Conner CFA1080A, CFA810A user manual

CFA810A/CFA1080A

Intelligent Disk Drive

Product Manual

Production Release Per EC 5687

P/N 00550-001

Revision A

May 1994

3081 Zanker Road

San Jose, CA 95134-2128

(408) 456-4500

FCC Notice

This equipment generates and uses radio frequency energy and, if not installed

and used properly; that is, in strict accordance with the manufacturer's

instructions, may cause interference to radio and television reception. It has

been designed to provide reasonable protection against such interference in a

residential installation. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause interference

to radio or television reception, which can be determined by turning the

equipment on and off, you are encouraged to try to correct the interference by

one or more of the following measures:

• Reorient the receiving antenna.

• Relocate the computer with respect to the receiver.

• Move the computer into a different outlet so that the computer and receiver

are on different branch circuits.

If necessary, you should consult the dealer or an experienced radio/television

technician for additional suggestions. You may find the following booklet

prepared by the Federal Communications Commission helpful:

How to Identify and Resolve Radio-TV Interference Problems

This booklet (Stock No. 004-000-00345-4) is available from the U.S. Government

Printing Office, Washington, DC 20402.

Warning: Changes or modifications made to this equipment which have not

been expressly approved by Conner Peripherals, Inc. may cause radio and

television interference problems that could void the user's authority to operate

the equipment.

Further, this equipment complies with the limits for a Class B digital apparatus

in accordance with Canadian Radio Interference Regulations.

Cet appareil numérique de la classe B est conforme au Règlement sur le

brouillage radioélectrique, C.R.C., ch. 1374.

Conner and the Conner logo are registered trademarks of Conner Peripherals,

Inc. All other trademarks mentioned in this manual are property of their

respective owners.

Copyright 1994, Conner Peripherals, Inc.

All rights reserved.

Document No. 501-065 5/94

Important Information About this Manual

All information contained in or disclosed by this document is considered

proprietary by Conner Peripherals, Inc. By accepting this material, the recipient

agrees that this material and the information contained therein are held in

confidence and in trust and will not be used, reproduced in whole or in part, nor

its contents revealed to others, except to meet the purpose for which it was

delivered. It is understood that no right is conveyed to reproduce or translate

any item herein disclosed without express written permission from Conner

Peripherals, Inc.

Conner Peripherals, Inc. provides this manual "as is," without warranty of any

kind, either expressed or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Conner

Peripherals, Inc. reserves the right to change, without notification, the

specifications contained in this manual.

Conner Peripherals, Inc. assumes no responsibility for the accuracy,

completeness, sufficiency, or usefulness of this manual, nor for any problem that

might arise from the use of the information in this manual.

Table of Contents

1. Overview of the Drive 1

2. Specifications 7

Description of the Drives 1

Features of the Drive 1

What the Drive is Composed Of 3

Mechanical Design Features 3

Drive Assembly Housing 4

Head Positioning Mechanism 5

Read/Write Heads and Disks 5

Data and Power Connections 5

Electrical Design Features 5

Integrated Circuit 5

Circuit Board 6

Firmware 6

Specifications In This Chapter 7

Drive Capacity 8

Physical Configuration 8

Performance Characteristics 9

Read/Write Characteristics 10

Reliability 10

Power Requirements 11

Environmental Tolerances 11

Safety Standards 12

Physical Characteristics 13

3. How the Drive Operates 15

Functions of the Drive 15

Drive Operational Modes 15

Error Correction 15

Universal Translate Mode 16

Master/Slave Configuration 16

Supported Master/Slave Modes 17

ISA Original Master/Slave 17

Conner Master/Slave 19

ATA/CAM Master/Slave 20

4. Installing the Drive 21

Take These Precautions 21

Installing the Drive 21

Attaching a Data Cable to the Drive 23

Attaching Power to the Drive 25

Mounting the Drive 26

Technical Reference Manual Page i

Table of Contents Filepro CFA810A/CFA1080A

5. Host Interface 27

About the Host Interface 27

Signal Conventions 27

Signal Levels 27

Signal Descriptions 28

ATA/CAM Master/Slave Reset Timing 31

ISA/Conner Master/Slave Reset Timing 33

Host PI0 16-Bit Timing Values 34

Host Demand Mode DMA 16-bit Interface Timing Values 35

6. Register Addresses and Functions 37

Host Address Decoding 37

Addressing the Data 39

Cylinder-Head-Sector (CHS) Mode 39

Logical Block Addressing (LBA) Mode 39

Descriptions of the Registers 40

Data Register 40

Error Register 41

Features Register (formerly Write Precomp Register) 42

Sector Count 42

Sector Number 42

Cylinder Low 43

Cylinder High 43

SDH Register 44

Status Register 45

Alternate Status Register 46

Digital Output Register 47

Drive Address Register 48

Command Register 48

7. Command Set 51

Command Register 51

Conner Specific 52

Get Drive Feature word (00) 53

Read the Drive Switches (02) 54

Power Lock (08) 54

Power Unlock (09) 54

Execute Drive Diagnostic 55

Format Track 56

Marked Bad Sector 56

Assign 56

Identify Drive 58

Initialize Drive Parameters 62

Physical Seek 62

Power Commands 63

Read DMA 64

Read Multiple 65

Read Sector(s) 66

Read Sector Buffer 67

Read Verify Sectors 68

Recalibrate 68

Retry Count 69

Page ii Filepro CFA810A/CFA1080A

Filepro CFA810A/CFA1080A Table of Contents

Seek 69

Set Features (Set Look Ahead Read) 70

Set Multiple Mode 71

Translate 71

Write DMA 72

Write Caching 72

Write Multiple 73

Write Caching 73

Write Sector(s) 75

Write Caching 76

Write Sector Buffer 77

8. Error Reporting 79

Error and Status Detection 79

Error and Status Messages 79

Technical Reference Manual Page iii

Table of Contents Filepro CFA810A/CFA1080A

Page iv Filepro CFA810A/CFA1080A

Overview of the Drive

Capacity (formatted):

