Consew 733R-5 User Manual

LDNSEIN

OPERATING

INSTRUCTIONS,

PARTS LIST

MAINTENANCE

PROCEDURES

CONSOLIDATED SEWING

MACHINE

Model

CORP.

733R-5

EXTRA

HEAVY

LONG

DUTY

ARM

SINGLE

DROP

ALTERNATING

LOCKSTITCH

CONSOLIDATED

COPYRIGHT (01989

CONSOLIDATED

NEEDLE

FEED

PRESSER

MACHINE

SEWING MACHINE

SEWING MACHINE

FEET

CORP.

CORPORATION

INTRODUCTION

-CONSEWMODEL

733R-5

Consew Model733R-5 is a single needle,flatbed,type

sewing machine used is the fabrication and repair

of

Consew Model 733R-5 is capable

nylon duck to multiple layers

Consew Model 733R-5 is able to fabricate and install

extraction-parachutes,

Machines should

accumulation which, when allowed to build up,mixes with oil and becomes caked on the

After use, sewing machines should

Once a week the inside

blown out with shop air

CAUTION:

Once a year the machine should be cleaned with a solvent such as Freon, then

immediately oiled thoroughly to prevent rust and corrosion.

CAUTION:

When the machines are

Using the proper oil is

ENSURE GOOD VENTILATION WHENUSING SOLVENTS.

bridle loops,locking stow loops,harnesses and multiple layer

Preventive Maintenance

be

kept covered when not in operation to prevent dust and dirt

if

available.If shop air is not available, clean with a soft bristle

USE EYE PROTECTION WHEN USING SHOP AIR.

in

constant use they should

of

utmost importance. For lubrication

quality sewing machine oil shoud

a.

Oiling points are shown in figures 10 and 11.

Use one drop at each oiling point.

b.

sewing fabrics that range from heavy cotton and

heavy webbing splices.

machine.

be

wiped down with oil and a soft cloth before

covering.

of

the machine and the motor should

brush.

301 stitch,reverse feed,industrial

of

aerial delivery equipment.

of

heavy webbing.

personnel-,cargo-and

be

be

oiled at least twice daily.

of

the machine, only good

be

used.

SECTION

MAINTENANCE

I1

OPERATING INSTRUCTIONS AND

PROCEDURES

Characteristics and Capacity

The CONSEW Model 733R-5 single needle, extra heavy duty lockstitch machine is

designed for sewing canvas,tents,sails,hamesses,safety belts, webbing and similar

products.

It

is equipped with altematingpressers,drop feed and a long-beak oscillating shuttle on a

horizontal axis.It has a

bed,at right

The machine is equipped with a stitching reverse lever which also regulates stitches in

of

cleanceof25.4mm(l"

needle is413mm(16

length from 3 to 13mm(2 to 8 stitches per inch).

t;4'

)under the presser foot. Clearance,on

)and length

ofbcd

655mm(25-3/4")

Alternating pressers consist of a vibrating presser

in

combination .In operation,the pressers alternately press

vibrating presser working

or

more

plies of material which

operated presser foot lift

minute.

The

in

unison with

are

and

reverse.The

balance wheel

THREAD

AND

the

feed,

being

sewn.

maximum

always

THREAD

rotates towards the operator.

