Conmed Sabre 180 Service manual

Service Manual

LIMITED WARRANTY

For a period of two years following the date of delivery,

CONMED Corporation warrants the Sabre 180

Electrosurgical Unit against any defects in

material or workmanship and will repair or replace (at

CONMED’s option) the same without charge, provided

that routine maintenance as specified in this manual has

been performed using replacement parts approved by

CONMED. This warranty is void if the product is used in

a manner or for purposes other than intended.

U.S. Patent Nos. 4,569,345 - 4,617,927 -

4,848,335 - 4,961,739 and other

patents pending.

© 1996 CONMED Corporation

Mailing Address:

310 Broad Street

Utica, New York 13501

Shipping Address:

7211 S. Eagle St.

Englewood, Colorado 80112

For Technical Services or Return Authorization Phone:

303-699-7600 / 1-800-552-0138

For Customer Services or to order parts phone:

1-800-448-6506 or contact your

CONMED Representative.

The revision level of this manual is specified by the

highest revision letter found on either the inside front

cover or enclosed errata pages (if any).

Manual Number 60-5803-001 Rev. L

Unit Serial Number ____________________________

Table of Contents

& List of Illustrations

1.0 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.1 Precautions in Equipment Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.2 Precautions in Patient Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.3 Precautions In Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.1.4 Precautions When Testing or Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3 Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.4 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

2.0 INSTALLATION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1 Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3.1 Preliminary Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3.2 Preliminary Performance Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 Controls, Displays and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.5.1 Preliminary Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.6 User Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.6.1 General Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.6.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.6.3 Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.6.4 Periodic Performance Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.6.5 Option Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.7 In Case of Difficulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

3.0 THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 RF Output Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2.1 RF Output Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2.2 Aspen Return Monitor Circuitry and Software . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2.3 Continuity Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.3 Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.4 Controller Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.4.1 Watchdog Timer (WDT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.4.2 Power On Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.4.3 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.4.4 Memories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.4.5 Base Voltage Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3.4.6 IFAIL and A.R.M. Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.4.7 Waveform Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.4.8 Tone Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Section Title Page

3.5 Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.5.1 RUN Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.5.2 CAL Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.5.2.1 CAL NOVRAM Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.5.2.2 CAL Mode Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.6 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.6.1 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.6.2 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.7 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.7.1 Mains Isolation Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.7.2 Low Voltage Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.7.3 RF Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

4.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1 General Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Periodic Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2.1 Ground Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2.2 Mains Frequency Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2.3 Aspen Return Monitor (A.R.M.) Calibration Check . . . . . . . . . . . . . . . . . .4-2

4.2.4 RF Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2.5 RF Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.6 RF Leakage from Inactive Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3.1 CAL Mode General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.3.2 RF Output Power Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.3.3 Aspen Return Monitor (A.R.M.) Calibration . . . . . . . . . . . . . . . . . . . . . . .4-8

4.4 Option Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.4.1 Mains Voltage Strapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.4.2 Power-up Default Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.5.1 Using and Interpreting HLP Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.5.2 Diagnostic Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.5.2.1 Watchdog Timer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.5.2.2 Pseudo RUN Diagnostics (dI2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.5.3 Base Voltage Generator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.5.4 Waveform Generator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.5.5 Aspen Return Monitor (A.R.M.) Troubleshooting . . . . . . . . . . . . . . . . . . . .4-14

4.5.6 Power Amplifier Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.5.7 Continuity Detector Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.5.8 RF Power Supply Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

5.0 TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Assembly Structure and Parts Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.1 Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.2 Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2.3 A4 Power PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2.4 A3 Controller PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.5 A2 Display PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.6 A1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.3 Parts Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

APPENDIX A HLP Codes and Possible Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Section Title Page

