Consew CN3115RB-1 User Manual

CONSOLIDATED

SEWING

MACHINE

CORP.

L

INDUSTRIAL

SEWING & CUTTING

EQUIPMENT

lnstructi n & Parts

. Manual

Intentionally left blank

Contents

1 . Brief introduction · · ·

2 . Main specifications .................... · · · · · · · · · · · · ...... · ·

3 . Installation and preparation · · ·

3 . 1 . Installation · .. · .. · ·

3.

1 . 1 . Location

3.

1.

2.

Installing drip pan

3.

1.

3.

Mounting machine head · · ·

3.1.4.

3.

3.

3.

3.

3.2.3.

3.2.4.

4.

4.

4.

4.

4.

4.

4.

4.

4.

4.

4.

Installing bobbin winder

1.

5.

Mounting knee lifter .. · · · ·

2.

Preparation .. · .. · ·

2.

1 . Cleaning machine ·

2. 2.

Examination · · · ..

Oiling

Trial - run

Operation ........................................................................................................................ 3

1 . Selection

2.

Installing needle ·

3 . Threading needle thread

4.

Winding bobbin thread · · · · · · · · · · · · .. · .. · .. · .. ·

5 . Replacing bobbin · .. ·

6.

Adjusting thread tension · · ·

6 .1 . Adjusting thread take - up spring .. · · · · · · .. · · · · · · · · .. · ·

6.

2.

Adjusting tension of needle thread and bobbin thread

7.

Adjusting stitch length

8.

Adjusting pressurt

of

...........................................................................................................................

of

sewing thread

.... · ..................

sewing machine · ·

.. · .. · .... · .. · ....

.....................................................................................................................

....

of

·.

· ................. · · · ·

· · .. · .. ·

..

· · .. · .. · .. · · · .. · · · .. ·

..

· .. · ·

.... · .... · ......

....

· · · · · · · · .. · · · ·

......................................................................................................

....

· · .. · · · · · · · .. ·

· · · · · .. · .. · .. · .. ·

.... · .. · ....

·"

· · · · · ·

· · · · .. ·

and

....

.....

presser foot

· · · · · .. · .. · .. · .. ·

..

· · .. · .. · .. · .. · · · · · · .. · · · · · .. · ·

.. · .... · ....

....

drawing bobbin thread

· · .. · · .. · ·

....

· ·

· ·

....

· · · · · .. · · · · .. · · · · .. · · ·

....

· · .. · .. · · · .. ·

· · .. · .. · .. · .. · · ·

..

· ·

.. · ....

· ·

....

· ·

............

.. · ..

..

· · · · · · ....... ·

.... · .... · ........

· .. · .. ·

........

....

· · · · · · .. ·· · .. ·

..

· · · · .. · .. · ·

......

...... · ....

· · ·

..

· ·

............ · ....

....

..

· · · ·

.. · ..

......

.... · ....

......

· ·

....

· ·

· ·

....

· ........ · ...................... · ·

....

· ..... · ................ · · · ..... · · · · · · · · · · · · · ·

·· .. · ..

· · · · · · · · ....... ·

· .. ·

....

· · .. · ·

.... · .. · ............

....

· .. · .. ·

........

· ·

....

· · · · · · · ·· ·

· · ·

..

· .. · .. · ·

................

· .. · .. ·

· .. · .. · · .. ·

· ·

· .. ·

...... · ................ · ....

....

· .. ·

..

· · · · · · ·

......

....

· .. · · · ·

· .. ·

....

· ·

· · · · ·

..

· · · · · · · .. ·

.... · ........

· · · · · · · ·

....

· · · · · ·

..

· .. · .. · .. · ·

....

....

· ·

.......... · ....

...... · ..

........

· · .. ·

....

· · .. · .. ·

......

· .. · .. ·

....

......

"·

.. · ·· ·

...... · ....

....

· · .. · · · ·

..

......

..

· · · · · · · .. ·

· ·

..

· ·

..

....

· · .. ·

....

· · .. ·

· · ·

....

· .. · .. · .. · · · · · .. · · · · · · .. · .. · · · · .. · ·

........ · .............. · .. · .. · .............. · ......

....

· · ·

.. · ..

.. · ..

· .... · · · · · · · · · · ·

· .. · · · · · · · · · · · · · · · · .. · .. · · · ·

· ..

·· ..

· .. · ·

.. · .......... · ................

· .. · .. · · · · .. · · · · .. · · ·

....

· · .. · · · · · · · .. · · · · · · · · · .. ·

· · · · .. · • · ·

· .. · .. ·

" · · · · · · · · · ·

· .. · · ·

· · · .. ·

· ·

· · · ·

.... · ......

....

· · · · · .. · .. · .. · ·

....

· ·

..

· · · · .. · ·

..

· · · · .. · ·

.... · .... · ...... · ..

..

· .. · .. · · · · · · · · ·

..........

......

· · .. · · · · .. · .. · .. · .. ·

....

· ·

..

· ·

....

..

· ·

....

· · · · ·

· · ·

.. · ....

· .. ·

· ·

.... · .... · .. · .... · ....

· · · · · · · · · · · · · · · · · · ·

..

· · · .... · · · · 1

.. · ..

· ·

..

· · ...... · · · · · · · I

· · .. · .. · · · ·

· · ·

· .. · · ·

....

...... · ...... · .... · .... · ·..

... · ··

....

.... · ....

....

..

· .. · .. · ·

.... · ..

· · ·

....

..

· · · ·

...... · ..

.... · ....

· · · · .. · ·

....... · ·..

...... · .. · ·"

........ · .... · ·..

· "

....

· · · .. ·

· ·

.... · ..

· ·

....

· .. ·

..........

· · ·

......

· · · · · · ·

......

· · ·

............

· ·

....

· ·

...... · .. · ..

........

· · · ·

..

· ·

..

·..

·..

· · · · · · · · · 1

·..

..

· · · · 2

· ·

·..

· 3

....

· 4

.. · ..

· · 4

· · ·

..

· 4

· .. · · ·

..

· 4

· · · · 5

· · ·

..

· 6

· · 6

....

·..

I

1

I

1

1

2

2

2

2

3

8

8

Parts catalog

1.

Arm with Bed .........................................................................................................

2.

Needle Bar and Thread

3.

Shuttle Mechanism ................................................................................................

4.

Feed Mechanism ....................................................................................................

5.

Stitch Length Regulating Mechanism ..................................................................

6.

Presser Foot Mechanism .......................................................................................

7 . Bobbin Winder

8 . !(nee Lifter

9.

Thread U n wmder ..................

10.

Accessories ................................................................................................................... 27

..

· · · ·

··

· · ... · · ·

..