810MB

1080MB

Description of the Drives

The Conner Filepro Advantage CFA810A and CFA1080A are high-performance,

low-profile hard disk drives designed to operate with an IBM PC/AT or

equivalent host computer system in translate mode. The drive supports

advanced ATA PIO Mode 3 and DMA Mode 1 data transfer protocols for superior

I/O performance. Logical Block Adressing (LBA) is supported for compatibility

with advanced systems (BIOS) which support greater than 528MB capacity IDE

drives, as well as Cylinder-Head-Sector (CHS) addressing for backward

compatibility. Either a compatible BIOS or a suitable device driver is necessary

to access all of the disk's capacity in a DOS environment.

1

Drive Model: Form Factor:

CFA810A inch high, 3.5 inch

CFA1080A inch high, 3.5 inch

For simplicity, we often refer to the two drives collectively in this manual as "the

drive"

Features of the Drive

The drive provides these features:

• Task File emulation and ATA compatibility allows installation in a wide

range of host systems.

• high-performance rotary voice coil actuator with embedded servoing

eliminate the need for T-cal

• one-of-seven run-length limited code

• high shock resistance

• sealed head/disk assembly

No. of disks/heads:

3 disk/6 heads

4 disk/8 heads

Technical Reference Manual Page 1

• automatic actuator latch against inner stop upon power-down

• microprocessor-controlled diagnostic routines that are automatically

executed at start-up

• 256KB segmentable cache buffer

• Read Look Ahead and selectable Write Caching

• automatic error correction and retries, single burst ECC on the fly

Chapter 1 Specifications

• supports ATA Standard PIO Mode 3 and DMA Mode 1

• 512-byte block size

• supports both CHS and LBA addressing

• allows daisy-chaining up to two drives on the AT interface

• Auto-Translate (Universal Translate)

• 4-byte ECC diagnostic check in read/write

The drive supports either of the following Master/Slave protocol standards:

• ATA/CAM (AT Attachment/Common Access Method)

• ISA/Conner (Industry-Standard Architecture)

Page 2 Filepro CFA810A/CFA1080A

Specifications Chapter 1

What the Drive is Composed Of

The drive is composed of mechanical, electrical, and firmware elements.

Mechanical Design Features

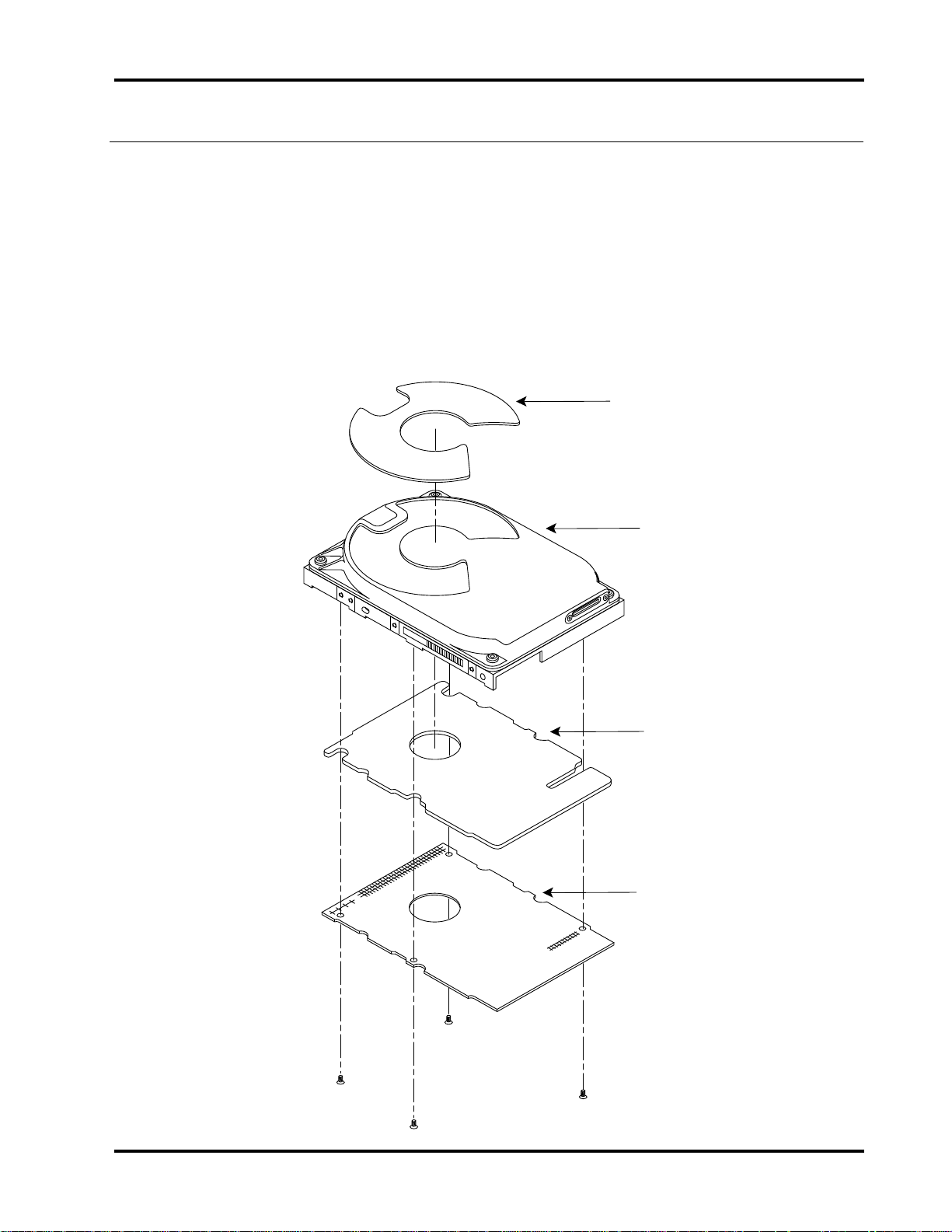

The drive’s hardware includes the components described in the following

sections. Figure 1-1 shows the drive top level assembly, which is a combination

of the drives major mechanical and electrical assemblies.

