Page 1

Page 2

------

To

get

the most

machine correctly.Please read this instruction Manual carefully before use.Whe hope you will enjoy the use

your machine for a long time.Please remember

1. Observe the basic safety measures,including, but not limited to

the

machine.

2. Read all the instructions,including,but not limited to this Instruction Manual before you use the machine.

In addition, keep this Instruction Manual

3.

Use

the machine after it has been ascertained that it conforms with safety rules/standards valid in your

Country.

4. All safety devices must be in position when

The

operation without the specified safety devices is not allowed.

5.

This

machine

6.

For your personal protection,

For

the following, turn off the power switch

receptacle.

7-1

For threading needle(s), iooper; spreader etc. And replacing bobbin.

7-2 For replacing part(s)

folder, cloth guide etc.

7-3

For

7-4

When leaving the working place

If

you should allow oil, grease, etc. used with

-er-s-k-~R--er-&vV-a+l-aw-an-y-a-f-s-o-ef-1-ltq'dict--b'1-·r-rh'8-t-a-ke-;-··-l-rrrm-e-diate-ly---wash--t'mn:

medical doctor.

--------

7.

8.

~--

out

of

shall be operated

repair work.

IMPORTANT

the many functions

by

appropriately-trained operators._

we

recommend

of

needle, presser foot, throat plate, looper,spreader, feed dog, needle guard,

or

SAFETY

of

this machine and operate

to

keep this manual in a safe place.

so

that

you may read it at

the

machine is ready for word

that

or

when

the

working place is unattended.

the

INSTRUCTIONS------

you

wear

disconnect the

machine and devices to

it

in safety,it is necessary to use this

the

following ones,whenever you use

anytime

safety glasses.

power

plug

when necessary.

or

in operation.

of

the machine from the

come

in contact with your eyes

..

uT,ta-c'reti-areasam:i----corrsuih:l-···

of

9.

Tampering with the live parts and devices, regardless

10.

Repc1irl

specially skilled personnel. Only spare parts designated by can be

11. General maintenance and inspection works have to be done

12. Repair and maint~n~nc;e works

technicians

Whenever

13. Before making repair and maintenance

an air cylinder,

has to be

has to be

appropriateiy

14. Periodically

15. Grounding the machine is always necessary

to be operated in an environment that is free from strong noise sources such

16. An appropriate power plug has to be attached to the machine by eledtric technicians. Power plug has to

be commected to a grounded receptacle.

17.

The

18. Remodel

effective

of

19. Warning hints are marked with the two shown symbols.

remodeling and adjustment works

of

electrical components shall be conducted by qualified electric

or

under

·the audit and guidance

you find a failur-e

the

air compressor has

cut

off. Existing residual air pressure after disconnecting

expelled.

trained technicians or specially skilled personnel.

clean the machine thrqughout

machine is only allowed to be used for the purpose intended.

or

modify the machine in accordance with the safely rules/standards while taking

the

machine.

safety

measures.

of

any

Exceptions

assumes

of

electrical components, immediately stop the machine.

to

must

of

specially skilled personnel.

works

on

to

be detached from the

this

are

only

the

period

for

no

respqnsibility

of

whether

only be done

the

machine

adjustments

of

use.

the normal operation

for

the

by

appropriately trainde technicians

used

by appropriately trained personnel.

equipped

machine

the

and

Other

damage

machine

for

air

of

used are not allowed.

by

is powered, is prohibited.

repairs.

with

pneumatic

and the compressed air supply

compressor from

performance

the

machine.

as

high-freauer1cy welder.

remodeling

parts such as

the

checks

The

machine has

an

or

modification

machine

done

the

by

or

Danger

Items requlring

of

injury to operator

special attention

or

service staff

ii

Page 3

CAUTION

1.

fo

avoid electrical

motor

the

1.

To

avoid personal injury, never operate the

Finger guard

2.

To

prevent

Keep

motor

3.

To

avoid

'[ON" the

4.

To

avoid

while the

5.

The

hook

posslb!e

the

hook

machine

6.

To

avoid

nor touch the

possible

your

fingers,

while the

personal

power

personal

machine

rotates

injury

during

when

possible

------r-nae-hfne-w-h-e-n-t-Ht-l-n-g/-ra-i-3-i-n

7.

To

avoid possible

power

to the

shock

or

safety devices removed.

machine

injury, never put

switch

injury, never put

is in operation.

at

to

hands,

operation.

replacing

personal

accidents

machine

hazards,

components

personal

head

and clothes

is operation, In addition, place nothing

or

a high

the

when

injuriescaused

operate

speed

be

sure

In addition, be

bobbin.

injuries,be

-th-e--m-a-eh-i-ne-h-e-a-cl

9

because

tilting the

neither

the

while the

to

open

mounted

away

your

hand

machine.

your

beep

careful

of

abrupt

machine

the

cover

inside the electrical box.

machine

by

being caught in

from

the

under

fingers

machine

your

sure

hands

to

not

·:

start

head.

into

--· - -- ------

of

the

with

any

of

handwheel, V belt

the

needle

the

thread

is in operation.

away

from

turn

OFF

to allow

your

- ·

of

the machine,

electrical

the

belt

the

around

when

take-up

the

the

power

fingers

turn

box for

cover,

machine,

and

the

them.

you turn

cover

To

prevent

vicinity

to

in

the

OFF

of

the

the

8. If

your

machine is

while the machine is at rest.

machine, be

9.

To

avoid electrical

ground wire for the

10.

To

prevent

components(s),

of

the

sure

possible

power plug.

[_s_E_F_O_R_E_O_P_E_R_A_T_IO_N

equipped

to

turn

shock

power

accidents

turn OFF the power switch in prior to the connection/disconnection

with a servo-motor,

To

avoid

possible

OFF

the

power

hazards, never operate

suppiy removed.

because

to

the

of

accidents

electric

the

motor

machine.

the

aewing

shock

does

due

machine

or

not

produce

to

abrupt

damaged

________________

Ii\ CAUTION:

~

• Before you put the machine into operation for the first time after the set up, clean it thoroughly.

• Remove all dust gathering during transportation and oil it well.

• Confirm that the power plug has been properly connected to the power supply.

• Never use the machine in the state where the voltage type

• The direction

side. Be careful not to rotate it in reverse direction.

of

rotation

To

avoid malfunction and damage

of

the sewing machine

of

the machine, confirm the following.

is

different from the designated one.

is

counterclockwise as observed from the handwheel

start

with

electrical

of

the

noise

the

J

iv

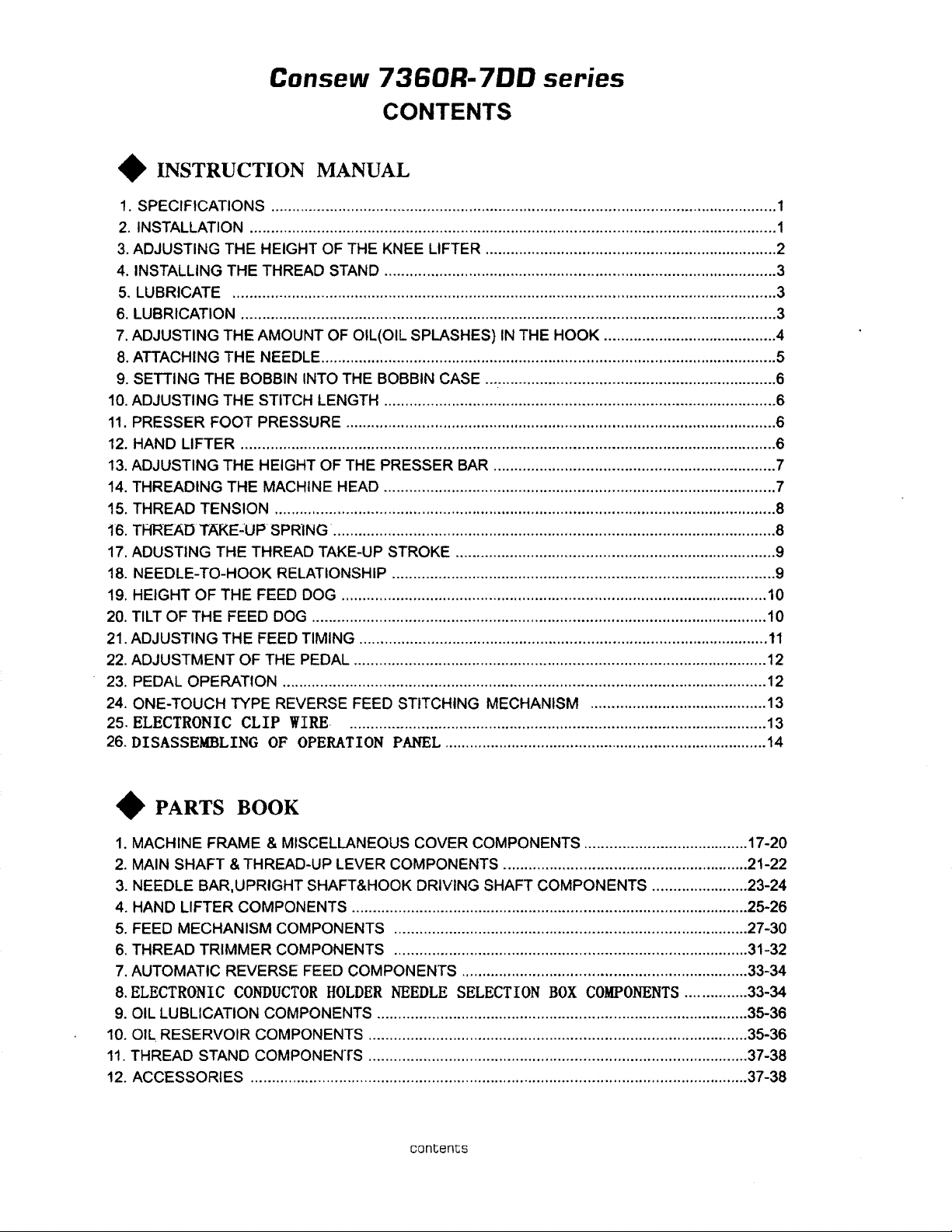

Page 4

Consew

7360R-

7DD

series

CONTENTS

♦

INSTRUCTION MANUAL

1.

SPECIFICATIONS ........................................................................................................................ 1

2. INSTALLATION ............................................................................................................................. 1

3. ADJUSTING

4. INSTALLING

5. LUBRICATE ................................................................................................................................. 3

6. LUBRICATION ............................................................................................................................... 3

7. ADJUSTING

8. ATTACHING

9. SETTING

10. ADJUSTING THE STITCH LENGTH ............................................................................................. 6

11.

PRESSER

12. HAND LIFTER ............................................................................................................................... 6

13. ADJUSTING

14. THREADING

15. THREAD TENSION ....................................................................................................................... 8

1·6.

THREAD' TARE~·up·

17. ADU STING THE THREAD TAKE-UP STROKE ............................................................................ 9

18. NEEDLE-TO-HOOK RELATIONSHIP ........................................................................................... 9

19. HEIGHT

20. TILT

21. ADJUSTING

22. ADJUSTMENT

23. PEDAL OPERATION ...................................................................................................................

24. ONE-TOUCH TYPE REVERSE FEED STITCHING MECHANISM .......................................... 13

25.

26. DISASSEMBLING OF OPERATION PANEL .............................................................................

OF

ELECTRONIC

THE

HEIGHT OF THE KNEE LIFTER ..................................................................... 2

THE

THREAD STAND ............................................................................................. 3

THE

AMOUNT OF OIL(OIL SPLASHES) IN THE

THE

NEEDLE ............................................................................................................ 5

THE

BOBBIN INTO THE BOBBIN CASE ..................................................................... 6

FOOT

OF

THE

PRESSURE ...................................................................................................... 6

THE

HEIGHT

THE

MACHINE HEAD ............................................................................................. 7

·sPR-ING

THE

FEED DOG .....................................................................................................

FEED DOG ............................................................................................................

THE

FEED TIMING .................................................................................................

OF

THE PEDAL ..................................................................................................

CLIP

OF

THE PRESSER BAR ................................................................... 7

.......................................................................................................... 8

WIRE.

..

................................................................................................. 13

HOOK

......................................... 4

10

10

11

12

12

14

♦

PARTS BOOK

1. MACHINE FRAME & MISCELLANEOUS COVER COMPONENTS ....................................... 17-20

2.

MAIN

SHAFT

3.

NEEDLE BAR.UPRIGHT SHAFT&HOOK DRIVING SHAFT COMPONENTS ....................... 23-24

4. HAND LIFTER COMPONENTS .............................................................................................. 25-26

5. FEED MECHANISM COMPONENTS .................................................................................... 27-30

6. THREAD

& THREAD-UP LEVER COMPONENTS .......................................................... 21-22

TRIMMER

COMPONENTS .................................................................................... 31-32

7. AUTOMATIC REVERSE FEED COMPONENTS .................................................................... 33-34

8.

