Page 1

Back Cover

Front Cover

MODEL

Ideal for alteration rooms, tailors, clothing rentals, dry cleaners,

department stores, dressmakers and home use

APPLICATIONS

Perfect for sewing all weights of materials including synthetics, woolens,

cottons, fabrics and knits

1 to 1 non-skip stitches, typical operations include felling edge tapes, bottoms

of trousers, cuffs, wigging in sleeves, facings to canvas and knit goods,

turned-up bottoms of fully lined coats, padding collars and lapels, and

reinforcing trouser seats

2 to 1 skip stitch for hemming dresses, skirts, slacks, trousers, sportswear,

ladies coats, draperies, blouses and other articles

Suitable for felling operations requiring a skip stitch to simulate hand-stitching

2 to 1 skip stitch is recommended for synthetics and other lightweight materials

and 1 to 1 for heavier cotton, woolen and linen goods

SPECIFICATIONS

Speed, Max. (S.P.M.) 1000 *

Stitch Length, Max. 3 / s.p.i. (7mm)

Needle Style LWX 6T

Looper 471

1

2

75T

MODEL

ALL PURPOSE, PORTABLE, SINGLE THREAD, CHAINSTITCH, BLINDSTITCH MACHINE

75T

SETUP and OPERATING

INSTRUCTION

MANUAL

PARTS

MANUAL

Cylinder Diameter 1 / " (40 mm)

Work Space (Needle to Arm) 4" (100 mm)

Stitch Type 103

* Speed depends on materials, operation and thread

Specifications subject to change without notice.

All photographs in this manual are additionally ©2015 - Ron Greenfield / Forest Litho Printing Co.

5

8

©2015 Consew USA -0815

Specifications subject to change without notice.