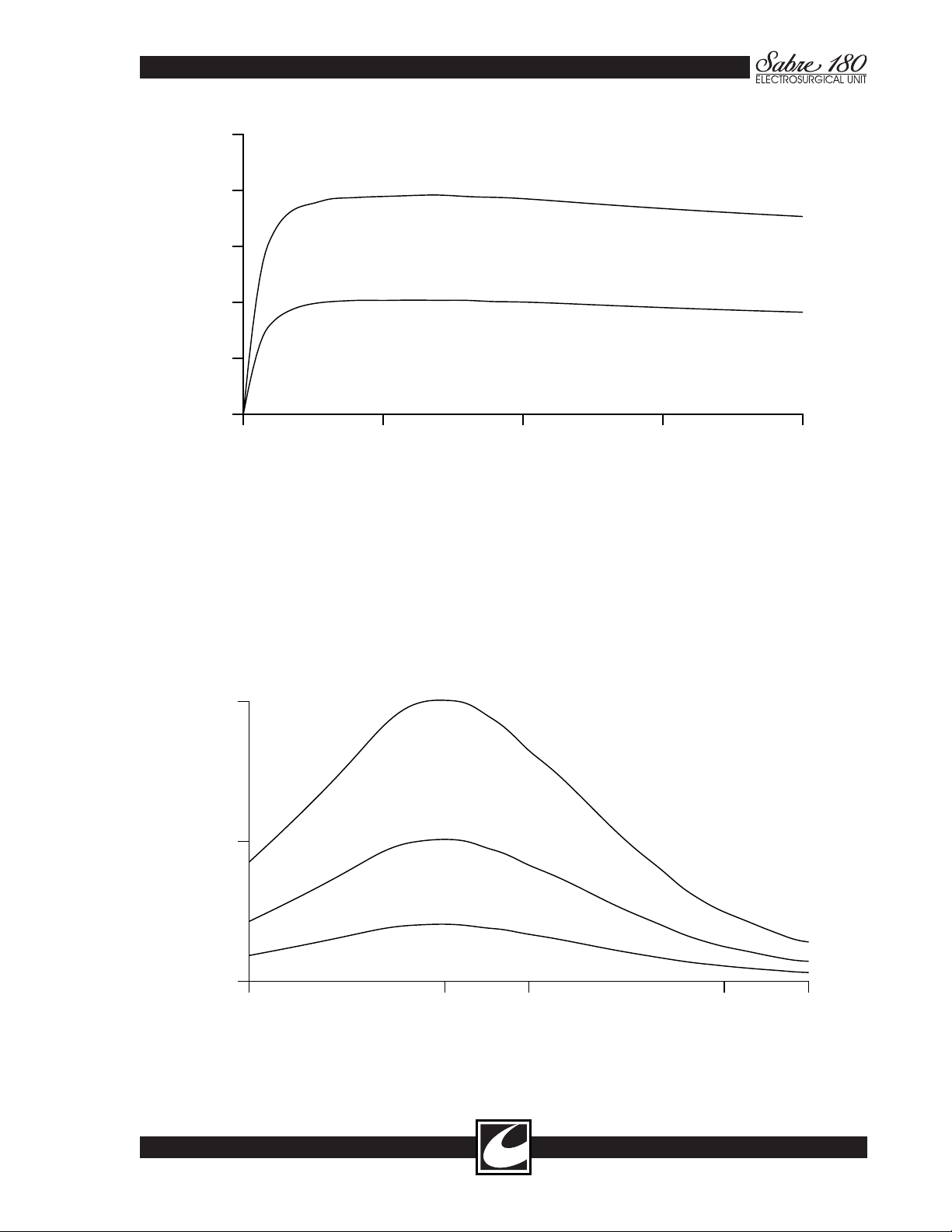

1.1 Output Power vs. Power Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.2 Pure Cut Load Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.3 Blend 1 Cut Load Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4 Blend 2 Cut Load Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.5 Monopolar Coag Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6 Bipolar Coag Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

