Consew CN2230R User Manual

I

OPERATING

LON

CONSOLIDATED SEWING

~IONS,

P~RTS

LIST

SEW

model

CN

2230

MACHINE

CORP.

R

CONSOLIDATED SEWING

COPYRIGHT@1989

CONSOLIDATED

MACHINE

SEWING

MACHIN£

CORP.

CORPORATION

SPECIFICATIONS

-CON

SEW

Model

medium

driven

located

and

and

automatically

at

the

medium

CN

22300

underside

is

designed

heavy-weight

lubricated

of

the

for

lock

materials

by

machine

stitch

at

means

bed.

sewing

speeds

of

a

pressure

up

of 1 igh

to

5000

pump

t,

-Maximum

-~aximum

-Needle

IMPORTANT NOTE

Do

not

been

on

page

HOW

TO

For

purpose

Unpack

assembly

foreign

corners

of

the

the

periphery

its

hole

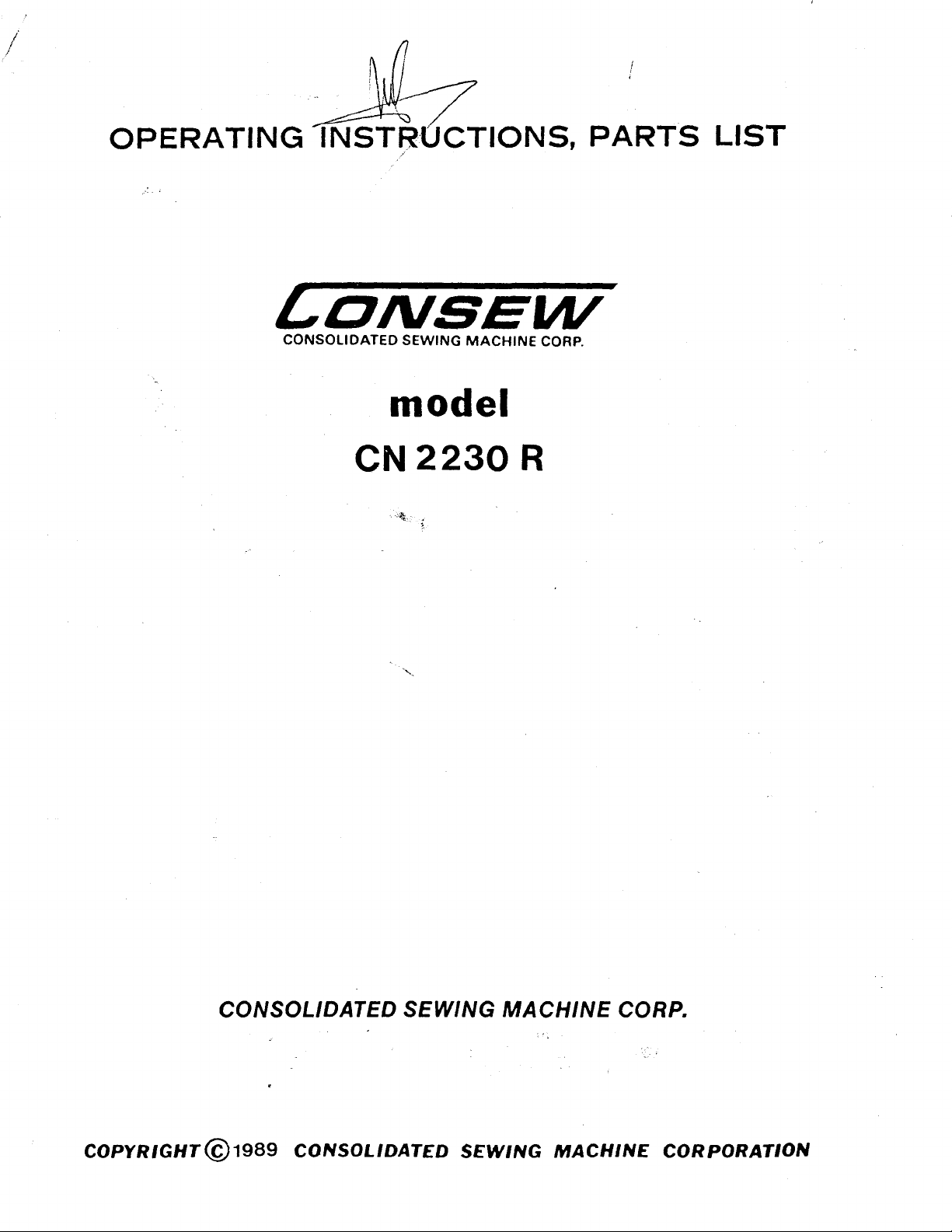

recess.

operate

filled

2 .

SET

the

table

stitch

presser

style

and

UP

machine

part.

matter.

of

the

in

(Fig.

of

the

length

16

machine

machine

shipment

Protect

oil

top.

of

oil

1)

foot

x

257

with

Place

pan

Place

the

Insert

oil

pan

6

lift

-

for

has

the

great

machine

the

(2)

and

stitches

1/4"

sizes

any

been

machine

resilient

and

the

oil

pan,

the

the

hinges

(6mm)

11

reason

care

head

insert

insert

filter

per

to

oiled

pan

inch

18

whatsoever

head

to

protect

and

rubber

the

gasket

the

(9)

(4mm)

according

and

oil

oil

knee

magnet

into

uriless

its

oil

against

pan

against

cushions

pan

(6)

into

lifter

(8)into

the

holes

to

instructions

pan

(1)

into

the

plunger

oil

are

the

loss

entry

at

the

groove

the

square-shaped

at

the

pan

separated.

of

of

the

cut-out

(7)into

rear

has

any

four

at

of

FIG.2

6 7

FIG.!

