conner CP30204 product manual

Conner Peripherals, Inc.

Cougar Series

CP30204

Intelligent Disk Drive

Product Manual

00501-043

Revision B

April, 1992

3081 Zanker Road

San Jose, CA 95134-2128

(408) 456-4500

Notice

Conner Peripherals makes no warranty of any kind with

regard to this material, including, but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Conner Peripherals shall not be liable

for errors contained herein or for incidental consequential

damages in connection with the furnishing, performance

or use of this material.

Conner Peripherals, Inc. reserves the right to change, without

notification, the specifications contained in this manual.

© Copyright Conner Peripherals, Inc. No part of this publication

may be reproduced or translated into any language in any form

without the written permission of Conner Peripherals, Inc.

IBM, PC/AT and PC/XT are registered trademarks of

International Business Machines Corporation.

1.0 Introduction

This manual describes the key features, specification

summary, physical characteristics, environmental

characteristics, functional description, electrical interface,

recommended mounting configuration, timing requirements, host address decoding, command description,

operations description, and error reporting for Conner

Peripheral's Cougar model CP30204.

Revision B - 1 -

2.0 Key Features

The CP30204 Cougar is a high performance 3.5-inch lowprofile (1.0 inch high) 213 megabyte (formatted) disk drive

with 12 ms average seek time that is designed to operate

on an IBM PC/AT

drives feature fast 12 ms average seek time, low 6.7 ms

average rotational latency and high shock resistance.

Because the drive contains the Task File within its control

logic, it requires a simplified adapter board to operate.

Conner Peripherals has developed an adapter board to be

used in conjunction with the drive on an AT or equivalent

system, the logic and a description of this adapter board

can be found in Appendix A of this document.

• High performance rotary voice coil actuator with

embedded servo system

• Auto translate feature, allowing operation as any

drive type (not exceeding its capacity)

®

or equivalent in translate mode. The

• 1,7 run length limited code

• High shock resistance

• Sealed HDA

• Automatic actuator latch against inner stop upon

power down

• Microprocessor-controlled diagnostic routines that

are automatically executed at start-up

• Automatic error correction and retries

• 512 byte block size

- 2 - Revision B

• Emulates IBM Task File and supports additional

commands

• Up to two drives may be daisy-chained on the AT

interface

• 256KB segmentable cache with LRU caching

algorithm

• Redundancy on entire data path from data

reception

• Single burst ECC on-the-fly

Revision B - 3 -

3.0 Specification Summary

3.1 Capacity

CP30204

Formatted Mbytes 212.6

3.2 Physical Configuration

Disk Type Thin film

Head Type Thin film

Actuator Type Rotary Voice-Coil

Number of Disks 2

Data Surfaces 4

Data Heads 4

Servo Embedded

Tracks per Surface 2,124

Track Density (TPI) 2,496 TPI

Formatted Track Capacity 25,088 bytes

Bytes per Block 512

Blocks per Drive 416,304

Sectors per Track (user): 49

Buffer Size 256KB segmentable

1

The physical parameters of the drive are listed in the table.

The drive's default native mode is 683 cylinders, 16 heads

and 38 sectors. This drive also supports Universal Translate.

1

CP30204

- 4 - Revision B

3.3 Performance

Seek Times

1

Physical Track to Track 3.0 ms

Logical (translated) track to track

Average

7.0 ms

12.0 ms

Maximum stroke 30.0 ms

Average Latency 6.7 ms

Rotation Speed (+0.1%) 4498 RPM

Controller Overhead < 500 µs

Data Transfer Rate (to/from Media) 2.5 Mbyte/second

Data Transfer Rate (to/from Buffer) 8.0 Mbyte/second

Start Time(Power Up)

(0 RPM - 4498 RPM)

3

typical: 10 seconds

maximum: 15 seconds

(0 RPM - Ready)

typical: 15 seconds

maximum: 20 seconds

Stop Time (Power Down) typical: 15 seconds

maximum: 20 seconds

Start/Stop cycles 20,000 minimum

Interleave 1:1

1

The timing is measured through the interface with the drive

operating at nominal DC input voltages. The timing is based

upon the physical parameters of the disk and may be affected

by translation and/or DOS overhead at the system level.

2

The average seek time is determined by averaging the seek

time for a minimum of 1000 seeks of random length over the

surface of the disk.

3

These numbers assume spin recovery is not invoked. If spin

recovery is invoked, the maximum could be 40 seconds.

Briefly removing power can lead to spin recovery being

invoked.

2

Revision B - 5 -

3.4 Read/Write

Interface Task File

Recording Method 1 of 7 RLL code

Recording Density (ID) 44,610 bits per inch

Flux Density (ID) 34,207 flux reversals per inch

3.5 Power Requirements (Typical)

+5V DC ± 5%

(Typical)

Read/Write Mode 440 ma 400 ma 7.0 W

Seek Mode 320 ma 420 ma 6.6 W

Idle Mode 320 ma 300 ma 5.2 W

Spin-up Mode 550 ma 1500 ma n/a

+12V DC ± 10%

(Typical)

Power

Maximum noise allowed (DC to 1 MHZ, with equivalent

resistive load):

Voltage Noise

+5 Volt 2%

+12 Volt 1%

Read/Write Mode occurs when data is being read from

or written to the disk.