©2015 Consew USA -0815

Page 2

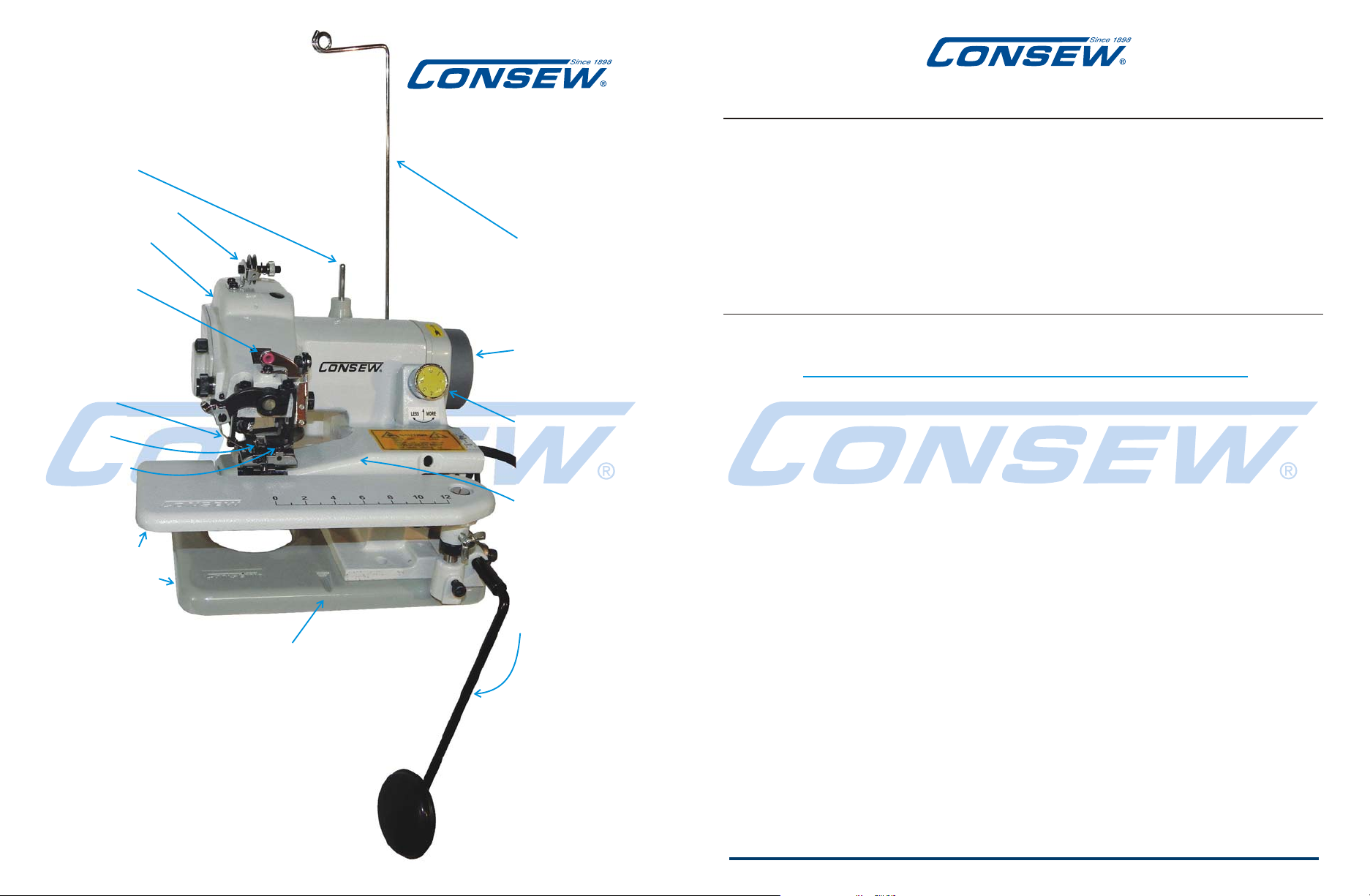

MODEL 75T

MODEL 75T

Spool Pin

Thread Tensioner

Machine Arm

Front Thread

Guide

Needle

Looper

Feed Dog

Work Plate

Machine Base

Front Groove

for seating of

Table Clamp

(There is also

a groove on

the right side

of machine for

table clamping

from that side.

Either will work)

Thread Guide

Hand Wheel

Needle

Penetration

Dial

Cylinder Bed

Knee Lifter

SET UP

and

OPERATING

MANUAL

Table of Contents

Section

Number Section Description

-- Overview Diagram of 75T

k

1. Setting up Machine for Work . . . 4

2. Lubrication

3

4. Needles and Thread . 10

5. Repla cing th e Needl e . . . . . . . . . . . . . . 10

6. Inserting the Work Piece and Starting to Sew . 11

7. Adjustment of Thread Tension . 12

8. Regulating Stitch Length 13

9. Adjustment of Needle Penetration . . . . . . . 14

10. Removal of the Work from the Machine . . . . 15

11. Skip Stitch Device . 16

12. Side/Back Cover

13. Back Cover

k PARTS BOOK: Table of Contents . . . . . . 19

-- Specifications & Applications . . . . Back Cover

(This Page) Table of Conten ts . . . . . . . . . 3

A. Location . . . . . . . 4

B. Installing Thread Stand 4

C. Connecting Motor Controller . . . . . . . 5

D. Assembly of Knee Lifter . . 5

E. Clear Acryllic Sheild . . . . . . . . . . . 6

(The Oil Access Ports) 7

. Threading Machine . . . . . . . . . . . . . . 8-9

(Notes on Lubrication) . . . . . . . . 18

. . . . . . . . . . .

. . . . . . . . . . . . . .

(Notes on Lubrication) . . . . . 17

. . . . . . . . . . . 2

. . . . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . . .

. . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . .

Page

Number

2

Specifications subject to change without notice.

©2015 Consew USA -0815

3

Page 3

1.Setting Up the 75T Machine for Work

Unpack machine from its shipping box, making certain that you

remove from box all component parts and accessories.

A. Location (Figs.1-2)

Place machine on a firm table, preferably near its right front corner.

Attach machine near edge of table using table clamp which is included

with the accessories. Table clamp is inserted into the groove in base in

either the front or on the right side, whichever works easiest.

Make sure machine is clamped tightly to keep it from moving when

you are using knee-lift.

See Figs. 1 and 2 for details of clamping.

C. Connecting the Motor Controller Pedal (Figs.4-5)

Insert three-hole plug on controller wiring into terminal block at right side of machine

and insert standard plug into wall outlet. Place controller on floor and regulate speed

of machine by stepping on of floor pedal.

Open the box and find

accessories on top and

the 75T on the bottom

From Front of 75T

Fig.1

B. Thread Stand and

Thread Guide Pole.

First, find the Thread Guide Stud (3);

it is black and just above the motor

in the back. Then insert the Thread

Guide Pole (2) into the hole in it

and tighten the thread guide Clamp

Screw (4).

so far as to hit the motor.)

