Page 1

Service Manual

TM

E L E C T R O S U R G I C A L U N I T

Page 2

LIMITED WARRANTY

For a period of two years following the date of delivery,

CONMED Corporation warrants the CONMED System

5000™ Electrosurgical Generator against any defects in

material or workmanship and will repair or replace (at

CONMED’s option) the same without charge, provided

that routine maintenance as specified in this manual has

been performed using replacement parts approved by

CONMED. This warranty is void if the product is used in

a manner or for purposes other than intended.

© 2008 CONMED Corporation

525 French Road

Utica, New York 13502 U.S.A.

U.S. Patent Nos. 4,961,739 - 5,152,762 - 5,626,575-

6,830,569 - 6,835,082 - 6,875,210 - 6,939,347 -

D477,082 - D477,408.

For Technical Service or Return Authorization Phone:

303-699-7600 / 1-800-552-0138 Extension 5274

Fax 303-699-1628

For Customer Service or to order parts phone:

1-800-448-6506 / 315-797-8375 / Fax 315-735-6235

or contact your CONMED Representative.

European Authorized Representative

MDSS GmbH

Schiffgraben 41

D - 30175 Hannover

Germany

The revision level of this manual is specified by the

highest revision letter found on either the inside front cover

or enclosed errata pages (if any).

Manual Number 60-8017-ENG Rev. R 01/08

Unit Serial Number_________________________________

Page 3

TM

Table of Contents

& List of Illustrations

Section Title Page

3.0 Theory of Operation ................................................................................... 3-1

3.1 Mode Descriptions .................................................................................................. 3-1

3.1.1 Cut Major Modes ..............................................................................................................................3-1

3.1.2 COAG Major Modes .........................................................................................................................

3.1.3 Bipolar Major Modes ........................................................................................................................

3.1.4 Advanced Specialty Modes ................................................................................................................

3.2 System Overview ..................................................................................................... 3-2

3.2.1 High Voltage Power Supply (HVPS) ................................................................................................3-3

3.2.2 RF Amplifier and Transformer ..........................................................................................................

3.2.3 Electrosurgical Outputs .....................................................................................................................3-5

3.2.4 Activation Command Sensing ...........................................................................................................

3.2.5 Automatic Return Monitor (A.R.M.

3.2.6 Low Voltage Power Sources ..............................................................................................................

3.2.7 System Controllers and Monitor .......................................................................................................

3.2.8 Low Voltage Power Monitoring ........................................................................................................

3.2.9 Operator Control Panel .....................................................................................................................

3.2.10 Activation Tones ................................................................................................................................

3.2.11 Activation Relay Connector ...............................................................................................................3-7

™) .............................................................................................3-5

3.3 Optional System Configurations ............................................................................. 3-7

4.0 Maintenance ................................................................................................ 4-1

4.1 General Maintenance Information ........................................................................... 4-1

4.2 Maintenance Personnel ............................................................................................

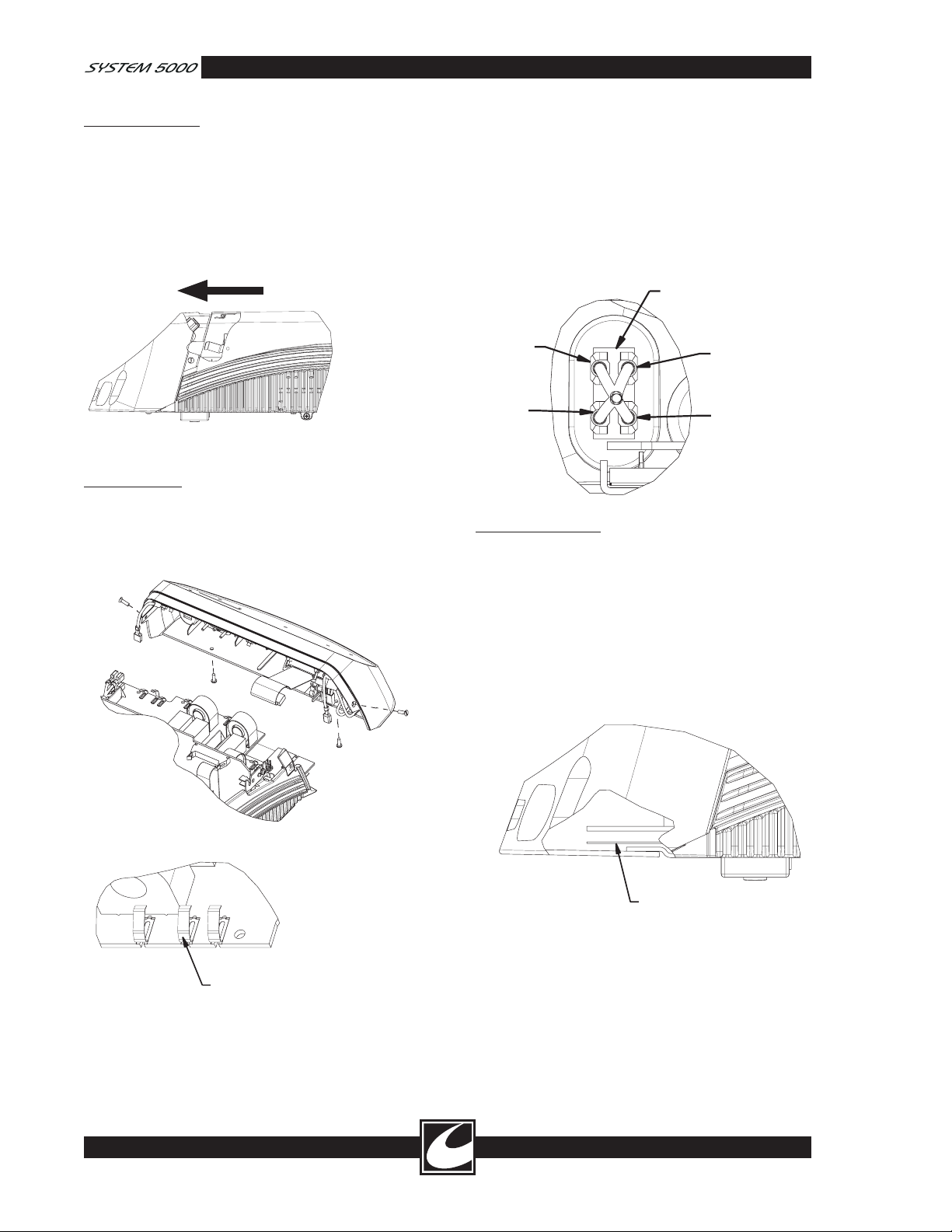

4.3 Assembly Breakdown/Parts Access .......................................................................... 4-1

4.3.1 Top Cover Removal and Replacement ...............................................................................................4-1

4.3.2 Bezel Removal and Replacement .......................................................................................................

4.3.3 Processor Board Removal and Replacement ......................................................................................4-3

4.3.4 Transformer Board Removal and Replacement ..................................................................................

4.3.5 Output Board Removal and Replacement .........................................................................................

4.3.6 RF Amp Board Removal and Replacement .......................................................................................

4.3.7 Low Voltage Power Supply Module Removal and Replacement ........................................................

4.3.8 High Voltage Power Supply Removal and Replacement ....................................................................

4.3.9 Rear Panel with Board Removal and Replacement ............................................................................

4.3.10 Back Panel Board Removal and Replacement ....................................................................................

4.3.11 Display Boards Removal and Replacement ........................................................................................

4.3.12 Power Transistor Replacement ...........................................................................................................

4.4 Cleaning ................................................................................................................. 4-8

4.5 Periodic Inspection .................................................................................................

4.6 Periodic Performance Testing ............................................................................................................4-9

4.6.1 Chassis Ground Integrity ...................................................................................................................

4.6.2 Displays, Alarms and Commands ......................................................................................................

4.6.3 Output Power ...................................................................................................................................

4.6.4 RF Leakage Measurement ...............................................................................................................

4.6.5 Line Frequency Leakage ..................................................................................................................

4.6.7 Output Coupling Capacitor Check ..................................................................................................

4.7 System Calibration ................................................................................................ 4-14

4.7.1 Calibration Preliminaries .................................................................................................................4-14

4.7.2 Selecting the Mode to Calibrate ......................................................................................................

4.7.3 Calibrating a Monopolar Mode .......................................................................................................

4.7.4 Calibrating Bipolar Modes ..............................................................................................................

3-1

3-2

3-2

3-4

3-5

3-5

3-5

3-6

3-6

3-6

4-1

4-2

4-3

4-4

4-4

4-5

4-6

4-6

4-7

4-7

4-8

4-8

4-9

4-9

4-9

4-10

4-12

4-14

4-16

4-16

4-16

Page 4

Section Title Page

4.7.5 Calibrating A.R.M.™ ......................................................................................................................4-16

4.7.6 Completing Calibration ...................................................................................................................

4-17

4.8 Last Fault Code Retrieval and Clear ..................................................................... 4-17

4.8.1 Last Fault Code Retrieval ...............................................................................................................4-17

4.8.2 Clearing Last Fault Codes ...............................................................................................................

4-18

4.9 Displaying Optional System Configuration ........................................................... 4-18

4.10 DACview ..............................................................................................................

4.11 Setting the Clock ..................................................................................................

4.12 Troubleshooting ....................................................................................................

4.12.1 HVPS Troubleshooting Hints .........................................................................................................4-23

4-20

4-21

4-21

4.13 Parts Ordering Information .................................................................................. 4-24

4.14 Fault Codes ...........................................................................................................

4-24

Figure/Title Page

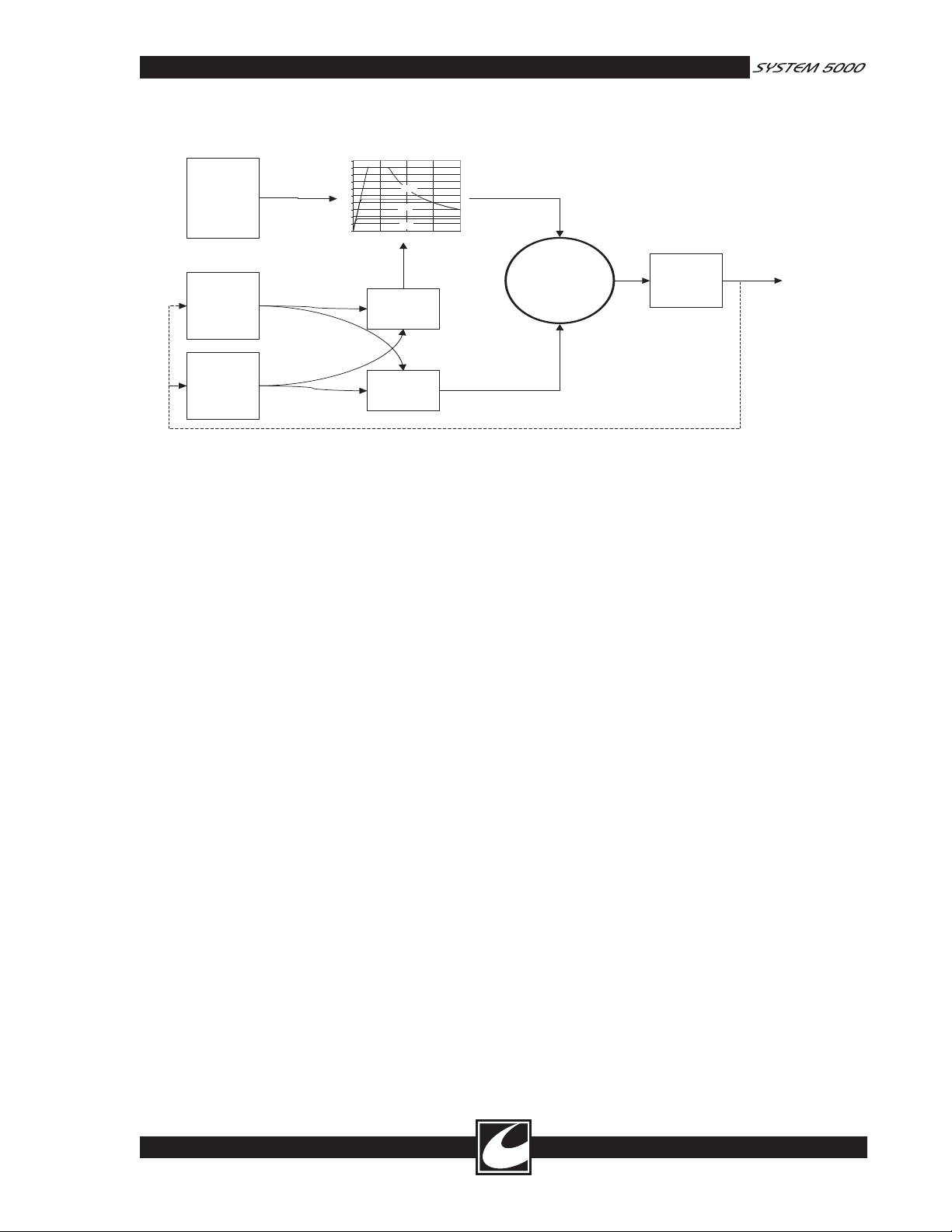

Figure 3.1 RF Controller Block Diagram ................................................................................................................3-3

