Conner CFP1080S, CFP1080E user manual

CFP1080S/CFP1080E

Intelligent Disk Drive

Product Manual

Production Release Per ECO 6561

P/N 20401007-001

Revision A

August 1995

3081 Zanker Road

San Jose, CA 95134-2128

(408) 456-4500

FCC Notice

This equipment generates and uses radio frequency energy and, if not installed

and used properly; that is, in strict accordance with the manufacturer's

instructions, may cause interference to radio and television reception. It has

been type tested and found to comply with the limits for a Class B computing

device in accordance with the specifications in Part 15 of FCC Rules, which are

designed to provide reasonable protection against such interference in a

residential installation. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause interference

to radio or television reception, which can be determined by turning the

equipment on and off, you are encouraged to try to correct the interference by

one or more of the following measures:

• Reorient the receiving antenna.

• Relocate the computer with respect to the receiver.

• Move the computer into a different outlet so that the computer and receiver

are on different branch circuits.

If necessary, you should consult the dealer or an experienced radio/television

technician for additional suggestions. You may find the following booklet

prepared by the Federal Communications Commission helpful:

How to Identify and Resolve Radio-TV Interference Problems

This booklet (Stock No. 004-000-00345-4) is available from the U.S. Government

Printing Office, Washington, DC 20402.

Warning: Changes or modifications made to this equipment which have not

been expressly approved by Conner Peripherals, Inc. may cause radio and

television interference problems that could void the user's authority to operate

the equipment.

Further, this equipment complies with the limits for a Class B digital apparatus

in accordance with Canadian Radio Interference Regulations.

Cet appareil numérique de la classe B est conforme au Règlement sur le

brouillage radioélectrique, C.R.C., ch. 1374.

Conner and the Conner logo are registered trademarks of Conner Peripherals,

Inc. All other trademarks mentioned in this manual are property of their

respective owners.

Copyright 1994,1995 Conner Peripherals, Inc.

All rights reserved.

Document No. 501-082 08/95

Important Information About this Manual

All information contained in or disclosed by this document is considered

proprietary by Conner Peripherals, Inc. By accepting this material, the recipient

agrees that this material and the information contained therein are held in

confidence and in trust and will not be used, reproduced in whole or in part, nor

its contents revealed to others, except to meet the purpose for which it was

delivered. It is understood that no right is conveyed to reproduce or translate

any item herein disclosed without express written permission from Conner

Peripherals, Inc.

Conner Peripherals, Inc. provides this manual "as is," without warranty of any

kind, either expressed or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Conner

Peripherals, Inc. reserves the right to change, without notification, the

specifications contained in this manual.

Conner Peripherals, Inc. assumes no responsibility for the accuracy,

completeness, sufficiency, or usefulness of this manual, nor for any problem that

might arise from the use of the information in this manual.

Table of Contents

1. Drive Overview 1

2. Specifications 9

Drive Description 1

Drive Features 2

Drive Components 3

Mechanical Design Features 3

Drive Assembly Housing 4

Drive Motor and Spindle 5

Head Positioning Mechanism 5

Read/Write Heads and Disks 5

Data and Power Connections 5

Electrical Design Features 5

Integrated Circuit 5

Circuit Board 5

Read/Write Channel 6

Firmware 6

Specifications in this Chapter 9

Drive Capacity 10

Formatted Capacity 10

Physical Configuration 10

Physical Configuration per Zone 10

Performance Characteristics 11

Seek Times (typical)

Average Latency 11

Rotation Speed (+0.1%) 11

Controller Overhead

Start Time(Power Up)