Seek Mode occurs while the actuator is in motion.

Idle Mode occurs when the drive is not reading, writing

or seeking. The motor is up to speed and DRIVE READY

condition exists. Actuator is residing on last accessed

track.

- 6 - Revision B

Spin-Up Mode occurs while the spindle motor is

accelerating from its rest state to its operating speed. The

specified current is the average value over the spin-up

cycle.

3.6 Physical Characteristics

Outline Dimensions ±.010" 1.00" x 4.00" x 5.75"

Weight 1.3 pounds

Revision B - 7 -

4.0 Environmental Characteristics

4.1 Temperature

Operating 5°C to 55°C

Non-operating -40°C to 60°C

Thermal Gradient 20°C per hour maximum

4.2 Humidity

Operating 8% to 80% non-condensing

Non-operating 8% to 80% non-condensing

Maximum Wet Bulb 26°C

4.3 Altitude (relative to sea level)

Operating -200 to 10,000 feet

Non-operating (maximum) 40,000 feet

4.4 Reliability And Maintenance

MTBF 150,000 hours (POH)

MTTR 10 minutes typical

Preventive Maintenance None

Component Design Life 5 years

Data Reliablity <1 non-recoverable error in

1013 bits read

1

Projected MTBF based on comparison of similar

Conner products.

- 8 - Revision B

1

4.5 Shock and Vibration

Shock 1/2 sine pulse, 11 millisecond duration

Vibration Swept sine, 1 octave per minute

Non-operating shock 75G's

Non-operating vibration

5-62 HZ (1/2 oct/min) 0.020 inch displacement (double amplitude)

63-500 Hz (1/2 oct/min) 4 G's peak

Operating Shock 5 G's (without non-recoverable errors)

Operating Vibration

5-22 Hz .010 inch displacement (double amplitude)

23-500 Hz .5 G's (without non-recoverable error)

4.6 Magnetic Field

The disk drive will meet its specified performance while

operating in the presence of an externally produced

magnetic field of 6 gauss DC maximum.

4.7 Acoustic Noise

The sound pressure level will not exceed 40 dBA at a

distance of 1 meter from the drive.

Revision B - 9 -

4.8 Safety Standards

Conner Peripherals disk drives are designed to comply

with relevant product safety standards such as:

• UL 478, 5th edition, Standard for Information

Processing and Business Equipment and

UL 1950, Safety of Information Technology

Equipment including Electrical Business

Equipment

• CSA 22.2 #220, Information Processing and

Business Equipment and

CSA 22.2 #950, Safety of Information Technology

Equipment including Electrical Business

Equipment

• TUV-IEC 380, Safety of Electrically Energized

Office Machines and

TUV-IEC 950, Safety of Information Technology

Equipment including Electrical Business

Equipment

• TUV-VDE EN60950

VDE 0805/5.9

• FCC Class B Part 15 Subpart J

- 10 - Revision B

5.0 Functional Description

The drive contains all necessary mechanical and

electronic parts to interpret control signals, position the

recording heads over the desired track, read and write

data, and provide a contaminant free environment for the

heads and disks.

5.1 Read/Write and Control Electronics

One integrated circuit is mounted within the sealed

enclosure in close proximity to the read/write heads. Its

function is to provide head selection, read preamplification, and write drive circuitry.

The dual microprocessor-controlled circuit card provides

the remaining electronic functions which include:

• Read/Write Circuitry

• Rotary Actuator Control

• Interface Control

• Spin Speed Control

• Dynamic Braking

At power down the heads are automatically retracted to

the inner diameter of the disk and are latched and parked

on a landing zone that is off of the data tracks at the inner

diameter of the disk.

5.2 Drive Mechanism

A brushless DC direct drive motor rotates the spindle.

The motor/spindle assembly is dynamically balanced to

provide minimal mechanical runout to the disks. A

dynamic brake is used to provide a fast stop to the spindle

motor and return the heads to the landing zone when

power is removed.

Revision B - 11 -

5.3 Air Filtration System

The head-disk assembly is a sealed enclosure with an

integral 0.3 micron filter which maintains a clean

environment for the heads and disks.

5.4 Head Positioning Mechanism

The read/write heads are supported by a mechanism

coupled to a rotary voice coil actuator.

5.5 Read/Write Heads and Disks

Data is recorded on 95mm diameter disks through

miniature 3370 type thin film heads.

5.6 Customer Options

C/D

Up to two drives may be daisy chained together utilizing

the 40 pin Task File connector. The maximum cable

length is 18 inches. In order to install more than one

drive, it is necessary to set a jumper option. The C/D

jumper is used to determine whether the drive is a master

(drive C) or slave (drive D). The drive is configured as a

master (drive C) when jumpered and as a slave drive (D

drive) when not jumpered. (Refer to description of

-PDIAG signal for further information on master/slave in

Conner drives.)