Figure 1-1

Hard Drive Top Level Assembly

Damper

Head-Disk

Assembly

Printed Circuit

Board Assembly

Shield

Printed

Circuit

Board

Assembly

1080_1_1

Technical Reference Manual Page 3

Chapter 1 Specifications

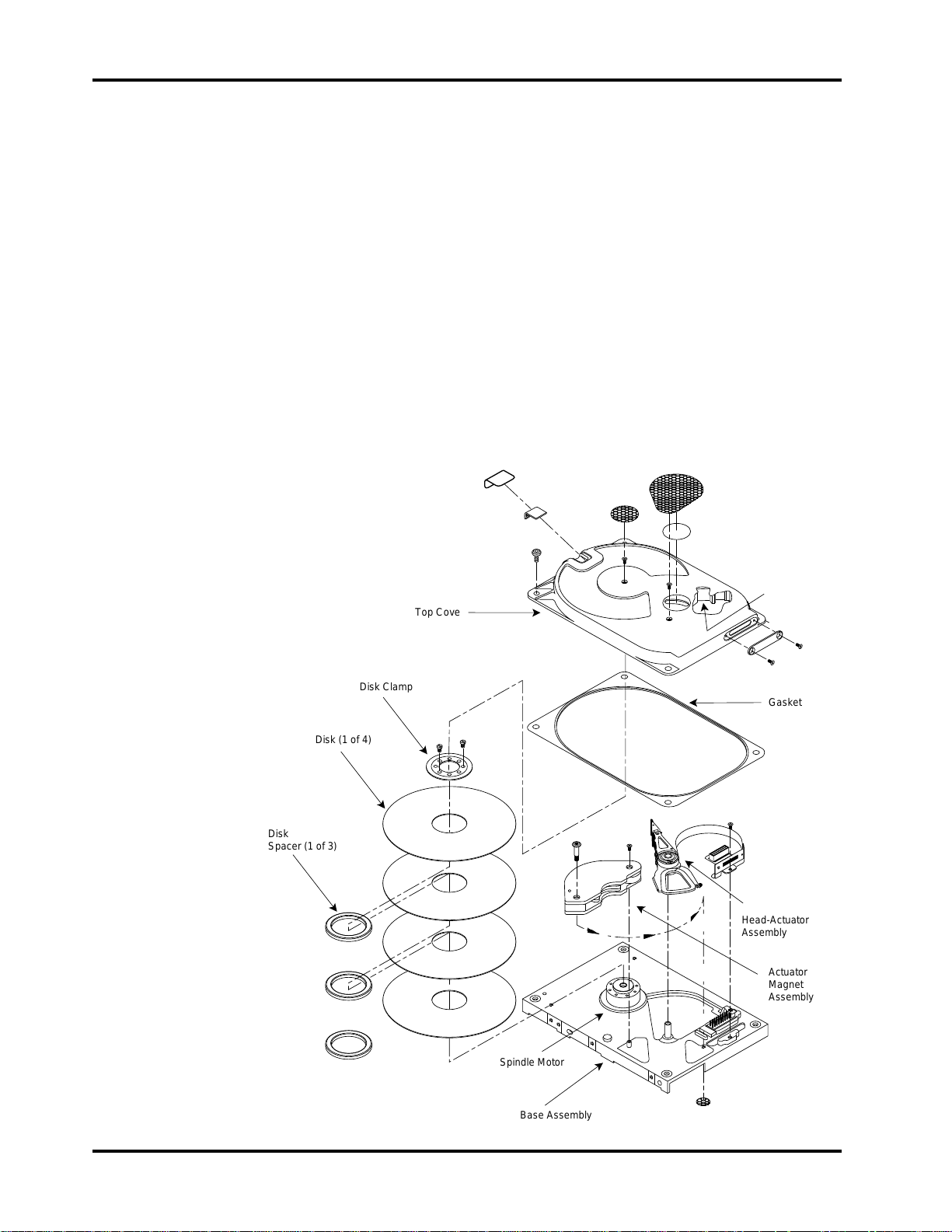

Figure 1-2 shows the details of the drive mechanism, which is called the headdisk assembly.

Drive Assembly Housing

The drive assembly housing consists of a die-cast aluminum base on which is

mounted a die-cast aluminum cover. Both the base and the cover are coated

with a special material designed to seal out contaminants which might degrade

head and media reliability. A gasket seals the joint between the base and cover

to retard the entry of moisture and environmental contaminants from the

assembly.

This assembly, the head-disk assembly, contains an integral 0.3 micron filter,

which maintains a clean environment. Critical drive components are contained

within this contaminant-free environment.

Figure 1-2

Head-Disk Assembly

Disk (1 of 4)

Disk

Spacer (1 of 3)

Filter

Top Cover

Disk Clamp

Gasket

Head-Actuator

Assembly

Actuator

Magnet

Assembly

Spindle Motor

Base Assembly

1080_1_2

Page 4 Filepro CFA810A/CFA1080A

Specifications Chapter 1

Drive Motor and Spindle

A brushless DC direct-drive motor assembly is mounted on the drive’s base. The

motor rotates the drive’s spindle at 4500 RPM. The motor/spindle assembly is

dynamically balanced to provide minimal mechanical runout to the disks. A

dynamic brake is used to provide a fast stop to the spindle motor and return the

heads to the landing zone when power is removed.