NEEDLE

foot

and

a lifting presser

down

on

so

that there

Additional features include pedal

operating speed

SELECTION

is

no

foot

the

material,the

slipping of

is

550

stitches per

working

the

two

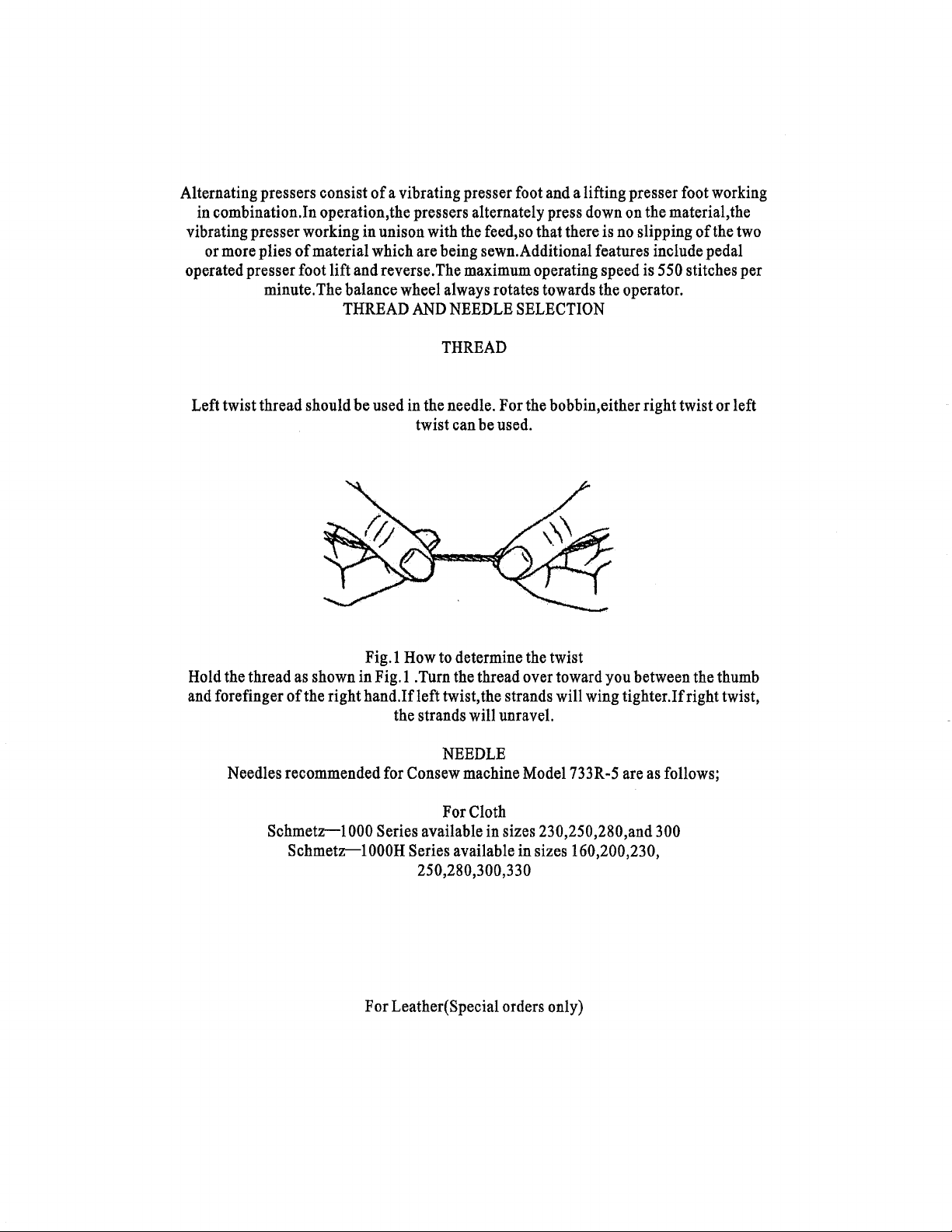

Left twist thread should

Hold

the

thread

as

shown

and

forefinger of the right

Needles recommended

Schmetz-1

Schmetz-1000H Series available

be

used

in

twist

Fig.1

How

in

Fig.1 . Turn

hand

.If left twist,

the

strands will unravel.

for

Consew

000

Series available

250,280,300,330

the

needle. For

can

to

determine

the

NEEDLE

machine

For Cloth

the

bobbin,either right twist

be

used.

the

twist

thread over toward

the

strands will

Model

in

sizes 230,250,280,and

in

sizes 160,200,230,

wing

733R-5

you

between

tighter .If right twist,

are

as

follows;

300

the

or

left

thumb

For Leather( Special orders only)