Thread Guide Loop (5) extends over the

thread spindle (6). The Thread Guide

Stud Set Screw (1) can be loosened to adjust

the vertical angle of the Thread Guide Pole,

and then tightened back up, but as long as the

Loop (5) is over the thread spindle (6), it’s OK.

(Don’t let the Pole (2) go down

Adjust it so the

(Fig.3)

From Right Side of 75T

Fig.2

D. Assembly of Knee Lifter (Fig.6)

Push sleeve (1) onto free end of shaft (2)

and allow pin (3) to enter L-shaped groove

in sleeve. If you need to adjust the angle of

knee lifter, loosen the set screw (4) and adjust

the knee lifter to a comfotable angle.

Then, tighten the set screw (4).

Knee

Lifter

4

5

Page 4

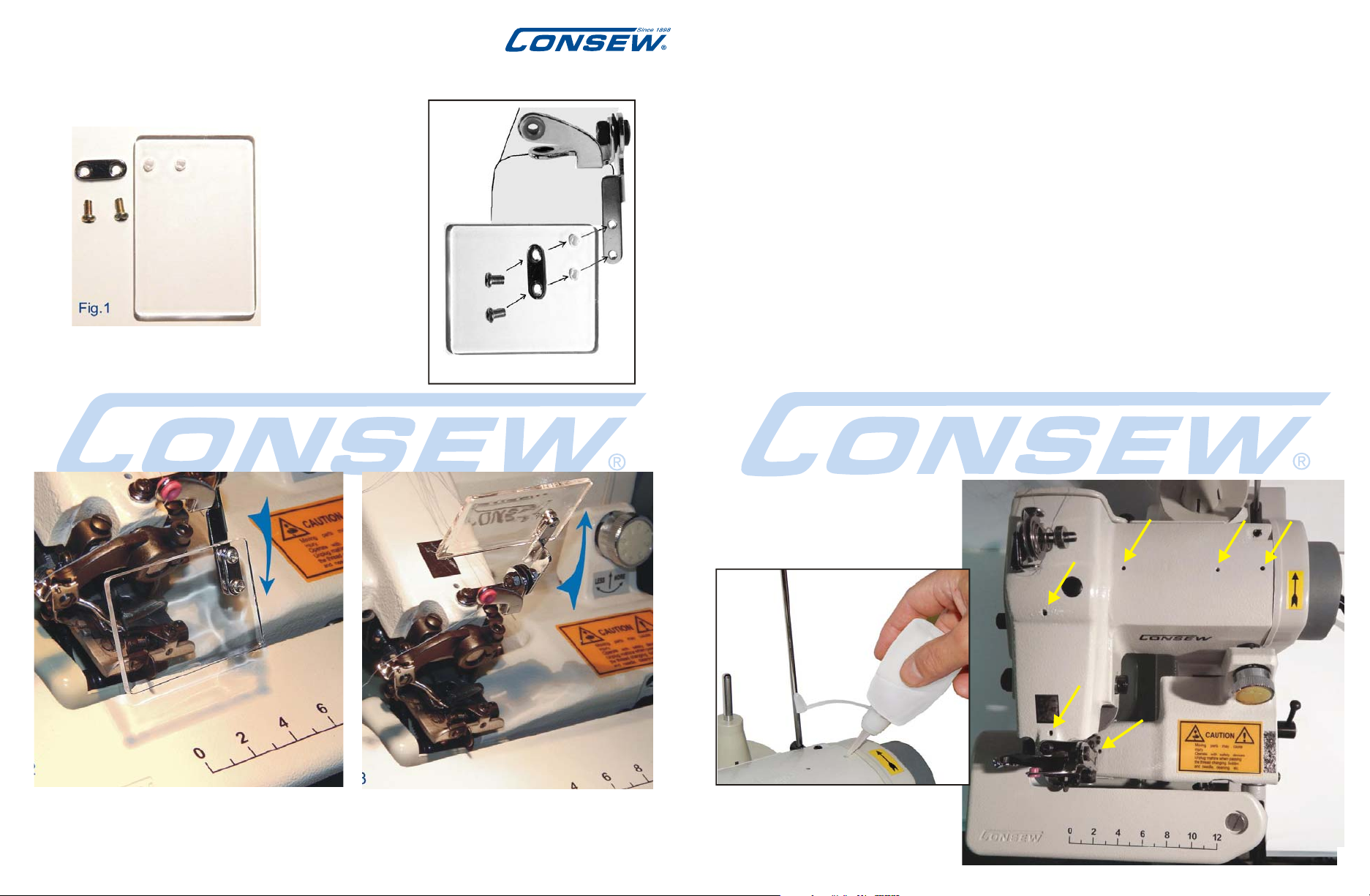

E. Optional Clear Acrylic Shield

(provided with machine - Fig Shield1)

To Install:

Using the two small

screws provided,

screw through the

metal plate and

the shield into the

two screw holes in

the swing arm

located just to the

right of the needle

Fig. Shield 1

In the “Down” position (Fig.Shield3)

the shield helps keep fingers

out of the needle area

assembly.