Head Positioning Mechanism

The read/write heads are supported by a mechanism coupled to a rotary voice

coil actuator.

Read/Write Heads and Disks

Data is recorded on 95mm diameter disks through 3370-type thin film heads.

The CFA810A contains:

• three disks with six data surfaces

• six read/write heads

The CFA1080A contains:

• four disks with eight data surfaces

• eight read/write heads

At power-down, the heads are automatically retracted to the inner diameter of

the disk and are latched and parked on a landing zone that is inside the data

tracks.

Data and Power Connections

The drive has a single 40-pin data connector, as well as an auxiliary connector

which is reserved for factory or evaluation use.

The drive has a standard 4-pin power connector and may optionally have a 3-pin

connector, only one of which should be used at a time.

The drive also has a jumper block located next to the auxiliary connector which

can be set to specify drive operational parameters. For more information on the

drive’s connectors and on setting jumpers, refer to chapters 3 and 4.

Electrical Design Features

Integrated Circuit

A single integrated circuit (IC) is mounted within the sealed hard drive assembly

in close proximity to the read/write heads. The IC provides head selection, read

pre-amplification, and write drive circuitry.

Technical Reference Manual Page 5

Chapter 1 Specifications

Circuit Board

The drive’s microprocessor-controlled circuit board provides the remaining

electronic functions, which include:

• read/write circuitry

• rotary actuator control

• interface control

• spin speed control

• auto-park

• power management

Firmware

The drive’s firmware includes a command set which the host uses to control the

drive. The command set allows the host to request the following types of actions:

• report drive status

• seek a specific point on the disk

• read and write data

For more information on the drive’s command set, refer to chapters 6 and 7.

Page 6 Filepro CFA810A/CFA1080A

Specifications

2

Specifications In This Chapter

This chapter defines the following specifications for the drive:

• drive capacity

• physical configuration

• performance characteristics

• read/write characteristics

• reliability

• power requirements

• environmental tolerances

• safety standards

• physical characteristics

Technical Reference Manual Page 7

Chapter 2 Specifications

CFA1080A:

Sputtered Thin Film

Thin Film

Rotary Voice Coil

4

8

8

Embedded

2801

256KB

3200 tpi

36,352 - 57,856 bytes

512

2,113,984

71 - 113

Universal*

Drive Capacity

Formatted Capacity:

• CFA810A: 810MB

• CFA1080A: 1080MB

* 1MB = 1 x 106 or 1,000,000 bytes

Physical Configuration

Specification CFA810A:

Disk Type

Head Type

Actuator Type

Number of Disks

Data Surfaces

Data Heads

Servo

Tracks per Surface

Buffer Size

Track Density

Formatted Track Capacity

Bytes per Block

Blocks per Drive

Sectors per Track (User)

Translate

* Refer to chapter 3 for a definition of Universal Translate Mode

Sputtered Thin Film

Thin Film

Rotary Voice Coil

3

6

6

Embedded

2801

256KB

3200 tpi

36,352 - 57,856 bytes

512

1,585,488

71 - 113

Universal*

Page 8 Filepro CFA810A/CFA1080A

Specifications Chapter 2

Performance Characteristics

Seek Times (typical)* :

• Track to track: 3.0 ms

• Average: 10.5 ms read, 11.5 ms write **

• Maximum: 20 ms

• The timing is measured through the interface with the drive operating at nominal DC input

voltage and nominal operating temperature. The timing also assumes that:

• BIOS and PC system hardware dependency have been subtracted from timing

measurements

• the drive is operated using its native drive parameters

• the controller overhead is the time it takes to assert +HOST IRQ after the host writes the

command register with a READ instruction, for the case where the data already resides

in the buffer

** The average seek time is determined by averaging the seek time for a minimum of 1000 seeks

of random length over the surface of the disk.

Average Latency:

• 6.67 ms

Rotation Speed:

• 4500 RPM (+ 0.1%)

Average Controller Overhead:

• <500 µsec

Start Time at Power-Up: *

• 0 RPM to 4500 RPM

- Typical: 7 seconds

- Maximum: 12 seconds

• 0 RPM to Ready

- Typical: 12 seconds

- Maximum: 20 seconds

* These numbers assume spin recovery is not invoked. If spin recovery is invoked, the

maximum could be 40 seconds. Briefly removing power can lead to spin recovery being

invoked.

Stop Time at Power-Down:

• Typical: 15 seconds

• Maximum: 20 seconds

Interleave:

• 1:1

Technical Reference Manual Page 9

Chapter 2 Specifications

Read/Write Characteristics

Interface:

• Task File

Recording Method:

• 1 of 7 RLL code

Recording Density (ID):

• 65,000 bits per inch

Flux Density (ID):

• 48,340 flux reversals per inch

Data Transfer Rate:

• To/From Media: 3.4 - 5.76 MB/second

• To/From Host: 11.1 MB/second burst, 8.3 MB/second sustained

Reliability

Data Reliability:

• < 1 non-recoverable error in 10

Component Design Life:

• 5 years

Start/Stop Cycles:

• 20,000 minimum

Mean Time Between Failures:

• 300,000 power-on hours

Mean Time to Repair:

• 10 minutes typical

Preventive Maintenance:

• none

14

bits read

Page 10 Filepro CFA810A/CFA1080A

Specifications Chapter 2

Power Requirements

+5 Volts

Mode: *

Read/Write

Seek (100%)

Seek (30%)

Idle

Standby

Sleep

Spin-Up

* Refer to chapter 3 for the definitions of the modes. Spin-Up Mode current draw is for 7 seconds,

maximum. Typical conditions are both voltages at nominal value, room temperature (25° C)

ambient to the drive. Maximum power is when the supply voltage is at the worse case condition.