Stop Time at Power Down 11

Interleave 11

Read/Write Characteristics 12

Recording Method 12

Recording Density (maximum) 12

Flux Density (maximum) 12

SCSI Characteristics 12

Command Set 12

Data Transfer Rate 12

Maximum Synchronous Transfer Offset: 12

Maximum Tagged Command Queue Depth: 12

Reliability 13

Data Reliability 13

Component Design Life 13

Start/Stop cycles 13

Mean Time Between Failures: 13

Mean Time to Repair 13

Preventive Maintenance 13

Power Requirements 13

Minimum/Maximum Voltage: 13

Environmental Tolerances 14

Magnetic Field: 14

1

3

4

11

11

11

Technical Reference Manual Page i

Table of Contents Conner CFP1080E/CFP1080S

Acoustic Noise: 14

Safety Standards 15

Physical Characteristics - CFP1080E 16

Physical Characteristics - CFP1080S 17

3. Drive Operation 19

Drive Functions 19

Drive Operational Modes 19

Error Correction 20

Read Retry Operations 20

Downloadable Microcode 21

Buffer Management and Command Execution 22

SCSI Look Ahead Control Code 22

Write Caching 24

SCSI Queuing Control Code 25

Command Re-ordering 25

Buffer Management 25

4. Installing the Drive 27

Take These Precautions 27

Installing the Drive 27

Installing a CFP1080E 28

Setting the Drive's Jumpers - CFP1080E 28

Setting the SCSI Bus Address - CFP1080E 28

Disabling Spin-Up at Power On - CFP1080E 29

Delaying Spin Up at Power On - CFP1080E 29

Host Interface Connection - CFP1080E 29

Attaching Power to the Drive - CFP1080E 31

Mounting the Drive - CFP1080E 31

Installing a CFP1080S 32

Setting the Drive's Jumpers - CFP1080S 32

Setting the SCSI Bus Address - CFP1080S 33

Disabling Spin-Up at Power On - CFP1080S 34

Disabling SCSI Bus Terminator Power (TERMPWR) -

CFP1080S 34

Setting the Bus Termination - CFP1080S 35

Cabling the Drive - CFP1080S 36

SCSI Bus Cable 36

Spindle Synchronization 36

Attaching Power to the Drive - CFP1080S 37

Attaching a Remote LED - CFP1080S 37

Mounting the Drive - CFP1080S 37

5. Interface Physical Characteristics 39

Electrical Description 39

Output Characteristics 39

Input Characteristics 40

Model-Specific SCSI Physical Characteristics 40

CFP1080E (WIDE, 80-pin Single Connector Attachment [SCA]) 41

External Terminator Power 41

Internal Termination 41

Cable Requirements 41

Page ii Conner CFP1080E/CFP1080S

Conner CFA850/CFA1275 Table of Contents

Connector Requirements 42

Single Connector Attachment (SCA) Signal Definitions 42

Power 42

Spindle Sync 42

LED Out 42

Motor Start Controls 43

SCSI ID Selection 43

Interface Pin Assignments 44

Model CFP1080S (Narrow, 50-pin SCSI) 45

External Terminator Power 45

Internal Termination 45

Cable Requirements 46

Connector Requirements 47

Interface Pin Assignments 48

Interface Timing Requirements 49

6. SCSI Command Implementation 51

SCSI Command Summary 51

Drive Dependent SCSI Mode Sense Data 51

Format Device Page - 03

Rigid Disk Geometry Page - 04

Notch Page - 0C

H

H

H

52

54

55

Technical Reference Manual Page iii

Table of Contents Conner CFP1080E/CFP1080S

Page iv Conner CFP1080E/CFP1080S

Drive Overview

Drive Description

The CFP1080S and CFP1080E are high performance 3.5-inch low-profile (1.0

inch high) disk drives. The both offer 11 millisecond average seek time for

Reading, 11.5 millisecond seek time for Writing, with an average latency of only

5.56ms. High capacity is achieved by utilizing a zone density recording

technique using 8 recording zones at an areal density of 247 Mbits per square

inch. These drives feature high performance while maintaining low power

consumption to reduce power supply current and system cooling requirements in

disk arrays.

They are designed to operate on the Small Computer System Interface (SCSI)

and are SCSI-2 command compatible. The mechanical and major electronic

components are identical between the models and differ only in the SCSI

physical interface.

Drive Model Form Factor Interface Capacity

CFP1080S

CFP1080E

1

1 inch high, 3.5 inch

1 inch high, 3.5 inch 80-pin Single Ended FAST 1080MB

50-pin Single Ended FAST

1080MB

For simplicity, we often refer to these drives collectively in this manual as “the

drive.”

Technical Reference Manual Page 1

Chapter 1 Overview of the Drives

Drive Features

The drives provide the following features:

• 256 KB segmented cache buffer in the CFP1080S and 512 KB segmented

cache buffer in the CFP1080E.