ELECTRONIC

9. OIL LU

10.

OIL.

11. THREAD STAND COMPONENTS .......................................................................................... 37-38

BU

RESERVOIR COMPONENTS .......................................................................................... 35-36

CONDUCTOR

CATION COMPONENTS ........................................................................................ 35-36

HOLDER

NEEDLE

SELECTION

BOX

COMPONENTS

............... 33-34

12. ACCESSORIES ...................................................................................................................... 37-38

contents

Page 5

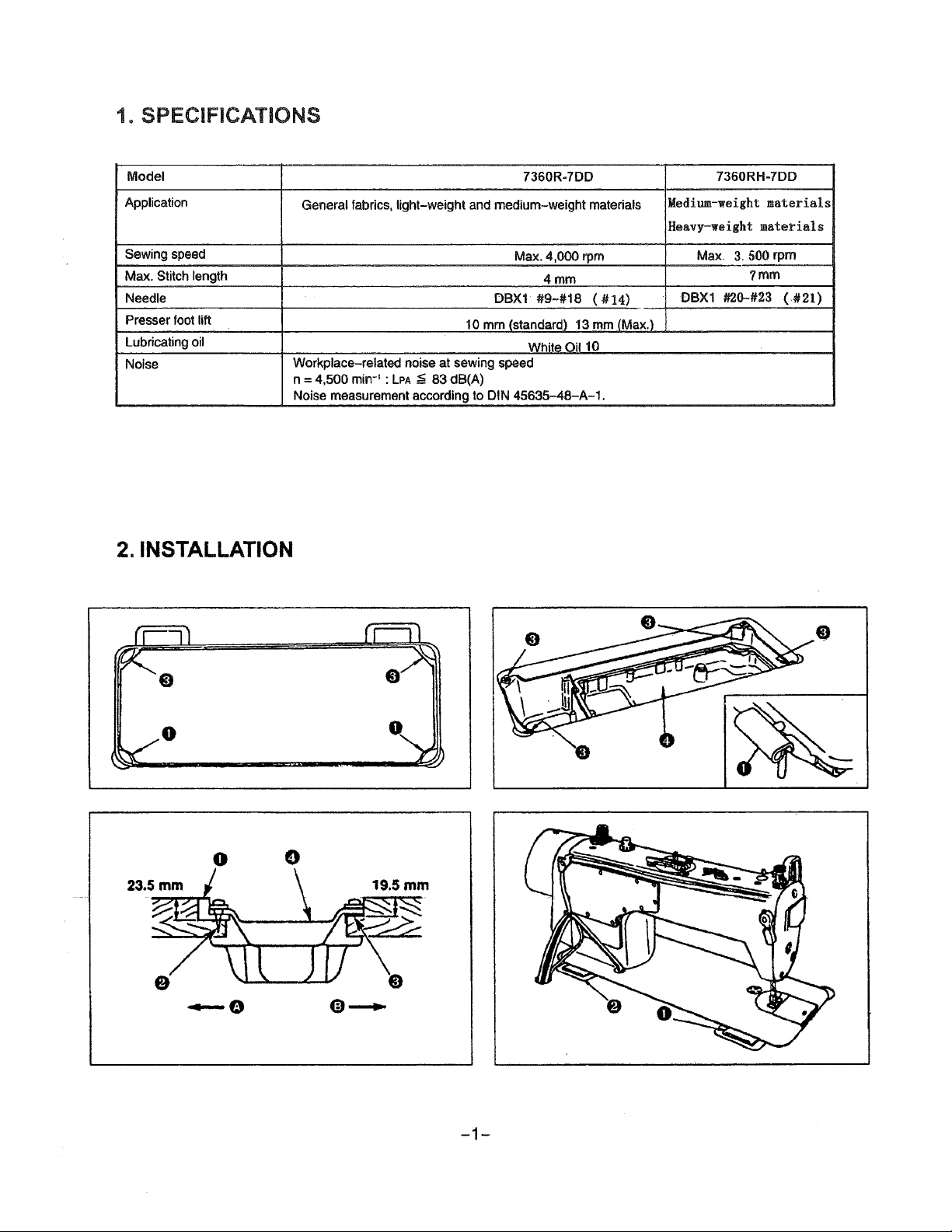

1.

Model

Application

Sewing speed

Max.

Stitch length

Needle

Presser

lubricating

Noise

foot

lift

oil

2. INSTALLATION

7360R-7DD

General fabrics, light-weight and medium-weight materials

1 o mm (standard) 13 mm (Max.)

Workplace-related noise at sewing

n = 4,500 min-

Noise measurement according

1

:

LPA

~

83 dB(A)

to

Max. 4,000

DBX1

White Oil

speed

DIN 45635-48-A-1.

4mm

#9-#18

rpm

(

10

#14)

7360RH-7DD

Medium-weight

Heavy-weight

Max.

3.

500 rpm

DBX1

#20-#23

materials

materials

1mm

(.#21)

0

0

0

-1-

Page 6

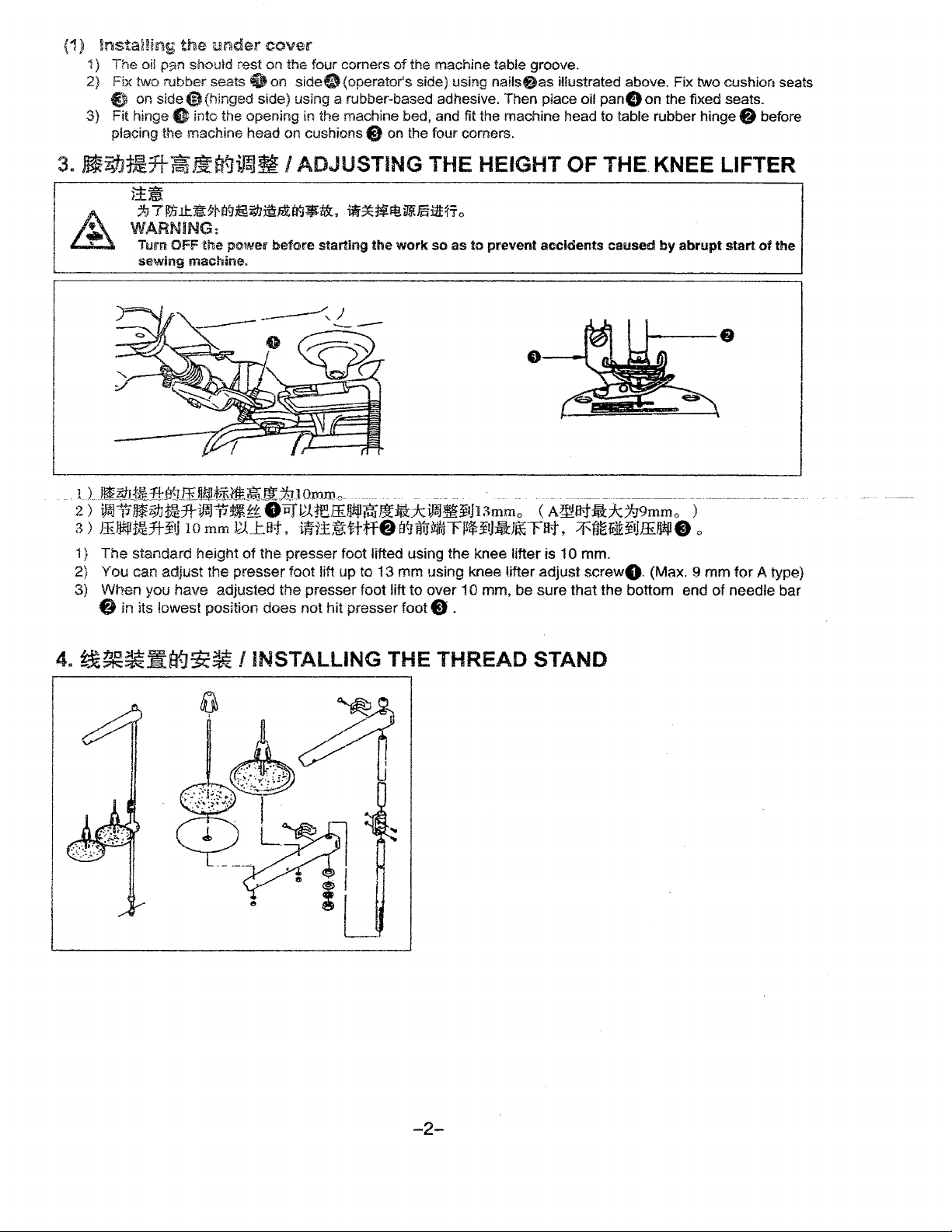

{1) Bnstamng

1)

The

2)

Fix two rnbber seats O on

E) on side (D (hinged side) using a rubber-based adhesive. Then place oil

3}

Fit hinge 8 into the opening in the machine bed, and fit the machine head to table rubber