· · ·

Take-up

..

· · · · .... · · · · · ·

..

· · · · · · · · · · ·

Mechanism ...................................................

··

· · · · ·

..

· · · ·

.. · ··

.....

···

· · · · ·

.. · .. · ..

· · · · · · · · · · · · ·

··

.....................................................................................

.. · .. · ..

· · · · · · ·

.. · ..

.. · ..

· ............ ·

· · ·

..

· · · · ·

..

· · · · ·

..

..

·· · ··

· · · · ·

... · ..

..

· ·

.. · .. · .. · ...

· ... ···

.. · ··

··

12-13

14-

1618-

20-21

·

22-

· 24

9-11

~

15

17

19

23

25

26

l.BRIEF

INTRODUCfiON

This sewing machine

sewing a wide variety

The

machine adopts lind thread take length· adjustment; and

stitch form and convenient operation can be guaranteed.

2.

MAIN SPECIFICATIONS

1 . Max. sewing speed

2.

Max.stitch length

3.

Presser foot lift

4.

Max . thickness

5.

Needle

bar

stroke:

is

a low speed, single needle 2 - thread lockstitch industrial sewing machine designde for

of

products including apparel, caps & shoes, luggage, leather articles and canvas products.

up,

shuttle for thread looping, lever type reverse feed and dial for stitch

is

provided with knee lifter mechanism. So the stable running, beautiful and uniform and tidy

1600 spm

5 mm

6.5

mm

6.5

mm

37.4

mm

3.1NSTALLATION AND PREPARATION

3 . 1 . Installation

3 . 1 . 1 . Location of sewing machine

To

ensure a smooth running ,'the machine should be located on rigid and flat floor, seating machine stand on rubber

mat could further reduce the running noise and vibration.

3 . 1 .

2.

Installing

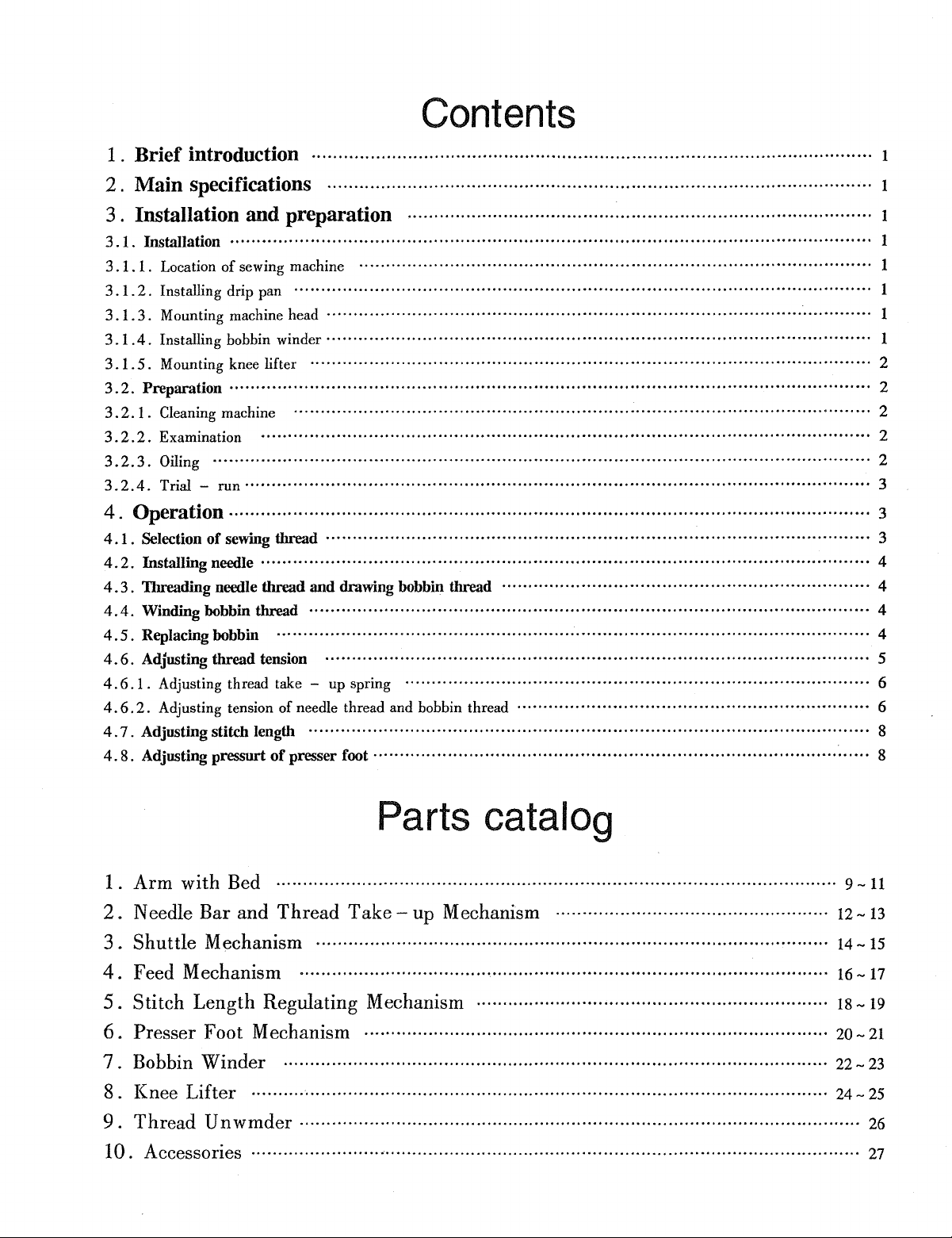

Fix drip pan 10 into table cutout and drive wire nails

pan.

drip

pan

6.

Working space:

7.

Needle

8.

Size:

9.N.