(Fig Shield 2)

MODEL 75T

Fig. Shield 2

In the “Up” position (Fig.Shield4)

it is out of the way

2. Lubrication (Fig.7)

Lubrication is important for the trouble-free operation and long service life of the

machine. Therefore, after setting-up machine as per instructions, you should lubricate

it before using.

A convenient oil dropper filled with fine machine oil is provided with the tool kit.

(Use a pin to pierce the tip of the spout. Be sure to snap the cap on tightly after

opening to avoid leakage. You may want to keep it in a small resealable plastic bag

when storing.)

Carefully place a drop sewing machine oil into all the holes indicated by arrows on

Fig.7. There are 6 of them. Remember to give the machine a wipe down to remove

any residual oi1 that might stain your work.

Lubrication Regimen

As a part of regular daily maintenance, you should oil the 6 oil holes with a drop of

machine oil (in Fig.7) before starting work.

Tip: It is suggested that you do this at the end of the previous days work because

this would allow any excess oil to settle and with a quick wipe the machine will be

clean and ready to go the next day.

Fig. Shield 3

6

Fig. Shield 4

Fig.7

Note: Internal Lubrication is

covered in sections

12 and 13.

OILING POINTS

7

Page 5

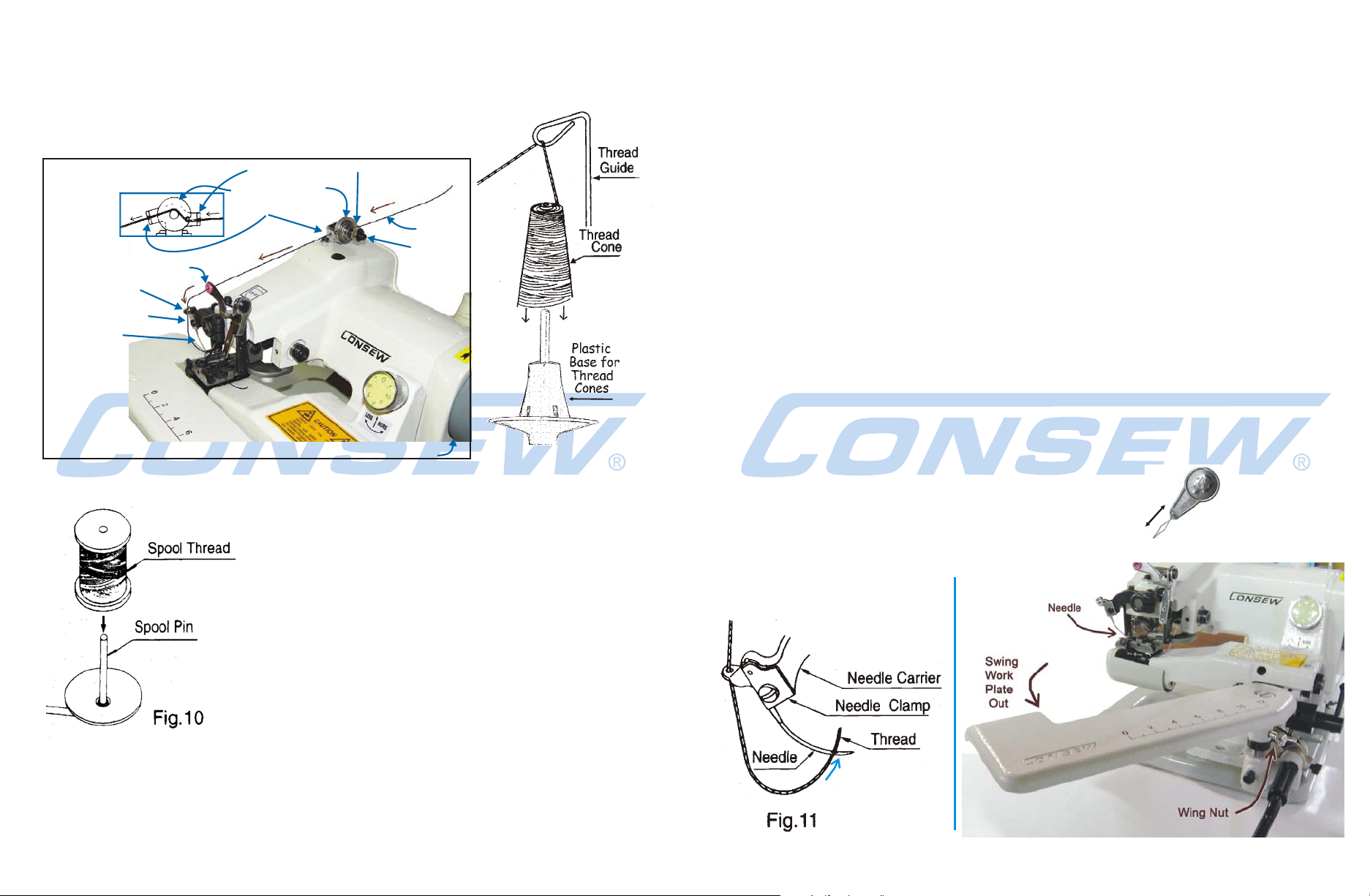

3.Threading the Consew 75T (Figs.9-12)

Threading the machine (continued)

Fig. 9 shows the path of thread from the overhead thread guide

through the tension nut, through the front guides and to the needle.

Fig.9

Front Thread Guide (3)

Needle Clamp Guide (4a)

Needle Clamp (4)

Needle (5)

Thread Guide (1a)

Tension Disc (2)

Thread Guide (1b)

Thread

Tension

Nut (6)

Hand wheel (7)

A. When using sewing thread

from a cone, place it over

plastic base on thread stand

(Fig.9B above)

Fig.9B

Take the thread through the vertical guide pole and pull it to the rear of the thread tension

device.

Put the thread first thru the rear thread guide eye (1a);

Then, between the two tension discs (2); and then through the eye of the forward thread

guide (1b) as per Fig.9.

Bring the thread to the front of the machine and put it through the plastic grommet which is

the front thread guide (3).

Then below that there is a guide hole (4a) on the left of the needle clamp (4). From there the