placing the machine head

3s

~~~fF~

oil

the

pem

should rest

t\ia{J~~

under

cover

on

the four corners

sicteO(operator's

on

cushions

of

the machine table groove.

side) using

6)

on the

four

comers.

nailsf)as

I ADJUSTING THE HEIGHT

illustrated above. Fix

pan8

on

OF

THE. KNEE LIFTER

t:wo

the fixed seats.

cushion seats

hinge@

it~

~7M~•*~&~8d~-~-~N*

WARNING:

Tum

OFF

sewing machine.

____

L)

__

~jf¾.fHJ~Lffi

2)

ijJ'f1"~i;JJ~3t-~-=p-~!!

the

power

before

starting

JWl}_il.fE_i\%_~

....

iJHlmm-0---- _

8PJWJE.ffiijt4J~~~.fdftiJ~Jtil3mmo

the

__

■

work

fimflo

so

as

to

prevent accidents caused

0

___

(

A~&rit:kn9mmo

_

______________________________________

by

abrupt

.,_

___

)

start

_

_

3)ffi~-*~1omm~k~.-~•ttff8~~~T~~-~T~,~-m~lli~80

1)

The standard height of the presser foot lifted using the knee lifter is 1 O mm.

2)

You can adjust the presser foot lift up to 13 mm using knee lifter

3) When you have adjusted the presser foot lift to over 1 O mm, be sure that the bottom end of needle bar

8 in its lowest position does not hit presser foot C, .

adjust

screw8. {Max. 9 mm for A type)

before

of

the

-2-

Page 7

Turn OFF

sewing machine.

the

power before starting

the

work

so as

to

prevent

l )

il~fl;p~tJ~~~fffflO

rJ~~~ff ffi o

accidents

B{J

/J\fL

caused

_ta{J/J"!illtr

11-J

o

Fo,

~j(ijffi-ij~tl:i~

start

2>•~fiTttff~mttm~Fo-~ttff~mtte.1.oo~

•n,

~Mffl-nl~tl:i~Hff~~tt

lr-yJ,fL~

of

the

o

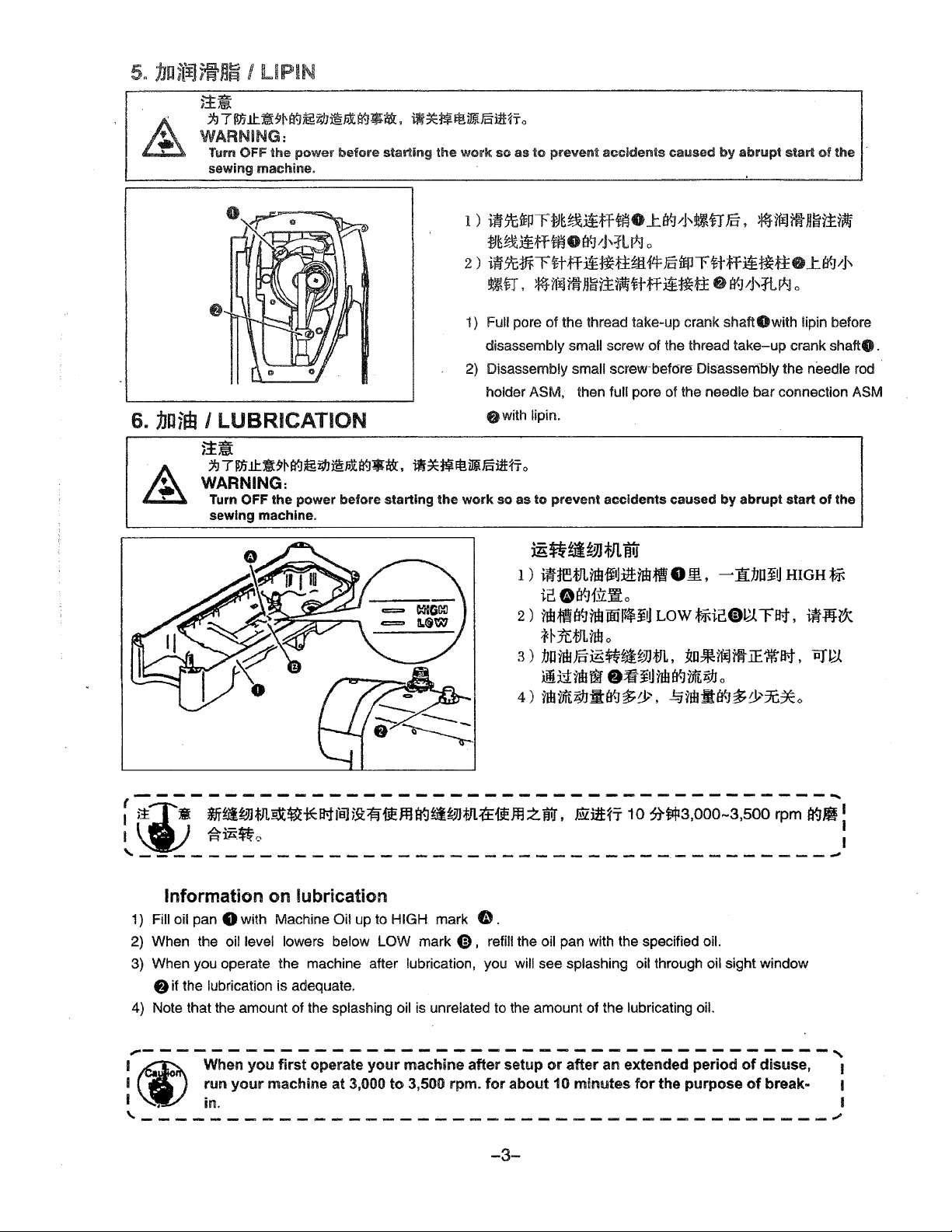

6.

1JIHW

I LUBRICATION

j!~

1) Full pore of the thread take-up crank

disassembly small screw of the thread

2) Disassembly small

holder ASM, then full pore of the needle

9with

lipin.

screw-before Dis-assembly the needle rod ·

shaftOwith

~7•~-#~~~-~~•-,•~N-~~mfio

WARNING:

Turn OFF the power before starting

sewing machine.

the

work so as to prevent accidents caused by abrupt start

m~~;,JJtJUtr

1)

ifHf'.tJLnb{itl:ittnb:ffN

811L

~

ic0891:V:~o

2)

nbffis{Jnblffi~J~

Low

t~icCD~.rFat,

~H:tt:tJLhBo

3)~nh~~~•wm,~•Mm-~nat,ey~

Ji.~ntJTM

4)nb~l9J-~~~,~ntJ•s{J~~x*o

Oifi~ilbaqvftigj

o

take-up

bar

connection ASM

1[1JOJ~

HIGH

lipin before

crank

shaft9

of

the

fj

i1i-NIX

.

~-----------------------------------~---~

f

{iji±

ii

tfr~~JWlrot~*B-tfsJ5j:1if-fiEJ:JHt~tif~JJffi.tt-fifflZwJ,

I

A•-t:

1=1

'IA~~ o I

Eilnrfi-

10

~tqt3,000~3,500

'------------------------------~---------~

Information on lubrication

1) Fill oil pan 8 with Machine Oil up to

2) When the oil level lowers below LOW mark

3) When

4) Note that the amount of the splashing oil is unrelated to the amount of the lubricating oil.

,----------------------------------------~

I (I) When

I

I , in. I

you

operate the machine after lubrication, you will see splashing oil through oil sight window

8

if

the lubrication is adequate.

you

first

run

your

machine at 3,000

operate

'-----------------·

HIGH

mark

0)

your

machine after setup

to

3,500 rpm.

----------------------~

f.b

.

, refill the oil pan with the specified oil.

or

after an extended period

for

about 10

mintl.lltes

for

the purpose

-3-

of

of

rpm

a9J!

disuse, I

break- 1

1

I

Page 8

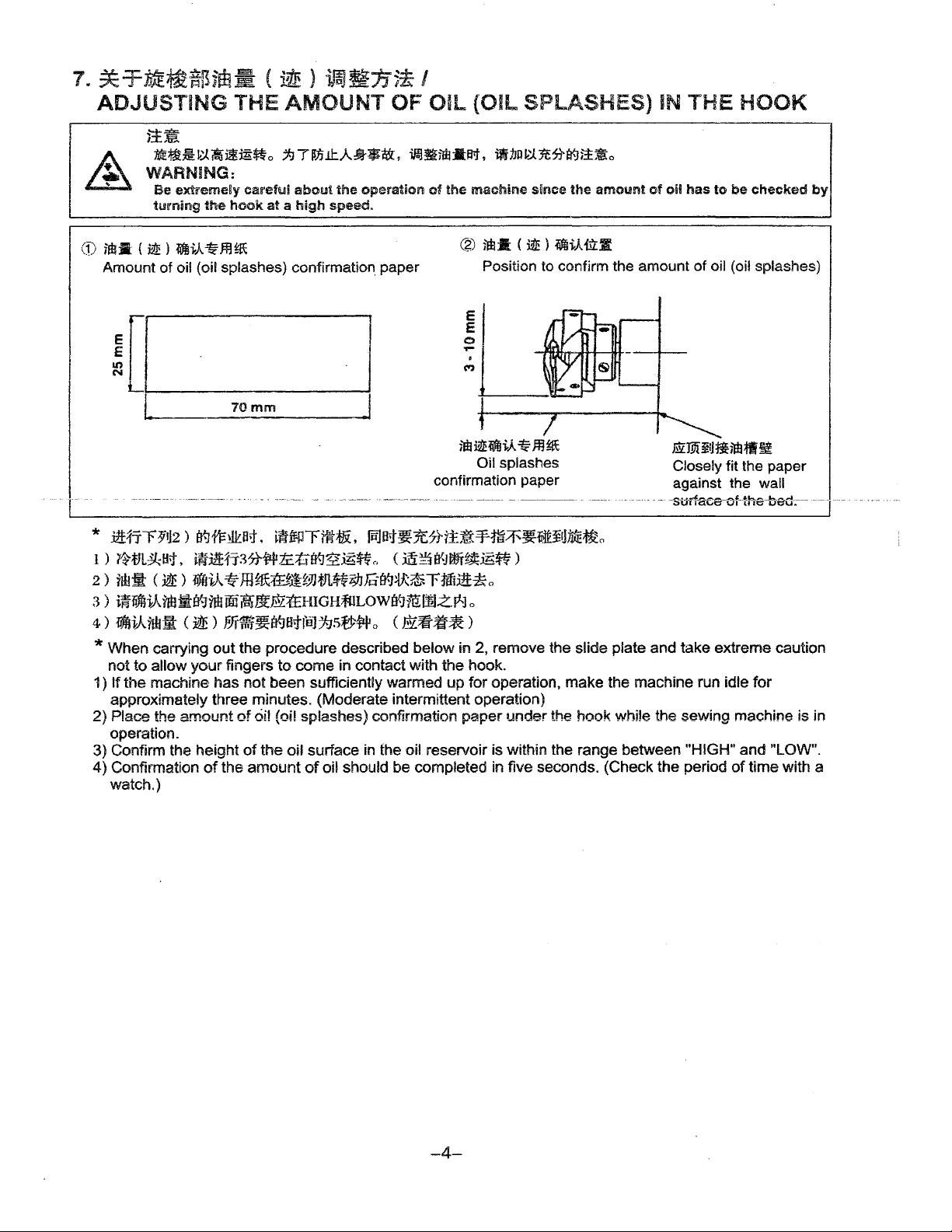

7.

*-rME~if~jf.E;;_

ADJUSTING

)±~

A :tdi~~

~

CD

WARNING:

iitl:R

(

i2! ) ?imi..A.

Amount

!

[i------

~:,i

Be

extremely

turning

the

-:ti

of

oil (oil splashes) confirmation. paper

THE

iti

~mtt

careful

hook

ffl~

_

70mm

(

~

)

ifaJ~:tf5*

AMOUNT

o

7-J 7 fIJJ

.tl:..A..

about

the

at a high

speed.

OF

Ji½

•t&,

operation

iJfJ

____,

/

OIL

{OIL

~im :lta-t,

of

the

machine

@

E

E

0

,..

.

(">

SPLASHES)

ii

nn

~

1t

,-h¥.H±~

since

im:Ji

(

iW!

)

iiffii-A

Position to confirm the amount

the

fil:lt

o

amount

of

IN

oil

THE

has

HOOK

to

be

checked

of

oil (oil splashes)

by

imi2l!i'Mi-A

Oil splashes

confirmation paper

-------

-----· -------

-----------

* .i!!fr~1~2 )

l ) ,ttJL~B;j,

2 )

ilh:!i

3 )

iffiiffiAnbili¥-Jnbffii~~Mt£HIGH~LOWEY-Jm:l:m~~l

4)

~i-Arru:it

* When carrying

not to allow

If

the

1)

approximately three minutes. (Moderate intermittent operation)

2)

Place the

operation.

3) Confirm the height

4)

Confirmation

watch.)

B'-11'1:~at.

~i:itt1iMtl1flic.tiEF-J~.6~(,

(

3dE

) iffliA-tf-JH~Miii3Jffl~;tJJciatf~~rM31r* o

()Qt)

EJr1Rr~~Htfe)7-15f'P~o

out

your

fingers

machine has

amount

of

the

t1tmrflt;fii, ~at~1EtHi:~¥m~~ittitlnte1Jt,

(

m~e'~~~-6~)

( EY~ff*)

the procedure described below in 2, remove the slide plate and take extreme caution

to

come

in contact with

not

been sufficiently warmed

of

oil

(oil splashes) confirmation

of

the

oil surface in the oil reservoir is within the range between "HIGH"

amount

of

oil should be completed in five seconds. (Check the period

o

the

hook.

up

for operation,

paper

~

ffl~

under

mlffiitltiiJHtl~

Closely fit the paper

--------------s-ti-rl-aee--cHhe-be-d-.---

make

the machine run idle

the

hook

white the sewing machine is in

against the wall

of

for

and

"LOW".

time with a

______

T

___

-

-4-

Page 9

•

im ~ (

hA.ttff~~~l±l*a{]im

)W-~~

Appropriate

im ~ )

( ,J,)

amount

~~tj;-ft