• Tagged Command Queuing with Minimum Access Time Re-ordering and

Write/Read Coalescing

• Down-loadable Code through SCSI Interface

• SCSI-2 Compatibility

• 88 bit Reed-Solomon EDAC with on the fly error correction

• Microprocessor-controlled diagnostic routines execute at start-up

• Automatic Spindle Synchronization

• Voltage Regulated Termination Power with removable Resistor Packs (SCSI-

2, Alternative 2)

• Active Negation output drivers

• High performance rotary voice coil actuator with embedded servo system

• No thermal recalibration required to maintain performance levels

• High Shock resistance

• Automatic actuator latch against the inner stop upon power down with

dedicated landing zone

• Sealed HDA

• 1,7 run length limited code

Page 2 Conner CFP1080E/CFP1080S

Overview of the Drives Chapter 1

Drive Components

The drive is composed of mechanical, electrical, and firmware elements.

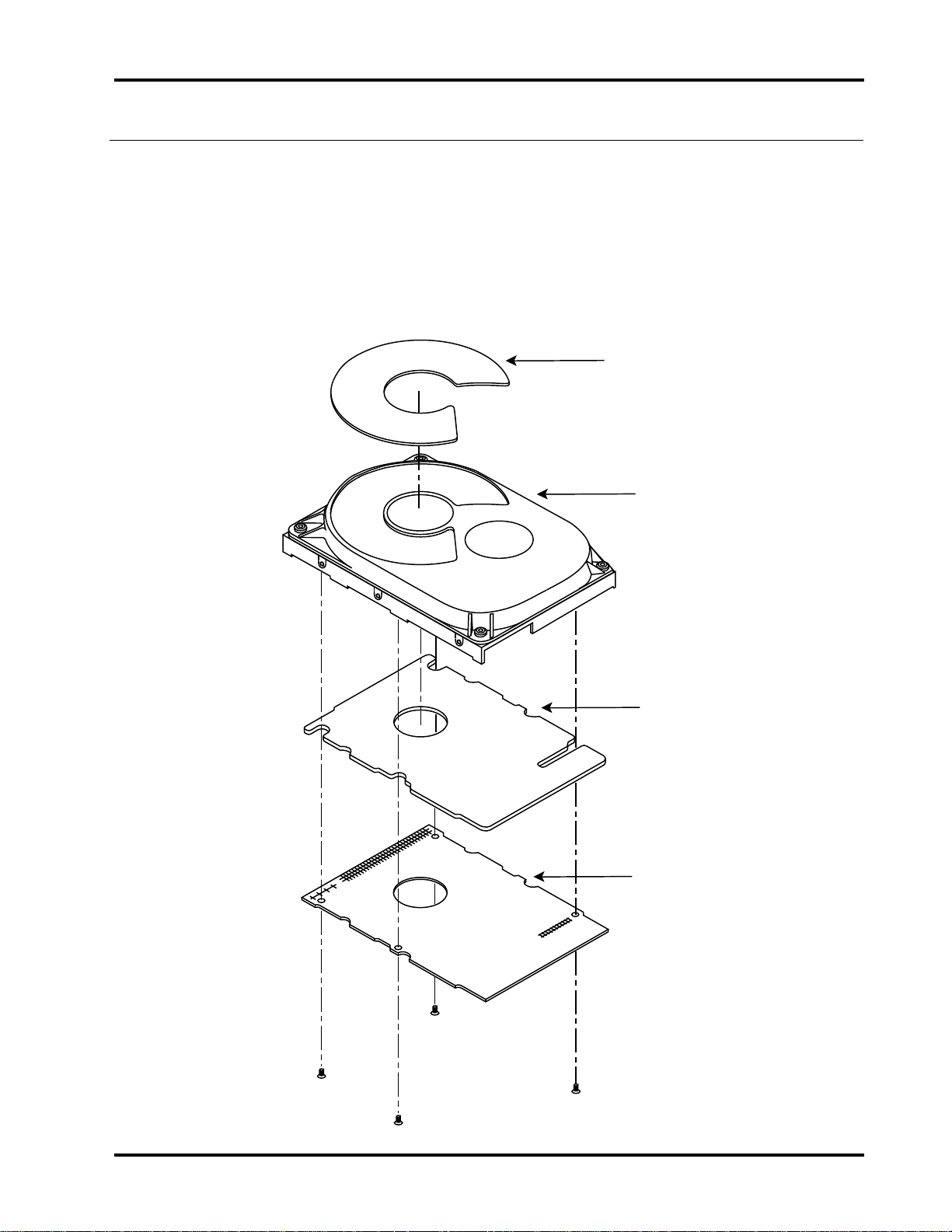

Mechanical Design Features

The drive’s hardware includes the components described in the following

sections. Figure 1-1 shows the drive top level assembly.