Weight:

10. Motor power

11

into both sides of the cutout

260x

130mm

#9-

525 x 178 x 340mm

28.5

0.37

(see

#21(16x73)

kg

kw

Fig. 1

)to

secure the drip

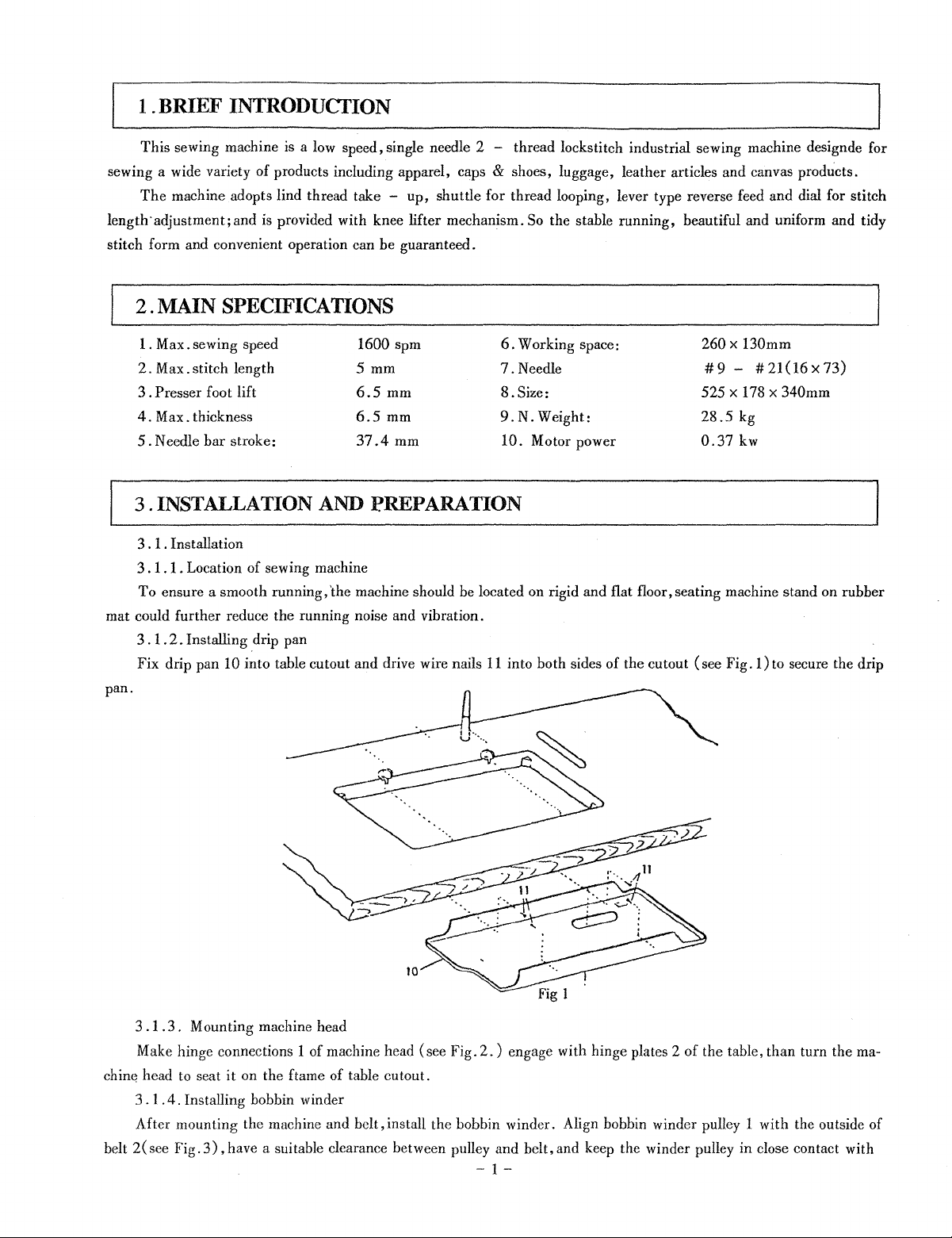

.1.3.

3

Make hinge connections 1 of machine head (see Fig.

chill(~

head to seat

3.

After mounting the machine and belt, install the bobbin winder. Align bobbin winder pulley 1 with the outside of

2(

belt

Mounting machine head

it

on the ftame of table cutout.

1 .

4.

Installing bobbin winder

see Fig.

3),

have a suitable clearance between pulley and belt, and keep the winder pulley in close contact with

2.)

engage with hinge plates 2 of the table, than turn the rna-

-

1-

the belt as the bobbin winder stot latce lever 9

screw

4.

1

2

is

pressed down, then, secure

the

bobbin winder on the table with wood

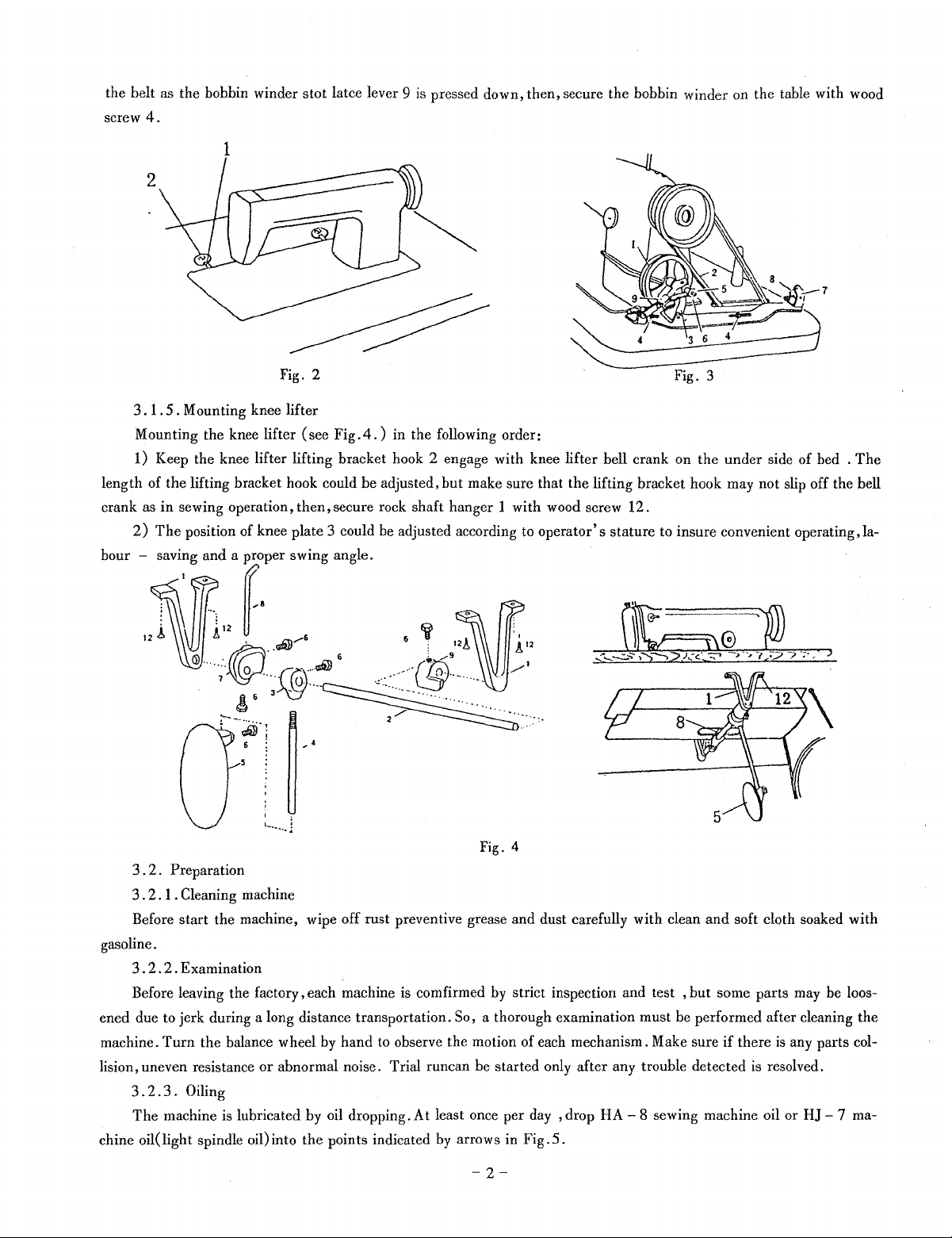

Fig. 2

3.