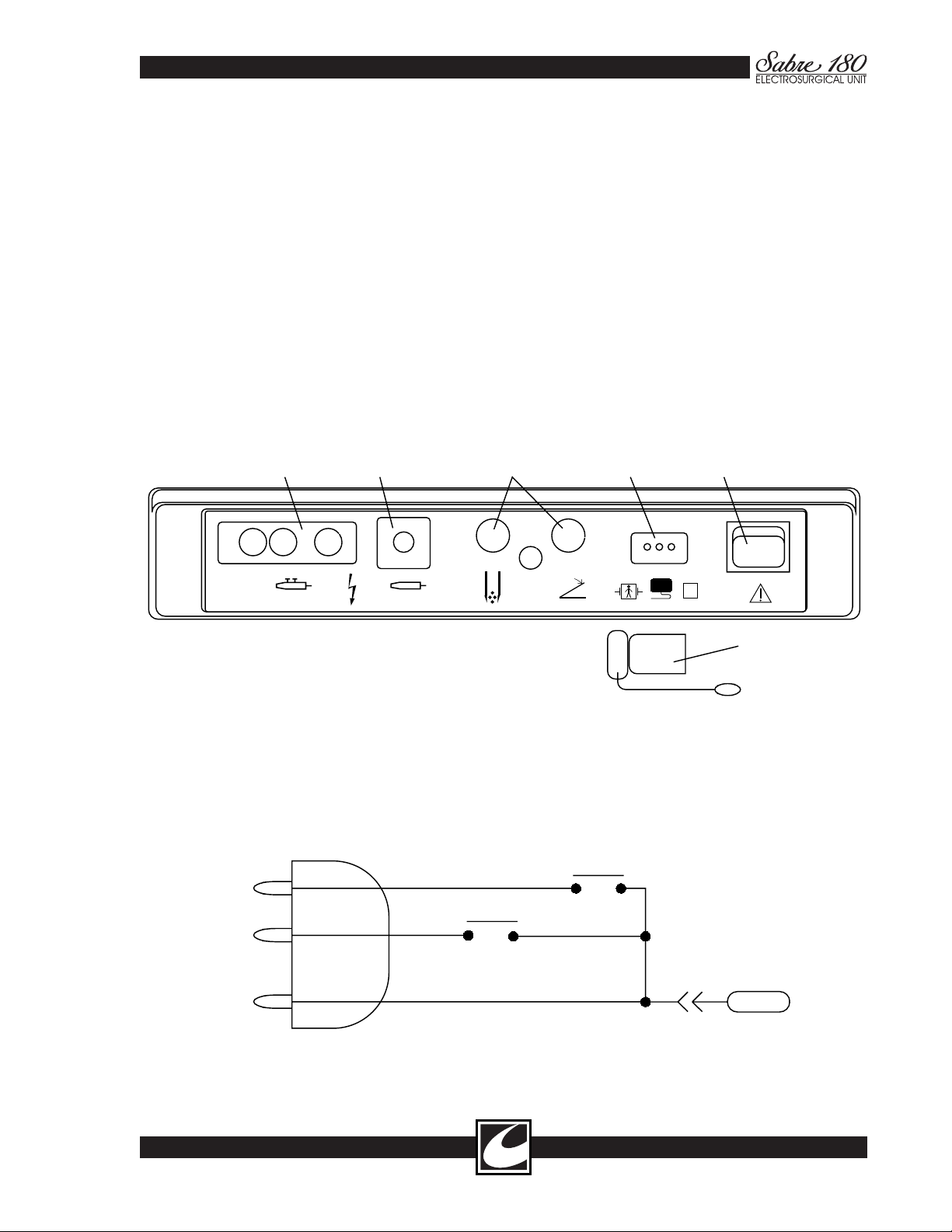

2.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2 Output Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