I Splashes

1 mm

of

oil

J..Atdt~~~tf:l*a{]jfil I Splashes

2mm

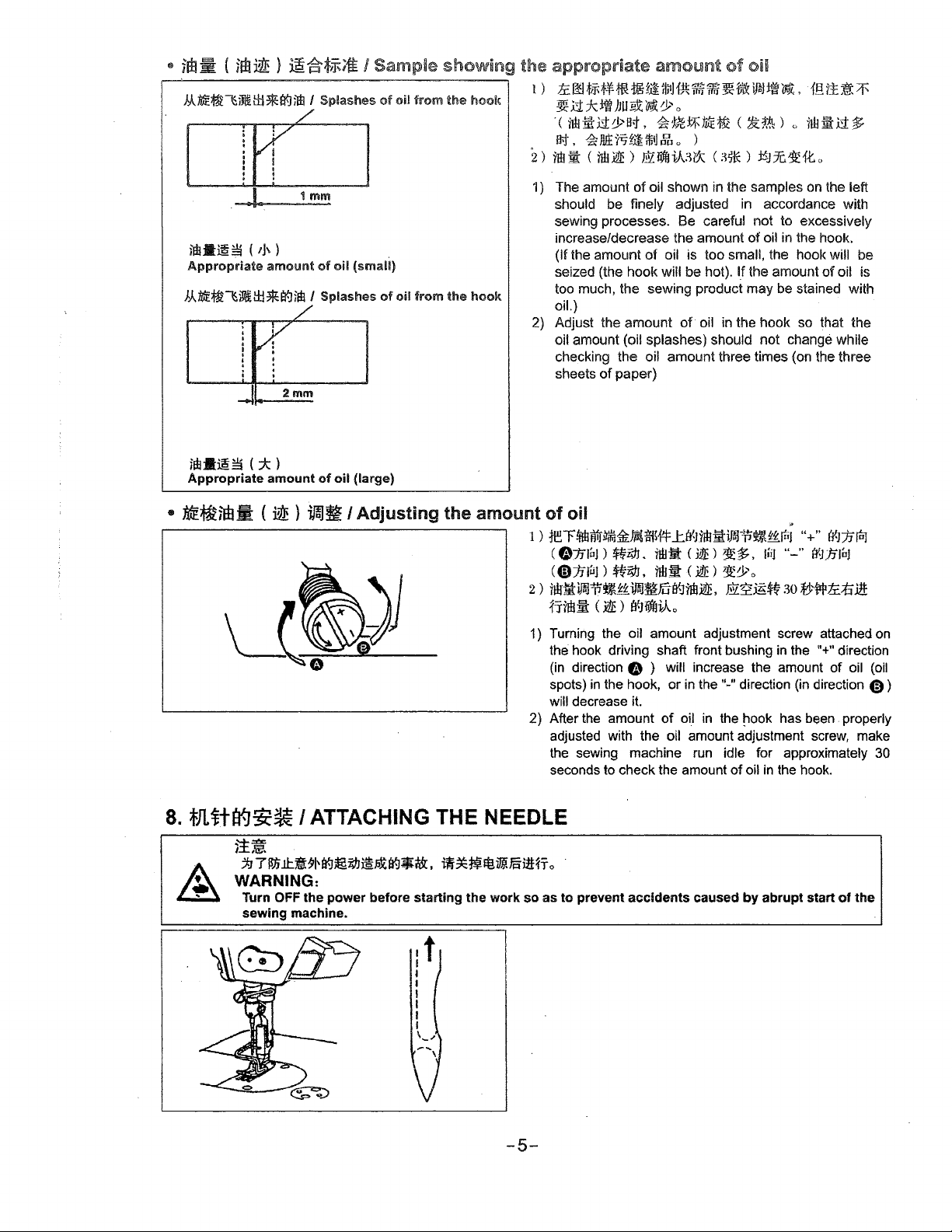

/ Sample showing the appropriate amount of oil

1)

of

(small)

of

oil

oil

from

from

the

the

hook

hook

ftoo~~m~~~~~~~~~~~.m~~~

~.u::k:lft

. (

11H

IJ;J,

2)

rmm

1)

The amount

should be finely adjusted in accordance with

sewing processes. Be careful not to excessively

increase/decrease the amount of oil in the hook.

(If the amount

seized (the hook will be hot).

too much, the sewing product may be stained with

oil.)

2)

Adjust the amount of- oil

oil amount (oil splashes) should not

checking the oil amount three times (on the three

sheets

)JUliX:~0>

ill

.ct

0>

B;j-

~

Jlltt5t.i1ffi!J

c

¥1ff

JQ'E)

of

paper)

0

,

~

'.l;?t

~

ME

it&

( ~ t& ) ()

g O )

~liffj-j,,A~,x

of

oil shown in the samples

of

oil is too small, the hook will be

c

~*)

l_f

in

the hook so that the

ilH

~Jx.~fto

on

the amount

change while

ii

.u

the left

of

oil is

$

im•~~

Appropriate amount of oil (large)

•

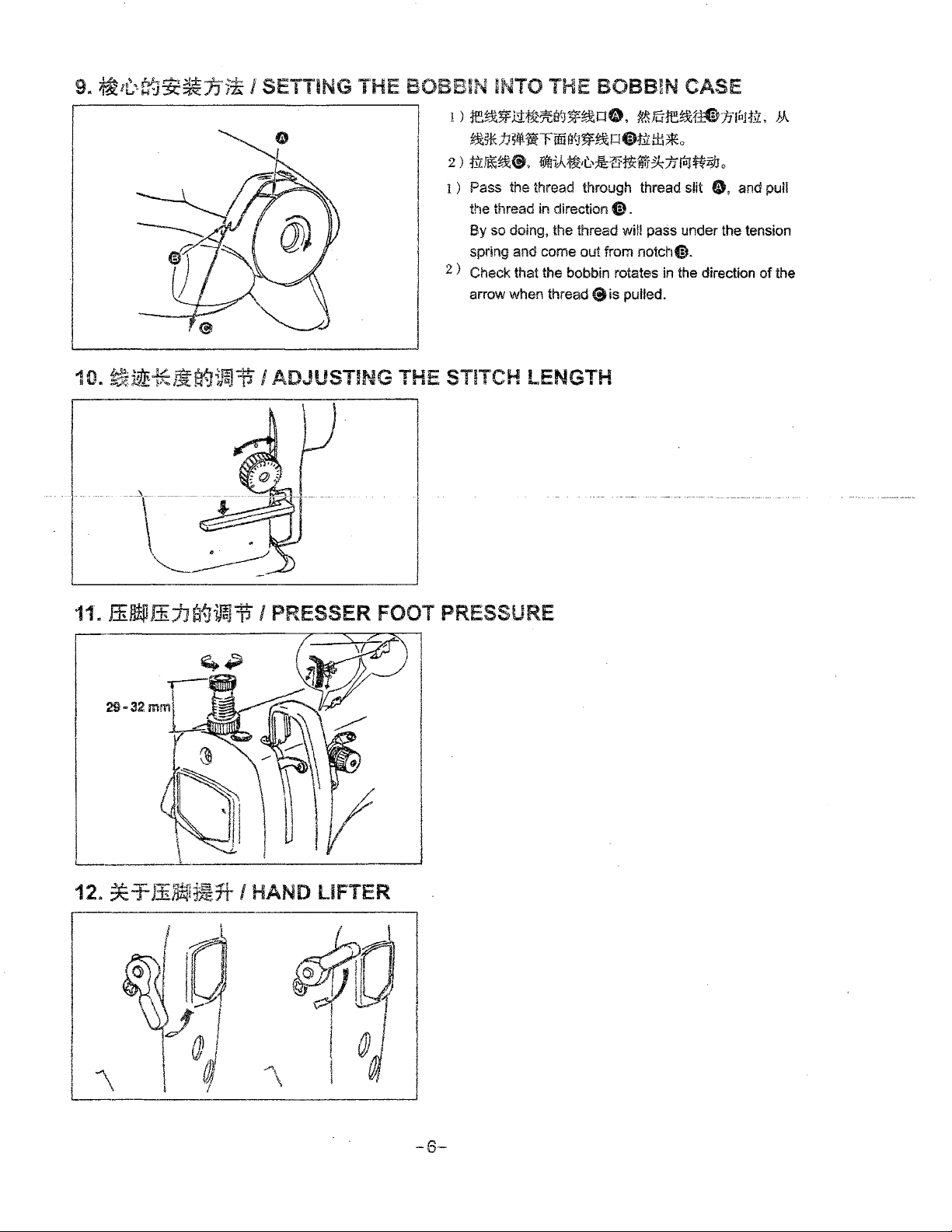

ME~im:m:

( * l

(

~ ) ~~

/

Adjusting

the

amount

1 )

of

rer~tr«irJ1Jmfi'i~tr1Wt=

(

01.ilnJ

C«D:nruJ)

2 >

rlkltl)lJ,'rij{~iiJiJ~FuB'1'imi2E,

frnll

1) Turning the oil amount adjustment screw attached

the hook driving shaft front bushing

(in direction

spots)

will decrease it.

2) After the amount

adjusted with the oil amount adjustment screw, make

the sewing machine run idle for approximately

seconds to check the amount

8. *llita{J~~ I ATTACHING THE NEEDLE

}±~

·~

, WARNING:

•

j;j71Jjjll:.~9~f,J~WJ1§~r-J•tt.

Turn

OFF

sewing machine.

the power before starting the work so as

-tff~Hf~vi.lEiiltJro

oil "

..tB'1nai!:iJWn~~t

)

~igj.

rwiit

<

.i1E)

1t~,

,,iJ

~zYJ,

11Bll'

<

JdE)

~:Po

m:~~~

:m:

(

.i1E

>

tr-J

iifffi-A

o

O ) will increase the amount of oil

in

the hook, or

to

prevent accidents caused

of

in

the"-"

direction

oi_l

in

the ~ook has been. properly

of

oil

in

by

abrupt start

rt1

"+"

t't1Jiful

.. _ ..

EY-J.fflnJ

30 tY~ti.;tiilt:

11

in

the

+"

direction

(in

direction

the hook.

of

on

(oil

C,)

30

the

,t

I

I

I

I

I

I

I

\_.,

-5-

Page 10

g_

~1t\og~~1nt I SETTING THE

BOBBIN

INTO THE

BOBBIN

CASE

1 ) re~~;1~~rt-J~~PO.

~s*h5ltl

2)

t.v:r~~@.

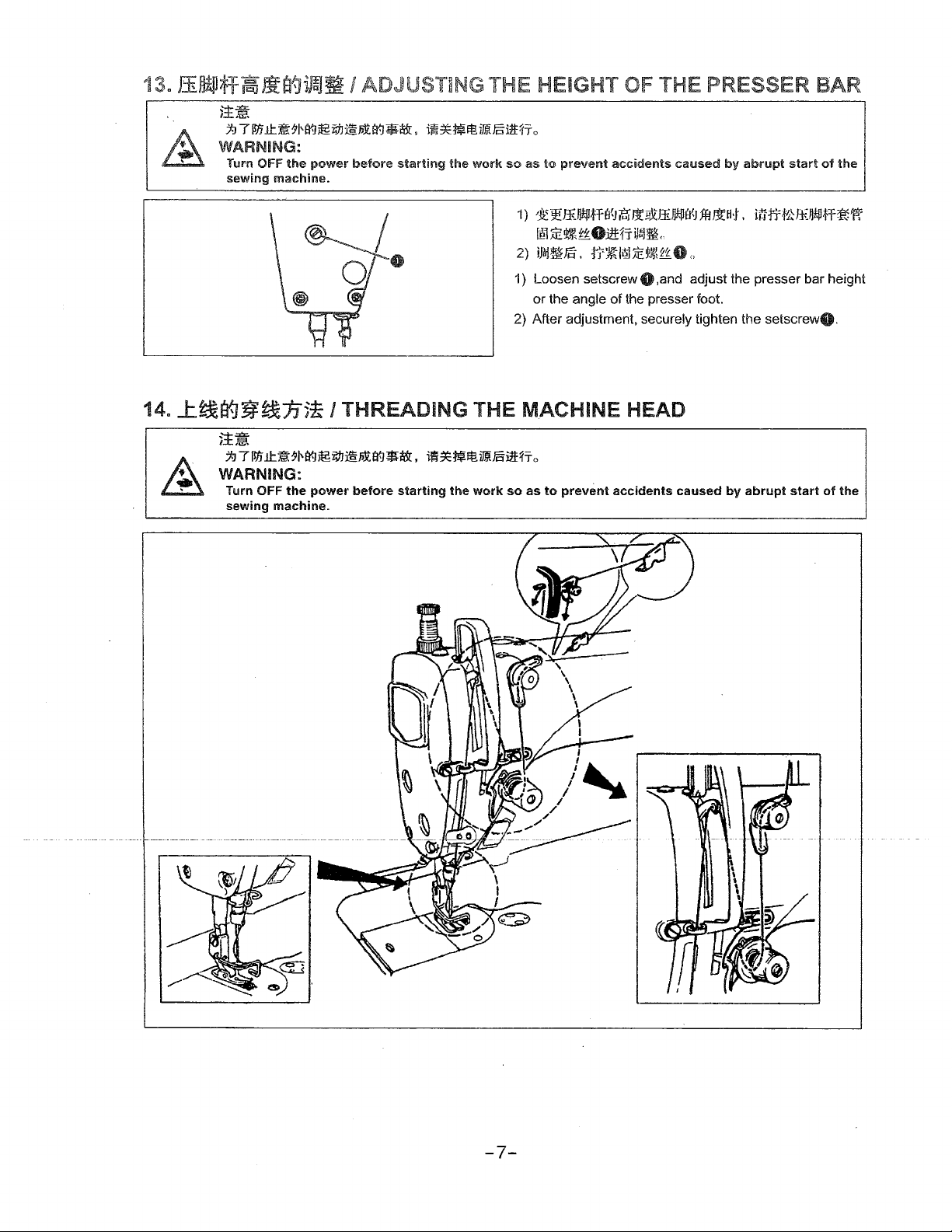

1)

Pass the thread through thread slit

the thread in direction 8 .

By

spring and come out from notch@.

2

) Check that the bobbin rotates in the direction

arrow when thread

10. ~~tEJ~agi~"ii I ADJUSTING THE STITCH LENGTH

,\•

''"

~

OJ

-• -••••+•••-•-••H

\

IJ

.

ti

iffoo

1iJfri-,A~,t.--¾tHi~~1ftoJtti9Jo

so doing, the thread

\"--

?&Fure~M»:nruJtiL,

1¥-J~t%o@Ht:

$is

tiB~o

wm

pass under the tension

pulled.

ti,

JA

and pull

of

the

11·.

ffifft.Pl.:b.:ha{J~,t I PRESSER FOOT PRESSURE

/d

~,.,111

~a

0 I

-,

al

\

-~r

If f

~

I

@

I

-6-

Page 11

13.

ffiOOff~Jla{Ji)aj~

~·

;1:JTm~•*~~~@-~-~.-~-~Bfilmfto

WARNING:

Tum

OFF

sewing

the

machine.

I ADJUSTING THE HEIGHT OF THE PRESSER BAR

power

before

starting

the

work

so

as

to

prevent

1)

~~ffi.f}!jlffa{J7$ijOocffiJJkl]B'~fl=J~M.

accidents

caused

!i!'lm:~t~Oilf:f=rU~f&"

2)

iJMm€.

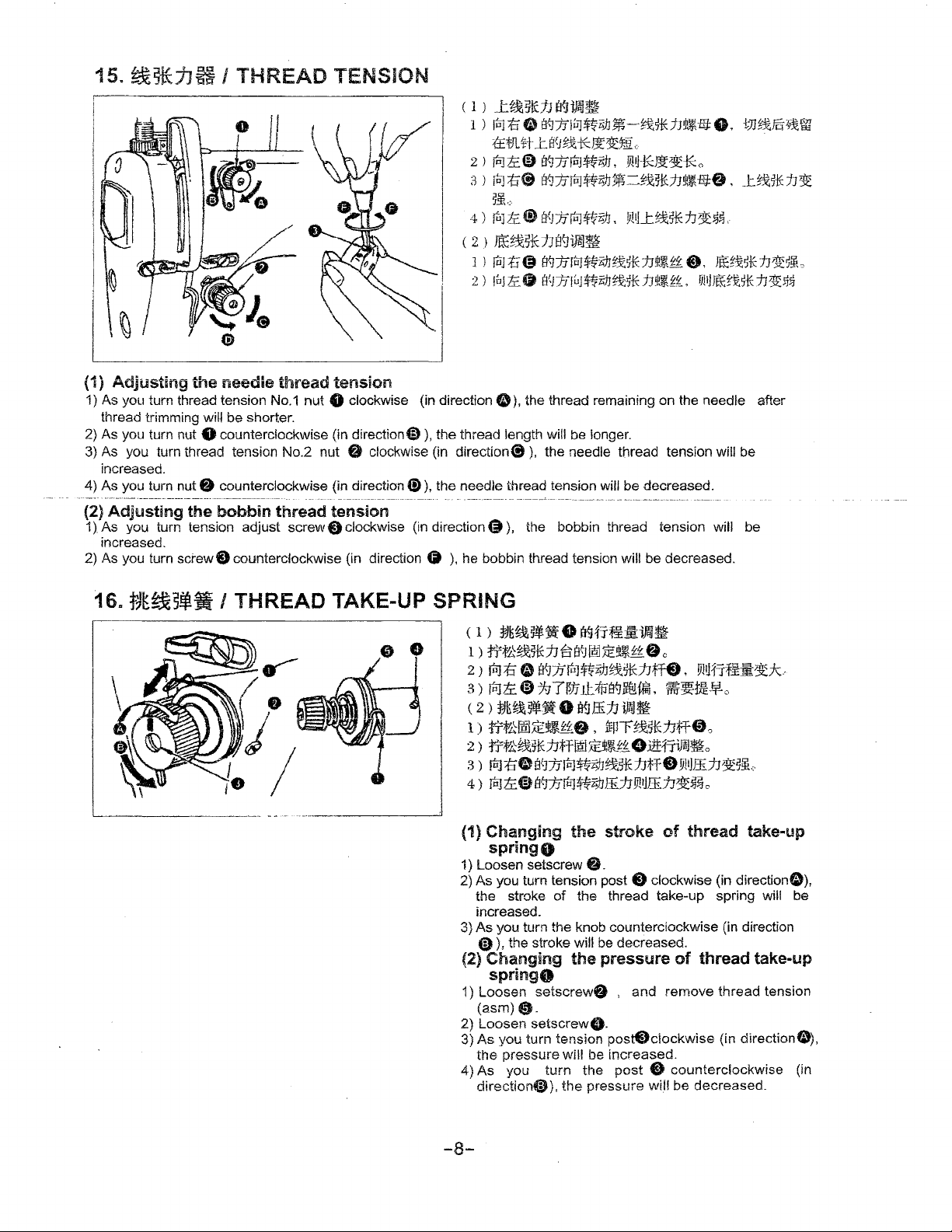

1) Loosen setscrew O ,and adjust the presser bar height

or the angle of

2) After adjustment, securely tighten the setscrewO.

tr~l~~~~~O"

the

presser foot.

14. 1:~a{J~~JJ51 I THREADING THE MACHINE HEAD

j!~

;/:J

TM"1J:JUHr-J~~m-tr-J$i&,

WARNING:

Tum

OFF

the

power

sewing

machine.

before

iU~J~~~mmfi-o

starting

the

work

so

as

to

prevent

accidents

caused

by

abrupt

start

itrtrt-'Jlt-]!ilH~~

by

abrupt

start

of

of

the

the

/

/'

-·-

~--•-.s•--•

---------·

-7-

Page 12

15.

~~*:h~

I

THREAD

TENSION

( 1 ) J:~s-itn

1)

luJtrG

tEtllH

2 )

fPJtr:tD

3 >

fuJ

~Ha.:.

4)

ruJti.

( 2 )

~~5f

1 )

rt1:tt@

2)

1tJt:c.O

(1)

Adjusting

1) As you turn thread tension No.1 nut 8 clockwise (in direction O

thread trimming

2) As you turn nut

3) As you

increased.

4) As you

- - . -

(2)

1).

2) As you turn

----------·----•------------·····----

Adjusting

As you turn tension adjust

increased.

the

needle

wiU

be

thread

shorter.

tension

8 counterclockwise (in direction@)), the thread length will be longer.

tum

thread tension No.2 nut O clockwise (in

turn nut O counterclockwise (in direction(!)), the needle thread tension will be decreased.

the

bobbin

screw9

counterclockwise (in direction O

----------------------------------------------

thread

screw&

tension

clockwise (in

direction(!)),

-

----------~----

direction~),

),

he bobbin thread tension will be decreased.

a{J]ij]~

B'.JJJlu1$¼iJJ~--~t5-IUJ!Pl-E;J:0,

J:.s{Jt~*1Jr~~1L

B{J7Jfn]~iJJ,

1:18

BkJ::iJfoJ!t~zifl~=§'~8-lth!Pl-E;J:0

®

s<Jn(u1$~iJJ,

::1J

89-iftu~

s~nrtJ$tRJJristE:fJ!l'J£t

sZ1frruJ$~iJJ~stEJJ!11Ji~,

),

the thread remaining on the needle after

the needle thread tension will be

the bobbin thread tension will be

WU*J3t~-ff:o

,

vrn_t~5-!E:fJ1t~t

e,

ntEttstE1J~5lL

m1JJ!tE~s-lf:n1t~ScJ

---•--·----·--

tJJt%€fl'fil

_UM~

1J1t

16m

tJK~s-'ti

/ THREAD TAKE-UP SPRING

< 1 )