Schmetz- J.003D Series,triangularpoint,available

Schnietz- 1

Schmetz-

Schmetz-

Schmetz

The

size

of

the needle

Do

not use rough

needle eye,as such thread will interfere with the successful use

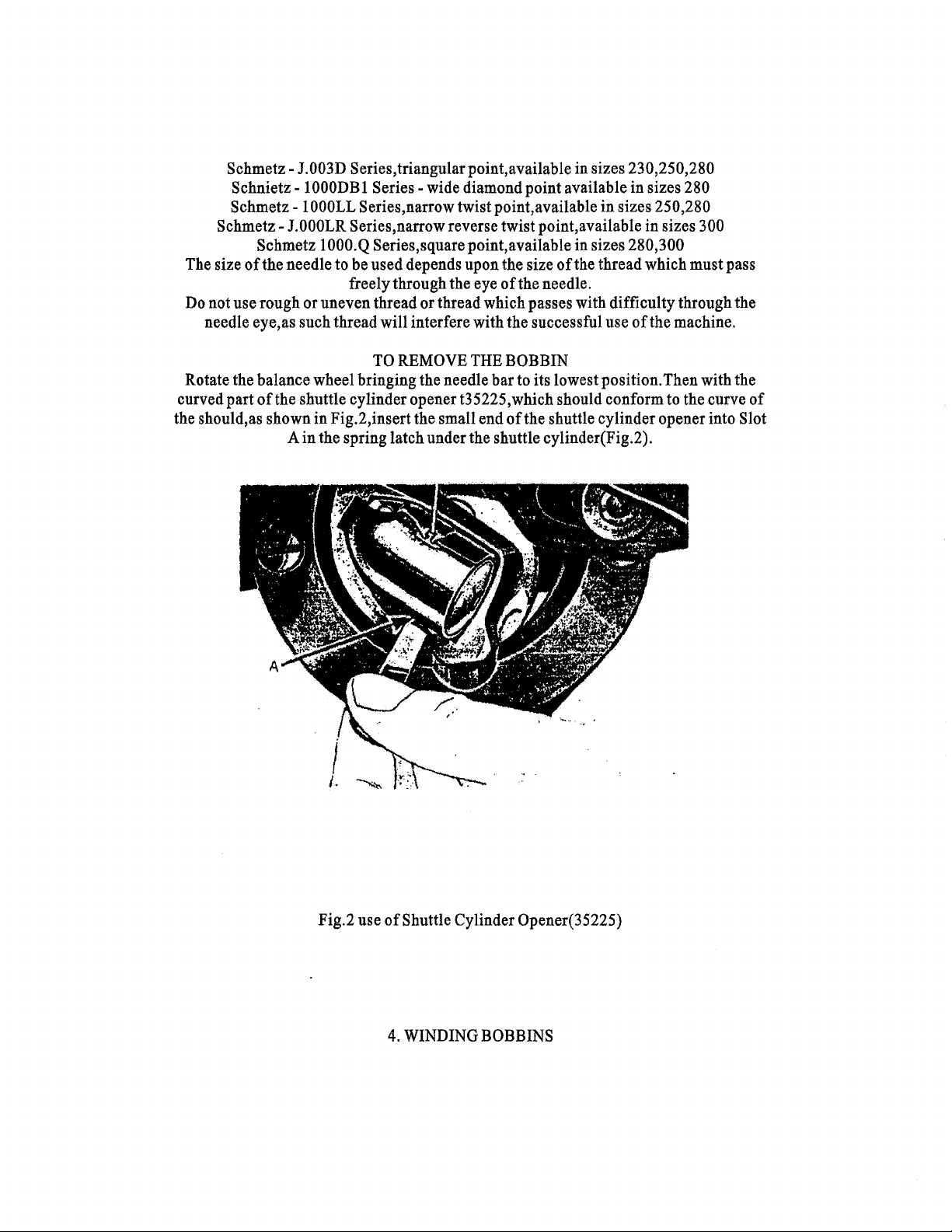

Rotate

curved part

the should,

the

balance wheel bringing

of

as

OOODB

lOOOLL

J.OOOLR

or

the shuttle cylinder opener t35225,which should conform

shown in Fig.2,insert the small

A in the spring latch under

1 Series-

Series,narrow twist point,available in sizes 250,280

Series,narrow reverse twist point, available in sizes

lOOO.Q

uneven thread or thread which passes with difficulty through the

Series,square point, available

to

be

used depends upon the size

freely through the

TO

wide

REMOVE

the

needle bar

diamond point available in sizes

eye

of the needle.