- 12 - Revision B

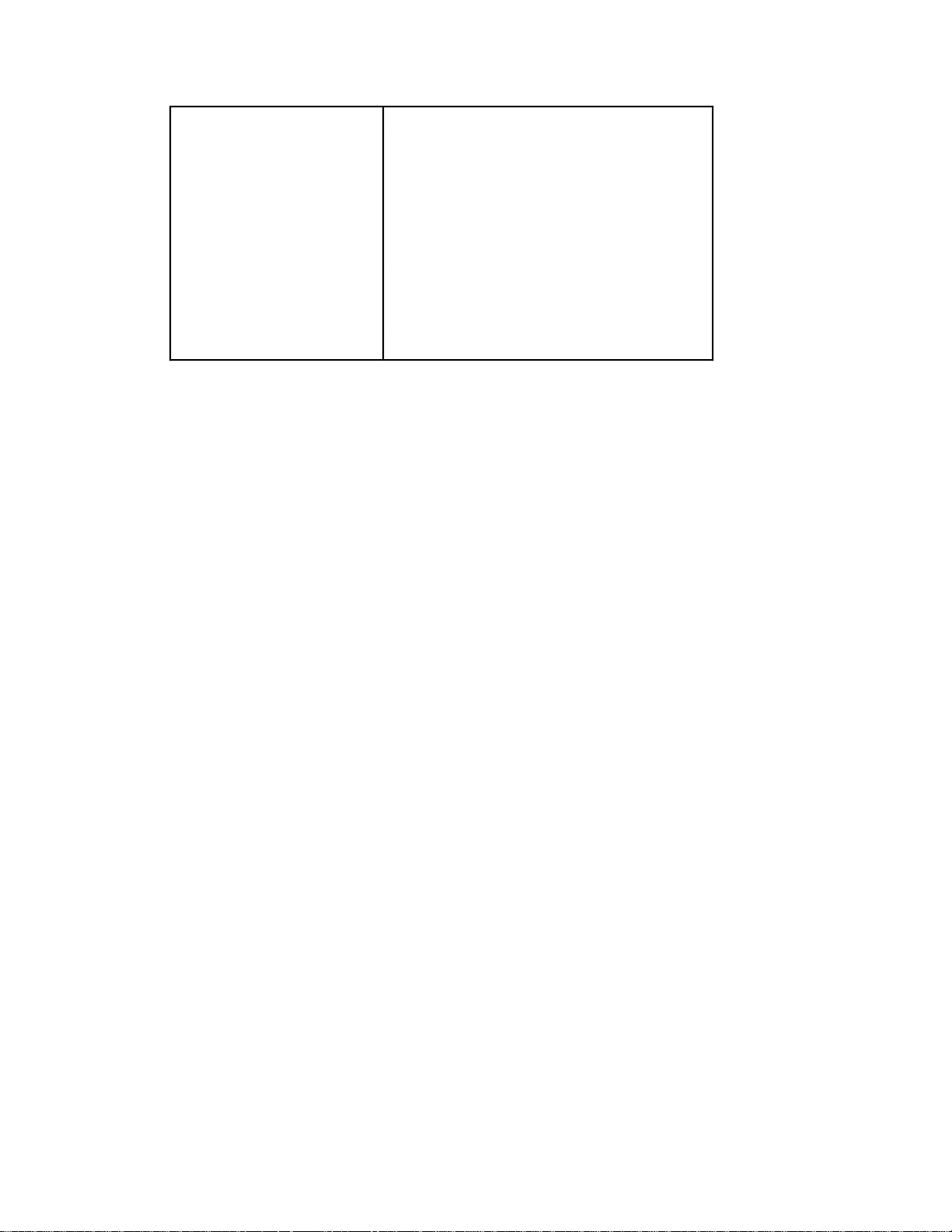

DSP & SS

This pair of jumpers determines the signals on pin 39 of

the interface connector.

Jumper

DSP SS Action

- spindle synchronization signal disabled on pin 39.

X

- activity LED signal available on pin 39.

- spindle synchronization signal enabled on pin 39.

X

- activity LED signal disabled from pin 39.

- pin 39 floating.

Master/slave in ATA compatible mode uses pin 39 in a

time multiplexed manner to indicate that a slave drive is

present. During power-on-reset or after RESET is

asserted, this line is asserted by the slave drive within

400 ms to indicate its presence. The master drive allows

up to 450 msec for the slave drive to assert -HOST

SLV/ACT. -HOST SLV/ACT is deasserted by the slave

drive following its acceptance of the first valid command

or after 31 seconds, whichever comes first.

Jumpers E1, E2, E3

E1 Jumper in disables spin-up at power-on. The drive will

automatically spin up when it receives a command which accesses

the drive.

E2 Unused

E3 Unused

Revision B - 13 -

J3 Connector

A drive select LED may be driven using two alternative

pins on this drive. Pin 39 on the interface connector can

be used to drive the LED with a current limited 5 volt

supply if it is not configured for Spindle Synchronization.

The 16-pin auxiliary connector (J3), pins 3 and 4 provide

an open collector drive signal and a current limiting

resistor connected to +5V.