~~~~•

..,--

f)

I

I

0 •

1 )

trt0~s-K:1J ~ a~

2 >

roJti

3)

foJtc@>

<

2)

};J~~stif

1)

rrt'llmJEtJ~f'.8, ffPT~1*1Jff0"

2 )

rrtl4%sKfJH!Et1

3 )

!oJi:t&

4)

foJli:@Hl97IfP1WzifJ&JJ!i!tlffi.JJ~5Jij

(1) Changing the stroke

springo

1) Loosen setscrew

2) As you turn tension post 8 clockwise (in directionO),

the stroke

increased.

3)

As

you turn the knob counterclockwise (in direction

@)),the

(2)

Changing

-

springO

1) Loosen

(asm)

2) Loosen

3)

As

you turn tension

the

pressure will be

4) As you turn

direction~),

e tt9frfiS:iM1~

1m

5E~l

t~ o c

o

091.ftoJt'½'ziflii1-K:1Jt=f8,

7'J

7~JJ

ltJtIErt7R1Mi,

O ~ffi:f.Jiij~

~l

ti'.

ag1.fftJWzifJ~stE:1JH8

49.

of

the thread take-up spring will be

stroke will be decreased.

the

pressure

setscrew&

, and

fit.

setscrewO.

post.9ciockwise

increased.

the

post 8 counterclockwise

the pressure

~~tJtfrl.o

OuH-=tiJll~o

of

of

remove

wH!

be decreased.

Yltifr:f¥_m1£.:k.-

YWffi.n1£~!iL-

o

thread take-up

thread

take-up

thread

tension

(in

directionO),

(in

-8-

Page 13

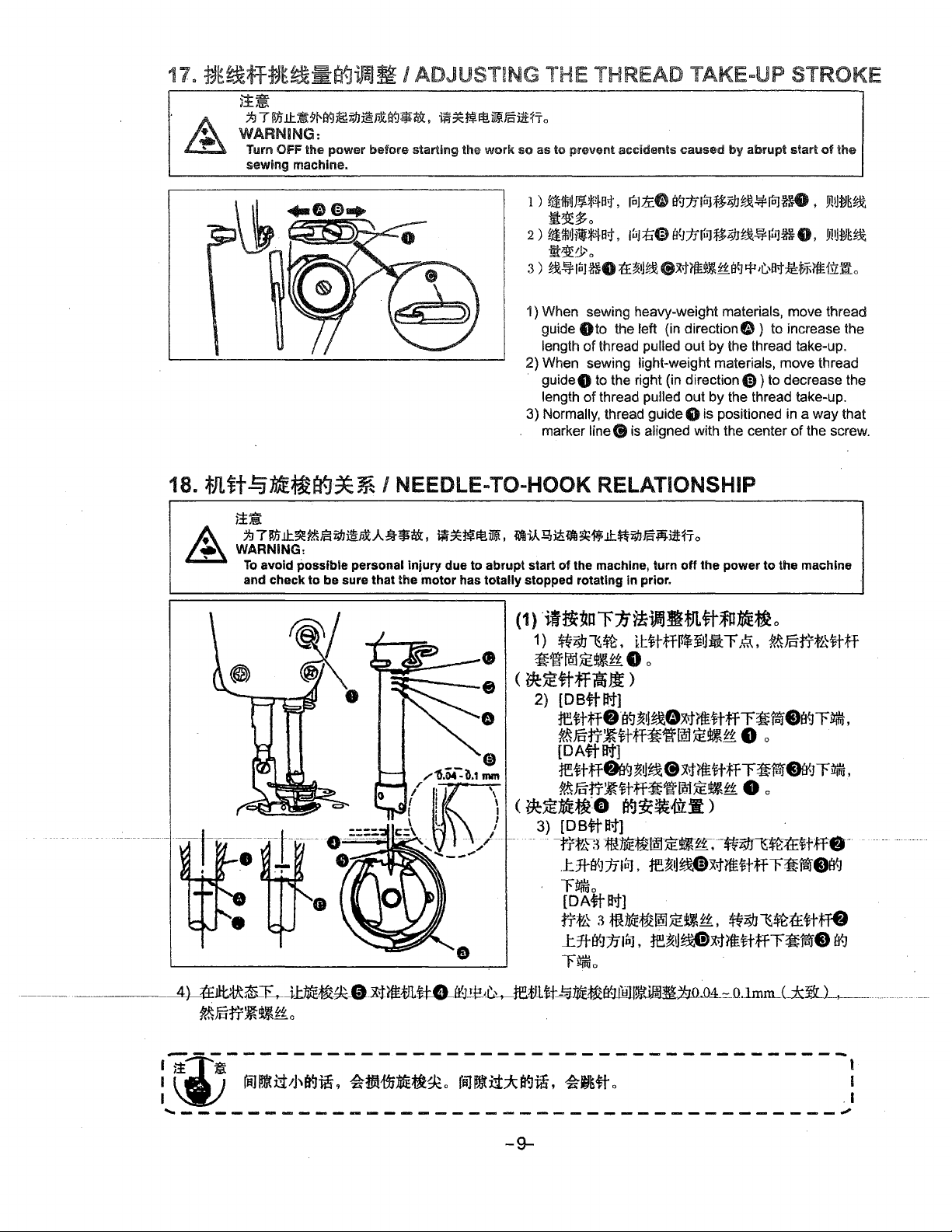

17.

~~~~~~~.ma{]ifaJ~

)±~

~7~.ll:.•#~~~~-~•tt.

WARNING:

Turn

OFF

the power before starting the work

18.

sewing machine.

*Jttt

~ttfE~a{J~~

it~

,A

~

j_J7~ll:.~m~i;tJ@filA~•tt,

WARNING:

To

avoid possible personal injury due to abrupt start of the machine, turn off the power to the machine

and check to be sure that

I ADJUSTING THE THREAD TAKE-UP STROKE

■

~N~D§mfio

so

as to prevent accidents caused by abrupt start

1)

iiiittJJ!J~a1,

ro1ti:O

Ef.JnlPJf:t;tJ~~icJd,

of

v11J~t~

~1t$o

2)

f;UJ,J1'~a-t,

1uJ1:16>

H'~JJfulli~~~1tJ1~8.

Y11JfJE~

fi~:P 0

3 )

~%

loJ

~-

t£~1J~

8~7fUI

1) When sewing heavy-weight materials, move thread

Oto the left (in direction O ) to increase the

guide

of

length

2) When sewing light-weight materials, move thread

guide8

length

3) Normally, thread guide 8 is positioned in a

marker line

thread pulled out by the thread take-up.

to the right (in direction

of

thread pulled out by the thread take-up.

8 is aligned with the center

£~

a<J

i:r

,(:.,a,j

Ci))

to decrease the

:M:tii'1£1irfL

way

of

the screw.

I NEEDLE-TO-HOOK RELATIONSHIP

~~~ij!j}j,

the motor has totally stopped rotating in prior.