thread continues down to the needle (5).

Important: At this point, make certain that needle is in extreme left-hand position (turn

the handwheel (7) so it is. The left edge of the Needle Carrier arm will be at its highest

point.)

Now put thread through needle eye from below as shown in Fig.11.

TIP 1: It is easier to get to the eye of the needle (5) when the work-plate is pulled out

of the way. Loosen the wing-nut below and to the right of the work-plate amd put the

work-plate towards you (Fig 12). Additionally, if you engage the knee-lifter, it will

move the Cylinder Bed downward, giving you even more room.

TIP 2: If you are having trouble getting the thread thru the needle,

a standard needle threading device (available everywhere) might

help. You would put the device wires thru the needle from the

top, put the thread in the wire loop and pull the thread through.

Common

Needle

Threading

Device

B. When using spool thread,

remove plastic cone base

before placing spool on thread

stand (Fig. 10).

Tip: Many spools of thread have a notch cut at the top edge

where the end of the thread is wedged in before being cut off.

Put the spool on upside down, so the notched edge is on the

bottom and the thread can’t catch on that notch as it unwinds

upwards to the thread guide.

C. For correct needle threading of the machine,

carefully the path of thread as shown in Fig.9 above

follow

and Fig 11 on the next page.

8

Thread the needle from below in

an upward direction as in Fig.11.

Fig. 12

9

Page 6

4. Needles and Thread

The recommended needle is system LW x 6T (or style 29-43)

Blindstitch Machine Needle. Size range from No.3 to No.4.

To assure satisfactory operation needles, thread and fabric

must be matched as suggested in the table below:

5. Replacing the Needle (Fig.8)

Turn handwheel away from you (clockwise direction) until needle reaches

to the end of its return stroke- as far left as possible. Remove needle to be

replaced by loosening needle clamp screw (1) about two turns. Insert new

needle into its seat on the needle carrier (2) pushing it as far to the left as it

will go. Now, tighten needle clamp screw (1) to hold the needle in place. .

Note: Fig.8 shows needle carrier parts in a disassembled view.