1.

5.

Mounting knee lifter

(see

Fig

.4.

Mounting the knee lifter

1) Keep the knee lifter lifting bracket hook 2 engage with knee lifter bell crank on the under side of bed .

length of

crank as

hour

the

lifting bracket hook could

in

sewing operation,

2)

The

position of knee plate 3 could be adjusted according to

then,

) in the following order:

be

adjusted,

secure rock shaft hanger 1 with wood screw 12.

hut

make sure that

the

lifting bracket hook may not slip off the hell

operator's

stature to insure convenient operating, la-

Fig. 3

The

Fig.

4

3 . 2. Preparation

3 .

2.

1 . Cleaning machine

start

Before

gasoline.

3.

2.

2.

Before leaving the factory, each machine

ened due to jerk during a long distance transportation.

machine.

lision, uneven resistance

chine oil

Turn

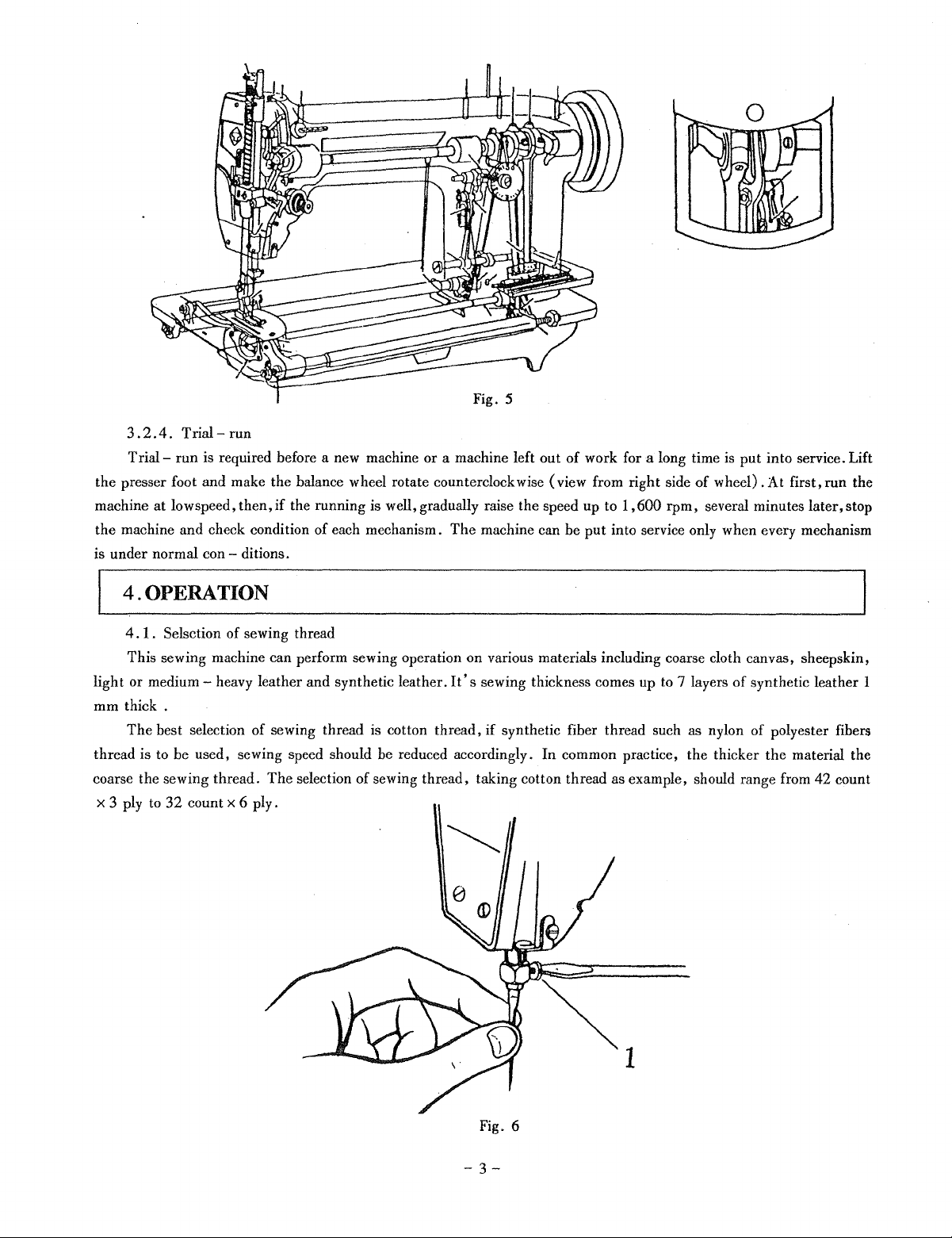

3 . 2 . 3 . Oiling

The

machine is lubricated by oil dropping. At least once per day , drop

(light

the machine, wipe off rust preventive grease and dust carefully with clean

Examination

is

com firmed by strict inspection and test ,

So, a thorough examination must he performed after cleaning the

the balance wheel by hand to observe the motion of each mechanism. Make sure

or

abnormal noise. Trial runcan he started only after any trouble detected

spindle oil) into the points indicated by arrows in Fig.

5.

-2-

and

but

HA-

8 sewing machine oil or

soft cloth soaked with

some parts may he loos-

if

there

is

any parts col-

is

resolved.

HJ-

7 ma-

3.2.4.

Trialthe presser foot and make the balance wheel rotate counterclockwise (view from right side

machine at lowspeed,

the machine and check condition of each mechanism.

is under normal

Trial-

run

run

is required before a new machine or a machine left out

then,

if

the running is well, gradually raise the speed up to

The

machine can be

con-ditions.

of

work for a long time

1,600

rpm,

put

into service only when every mechanism

4.0PERATION

4.