8

the

machine

the

rubber

(10)

along

table

the

so

within

cushions.

the

longer

lifter

shorter

rod

stop

mechanism

only

starts

foot

raised

any

parts

to

head.-

into

the

cut-out.

machine

that

knee

bracket.

of

minimal

and

strain

and

lift

the

rear

the

the

lifter

portion

rod

end

the

so

to

lift

that

all

without

the

bed

hinge

two

into

hinges

rubber

(Fig.2)

and

to

Adjust

knee

that

play

it

the

on

the

entire

and

cushions

recesses

edge

Finally

its

rest

hinge

Attach

pad

of

the

fasten

the

lifter

lifter

there

before

the

can

way

without

lifter

tendency

machine

place

of

the

drop

place

to

the

knee

its

the

presser

be

is

it

-I-

LUBRICATION

Oiling

automatic.

parts

filled

SAE

10

See

Fig.

of

which

with

to

3.

the

Oil

require

a

a

operating

good

level

Oil

3

is

between

level

parts

contained

lubrication

quality

should

of

in

sewing

marks

be

permitted

lest

capacity

pints

rotating

ment

of

the

is

adjusted

amount

either

flow

oil

supplied

tissue

operate

of

operation

become

flow

remove

any

accumulation

matter,

from

and

replace

CONSEW

the

and

(2)

checked

the

(24

of

machine

of

an

to

or

visible

and

from

the

oil

cooling.

machine

on

to

fall

machine

of

the

oz.).

hook

the

needle

at

lubricant,

increase

the

hook.

to

similar

machine.

a

adjustment

oil

at

the

bottom

it.

Model

pan

the

daily

oil

can

bed

the

the

slight

on

screen

same

of

and

oil

surface

below

be

The

be

value

(Fig.

factory

or

To

paper

After

the

of

the

CN

2230R

is

The

oil

of

a

and

the

damaged

pan

is

oil

controlled

conditions

a

decrease

determine

hook,

under

a

trace

paper.

of

needle

at

lint

time

oil

is

circulated

pan

grade

of

should

approximately

supply

"V"

4).

to

hold

very

bottom

or

lift

pan,

similar

oil

right

seriously.

at

While

feed

a

the

brief

of

oil

If

value.

other

the

entirely

is

to

pan

not

hand

for

the

through

the

underside

the

may

require

in

the

the

amount

piece

hook

should

not,

of

oil

foreign

magnet

wipe

to

all

be

to

(1).

be

mark

Total

this

correct

of

and.

period

check

Also,

it

1 !

adjust-

value

oil

of

pump

from

clean

FIG.4

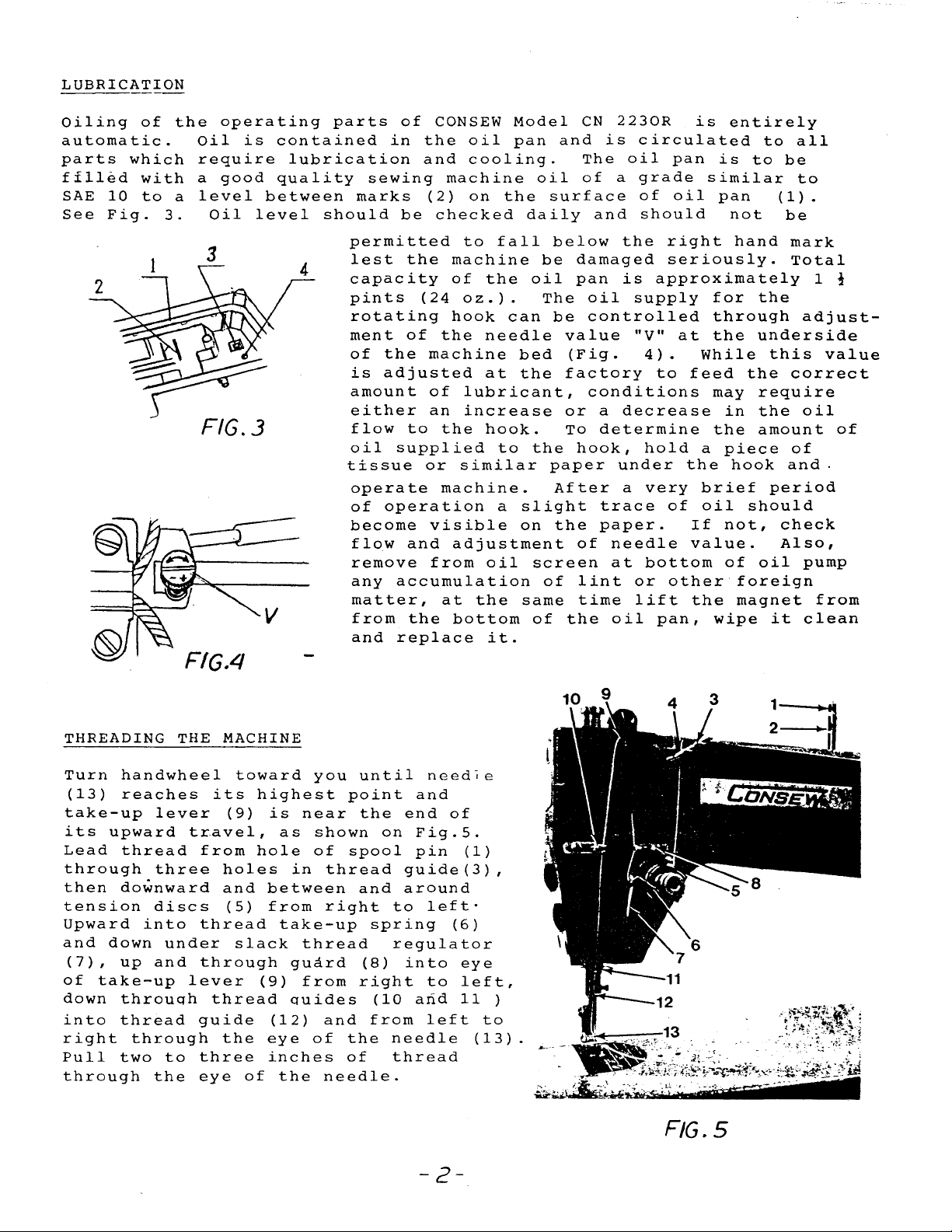

THREADING THE MACHINE

Turn

(13)