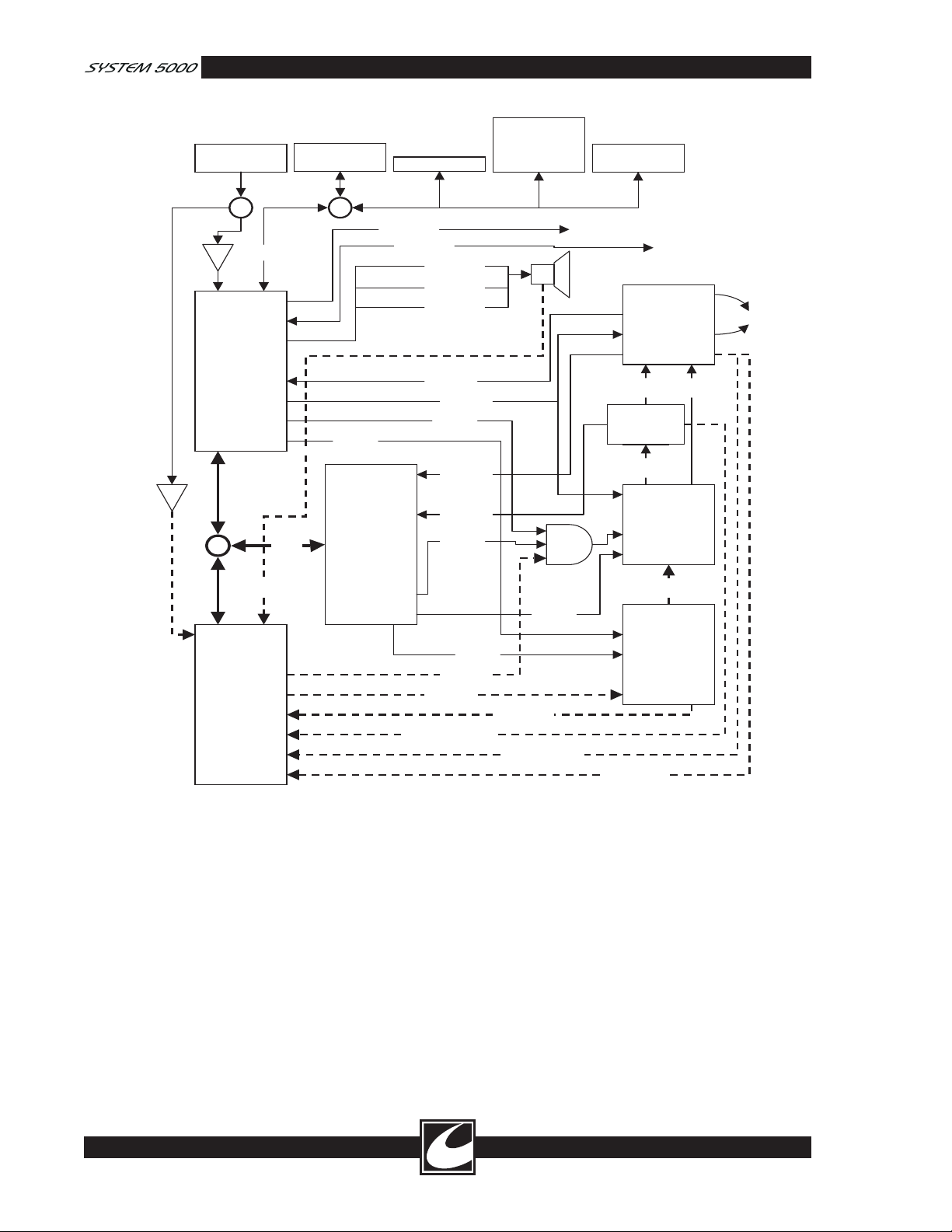

Figure 3.2 System Block Diagram ...........................................................................................................................

Figure 4.1 Calibration Procedure Flow Chart ........................................................................................................

Figure 4.2 DIP Switch Positions ...........................................................................................................................

Figure 4.3 Module Diagram ...................................................................................................................................

Figure 4.4 A12 Back Panel PCB Assembly .............................................................................................................

Figure 4.5 A9 RF Power Supply PCB Assembly ....................................................................................................

Figure 4.6 A7 RF Transformer PCB Assembly .......................................................................................................

Figure 4.7 A6 RF Amplifier PCB Assembly .........................................................................................................

Figure 4.8 A5 RF Output PCB Assembly ............................................................................................................

Figure 4.9 A4 Microcontroller PCB Assembly ......................................................................................................

Figure 4.10 A2 Display Controller PCB Assembly ...............................................................................................

Figure 4.11 A3 Display Light Panel PCB Assembly .............................................................................................

3-4

4-15

4-18

A-1

A-4

A-7

A-9

A-11

A-14

A-19

A-21

A-23

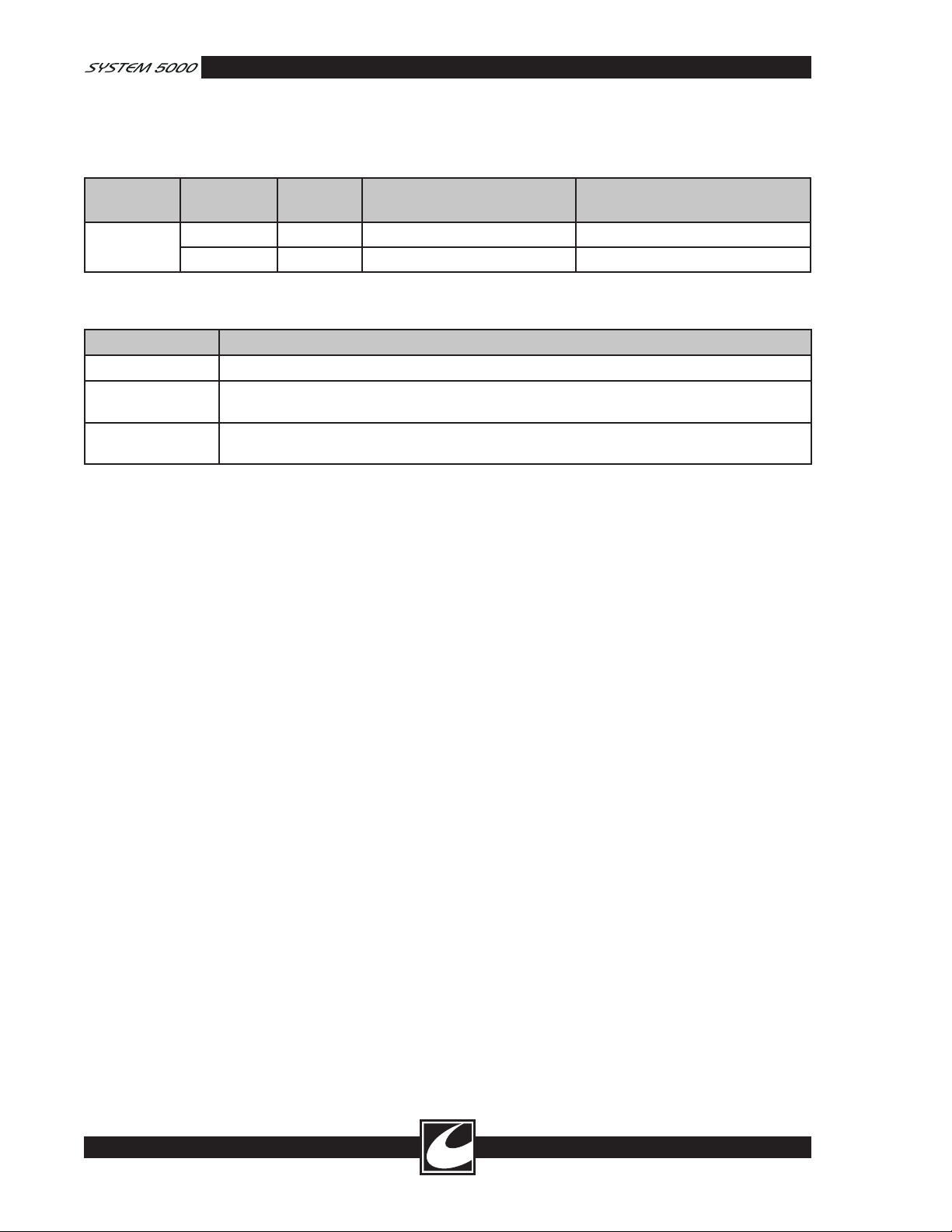

Table 4.1 Monopolar Cut Mode RF Output Power Accuracy .................................................................................

Table 4.2 Monopolar Coag Mode RF Output Power Accuracy .............................................................................

Table 4.3 Bipolar Mode RF Output Power Accuracy ............................................................................................

Table 4.4 Allowable RF Leakage Current to Ground ............................................................................................

Table 4.5 Allowable RF Leakage Current - Inactive Monopolar Outputs ..............................................................

Table 4.6 Allowable RF Leakage Current - Inactive Bipolar Outputs ...................................................................

Table 4.7 Line Frequency Allowable Leakage - Inactive .........................................................................................

Table 4.8 Line Frequency Allowable Leakage - Active ...........................................................................................

Table 4.9 DIP Switch Settings ...............................................................................................................................

Table 4.10 DACview Channels ..............................................................................................................................

Table 4.11 Troubleshooting ...................................................................................................................................

Table 4.12 Fault Codes ..........................................................................................................................................

Schematic 4.1 Interconnect Diagram ......................................................................................................................

Schematic 4.2 A12 Back Panel PCB .......................................................................................................................

Schematic 4.3a A9 RF Power Supply PCB - Power Factor Controller ....................................................................

Schematic 4.3b A9 RF Power Supply PCB - Forward Converter ...........................................................................

Schematic 4.4 A7 RF Transformer PCB .................................................................................................................

Schematic 4.5 A6 RF Amplifier PCB ...................................................................................................................

Schematic 4.6a A5 RF Output PCB - Interconnect & Switching Isolation ...........................................................

Schematic 4.6b A5 RF Output PCB - Relays & Sensing ......................................................................................

Schematic 4.7a A4 Microcontroller PCB - Controller Interconnect ......................................................................

Schematic 4.7b A4 Microcontroller PCB - Microcontroller ..................................................................................

Schematic 4.7c A4 Microcontroller PCB - RF Controller .....................................................................................

Schematic 4.7d A4 Microcontroller PCB - RF Monitor .......................................................................................

Schematic 4.8 A2 Display Controller PCB ...........................................................................................................

Schematic 4.9 A3 Display Light Panel PCB .........................................................................................................

4-9

4-10

4-10

4-11

4-12

4-12

4-12

4-13

4-19

4-20

4-21

4-25

A-2

A-3

A-5

A-6

A-8

A-10

A-12

A-13

A-15

A-16

A-17

A-18

A-20

A-22

Page 5

TM

Theory of Operation

Section 3.0

System 5000™ functions and essential circuit information are provided in this section. This section begins

with a description of the key parameters for each mode. This is followed by an overview of how the system

functions and some key operational information for the modules within the system.