1 . Selsction of sewing thread

on

This sewing machine can perform sewing operation

light or

mm

thread is to be used, sewing speed should be reduced accordingly.

coarse the sewing thread.

X 3 ply to

medium-

thick.

The

best selection of sewing thread is cotton

32

heavy leather and synthetic leather.

The

selection of sewing thread, taking cotton thread as example, should range from

count X 6 ply.

thread,

various materials including coarse cloth canvas, sheepskin,

It's

sewing thickness comes up to 7 layers

if

synthetic fiber thread such as nylon of polyester fibers

In

common practice, the thicker

is

put into service. Lift

of

wheel).

several minutes

At

of

synthetic leather 1

the

first,

run

the

later,stop

material the

42

count

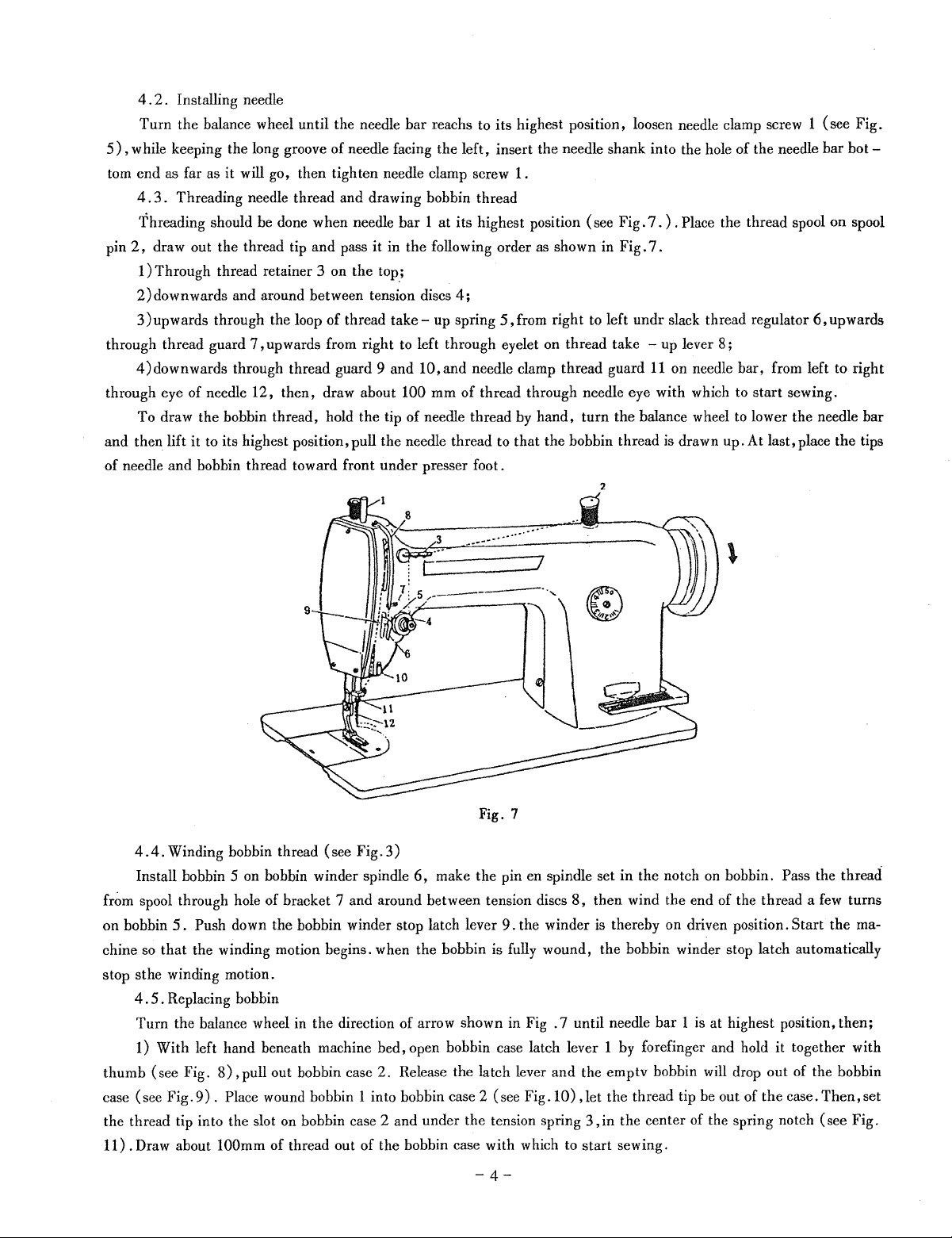

Fig. 6

-3-

4.

2.

Installing needle

Turn

the balance wheel until the needle bar reachs to its highest position, loosen needle clamp screw 1 (see Fig.

5),

while keeping the long groove of needle facing the left, insert the needle shank into the hole of the needle bar

tom end as far as it will go, then tighten needle clamp screw

4.

3.

Threading needle thread and drawing bobbin thread

Threading should be done when needle bar 1 at its highest position (see Fig.

2,

draw out the thread tip and pass it in the following order as shown in Fig.

pin

1)

Through thread retainer 3 on the

2)downwards and around between tension discs

3)upwards through the loop

through thread guard

4)

down wards through thread guard 9 and

through eye of needle 12, then, draw about

To draw the bobbin thread, hold the tip

and then lift it to its highest position, pull the needle thread to that the bobbin thread is drawn up. At last, place the tips

of needle

and

bobbin thread toward front under presser foot.

7,

upwards from right to left through eyelet on thread take - up lever

of

thread

top.;

4;

take-

up spring

10,

and needle clamp thread guard

100 mm

of

of

needle thread by hand, turn the balance wheel to lower the needle bar

1.

7.).

Place the thread spool on spool

7.

5,from

thread through needle eye with which to start sewing.

right to left undr slack thread regulator

8;

11

on needle bar, from left to right

2

bot-

6,upwards

Fig. 7

4.

4.

Winding bobbin thread (see Fig.

Install bobbin 5 on bobbin winder spindle

fr~m

spool through hole of bracket 7 and around between tension discs

on bobbin

chine

stop sthe winding motion.

thumb (see Fig.

case (see Fig.

the thread tip into the slot on bobbin case 2 and under the tension spring

11) . Draw about

5.

Push down the bobbin winder stop latch lever

so

that the winding motion begins. when the bobbin is fully wound, the bobbin winder stop latch automatically

4 . 5 . Replacing bobbin

Turn the balance wheel in the direction of arrow shown in Fig . 7 until needle bar 1

1) With left hand beneath machine bed, open bobbin case latch lever 1 by forefinger and hold it together with

8),

pull out bobbin case

9).

