Page 1

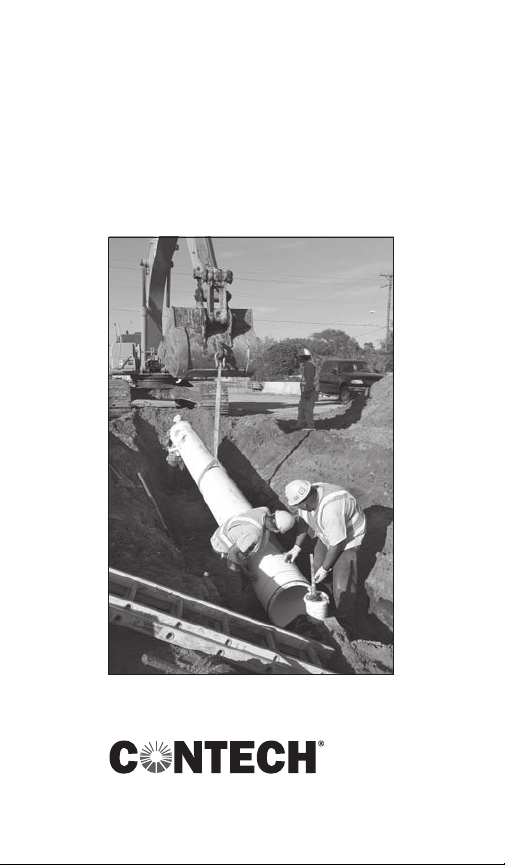

A-2000™

ENGINEERED SOLUTIONS

Unloading, Handling

and Installation Guide

Page 2

Preface

This instruction book is for your crews. Distribute it

to help them install Contech® A-2000™ correctly.

They are flexible pipes that must be installed

following the trench construction, bedding,

haunching, initial backfill, and other requirements

of ASTM D 2321,“Standard Recommended

Practice for Underground Installation of Flexible

Thermoplastic Sewer Pipe.”

Don’t assume experienced workers know all

the answers. Review these instructions with your

supervisors and crews. It can mean a better job

for you and your customer.

We suggest that you adopt a policy of

performance testing the first few manhole runs.

It will give you an early check that installation

procedures are correct.

If you have any questions about these instructions,

call your Contech Distributor or your Contech

Sales Engineer, or carefully review the installation

guide in the Contech A-2000 catalogs and ASTM

D 2321.

2

Page 3

Contents

Cold Weather Installation ......................... 5

Unloading and Handling .......................... 6

Trenching ................................................ 8

Installation Tips ........................................ 9

Assembly of Pipe .................................... 10

A. Gasket/Pipe Connection .............. 10

B. Manhole Connection .................... 12

C. Field Cutting Pipe ........................ 14

D. Caps ...........................................14

E. Mechanical plugs ......................... 14

F. Tapping/Saddle Connections ......... 15

Repairs .................................................. 18

Installation of Pipe ................................. 20

A. Pipe Zone/Embedment Material .... 20

B. Deflection Control ........................ 26

Deep Laterals ........................................ 27

Special Notes ........................................ 28

Standard Details ..................................... 30

This safety alert symbol indicates

important safety messages.

When you see this symbol,

be alert to the possibility of

personal injury and be sure you

understand the message that follows.

3

Page 4

Terms You Should Know

Alerts you to

hazards or unsafe

practices that CAN result in severe

personal injury or property damage.

Messages about

procedures or actions

that must be followed for safe

handling and installation of A-2000

Pipe.