~i,kQ,Jii~~ff;ll:.~f;fj.g~ii!fio

the

that

--~4)-~Jlt!lt~~-il:1iti~-~-0-:xitt111.-t±e-fr~lk&,-retJUt_!J_11fe~EfilM~~j;_Q~o_4_~_n.1mm___(_±it_L_,_______

M.15tr~~£f'.

o

-9-

__

_

Page 14

(1)

Adjust

1) Turn the handwheei to bright the needle bar down to the lowest point

(Adjusting

2)

(For a IDB

(For a DA

{Adjusting

3)

(For a DB

ascending needle bar with the bottom end

(For

ascending needle bar with the bottom end

4) After making the adjustments mentioned in the above steps, align hook blade point e with the center

needleG. Provide a clearance

then securely tighten setscrews in the hook.

[

~-

i

the

timing

the

needle

needBe) Align marker

thentighten setscrew

needle)

then tighten setscrew

position

nieedie) Loosen the three hook setscrews, tum the handwheel and align marker line

a

DA

needle)

- -

!f~h-;

specified

sidppfing

Align marker linee>on needle

Loosen the three hook setscrews, tum the handwheel and align marker line G on

cle-;,;;

value,

wm

betweero

bar

height)

8.

9.

of

the

hook

be;.;e;

the

result.

the

needle

!ineOon

f))

of

0.04 mm to 0.1mm (reference value) between the needle and the hook,

llie-

blade

point

and

the

hook

as

needle

bar&

with the bottom end

bar&

with the bottom end

of

needle bar lower bushing

of

needle bar lower bushing $ .

bfia;

of

hook

;;nt;

wm

ho;k

be

damaged.

follows:

of

its stroke, and loosen setscrew

of

needle bar lower

of

needle bar lower

f)

.

~;.

~,;;

If

the

;;e;d;;

clearance

i;

;,;.;

is

larger,

'----------------------------------------

19.

~=Ai~~~~

I HEIGHT OF THE FEED DOG

8.

bushingf)

bushing&

€)

on

of

fua-;;

ihe-1

stitch

,

,

I

I

.,,,,....,

eaz=r.

....

- - -

If

i

\

____

20a

~

the

~~3fa{]ftffi:~ I TILT OF

~~

WARNING:

....

--=:.

-

the

motion

calmping

~

pressure

of

b,!C2_~S_.!1~'2'·-

::J.J

7 flJ.LI.tiO~l'f.l~ilh@Pli'fl*tt,

Tum

OFF

the

sewing

power

machine.

0.8-0.9

- - ue:111'

the

forked

________

before

mm

aa.D

- - - -

tis

insufficient,

portion

THE

~~~1$JJtsiUT

starting

imi7

Q) tr~~-tT~;ffr.~3;!_ 9 Et~~ffi'l~~~-

®

@

,-------------------,

1

~

~

-------------------✓

To

~

adjust the height

CD

i

® Move the feed bar up

!

® Securely tighten screwf).

I

FEED DOG

o

the

work

so

as

.iliifti

.sFa<J?J!i~at

J:

r~~*~f1ittfi~i1

tr~reti~~tt8

ii

it

miffiJJ

1t~~mT

Loosen

to

prevent

screw@

accidents

,,

o

0

i:UO~ffi",

o I

of

the feed dog:

of

~

.,f

3'l

~

~;JJ fi:

crank

t)

.

or

down to make adjustment.

ca1U1sed

by

abrupt

start

of

Ji!tl

the

~

I

0

~)ft

0

G

wJJ.:.

wrF

/ Front

/ Front

up

down

E) tt:fii / Throat plate

/ Standard

-10-

Page 15

~-----------------------------------------,

I

it

II

I

I J

~

- llillllllll!l3 -

1) 'The standard tilt (horizontal)

2)

3)

~~7*$~ZFA,m~ffi~~~~~~~,~~~~~o

-.:I

- - - - - - -

aligned with marker dot

shart by

To

feed bar shaft

To

shaft 90°

90°,

as standard).

tilt the feed dog with its front up in order to prevent puckering, loosen the setscrew, and tum the

90°

tilt the feed dog with its front down in order

in

the opposite direction from the arrow. (The standard tilt for.)

...

- -

~

- - - - - - - - - - - - - - - - - - - -

of

the feed

CD

on feed rocker O . (the marker dot@) inclines forward the feed rocker

in

the direction of the arrow, using a screwdriver.

dog

is obtained when marker

to

prevent uneven material feed,

....

-

dot

G on the feed bar shaft is

tum

~

the feed

- -

I

I

~

bar

~-----------------------------------------,

I

I

Whenever

necessary

the

to

feed

check

dog

the

tilt

is

height

adjusted,

after

tilt

the

feed

dog height

adjustment. I

will

be

changed. So,

it

is

I

'--~~-------~--------~--------------------~

/ ADJUSTING THE FEED TIMING

~-

~7~~~~~~~~A~•tt.~~~~~,ffl~~~~~~tt~~~~~fio

WARNING:

To

and

--~--

avoid

check

possible

to

be

personal

sure

Injury

that

the

Standard feed timing

~

.is4fifflul~mf

Advance_d

0

( j,;:{j;fflf,L!fl;)g

~=

Delayed

=+=

due

motor

:fitff

feed

feed

to

abrupt

has

totally

timing

timing

-

start

of

the

machine,

stopped

1)

2)

rotating In prior.

rN1~*~~,t.,8~0EBffiHE~tt

~~~&-~~~-~*$-~8~,~~~

ffij~~fio

~$~~&~¾*$~~tt~T~~.*m~L

00 ~ tHL.r.t41tx-t

3)

•~*$fflm~~~$MM~,M~&~~~-

~*tliffi,t.,

4)

~7~»a{J•~~-~fflm~.•~•~~~•

;tJ{fU"',8~a

turn

$ ttif1i_t iii

8/(e

0

off

the

power

a{J

1ft:i:

to

8,

the

o

machine

8,

~•~

··

···

·•-----

------· ·--1TToose·n

the

For

2)

eyelet

3)

To

cam

4)

To

opposite,

:,...

~

I

~

.....

- -- - - - - -- - - -- -

screws·•

arrow

or

the

standard

are

flush

advance

in

the

direction

delay

the

direction

Be careful not to move the feed eccentric cam too far, or else needle breakage may result. · :

and

opposite

adjustment,

with

the

the

feed

feed

timing

from

o-ifffeea

direction

top

surface

timing

of

the

arrow.

in

order

the

arrow.

·ecc·enfric

of

the

arrow, and

adjust

so

of

throat

in

order

to

increase

-.

- -

·c-~im

e-

,-move··mefeecJ

firmly

tighten

that

the

top

surface

plate

when

the

to

prevent

....

-- - - - - - - - - - -

stitch

uneven

tightness,

of

feed

material

the

feed

dog

move

·eccentnc·c~fm

screws.

dog

and

descends

feed,

move

the

feed

--

the

top

below

the

eccentric

...., - -

·

in

the

-11-

tne··mrecfion

end

of

throat

feed

cam

~

-

--

or· ---

needle

plate.

eccentric

in

the

- - --

J

Page 16

22.

~*.&1¥Jila.l~

~~

7;J

; WARNING:

Turn OFF the power before starting the work

sewing machine.

7

I ADJUSTMENT OF THE

ltti

.it~

1Nt-.1

~~X§'.PJt 29~$: ,

~~~It!

· I

PEDAL

~J5i!fi

o

so

as to prevent accidents caused by abrupt start of the

(

1)

,t*~~~~

I )

fulf.r~::irrtJ1tisiJ~ffi:ijijT,iffi:

.itmtt.

(

2)

•t]itt-Jjn)jf

1 )

iJ~11itmHs~*lfHJtufgl_

~o

2)

trfliJ~il~li~G, iilili!mA~mH 8111:fi-~~o

(1}Installing the connecting rod

1) Move pedal 8 to the right

the arrow so thtat motor control lever

connecting rod 8 are straightened.

(2)Adjusting the pedal angle

1) The pedal tilt can be freely adjusted by changing

the length

2) Loosen adjust screw 8 , and adjust the length

------

-eewifleefn"l§-md-8-~-

¥.-1t~o

of

the connecting rod.

8,

iJ:~~tt;f:f -

Fl

r:a:ttf!&i3£Mtt&B'-Jftw~JJ.

or

left as illustrated by

~

8 and

of

(1) The pedal is operated

1)

The

2)

3)

The

The

machine

machine

machine

runs

at

low

runs

at

high

stops {with its

in

the following four steps:

sewing

sewing

speed

speed

needle

up

when

when

or

down)

you lightly

you

( 1 )

lfil}i~41'rm-&j£fifflf1:

1 )

1°J

wJ~~~iif :f&A1~.ilffitl6) o

2 )

WfflnrtJwr~~:f&YW~~ifli~f;tt1JGo

3)

re~~fulftlJJt.lJ~~:itl!:li!{itl~l&_tfl'-JfiziUl

further

when

mm~1r.eo

depress

depress

you

reset

the

the

the

c

front

front

pedal

0

mt+

tWlt~r~ll:ffiit)

part

of

the

part

of

the

to

its original position.

pedal.

pedal. G

CD

(9

-12-

Page 17

24.

~!ktl=f~fflJtif

I

ONE-TOUCH TYPE REVERSE FEED STITCHING MECHANISM

(1)

How

to operate

1) The moment switch lever 8 is pressed, the

machine performs reverse feed stitching.

2) The machine performs reverse feed stitchng as

long as the switch lever is held pressed.

3)

The machine resumes normal feed stitching the

moment the switch lever is released.

WARNING:

.___

____________

==-----]

_____,

Turn OFF

work

by

abrupt start

(2)

Height

1) Adjust the height

easily operated.

(

l)

1!ffl

1 )

tJHf

2 ) rtrfttiffstJatfaJ,

3 ) 1nGfttff,

of

jJ

~

*f£iff

the switch lever

8 ,

911Jif.~Pis@IitliEflo

the

power

so

as

to

prevent

of

the

of

switch

lever8

fJ'!i3JVL.:fr.l:tP~:h71i

PJI».:iHJriftJf.iio

before

starting the

accidents

sewing machine.

so that it can be

1

1*

caused

,

Jt!:fiimil

o

25.

Eg-r~~

Jt~

1-1

T

WARNING:

Turn OFF the

sewing machine.

I

ELECTRONIC

!S'h

J.l:.~~Hfl~i;f:l~PXl¥.f~~,

power

before

CLIP

starting the

WIRE

iN~Jf~imtJ§ni:fi o

/2\

ill

(

2)

1 ) iltEfF:¥:t.Uf8a{J~JJt~~J1J~fflJJ~agfftila

work

so

1)

2)

..

II

,&

i£

,93:f,.

jf3cf£::f.f~~Jt

as

to

prevent

Electronic

Electronic

accidents

1;J

7

WJ

lr..

*

~~

if*~~iffifflltfrr

caused

clip

clip

wire

wire

by

8

& open

;Jj

niJi\t

o

abrupt

~

start

as

*Mr

9

of

the

lmm,.,

·-1

-13-

Page 18

26.

-~ffi~,

~~

J:J

7 ~ .tl:.~5'Hl9~i;iJ~~B9¥?&,

WARNING:

Turn OFF the power

sewing machine.

~~}®!~

DISASSEMBLING

~*tf

lt~Fcillff

before

starting the work

so

OF

OPERATION

~'

as

to

prevent accidlents caused

PANEL

by

abrupt start of the

Disassembling

<Qf!-

{00~@@®@0~:

I

®@0000&11~

1.Use needle

to

--

open

steps

a.b.c.

:1

~';

~

-

•

: ®

@@(±)

®eeee

2.

*-2*-2~3f~~ffil&A.

---

------------

$J[a{tr.~.

2.·

operation

see

the

3.Twist

screw

down

panel a.

the

B.

b.

screw

r::::nn

C.

,ffl~,

c.

•..

"

Jlf:fjil

place

To

4.Remove

~zvil

Install

the

assembling

first

the

the

of

operation

steps

operation

disassembly

•

panel, Set

panel according

after

aside

assembly.

-14-

to

Page 19

0

PARTS

SECTION

- 15 -

Page 20

1

JJl~

MACHINE FRAME&MISCELLANEOUS COVER COMPONENTS

*

9~~

14::

71

j 72

12

50

29

28

2

~-◊--~~

I • I

I ' 1

:s2

~I

I 53-

I

54

L-------

~

--J:

"1

I

I

I

I

73

-16-

Page 21

1 .

FF%

Ref. NO.

l 102.01-01-P

2

3 02-608440421-1

4 102.01-04

5

6

7 102.01-07

8 02-412280923-1

9 102.01-09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28 102.01-28

29

30 102.01-30

31

32 101.01-32

33 101.01-11

34

35

36

37 101.0

38

39 101.01-39

40

41

42

43

44

45

46

102.01-02-P

102.01-05

102.01-06

102.01-10

102.01-11

102.01-12

!02.01-13

02-412281423-l

102.01-15-P

102.01-16

02-512281821-l

102.01-18

102.01-19

102.01-20

101.01-21

101.01-22

101.01-23

101.01-24

101.01-25

101.01-26

02-412280623-1

02-412280623-1

02-611400621-1

101.01-34

101.01-5

101.01-36 :#(:~t/i

101.01-38

101.01-40

02-90940042 l-l

02-815280711-l

101.01-43

101.01-44

02-211400621-1

02-211400623-1

{ct

Part

l-37

Cl

'J

NO.

~

~

ffi~

ffiitlim

~rdJ~~~

oo

:tli~JJ

rm

ti$#

~E~lilf

ffi~fL~

ttnaam~:rL~

~mtttr~~

JfiiH&tin

%~~;j:Ji

Fofilif&

J§-fiJ

tHL~

ffii

~

~tffi

Jt

Face plate

Face plate agsket

Screw 1/8x44 L=4

Arm oil shifld asm.

Rubber

Rubber plug

Three eye line board

Screw 3/16x28 L=9

Cord holder

Side plate

Gasket

Face plate

Description

plug

~~i~jf-:M! Safety label

Po

m

ifJi~

fT

m1c

J!;JBl.

~11

IHL

~

,,1ti~