6. Inserting the work piece and Starting to Sew (Figs.13-14)

Depress knee lifter. This causes the cylinder bed of the machine to

swing downward and creates a gap between the presser foot and

the cylinder bed. Insert the work in the gap just opened in such a

manner that the folded or sewn edge of the article is alongside the

edge guide of the presser foot.

10

Needle

Carrier (2)

Needle

Clamp

Needle

Clamp

Screw (1)

Needle

Fig.8b

When the article is in proper position, completely release the knee lifter.

This will bring the bed back up and securly grab the material

Depress the foot controller and started sewing slowly. Watch as the material

passes the edge guide (Tip:

attention on the item you are sewing and guide it where you want it to sew.

Don’t watch the needle go back and forth. Keep your

)

Fig.14-1 shows how to insert material for double folded edge sewing.

Fig.14-2 single folded edge sewing.shows how to insert material for

11

Page 7

7. Adjustment of Thread Tension

Safety Warning: Pull out the AC power plug before working inside machine!

Different kinds and weights of material and the various sizes of thread require

respective thread tensions. Thread tension is regulated by turning the tension

nut located at the top of the machine arm.

Tension

Discs

Tension

Spring

Tension

Nut

To increase thread tension, turn the nut away from you (clock wise).

To decrease the tension, turn the nut towards you (counter-clockwise).

Do not turn, tighten, or loosen tension more than about one quarter

turn at one time. Test for results and readjust, if necessary.

Fig.15 below shows the results of more and less thread tension.

Thread

Guide

8. Regulating Stitch Length (Fig.17)

Open side/back cover by just loosening the rear thumb screw and removing

the side thumb screw (Fig.17A).

Inside, Loosen the two set screws (1) in stitch regulating collar. You can see one in

Fig.17B. You can see the other one by Rotating the Gray Handwheel on the side of

the machine 1/3 of a turn clockwise. You are best off loosing that one first.

Then go back and loosen the one next to the number “8” so as soon as it is

loose, you can make the adjustment. Now you should be able to turn the co11ar

until desired stitch length number is lined up next to the indicator notch (2) in the

eccentric wheel . Then, tighten both screws (1) securely.

The factory setting for stitch length is usually set at "6" or “7”.

Just Loosen

this one

Take Off

this one

Back and Side

Cover

Fig.17A

Removing side/back cover.

Fig.17B

(1) Set Screw is

in this threaded

hole in the

stitch regulating

collar. There

are two of them!

Use small

Allen Wrench

(2) This is the

notch in the

eccentric wheel.

The number next

to it indicates

the stitch length.

In this case it

is set at “7”.

12

Each number on the collar (1) corresponds to the following stitch length in millimeters:

In order to choose a stitch length, you willprobably want to test various stitch lengths

on different materials so as to get an idea as to what works best in each situation.

13

Page 8

9. Adjustment of Needle Penetration (Fig.18)

The depth of needle penetration into the cloth can be adjusted by turning the

needle depth regualtor knob located on front of the machine (Fig.18).

Fig.18

To prevent damage to the needle and the machine, it is recommended to begin sewing with

the least degree of penetration (a higher dial setting), and sew a short length of seam to

test it. Check for catching of the material and appearance, making whatever penetration

adjustments are required until stitching is as desired.

NOTE: Beginning and end of penetration adjustments are controlled by built-in stops.

Do NOT force the dial to go beyond its stops!

In Fig.18 at left you can see that the arrow at bottom

points to the depth setting.

Here you can see it is set at “4”.

To increase needle penetration for light materials,

turn the regulator counter-clockwise. The greater the

number the arrow below the dial is pointing at, the

deeper the penetration of the needle.

To lessen the penetration for thick materials, turn

regulator clockwise. The lower the dial setting, the less

needle penetration. See Fig.18b for clarification.

10. Removal of the Work from the Machine (Fig.19)

Stop machine by taking your foot off the controller pedal. Turn handwheel (1a)

away from you until needle is moved as far left as it goes (1b) and is completely

out of the material. Press knee lifter (2) to the right and this will cause the

cylinder arm to drop down (2b). Now you will be a be to pull the work piece

towards you with a quick stroke. This action will lock the last stitch and

break the thread. Now your work piece is safely removed from the machine.

(1b)

(2b)

(1a)

14

The higher the number on the

dial, the closer the bottom

guide is to the needle.

(2a)

When you lower the number on the dial,

it moves the bottom guide slightly down

and away from the needle thus making

more room for thicker materials.