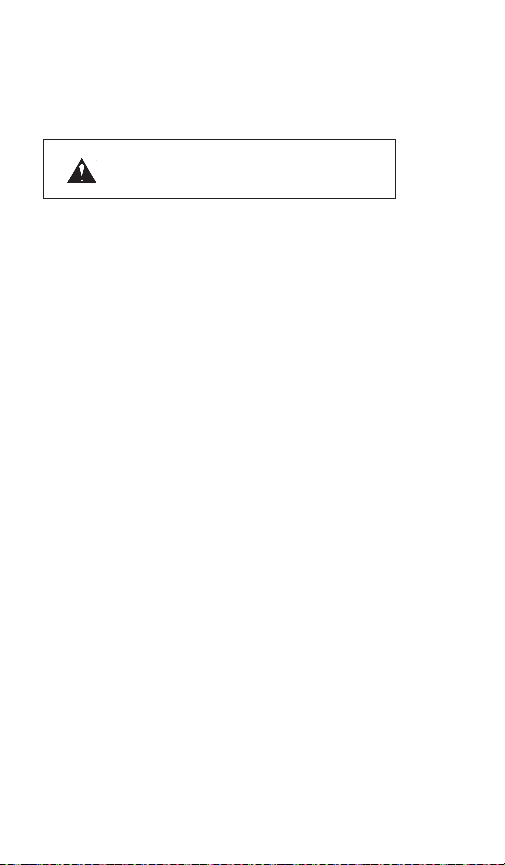

Falling or rolling pipe

can cause severe

personal injury

or death.

Read and follow all safety instructions

before unloading pipe.

4

Page 5

Cold Weather Installation

1. Handle the pipe with more care in cold

weather. PVC outer walls can become

hardened as temperatures drop. When placing

embedment materials in deep trenches and

temperatures 0° - 32° F, it is required to use

smaller aggregate (3/4- inch max.) and limit

the height of dumping stone, not to exceed

20 feet.

2. Rubber gaskets become harder as the

temperature decreases, gaskets tend to

compress less, and when combined with PVC

bells that become more installation sensitive,

jointing becomes less forgiving. Proper

bell-spigot alignment, adequate bell and

spigot lubrication, and recommended joining

procedures (-i.e. bar and block) all become

more essential as temperature decreases.

In addition, it is recommended to store the

gaskets in a warm place prior to use.

5

Page 6

Unloading and Handling

The following equipment is recommended for

unloading pipe pallets:

Forklift with full-length forks to engage entire

pallet width, front-end loader or backhoe

with fork adapters full length to engage entire

pallet width.

Nylon lifting slings of sufficient strength and

length to safely handle entire pallet. Do

not stand or ride on the pipe load during

unloading.

NOTE: Pipes sizes 18” and less are palletized with

steel straps around a wood frame. Full trailer width

pallets (21” to 36”) are not framed. Only forks of

sufficient length to engage entire pallet width are

recommended for unloading.

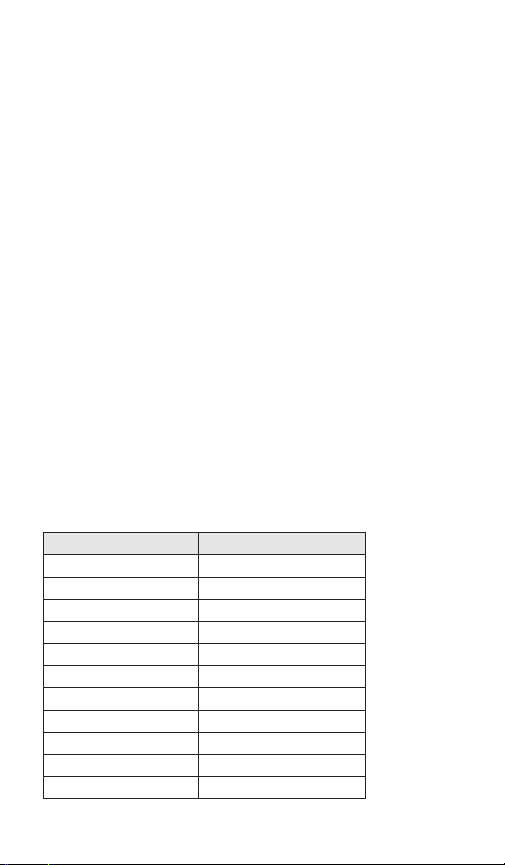

Table 1. A-2000 PVC Handling Weights

Diameter (in) Weight (lbs/ft)

4 1.00

6 1.25

8 2.00

10 3.00

12 4.25

15 7.00

18 10.00

21 13.00

24 17.00

30 25.00

36 34.00

6

Page 7

Failure to follow these instructions can result in

serious injury or death and/or damage to pipe.