~~~~tr

fftlttliHJL~ Reverse feed lever stopper

r~lHUl

~~~~~

OO~~~~tll#

oo~~~~ir

~~M~JUJi

/j\~~{!i

/j\~~-

/j\~~~iij:

/J\~~~til-ttt~n

tittJUfWitfl.a

tJt~fflP

~tin

tr~~

~~~~tr

~~~fli1Lt

~~ti-m:

~~iff!J~-ti

~~-

~~~

#(:~~tr

i:Jt~Jl

13lt~jfWJ-=p

~

~~~n~iMt~n

~~$iJtr

tl~$J

H~

n~~n

it~t,n

Screw 3/16x28

Machine cover

Rubber

Screw 3/16x28

Rubber plug

Magnet cord rubber

Thread

Thread tension

Thread tension guide

Thread tension disk

Thread tension spring

Thread tension

Screw 3/16x28 L=6

Thread take-up lever cover

Screw 3/16x28

Arm

Screw 1

Thread

Tension

Rotating stopper

Tension spxjng

Thread tension disk presser

Thread tension disk

Tension post

Take-up spring

Tension post socket

Screw 9/64x40 L=5.5

Screw 15/64x28 L=7

Tension releasing

Throat plate

Screw l

plug

tension asm.

thread guide Right

tension asm.

Screw l

l/64x40

nut

l/64x40

l/64x40

L=l4

L=l8

post

nut

L=6

L=6

L=6

L=6

~

Qty

It

~

It

Note

1

l

1

1

3

1

1

7

1

l

l

l

l

3

l

l

l

l

1

l

1

l

1

2

1

1

1

l

I

1

l

1

1

1

1

1

2

1

l

1

l

l

1

l

1

1

-17-

Page 22

1.tll~

~

9~~ffB14:

MACHINE FRAME&MISCELLANEOUS COVER COMPONENTS

~

61-'f 1

60-~

12

50

a I

29

28

2

I

-

r------.

lo")

I

l '

1s2

I 53-

I

L

_______

~I

~

~ I

54

..

8 9 10

I

I

!

I

I

~

11

30

57

43

,

'

31

~

.;

'

/

4140'

I 38

39

'-

',

',

37

,._,_

36 ,

35

","',

34

~

~

.,A(

'---......,_

~

'--1--·J

32

~

33)

7i

17

18

19

~

1

',

',

~

5261

''

.,_

___

I

I

_J

73

I

I

-18-

Page 23

1 .

ff~

Ref. NO.

47 101.01-47

48

49 101.01-49

50 02-412280923- l

51

52 101.01-52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

02-61140062 l-1

101.01-51

101.01-53

02-606560221-3

102.01-55

101.01-61

02-911400611-1

101.01-63

102.01-64-P

102.09-32

102.09-33

102.09-34

102.09-35

102.09-36

102.09-36-01

102.09-36-02

102.09-36-03

102.09-36-04

102.09-36-05

102.09-36-06

102.11-34

102.11-35

14=

Part

~

NO.

~

~

ii:.~¥-J

ii:.~~~tr

ffiftli~Ti-:JL~

oot&~n

mtlitflWt

;JttJi

tttliiif

tt~Jfffltr

~~Jttt

~3tlff

~mff.~n

~%AA!

~%AA!

t3t~ff.t.H.

t)t~ff.~tr

1

~~ntin

i~~~~tUa#

t]t~

f)t~~~~tr

~~~~JBfti~

g}t~~~~

~~;ii~~

~~~~!l~-ffJ: (

lt!tll.~%

ij!

1

1~n

~~!l;l

mJJ.~

iYP

tr

,flf Bobbin base

-BJ:

lffi

• tr

Ann

thread guide Left

Screw

ll/64x40

Ribber plug

Screw 3/ l 6x28 L=9

Slide plate asm.

Slide plate

Bed slide spring

Screw 3/32x56 L=2.2

Bed

screw stud

Ruler stopper

Screw 11/64x40 L=6

Pole

Model plate

Screw

Knife

Knife screw

Thread

tension asm.

Tension nut

Tension post

Tension spring

~)

Thread

T~ead

Tension nut

Motor

tension disk presser

tension guide

cover

screw

Description

L=6

J

~

It

~

a:

Qty

l

l

Note

2

3

1

l

l

2

4

l

2

2

1

1

3

l

2

1

1

1

1

2

l

1

l

3

- - -----····--

-----

- +

-

--

--

---

--

- ---

--

---

-----

--·

---

----- - ---------

--

----- -

----

-----.

----·-----------~-------

----

-

-19-

----

-

---

Page 24

2 .

.l:$dl

MAIN SHAFT&THREAD-UP LEVER COMPONENTS

· ~t~$14:

jJ'--29

30

4 1·

42

2~.

1~

'1:4

6

~5

6

46--c4)

_/"',..._I

40

45

~

34

-20-

Page 25

PF%

Ref.

NO.

1

02-815281151-l

2

101.02-02

3 101.02-03

4

101.02-04

5 101.02-05

6 101.02-06

101.02-07

7

8

101.02-08

9 101.02-09

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25 101.02-25

26

27 102.02-27

28

29

30 101.02-30

31

32 102.02-34

33

34

35 101.02-41

36

37 102.02-43

38

39

40

41

42

43 102.02-49

44

45

46

102.02-10

11

02-818281651-1

02-816400611-1

101.02-13

02-418281651-1

102.02-15

101.02-16

02-516401111-l

101.02-18 *flifii,c,~

02-409400623-1

102.02-20

102.02-21

101.02-22

102.02-23

02-816400611-l

101.02-26

101.02-28

101.02-29

02-815281051-1

102.02-38

101.02-40

101.02-42

102.02-44

102.02-45

102.02-46

102.02-47

102.02-48

102.11-36

102.11-37

102.11-38

Part

%

NO.

15

tlt~5tff~~tr

i:JE~5tffffi

lfl3

WHm

it~

~t~~ff

tt~~ff

tlt~iff~it~~

7tffl

~

Screw 15/64x28

Thread take-up crank shaft

iWJ

g Roller felt

Jhread

14

Thread take-up

Needle bearing

take-up lever

tt~llbm$14 Needle bar

ttffl!ff

~t~

db m tcME~

n

ttffdbmm#

ttff

lin

m~

1~u1n

tt~dbm'AI m•n

~

1il•tro~l!J

ttff

dlrWtiE

un•

tr

ttffdbm

*~~,c,~m-w:

*fH~,c,~•tr

*flifii,c,~m:¾&~tr

!ftbjf(

J:

!fib

nb

jg'

tit

;f

~tHf

J:

$W~

_t

!fib~

J:

!fdlmJ!ftb~

db

ft1i

rfh

_t

!fib

tp $di~

~~~

1=1m

Ill m 14

Ill ~n

A~iHij

Ill Snap ring

~El~

tJt~~ffffl~tg

:f-~ffltr

¥~

..t!ftb

J:~nb:!tiftilil~

_t

!fib

nh

:ltiffiJ

Ti

mo~

*fl~,t.,flil1&lii

J:~

JP

!fth~•n

~$fbff

(A)

~!fdl$~Mt!J

~$ib1Ultr

~jJ\m

~!ftbff

~!Mff (

lt~~~:tJUll#

~m~~~n

~m~~~n=tsJt

(

B)

B)

ffil~~fJ

Needle bar

Left screw 9/64x40 L=4.8

Counter weight asm.

Screw 9/32x28

Screw 1/4x40

Rubber ring

Screw 9/32x28

Counter weight

Feed drive eccentric

Screw 1/4x40

Feed drive eccentric

Screw 9/64x40

Needle bearing

Oil seal

Thrust collar asm.

Screw

l/4x40

Main shaft front bushing asm.

Oil adjusting collar

Bushing,intermediate

Cable band

Rubber

Thread take-up

Screw 15/64x28

Hand wheel

Main shaft

Oil amount adjusting

IIJ

Rubber ring

Thrust collar

Screw

Connect

Connect

Screw

Needle bearing plate

Connect block B

Screw

Motorasm.

Screw

Washer

block

rubber

Description

L=l0.5

le_ver

asm.

crank

crank

rod

L=l6

L=6

L=l5.5

cam

L=l

l

cam

L=6

L=6

crank

L=l0

A

A

~

asm.

shaft felt

pin

Wt:

Qty

;,

~a:

Note

1

l

l

I

l

2

l

l

l

l

1

2

1

l

1

I

2

1

2

l

l

1

1

2

I

1

1

1

1

1

1

1

l

1

1

1

1

1

1

3

l

1

3

1

4

4

-21-

Page 26

3.ttff- · ~;HI •

7';&1~14:

NEEDLE

1-g

BAR,

UPRIGHT SHAFT&HOOK DRIVING SHAFT COMPONENTS

r--------------7

:

r-

r-----7

I I I

11

11

I I

I I

I I

I I I G

I I L

I I

I I I I

I : I

• t J I ,

I

, I I

I L

L

ti-,-1s

1

l

~

~

I

~,

I " I I I

I I I I

_____

r--~o-

~17

I.

_____

__________

r----------7

, r

I I

11

19

11

+·-

-1-----

I I L

20

l~I

I I I I

-i-

~-

____

,----7

l~l-1

I~

I I I I

I I I

LL

~

w----221

L

_____

--7 :

I I I

1

I I I

14

'-

~

I

_J

7

l---15

I I

_j

~7

r'

I I I

+

_J

~21

::J

--

11

I I

l-13

I I

I I

I I

_J

, I

I l

--+·--··---j---

118

: :

I I

I I

I I

_J

__

_:

I

I

I·

l-

12

-·

I

I

(

I

I

36

I.,,.,.-

/

38

37

- 7

\

\

I l )

1

L

____

®-30

_j

I

-22-

Page 27

3.

ff%

Ref. NO.

I 102.03-01

2

102.03-02

3 102.03-03

4

102.03-04

5

02-50940082

6

102.03-06

7

!02.03-07

8

102.03-08

9

02-50844052 l-1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

102.03-10

101.03-11

101.03-12

101.03-13

101.03-14

02-816400811-1

101.03,-16

02-816400811-1

101.03-18

101.03-19

02-816400811-1

101.03-21

02-8164008 l l-1

102.03-23

101.03-24

102.03-25

102.03-26

102.03-27

02-812280711-1

102.03-29

02-511400511- l

102.03--31

101.03-32

02-511401021-1

02-81228071

102.03-35

101.03-38

101.03-39

101.03-40

101.03-41

101.03-42

101.03-43

02-612281311-1

101.03-46

#

Part

%

NO.

l-l

l-l

:g

Htt

_tfL~

Hff_t~

Hff

Hff~~tHR#

tHf

itttti:tJtJ

Hffitmttttm

HffT~~~

Htfr~

mttt,n

Hfft\t~

mn

{it:

m-

$£

~il

ftj:

__t

t&~!il

_t

$HI~

is

14

ft:

f_g

1tt:

{il:w~~n

!!£

~__t1¢t!Httli

*t!t~~n

Tili~t!l#

Yz~Tffi~ift#

~W~tin

r~~w~~Ji#

~m~~n

~~

~~

~$WJ:.~~

~~Ttml~

r$mE$W~

~

$1

__t

~~ml

T$mt~l!ltii#

T~t~~~n

T~

1iJE~~1ft~

:111e~~fft~ffltr

rtfinru~~~tr

T

~anru!fm

T~IS&nb~Ji11

T ~ !~I.Um

T~~im~tr

~Jc

...