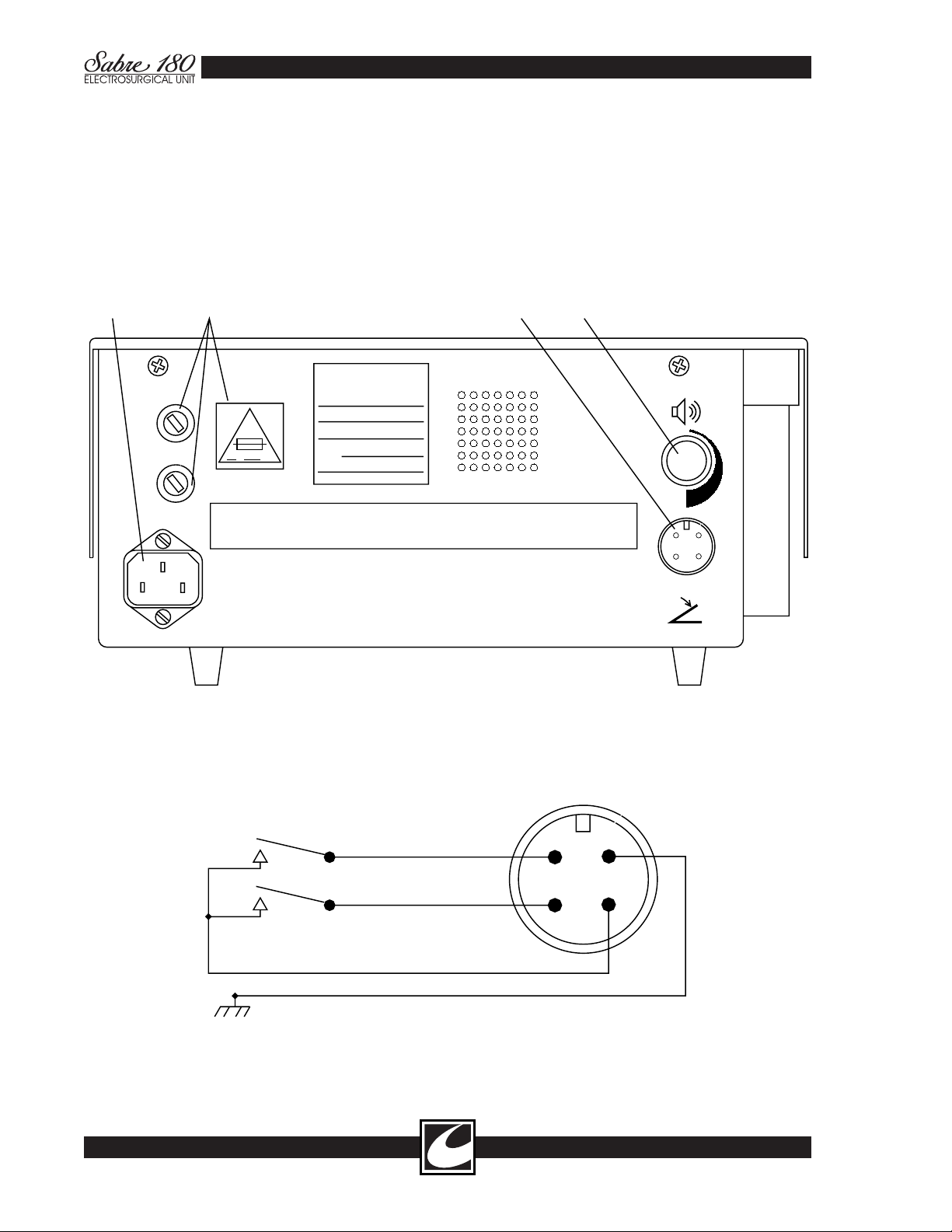

2.3 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

3.1 RF Output Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.2 A.R.M. Oscillator Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.3 Continuity Detector Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.4 Basic Hybrid Cascode Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.5 Power Amplifier Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.6 Base Voltage Generator Transfer Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.7 Basic Inverting Break Point Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

5.1 Access Fastener Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.2 Major Assembly and Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3 Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.4 Interconnect Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.5 A2 Display PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.6 A3 Controller PWB, Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.6 A3 Controller PWB, Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.7 A4 Power PWB, Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.7 A4 Power PWB, Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

3.1 A.R.M. Resistance Bar Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

4.1 RF Output Power Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2 RF Leakage to Earth Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.3 RF Leakage Test from Inactive Outputs Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.4 CAL Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.5 dI1 Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Figure Title Page

Table Title Page

This page intentionally left blank.

The Conmed Sabre 180 Electrosurgical Unit

(ESU) provides the modern surgicenter and office

clinic with a broad range of electrosurgical capabilities. It is suitable for use in minor, general

and laparoscopic procedures. The bipolar option

extends applications to gynecological, neurological and other microsurgery. CONMED offers

other higher powered ESUs better suited to the

most demanding procedures, such as transurethral

resections.