1. Only trained and authorized equipment

operators are to be permitted to unload the

trailer.

2. Wear approved safety hat and shoes, gloves, and

eye protection.

3. Park the truck and trailer on level ground before

you start unloading.

4. Keep all unauthorized persons clear of the area

when the driver releases the binders from the

trailer and during unloading.

5. Do not release steel strapping around the wood

frame until the pallets have been placed on level

ground and will not be moved again as a unit.

6. Know the capabilities and rated load capacities

of your lifting equipment. Never exceed them.

7. Do not stand or ride on the load of pipe while it

is being unloaded. Do not stand beneath or near

the pipe when it’s being unloaded.

8. If unloading at multiple points,

secure pallets between drop

off points. For each unit of

four pallets, always unload the

top pallets first. (See diagram)

9. Never attach chains or wire

rope to the pipe. They could damage the pipe.

10. Do not push pallets off the trailer or permit pipe

to drop to the ground.

11. Do not drag A-2000 Pipe across the ground.

12. Do not stack A-2000 Pipe over two pallets high.

Stacks of three or more pallets can damage

bottom pipes and can become unstable.

13. Handle A-2000 Pipe with extra care in freezing

or cold weather.

7

Page 8

Trenching

Trenching practice and bedding materials shall be

in accordance with ASTM D2321 and OSHA rules.

1. The excavation needs to be wide enough

and be supported adequately to allow a

person to work safely.

2. Where trench walls are unstable, the contractor

may elect to use sheeting, stay bracing, or

a trench box for stabilization during pipe laying. If

the conditions are severe, sheeting may be left in

place.

3. Excessive groundwater may necessitate dewatering.

4. An unstable trench bottom must be stabilized at the

engineer’s direction. In such cases, install special

foundation and bedding materials in 6-inch layers

and compact.

5. Excavation from 6 inches to 12 inches below the

pipe should be filled with acceptable bedding

material and compacted to a minimum 90%

Standard Proctor Density. Fill areas of over

excavation beyond 12 inches with processed stone

or gravel following standard bedding practices

6. Before installing the pipe, bring bedding material

to grade along the entire length of the pipe.

7. When excavating in Class IV materials (silt, silty

clays, and clays), provide a uniform, undisturbed

foundation.

8

Page 9

Installation Tips

1. At manholes, flexible manhole connections like

rubber boots, A-Loks, etc. can be used.

With rubber boot manhole connectors, install

either a standard A-2000 double

gasket (8”-10”) or an A-2000 manhole gasket

(12”-36”) on the pipe spigot under the stainless

steel strap (see manhole connection detail on page

12). Where manholes are manufactured with A-Lok

connections, use a Contech PVC manhole sleeve.

2. Do not probe for the pipe with rods, shovels, or

other sharp objects when excavating down to

install laterals, etc. Instead, mark the elevation of

the pipe with stakes or other markers to help locate it.

3. When haunching the pipe or digging down to

install laterals, take care not to damage the pipe

with shovels, or other construction equipment.

4. String only enough pipe to use during the day’s

laying operations.

5. A full line of adapters to other pipes is available. See

Contech A-2000 Fittings Catalogs.

6. After proper assembly, the first load of backfill

should be placed over the middle of the pipe.

While the first load is being placed, the free bell

end should be held safely on line by the pipe layer.

This technique will minimize pipe movement during

backfilling. Subsequent loads of backfill may be

placed in a normal fashion.

9

Page 10

Assembly of Pipe

A. Gasket/Pipe Connection

1.The double sealing surface A-2000 gaskets

are fitted to the first two full corrugations on the

spigot end of the pipe as shown in the drawing.

The single sealing surface A-2000 Drainage

gaskets are fitted in the first corrugation valley

as shown in the drawing.

Gaskets are shipped loose and require field

installation on the pipe spigot. The leading

(lower) edge of the gasket is marked with the

Contech logo and wording to distinguish it from

the seating (higher) edge.