Place wound bobbin 1 into bobbin case 2 (see

lOOmm

of thread out of the bobbin case with which to

3)

6,

make the pin en spindle set

8,

9.

the winder

2.

Release the latch lever and the emptv bobbin will drop out of the bobbin

Fig.IO),

-4-

in

the notch

then wind the end of the thread a

is

thereby on driven position.

let the thread tip be out of the case.

3,

in the center of the spring notch (see Fig.

start

sewing.

on

bobbin. Pass the thread

few

Start

is

at highest position, then;

Then,set

turns

the ma-

3

Fig. 8

Fig.

Fig.

Fig. 9

10

II

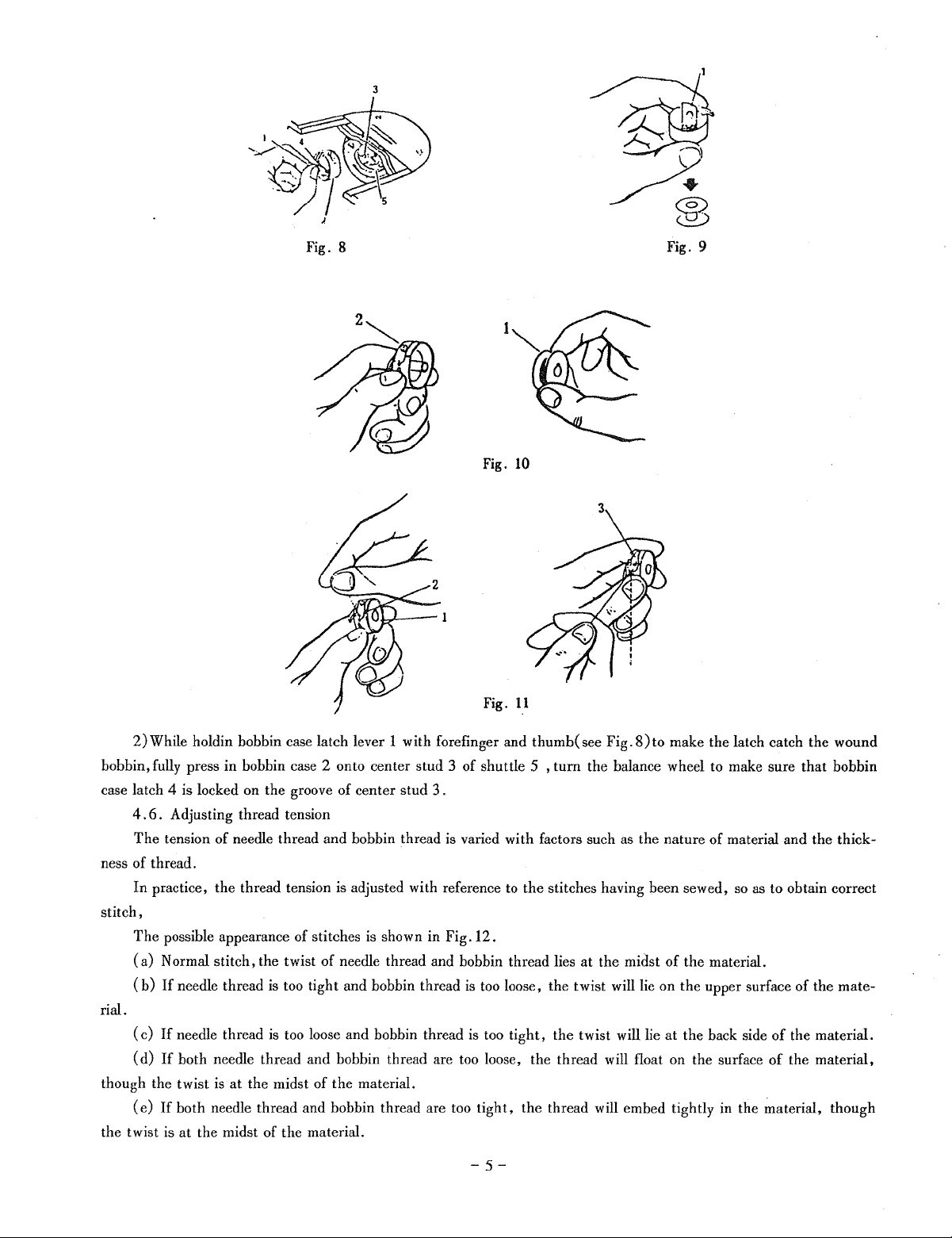

2)While holdin bobbin case latch lever 1 with forefinger and thumb( see

bobbin, fully press in bobbin case 2 onto center stud 3 of shuttle 5 , turn the balance wheel to make sure

case latch 4 is locked on the groove of center stud 3 .

4.

6.

Adjusting thread tension

The

tension

ness of thread.