Salient features of this ESU include:

•DIGITAL KNOB POWER CONTROLS:

Combines the speed and ergonomics of analog

controls with the precision of pushbuttons.

•LAST USED SETTINGS ON POWER UP:

Power and mode settings used during previous

procedures are automatically restored when unit is

turned on, minimizing preop setup effort.

Optionally, the unit may be configured to default

to zero power and standard modes. In either case,

the previously used A.R.M. single/dual pad mode

selection appears every power up.

•ASPEN RETURN MONITOR: When used

with A.R.M. or compatible dual-foil return electrodes, the Aspen Return Monitor (A.R.M.) provides an extra margin of safety against possible

patient burns at the return site. The Resistance

Indicator displays the resistance of the patient

measured between the conductive contacts of the

return electrode. This information can be used to

note high risk patients and to indicate a loss of

electrode contact with the patient. The A.R.M.

also allows use with non-monitoring electrodes

when set to the Single Foil mode.

•ISOLATED OUTPUT CIRCUITRY: This feature minimizes the probability of alternate ground

site burns. Complies with all current international standards for RF leakage.

•INDEPENDENT OUTPUTS: Only one output is active at a time for maximum patient and

operator safety. Interlocked controls prevent

mishaps in the event of conflicting commands.

•POWER ADJUSTABLE WHILE ACTIVATED: The power settings can be adjusted while the

unit is activated. The change is limited to the

greater of +

5W or + 25% of the power setting

at the beginning of the activation.

•VERSATILE, EFFECTIVE, MONOPOLAR

CUTTING: A selection of three different crest

factors provide the user with a range of hemostasis, from negligible for minimal-damage biopsies,

through a moderate blanch for ordinary incisions

to near-coag quality heavy hemostasis. A broad

load regulation helps sustain an effective cutting

arc in both wet and dry fields.

•CIRCUIT REDUNDANCY: This feature, in

conjunction with a fault tolerant design, provides

a wide safety margin against catastrophic failures.

•MICROPROCESSOR CONTROL: Provides

the user with a superior degree of safety and control in solid state electrosurgery. The programmed

intelligence of the microprocessor has been

exploited to provide accurate, well controlled

therapeutic power, digital power display, and a

comprehensive set of internal diagnostics which

continually guard against the consequences of an

internal failure. Internal fault isolation simplifies

troubleshooting to ensure a minimum delay in

returning the unit to service.

•FULGURATION/COAGULATION: Up to

80 watts of high crest factor coagulation with

over 5000V peak to peak output voltage provides

effective contact dessication as well as easy fulguration of diffuse bleeders.

•IMPROVED BIPOLAR: Optionally available

as a footswitched alternate coagulation mode, the

Sabre 180 bipolar is designed to start quickly and

conclude gracefully with minimal sparking and

tissue sticking.

•SIMPLIFIED CONTROLS: The user may

command the full range of capabilities of the

Sabre 180 by means of a few easily understood

controls.

General Information

Section 1.0

1-1

1-2

•RUGGED, HIGH-EFFICIENCY CIRCUITRY: Cool, long-life operation. There are no fans

to compromise the sterile field.

•CIRCUIT PROTECTION: Includes

individually fused output transistors, thermally

fused power transformer and double fuses for

power line protection.

•EASE OF MAINTENANCE: To minimize

maintenance effort, the Sabre 180 features easy

access to all internal components, built-in fault

isolation and troubleshooting aids.

•MOUNTING FLEXIBILITY: The Sabre 180 is

designed to be placed on any suitable table top

surface, or it may be secured to the top of an

available cart.

•VIDEO TAPE: An instructional video tape is

available to aid inservice training.

1.1 PRECAUTIONS

The safe and effective use of electrosurgery is

dependent, to a large extent, upon factors under

the control of the operator, and not entirely controllable by the design of this equipment. It is

important that the instructions supplied with this

equipment be read, understood, and followed in

order that safety and effectiveness be enhanced.