The low height seal is fitted into the first

corrugation. The double sealing gasket is fitted

into the first two full corrugation valleys.

10

Pipe

end

Spigot

Gasket location

on 4” to 36”

diameter

A-2000

Bell

(plantformed)

Gasket location

on A-2000 pipe

Page 11

2. Thoroughly clean the bell and spigot ends,

making sure they are free of mud and grit. If the

gasket has been removed, make sure the gasket

seat (the first two full corrugation valleys) is

clean. Reinstall the gasket by stretching it over

the spigot end and nesting it into the seat.

3. Use a Johnny mop or brush to apply a liberal

amount of gasket lube to the gasket and to

swab the inside of the bell. Take care to lube

the chamfered (leading) edge of the bell. Keep

lube and lubed surfaces free of debris.

4. Align the joint and push the spigot to the

corrugation with the homemark. The total

corrugation, with the homemark, should be

visible when the pipe is properly “homed.” When

using a bar and wood block, make sure the

block protects the pipe end from the bar. It is

recommended to use a nylon sling to facilitate

handling and joining 21” diameter and larger

A-2000. When joining, NEVER use the backhoe

bucket to push against the pipe bell. When

pushing the joint home, make sure the bedding

material is not pulled into the bell by the spigot.

Material such as small stones or sand pulled into

the bell as the pipe is stabbed can impair gasket

sealing and cause leaks.

11

Page 12

B. Manhole Connection

At manholes, flexible manhole connections like

rubber boots, A-Loks, etc. can be used.

1. Boot: With rubber boot manhole connectors,

install either a standard A-2000 double gasket

(8”-10”) or an A-2000 manhole gasket (12’-36”)

on the pipe spigot under the stainless steal strap

(See manhole connection detail A.)

2. A-Lok: Where manholes are manufactured

with A-Lok connections, use a Contech PVC

manhole sleeve (See manhole

connection detail B.)

If the manhole sleeves are

not attached and the need

arises in the field, follow the

procedure below.

• Place a standard gasket

on the pipe about 6” from the end. Lube

the gasket and the manhole sleeve and

slide the manhole sleeve onto the pipe end.

Restrict the coupling from sliding and push

the unit (pipe and coupling) into the A-Lok

connection (lube the A-Lok).

Manhole Detail B

12

Manhole Detail A

Page 13

3. Waterstop type manhole connections can be

accomplished using A-2000 pipe gaskets. For

cast-in-place concrete bottoms, precast bottoms

with “mouse hole” or similar pipe-to-manhole

entry that does not incorporate a flexible

connection, use two standard A-2000 double

gaskets for 8”-and 10”-diameter pipe, positioned

on the pipe in the center of the manhole wall

with the leading (the lower) edge of the gaskets

in adjacent corrugations, then concrete grout or

seal the pipe/manhole connections as required.

For pipe with diameters of 12”-36” inches, use

one standard A-2000 double gasket, positioned

on the pipe in the center of the manhole wall,

with the leading (lower) edge of the gasket closest

to the inside of the manhole.

Waterstop Manhole Connection

13

Page 14

C. Field Cutting Pipe

A-2000 can be field cut to length. Cut through

a corrugation valley using a hand or power

saw. Fit the gasket following the procedure

listed in “Gasket/Pipe Connection.”

D. Installing Caps

Caps are installed the same way you make a

gasketed joint. Caps need to be staked to make

sure they are secure. Mark the lateral location and

depth with a lath or other marker so that probing,

etc. to locate the pipe is not required.

E. Installing Mechanical Plugs

Mechanical plugs may be used, but caps

are recommended. (Mechanical plugs

should not be used for air testing.)

Install mechanical plugs by following

these steps:

1. DO NOT USE LUBRICANT.

2. Insert into the pipe barrel, beyond the

bell, until the back of the washer seats

against the bell hub transition.

3. Hold and tighten the wing nut until

firmly seated.

4. Stake the plug to keep safely secured during

testing. Proper staking requires a spacer from

the plug in the bell to a stake driven outside

the bell.