3.1 Mode Descriptions

The key functional parameters for each mode are presented here. Nominal mode specifications are provided

in section 1.2.11.

3.1.1 Cut Major Modes

Major

mode

CUT PURE 391 KHz None None

Minor

Mode

BLEND 1 391 KHz 16 pulses

BLEND 2 391 KHz 11 pulses

BLEND 3 391 KHz 10 pulses

Activation of Pulse Cut will make the selected cut

mode, Pure Cut, Blend 1, Blend 2, or Blend 3

active for 70 milliseconds every 600 milliseconds.

NOTE: The low duty cycle of Pulsed Cut mode

makes the average power very low – about 12%–

when compared with the power displayed on the

RF frequency Modulation: Number of

Pulses, Time on/off

40µs/10µs

28µs/23µs

26µs/24µs

front panel. The period is also long causing most

ESU analyzers to provide erratic or erroneous

readings. Correct power can be verified by mea

suring the peak to peak current and comparing the

value with the current measured in the non-pulsed

mode.

Modulation: Frequency &

period

20 KHz

50µs

20 KHz

50µs

20 KHz

50µs

3.1.2 COAG Major Modes

Major

mode

COAG PINPOINT 391 KHz 4 pulses

Minor Mode RF frequency Modulation: Number

of Pulses, Time on/off

10µs/40µs

STANDARD 562 KHz Single pulse 39 KHz

SPRAY 562 KHz Single pulse 19 KHz

-

Modulation:

Frequency & period

20 KHz

50µs

Activation of Pulse Coag will make the selected

coag mode, either Standard or Spray, active for

2.5 milliseconds every 5 milliseconds. Displayed

power setting will represent the average power

being delivered which is approximately half the

power delivered during the pulses.

Standard and Spray Coag modes are fundamental

ly different from the Cut modes in that the reso

nant circuit of the RF Amplifier and Transformer

combination is excited by the energy of a single

pulse, causing the resonant circuit to ring until

the energy is dissipated. Circuitry in the amplifier

3-1

-

Page 6

provides further damping to dissipate the energy more quickly to minimize RF leakage effects. Spray Coag

provides the maximum open circuit voltage for which the system is rated.

3.1.3 Bipolar Major Modes

Major

mode

BIPOLAR MACRO 391 KHz None None

Minor

Mode

MICRO 391 KHz None None

RF fre

quency

Modulation: Number of

Pulses, Time on/off

Modulation: Frequency &

period

3.1.4 Advanced Specialty Modes

Specialty Mode Effect

General Normal open surgery mode – Parameters noted above.

Fluids Temporarily increases power upon activation for faster initiation. Duration and power increase

vary with mode and power setting

Lap Limits maximum peak voltage for safer laparoscopic surgery. This action does affect the load

curves when in high impedance tissue, or using normally high voltage modes.

3.2 System Overview

Mains power is converted to electrosurgical output

power through the High Voltage Power Supply

(HVPS), the RF Amplifier, and the Transformer

and Output sections of the system.

Mains power is converted to high voltage direct

current power in the HVPS to supply the RF

Amplifier. This universal input power factor cor

rected, single output, switch mode power supply

is adjustable under software control with 10-bit

resolution. The HVPS output and power factor

correction sections of the HVPS can be enabled

or disabled under software control. The HVPS

uses a current mode two-switch forward converter

topology with short circuit protection and over

voltage limiting.

Pulses generated in the RF Controller are ampli

fied to electrosurgical power and voltage levels in

the RF Amplifier and Transformer portions of the

power train. The RF Amplifier and Transformer

form a resonant switched mode amplifier with

multiple outputs that are selected on a mode-bymode basis using relays on the primary and sec

ondary side of the transformers. One transformer

is used for monopolar outputs, while the other

transformer is for the bipolar output.

Electrosurgical power flows from the RF

Amplifier and Transformer sections to the Output

section where the power is switched to the specific

electrosurgical outputs. The Output section also

has circuitry to detect activations from accessories

-

-

-

and the circuitry to perform the Automatic Return

Monitor (A.R.M.™) function to ensure the integ

rity of the dispersive electrode connection.

The power section also includes a number of out

put voltage and current sensors that are used by

the RF Controller for control of power delivery

and by the Monitor to detect errant output condi

tions.

The RF Controller is a Digital Signal Processor

(DSP) that generates an RF Amplifier drive sig

nal based upon measured parameters compared

with settings-based parameters. The pulse train

sequence is a settings-based parameter that is

dependent on the selected mode. Target power,

current limit, voltage limit, and impedance thresh

olds are all settings-based parameters derived

from a load curve that is specific to the front

panel power setting. The RF Controller samples

electrosurgical output voltage and output cur

rent from sensors over 450,000 times per second

and uses these sampled values to calculate output

power and sensed impedance. The output power,

output current, output voltage, and sensed imped

ance are compared with corresponding settingsbased parameters of target power, current limit,

voltage limit, and impedance threshold; respec

tively; and the RF Controller adjusts the width of

individual pulses within each mode-based pulse

train sequence in a closed-loop fashion to control

corresponding output power. The RF Controller

also adjusts the HVPS output more slowly, allow

ing adjustment of the RF Amplifier drive pulses

-

-

-

-

-

-

-

-

-

3-2

Page 7

Voltage

sampled

450,000

times per

second

Current

sampled

450,000

times per

second

Power

setting –

watts

displayed

on the front

panel

Calculate

measured

resistance

Calculate

measured

power

Compare

Desired

Power

Measured

Power

Adjust

output

waveform

(power)

Patient

0

20

40

60

80

100

120

140

160

180

200

0 500 1000 1500 2000

90

35

180

Figure 3.1 RF Controller Block Diagram

to optimize the electrosurgical output waveform.

Finally, the RF Controller minimizes RF leakage

currents using the CONMED Leakage Abatement

System (CLAS™), which imposes a duty cycle on

the electrosurgical output when sensed impedance

and output voltage exceed settings-based imped

ance thresholds and voltage limits in the Coag

modes.

The RF Monitor is also a DSP, but it is used to

monitor the system for a variety of conditions that

could lead to safety problems, including:

• The Monitor has independent sensors for out

put voltage and current, which it uses to cal

-

culate power for comparison with the power

that the RF Controller senses and for com

-

parison with the generator power setting.

• To ensure that the correct outputs are acti

vated, the Monitor also independently

senses current at each of the outputs, look

ing for current flow that would indicate

electrosurgical power at outputs other than

the selected output.

• The Monitor senses the voltage at the output

of the HVPS to ensure that it is reasonable

for the power setting.

• The Monitor senses the audio output to ensure

that a tone occurs whenever electrosurgical

outputs are active.

• The RF Amplifier drive signal is sensed by

the Monitor to detect improper frequencies

or improper pulse sequences for the selected

mode.

• The Monitor independently compares the

activation signal with that seen by the System

Controller to ensure that the activation signal

is consistent.

The Monitor has the capability to independently

disable the electrosurgical output if a problem is

detected.

The System Controller provides the primary con

trol interface to the user and other outside sys

tems, including the serial interface, the activation

relay, tone generation, and displays.

Finally, the Display accepts all user input and provides all user feedback. The Display is controlled

by the System Controller through a serial interface

and illuminates the LED display elements in a

time division multiplexed fashion; the illuminated

LED display elements are actually on less than half

the time. The Display also provides for user input

through the buttons on the control panel, includ

ing switch de-bouncing and conditioning.

Figure 3.2 illustrates the key elements of the sys

tem in block diagram form.

3.2.1 High Voltage Power Supply (HVPS)

The HVPS is comprised of a Power Factor

Control (PFC) section and a Forward Converter

(FC) section. The PFC converts Mains power

to approximately 400 volts using techniques

that ensure the mains current into the supply is

sinusoidal and in phase with the mains voltage.

By doing so, RMS current and harmonic distor

tion are reduced. The Forward Converter then

-

-

-

-

-

3-3

Page 8

Real Time

Clock (5K)

Indicators:

Power, Mode,

& bipolar

current

Displays

Keyboard

Modes / Power

Activation

Request

System

Controller

RF Controller

RF Monitor

RF Amp

RF Output

Board

HV Power

Supply

Bip

Mon

RFHVSup

MRF H1 SN

MRF H2 SN

MRF FT SN

MRF BP ISN

MRF BP VSN

MRF MP ISN

MRF MP VSN

M HVDC

/HV EN

Tone

Mon

WF EN

WFORM

DAMP

CNTL

RLY DRV

RF BP IS

RF BP VS

RF MP IS

RF MP VS

HV SET

PFC EN

BIP TONE

ACT TONE

AL TONE

RS232

ACT RLY

Serial Interface

Connector

Activation Relay

Connector

Host

Bus

SPI

Patient

RF INH

Mon

RF

Transformer

Board

VARM

Figure 3.2 System Block Diagram

converts the PFC output to an adjustable DC

voltage for use by the RF amplifier.

The System Controller can enable or disable the

PFC section of the HVPS. The PFC is normally

enabled during operation to ensure a resistive load

is presented to the Mains.

The Forward Converter is a switch-mode power

converter that adjusts its operating frequency

between 25KHz and 100KHz to ensure proper

resolution for the commanded output volt

age. Isolation between Mains power and the

-

3-4

HVPS output occurs in the Forward Converter.

Forward Converter output voltage is set from the

RF Controller by the /HVSET signal. The RF

Monitor enables the output of the HVPS. The

forward converter includes current limiting on the

output and has provisions to shutdown when the

output of the Low Voltage Supply exceeds limits.

3.2.2 RF Amplifier and Transformer

The RF Amplifier and Transformer portions use

a switch-mode resonant amplifier to convert the

power from the HVPS to the RF energy neces

-

Page 9

sary for electrosurgery. One may think of the

amplifier as a high-speed switch that pulses cur

rent through a resonant circuit, which is formed

by the monopolar or bipolar transformer together

with capacitors and inductors connected to the

transformer primary and secondary windings.

Two Metal-Oxide-Semiconductor Field Effect

Transistors (MOSFETs) are connected in a paral

lel fashion provide the switching. The pulses to

drive the gates on the MOSFETs in this arrange

ment come from the RF Controller. Adjusting

the width of the drive pulses regulates the output

power in this arrangement; as the pulses become

longer, the output power increases. As noted in

the RF Controller discussion, the RF Controller

compares the output power with the desired

power and adjusts the pulse width to minimize

the difference.

A drive of several pulses at a frequency that closely

matches the resonant frequency of the amplifier

characterize Cut, Blend, and Pinpoint modes, and

the output pulses substantially correspond to the

drive. Spray and Standard Coag modes, how

ever, are characterized by pulses that occur less

frequently where the amplifier is allowed to “ring”

at its resonant frequency. A damping capability is

provided to enhance the surgical effect by damp

ing the ringing effect for each drive pulse.

Because the transformer windings and the reso

nant frequencies between the cut and coag modes

are different, a method of selecting resonating

components is implemented using relays. These

relays switch in the relevant components for the

selected mode based upon commands from the

System Controller.

A Balun transformer is provided for the

monopolar modes to reduce differences between

the source and return currents, thus reducing RF

leakage.

Finally, the RF Amplifier and Transformer provide

capabilities for sensing RF output current and

voltage. These are transformer-isolated representations of the current flowing in the leads and the

voltage across the output, which are supplied to

the RF Controller and the Monitor processors.

3.2.3 Electrosurgical Outputs

Relays are provided to isolate electrosurgical out

puts and select which outputs are active. The

System Controller selects the appropriate output

relays based upon activation command inputs.

-

-

-

-

-

-

-

The Monitor utilizes sensors implemented on each

electrosurgical output to determine whether cur

rent is flowing only to the correct outputs. In the

event that current flows in an output that is not

selected, the Monitor can independently disable

RF.

The System 5000™ output panel connectors are

illuminated to aid visibility in low lighting situ

ations. This illumination is provided by a single

LED on the display board that is distributed to

the receptacles through a fiber-optic bundle.

