Consew 616 User Manual

I

1. Starting

After

nect

Supply

manually

times

switch A

D

is

lever

If

hold

A

rated

er

During

weather,

of

into oil

three

several

2.

Presser

Grip

the

rod

presser

be

down.

making

terminal

to

does

engaged

H.

hand

lever I with

with

rpm,

to

the

non·use,

times,

times

handle J and

fingers

adjustment.

cut

sure

B and

5-6

drops

rotate

hand

see

if

it

to

start

not

rotate

and

it

pulley D still

the

stop

the

or

cup

one

other.

release lever I

position.

first week

when

be

sure

C,

rotate

and

turn

to

lubricate

Foot

of

the

foot M to

by moving

the

starting

gripping

Then,

3. Knife Sharpening

Turn

on

are

G

sharpener

sharpen

lowers

located

not

repeat.

only,

release it

lever G

base 0 begins rising).

returns

(neutral)

bottom

seconds,

sharpener

plete

Do

since frictional

switch A

no

obstacles

is

pushed

base 0 moves

knife

by

at

obtained

For

push

automatically

to

position.

of

release

sharpening.

not

continue

on

completely

K.

(Presser

means

the

top.)

with a single

sharpening

sharpener

to

lower

the

end,

the

knife

from

base 0

heat

sharpening

w.

Precaution:

Do

knife

er

will

not

is

that

switch A is

power

supply

of

oil

into

pulley D two

rotates

must

to

squeeze

the

shaft

after

bed

of a special device if it

automatically

not

be damaged.

smoothly.

machine.

smoothly,

be

released

does

not

hand

and

When

the

to

return

of

operation,

after

supply

If a

sharpener

By

is

is

operate

5-6

hand

pulley D

switch A

major

brake

hand

adjust

thickness

rod

confirming

P.

When

and

up

and

foot M automatically

satisfactory

sharpening

the

bottom

lever G

returns

Then

squeeze

doing

sharpened.

sharpener

caused

the

installed,

OFF,

with

cord X.

oil

cup

C,

or

Turn

If

hand

pulley

the

sharpener

by

lifting

rotate

smoothly,

turn

on

switch

motor

reaches

the

sharpen-

in cold

a long period

drops

of

two

on

and

off

components.