5. Mark the lateral location and depth with

a lath or other marker so the probing

etc. to locate the pipe is not required.

14

Page 15

F. Tapping/Saddle Connections

Saddle fittings are used for tapping

in-service systems. Use inline fittings

for new construction. Ribbed A-2000

saddles must line up with pipe corrugations.

Stick-on templates are marked for proper

orientation.

Follow these steps:

1. Place template on the pipe to mark the

outline of the hole. Take care to line up the

template with the corrugation valley properly.

Instructions are located on the template.

2. Use keyhole or saber saw to cut the

hole. Do not start the hole with a

hammer or hatchet. Use a drill, awl, or

other sharp cutting tool.

3. Thoroughly clean the pipe and saddle

mating areas (e.g. MEK cleaner or other).

Place the saddle in position on the pipe

and draw a line around the outer

edge of the saddle skirt to mark the

area of pipe to be covered by the

saddle. Use the recommended adhesive

(Sikaflex® or similar) provided by others.

Adhesive is in the caulking tube that uses a

standard caulking gun. Proceed as

described on the following page.

15

Page 16

3.A. For saddles with ribbed skirt.

3.A.1. Place a 1/4 -inch bead around the

cut opening in the pipe. Continue to make

concentric rings with 1/4 -inch beads of

adhesive about 1/4 -inch apart. The final

ring should be just inside the area to be

covered by the saddle skirt. Make certain

when crossing corrugation valleys that the

adhesive bead flows into the valley.

3.A.2. Apply adhesive to the underside of

the saddle skirt in a similar fashion.

3.B. For saddle with smooth (underside) skirt.

3.B.1. Completely fill the corrugation

valleys of the pipe with adhesive. The

bead should completely fill the valleys

and bulge above the corrugation crests

throughout the area to be covered by the

saddle.

3.B.2. Place a 1/4 -inch bead around the

cut opening in the pipe. Continue to make

concentric rings with 1/4 -inch apart. The

final ring should be just inside the area to

be covered by the saddle skirt.

16

Page 17

3.B.3 Apply adhesive to the underside of the

saddle skirt in a similar fashion.

With either type of skirt, a bead of adhesive can

be applied to the cut edge of the pipe wall to seal

the profile if desired.

NOTE: 8-inch to 36-inch saddle gaskets are also

available to be used with smooth skirt saddles.

Step 3.B.1. is not required for saddles with

gaskets. In steps 3.B.2. and 3.B.3., adhesive may

be applied to either the saddle or gasket surface.

4. Place saddle in position on the pipe

and cinch in place with the two steel

straps provided. Tighten straps

uniformly by alternating back and forth

between them, tapping the saddle

lightly with a rubber mallet to aide in

firmly seating the saddle in position (do

not over-tighten the straps).

5. For attaching 21-inch to 36-inch (only)

A-2000 saddle fittings with

the smooth saddle skirt, follow the

procedure described in Steps 1, 2, 3,

and 3B above. In addition, place

saddle in position on the pipe and

fasten in place with the stainless steel

screws provided. Holes are predrilled in

saddles for location of screws.

17

Page 18

Repairs

Cut out damaged areas and cut a length of

replacement pipe to fit. Use two flexible rubber

couplings and follow these steps:

1. Expose the existing cut pipe ends to give working

room under them.

2. Install a flexible rubber adapter on each end of

the replacement section. Using gasket lube or

vegetable oil as a lubricant, slide (or roll) the

adapters back and position the replacement

section.

3. Slide (or roll) the adapters over the joint at each

end of the replacement section so they

are centered over the joint. Use gasket lube or

vegetable oil as a lubricant.

4. Tighten the two stainless steel bands, making

certain they are properly positioned.

5. When optional shear stops are required, the

split plastic ring is snapped around the repair

coupling between the stainless steel bands

(Steps 3 and 4). This ring is held in place by two

additional stainless steel straps. The shear stop is

installed prior to re-establishing bedding support.

6. Tamp bedding material under the points where

it was disturbed. Replace haunching and initial

backfill throughout the disturbed area.

Alternate Repair Procedure

18

Page 19

Cut out damaged areas.