3.2.4 Activation Command Sensing

Each of the Hand Controlled Accessory recep

tacles incorporate inputs that are used to sense

an activation command from the user. Each

monopolar hand controlled accessory receptacle

has an input for cut and an input for coag. The

bipolar receptacle incorporates a single activation

input. Each of these five inputs is isolated from

the other electrosurgical outputs and from other

low-level circuitry in the system. All are powered

by a multiple output isolated power supply. The

footswitch activation inputs on the back panel are

configured in a similar way and share one of the

isolated power supply outputs.

3.2.5 Automatic Return Monitor (A.R.M.™)

The patient return connector interfaces to single

and dual dispersive electrodes using a two-pin

connector. A.R.M.™ circuitry uses an actively

driven impedance measurement circuit, which

allows the System Controller to detect the type

of dispersive electrode connected and verify its

integrity.

3.2.6 Low Voltage Power Sources

The low voltage power supply is a medical-grade

universal input offline triple output switching

power supply. The power supply is active anytime

Mains power is connected to the unit with the

Mains power switch turned on.

3.2.7 System Controllers and Monitor

Three processors are used for system interface &

control, RF control, and system monitor func

tions. The ESU control section consists of dual

channel architecture with two independent chan

nels where one is used exclusively for RF output

control and the other is used for safety monitor

ing. All three of these processors are located on

-

-

-

-

-

-

3-5

Page 10

the Control board, along with circuitry to isolate

them from RF noise.

• System Controller (System Microcontroller):

A dedicated microcontroller that handles the

entire user interface, Serial Interface, real

time clock functions, and enables/disables the

power factor control section of the HVPS

using the PFC_EN signal. The System

Controller can also disable the signal used to

drive the RF Amplifier and can terminate RF

drive at any time without interaction from

either the RF Controller or the Monitor. The

System Controller is comprised of an standard

architecture microprocessor together with

Field Programmable Gate Array (FPGA),

which provides interface logic to a variety of

signals, a 3.68MHz oscillator, independent

voltage regulators, a processor supervisory

reset circuit, and other interface logic.

• RF Controller: A DSP that is dedicated to

the output and control of RF power using

the DAMPCNTRL and RF_DRV outputs.

To reduce the effects on the microproces

sor circuits on the Controller board from

RF noise at the output, DAMPCNTRL and

RF_DRV are both differential mode signals

running between the RF Controller and the

RF Amplifier. The RF Controller is capable

of disabling RF output power and put

ting the system into a safe state without any

interaction from the Monitor or the System

Controller. The RF Controller indepen

dently monitors the RF output voltage and

current for control purposes through several

scaled inputs. It sets the output voltage of the

HVPS using the HV_SET signal dependent

on the output Mode and power selected. The

RF Controller controls the fan based upon

temperature measurements supplied from the

RF Amplifier through the System Controller.

The RF Controller is comprised of a DSP,

together with circuitry necessary for convert

ing the signals used for control purposes

between analog and digital form, independent

voltage regulators, and other interface logic.

• RF Monitor: A DSP that is dedicated to safety

monitoring activities. The Monitor is capable

of disabling RF output power and putting the

system into a safe state without any interac

tion from the RF Controller or the System

Controller. To ensure that the Monitor can

correctly perform its function, the Monitor is

-

-

-

-

resistively isolated from the other two proces

sors and has independent voltage regulation.

The RF Monitor independently monitors a

variety of inputs to detect safety problems

and has control of disable signals for both the

HVPS and RF Amplifier drive. The Monitor

is comprised of the same DSP as the RF

Controller, together with circuitry necessary

for converting the signals monitored between

analog and digital form, an FPGA to provide

interface logic, independent voltage regula

tors, isolation resistors and other interface

logic.

3.2.8 Low Voltage Power Monitoring

The low voltage power supply is monitored in

hardware and resets the processors if it is out of

range. The microprocessor supervisory device on

the Controller board monitors +5V and +3.3V

and will reset the system should the levels drop

approximately 0.3V. The Controller assembly

has the circuit that will reset the system should

the 3.3V supply exceed 3.6V. The High Voltage

power supply has a circuit that will inhibit HVDC

should the +5V supply exceed 5.7V.

3.2.9 Operator Control Panel

Keyboard: The main operator input device for

choosing operating modes and settings is the

membrane keyboard panel. Tactile-feedback

mechanical switches allow the operator to set

modes and adjust power settings.

Display Panel: Consists of 7-segment displays,

discrete dual colored LED’s, and light bars that

will display all controls and settings. LED display

elements are illuminated in a time division multi

plexed fashion; the illuminated LED display ele

ments are actually on less than half the time.

Bipolar Current Meter: The System 5000™

has a bargraph display that provides an indication of measured bipolar impedance. A special

-

tone works in conjunction with this bargraph to

indicate when the measured bipolar impedance

exceeds a particular limit.

3.2.10 Activation Tones

Tone is generated for all activation requests, fault

detection and changes made on the Control Panel.

The System Controller generates the tone signal

(ACT_TONE, AL_TONE, & BP_TONE), which

is amplified by a driver on the Backpanel PCB

Assembly. The activation tone and bipolar tone

-

-

-

-

3-6

Page 11

are individually adjustable, but alarm tones are

not adjustable and are set to generate tone greater

than 65 dB.

Circuitry on the Backpanel PCB permits the

Monitor to verify the oscillation from voltage

measured across the speaker, which provides

confirmation that the speaker is indeed generat

ing audible tones during activation. RF output

is inhibited should the speaker drive current be

absent or too low.

3.2.11 Activation Relay Connector

There is an Accessory Relay Connector, which

provides a relay closure (SPST switch) that may

be used for activating external accessories such as

smoke evacuation units.

-

3.3 Optional System Configurations

An eight-position configuration dipswitch (S2),

located on the Controller PCB Assembly (A4)

allows a qualified service technician to change

some of the factory default settings. With the

exception of the DACview switch, the configura

tion dipswitch settings are only detected when

power is initialized, so any changes to the switch

positions must be made with the main power

off. Each switch is OFF in the Down position

and ON in the UP position. The system detects

changes in the DACview switch while power is

on, so it is treated differently. Relevant informa

tion for the configuration dipswitches appears in

Section 4.9.

-

-

3-7

Page 12

This page has been intentionally left blank.

3-8

Page 13

Maintenance

Section 4.0

TM

This section contains information useful in the

maintenance and repair of the System 5000™.

WARNING: High voltages are present at the

connections and within the System 5000™.

Maintenance personnel should take precautions

to protect themselves. Read the safety sum

mary in Section 1.1.4 before working on the

ESU.

-

4.1 General Maintenance Information

Although the System 5000™ has been designed

and manufactured to high industry standards, it is

recommended that periodic inspection and perfor

mance testing be performed to ensure continual

safe and effective operation.

Ease of maintenance was a primary consideration

in the design of the System 5000™. Maintenance

features of this unit include microprocessor aided

troubleshooting aids and push button calibration,

built in fault detection, circuit protection, and easy

access to circuitry while the unit is operational.

These features, coupled with the warranty, local

support, loaner equipment, factory support, toll

free phone service to the factory and available fac

tory training ensure the user of a minimal mainte

nance effort with extensive support available.

-

-

-

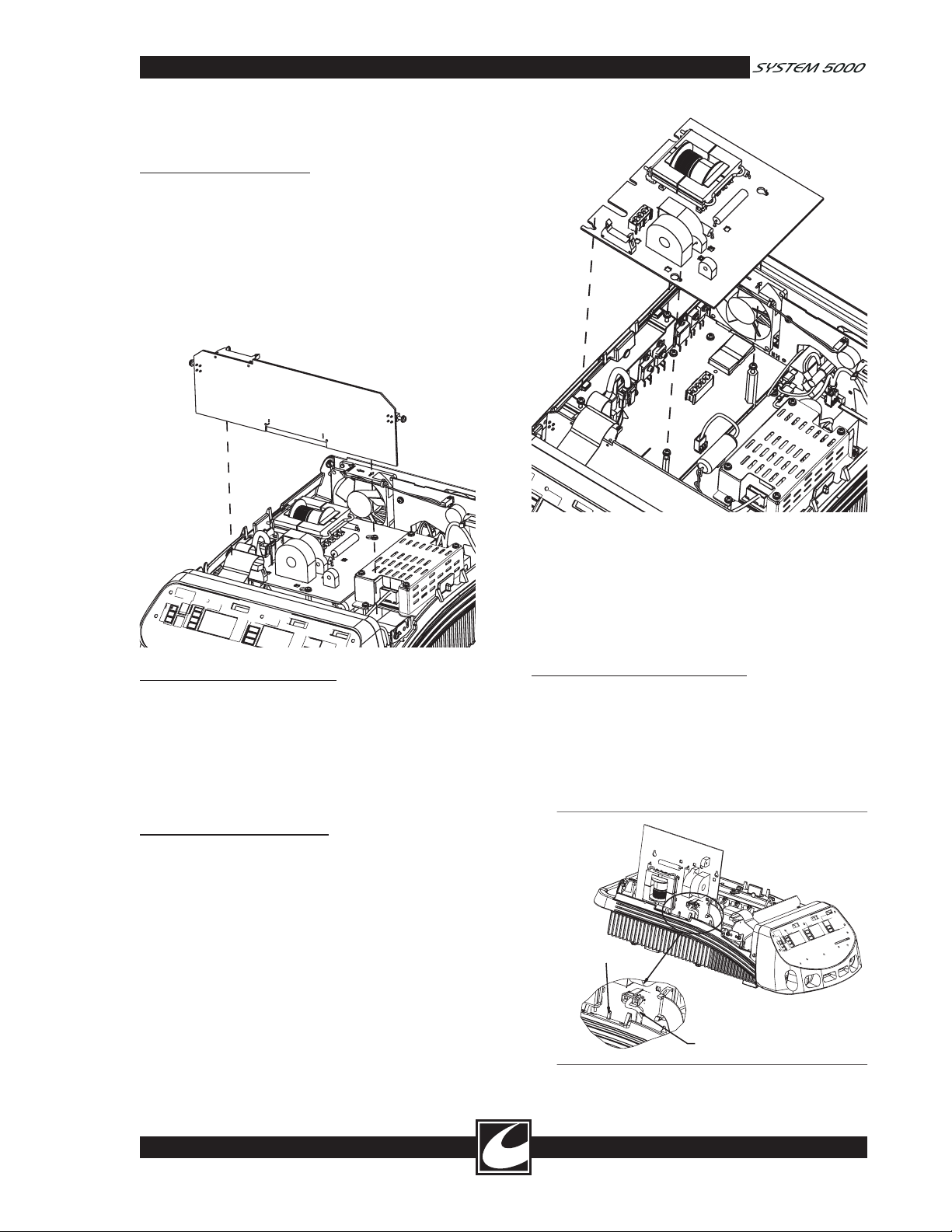

4.3.1 Top Cover Removal and Replacement

Top Removal:

1) Remove the two screws located on rear of

unit as shown.

2) Pull back and up to remove top.

Cover Screws

Cover

Screws

Cover

Screws

4.2 Maintenance Personnel

Only qualified biomedical engineers should perform service on the System 5000™. Refer all

servicing to a qualified biomedical engineer. If

necessary, your CONMED sales representative will

be happy to assist you in getting your equipment

serviced.

4.3 Assembly Breakdown/Parts Access

CAUTION: This device contains components that can be damaged by static electricity.

Proper handling by grounding of personnel

during servicing is mandatory.

Following are instructions for unit disassembly

and reassembly instructions.

Side Clips

4-1

Page 14

Top Replacement:

1) Place top approximately ¾” from front bezel

on top of unit.

2) Press forward, aligning lip of front bezel with

groove in top and side clips with tabs on cast

ing.

3) Re-install screws.

3) Unlatch display ribbon cable, dispersive electrode connector, ReadiPlug™ cable connector

and two ground connectors.

4) In most situations, it is not necessary to

-

remove the four power switch connectors.

The bezel can be rotated off to the right side

for output board removal. To fully remove the

bezel, these connectors must be disconnected.

Slide top forward.