~~

:titi~~1€~ii#

T!tilljj§-!fm~tin

tttf

~~ttffl-:!k~

~tr

~

;rt

~

1tJ:

Description

Cap

Needle

Needle

Needle

Screw

Slide

Needle

Needle

Screw

Needle

Needle DBX1 #14

Gear&pinion

Gear&pinion

Gear

Screw 1 /4x40

Pinion asm.

Screw

Gear&pinion

Gearasm.

Screw

Pinion asm.

Screw

Upright

Hook asm.

Upright

Upright

Bushing

Screw

Thrust

Screw 1 l/64x40

Lower

Bobbin

Screw l l/64x40

Screw

Lower

Oil seal

Oil

Oil

Bobbin

Bobbin

Hook

Screw

Slide

bar

bushing

bar

rod

holder

9/64x40

block

bar

thread guide

bar

bushing,lower

1/8x44

L=4.8

bar

thread guide

asm.

asm.,upper

asm.

L=8

1/4x40 L=8

asm.,lower

l/4x40

L=8

l/4x40

L=8

shaft

shaft

bushing,~pper

shaft

bushing,lower

rear

3/16x28

collar

asm.

shaft

case

holder

3/16x28

shaft front metal

screw

asm.

wick

seal

screw

cas_e

bobbin

block

case

3/16x28

base

L=7

L=7

L=7

L=l3

upper

asm.

.5

L=S

L=9.5

asm.

~

Qty

1

1

1

1

3

1

I

1

1

1

1

I

1

1

2

1

2

1

1

2

1

2

l

1

l

l

I

1

1

2

1

I

1

1

1

1

l

1

l

1

1

1

1

it

~

Note

ti:

-23-

Page 28

4.ffi;ff

HAND LIFTER

'$1!:f

2

COMPONENTS

~-17

·~

I

-24-

Page 29

ff%

Ref.

NO.

1

2

3

4

5 102.04-05

6

7 102.04-07

8

9 101.04-09

10 102.04-10

11

12

13 102.04-13

14

15

16

17 02-515281521-1

18

19

20

21

22

23

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

1tt:

Part

101.04-01

02-50940 l 023-1

101.04-03

102.04-04

02-409400821-

101.04-08

102.04-11

102.04-12

102.04-14

02-411400521-l

02-411400521-1

102.04-18

02-412280623-

102.04-20

04-612320400-

101.04-22

101.04-23

102.04-25

102.04-26

02-412280623-

102.04-28

102.04-29

102.04-30

102.04-31

102.04-32

102.04-33

101.04-35

102.04-~6

02-816400811-l

02-50940082 ! -1

102.04-39

102.04-40

102.04-41

102.04-42

102.04-43

102.04-44

102.04-45

_a

7

NO.

1s

~

&~~¥

BiJJl;llt&¥~n Screw

&~

~

-=j=.

~Ofill It]

ffifJilltm-¥8~${4

fftf~~

l

mff~~tr

riitIJf

~rt

ffl

~~~3ft=lt4i~

ni1EJ'41$,f4=

Tff~~,lli

tft

ffiJJ!IJ:m

ff~

n

Jsttff$Jilltitr

rttlliJJil!JJUf

~ttJJil!Fotiff

Tff~~~~tr

_tffiAJi~

~

t~n

Ttttlitll#~~~n

m~ml:k~

l

_tf[

~gJi

,ftf=

~~-tr

_t,8£~~ti

l

:m~fflieOOTi'~-BJ:

~tt

ffl3f

a~

Fi

¥.HJUvU&~

!fkiftr~~

fl~~tl°

l

~1S;fliiH~

fl~JJi~

f'l~JJUJi~~ffi

~

ffi~

ifµ]

lli

•tr

~J.li~

E[tf~Yi@

EEff

~~~--Viti]

Biff~~~n

~~~-=µ~~tr

oottff

tf:i

tt~~;f:Iff

~ffffct~III

lliHkPfHffli

:ff-~i~~m:ffu~;J

te-

ffi1}1q1jiz

~ffi~ff

1ftjf

~fr

-BJ:

m #

tlHtt:

ff

Description

Hand lifter

9/64x40

Rubber ring

Hand lifter

Presser

Screw

Link

E-ring 5

Presser foot asm.

Wire

Hinge

· Hinge

Knee

Lifting

Screw 1

Screw l l/64x40

Screw

Wire

Screw

Wire

Nut

E-ring

Tension release

Wire

Tension release supporting

Screw

Thread

Tension

Presser

Presser

Presser

Presser

Presser

Presser

Screw

Screw

Knee

Hand

E-ring

Lifting

E-ring 5

Knee

Presser

bar

9/64x40

shaft

holder

screw

screw

lifter

lever

15/64x28

holder

3/16x28

holder

3/16x32

5

cable

3/ l 6x28

tension release wire

adjusting

spring

adjusting spring

bar

bar

bar

l/4x40

9/64x40

lifti~g

lifter link

5

lever

lifting

guide

L=lO

cam

bushing

L=8

bracket,lower

connecting

link

l/64x40

L=6

bracket,upper

return

holder

L=6

release

shaft

regulator

guide

thread guide

L=8

L=8

cross

cross

bar

asm.

lower

L=5

L=S

L=l4.5

screw

.brocket

rod

rod

rod

spring

nut

asm

pin

,'.~ty

1

I

1

1

1

l

2

3

l

1

1

l

1

1

1

1

l

2

l

l

2

2

1

I

1

1

1

1

I

l

I

. I

l

1

1

2

l

1

1

l

l

l

l

~

Note

ff

-25-

Page 30

5.~~$14=

FEED

MECHANISM COMPONENTS

1

~b~89

18

2

~

17

16

6

10

11

12

~

13

15

£?

~

27 •

28=.j

29

30 32

~

I

I .

',

l'~_j

53

I

t

55--j

I

l s6 I

L-----~

I

I

33

31

I

'1--51

"-.

35

36

59

_:J

Lsa

I

r

I

I

l._

---...

45 '

44

41

-26-

Page 31

FF%

Ref.

NO.

1

2

3

4

5

6

7

8

9

lO

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

02-412281621-1

44

45

46

¥F

Part

NO.

102.05-01

102.05-02

02-50940062 l-l

101.05-04

101.05-05

02-31228072

102.05-07

102.05-08

102.05-09

102.05-10

02-512281821-1·

102.05-12

102.05-13

02-809400424-

102.05-15

102.05-16

102.05-17

101.05-18

102.05-19

102.05-20

101.05Q2]

102.05~22

102.05-23

102.05-24

102.05-25

l02.05-26

102.05-27

02-815280711-l

02-809400424-1

102.05-30

102.05-31

101.05-32

02-608440621-1

102.05-34

101.05-35

02-411400523-1

102.05-37

102.05-38

102.05-39

02-509400621-l

04-618280400-1

101.05-42

102.05-44

02-412281421-1

102.05-46

l-1

%

15

~

1iu~~aff

1ftl

~?}Bl

i~H~

~tH~~B

*~iffiJ~S

~~~=µ'~$~

*~ifti3i'5"$~~~n

*~

i)~

TJ

~ti

~~

Re

tm

fr1ii

J!~1€

js~

~~

tJJf

1H~

HeiifEm

ie111Em ~ n

~fHtitf

*~:iifff§

l

*~jiff~n

t€i~~;ff

*

;f6i.

ifµj-=p

~~

:t&~:tl

ff~*~

fftl~~

~fiOID!

:i&ff

ab

WWHtf:

urJI

WH~

lffl

[II

1ftlm~eam~$)"

1ftl~~:itffft~

~

1ftl~~H:ft~

~"1i91if&~~~ Walking

~~*

~~m:mig]

*~ffl!

m

;tJ

:f!i

lf1i

igJ

t&~iil #

*fl~i91ifli~ti.ti~

le ;;ii ffl

~

tr

~ffffi~fT

;f~ffi

*~~

$IBJlH'~

Im

~~5f

*fl5f~tr

5f~W#

m~t1i~~

~

1irt&~~~tr

mti

tHt~JE;ti

~~·fih

*#liil:ftJiffl

(MrfW~~n

t~

5f J!ff~1il•-Ht

~~

lttl

tvmHtt:

~~aam•ir

rg.

w

;gab

tw

t1l

1lt

tfr5f

Fooom•n

1ft 9.fitfftfBI1iz~tr

Description

Feed adjust rod

Feed regulator pin

Screw 9/64x40 L=6

Feed regulator

Feed regulator bushing

Screw 3/16x28 L=7

Feed regulator screw

Spring

Feed

adjust

pin

Feed

dial

Screw

3/16x28 L=18

Rocker shaft connecting rod

Walking foot long pin

Screw

9/64x40

Connecting

Rubber

Feed

E-ring 5

Feed

Screw

E-ring 5

Spring

Connecting

Connecting

Feed

Adjusting

Screw

Screw

Feed

Retaining

Fedd

Screw

Feed

Adjusting

Screw l l/64x40

Feed

Feed

Walking

Screw 9/64x40

Nut

Feed

Screw

Lifting

Screw

Hinge

ring

reverse spring

reverse

adjust

l 5/64x28

9/64x40

bar

dog

l/8x44

bar

spring

rocker

9/32x28

rocker

3/16x28

rocker

3/16x28

screw

rod

arm

foot

short

link long

link short

link

link

shaft

ring

I

asm.

link

hood

shaft

foot

middle

shaft

L=4

asm.

pin

asm.

fulcrum

L=7

L=4

L=6

spring

L=5

L-6

crank

L=l5.5

asrn.

L=l4

pin

pin

shaft

guide

pin

asm.

~

Qty

2

2

2

2

2

2

2

2

~

1±

Note

1

l

2

1

l

1

I

l

1

1

l

1

1

1

1

1

1

1

1

1

1

I

I

1

1

1

1

1

1

1

1

1

I

l

l

1

l

1

-27-

Page 32

5.~~iB14

FEED MECHANISM COMPONENTS

18

~

12

2r

24 -2sj)

o-~

Ill

I

31

2E,

l__

19

I

_,,,,.-

G

- JJ-20 1

/.

22

'

I

17

11

~

~

---~t4

---..._,

r

45 '

I

I

~

44

___

_

41_

I

L4a

49

'7.:-._'...J

I

I

',

53

55---f

l',~4_1

I

I

I

I

56

I

~51

I

L----~

I

59

_:J

L5a

I

-28-

Page 33

}¥%

Ref.

NO.

47

48

49

50

51

52

53

54

55 102.05-52

56

57

58

59

60

61

62

63

64 02-816401041-1

65

1tt=

Part

102.05-47

102.05-48

02-816400611-1

102.05-49

02-411400721-1

102.05-50

102.05-51

02-412281421-l

02-511401121-1

102.05-59

102.05-61

02-816400611-l

102.05-63

102.05-64

102.05-65

02-816400911-1

102.05-68

-'%

NO.

~

t~5f~

tit

5f

~t4i

liWl

#

~

fi-

$la

t4i

!!l

~

n

J!~HrtrwJ$la~

5f$W~tur

tit

5f

$lb~

ffl

t4i

111

5f

~

RJH.fl

1lf

5f~~~n

ta

5f

x

db

m i!l

14

ta5fx!ihmtin

iftl~~i&

!ft3f~t~II

tft

5f

1ftl

*~Hmo~

1ftl*~$ia

1ftl

~)M

1itl*;p1-tJi

1itl*;pj.tJi

itl*~if¥

~

rli

$in

¥~ii

!m

~ n

im

$la~

¥ttir

¥

~

14

fft~n

~

Description

Feed driving shaft

Thrust collar asm.

Screw

l/4x40

L=6

Feed rocker shaft bushing

Screw l l /64x40 L=7

Retaining ring

Feed

bar

crank asm.

Screw 3/16x28

Driving shaft crank asm.

Screw

ll/64x40

Reverse

Thrust

collar

Screw

1 /4x40

Rubber

ring

Feed

reverse

Feed

lever

Screw

l/4x40

Screw

l/4x40

Reverse

feed

metal

feed

L=l4

L=l0.5

control

asm.

L=6

shaft

L=8.5

L=IO

control

lever

lever

asm.

~

Qty

1

l

1

2

2

l

1

l

1

l

1

1

2

I.

I

1

1

I

1

•

-~

~

Note

1£

-29-

Page 34

6.

~

WtJJtUtiftt=