Place couplings over each spigot end of embedded pipe.

Place gaskets on each spigot end of the

embedment pipe backwards (with the higher or

seating edge of the gasket adjacent to the pipe

cut.) Place gaskets on each end of the replacement

piece in the recommended fashions. Draw

homemarks a half coupling length from end

of each spigot end on the replacement length.

Liberally lube all gaskets and inside of couplings.

Align replacement length with existing spigots and push repair couplings to

homemarks.

19

Page 20

Installation of Pipe

A. Pipe Zone/Embedment Material

Embedment Materials

Embedment materials are those used for bedding,

haunching, and initial backfill. All materials should

be installed and compacted in 6-inch maximum lifts.

ASTM D2321 classifies soil materials as:

Class IA Manufactured aggregates: Open graded

clean, angular, crushed stone or rock, crushed gravel,

broken coral, crushed slag, cinders or shells, large void

content, with little or no fines. These materials compact

with little or no mechanical effort.

Class IB Manufactured, processed aggregates: Dense,

graded clean, angular, crushed stone (or other Class

IA materials) and stone/sand mixtures with gradations

selected to minimize migration of adjacent soils,

containing little or no fines. Compact to 85% Standard

Proctor Density with hand tampers or vibratory

compaction.

20

Page 21

Class II Clean, coarse-grained materials, such as

gravel, coarse sands, and gravel/sand mixtures (1 1/2

inches maximum size). These materials are classified by

the USC System as GW, GP, SW, SP, and GW-GC or SPSM. Hand tamping or mechanical vibration is required

to provide the necessary 85% Standard Proctor Density.

Class III Coarse-grained materials with fines including

silty or clayey gravels or sands. Gravel or sand must

comprise more than 50 percent of Class III materials

(1 1/2 inches maximum size). Soils classified as

GM,GC,SM, or SC meet these requirements. Hand

tamping or mechanical vibration is required to provide

the necessary 90% Standard Proctor Density.

Class IV Fine-grained materials, such as fine sands and

soils, containing 50 percent or more clay or silt. Soils

classified as Class IVA (ML or CL) have medium to low

plasticity and the restrictive installation requirements

may make their use prohibitive in the embedment

zone. Soils classified as Class IVB (MH or CH) have

high plasticity and are not allowed as embedment

materials.

Class V These materials include organic silts and

clays, peat, and other organic materials. They are not

allowed as embedment materials.

1. Foundation

When the trench bottom is soft or unstable,

overexcavate and replace with compacted

embedment materials, as directed by the

engineer.

21

Page 22

2. Bedding

The bedding material provides uniform

support to hold the pipe on line and

grade. A 4-inch to 6-inch compacted

bedding thickness is usually adequate. A

flat shovel can be used to level the surface

to grade. Bedding materials can be Class

I, II, or III. It is recommended to use the

same material for haunching as for

bedding. However:

Class IA materials if used for bedding,

must be used as haunching material to the

spring line in a dry trench. To minimize

the potential for migration, Class IA

materials should be used to the top of the

pipe in wet trenches or in trenches that

will fall below the water table.

Class IB Install in 6-inch maximum lifts and

compact to minimum 85% Standard

Proctor Density.

Class II Install in 6-inch maximum lifts and

compact to 85% Standard Proctor Density.

Class III materials are suitable only in

dry conditions. Install in 6-inch maximum

lifts and compact to 90% Standard

Proctor Density.

Class IV and V materials are not allowed

as bedding.

22

Page 23

3. Haunching

Proper haunching provides a major portion

of the pipe’s strength and stability. Poor

workmanship will lead to excessive pipe

deflection and grade and alignment problems.

Haunching materials can be Class I, II, or III.

Class I Materials

• Where the pipe will be below existing or future

ground water levels or where the trench will be

inundated, Class IA materials, when used, must

be placed to the top of the pipe.

• Where conditions are dry and will remain dry,

Class I materials need only be placed to the

springline allowing Class II, III, or low plasticity

Class IVA materials to be used as initial backfill.

Class IA materials require less compactive

effort than other haunching materials.