take-up

its

Lead

through

then

tension

Upward

and

(7),

of

down

into

right

Pull

through

handwheel

reaches

upward

thread

downward

into

down

up

take-up

throuqh

thread

through

two

lever

three

discs

under

and

to

the

its

travel,

from

holes

and

thread

through

lever

thread

guide

the

three

eye

toward

highest

(9)

hole

(5)

slack

of

is

as

between

from

take-up

(9)

(12)

eye

inches

the

you

near

shown

of

in

thread

right

thread

guard

from

quides

and

of

needle.

until

point

the

spool

and

spring

(8)

right

(10

from

the

of

needle

and

end

on

Fig.S.

pin

guide(3),

around

to

left·

regulator

into

to

arid

left

needle

thread

of

(6)

eye

left,

11

(1)

)

to

(13)

-2-

F!G.S

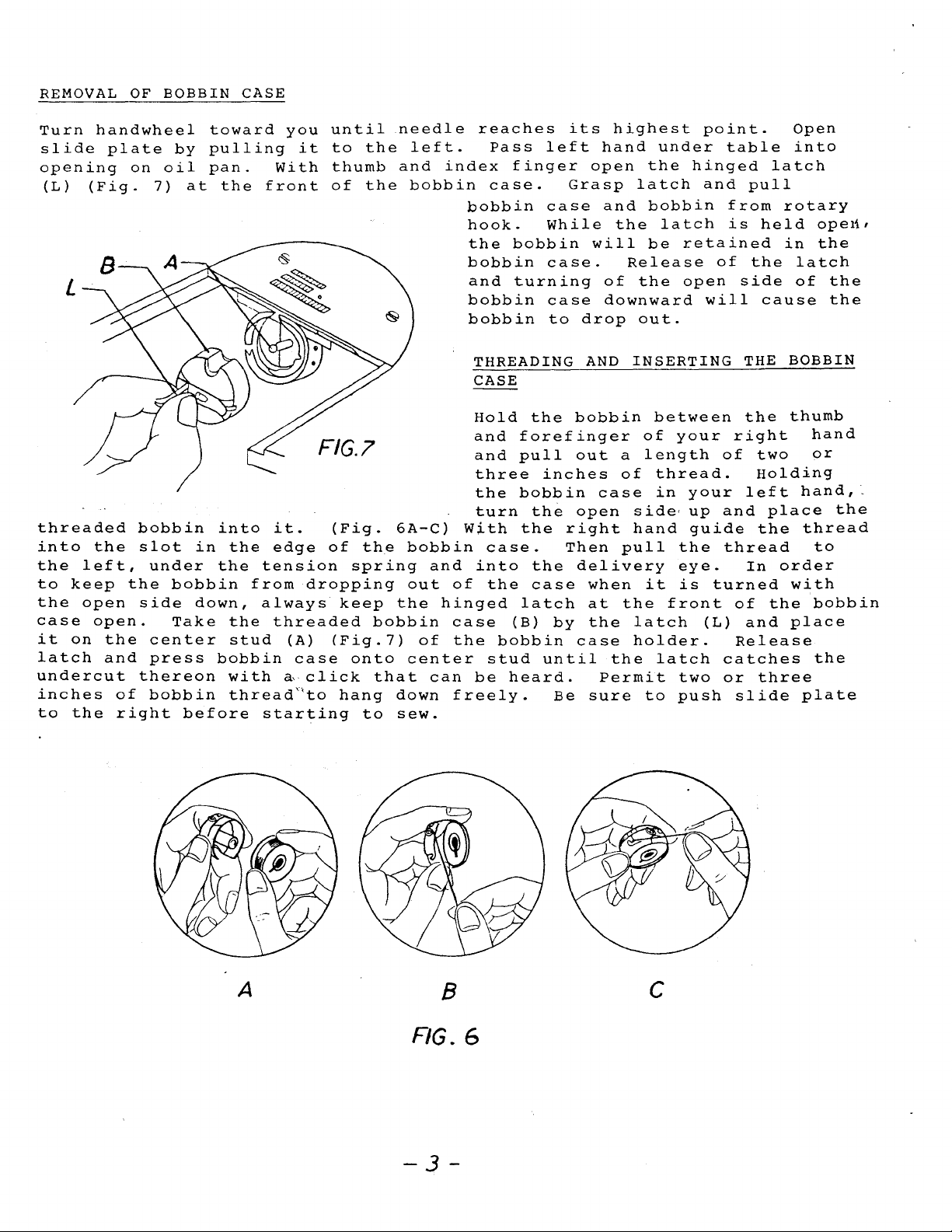

REMOVAL

OF

BOBBIN

CASE

Turn

slide

opening

(L)

(Fig.

threaded

into

the

left,

to

keep

the

open

case

it

on

latch

undercut

inches

to

the

handwheel

plate

on

7)

bobbin

the

slot

under

the

side

open.

the

center

and

press

thereon

of

bobbin

right

by

oil

at

in

bobbin

down,

Take

before

toward

pulling

pan.

the

into

the

the

from

the

stud

bobbin

with

thread''to

you

it

With

front

it.

edge

tension

dropping

always

threaded

(A)

case

~

click

starting

until

to

the

thumb

of

the

(Fig.

of

the

spring

keep

(Fig.7)

onto

hang

to

needle

left.

and

bobbin

6A-C)

bobbin

out

the

bobbin

center

that

down

sew.

and

of

can

reaches

Pass

index

case.

bobbin

hook.

the

bobbin

and

bobbin

bobbin

THREADING

CASE

Hold

and

and

three

the

turn

With

case.

into

of

the

hinged

case

the

bobbin

stud

be

freely.

left

finger

case

While

bobbin

case.

turning

case

to

the

forefinger

pull

inches

bobbin

the

the

the

case

latch

(B)

by

until

heard.