1.1.1 Precautions in Equipment Preparation

•Visually inspect all accessories before each use to

verify the integrity of insulation and the absence

of obvious defects.

•The Sabre 180 is equipped to connect two

monopolar accessories at one time for the convenience of the surgical staff. Despite the fact that

the unit will deliver power to only the commanded electrodes, unused accessories that are connected should be stowed in a safe, insulated place

such as a non-conductive holster or test tube. We

recommend that accessories not be connected

unless it is known that they will be needed.

•This unit is equipped with a hospital grade, 3

prong, power cordset that meets all of the

requirements for safe grounding of the unit. The

user should verify that the power receptacle which

this unit uses is properly grounded and correctly

polarized. Do not use ground cheater plugs or

extension cords.

•Do not place liquid containers on top of the

unit. Wipe spilled liquids off the unit immediately. To preclude inadvertent entry of liquids, do

not operate this unit except in its normal position.

•Verify that the return electrode cable is connected to the return electrode connector.

•Do not reuse disposable (single use) accessories.

•Do not use cords as handles; damage to the

insulation and increased risk of burns or other

injury may result.

•This unit is not supplied with all accessories necessary for the full breadth of electrosurgical applications. Hazardous conditions may result from

inappropriate selection, connection or use of

accessories. Accessories supplied by CONMED

are safe and effective for use with this ESU when

used according to their accompanying instructions and further instructions in this manual. For

further guidance, refer to “IEC Recognized

Electrosurgical Accessories”, CONMED catalog

number 60-5206-001, supplied with some models, or contact your CONMED representative.

1.1.2 Precautions in Patient Preparation

•Electrosurgery should NEVER be performed in

the presence of flammable anesthetics, flammable

prep solutions, or in oxygen-enriched environments. The risk of igniting flammable gases or

other materials is inherent in electrosurgery and

cannot be eliminated by device design.

Precautions must be taken to restrict flammable

materials and substances from the electrosurgical

site, whether they are present in the form of an

anesthetic or skin preparation agent, or are produced by natural processes within body cavities,

or originate in surgical drapes or other materials.

There is a risk of pooling of flammable solutions

in body depressions such as the umbilicus and in

body cavities, such as the vagina. Any excess fluid

pooled in these areas should be removed before

the equipment is used. Due to the danger of ignition of endogenous gases, the bowel should be

1-3

purged and filled with non-flammable gas prior

to abdominal surgery.

•This unit is equipped with the Aspen Return

Monitor (A.R.M.) which verifies that the return

electrode cable is unbroken and connected to the

return electrode and to the electrosurgical unit

when in Single Pad mode. It DOES NOT verify

that a single pad return electrode is in contact

with the patient. When in Dual Foil Pad mode,

the A.R.M. confirms that the total resistance is in

the expected range. Do not depend solely on the

Resistance Indicator in the Dual Foil Pad mode.

Proper application and visual inspection are

required for safe operation.

•The use and proper placement of a return electrode is a key element in the safe and effective use

of electrosurgery in monopolar procedures, particularly in the prevention of burns. Follow directions and recommended practices for the preparation, placement, use, surveillance, and removal of

any return electrode supplied for use with this

electrosurgical unit.

•Apply the return electrode to a clean-shaven

surface of the patient that is thoroughly clean and

dry. Avoid placement on scar tissue, bony prominences or other areas where pressure points on

small areas might develop.

•Because of the risk of burns, needles should

never be used as return electrodes for electrosurgery. Return electrodes should be placed such

that as much of their conductive area as possible

is in firm contact with an area of the patients’

body that has a good blood supply and as close to

the operative site as is practical. Adhesive-type

return electrodes should be reliably attached with

their entire area in contact with the patients’ body.

•In general, electrosurgical current paths should

be as short as possible and should run either longitudinally or in a diagonal direction to the body,

not laterally and under no circumstances lateral to

the thorax.