• Class IB materials should be placed in 6-inch

maximum lifts and compacted to 85% Standard

Proctor Density by hand tampers or vibratory

compaction.

• Where Class I materials are used for bedding.

Class I materials must be used for haunching

materials to the springline in dry conditions and

to the top of the pipe in wet conditions.

Class II Materials

• Need to be compacted to a minimum 85%

Standard Proctor Density by hand tamping,

mechanical vibrations, or where trench

conditions allow, by flooding or puddling.

• Compaction by tamping or vibration must be

done in 6-inch maximum lift thicknesses.

23

Page 24

• Flooding or puddling requires a trench

foundation capable of absorbing the water

quickly so water movement down into the

foundation consolidates the haunching

materials.

Class III materials used as haunching materials

must be compacted by hand or mechanical

tamping.

• Place material under the lower haunch area

of the pipe and compact to 90% Standard

Proctor Density.

All Class IV and Class V materials should not be

used as haunching material. They are difficult

to compact and often don’t supply continuing

support.

NOTE: If care has been taken to shape the

bedding material to the curvature of the pipe, only

one stage of placement is required to bring the

haunching material to the springline on smaller

diameter pipe.

Haunching Tips

• Work enough material under the haunch

of the pipe by hand to provide proper

compaction and side support.

• Where trench walls are unstable, prevent the

loss of side support by controlling sloughing,

etc.

• Don’t let the pipe move when placing material

under the haunch of the pipe.

• Take care not to damage the pipe with shovels

or tamping equipment.

24

Page 25

4. Initial Backfill

Initial backfill materials extend from the

springline to 6 inches to 12 inches above the

pipe to provide the remainder of the pipe

support and protect the pipe from stones or

cobbles in the final backfill. Class I, II, III, or

low plasticity Class IVA materials may be used.

However:

Class IA materials must be used in wet trenches

in Class IA bedding and haunching materials

are used.

Class IB and Class II materials must be

compacted in 6-inch lifts to 90% Standard

Proctor Density.

Class III materials must be compacted in 6-inch

lifts to 90% Standard Proctor Density.

Class IVA low plasticity materials (CL-ML) are

not recommended since they must be

compacted in thin lifts while they are at or near

optimum moisture content to provide proper

pipe support. These materials may be used only

under the direction of the engineer.

High plasticity clays and silts (Class IVB), and

all Class V materials are not to be used for

initial backfill.

25

Page 26

B. Deflection Control

• Embedment materials should be selected,

placed, and compacted to minimize total

deflections, and to maintain installed

deflections within specified limits. Methods

of placement, compaction, and moisture

control should be selected based on soil types

and installation recommendations.

• Lack of adequate compaction of embedment

material in the haunch zone can result in

excessive deflection, since it is this material

that supports the vertical loads applied to

the pipe. A key objective during installation

of flexible thermoplastic pipe (or any pipe)

is to work in and compact embedment

material under pipe haunches, to ensure

complete contact with the pipe bottom, and to

fill voids below the pipe.

NOTE: Protect the pipe from stones or cobbles

larger than 1 1/2 inches. When these materials

are present in the final backfill, use initial backfill

materials to a level of 12 inches above the pipe.

26

Page 27

Deep Laterals, Laterals, Risers, and Drop

Manholes

When laterals, deep lateral, risers, or drop

manholes are required, the installation must be

designed to ensure that the pipe and fittings are

not damaged by loads generated due to soil

settlement, dragdown, and/or poor installation

practices. Generally, as sewer depths increase

and/or soil quality declines, additional attention

must be given to these loads to ensure a

satisfactory installation.

In order to minimize lateral pipe “punch-through”

potential, it is recommended to install wye or tee

fittings at an angle no greater than 45 degrees

from the horizontal centerline. Stacks (installing

wyes or tees at a 90 degree angle from the pipe

horizontal centerline) should not be allowed.

27

Page 28

Special Notes

1. Excavate bell holes in bedding material to ease

assembly. Keep bell holes as small as possible.

After the joint is made, fill the bell hole with

bedding or haunching material to provide

uniform support throughout the pipe length.