The spindle synchronization signal is also available on

Pin 2 of J3.

- 14 - Revision B

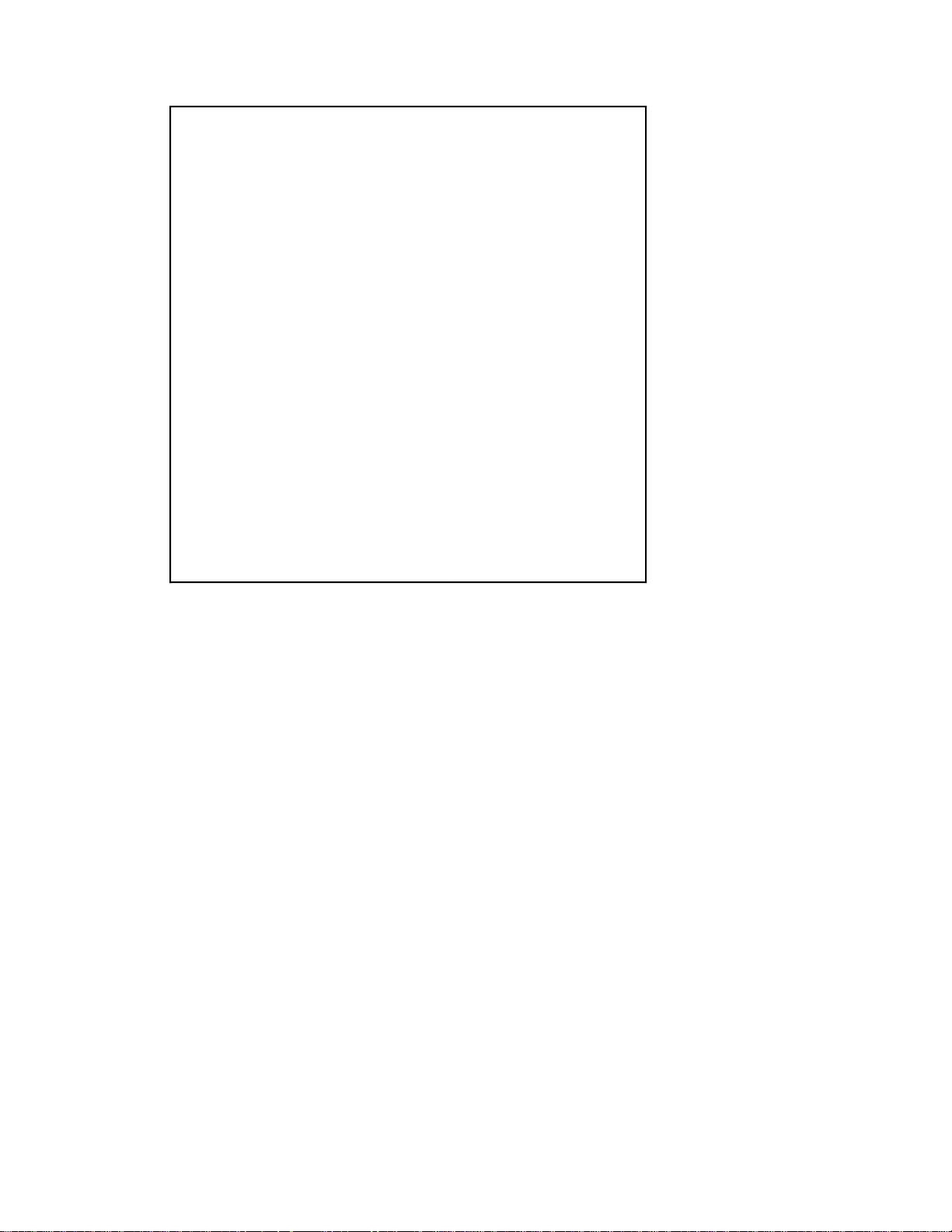

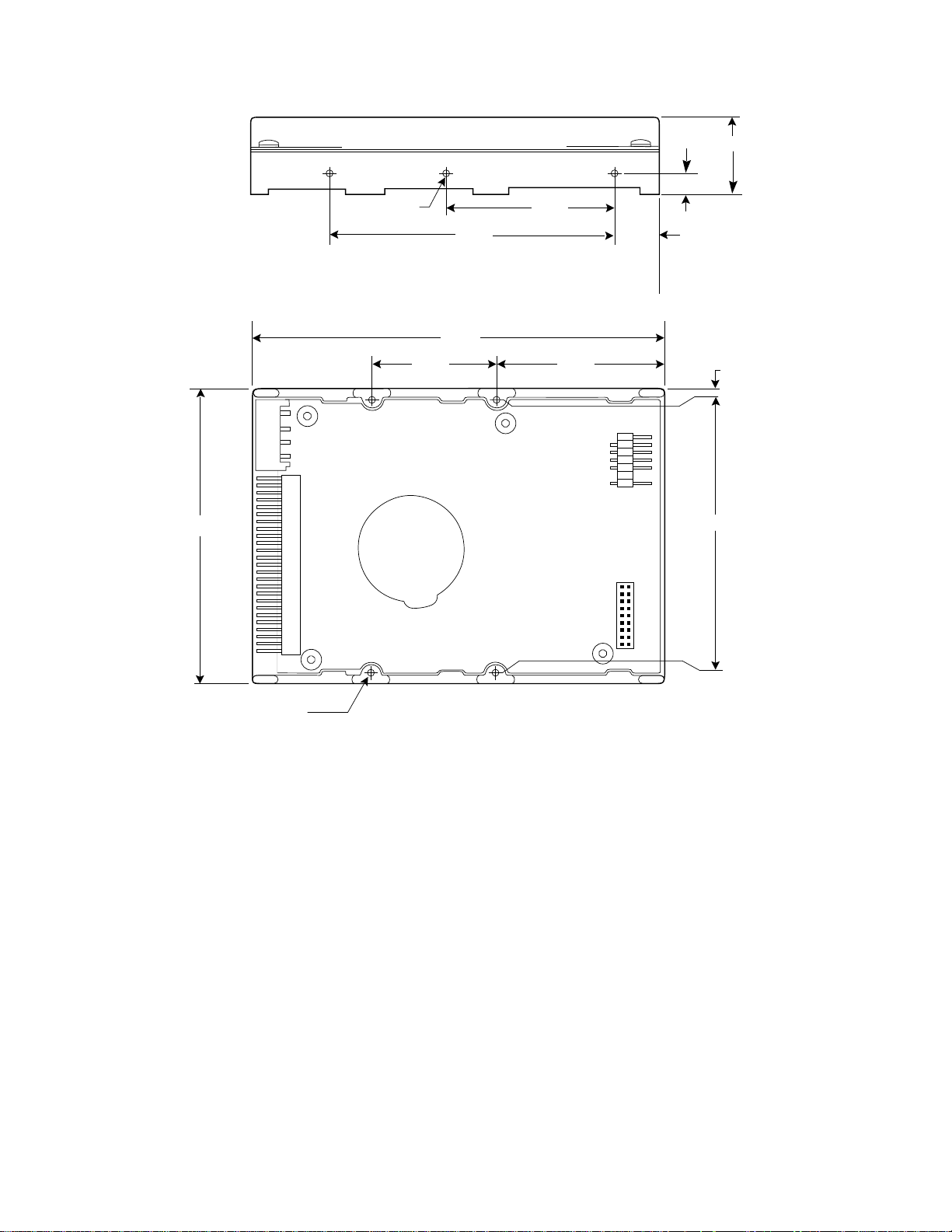

6.0 Mounting Configuration

6-32 UNC 2B

5/32" MAX (6X)

4.000

5.75

1

2

3

4

2.362

2.3751.750

1.00

.250

.630

.125

4.00

6-32 UNC 2B

3/8" MAX (4X)

TOLERANCES: .XXX .010

Figure 1. Mounting Configuration

Revision B - 15 -

3.750

+

–

7.0 Measuring Drive Specifications

7.1 Seek Times

The timing is measured through the interface with the

drive operating at nominal DC input voltages. The timing

also assumes that the BIOS and PC system hardware

dependency have been subtracted from timing

requirements and that the drive is operated using its

native drive parameters.

Average seek time is determined by averaging the seek

time for a minimum of 1000 seeks of random length over

the disk surface.

7.2 Start Time (Power Up)

Numbers specified assume that spin recovery is not

invoked. If spin recovery is invoked, the max could be 40

seconds. Briefly removing power can lead to spin recovery

being invoked.

7.3 Shock

Drives are subjected to specified G level shock for 11

milliseconds with a 1/2 sine wave pulse. The drive meets

specification without suffering non-recoverable READ or

WRITE errors or other damage.

7.4 Vibration

Drives are subjected to specified vibration levels at 1/2

octave per minute sweep. The drive meets the

specification without non-recoverable errors, READ or

WRITE errors, or other damage.