•Electrodes and probes of monitoring, stimulating, and imaging devices can provide paths for

high frequency currents even if they are battery

powered, insulated or isolated at 60 Hz. The risk

of burns can be reduced but not eliminated by

placing the electrodes of probes as far away as

possible from the electrosurgical site and the

return electrode. Protective impedances incorporated in the monitoring leads may further reduce

the risk of these burns. Needles should not be

used as monitoring electrodes during electrosurgical procedures.

•The active electrode should not be used in the

vicinity of electrocardiograph electrodes.

•Heat applied by thermal blankets or other

sources is cumulative with the heat produced at

the return electrode (caused by electrosurgical

currents). Risk of a patient injury may be minimized by choosing a dispersive electrode site that

is remote from other heat sources.

•When using injection cannulas as electrocardiograph electrodes, the metal cone must not be

placed on the skin; this also applies to the leads to

monitoring instruments.

•During the use of this RF isolated output unit,

the patient should not be allowed to come in contact with metal parts that are grounded or other

conductive surfaces that have an appreciable

capacitance to ground. This will minimize the

possibility of localized burns resulting from stray

electrosurgical currents to the ground.

•Skin to skin contacts, such as between the arm

and the body of a patient, should be avoided by

the insertion of a cloth.

•The use of electrosurgery on patients with cardiac pacemakers or pacemaker electrodes is potentially hazardous because the pacemaker may be

irreparably damaged and/or the high frequency

energy of the electrosurgical output may interfere

with the action of the pacemaker and ventricular

fibrillation may occur. Precautions should be

taken to ensure that the patient’s well-being is

maintained in the event of such interference. We

recommend that the Cardiology Department and

the manufacturer of the pacemaker be consulted

for advice before operating on a patient with a

pacemaker. These precautions also apply to operating room personnel with cardiac pacemakers.

•To minimize the possibility of cardiac pacemaker

interference, place the return electrode such that

the electrosurgical current path is as near orthogonal as possible to the pacer lead.

1-4

1.1.3 Precautions in Use

•The use of monopolar electrosurgery on small

appendages, as in circumcision or finger surgery,

can cause thrombosis and other unintended injury

to tissue proximal to the surgical site. Bipolar

techniques avoid these complications.

•Apparent low power output or failure of the

electrosurgical equipment to function correctly at

otherwise normal settings may indicate faulty

application of the return electrode, failure of an

electrical lead, or excessive accumulation of tissue

on the active electrode. Do not increase power

output before checking for obvious defects or

misapplication. Check for effective contact of the

return electrode to the patient anytime that the

patient is moved after initial application of the

return electrode.

•If a Dual Foil RETURN Alarm is sounded

intraoperatively, visually confirm proper return

electrode attachment to the patient prior to pressing the Monitor Set Button.

•Electrosurgical leads should not be allowed to

contact the patient, staff, or other leads connected

to the patient.

•The output power selected should be as low as

possible and activation times should be as short as

possible for the intended purpose.

•When uncertain of the proper control setting for

the power level in a given procedure, start with a

low setting and increase as required and/or consult your Conmed representative.

•Observe all caution and warning notices printed

on the cover of the unit.

•The staff should never contact electrosurgical

electrodes (either active or dispersive) while the

RF output of the unit is energized.

•The tips of recently activated accessories may be

hot enough to burn the patient or ignite surgical

drapes or other flammable material. Place hot

accessories in a test tube after use. An alternative

is to wait a few seconds after activation for the tip

to cool, and then place the accessory into the supplied holster.

•Electrosurgical currents can produce severe electrical interference with or damage to other nearby

electronic devices. Physiologic monitors should be

equipped with electrosurgical filters and currentlimiting devices (RF chokes). Monitoring electrodes should be placed as far as possible from the

surgical site. Video endoscopy equipment, especially camera cables, should have adequate and

undamaged electrical shielding.

1.1.4 Precautions When Testing or Servicing

•This electrosurgical unit should be tested by

qualified maintenance personnel on a periodic

basis to ensure proper and safe operation. We

suggest examination of the unit at least once a

year.