4.3.2 Bezel Removal and Replacement

Bezel Removal

:

1) Remove Top.

2) Remove two flat-head screws on side of bezel

and two pan-head screws on bottom of bezel.

AC Power Switch

White

Blue

Black

Brown

Bezel Replacement:

1) Connect power switch connectors as shown,

if required.

2) Connect dispersive electrode connector and

ReadiPlug

™ cable connector prior to sliding

bezel into place.

3) Slide bezel into unit. As shown in figure, the

output board insulator is positioned between

the sheet metal base and the Output Board.

4-2

Insulating Sheet

4) Reconnect cables and replace and tighten

screws.

Spring contacts are exposed and

can be deformed, causing erratic

operation. Handle with care.

Page 15

4.3.3 Processor Board Removal and

Replacement

Processor Board Removal

:

1) Remove Top.

2) Loosen the two screws holding the board to

slots in the brackets.

3) Unlatch the ribbon cable going to the display.

4) Pull board up and out of unit.

Processor Board Replacement:

1) Align board into the two slots of the brackets

attached to the heatsinks. Align with con

nector on Output Board and press firmly to

engage it fully. Tighten the two screws.

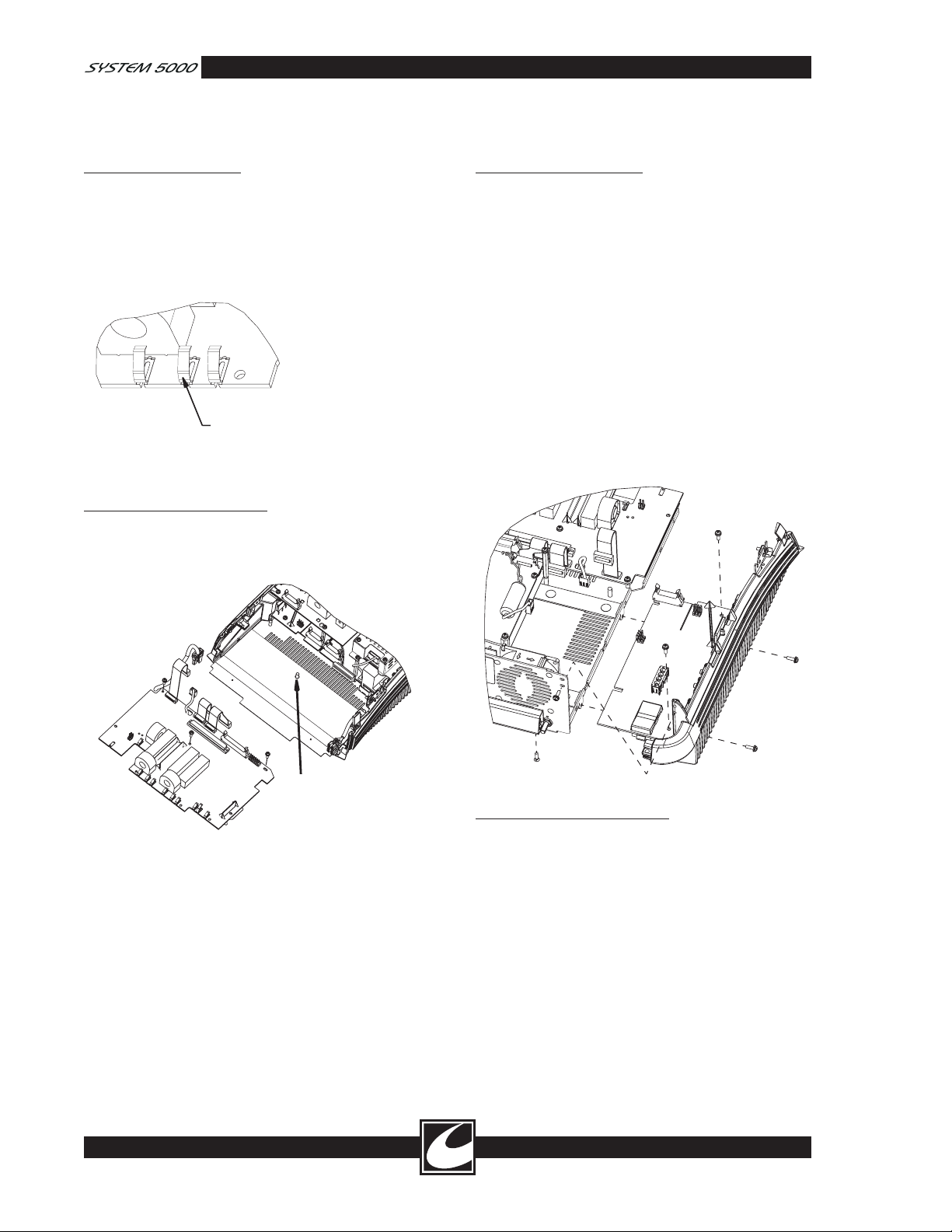

4.3.4 Transformer Board Removal and

Replacement

3) Unlatch the ribbon cable and power cable on

the top of the board.

4) Pull board towards inside of unit so screws

line up with keyholes, then up and out of

unit. The power cable to RF Amp must be

unplugged to completely remove transformer

board.

Transformer Board Replacement

:

1) Reverse board removal operation.

NOTE: When servicing unit, board can be sup

ported in heatsink as shown. This will provide

access to the lower boards while the unit is func

tional.

-

-

Transformer Board Removal

:

1) Remove Top.

2) Loosen the two screws mounting the board

to the keyhole slots on standoffs and two

screws mounting the board to the heatsink.

Align slot

in board

with rib on

heatsink.

Route cable through slot.

4-3

Page 16

4.3.5 Output Board Removal and

Replacement

4.3.6 RF Amp Board Removal and

Replacement

Output Board Removal

:

1) Remove Top, Bezel and Processor Board.

Note: It is not necessary to remove power switch

connections from the bezel.

2) Remove the seven cables along the rear side

of the board and the three screws shown.

Spring contacts are exposed and

can be deformed, causing erratic

operation. Handle with care.

Output Board Replacement:

1) Prior to replacing board, assure that the insu

lator sheet is positioned properly as shown.

RF Amp Board Removal

:

1) Remove Top, Bezel and Transformer Board.

2) Remove the four screws that attach the

heatsink to the sheet metal chassis. One for

the handle, one on the back panel, and two

below the heatsink. Remove the two screws

that attach the board to the sheet metal chassis as shown. Note: These screws are in

holes, not slots.

3) Unlatch three cables – two cables from the

RF Output Board and a cable from the RF

Power Supply Board.

4) Loosen the smaller hex standoff.

5) Slide RF Amp Board with heatsink off the

base as shown.

-

Note: The insulator

sheet provides an

important dielectric

barrier. For safe

operation, position

over center standoff as

shown.

2) Replace board on standoffs.

3) Route cables as they were prior to removal

and connect them back to their proper con

nectors.

4) Replace and tighten the three screws.

4-4

RF Amp Board Replacement:

1) Slide board with heatsink back into its previ

ous position on the sheet metal chassis. The

heatsink has two pins that align into holes on

the sheet metal chassis.

2) Tighten hex standoff onto board. It provides

an electrical ground to Transformer Board.

-

3) Reinstall and tighten the six screws and latch

the three cables.

Page 17

4.3.7 Low Voltage Power Supply Module

Removal and Replacement

NOTE: This module is not user serviceable at

the component level. If faulty, the entire cir

cuit board must be replaced. Replacements are

available from CONMED Customer Service.

Do not discard the module cover, mount

ing plate and hardware; the replacement part

includes only the circuit board.

Low Voltage Power Supply Module Removal:

1) Remove Top Cover.

2) Loosen four screws located in slots and

unlatch the two cables.

3) Slide Low Voltage Power Supply Module

inward off the slots, then upward to remove.

Circuit Board

4) Remove the cover by removing four screws.

Then remove the four standoffs to separate

the Low Voltage Power Supply from its

mounting plate.

NOTE: When servicing unit, board can be held in

heatsink as shown. This will provide access to the

lower boards while the unit is functioning.

Low Voltage Power Supply Module Replacement:

1) Replace Low Voltage Power Supply on

mounting plate, fasten standoffs, replace cover

and tighten screws.

2) Place Low Voltage Power Supply Module

into unit on standoffs. Tighten the loose

screws and latch the two connectors.

4-5

Page 18

4.3.8 High Voltage Power Supply Removal

and Replacement

High Voltage Power Supply Board Removal

:

1) Remove Top Cover. Position Transformer

Board in its servicing position to gain access

to screws. If desired, remove the Low

Voltage Power Supply.

2) Unlatch the Mains Power Cable, RF Amp

Cable, and Output Board Ribbon Cable.

3) Loosen the two screws holding the edge of

the board to the chassis.

4) Remove the screw to the handle, the screw to

the back panel, the two screws on the bottom

of the heatsink and slide out the heatsink with

the board attached.

Note: Observe the position of the insulating sheet

under the High Voltage Power Supply. If the

insulating sheet is removed, replace it as shown.

It is important to maintain its function as a

dielectric barrier and to protect the ribbon cable

from the leads of the High Voltage Power Supply

Board.

Insulating Sheet

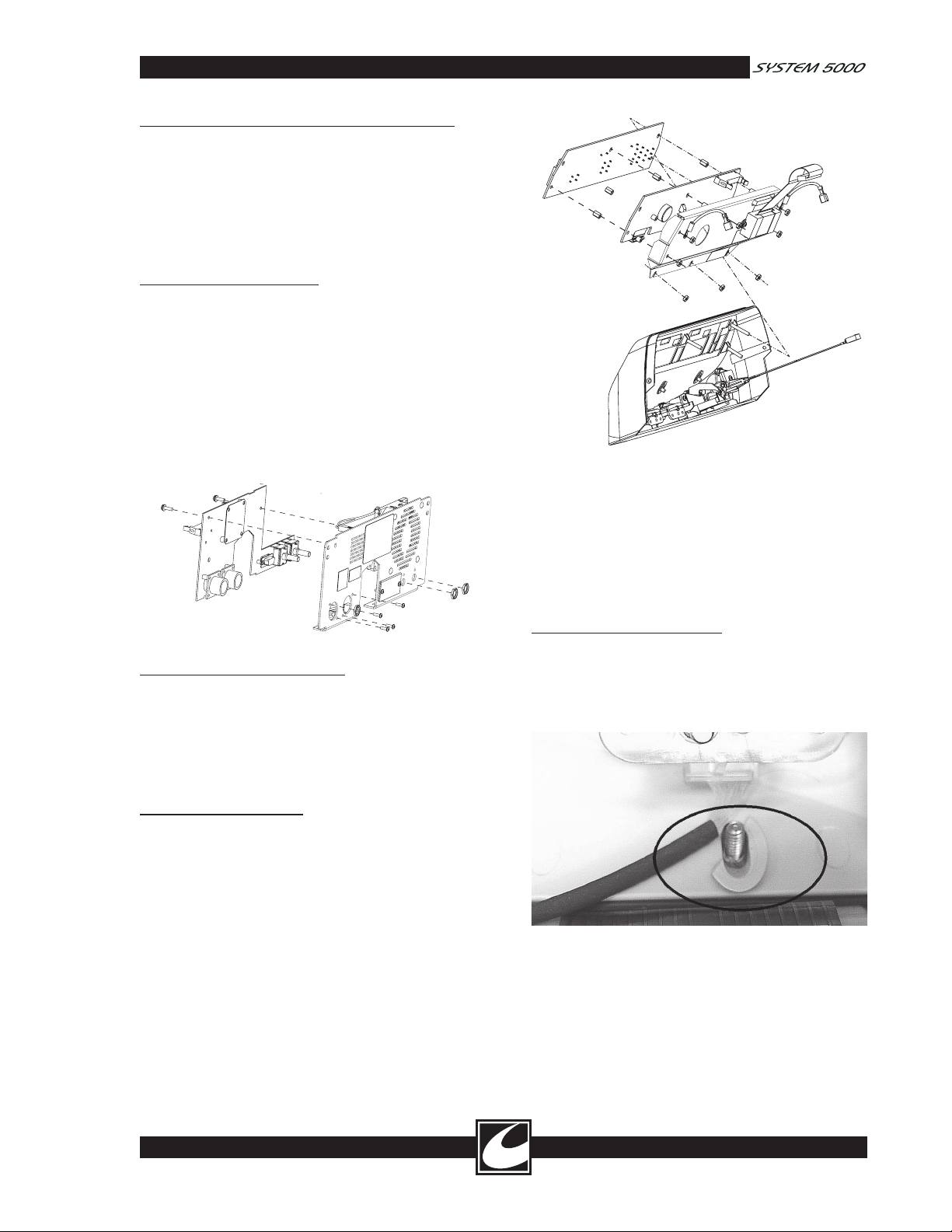

4.3.9 Rear Panel with Board Removal and

Replacement

High Voltage Power Supply Board Replacement:

1) Slide board with heatsink back into its previ

ous position on the sheet metal chassis. The

heatsink has two pins that align into holes on

the sheet metal chassis.