Figure 1-1

Drive Top Level Assembly

Damper

Head-Disk

Assembly

Printed Circuit

Board Assembly

Shield

Printed

Circuit

Board

Assembly

Technical Reference Manual Page 3

Chapter 1 Overview of the Drives

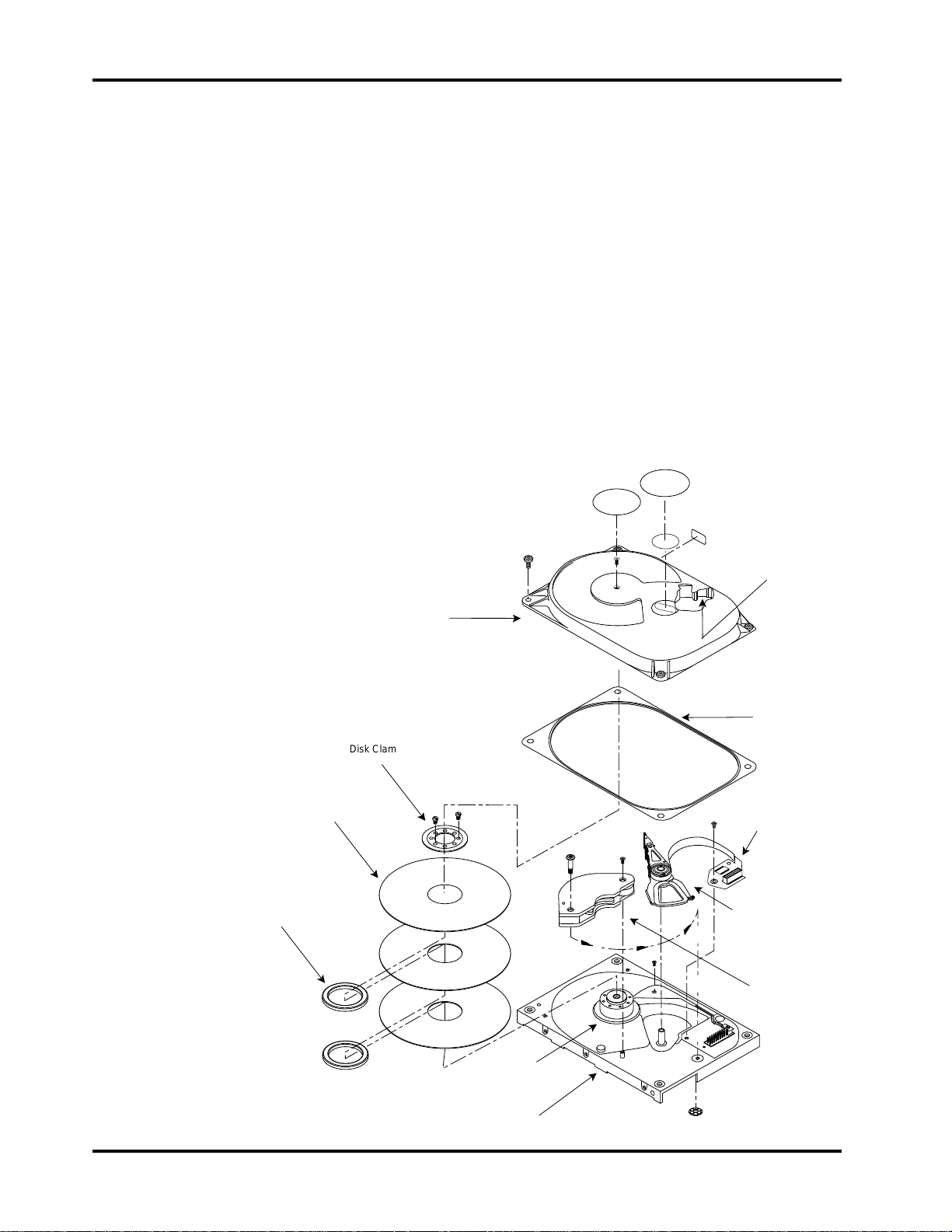

Drive Assembly Housing

The drive assembly housing, or Head-Disk Assembly (HDA) consists of a die-cast

aluminum base on which is mounted a die-cast aluminum cover. Both the base

and the cover are fabricated using an alloy and surface finishing process

designed to inhibit oxidation. A gasket seals the joint between the base and

cover to retard the entry of moisture and environmental contaminants from the

assembly.