THE

BOBBIN

to

its lowest position. Then with the

end

of

the shuttle cylinder opener into Slot

the

shuttle cylinder(Fig.2).

in

sizes 230,250,280

in

sizes 280,300

of

the

thread which must pass

of

the machine.

280

300

to

the curve of

of

Fig.2 use

Shuttle Cylinder Opener(35225)

4.

WINDING

BOBBINS

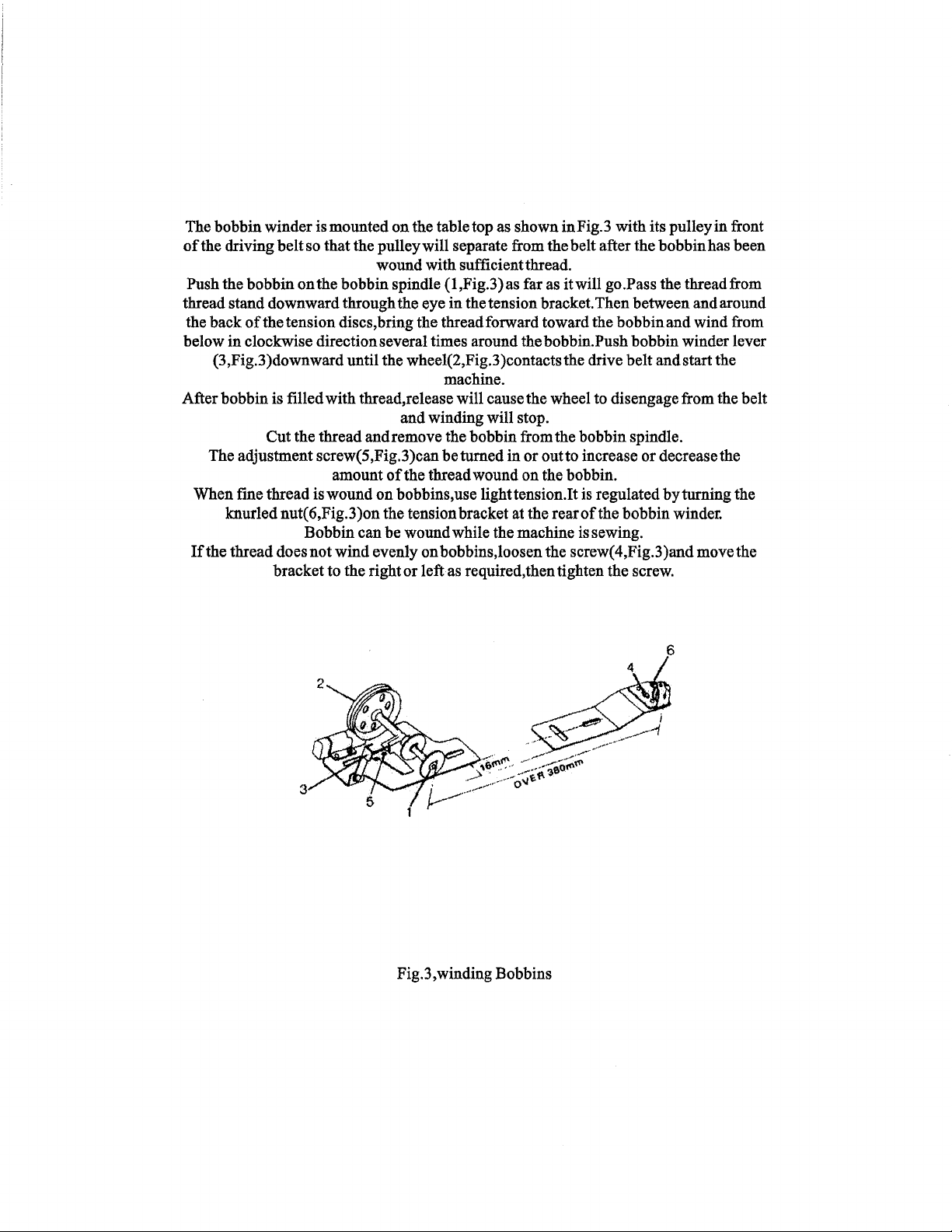

The bobbin winder is mounted

of

the driving

Push the bobbin

thread stand downward through the eye

the back

below

in

{3,Fig.3)downward until the wheel{2,Fig.3)contactsthe drive belt and start the

After bobbin is filled with thread,release will cause the wheel to disengage from the belt