lever K

to

allow

the

height

of

material

bracket L up

that

sharpener

then

released,

down

once

result

operation,

of

the

completely

0,

(sharpener

and

sharpener

before

the

for

on

lever G

lever

this,

only

After

lever G

rises

to

a long

sharpener

sharpener

or

the

sharpen-

2

three

oil

or

shaft

there

knife

at

con-

and

on

with

of

to

or

lever

to

and

the

to

and

com-

time

belt

if

N

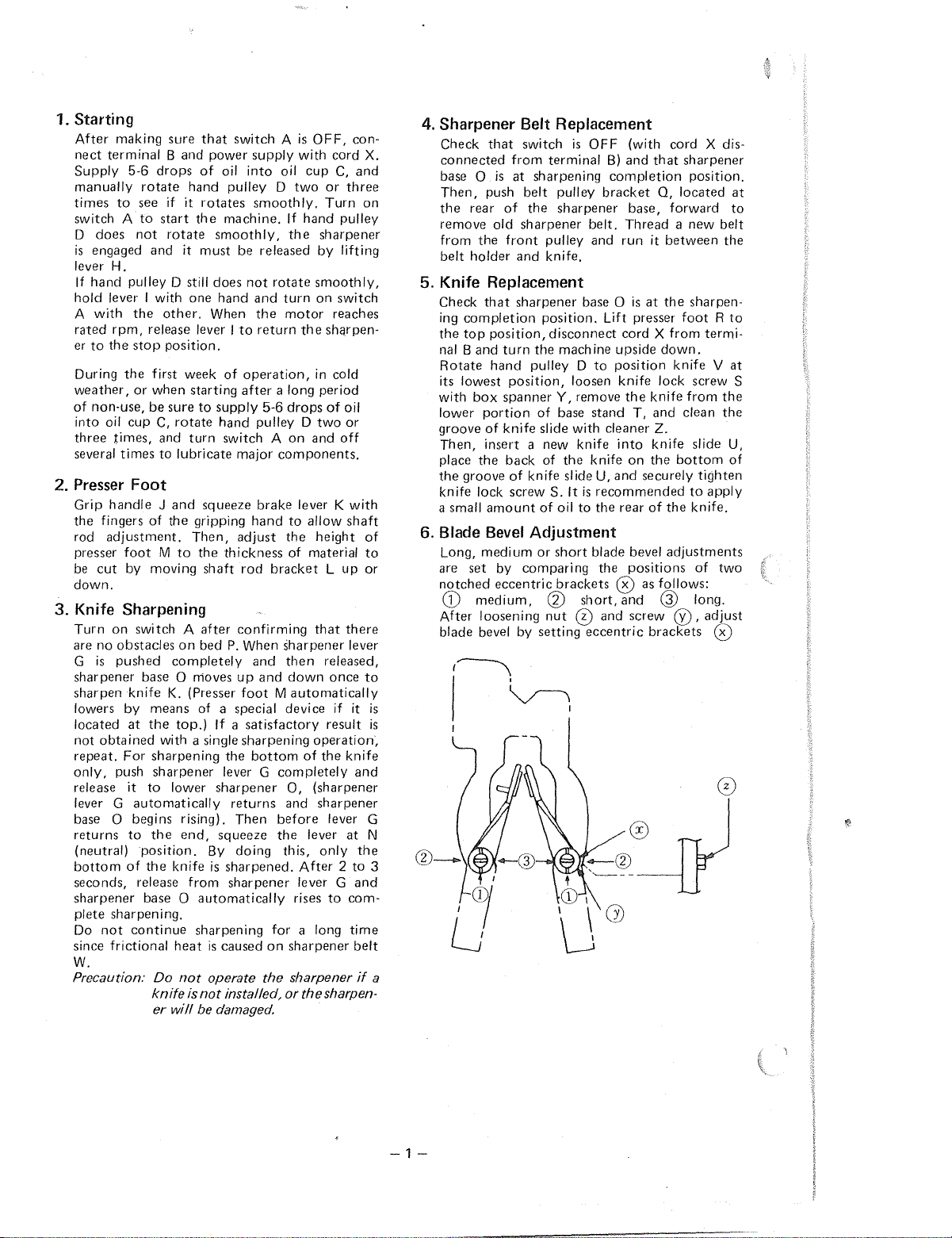

4. Sharpener Belt Replacement

Check

connected

base 0

Then,

the

remove

from

belt

5.

Knife Replacement

Check

ing

the

nal

Rotate

its lowest

with

lower

groove

Then,

place

the

knife lock screw

a small

6.

Blade

Long,

are

notched

After

blade bevel by

is

is

3

a

rear

the

holder

completion

top

Band

box

the

groove

set

G)

medium,

loosening

that

switch

from

terminal

is

at

sharpening

push

belt

of

the

old

sharpener

front

pulley and

and

knife.

that

sharpener

position,

hand

portion

of

insert a new

amount

Bevel

medium

position.

turn

the

pulley D

position,

spanner

of

knife

slide

back

of

of

knife slide U,

of

Adjustment

or

by

comparing

eccentric

disconnect

S.

@

nut

setting

is

OFF

pulley

bracket

sharpener

belt.

base 0

machine

to

loosen

Y,

remove

base

stand

with

knife

the

knife

It

is

recommended

oil

to

the

short

blade bevel

the

brackets

short,

® and

eccentric

(with

cord

B)

and

that

completion

0,

base,

forward

Thread a new

run

it

between

is

at

the

Lift presser

cord X

upside

position

knife

cleaner

into

and

rear

down.

lock screw S

the

knife

T,

and

Z.

knife

on

the

securely

of

the

adjustments

positions

from

knife V at

0 as follows:

and

G)

screw

(j),

brackets

X dis-

sharpener

position.

located

belt

sharpen-

foot R to

termi-

from

the

clean

the

slide U,

bottom

tighten

to

apply

knife.

of

two

long.

adjust

0

at

to

the

of

-1-

H

E

A

CD

ie\

\j

c

__

~

X \

s

w

R

5-6

oil

c

Daily

drops

in

oil

of

cup

Weekly

1. 0

2.