2) Reinstall and tighten the six screws and latch

the three cables.

Rear Panel with Back Panel Board Removal

:

1) Remove Top Cover.

2) Unlatch the Ribbon Cable.

3) Remove the four screws on the bottom of the

Rear Panel, and the three screws shown on

the Rear Panel.

-

4) Slide the Rear Panel with Back Panel Board

back toward the handle and then down to

remove.

4-6

Page 19

Rear Panel with Back Panel Board Replacement:

1) Slide Rear Panel with Back Panel Board back

into place on the unit.

2) Reinstall and tighten the seven screws and

latch the ribbon cable.

4.3.10 Back Panel Board Removal and

Replacement

Back Panel Board Removal

1) Remove Top Cover and Rear Panel.

2) Unlatch the Activation Relay and Fan connectors.

3) Remove the four screws for the foot switch

connectors, the two nuts on the volume

potentiometers and the two screws to the rear

panel sheet metal standoffs. This will free the

Back Panel Board from the Rear Panel.

Back Panel Board Replacement:

1) Install Back Panel Board to Rear Panel

2) Reinstall and tighten the six screws, two nuts.

Latch the RSA and fan cables.

:

7) Remove the Display Controller Board by separating it from the display board and pulling

it off the studs. There are two 40-pin connec

tors between these boards that may require

separation by prying with a blunt object.

8) Remove the five hex standoffs and pull the

Display board off the studs.

Display Boards Replacement

Caution: When reinstalling Boards and display

shield, take care to route fiber optic cable as

shown to avoid crimping it between the bezel

and display shield.

:

-

4.3.11 Display Boards Removal and

Replacement

Display Boards Removal

1) Remove the Top Cover and Bezel.

2) Remove 8 nuts and two ground cables on the

back of the display shield.

3) Disconnect the ribbon cable and remove the

sheet metal display shield.

4) Slide the round spacers off their studs.

5) Disconnect the flex circuit connector.

Caution: The flex circuit has a short service

loop and is fragile; handle with care.

6) Pull to disconnect the fiber optic cable from

LED. Caution: The fiber optic cable is frag

ile; handle with care.

:

1) Reinstall boards in the reverse order described

above. Latch the flex circuit connector, press

fiber optic cable onto the LED and press the

Display Controller Board firmly into place on

the two 40 pin connectors.

-

4-7

Page 20

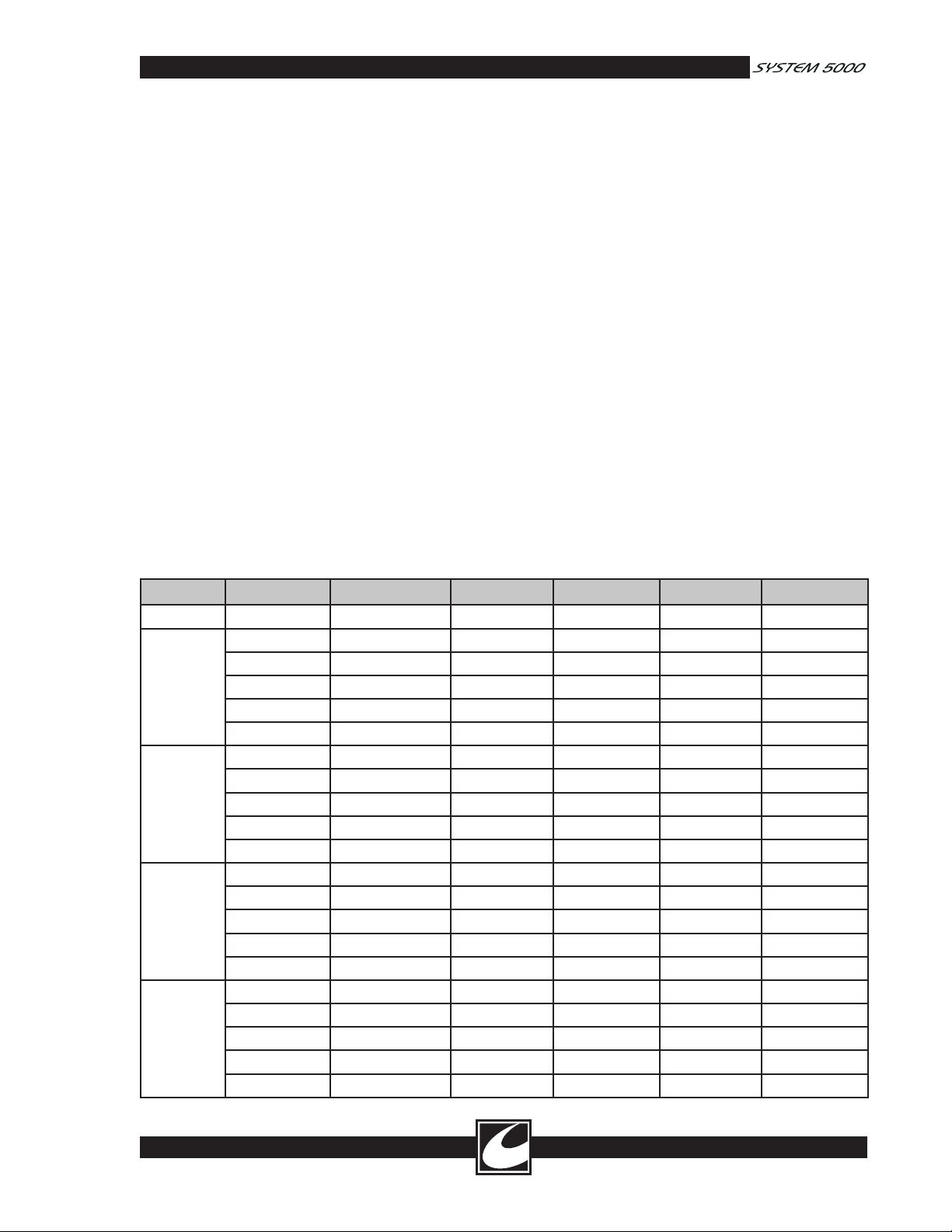

4.3.12 Power Transistor Replacement

Caution: This device contains components that

can be damaged by static electricity. Proper

handling by grounding of personnel during

servicing is mandatory.

All RF Power Supply and RF Amp components

mounted to the heatsink may be replaced.

only components supplied by CONMED.

Follow these instructions for replacement:

1) No thermal compound is necessary, but the

mating surfaces of the transistor, insulator

pad and surface of casting should be clean.

Always replace the insulator pad associated

with the transistor. Always fasten or clamp

the part to the heat sink surface prior to sol

dering it to the board. This will assure good

thermal contact is maintained.

2) In order to maintain alignment with the heat

sink surface, the leads of these parts have been

bent to the proper shape. They should be

purchased from CONMED with bent leads.

3) When installing the RF Amp transistors or

diodes, be sure to orient the Bellville washer

as shown with the convex surface next to the

head of the screw. Tighten screws to 5-7 inch

pounds.

Use

-

4) When installing the RF Power Supply transistors or diodes, replace components as shown

and ensure the insulating tube is installed over

the clip. Locate the part on the clip so that

the bend of the clip is approximately centered

on the body of the part as shown. Tighten

screw to 8-10 in-lbs. When tightening screw,

hold the clip to prevent it from rotating.

Clamp the part to the heatsink surface prior

to soldering to the board.

4.4 Cleaning

The interior of the unit may be vacuumed or

blown out as required. The exterior of the unit

may be cleaned by wiping it with a cloth that

has been dampened (not dripping) with a mild

detergent such as Windex® or Formula 409®.

Windex® is a registered trademark of the S.C.

Johnson Company. Formula 409® is a registered

trademark of the Clorox Company.

4.5 Periodic Inspection

The System 5000™ should be visually inspected

at least every six months. This inspection should

include checks for the following:

1) Damage to the power cord and plug.

2) The proper mating and absence of damage to

the accessory connectors.

3) Any obvious external or internal damage to

the unit.

4) An accumulation of lint or debris within the

unit or heatsink.

5) Control Panel cuts, punctures, or dents.

4-8

Page 21

4.6 Periodic Performance Testing

4.6.3 Output Power

The System 5000™ should be tested for correct

performance at least once every year. Every unit

is supplied with a serialized Production Test Data

Sheet that tabulates the results of the factory tests

that were performed on the unit. This data is

supplied so that it may be used as a reference for

subsequent tests. Recommended periodic perfor

-

mance tests are listed in the following sections.

4.6.1 Chassis Ground Integrity

Connect a standard ohmmeter between the

earth ground prong on the power plug and the

Equipotential Ground Connection. Compensate

for lead resistance. Confirm less than 0.2 ohms

resistance is measured.

4.6.2 Displays, Alarms and Commands

Perform the Preliminary Functional Test procedure

described in section 2.3.1 of this manual to verify

proper operation of displays, alarms and com

-

mands.

1) Equipment Requirements:

a) Monopolar Footswitch

b) Bipolar Footswitch

c) Commercial ESU Tester (e.g. Dynatech

454A or equivalent) with 50 and 300

ohm loads for bipolar modes and a 500

ohm load for monopolar modes.

Note: Micro Bipolar is particularly sensitive to the

load resistance. A 50 ohm load should be used for

checking power to obtain the best results.

2) Use test leads to connect the ESU tester to

the unit’s return electrode output and the

footswitch controlled active output. Set the

Load resistance per mode as indicated in

Tables 4.1 and 4.2.

3) Perform the monopolar power tests indicated

in Tables 4.1 and 4.2. The acceptance range

is given in both Watts and Amps to accom

modate available test equipment. It is not nec

essary to test for both power and current.