This assembly, the head-disk assembly (HDA), contains an integral 0.3 micron

filter, which maintains a clean environment. Critical drive components are

contained within this contaminant-free environment. Figure 1-2 shows the HDA

and the major assemblies contained within it:

Figure 1-2

Head-Disk Assembly

Disk (1 of 3)

Disk

Spacer (1 of 2)

Disk Clamp

Top Cover

Filter

Gasket

Preamplifier/

Flex Circuit

Assembly

Head-Stack

Assembly

Actuator

Magnet

Assembly

Spindle Motor

Base Assembly

080S_1_2

Page 4 Conner CFP1080E/CFP1080S

Overview of the Drives Chapter 1

Drive Motor and Spindle

A brushless DC direct-drive motor assembly is mounted on the drive’s base. The

motor rotates the drive’s spindle at 5400 RPM. The motor/spindle assembly is

dynamically balanced to provide minimal mechanical runout to the disks. A

dynamic brake is used to provide a fast stop to the spindle motor and return the

heads to the landing zone when power is removed.

Head Positioning Mechanism

The read/write heads are supported by a mechanism coupled to a rotary voice

coil actuator.

Read/Write Heads and Disks

Data is recorded on 95mm diameter disks through 3370-type 70% nano-slider

thin film heads. The drive contains three sputtered thin film disks with six data

surfaces and six read/write heads.

At power-down, the heads are automatically retracted to the inner diameter of

the disk and are latched and parked on a landing zone that is inside the data

tracks.

Data and Power Connections

Data and power connections to the drive are differ between the drive models.

Refer to chapter 4 for information regarding a specific model's requirements.

Electrical Design Features

Integrated Circuit

A single integrated circuit (IC) is mounted within the sealed hard drive assembly

in close proximity to the read/write heads. The IC provides head selection, read

pre-amplification, and write drive circuitry.

Circuit Board

The drive’s microprocessor-controlled circuit board provides the remaining

electronic functions, which include:

• read/write circuitry

• rotary actuator control

• interface control

• spin speed control

• auto-park

• power management

The processor is a 16-bit Motorola 68HC16. The entire data path between the

serializer-deserializer and the interface chip, including the buffer (cache) is 8

bits wide to provide high data throughput. The CFP1080E has a 16-bit wide

data path.

Technical Reference Manual Page 5

Chapter 1 Overview of the Drives

The data buffer (cache) utilizes two 256 KB x 4 Dynamic RAMs in the CFP1080S

and a single 256K x 16 Dynamic RAM in the CFP1080E. Data path integrity is

ensured by appending a 4-byte CRC to blocks as they are transferred from the

interface to the buffer through the SCSI controller chip. This CRC is verified by

the buffer manager chip as blocks are transferred from the buffer to the disk. A

sector data field consists of 512 bytes of data, 4 bytes of CRC and 11 bytes of

Error Detection And Correction (EDAC) code. The CRC is checked by the SCSI

controller chip as blocks are transferred from the buffer to the interface. The

CRC is not sent to the initiator.

Low SCSI transaction overhead is maintained by automating common SCSI bus

phases with the SCSI controller chip.

Read/Write Channel

The Read/Write channel, in addition to the preamplifier discussed earlier,

consists of three integrated functions in a single IC:

• Pulse Detector

• Data Separator

• Time base

Firmware

The drive’s firmware can be considered in three parts. There are two types of

SCSI control code and the disk control code with SCSI boot code.

The disk control and SCSI boot code reside in the ROM for the 68HC16

processor. This firmware is responsible for:

• starting the spindle motor and maintaining precise rotational speed

• controlling track following and actuator motion during seeking

• managing disk (media) R/W activity

• power management

• monitoring the overall health of the drive

• serial port communications

• uploading SCSI control code from the disk to RAM

• downloading SCSI control code to the disk

• supporting SCSI commands which do not require disk access

Page 6 Conner CFP1080E/CFP1080S

Overview of the Drives Chapter 1

The SCSI control microcode resides in both ROM and RAM. The RAM portion of

the code can be upgraded in the field with the SCSI Write Buffer command or

through the drive’s serial port. Additional information regarding the RAM code

can be found in Chapter 3, page 21. The SCSI firmware functions include:

• Operating the SCSI bus through the SCSI controller chip.