- 16 - Revision B

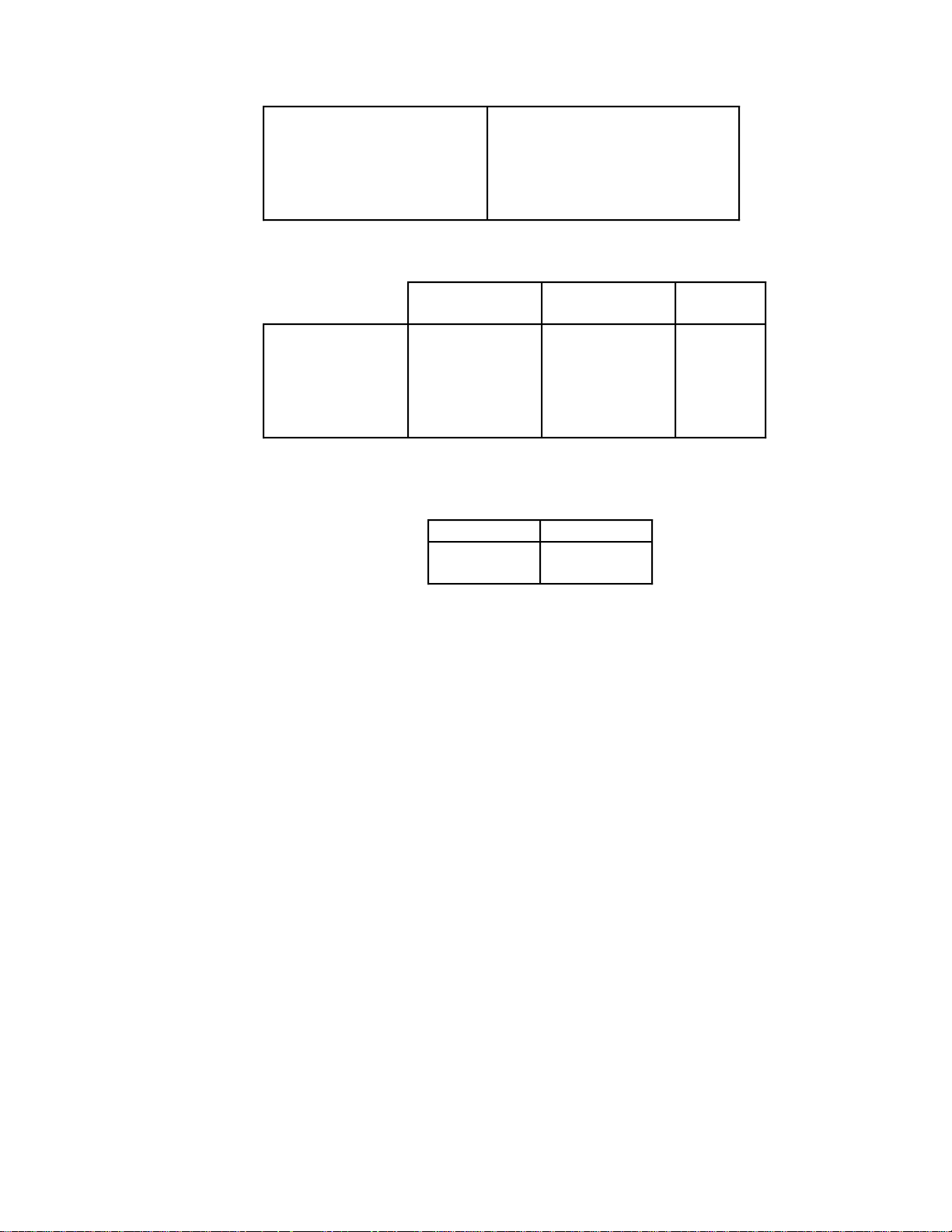

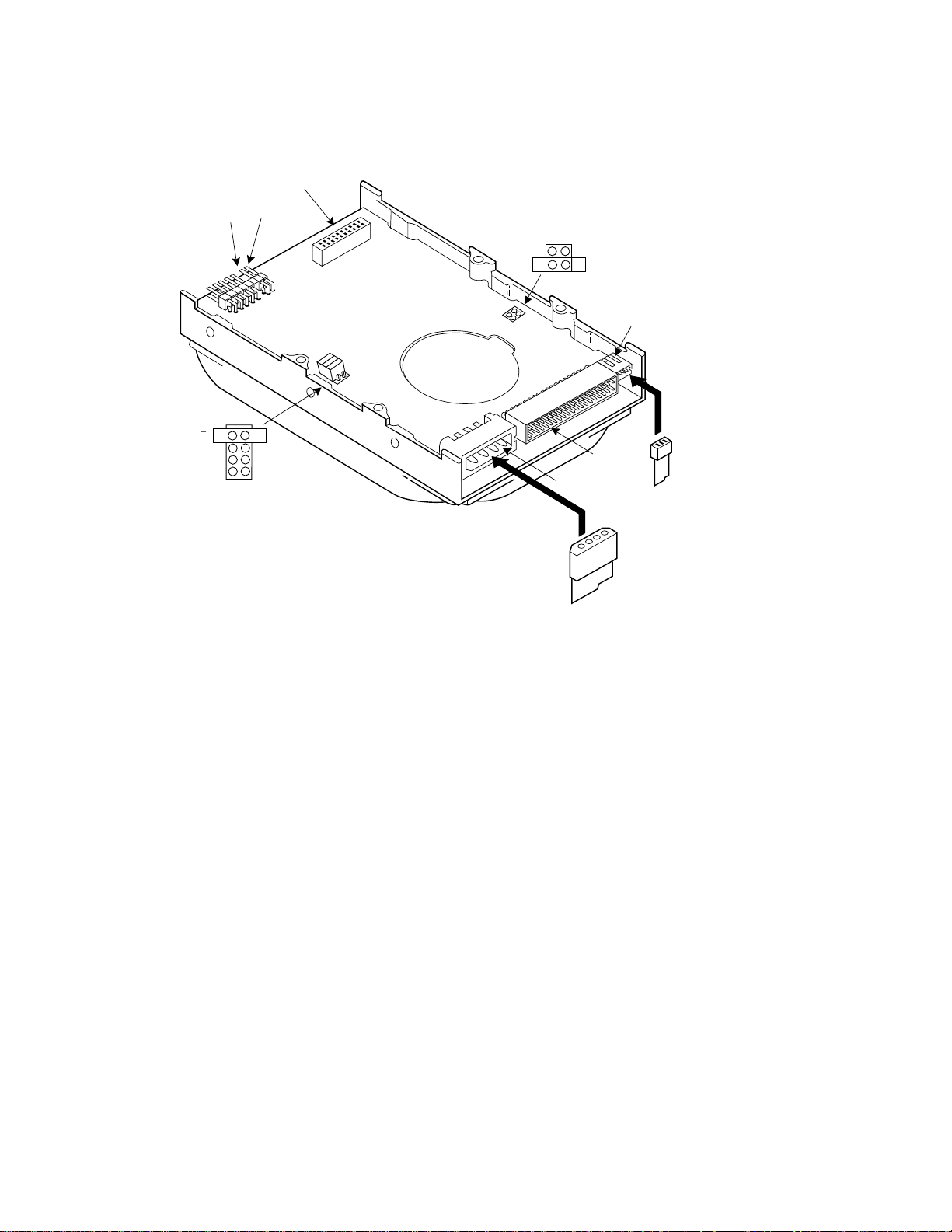

LED

SPINSYNC

HDA

SPNSYNC

DSP

POWER

CONNECTOR

J4

C/D

E1

E2

E3

Figure 2. Connectors and Jumper Options

Revision B - 17 -

J6

POWER

1

J2

40 PIN

TASK FILE