(typical):

640 mA 190 mA 5.5 W 6.1 W

620 mA 490 mA 9.0 W 10.1 W

440 mA 230 mA 5.0 W 5.4 W

420 mA 180 mA 4.3 W 4.7 W

380 mA 80 mA 2.9 W 3.3 W

260 mA 80 mA 2.3 W 2.5 W

720 mA 1600 mA N/A N/A

+12 Volts

(typical):

Watts

(typical):

Watts

(maximum):

Minimum/Maximum Voltage:

• +5V: +5%

• +12V: +10%

Maximum Peak-to-Peak Noise Allowed

(DC to 1 MHz, with equivalent resistive load):

• +5V: 2%

• +12V: 1%

Environmental Tolerances

Temperature:

• Operating: 5° to 55° C

• Non-operating: -40° to 60° C

• Thermal Gradient: 20

Relative Humidity (non-condensing):

• Operating: 5 to 95%

• Non-operating: 5 to 95%

• Wet Bulb: 29

Altitude (relative to sea level):

• Operating: -200 to 15,000 feet

• Non-operating: 40,000 feet (maximum)

• Altitude Gradient: 1,000 feet/minute

Shock (half-sine pulse, 11 ms duration):

• Operating: 5G without non-recoverable errors

• Non-operating: 75G without non-recoverable errors

o

C per hour maximum

o

C

Technical Reference Manual Page 11

Chapter 2 Specifications

Vibration (swept-sine, one octave per minute):

• Operating

- 5 - 32 Hz: 0.01 inch displacement; double amplitude

- 32 - 400 Hz: 0.5G without non-recoverable errors

• Non-operating

- 5 - 28 Hz: 0.10 inch displacement; double amplitude

- 28 - 400 Hz: 4G peak

Magnetic Field:

• The disk drive will meet its specified performance while operating in the

presence of an externally-produced magnetic field under the following

conditions:

Field Frequency Intensity

Acoustic Noise:

• The sound pressure level will not exceed 38 dBA in Idle Mode at a distance

Safety Standards

The drive is designed to comply with relevant product safety standards,

including:

• UL 478, 5th edition, Standard for Safety of Information Processing and

• UL 1950, Standard for Safety of Information Technology Equipment

• CSA 22.2 #220, Information Processing and Business Equipment

• CSA 22.2 #950, Safety of Information Technology Equipment

DC

to 700 Khz

700 Khz to 1.5 Mhz

of 1 meter from the drive. The sound power level measured based on ISO

7779 will not exceed 4.3 Bel in Idle Mode.