• reporting drive status and error conditions to the initiator

• manage operating parameters for the drive

• parsing the Command Descriptor Block

• converting the LBA to the respective physical address, then initiating read

and write operations by the disk control code

• grown defect management

• cache management

• queued command reordering (queuing SCSI only)

For more information on the drive’s interface implementation and command set,

refer to the Eighth Generation Disk Drive SCSI Interface Manual.

Technical Reference Manual Page 7

Chapter 1 Overview of the Drives

Page 8 Conner CFP1080E/CFP1080S

Specifications

2

Specifications in this Chapter

This chapter provides the following specifications for the drive:

• drive capacity

• physical configuration

• performance characteristics

• read/write characteristics

• reliability

• power requirements

• environmental tolerances

• safety standards

• physical characteristics

Technical Reference Manual Page 9

Chapter 2 Specifications

CFP1080E:

Sputtered Thin Film

Thin Film

Rotary Voice Coil

3

6

6

Embedded

3658

512 KB

3849 tpi

512

2,110,812

Drive Capacity

Formatted Capacity

• CFP1080S: 1080.7MB

• CFP1080E: 1080.7MB

*1MB is equal to 106 or 1,000,000 bytes

Physical Configuration

Specification

Disk Type Sputtered Thin Film

Head Type Thin Film

Actuator Type Rotary Voice Coil

Number of Disks 3

Data Surfaces 6

Data Heads 6

Servo Embedded

Tracks per Surface (user) 3658

Buffer Size 256 KB

Track Density 3849 tpi

Bytes per Sector 512

Sectors per Drive (user) 2,110,812

*

CFP1080S

Physical Configuration per Zone

Zone 0 (OD)

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7 (ID)

Data Rate

(Mbits/sec)

55.7 4.53 119

50.4 3.96 104

47.9 3.77 99

43.1 3.39 89

40.7 3.20 84

37.3 2.93 77

34.4 2.70 71

31.5 2.74 65

Sustained Data

Rate (MB/sec)

Sectors per

Averaged sustained data rate for the entire disk: 3.66MB/second.

* The physical track configuration includes one spare sector per track.

User

Track *

Page 10 Conner CFP1080E/CFP1080S

Specifications Chapter 2

Performance Characteristics

Seek Times (typical)

1

• Track to Track: 3.0 msec

• Average (read/write): 11/11.5 msec

2

• Full Stroke: 26 msec

1

Drive operating at nominal DC input voltage and nominal operating temperature.

2

The average seek time is determined by averaging the seek time for a minimum of

1000 seeks of random length over the surface of the disk. The apparent average seek

time is reduced if multiple tagged commands are queued to the drive.

Average Latency

• 5.56 milliseconds

Rotation Speed (+0.1%)

• 5400 RPM

Controller Overhead

3

• 700 µsec, typical

3

Measured from the time the disconnect message is acknowledged by the host to the

time the drive begins to execute the command.

Start Time(Power Up)

4

• 0 RPM to Ready

− Typical: 8.5 seconds

− Maximum: 20 seconds

4

These numbers assume spin recovery is not invoked. If spin recovery is invoked, the

maximum could be 40 seconds. Briefly removing power can lead to spin recovery being

invoked.

Stop Time at Power Down

• Typical: 15 seconds

• Maximum: 20 seconds

Interleave

• 1:1

Technical Reference Manual Page 11

Chapter 2 Specifications

Read/Write Characteristics

Recording Method

• 1,7 RLL code

Recording Density (maximum)

• 64,600 bits per inch

Flux Density (maximum)

• 48,400 flux reversals per inch

SCSI Characteristics

Command Set

• SCSI-2 (refer to the Eighth Generation Disk Drive SCSI Interface Manual for

command implementation)

Data Transfer Rate

• To/from Buffer, synchronous narrow: 10.0 MByte/second

• To/from Buffer, synchronous wide (CFP1080E only): 20.0 MByte/second

Maximum Synchronous Transfer Offset:

• 15 bytes

Maximum Tagged Command Queue Depth:

• 32 commands

Page 12 Conner CFP1080E/CFP1080S

Loading...

Loading...