Be

its

hand

open

Grasp

and

will

of

downward

drop

AND

bobbin

out

case

open

right

Then

delivery

when

at

the

case

Permit

sure

highest

under

the

latch

bobbin

the

latch

be

Release

the

out.

INSERTING

between

of

a

length

of

thread.

in

side,

hand

pull

it

the

front

latch

holder.

the

latch

to

point.

hinged

and

retained

of

open

will

your

your

up

guide

the

eye.

is

turned

(L)

two

push

table

pull

from

is

held

the

side

cause

THE

the

right

of

two

Holding

left

and

the

thread

In

of

and

Release

catches

or

three

slide

Open

into

latch

rotary

in

latch

of

BOBBIN

thumb

hand,

place

thread

order

with

the

place

plate

opert•

the

the

the

hand

or

the

to

bobbin

the

A

8

RG.6

-3-

c

INSERTING

A

NEW

NEEDLE

Turn

point.

push

face

machine.

TO

Turn

moves

(bobbin)

and

in

handwheel

needle

toward

COMMENCE

the

the

the

Loosen

down

bobbin

needle

up

the

Tighten

SEWING

balance

and

thread.

of

set

into

left

wheel

up

thread

olate.

machine

screw

bar

and

needle

again

Now

null

will

as

toward

in

as

the

set

toward

to

shown

you

needle

far

as

it

eve

must

screw

its

the

be

back

upon

TO

Raise

the

to

few

TO

you

brouoht

with

highest

end

in

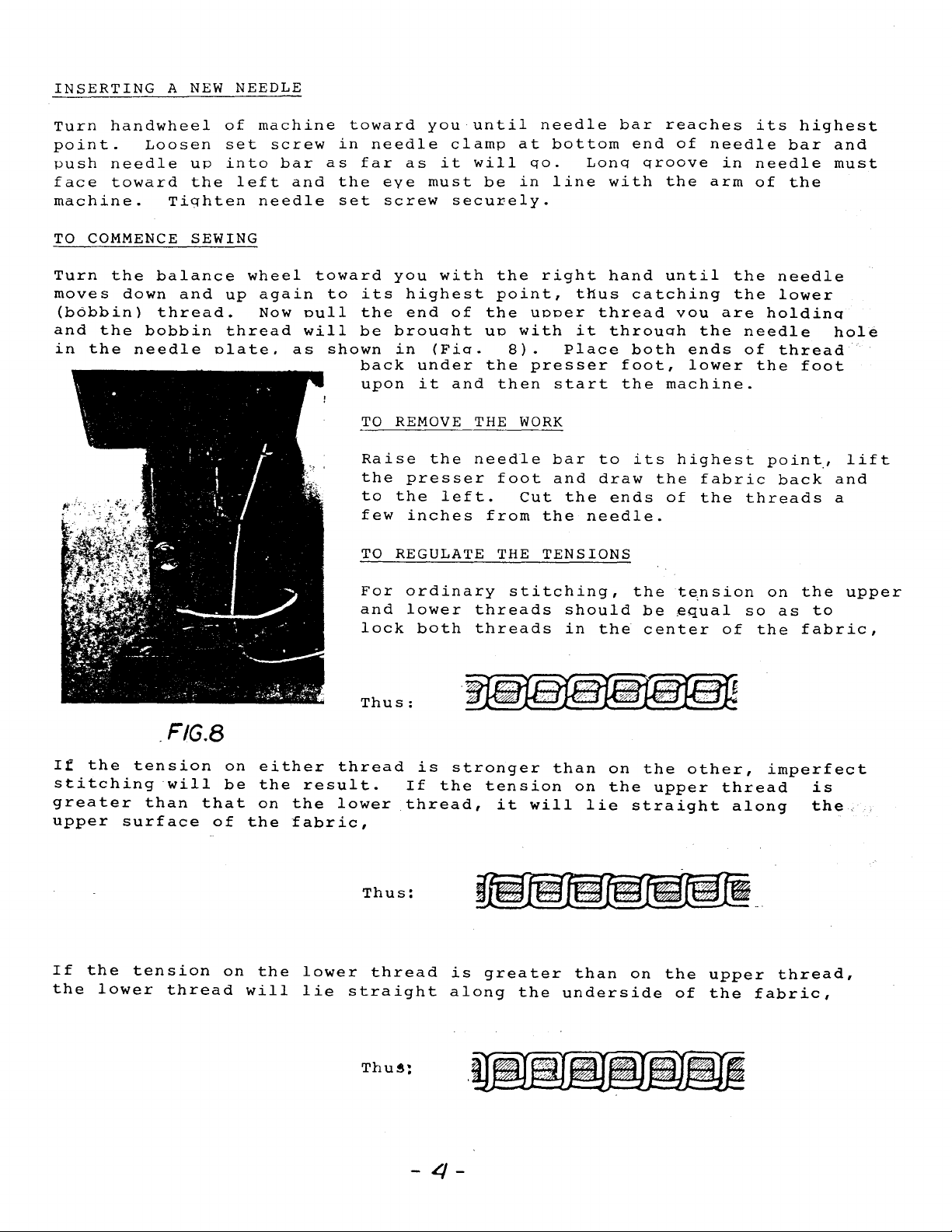

(Fio.