Business Equipment

6 gauss

7 milligauss

3 milligauss

• IEC 380, Safety of Electrically Energized Office Machines

• IEC 950, Safety of information Technology Equipment Including Electrical

Business Equipment

• VDE 0805, VDE 0805 TIEL 100, and VDE 0806

• Complies with FCC Class B, Part 15, Subpart J

Page 12 Filepro CFA810A/CFA1080A

Specifications Chapter 2

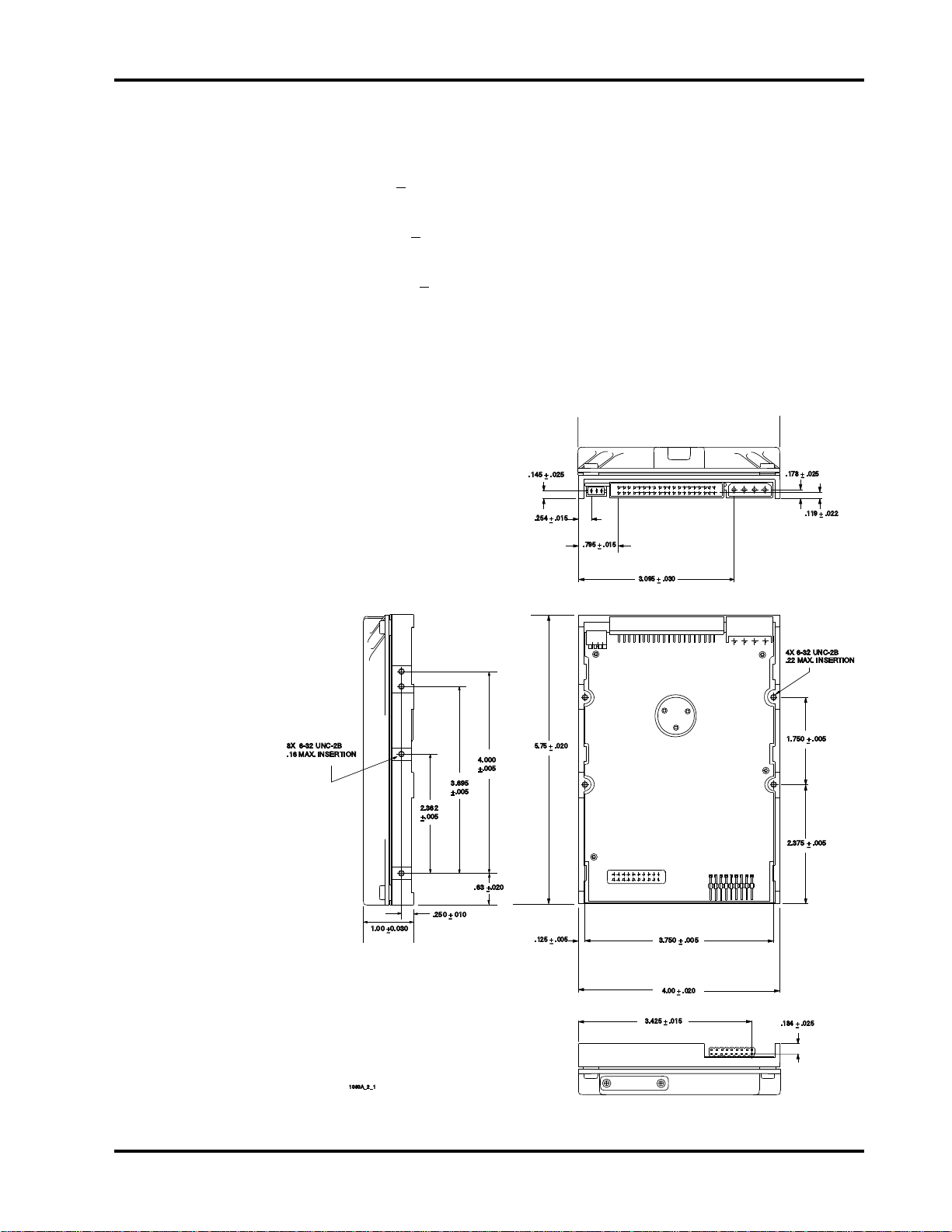

Physical Characteristics

Height:

• 1.0 inch + .030

Width:

• 4.0 inches + .020

Depth:

• 5.75 inches + .020

Weight:

• 1.30 pounds

Figure 2-1

The Drive’s Physical Dimensions

8X 6-32 UNC-2B

.16 MAX. INSERTION

1.00 +0.030

2.362

+.005

3.695

+.005

.250 + 010

4.000

+.005

.63 +.020

.145 + .025

.254 + .015

5.75 + .020

.125 + .005

.795 + .015

3.095 + .030

3.750 + .005

.178 + .025

.119 + .022

4X 6-32 UNC-2B

.22 MAX. INSERTION

1.750 + .005

2.375 + .005

4.00 + .020

1080A_2_1

3.425 + .015

+

+

.184 + .025

Technical Reference Manual Page 13

Chapter 2 Specifications

Page 14 Filepro CFA810A/CFA1080A

How the Drive Operates

3

Functions of the Drive

This chapter describes certain operational aspects of the drive, including

discussions of:

• drive operational modes

• error correction

• Universal Translate Mode

• master/slave configurations

Drive Operational Modes

The drive operates in the following modes:

• Read/Write Mode occurs when data is read from or written to the disk.

• Seek Mode (100%) occurs when the actuator is in motion.

• Seek Mode (30%) is composed of 1/3 stroke seeks with a 30% duty cycle.

Error Correction

• Idle Mode occurs when the drive is not reading, writing, or seeking. The

motor is up to speed and the Drive Ready condition exists. The actuator is

residing on the last-accessed track.

• Standby Mode occurs when the motor is stopped and the actuator is

parked. Standby Mode occurs after a programmable time-out since the last

host access occurs. The drive will leave Standby Mode upon receipt of a

command which requires disk access, or upon receipt of a spin-up command.

• Sleep Mode occurs when all electronics are disabled. The host is required

to issue a Reset command to exit the Sleep Mode.

• Spin-Up Mode occurs while the drive is spun up to speed after being

powered on or after exiting Standby or Sleep Mode.

The drive uses a Reed-Solomon code to perform error detection and correction.

For each 512-byte block, the software error correction polynomial is capable of

correcting:

• one error burst up to 22 bits

• two error bursts up to 11 bits each

Single bursts of 11 bits or less are corrected on the fly (OTF) with no

performance degradation.

Technical Reference Manual Page 15

Chapter 3 How the Drive Operates

No. of

Sectors:

63

63

Universal Translate Mode

Conner has established a Universal Translate Mode which enables you to

configure the drive in an AT environment to any cylinder, head, and sector

configuration desired. The translate configuration is limited by the maximum

capacity of the drive and host system parameters. Upon initial power-up of the

drive, it will default to the configuration shown below:

No. of

Drive:

Cylinders:

No. of Heads

CFA810A

CFA1080A

After the drive is ready, the host system may issue an Init Drive Parms

command (command code 91

heads and number of sectors per track). The drive will then:

• calculate the total number of available logical tracks based upon the entered

sector and head values

• save the drive parameters in non-volatile memory for subsequent drive

operations

☞ Note: BIOS in older systems may be limited to a maximum of 1024 cylinders. It may be

necessary to manually enter 1024 cylinders into the User Defined parameter list in this

case. Device drivers are available to overcome this limitation and the instructions which

accompany the driver should be followed for installation.

Master/Slave Configuration

When two drives are daisy-chained on the host interface, one must be designated

as the master drive (C: drive) and one as the slave drive (D: drive).

Commands from the host are written in parallel to both drives.

1572 16

2097 16

hex) to alter the translate configuration (number of

When the C/D jumper on the drive is closed, the drive will assume the role of a

master. When C/D is open, the drive will act as a slave. In single-drive

configurations, C/D must remain in the closed (master) position. For more

information on setting the C/D jumper, refer to chapter 4.

For each command sent from the host, the DRV bit in the drive/head register

selects the master or the slave drive. When the DRV bit is reset (0), the master

drive is selected, and when the DRV bit is set (1), the slave drive is selected.

Once the drives receive the command, only the drive with jumper C/D set to the

appropriate position will execute the command. For example, if the DRV bit is

set, only the slave drive (jumper C/D open) will execute the command.

☞☞ Note: If the command is a diagnostic command, both drives will execute the command

and the slave will report its status to the master via the Host PDIAG signal.