In

practice, the thread tension is adjusted with reference

stitch,

The

possible appearance of stitches

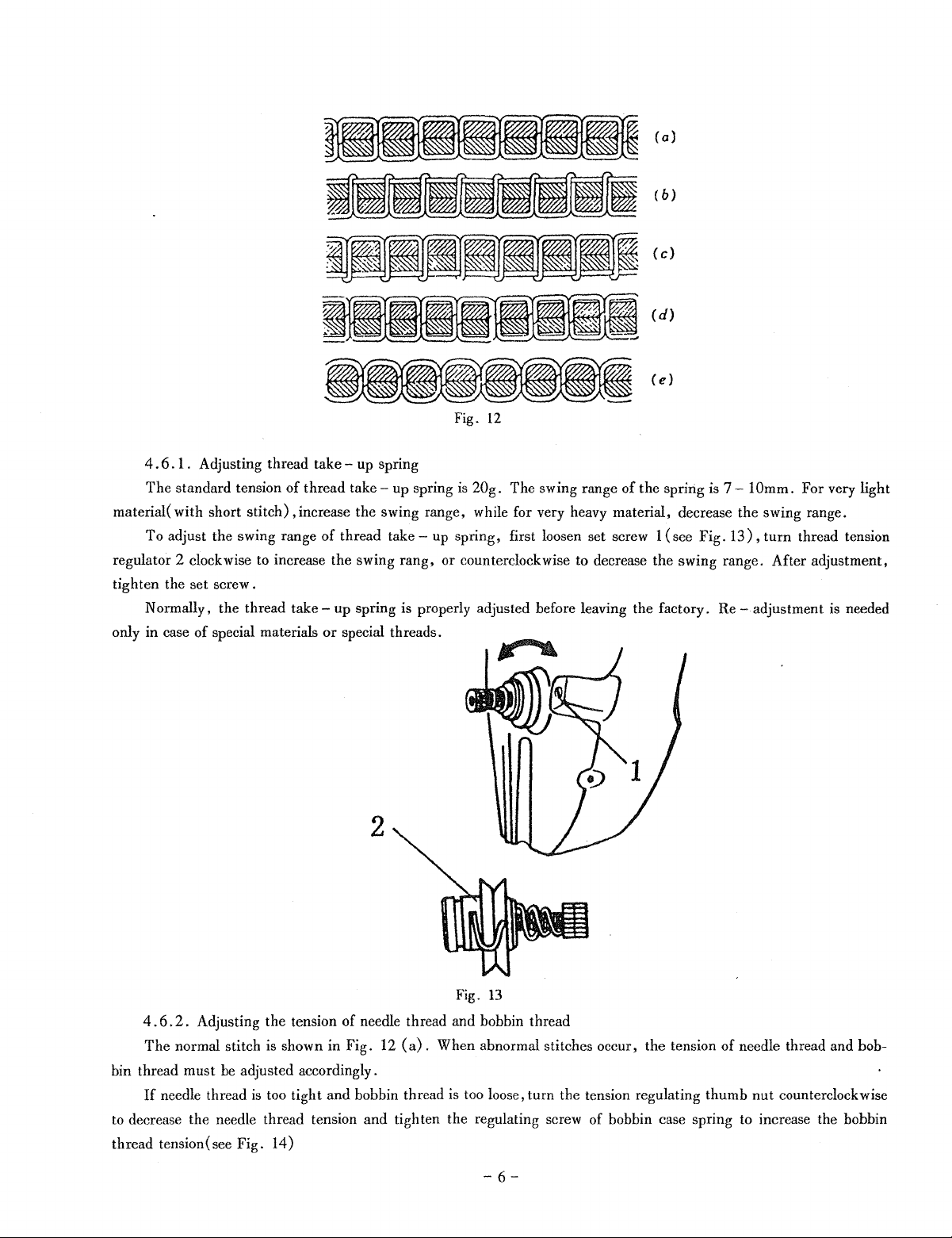

(a)

Normal stitch, the twist of needle thread and bobbin thread lies at the midst

(b)

If

rial.

(c)

If

(d)

If

though the twist

(e)

If

the twist is at the midst of the material.

of

needle thread and bobbin thread is varied with factors such as the nature of material and the thick-

to

the stitches having been sewed,

is

shown in Fig. 12.

needle thread is too tight and bobbin thread

needle thread is too loose and bobbin thread is too tight, the twist will lie at the back side

both needle thread and bobbin thread are too loose, the thread will float on the surface

is

at

the midst of

both needle thread and bobbin thread are too tight, the thread will embed tightly

the

material.

is

too loose, the twist will lie on the upper surface

Fig.S)to

make the latch catch the wound

so

as

to

of

the material.

of

of

in

the material, though

-5-

that

bobbin

obtain correct

of

the mate-

the material.

the material,

(a)

(b)

(c)

(d)

(e)

Fig.

12

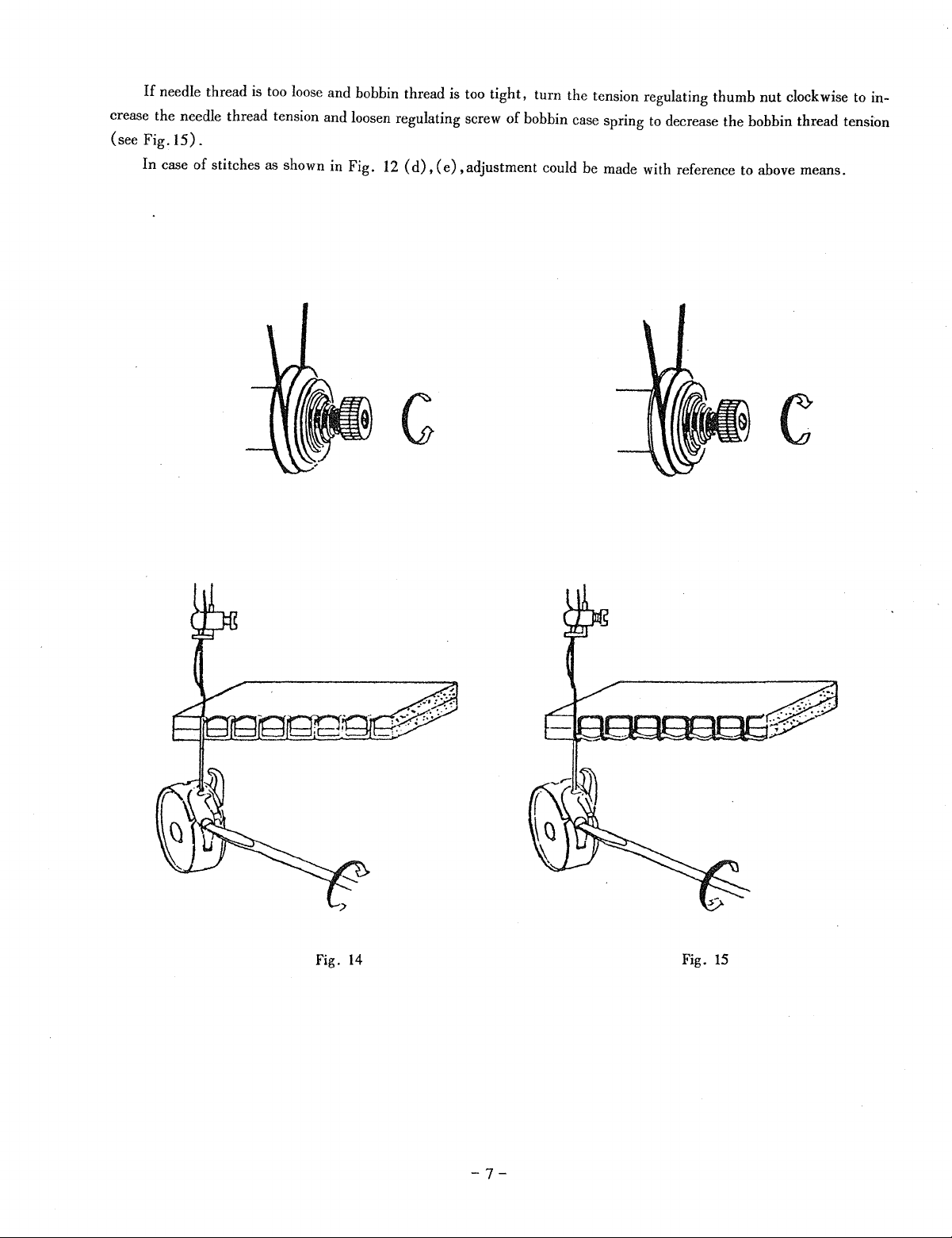

4.