2. Minimum cover:

a. For H20-Live loads, at least 12 inches of

cover are required for Class IA embedment.

Minimum cover shall be measured from the

top of a rigid pavement or the bottom of a

flexible pavement.

b. Before allowing construction equipment to

cross the trench surface, a minimum of 24

inches or one pipe diameter (whichever is

larger) is required for class I embedment. A

cover of at least 36 inches is required for

class II, III, and IVA embedment.

c. 48 inches of cover are required before using

a hydrohammer during construction.

3. Recommended cover is limited to 30 feet.

It should be noted that the

deeper the pipe is installed, the greater the

load applied to the pipe. Depending on

specific job site conditions, A-2000 can be

successfully installed deeper than 30 feet.

Contact your Contech Sales Engineer for

specific recommendations.

28

Page 29

4. Compaction equipment:

a. Do not allow compaction equipment to

contact pipe.

b. During haunching and initial backfill, do not

use compaction equipment above the

pipe until sufficient backfill is placed. This

keeps compaction equipment from

damaging the pipe.

5. When removing sheeting or other trench

protection, don’t disturb the embedment

material. If sheeting or trench protection must

be used below the top of the pipe, consider

leaving it in place so as not to jeopardize side

support for the pipe.

6. When trench box is being used, always stake

the end of pipe prior to moving the box

forward.

29

Page 30

Curved Sewers

Curved sewers may be built by cocking the joint

to a maximum of 3 degrees for 4-inch to 10-inch

diameters and to a maximum of 2 degrees for

larger diameters. Table 1 below, provides necessary

installation data:

Table 2. Joint Angularity

Minimum Radius of Curvature

Pipe Diameter (in.) Minimum Radius (ft.)*

4 - 10 238

12 - 18 358

21 - 36 372

* 12” - 36” diameters based on 14’ laying lengths

Table 3. Standard Dimensions

A-2000 PVC Pipe

(4”-10” diameters = 12’6”; 12”-36” diameters = 14’ or 22’

Nominal

Diameters (in.)

4 4.3 4.8 3.9

6 6.4 7.0 5.9

8 8.6 9.4 7.9

10 10.8 11.7 9.8

12 12.8 13.9 11.7

15 15.7 16.9 14.3

18 19.2 20.6 17.6

21 22.6 24.6 20.7

24 25.6 27.9 23.5

30 32.2 35.1 29.5

36 38.7 42.3 35.5

(Standard Laying Lengths)

Avg. O.D.

Spigot (in.)

Avg. O.D. Bell

(in.)

Avg. I.D. (in.)

30

Page 31

Your Contech Sales Engineer is:

____________________________________________

Cell Phone Number:__________________________

____________________________________________

Your Customer Service Representative (CSR) is:

__________________________________________

Phone Number:_____________________________

Notes:

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

31

Page 32

NOTHING IN THIS CATALOG SHOULD BE CONSTRUED AS A

ENGINEERED SOLUTIONS

WARRANTY. APPLICATIONS SUGGESTED HEREIN ARE DESCRIBED

ONLY TO HELP READERS MAKE THEIR OWN EVALUATIONS

AND DECISIONS, AND ARE NEITHER GUARANTEES NOR

WARRANTIES OF SUITABILITY FOR ANY APPLICATION. CONTECH

MAKES NO WARRANTY WHATSOEVER, EXPRESS OR IMPLIED,

RELATED TO THE APPLICATIONS, MATERIALS, COATINGS, OR

PRODUCTS DISCUSSED HEREIN. ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND ALL IMPLIED WARRANTIES OF FITNESS

FOR ANY PARTICULAR PURPOSE ARE DISCLAIMED BY CONTECH.

SEE CONTECH’S CONDITIONS OF SALE (AVAILABLE AT

WWW.CONTECHES.COM/COS) FOR MORE INFORMATION.

For additional safety information, visit www.ContechES.com/safety.

© 2019 Contech Engineered Solutions LLC , a QUIKRETE Company

10/19 MC

All rights reserved. Printed in USA.

Loading...

Loading...