under

it

REMOVE

the

presser

the

left.

inches

REGULATE THE

until

clamp

will

be

securely.

the

point,

of

the

uo

8).

the

and

then

THE

needle

foot

from

needle

at

bottom

qo.

in

line

right

uooer

with

Place

presser

start

WORK

bar

and

Cut

the

the

TENSIONS

Lonq

with

hand

thus

thread

it

throuoh

to

draw

ends

needle.

bar

end

qroove

catching

both

foot,

the

its

the

reaches

of

needle

in

the

arm

until

vou

are

the

ends

lower

machine.

highest

fabric

of

the

its

needle

of

the

the

holdinq

needle

of

the

threads

highest

bar

the

needle

lower

thread

foot

point,

back

and

must

hole

lift

and

a

If

the

stitching

greater

upper

If

the

the

lower

.FIG.B

tension

will

than

surface

tension

thread

that

of

on

be

on

either

the

on

the

the

will

result.

the

fabric,

lower

lie

For

and

lock

Thus:

thread

lower

Thus:

thread

straight

ordinary

lower

both

is

stronger

If

the

thread,

is

along

stitching,

threads

threads

tension

it

will

~~~

greater

the

should

in

the

than

on

lie

than

underside

the

on

the

straight

on

t~nsion

be

~qual

center

the

upper

the

of

of

other,

thread

upper

the

so

the

along

-.

fabric,

on

the

as

to

fabric,

imperfect

is

the

thread,

upper

Thu~:

-

4-

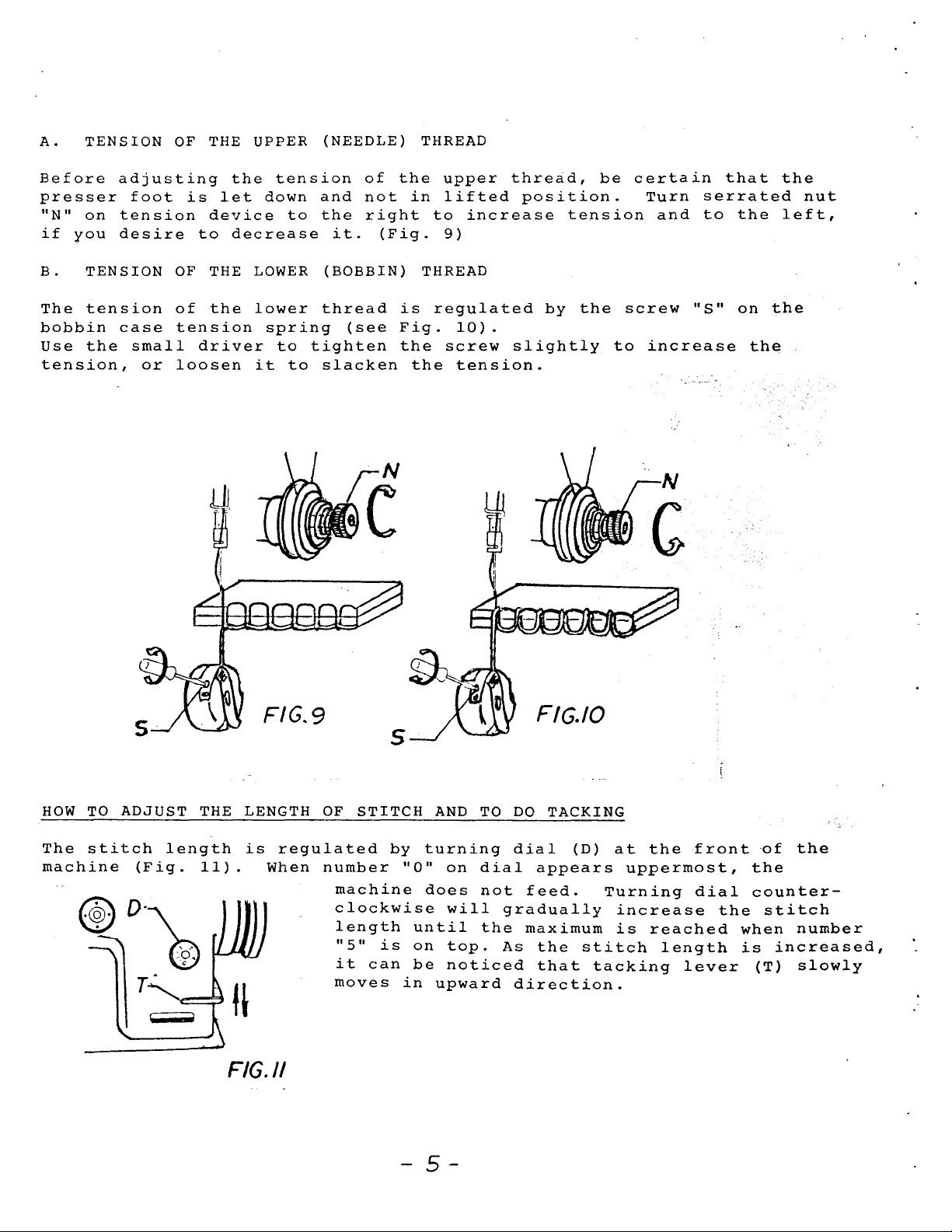

A.

TENSION

OF

THE UPPER (NEEDLE) THREAD

Before

presser

"N"

on

if

you

B.

TENSION

The

bobbin

tension

Use

the

tension,

adjusting

foot

tension

desire

OF

of

case

small

or

tension

loosen

is

device

to

THE

the

driver

the

let

down

decrease

LOWER

lower

spring

it

tension

and

to