The adjustment screw{S,Fig.3)can

When fine thread is wound

knurled nut{6,Fig.3)on the tension bracket at the rear

If

the thread does

belt

so that the pulley will separate from the belt after the bobbin has been

on

the bobbin spindle

of

the tension discs,bring the thread forward toward the bobbin and wind from

clockwise directionseveral times around thebobbin.Push bobbin winder lever

Cut the thread and remove the bobbin from the bobbin spindle.

amount

Bobbin can

not

wind

bracket to the right

on

the table top as shown inFig.3

wound with sufficient thread.

{l,Fig.3)as

in

the tension bracket. Then between and around

machine.

and winding will stop.

be

turned in

of

the thread wound on the bobbin.

on

bobbins, use lighttension.lt is regulated

be

wound while the machine is sewing.

evenly on bobbins,loosen the screw( 4,Fig.3)and move the

or

left as required, then tighten the screw.

far as

itwill

or

out to increase

with

its pulley

go.Pass the thread from

or

decrease the

by

turning the

of

the bobbin winder.

6

in

front

3

Fig.3, winding Bobbins

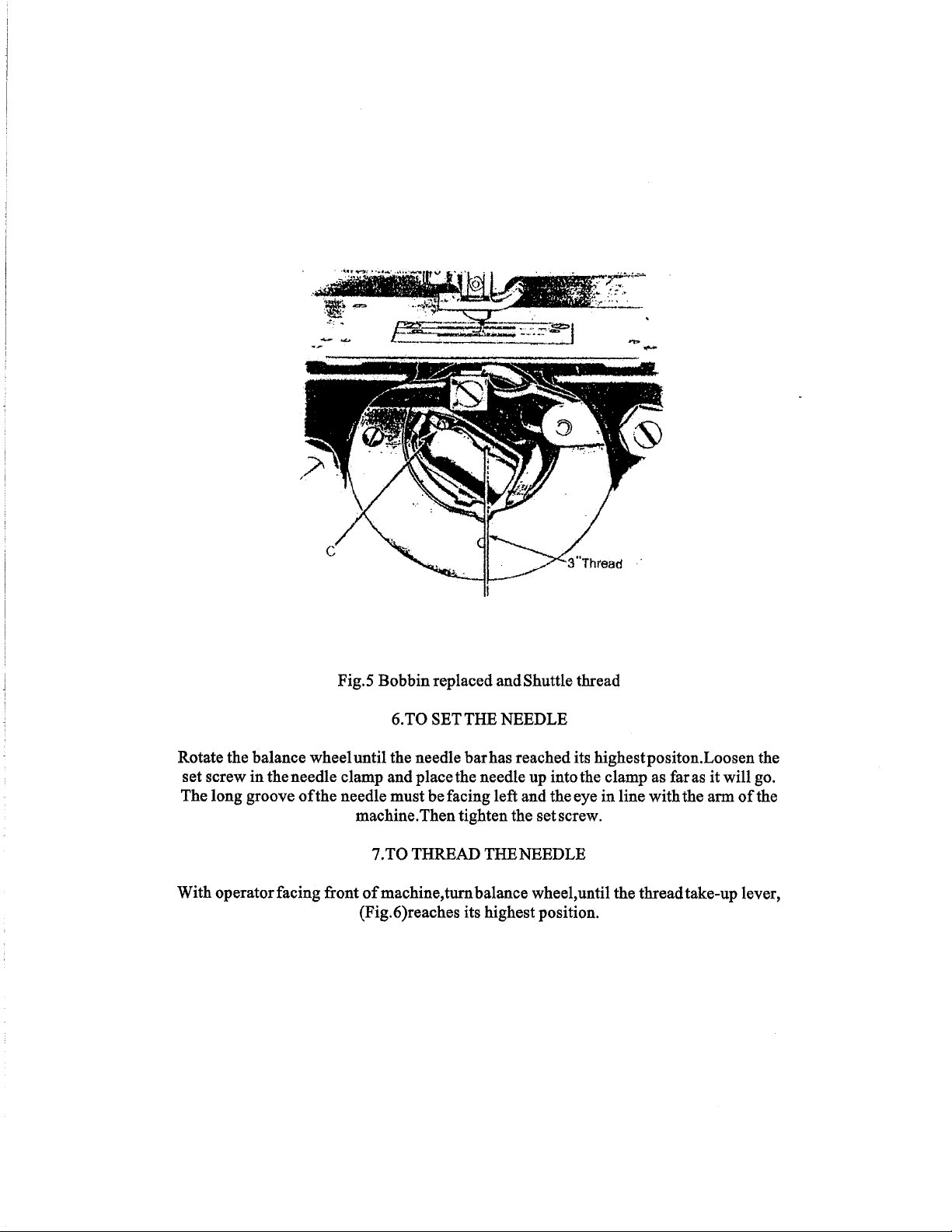

5. TO REPLACE THE BOBBIN AND THREAD THE SHUTTLE

of

Hold the bobbin between the thumb and index finger

thread is drawing off from the underside toward the right as shown

in

bobbin

cylinder and under the tension spring, then into the delivery eye A.Fig.4, then push the

cylinder back until

hang free from the shuttle Fig.S so that

the cylinder as far as

it

is locked

it

will go,draw the thread in the slot

by

the spring latch, and allow about 3 inches

it

can be drawn up through the throatplate,as

noted in Fig.

the lefthand,at the sane time the

in

Fig.4.Place the

B,Fig.4in

8.

of

thread to

the

Fig.4 Bobbin Replacement and Threading the Shuttle

Fig.5 Bobbin replaced and Shuttle thread

6.TO SET THE NEEDLE

Rotate the balance wheel until the needle

in