Page 16 Filepro CFA810A/CFA1080A

How the Drive Operates Chapter 3

Throughout this manual, drive selection always refers to the state of the DRV

bit and the position of the C/D jumper.

The drive supports two master/slave modes via the A/C jumper. When A/C is

closed, ATA/CAM master/slave mode is selected. When A/C is open, Conner

master/slave mode is selected. For more information on setting the A/C jumper,

refer to chapter 4.

Supported Master/Slave Modes

There are three different master/slave methods that Conner supports.

• ISA Original

• Conner

• ATA/CAM

Of these three methods, the drive supports all except ISA/Original mode, with

which it is compatible.

☞☞ Note: The ATA/CAM master/slave method is not compatible with the other two methods.

The Conner mode is backward-compatible to the ISA Original mode, but is not

compatible with the other.

These three methods are explained in the following sections. For signals

followed by a ‘~’, activate means go low and deactivate means go high.

ISA Original Master/Slave

The signals used for master/slave operation and determination are Host DASP~

and Host PDIAG~.

Host DASP~ can be used to:

• drive an activity LED

• indicate that the slave drive is present to the master

The Host PDIAG~ is used to indicate that the slave has passed diagnostics both

at power-on reset (POR) and when the diagnostic command is issued.

At power-on time, the slave drive activates Host PDIAG~ and Host DASP~.

Host PDIAG~ remains activated from POR until a diagnostic command is issued

by the host. Once a diagnostic command is issued by the host, the slave

deactivates Host PDIAG~ until either:

• the slave successfully completes the diagnostic command

• the host issues a reset

There are no real timing constraints on Host PDIAG~ and Host DASP~. At

POR, they are both activated within a second or two. When the diagnostic

command is issued by the host, the slave inactivates Host PDIAG~ within 100-

Technical Reference Manual Page 17

Chapter 3 How the Drive Operates

200 microseconds and is required to reactivate it within 5 seconds (the only

timing constraint) if it successfully completes the command.

This scheme works fairly well except for two problems:

• There is no way to tell when the slave becomes ready. If the slave becomes

ready much later than the master, the slave will miss any commands that

are issued before it goes not busy because the host only polls the master to

see if the “controller” is ready.

• In a two-drive configuration, the Host DASP~ line is not available to drive a

drive activity indicator.

In this mode of master/slave, master/slave re-configures with either a hardware

or software reset. A hardware reset is either a POR or host reset.

This version of master/slave is present on generations 1, 2 and 3 of Conner

drives.

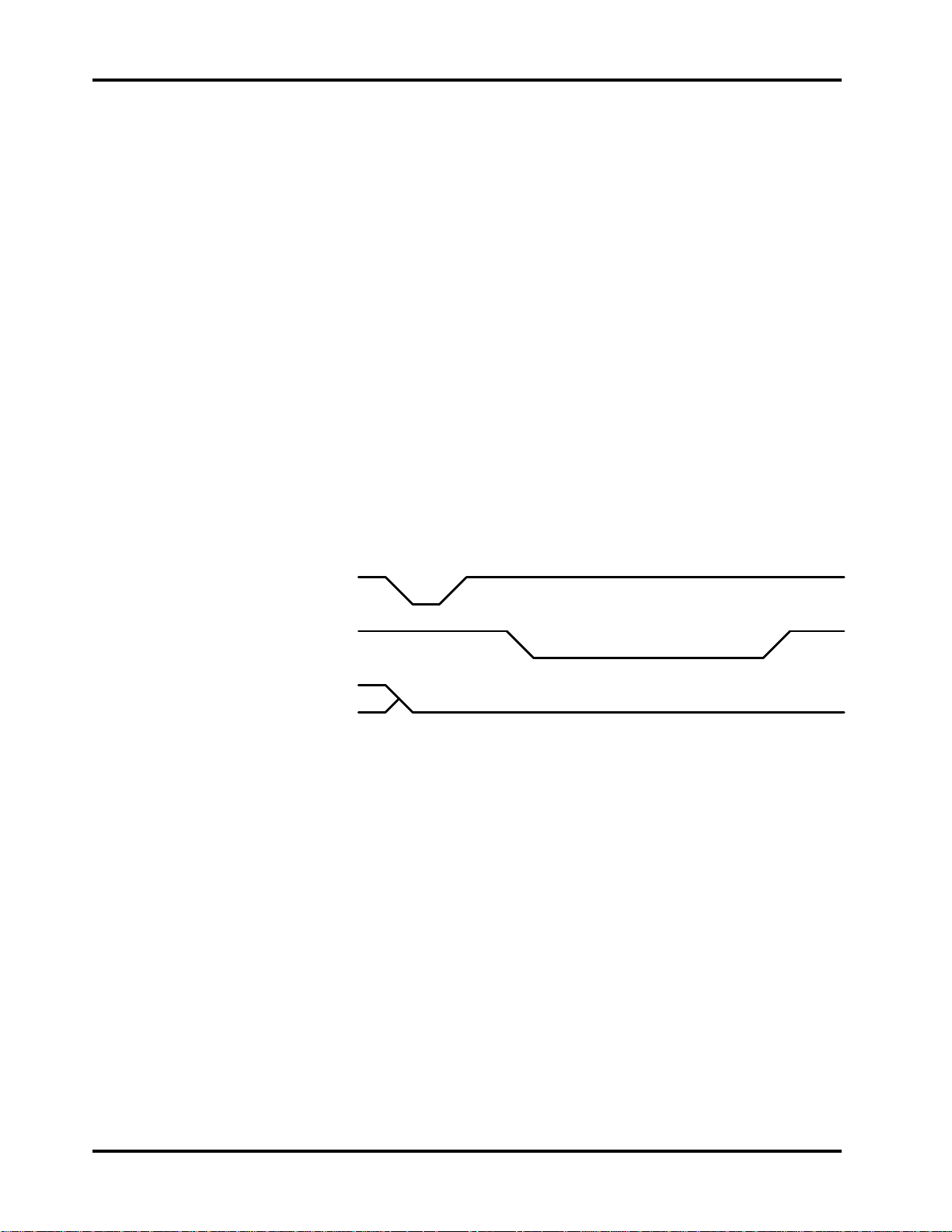

Figure 3-1

ISA Original Master/Slave Timings

Any Reset

Host PDIAG~

Host DASP~

Page 18 Filepro CFA810A/CFA1080A

How the Drive Operates Chapter 3

Conner Master/Slave

To remedy the problem of the host not knowing when the slave was ready,

Conner developed a backward-compatible solution, which we call Conner

Master/Slave.