the

thread

to

tighten

to

slacken

of

not

right

it.

(BOBBIN)

(Fig.

(see

the

in

THREAD

is

Fig.

the

the

upper

lifted

to

increase

9)

regulated

10).

screw

tension.

thread,

position.

by

slightly

be

tension

the

certain

screw

to

Turn

and

"S"

increase

N

that

serrated

to

the

on

the

the

nut

left,

the

HOW

TO

The

stitch

machine

5

FIG.9

ADJUST THE LENGTH

length

(Fig.

11).

is

When

regulated

FIG.//

OF

STITCH

number

machine

clockwise

length

"5"

it

can

moves

is

s

by

-

turning

''0"

does

until

on

be

in

5-

AND

TO

on

dial

not

will

the

top.

noticed

upward

F/G./0

DO

TACKING

dial

appears

feed.

gradually

maximum

As

the

that

direction.

(D)

stitch

tacking

at

the

uppermost,

Turning

increase

is

reached

front

dial

length

lever

the

~f

the

counter-

stitch

when

is

increased,

(T)

the

number

slowly

When

depress

To

depress

material.

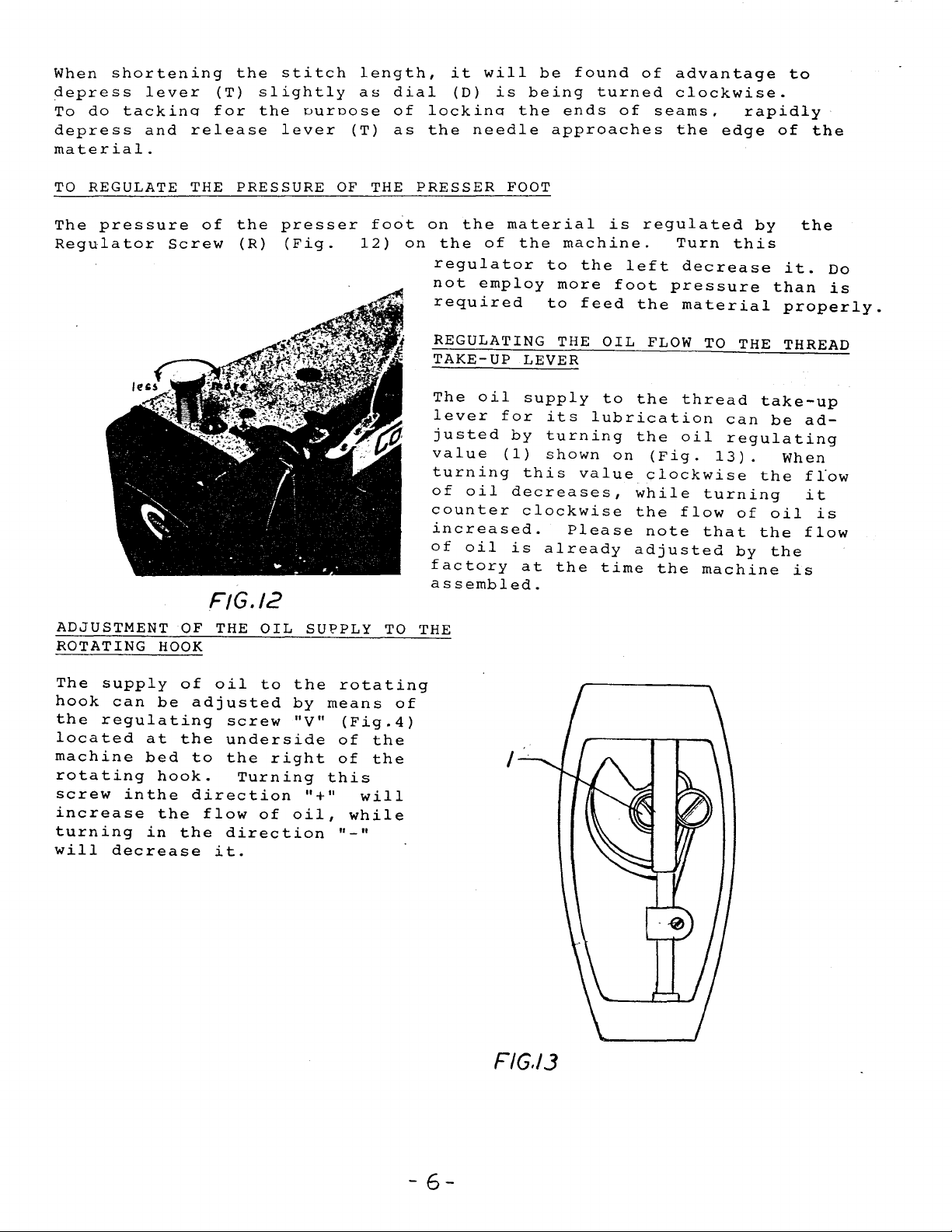

TO

The

Regulator

shortening

lever

do

tackino

and

REGULATE THE PRESSURE

pressure

Screw

(T)

for

release

of

the

the

(R)

stitch

slightly

the

ouroose

lever

presser

(Fig.

(T)

OF

length,

as

dial

of

as

THE

foot

12)

it

(D)

lockino

the

PRESSER

on

on

the

regulator

not

required

will

needle

the

of

employ

is

being

the

FOOT

material

the

be

found

turned

ends

approaches

machine.

to

the

more

to

feed

of

is

left

foot

of

advantage

clockwise.

seams,

the

regulated

Turn

decrease

pressure

the

material

rapidly

edge

this

of

by

it.

than

properly.

to

the

the

Do

is

F/G./2

ADJUSTMENT OF THE

can

inthe

HOOK

be

at

bed

hook.