@)

@

3.

0

(')

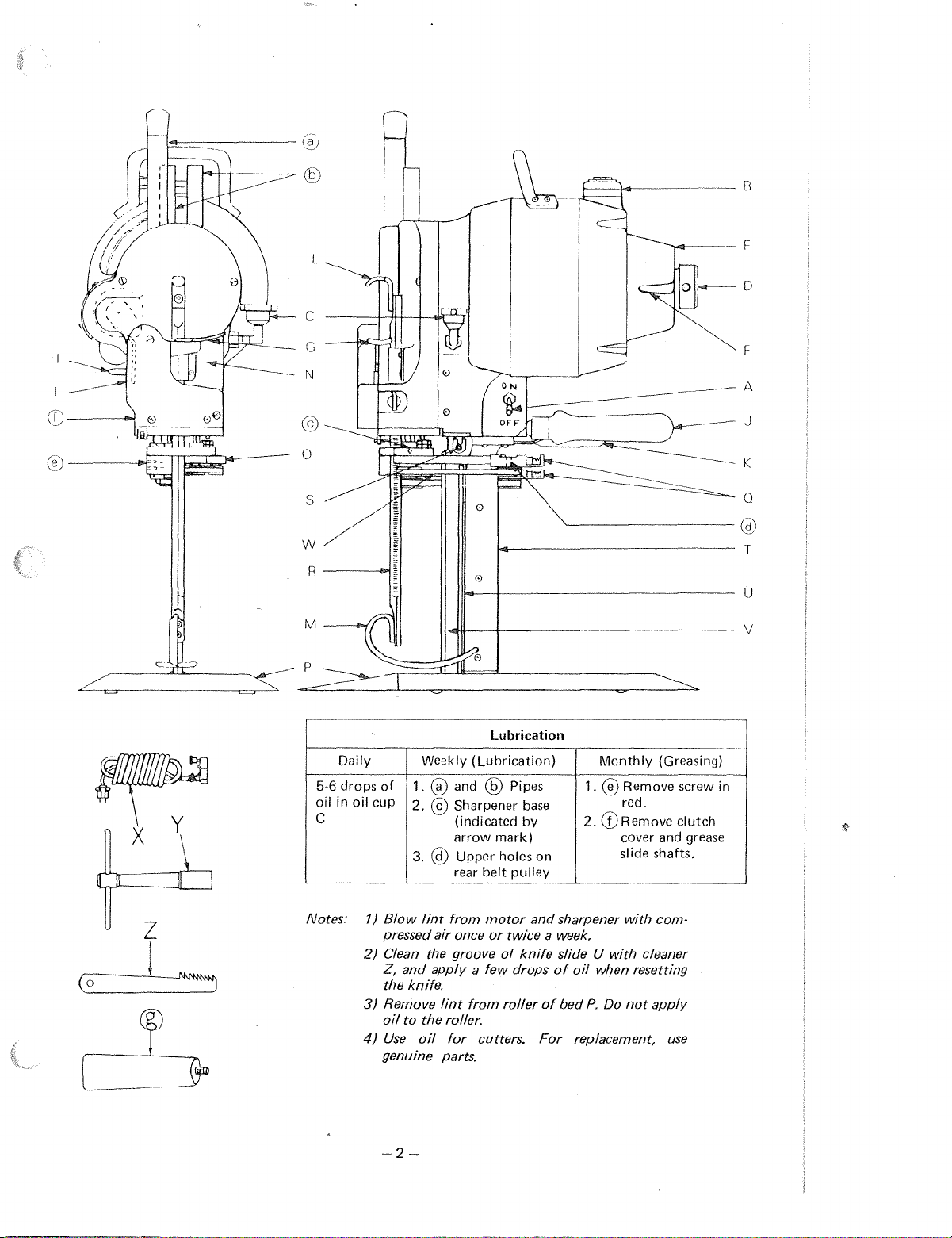

Lubrication

(Lubrication)

and®

Sharpener

(indicated by

arrow

Upper

rear

mark)

belt

Pipes

base

holes

pulley

on

Monthly

1.