INTERFACE

4

3

2

3

2

1

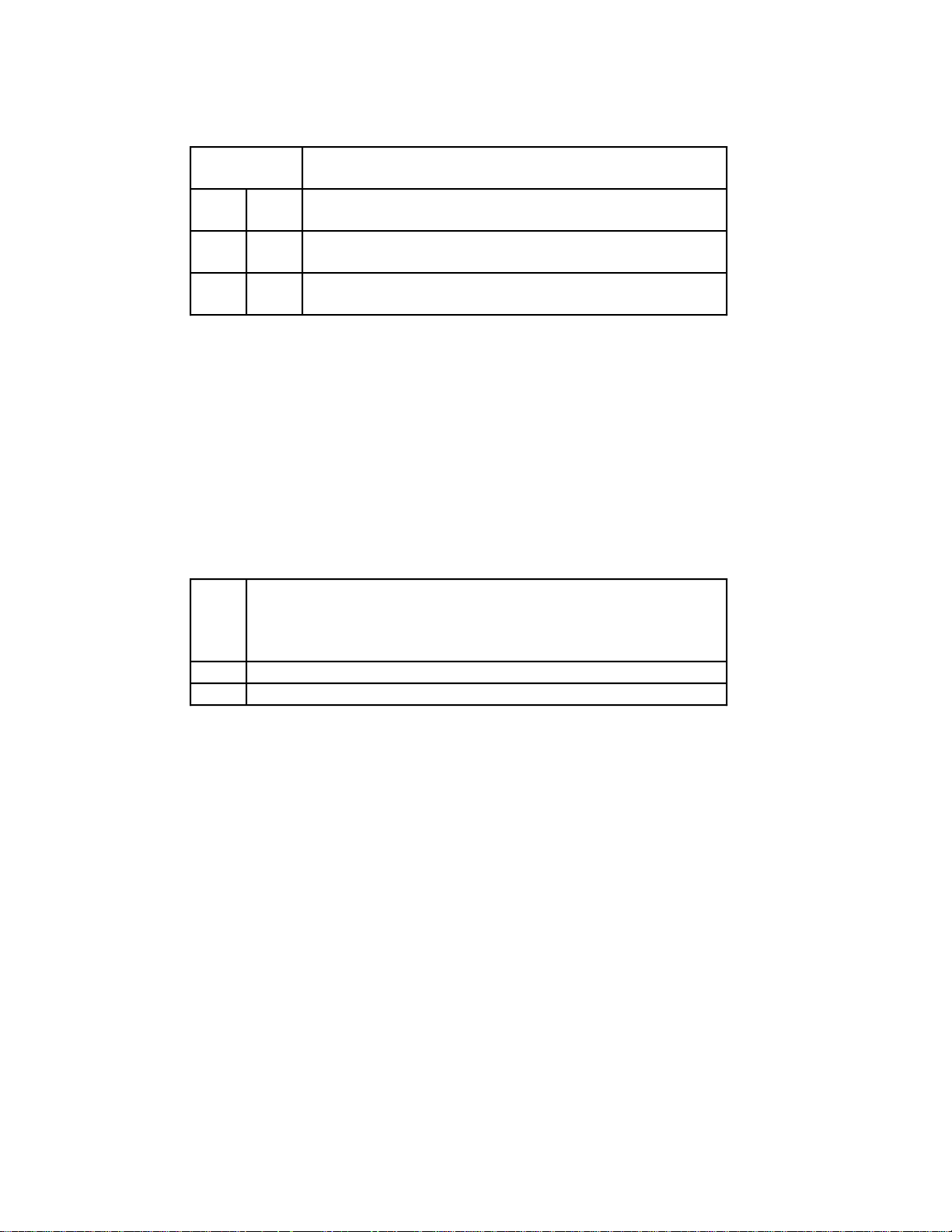

8.0 Electrical Description

8.1 Power Connectors

The drive has two power connectors; a standard 4 pin DC

power connector and a smaller 3 pin connector. Power

must only be supplied at one source.