the

in

of

oil

adjusted

the

to

direction

flow

the

direction

it.

screw

underside

the

ROTATING

The

supply

hook

the

regulating

located

machine

rotating

screw

increase

turning

will

decrease

OIL

to

right

Turning

of

SU~PLY

the

rotating

by

means

"V"

of

of

this

"+"

oil,

"-"

TO

(Fig.4)

the

the

will

while

REGULATING THE

TAKE-UP

The

oil

lever

justed

value

turning

of

counter

increased.

of

factory

assembled.

THE

of

for

(1)

oil

oil

LEVER

supply

its

by

turning

shown

this

decreases,

clockwise

Please

is

already

at

the

I

OIL

to

the

lubrication

the

on

value

while

the

adjusted

time

FLOW

(Fig.

clockwise

note

the

TO

thread

oil

turning

flow

that

machine

THE THREAD

take-up

can

be

regulating

13).

of

by

When

the

oil

the

the

ad-

flow

it

is

flow

is

F/G./3

-

6-

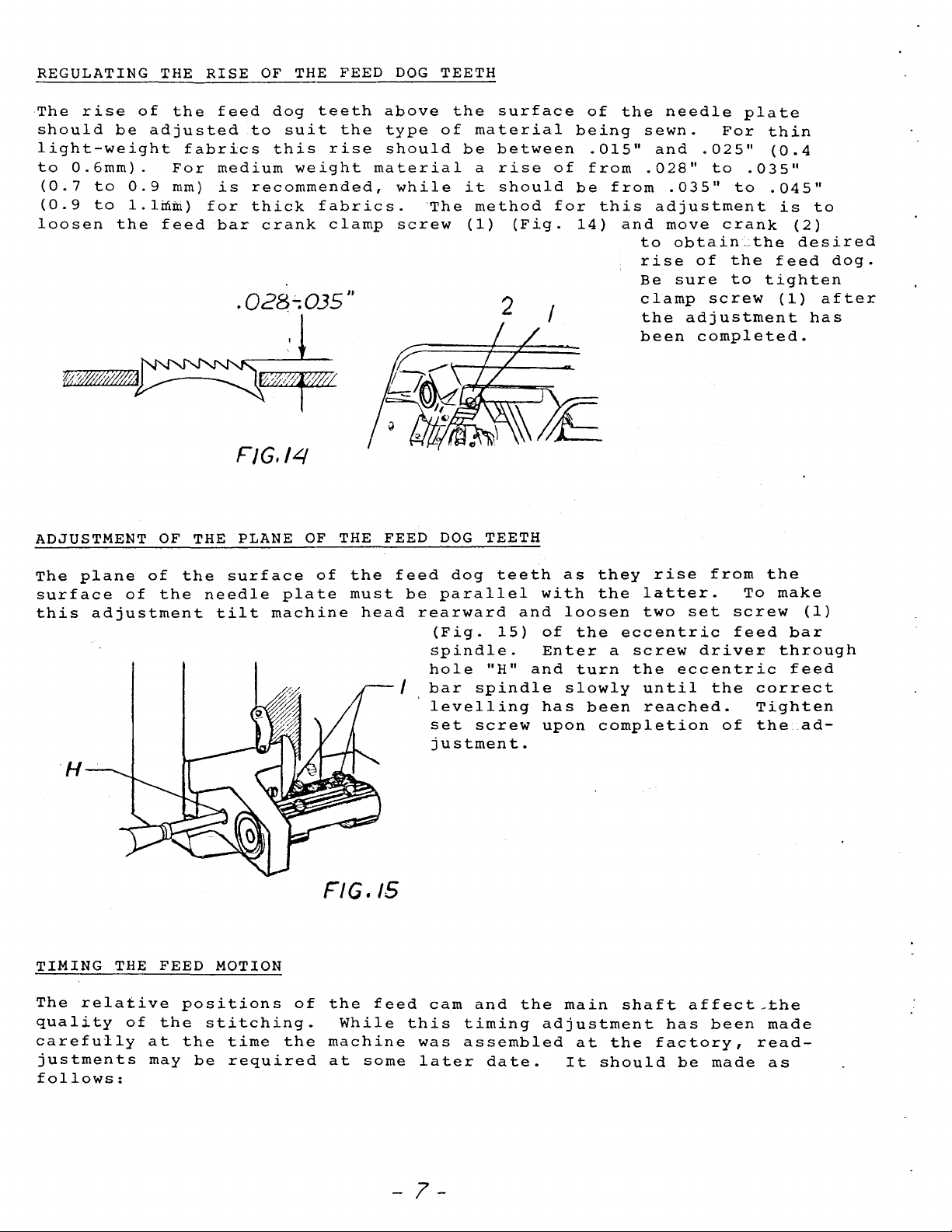

REGULATING THE

The

rise

should

light-weight

to

0.6rnrn).

(0.7

(0.9

loosen

to

to

of

be

0.9

l.lmm)

the

the

adjusted

For

rnrn)

feed

RISE

feed

fabrics

medium

is

for

bar

OF

THE FEED

dog

teeth

to

suit

this

recommended,

thick

crank

the

rise

weight

fabrics.

clamp

DOG

above

type

should

material

while

screw

.028~035"

FJG,

14

TEETH

the

of

be

it

The

surface

material

between

a

rise

should

method

(1)

2

(Fig.

of

for

I

of

being

.015"

from

be

this

14)

the

from

and

Be

been

needle

sewn.

and

.028"

adjustment

to

rise

clamp

the

.025"

to

.035"

move

obtain~the

of

sure

screw

adjustment

completed.

plate

For

.035"

to

crank

the

to

thin

(0.4

.045"

is

(2)

desired

feed

tighten

(1)

to