6.

1 . Adjusting thread take - up spring

The

standard tension

material( with short stitch) ,increase the swing range, while for very heavy material, decrease the swing range.

To

adjust the swing range

regulator

tighten the set screw.

only in case

2 clockwise to increase the swing

Normally, the thread

of

special materials

of

take-

thread

take-

up spring

of

thread take - up spring, first loosen set screw 1

rang,

up spring is properly adjusted before leaving the factory. Re - adjustment is needed

or

special threads.

is

20g.

The

swing range

or

counterclockwise to decrease the swing range. After adjustment,

of

the

spring is 7-10mm.

(see

Fig.

13) ,

For very light

turn

thread tension

2

Fig.

13

4.

6.

2.

Adjusting

The

normal stitch is shown in Fig. 12

bin thread

to decrease the needle thread tension

thread tension (see Fig. 14)

must

If

needle thread

the

tension

be

adjusted accordingly.

is

too tight and bobbin thread is too loose, turn the tension regulating

of

needle thread and bobbin thread

(a).

When abnormal stitches occur,

and

tighten the regulating screw

-

6-

the

tension

of

bobbin case spring to increase the bobbin

of

needle thread and bob-

thumb

nut

counterclockwise

If

needle thread

crease the needle thread tension and loosen regulating screw

(see

Fig.l5).

is

too loose and bobbin thread is too

tight,

turn the tension regulating thumb

of

bobbin case spring to decrease the bobbin thread tension

nut

clockwise to in-

In case

of

stitches as shown in Fig. 12

(d),

(e),

adjustment could be made with reference to above means.

Fig.

14

-7-

Fig.

15

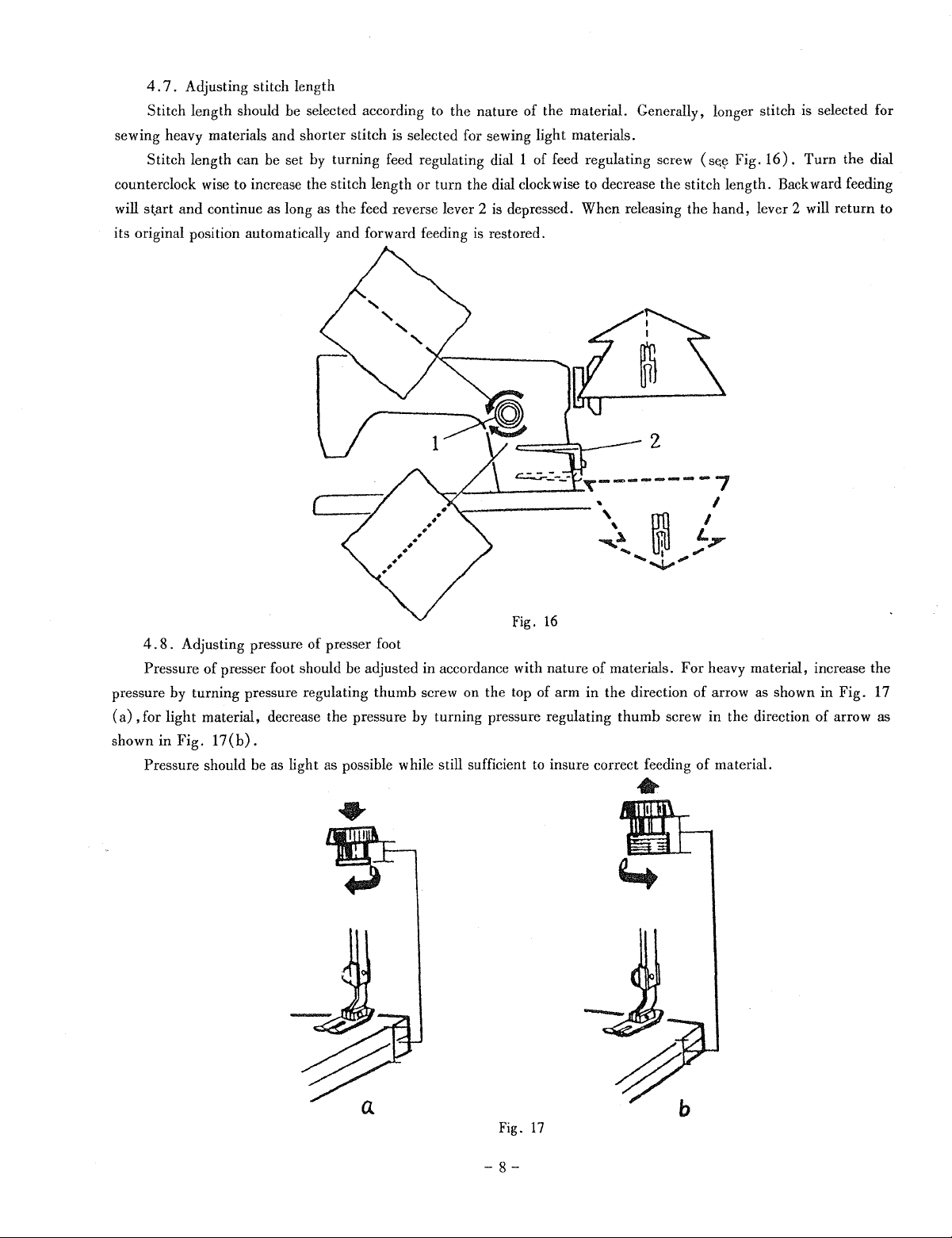

4.

7.

Adjusting stitch length

Stitch

length should be selected according to

sewing heavy materials and

Stitch

length ean be set by turning feed regulating dial 1 of feed regulating screw (

counterclockwise

will st,art

its original position automatically

and

to increase the stitch length

continue

as

long as

shorter

(

the

nature

of

the material. Generally, longer stitch is selected for

stitch is selected for sewing light materials.

or

turn

the dial clockwise to decrease the stitch

the

feed reverse lever 2 is depressed.

and

forward feeding is restored.

When

releasing

the

St:<y

length.

hand,

Fig.

16).

Backward feeding

lever 2 will

Turn

the dial

return

to

fig.

16

4.

8. Adjusting pressure

of

Pressure

pressure by turning pressure regulating

(a)

, for light material, decrease the pressure by turning pressure regulating

shown

in

Pressure should be as light as possible while still sufficient to insure correct feeding

presser foot should be adjusted in accordance with

Fig.

17(b).

of

presser foot

thumb

nature

screw on the top of arm

of

materials.

in

the

For

heavy material, increase the

direction of arrow as shown in

thumb

screw

in

the direction

of

material.

•

Fig.

of

arrow as

17

a

Fig.

17

-8-

b

Loading...

Loading...