set screw

The long groove

With operator facing front

the needle clamp and place the needle up into the clamp as far as it will go.

of

the needle must be facing left and the eye

machine. Then tighten the set screw.

.TO THREAD THE NEEDLE

7

of

machine,

(Fig.6)reaches its highest position.

tum

bar

has reached its highestpositon.Loosen the

in

line with the arm

balance wheel, until the thread take-up lever,

of

the

Fig.6 Threading the needle

Open the lid

in the right side

in the left

over from right to left between the thread retainer discs 3,down under and from thread

of

loop

front through the hole 7 ,in the thread take-up lever,down through the thread guide

Fig. 7 into the slot 9

clamp,and from left to right through the eye

through the hole in the lifting presser foot 12. Draw about four inches

the hole

Note:Ifthread

ofCup

sideofcup.Then

the thread take-up spring S,under the staple 6,Figs.6 and

of

the lifting presser foot with which to pull up the bobbin thread as shown

C;pass the thread from the cotton stand downward through the hole

of

cup, then through the thread post 1 undes the lid , then through the hole

close the lid and pass the thread through the thread guide 2,

13

guide

lubrication is not required,omit thread from cup C Fig.6 andstsrt

to let around the tension wheel4,into the

7,upand

in

the vibrating presser bar ,into thread guide 1 0 on the needle

of

the needle

Fig.8.

threading machine at thread guide 2(Fig.6.)

11

then pass the thread down

from back to

of

thread through

8,

in

7

Fig.7 Threading the Needle

B.

With the

needle.

left

hand

hold

Turn

the

balance

position,thus catching

thread

will

come

up

TO PREPARE

the

end

of

the needle thread, leaving it slack from the

wheel

until the needle moves down

the

bobbinthread;draw

with

it

through

threads

back

FOR

SEWING

up the needle

the hole

under the presser feet.