dog.

after

has

ADJUSTMENT OF THE PLANE

The

plane

surface

this

adjustment

of

of

the

the

surface

needle

tilt

plate

machine

H

TIMING

THE

FEED MOTION

OF

THE FEED

of

the

must

FIG.

head

IS

feed

be

rearward

spindle.

hole

I

bar

levelling

set

DOG

TEETH

dog

parallel

(Fig.

"H"

spindle

screw

justment.

teeth

and

15)

with

of

Enter

and

has

upon

as

they

the

loosen

the

turn

slowly

been

completion

rise

latter.

two

eccentric

a

screw

the

until

reached.

from

set

screw

feed

driver

eccentric

the

of

the

To

make

through

correct

Tighten

the

(1)

bar

feed

.ad-

The

relative

quality

carefully

justrnents

follows:

of

the

at

may

positions

stitching.

the

time

be

required

of

the

the

feed

While

machine

at

some

-

this

was

later

7-

earn

timing

assembled

and

date.

the

adjustment

main

at

It

shaft

the

should

affect-the

has

factory,

be

been

made

made

read-

as

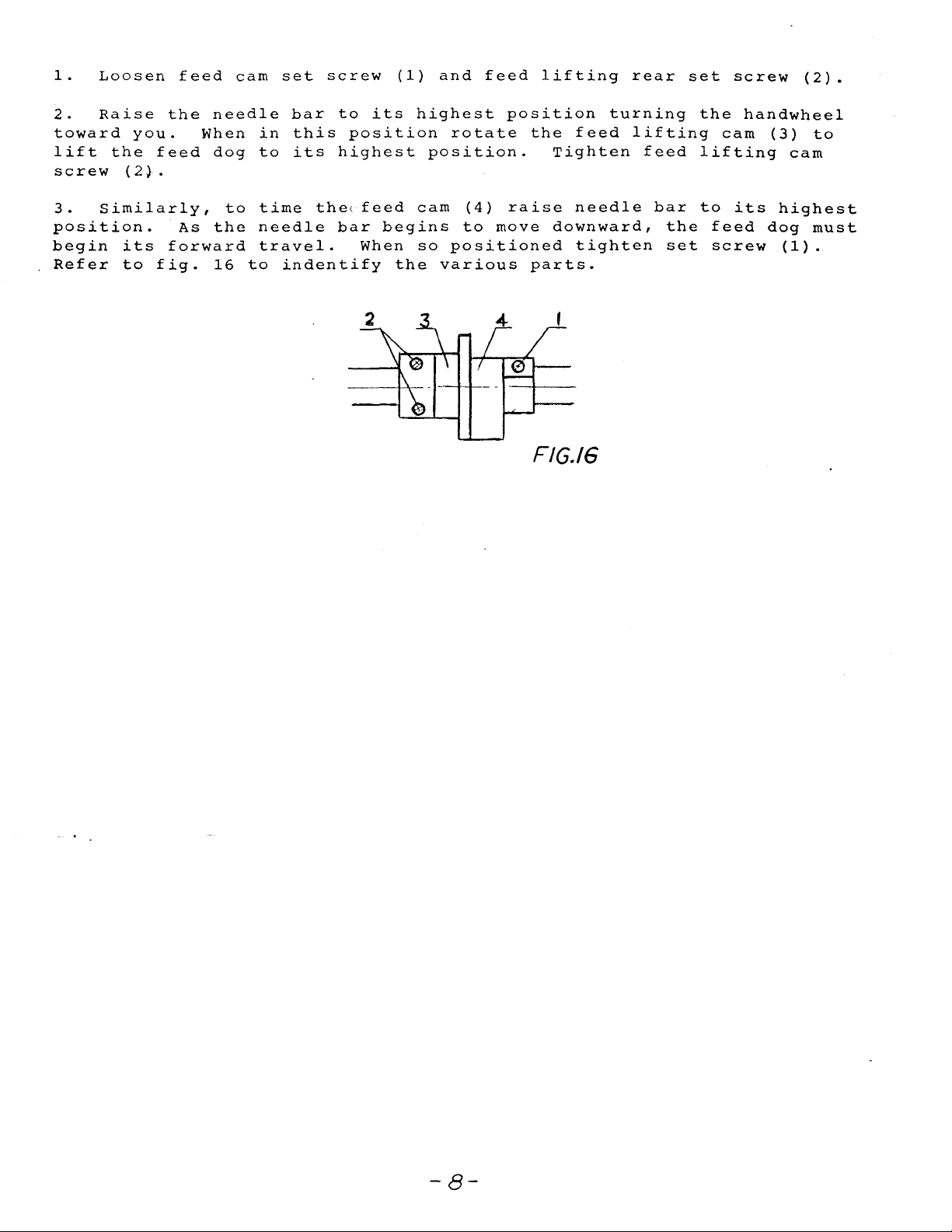

1.

Loosen

2.

Raise

toward

lift

screw

3.

Similarly,

position.

begin

Refer

the

(2).

its

to

you.

feed

fig.

feed

the

needle

When

dog

As

the

forward

16

to

cam

in

to

time

needle

travel.

to

set

screw

bar

indentify

this

its

to

highest

the(

bar

(1)

its

position

feed

begins

When

the

and

highest

rotate

position.

cam

so

positioned

various

(4)

to

feed

position

raise

move

lifting

the

feed

Tighten

needle

downward,

tighten

parts.

FIG./6

rear

turning

lifting

feed

bar

the

set

set

the

lifting

to

feed

screw

screw

handwheel

cam

its

dog

(2).

(3)

cam

highest

(1).

to

must

-8-

Loading...

Loading...