15

Page 9

11. Skip-stitching device (Fig.20-21)

The black Skip-Stitch Lever in on the right side of the machine (fig.20). When it is

in the forward position, the machine will sew in "No Skip" mode as indicated on the

shiny label above it. In No Skip Stitch mode, the fabric shall be sewn every stitch.

When the Skip-Stitch Lever is pulled back to the "2:1 Skip" position, the machine

is in Skip-Stitch mode and the fabric will be sewn every other stitch (Fig21).

Safety Warning: Pull out the AC power plug before working inside machine!

12. SIDE-REAR COVER / INTERNAL LUBRICATION

Consew recommends having your machine professionally serviced by a qualified sewing

machine mechanic on a regular basis. Having your machine cleaned and lubricated once a

year by a service professional can go a long way to assuring long and trouble free service

from your machine.

The following outlines the general ideas behind cleaning and lubrication.

Do’s and Dont’s: 1. Never move the Skip-Stitch Lever while the machine

is running. It must be completely stopped before you shift sewing modes.

2. The Skip-Stitch Lever is made to be set either all the way forward or all

the way back. There is no purpose in putting it in the middle postion. The

machine will not run correctly like that.

3. TIP:

should check on your needle penetraton setting (Section 9.) It may need adjusting.

When a shift of sewing modes between"Skip"and"No Skip"is made, you

Fig.20

Fig.21

Mode

No Skip-Stitch

Mode

Fig.23 Stitching Sample

Skip-Stitch

The Skip-Stitch / No-Skip-Stitch Lever

In Fig.23 at right, note the back of

the sewn samples where you can plainly

see where the Non-Skip stitch version

has sewn through on every stitch and

the Skip Stitch version has only sewn

through on every other stitch.

16

Non-Skip

Stitch

Skip Stitch

When working internally with any sewing machine the first rule of safety is to unplug the

AC power from the machine. Be careful to keep ones fingers away from any parts while you

are turning the hand wheel to move them.

Your authorized sewing machine service professional will use real sewing machine oil and lubricants!

Sewing machines use special light lubricants that resist gunking and gumming up.

General lubricants that one would normally use in ones car or home are NOT correct for a sewing machine.

Removal of Side/Back Cover

In Fig.17 the Side/Rear Cover (1) can be removed

Fig.17

(2)

by loosening thumb screw (2) a few turns, but

thumbscrew (3) must be unscrewed completely.

Then the cover comes right off.

As you will remember from Section 8 (on pg.13),

One reason to go into this area is to adjust the

Stitch Length of the machine.

Also, as a part of regular maintenance,

there are parts in here that can use

lubrication once in a while.

Fig.18

Your authorized sewing machine service

professional will know how to lubricate

your machine properly. If possible you

should leave it up to him/her.

Generally speaking:

A drop of fine sewing machine oil

should be applied to the places where

two moving parts meet.

motor oil or household oils, etc.)

If one slowly rotates the Hand Wheel,

one can see everything turn and it will

become apparent where these points are.

Do NOT flood the area with oil. A drop of

oil to the joints of the moving parts is all that

is needed to keep the machine working smoothly.

Wipe off dripping excess oil.

(Do not use regular

(3)

(1)

17

Page 10

13. Removal of Rear Cover

Safety Warning:

Pull out the AC power plug before working inside machine!

Unscrew the two

screws shown

(Fig.19)

Back Cover then

lifts off easily.

(The thread holder

base is attached to it)

(Fig.20)