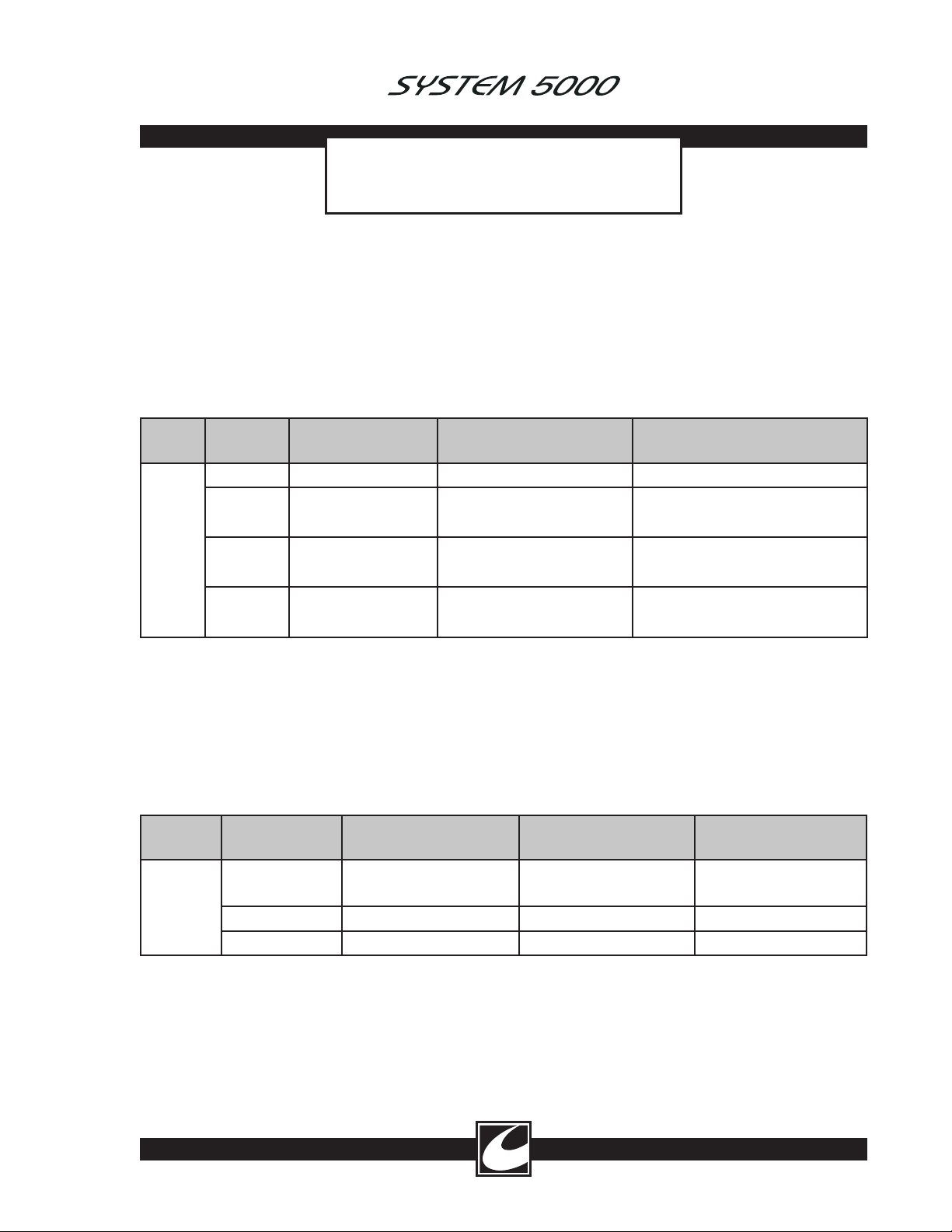

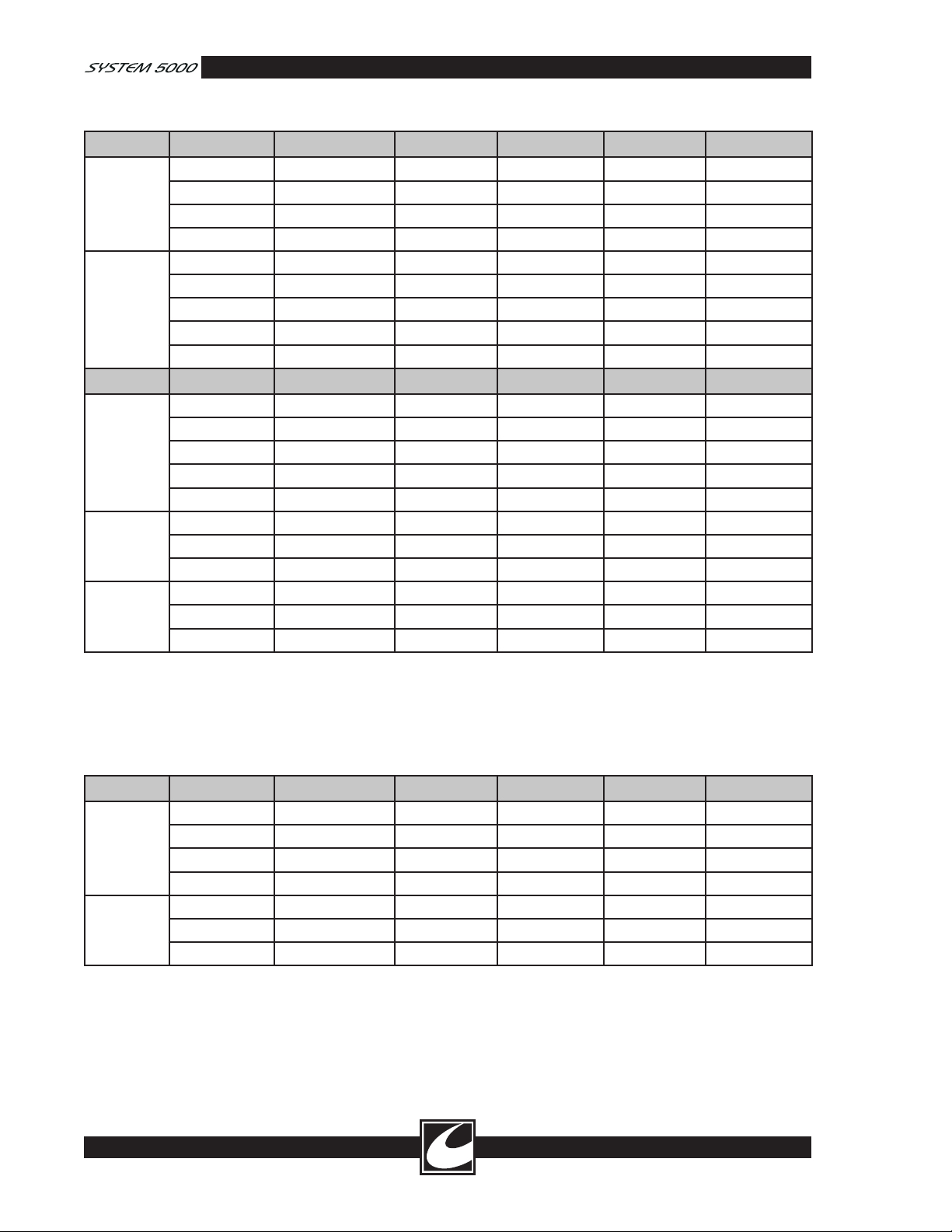

Table 4.1 Monopolar Cut Mode RF Output Power Accuracy

Mode Load (ohms) Power Setting Watts (min) Watts (max) Amps (min) Amps (max)

Pure 500 10 7 13.0 0.118 0.161

Standard

Blend 1 500 10 7 13.0 0.118 0.161

Blend 2 500 10 7 13.0 0.118 0.161

Blend 3 500 10 7 13.0 0.118 0.161

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 100 90 110 0.424 0.469

500 200 180 220 0.600 0.663

500 300 270 330 0.735 0.812

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 100 90 110 0.424 0.469

500 200 180 220 0.600 0.663

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 100 90 110 0.424 0.469

500 200 180 220 0.600 0.663

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 100 90 110 0.424 0.469

500 200 180 220 0.600 0.663

-

-

4-9

Page 22

Table 4.2 Monopolar Coag Mode RF Output Power Accuracy

Mode Load (ohms) Power Setting Watts (min) Watts (max) Amps (min) Amps (max)

Spray 500 10 7 13.0 0.118 0.161

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 80 72 88 0.379 0.420

Standard

500 10 7 13.0 0.118 0.161

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 100 90 110 0.424 0.469

500 120 108 132 0.465 0.514

Mode Load (ohms) Power Setting Watts (min) Watts (max) Amps (min) Amps (max)

Pinpoint 500 10 7 13.0 0.118 0.161

500 20 17 23.0 0.184 0.214

500 50 45 55 0.300 0.332

500 100 90 110 0.424 0.469

500 120 108 132 0.465 0.514

Standard

pulse

Spray pulse

500 10 7 13.0 0.118 0.161

500 20 17 23 0.184 0.214

500 60 54 66 0.329 0.363

500 10 7 13.0 0.118 0.161

500 20 17 23 0.184 0.214

500 40 36 44 0.268 0.297

4) Disconnect the ESU tester from the unit.

5) Use test leads to connect the ESU tester to

the Bipolar Accessory outputs.

6) Perform the bipolar power tests indicated in

Table 4.3. This table only provides the mini

mum number of points to be tested.

Table 4.3 Bipolar Mode RF Output Power Accuracy

Mode Load (ohms) Power Setting Watts (min) Watts (max) Amps (min) Amps (max)

Macro

Bipolar

Micro

Bipolar

4.6.4 RF Leakage Measurement

RF Leakage can present a hazard in the operating

room because electrosurgical currents can flow

to the patient and operating room staff through

unintended paths, which can cause injury. RF

300 10 7 13.0 0.153 0.208

300 20 17 23.0 0.238 0.277

300 50 45 55 0.387 0.428

300 90 81 99 0.520 0.574

50 10 7 13.0 0.374 0.510

50 25 22 28.0 0.663 0.748

50 50 45 55 0.949 1.049

leakage occurs because the total energy in the

output voltage waveform is provided with a con

ductive path through stray parasitic capacitance

distributed within the generator and along the

length of the leads. Table 4.4 presents the allowed

RF leakage currents to ground.

-

-

4-10

Page 23

Table 4.4 Allowable RF Leakage Current to Ground

MEASURED TERMINAL ACTIVATED ACCESSORY MODE RF LEAKAGE (Ma)

Dispersive Electrode Coag Footswitch Standard Coag < 100

Dispersive Electrode Cut Footswitch Pure Cut < 100

Dispersive Electrode Left Hand Controlled Standard Coag < 100

Dispersive Electrode Right Hand Controlled Standard Coag < 100

Footswitched Active Coag Footswitch Standard Coag < 100

Left Hand Controlled Active Left Hand Controlled Standard Coag < 100

Right Hand Controlled Active Right Hand Controlled Standard Coag < 100

Bipolar Right Bipolar Footswitch Bipolar Macro < 67

Bipolar Left

Bipolar Footswitch

Bipolar Macro

< 67

Equipment:

• ESU Tester with RF Leakage function -OR-

• 0-250 mA RF Ammeter with a 200 ohm 10

W Non-inductive Resistor

• Patient Plate Adapter Plug

• 2 - Test leads, 1 m max. length

• 3 - Test leads, 10 cm max. length

• Wooden table approximately 1 m from floor.

NOTE: The CONMED Leakage Abatement

System (CLAS™) controls RF leakage by puls

ing the output to reduce the RMS voltage during

open circuit conditions, thus keeping the hazard

ous energy below IEC safe limits. Use a measur

-

ing device that meets IEC specification for RMS

measured over one second.

Procedure:

1) Ensure that the unit is fully assembled and all

fasteners are tight.

2) Place the ESU tester or meter with resistor on

the table so that they are at least 0.5m away

from the unit under test and any other con

-

ductive surface.

3) Set the unit for full power for the modes

noted in the table. Connect the ESU tester in accordance with the manufacturer’s

instructions -OR- connect the 200-ohm noninductive resistor in series with the 250 mA

RF ammeter to the Equipotential Ground

Connection on the Rear Panel. Also make

sure there are no connections to any output

other than the one you are measuring.

WARNING: HAND CONTROL

ACTIVATIONS SHOULD BE KEYED

USING 3” OR LESS WELL-INSULATED

JUMPER. USE OF AN INSULATING ROD

TO INSERT THE JUMPER IS ADVISED

TO PREVENT RF BURNS.

3) One at a time, connect test setup to each RF

output terminal indicated in Table 4.4 and

activate the unit using the corresponding

command. Confirm no meter readings exceed

the specified maximum. Hand control coag

activations are accomplished by connecting a

jumper between the left jack and center jack

of the desired hand switched accessory jack.

RF leakage should also be measured between inac

tive outputs and the Dispersive Electrode connec

-

tion. The procedure is as follows:

1) Set the unit for full power for the modes

noted in Table 4.5. Connect the ESU tester

according to manufacturer’s instructions OR- the 200-ohm non-inductive resistor in

series with the 250 mA RF ammeter to the

Dispersive Electrode connection on the front

panel. Also make sure there are no connec

tions to any output other than the one you

are measuring.

2) One at a time, connect this series combination to each RF output terminal indicated

in Table 4.5 and activate the unit using the

corresponding command. Confirm that no

meter readings exceed the specified maximum.