@Remove

red.

2.

®Remove

cover and grease

slide

(Greasing)

screw

clutch

shafts.

J

K

0

@

T

u

v

in

z

Notes:

i

1)

Blow

lint

pressed

2)

Clean the groove

Z,

the knife.

3)

Remove

oil

4)

Use

genuine parts.

air

and

applv a few

lint

to

the roller.

oil

from

once

for

motor

or

of

from

cutters.

and

sharpener

twice a week.

knife

slide U

drops

of

roller

of

bed

For

oil

replacement,

-2-

with

com-

with

cleaner

when resetting

P.

Do

not

applv

use

SC14A

\

\ \

~~©

SC14B

(

SC21B

I

~

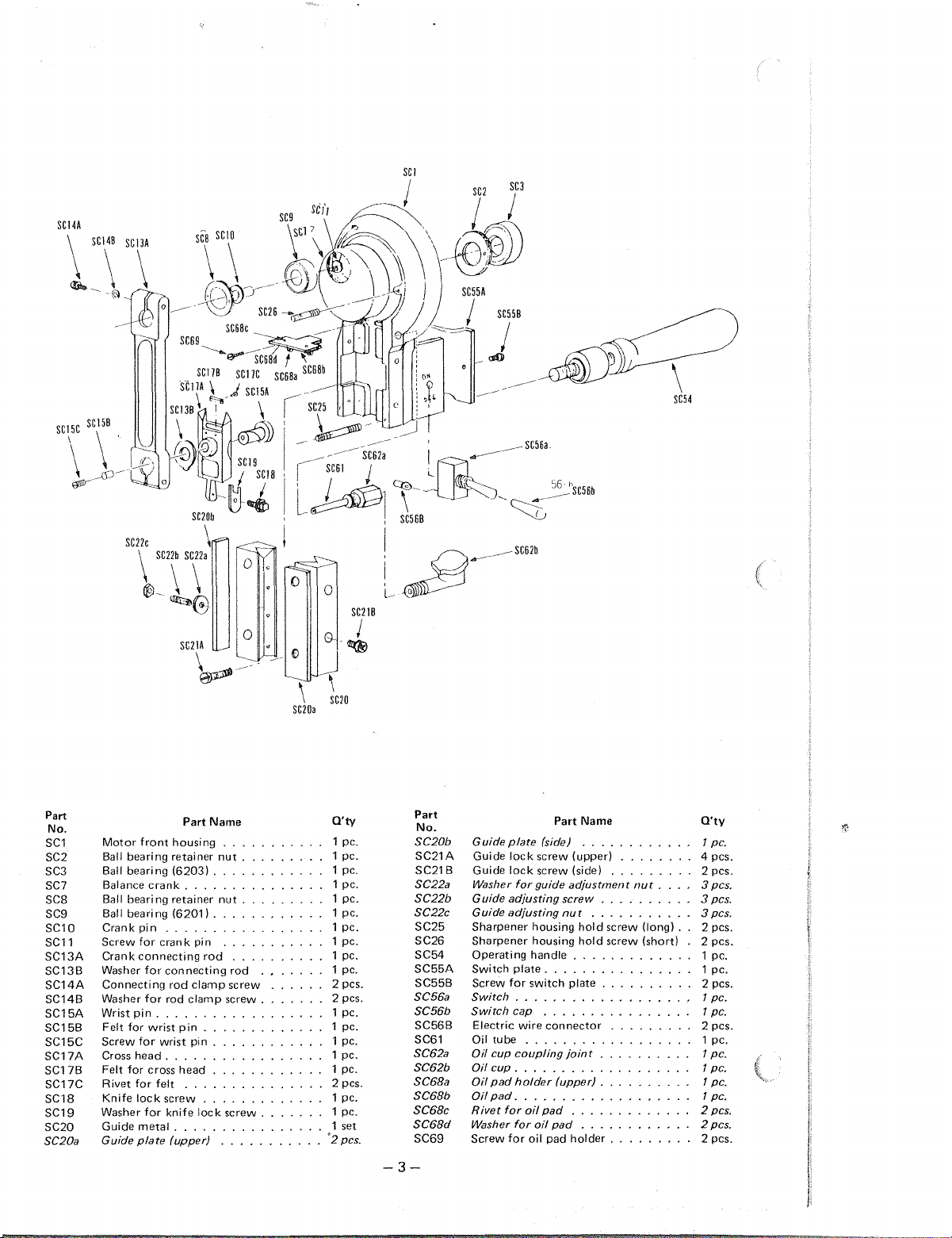

Part

No.

SC1

SC2

SC3

SC7

scs

SC9

SC10

SC11

SC13A

SC13B

SC14A

SC14B

SC15A

SC15B

SC15C

SC17A

SC17B

SC17C

SC18

SC19

SC20

SC20a

Motor

front

Ball

bearing retainer

Ball

bearing

Balance

crank

Ball

bearing retainer

Ball

bearing (6201) .

Crank

pin

Screw

for

Crank

Washer

Connecting

Washer

Wrist

Felt for wrist

Screw

Cross

Felt for cross

Rivet for felt

Knife

Washer

Guide

Guide

crank

connecting

for

for

pin

.

for

wrist pin .

head.

lock

screw

for

metal

plate

Name

Part

housing

(6203) .

. . . .

. .

pin

rod

connecting

rod

clamp

rod

clamp

. .

. .

pin

.

head

knife

lock

.

(upper)

. .

nut

nut

rod

screw

screw .

screw

. .

O'ty

1 pc.

. .

1 pc.

1 pc.

1 pc.

1 pc.