In Conner Master/Slave, the use of the Host PDIAG~ signal has been changed

slightly during reset so that the slave will indicate when it will go not busy. Its

use in the diagnostic command has not been changed.

During POR or any host reset, the slave drive activates Host PDIAG~ within

1ms. The master drive waits slightly longer than 1 ms for Host PDIAG~ to be

activated before it determines that no slave is present. The slave then

deactivates Host PDIAG~ when it is ready. The master waits:

• up to 14 seconds for the slave to deactivate Host PDIAG~ on either a POR or

a host reset

• 450 ms for the slave to deactivate Host PDIAG~ on a host software reset

If the master times out, it goes not busy.

In this mode of master/slave, master/slave re-configures with either a hardware

or software reset. A hardware reset is either a Power On Reset (POR) or host

bus reset.

This solution was implemented in generations 4 and greater of Conner drives.

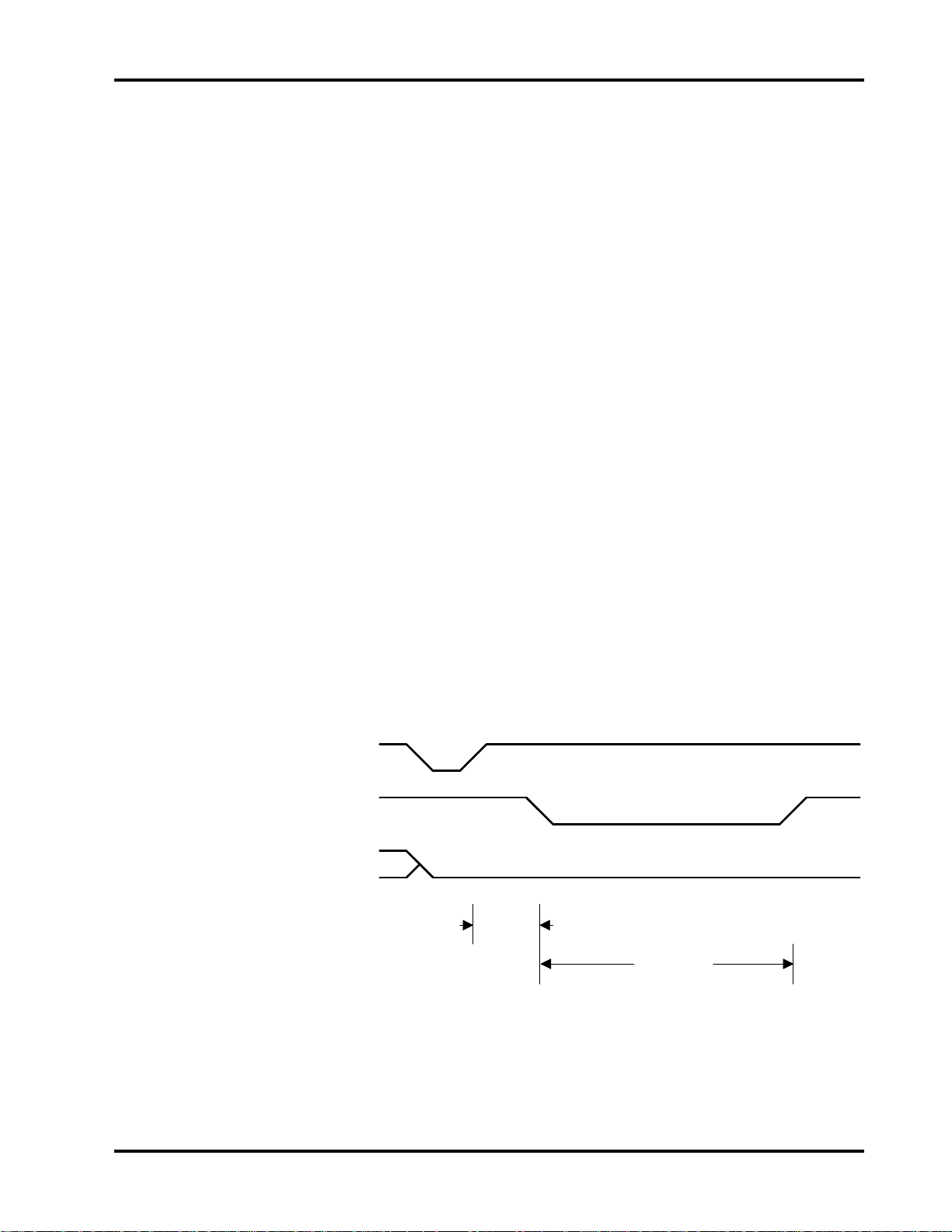

Figure 3-2

Conner Master/Slave Timings

Any Reset

Host PDIAG~

Host DASP~

1 ms

14.5 s *

450 ms

* 1.45 s for hardware reset, 450 ms for software reset

Technical Reference Manual Page 19

Loading...

Loading...