Lubrication

Fig.19

MODEL 75T

PARTS BOOK

Fig.20

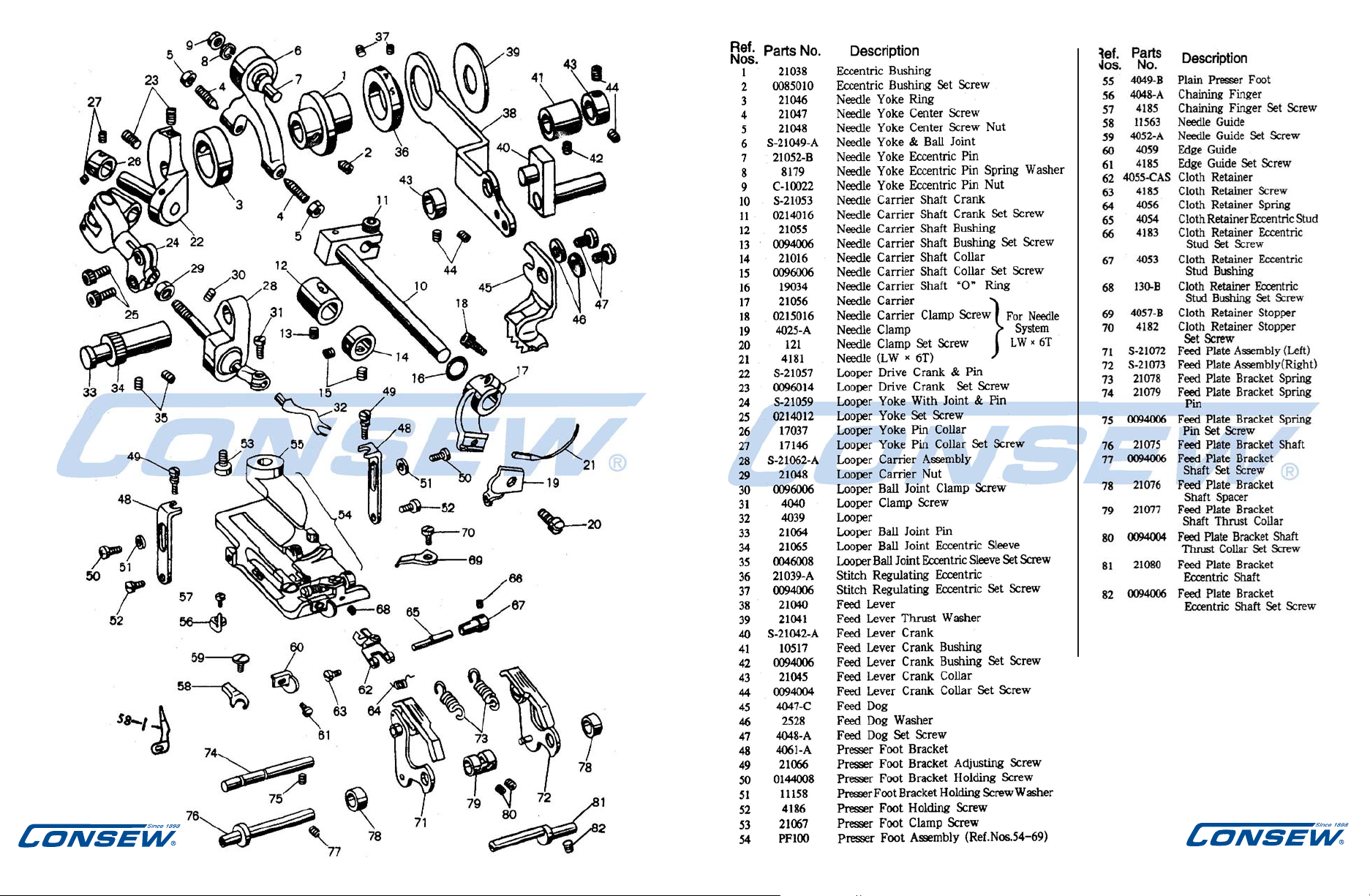

Pg.20 - Parts Drawing - External (Parts Numbers Pg.21)

Pg.22 - Parts Drawing - Drive (Parts Numbers Pg.23)

WARNING: The machine will have

fine grade sewing machine grease inside

on the moving parts and gears. This is the

way it is supposed to be. If machine seems

excessively dirty or dry of grease it is

recommended to have an authorized sewing

machine service professional clean and grease

your sewing machine.

The proper amount of fine sewing machine

grease and oil must be used.

Fig.21: Inside showing gears

and drive parts of machine.

A proper amount of grease

should be present to minimize

heat and friction and keep the

machine running smoothly.

If the machine is in constant

daily use, one may want to

have it professionally serviced

twice a year.

If the machine is only used

once or twice per week, or

less It will need servicing care

much less often.

18

Fig.21

Pg.24 - Parts Drawing - Miscellaneous (Parts Numbers Pg.25)

Pg.20 - Parts Drawing - Accessories (Parts Numbers Pg.26)

Pg. 26 - Photos of Accessories

19

Page 11

© Consew 2015

20

21

Page 12

22

23

Page 13

R

N

24

25

Page 14

Notes:

H

H

H

*

*

These parts come already attached to the machine now.

*

There are now five sizes of Allen wrenches that come with machine

H

12

11

26

8

1

7

14

17

2

4, 5, 6 +

H

18

9 & 10

3

13

27

Loading...

Loading...