1 pc.

1 pc.

1 pc.

1 pc.

1 pc.

2 pes.

2 pes.

1 pc.

1 pc.

1 pc.

1 pc.

1 pc.

2 pes.

1 pc.

1 pc.

1 set

'2pcs.

.

.

.

. .

. .

Part

No.

SC20b

SC21A

SC21B

SC22a

SC22b

SC22c

SC25

SC26

SC54

SC55A

SC55B

SC56a

SC56b

SC56B

SC61

SC62a

SC62b

SC68a

SC68b

SC68c

SC68d

SC69

Guide

plate

Guide

lock

lock

Guide

Washer

for

Guide

adjusting

Guide

adjusting

Sharpener

Sharpener

Operating

Switch

plate.

Screw

for

tube

cup

cup.

pad

pad.

for

switch

..

cap

..

coupling

holder

oil

for

for

oil

Switch

Switch

Electric wire

Oil

Oil

Oil

Oil

Oil

Rivet

Washer

Screw

Part Name

(side J

screw

(upper)

screw (side)

guide

adjustment

screw

nut

housing

housing

handle .

plate

. . . . . .

. . . . . . . . . . . . . 1

connector

. . . . .

joint

.

..

. .

(upper)

...

. . . . . . . . . . .

pad

oil

pad

pad

holder

-3-

. . . .

. .

. . . . . .

. . .

hold

screw

hold

screw (short)

. . .

...

..

..

..

. . .

.

..

.....

.....

..

. . . .

nut

. . . .

(long) .

..

. .

. . . .

..

. .

. .

. .

. . .

. . 1

. .

.

. .

. .

. .

. . 2 pes.

.

...

O'ty

pc

4 pes.

2 pes .

3pcs

3pcs

3pcs

2 pes .

2 pes.

1 pc.

1

pc

1

pc

pc

2 pes.

1 pc.

1

pc.

1 pc.

1 pc.

1 pc.

2 pes.

2pcs.

2 pes.

.

~

.

.

.

.

.

.

Loading...

Loading...