-

4-11

Page 24

Table 4.5 Allowable RF Leakage Current - Inactive Monopolar Outputs

MEASURED TERMINAL ACTIVATED ACCESSORY MODE RF LEAKAGE (Ma)

Footswitched Active Left Hand Controlled Standard Coag <50

Footswitched Active Right Hand Controlled Standard Coag

Footswitched Active Bipolar Footswitch Bipolar Macro

Left Hand Controlled Active Right Hand Controlled Standard Coag

Left Hand Controlled Active Bipolar Footswitch Bipolar Macro

Right Hand Controlled Active Bipolar Footswitch Bipolar Macro

Bipolar Left Right Hand Controlled Standard Coag

<50

<20

<50

<20

<40

<48

Finally, RF leakage should be measured between

the inactive bipolar outputs while a monopolar

accessory is activated. Do the following:

1) Set the unit for full power for the bipolar

mode noted in Table 4.6. Connect ESU tester

according to manufacturer’s instructions -ORthe 200-ohm non-inductive resistor in series

with the 250 mA RF ammeter between the

two bipolar output connections.

2) Activate and verify the limit in Table 4.6.

Table 4.6 Allowable RF Leakage Current - Inactive Bipolar Outputs

MEASURED TERMINAL ACTIVATED ACCESSORY MODE RF LEAKAGE (Ma)

Bipolar Right to Left Right Hand Controlled Standard Coag

4.6.5 Line Frequency Leakage

CAUTION: To prevent RF current from destroy

ing the test equipment and/or affecting leakage

readings, set all power settings to zero.

Circuit ground and the Neutral (Low MAINS)

must be connected together for UUT MAINS

leakage testing.

WARNING: Electrocution Hazard. DO NOT

Equipment:

These tests are performed most conveniently using

any good quality biomedical electrical safety tester.

Procedure:

1) Connect the electrical safety analyzer to make

the measurements indicated in Table 4.7.

2) Mode: Measure leakage for Bipolar to Neutral

and Chassis to Neutral.

<48

DISCONNECT circuit ground from Earth

Ground unless an isolated MAINS power sup

-

ply is used.

Table 4.7 Line Frequency Allowable Leakage - Inactive

RF output to Neutral LINE GND LIMIT max

Equipotential Ground Normal Closed 30 µA

Equipotential Ground Reversed

Equipotential Ground

Equipotential Ground Reversed

Dispersive Electrode

Dispersive Electrode Reversed

Dispersive Electrode

Dispersive Electrode Reversed

Bipolar Output*

Bipolar Output* Reversed

Bipolar Output*

Bipolar Output* Reversed

*Measure the Bipolar Output with Bipolar connections shorted together.

Normal Open 270 µA

Normal Closed 15 µA

Normal Open 15 µA

Normal Closed 15 µA

Normal Open 15 µA

Closed 30 µA

Open 270 µA

Closed 15 µA

Open 15 µA

Closed 15 µA

Open 15 µA

4-12

Page 25

5) Since the System 5000™ monopolar active

outputs are disconnected by relays when the

unit is not activated, active-to-neutral leakage

tests must be performed with the unit acti

-

vated in order to be valid.

6) With all power controls set to zero, measure

the leakage current as in step 1 from each of

see Table 4.8; while that output is activated

in Cut by the appropriate footswitch or hand

control jumper. Hand control cut activations

are accomplished by connecting a jumper

between the two outer jacks of where the

handcontrol accessory is plugged into the

unit.

the three active output terminals to neutral;

Table 4.8 Line Frequency Allowable Leakage - Active

RF output to Neutral LINE GND ACTIVATION LIMIT max

Footswitched Active Normal Closed Monopolar Footswitched Cut 15 µA

Footswitched Active Reversed

Footswitched Active

Footswitched Active Reversed

Left Hand Controlled Active

Left Hand Controlled Active Reversed

Left Hand Controlled Active

Left Hand Controlled Active Reversed

Right Hand Controlled Active

Right Hand Controlled Active Reversed

Right Hand Controlled Active

Right Hand Controlled Active Reversed

Normal Open Monopolar Footswitched Cut 15 µA

Normal Closed Left Hand Controlled Cut 15 µA

Normal Open Left Hand Controlled Cut 15 µA

Normal Closed Right Hand Controlled Cut 15 µA

Normal Open Right Hand Controlled Cut 15 µA

Closed Monopolar Footswitched Cut 15 µA

Open Monopolar Footswitched Cut 15 µA

Closed Left Hand Controlled Cut 15 µA

Open Left Hand Controlled Cut 15 µA

Closed Right Hand Controlled Cut 15 µA

Open Right Hand Controlled Cut 15 µA

4.6.6 Automatic Return Monitor (A.R.M.™)

Check

A.R.M.™ has two specific ranges that will be

tested initially and then the circuit will be tested

to verify that the circuit measures dissipative elec

trode resistance correctly. For this testing, only a

Decade Resistance Box (DRB) and a dispersive

electrode cable adapter are required. Connect the

DRB to the Dispersive Electrode Receptacle using

the dispersive electrode cable adapter.

A.R.M.™ may be reset by disconnecting the

dispersive electrode connector or adjusting the

DRB above 10K Ohms until the Single and Dual

Dispersive Electrode Status/Alarm Indicators flash

red in alternating fashion. Allow approximately

two seconds after the DRB is changed before

proceeding to the next step in the procedure.

A.R.M.™ indicators not mentioned in the proce

-

dure must be off for each test.

1) Dual Electrode Alarm Limit: Set the DRB to

158 Ohms, then connect it to the Dispersive

Electrode Receptacle and verify that the

Single and Dual Dispersive Electrode Status/

Alarm Indicators flash red in alternating fash

ion.

2) Dual Electrode Upper Limit: Set DRB to

140 Ohms and verify that the Dual Dispersive

Electrode Status/Alarm Indicator is flashing

Green and a single bar in the Bargraph is illu

minated.

3) Dual Electrode Lower Limit: Set the DRB

to 15 Ohms and verify the Dual Dispersive

Electrode Status/Alarm Indicator is flashing

Green and eight bars in the Bargraph are illu

minated.

4) Single Electrode Upper Limit: Set the DRB

to 7 Ohms, then reset A.R.M.™ and verify

the Single Dispersive Electrode Status/Alarm

Indicator is Green and not flashing.

-

-

-

4-13

Page 26

4.6.7 Output Coupling Capacitor Check

WARNING:

SETTINGS ARE AT 0 WATTS BEFORE

CONDUCTING THIS TEST TO PREVENT

INJURY TO PERSONNEL AND DAMAGE

TO TEST EQUIPMENT.

NOTE: Not all capacitance meters will read prop

erly for this test. The test frequency should be at

or below 1 kHz for best accuracy. The following

meters have been tried successfully: Fluke 189,

Extech 285, Sencor LC75 and HP4284A (1 kHz

setting or below).

1. Connect shorting plug to banana adapter to

the two pin Dispersive Electrode Receptacle.

Use 6” or less test leads to connect a capaci

tance meter between the shorting plug

adapter and the footswitched ReadiPlug

Universal Accessory Receptacle.

2. Measure capacitance and confirm it is less

than 0.5 nF.

3. Confirm cut power is set to 0, then activate

and confirm capacitance is between 4.3 and

6.3 nF.

4. Do not activate for this bipolar test. Move

test leads to Bipolar Output Accessory

Receptacles. Confirm capacitance is between

9.6 and 14 nF.

ENSURE ALL POWER

™

-

-

4.7 System Calibration

The System 5000™ is calibrated during manufacture using equipment traceable to National

Institute of Standards & Technology (NIST)

standards and should retain its accuracy for a long

period of time. Recalibrate the generator after

repair or if it performs out of specification. Check

the calibration in normal operating mode and only

perform calibration if errors are identified.

The System 5000™ stores its calibration in non

volatile semiconductor memory, so the calibration

will be retained without any action on the part of

the user or maintenance staff. Calibration should

be checked in normal operating mode during

annual preventative maintenance to ensure there is

no change. Calibration is required when:

• “Err 140” occurs: An error is detected with

the stored calibration values.

• “Err 143” occurs: One or more modes require

calibration.

-

• The Controller board assembly (P/N 61-

6431), the Transformer board assembly (P/N

61-6445), or the Output board assembly (P/

N 61-6461) is replaced.

• Calibration differences are found during pre

ventative maintenance.

4.7.1 Calibration Preliminaries

Calibration on the System 5000™ occurs in

Calibration Operating Mode, which is entered by

setting the system configuration DIP switches on

the Controller board. Set the Calibration system

configuration DIP switch (A4SW2.2) to the ON

(UP) position and the Test system configuration

DIP switch (A4SW2.1) to the OFF (DOWN)

position. Other configuration DIP switch settings

positions will not affect this. See Section 4.9 for

system configuration DIP switch details.

With this configuration set, turn on power while

pressing and holding the Remote Power Control

Key. Release the Key when you hear the 4-tone

sequence. When the Remote Power Control Key

is released, CAL will appear in the Monopolar Cut

Power Digital Display and the software revision

will appear in the Monopolar Coag Power Digital

Display for a few seconds. The display will then

provide an indication of the calibration status:

ALL” will appear in the Monopolar Cut

• “

Power Digital Display if the calibration mem

ory is empty.

• “

nEr” will appear in the Monopolar Cut

Power Digital Display, where “n” indicates

how many major modes require calibration,

will be displayed if only particular modes

require calibration. All of the minor mode

indicators will be illuminated and the minor

modes needing calibration will flash.

[V”, “[0A”, “bP”, or “Pad” will appear in

• “

the Monopolar Cut Power Digital Display to

indicate the major mode when only minor

modes under that major mode require calibra

tion. All of the minor mode indicators will

be illuminated and the minor modes needing

calibration will flash.

[V” will appear in the Monopolar Cut Power

• “

Digital Display with the Pure Cut Mode

Indicator illuminated if all modes are cali

brated.

-

-

-

-

4-14

Page 27

Calibration

888 888 88

CAL rn

2Er

3Er

Cu

Cu 500 P

COA

bP

PAd

ALL

Press Remote Power Control Key,

release when tones begin.

Press Remote Power Control Key.

Press Cut Mode

Scroll Key to select

Pure, Blend 1,

Blend 2 and Blend 3.

Press Monopolar Cut Power Adjustment

Keys to select Cu, COA, bP and PAd.

Set the Calibration System Configuration

Dipswitch on the Controller to the ON position

Turn main power switch on.

Connect indicated load

with meter to output

Activate.

Press Monopolar Coag Power Adjustment keys to

match power/current to Calibration Target.

Minimum activation 2 seconds, release.

COA

bP

Cu

PAd 10

Press Coag

Scroll Key to select

Pinpoint, Spray

and Standard

Connect 10 ohm load Two-Pin

Dispersive Electrode Receptacle

Press Remote Power Control Key

Press Remote Power Control Key.

Press Remote Power Control Key

Press Bipolar Power Adjustment Key

Connect 150 ohm load Two-Pin

Dispersive Electrode Receptacle.

Press Monopolar Coag Power Adjustment Key

Press Bipolar Power Adjustment

Key.

PAd 150

End - Main power

switch off.

Set the Calibration System Configuration

Dipswitch on the Controller to the OFF position

Figure 4.1 Calibration Procedure Flow Chart

4-15

Page 28

For all except the last of these, a single Press

and release of the Remote Power Control Key is

required to proceed past this point on the menu.

After pressing this key, “

Monopolar Cut Power Digital Display with the

Pure Cut Mode Indicator illuminated.

4.7.2 Sele

Press the Monopolar Cut Power Adjustment Keys

to select the major mode to calibrate as displayed

in the Monopolar Cut Power Digital Display. The

selections are “

for Bipolar, or “

A.R.M.™ connection. If any of the minor modes

under these major modes are not calibrated, the

displayed major mode will flash.

Scroll between the monopolar minor modes using

the Cut Mode Scroll Key or the Coag Scroll Key,

as appropriate. Macro Bipolar is used to calibrate

both of the Bipolar modes, so no scrolling is nec

essary.

4.7.3 Calibrating a Monopolar Mode

This section applies to the Pure Cut, Blend 1,

Blend 2, Blend 3, Pinpoint Coag, Standard Coag,