10*

24 x 12 APG24BR12*

24 x 15 APG24BR15*

24 x 18 APG24BR18*

24 x 21 APG24BR21*

30 x 4 APG30BR4*

30 x 6 APG30BR6*

30 x 8 APG30BR8*

30 x 10 APG30BR10*

30 x 12 APG30BR12*

30 x 15 APG30BR15*

30 x 18 APG30BR18*

30 x 21 APG30BR21*

30 x 24 APG30BR24*

36 x 4 APG36BR4*

36 x 6 APG36BR6*

36 x 8 APG36BR8*

36 x 10 APG36BR10*

36 x 12 APG36BR12*

36 x 15 APG36BR15*

36 x 18 APG36BR18*

36 x 21 APG36BR21*

36 x 24 APG36BR24*

36 x 30 APG36BR30*

9

Page 10

Drain Basins and Inline Drains

Basin Dia.

1.00”

Drain Dia.

1.00”

B

A

Inlet/Outlet

Dia.

C

Drain Basin

Basin Inlet/Outlet A B C

Diameter Diameter (2)

(inches) (4) (inches) (inches)

8 4-8 (1) (1) 6.0

10 4-10 (1) (1) 6.0

12 4-12 (1) (1) 6.0

15 4-15 (1) (1) 6.0

18 4-18 (1) (1) 6.0

21 4-21 (1) (1) 6.0

24 4-24 (1) (1) 6.0

27 4-27 (1) (1) 8.0

30 4-30 (1) (1) 8.0

36 4-30 (1) (1) 8.0

NOTES: (1) Variable elevations available. (2) Values shown are minimum.

(3) A, B or C dimensions (for each inlet/outlet) must be provided when ordering.

A

B

C

Riser Dia.

Inline Drain

Drain Riser B C

Diameter Diameter (2)

(inches) (1) (inches) (inches)

8 4 12.25 (2)

10 4-6 12.25 (2)

12 4-8 12.50 (2)

15 4-10 12.50 (2)

18 4-12 12.75 (2)

21 4-15 12.75 (2)

24 4-18 12.75 (2)

27 4-21 13.00 (2)

30 4-24 13.00 (2)

36 4-30 13.00 (2)

NOTES: (1) Must be equal to or smaller than sewer diameter.

(2) This fixed dimension varies depending on drain and riser diameters.

The illustrations below show a typical installation of a Contech Drain

Basin and Inline Drain.

Inlet Drain

Inlet Drain

Drain Basin

Change Elevation

Variable Elevation

1) Change Elevation

D2

10

10 11

2) Change Diameters

D1

Page 11

1110 11

Page 12

ENGINEERED SOLUTIONS

Contech A-2000™ products

A2™ Liner Pipe for rehabilitating aging structures

Using the proven double wall A-2000 design, Contech

developed A2 Liner Pipe for sliplining deteriorating pipelines,

eliminating the need for disruptive open trench replacement.

A2™ Casing Liner Pipe for crossing under highways/railroads

Crossing under a highway or railroad is common with new

sanitary or storm sewer construction. Typically, crossings are

accomplished by boring and installing a casing pipe. The sewer

(carrier) pipe is then installed inside the casing.

By using the “no-bell,” constant outside diameter design of A2

Liner Pipe for the carrier pipe, downsizing of the casing can

result in a significant cost saving. In addition, A2 Liner Pipe can

be supplied with runners (spacers) already attached, eliminating

the need and cost to attach them in the field.

A-2000™ perforated pipe for subdrainage systems

Contech A-2000 perforated pipe (4”-36” diameters) has several

important features that make it the designer’s first choice for

subsurface drainage systems:

• 46 psi pipe stiffness for deflection control.

• Smooth interior for improved hydraulic capacity.

• Double wall design that provides essential beam strength

for improved alignment and installation grade control.

• Positive gasketed jointing system.

A-2000™ Drainage Pipe

Contech PVC double-wall pipe is the latest in drainage pipe

technology and engineering design. A-2000 Drainage Pipe,

available in 12”-36” diameters, combines the proven durability and

corrosion resistance of PVC, plus a smoother interior for improved

hydraulics, tight rubber gasketed joints, light weight and long

lengths (20’) for easier handling and less costly installation.

Contech A-2000 Storm Sewer Pipe is manufactured per ASTM

F949, F794 and AASHTO M304. When designed in accordance

with AASHTO LRFD Section 12 methodology and using 50-year

material properties with Class I or Class II backfill per ASTM

D2321 compacted to 95% standard Proctor density, the maximum

allowable heights of cover for A-2000 exceed 50’ while the

minimum cover for highway loading is 12”.

Contech products can solve most sewer or drainage problems. Their

strength, durability and economy are proven with nearly a century of

research and field performance.

A-2000™ PVC Pipe for Sanitary Sewers

A-2000 is a seamless profile wall pipe extruded with a smooth

interior and corrugated exterior. Made from polyvinyl chloride (PVC)

compound, 12454, the most widely accepted sewer pipe material,

A-2000 provides excellent durability and resistance to abrasion and

scour. It withstands corrosive attack from both acidic and alkaline

soils and is unaffected by chemicals found in normal sewage.

Engineered for gravity flow applications to installed depths

exceeding 30 feet*, A-2000 should be specified whenever you

consider using PVC sewer pipe. It has passed rigorous testing and

meets the requirements of ASTM Specifications F949 and F794.

Contech Engineered Solutions LLC provides site solutions

for the civil engineering industry. Contech’s portfolio

includes bridges, drainage, sanitary sewer, stormwater, earth

stabilization and wastewater treatment products.

For more information, call one of Contech’s Regional Offices

located in the following cities:

Ohio (Corporate Office) 513-645-7000

Colorado (Denver) 720-587-2700

Florida (Orlando) 321-348-3520

Maine (Scarborough) 207-885-9830

Maryland (Baltimore) 410-740-8490

Oregon (Portland) 503-258-3180

Texas (Dallas) 972-590-2000

Visit our web site: www.ContechES.com

800.338.1122

NOTHING IN THIS CATALOG SHOULD BE CONSTRUED AS AN EXPRESSED WARRANTY

OR AN IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE. SEE THE CONTECH STANDARD CONDITIONS OF SALE (VIEWABLE AT

WWW.CONTECHES.COM/COS) FOR MORE INFORMATION.

Your Local Sales Office is:

A-2000 is manufactured under U.S. patent numbers 4,702,502; 4,846,660 and 5,124,109

BRO-A-2000 FC 8/14 2.5M

RECYCLED

PAPER

©2014 Contech Engineered Solutions LLC

All rights reserved. Printed in USA.

Loading...

Loading...