The mating connector for the 4 pin connector is AMP 1480424-0 (Housing) and AMP 60619-4 (loose piece) or

61117-4 (strip) contacts.

The following table describes the 4 pin power connector

pins:

Pin Signal

1 +12V

2 GND

3 GND

4 +5V

The mating connector for the three pin connector is Molex

series 54-84 Header, housing Molex part number 39-010033 and terminal part number 39-00-0031 (loose) or 3900-0023 (strip).

The following table describes the 3 pin power connector

pins.

Pin Signal

1 +5V

2 +12V

3 GND

- 18 - Revision B

9.0 Host Interface

9.1 Description

The interface between the drive adapter and the drive is

called the Host Interface. The set of registers in I/O space

of the Host controlled through the Host Interface is

known as the Task File. The physical interface from the

drive to the host is implemented using a 40 pin connector.

9.2 Interface Connector

The recommended mating connector is Molex P/N 15-473401 or equivalent. Two drives may be daisy chained on

this connector, and the maximum cable length is 18

inches.

9.3 Signal Levels

All signal levels are TTL compatible. A logic 1 is > 2.0

Volts. A logic 0 is from 0.00 Volts to .70 Volts.

9.4 Signal Conventions

All signals on the Host Interface shall have the prefix

HOST. All active low signals shall be further prefixed

with a "-" designation. All active high signals shall be

prefixed with a '+' designation. Signals driven only by the

Host will be indicated with an O, the signals driven by the

drive with an I, and signals which can be driven by either

the Host or the drive will be indicated with an I/O.

Revision B - 19 -

9.5 Pin Descriptions

The following table describes all of the pins on the Task

File Interface.

Pin Signal Pin Signal

01 -HOST RESET 02 GND

03 +HOST DATA 7 04 +HOST DATA 8

05 +HOST DATA 6 06 +HOST DATA 9

07 +HOST DATA 5 08 +HOST DATA 10

09 +HOST DATA 4 10 +HOST DATA 11

11 +HOST DATA 3 12 +HOST DATA 12

13 +HOST DATA 2 14 +HOST DATA 13

15 +HOST DATA 1 16 +HOST DATA 14

17 +HOST DATA 0 18 +HOST DATA 15

19 GND 20 KEY

21 RESERVED 22 GND

23 -HOST IOW 24 GND

25 -HOST IOR 26 GND

27 RESERVED 28 +HOST ALE

29 RESERVED 30 GND

31 +HOST IRQ14 32 -HOST IO16

33 +HOST ADDR 1 34 -HOST PDIAG

35 +HOST ADDR 0 36 +HOST ADDR 2

37 -CS0 38 -CS1

39 -HOST SLV/ACT 40 GND

- 20 - Revision B

Signal Name Dir Pin Description

-HOST RESET O 1 Reset signal from the Host

system which is active low

during power up and inactive

thereafter.

GND O 2 Ground between the drive and

the Host.

+HOST DATA I/O 3-18 16 bit bi-directional data bus 0-

15 between the host and the

drive. The lower 8 bits, HD0HD7, are used for register &

ECC access. All 16 bits are

used for data transfers. These

are tri-state lines with 24 mA

drive capability.

GND O 19 Ground between the drive and

the Host.

KEY N/C 20 An unused pin clipped on the

drive and plugged on the cable.

Used to guarantee correct

orientation of the cable.

RESERVED O 21,27,29

GND O 22 Ground between the drive and

the host.

-HOST IOW O 23 Write strobe, the rising edge of

which clocks data from the host

data bus, HD0 through HD15,

into a Task File register on the

drive.

GND O 24 Ground between the drive and

the host.

Revision B - 21 -

Signal Name Dir Pin Description

-HOST READ IOR O 25 Read strobe, which when low

enables data from Task File on

the drive onto the host data bus,

HD0 through HD15. The rising

edge of -HOST IOR latches

data from the drive at the host.

GND O 26 Ground between the drive and

the Host.

+HOST ALE O 28 Host Address Latch Enable. A

signal used to qualify the

address lines. This signal is

presently not used .

GND O 30 Ground between drive and host.

+HOST IRQ14 I 31 Interrupt to the Host system,

enabled only when the drive is

selected, and the host activates

the -IEN bit in the Digital Output

register. When the -IEN bit is

inactive, or the drive is not

selected, this output is in a high

impedance state, regardless of

the state of the IRQ bit. The

interrupt is set when the IRQ bit

is set by the drive CPU. IRQ is

reset to zero by a Host read of

the Status register or a write to

the Command register. This

signal is a tri-state line with 8 ma

drive capacity.

- 22 - Revision B

Loading...

Loading...