in

the throat plate( see Fig.8)Lay

hand

and

up again to its highest

thread

and

the

to the

bobbin

both

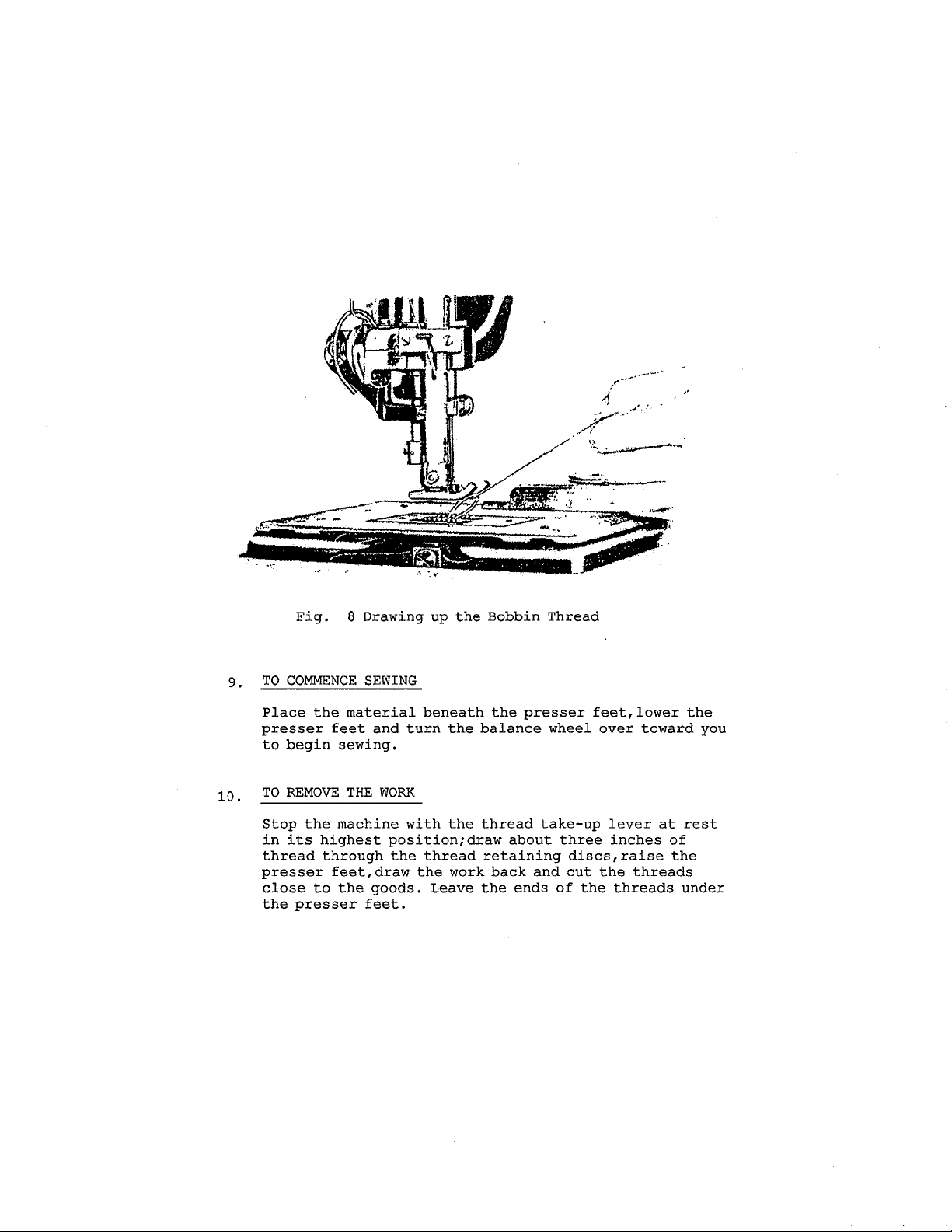

9.

Fig.

TO

COMMENCE

8

Drawing

SEWING

up

the

Bobbin

Thread

Place

presser

to

10 • TO

Stop

in

thread

presser

close

the

the

begin

REMOVE

the

its

highest

through

to

presser

material

feet

and

sewing.

THE

WORK

machine

position;draw

feet,draw

the

goods.

feet.

the

beneath

turn

with

thread

the

Leave

the

the

work

the

presser

balance

thread

about

retaining

back

and

the

ends

wheel

take-up

three

discs,raise

cut

of

the

feet,lower

over

toward

lever

inches

the

threads

threads

at

the

you

rest

of

the

under

Loading...

Loading...