•Refer all servicing to qualified personnel. Your

Conmed representative will be happy to assist you

in getting your equipment serviced.

•High voltages are developed within the unit that

are accessible when the top cover is removed.

These voltages are potentially dangerous and

should be treated with extreme caution.

•Never remove or install any parts with power

on.

•Avoid contact with the output leads when the

unit is activated. Periodically inspect the test leads

used for the output connections for obvious

defects.

•Although this unit will withstand momentary

short circuits on the output, prolonged short circuits may damage the unit. Short-circuiting the

output should be avoided since it is neither necessary nor desirable.

•Since the clinical use of electrosurgical units is

intermittent in nature with duty cycles on the

order of 10%, this unit is not designed to operate

for extended periods of continuous output. When

testing, it is recommended that duty cycles be

limited to 50% with maximum activation times

of 30 seconds.

•Life of the equipment will be extended by minimizing operating temperature and extreme thermal cycles.

1.2 SPECIFICATIONS

MAINS INPUT REQUIREMENTS:

•Single Phase AC / 48-62 Hz / 200W

•Power Cord: 3 conductor, #18 AWG (1.5mm2) Cu, CEE22 250V 6A Mains Connector

MAINS FREQUENCY LEAKAGE:

•Chassis: <100 uA IEC Class 1, Type CF, Defibrillator Proof

•Patient: <10 uA

RF OUTPUT SPECIFICATIONS:

RF LEAKAGE: <100 mA, RF ISOLATED

DUTY CYCLE: 15s ON, 30s IDLE

COOLING: Natural convection, no fan

1-5

•The heat dissipation capability of the heat sink is

severely impaired by activating the Sabre 180 in

other than its normal operating position. There

are no tests requiring operation in any other position.

•Consult the factory for advice before making

any modifications to the unit.

•Ensure that the RUN-RST-CAL switch is set to

RUN and that the two top cover screws are tightened before returning the unit to service.

MAX. OPEN

MAX. RATED CARRIER CREST FACTOR CIRCUIT PULSE

POWER LOAD FREQ. 50% POWER VOLTAGE REPETITION

MODE WATTS OHMS KHz RATED LOAD VPP FREQ. KHz

CUT PURE 100 500 417 1.8 1600 CONTIN.

CUT BLEND 1 65 500 417 2.3 1650 20 KHz

CUT BLEND 2 50 500 417 3.5 1750 20 KHz

MONO. COAG 80 500 540 7.0 6500 33 KHz

BIPOLAR COAG 50 50 1050 2.4 400 20 KHz

MAINS VOLTAGE CURRENT

VRMS ARMS

CATALOG NO. RATED MIN MAX MAX IDLE

60-5800-001 120 104 127 2.4 0.5

60-5800-002 100 90 110 2.9 0.6

60-5800-003 230 208 254 1.3 0.3

F

1-6

OUTPUT ACCURACY:

•Setting: +/- 10%, +/- 5W to rated load @ rated mains.

•Mains: < 5% over mains voltage range.

•Power Decrease: < 5%, 50W output, 20 sec.

OUTPUT ADJUSTMENT:

•Settings: by digital knob from 0 to maximum in 1 watt steps.

•Display: seven segment digital display of watts to rated load resolved to 1 watt.

ACTIVATION CHARACTERISTICS:

•Activation tone volume adjustable 40-65 dbA via rear panel knob.

•Independence: Only the activated accessory will be live. Only one accessory may be activated at a time.

•Control switch activation resistance: < 1000 ohms.

ACCESSORY CONNECTIONS:

•CONMED makes available adapters to permit use of accessories with other than standard connectors:

•Monopolar Active: 3-pin handswitched and Bovie #12 footswitched.

•Monopolar Return: 2-pin A.R.M./REM capable.

•Bipolar: Two 1/4” (6.4mm) banana jacks.

•Footswitch: 4-pin MS connector for Aspen dual-treadle footswitch.

ALARMS:

•Return Electrode: 1000 Hz, > 65 dbA

•Single Foil acceptance: 0-10 ohms nominal

•Dual Foil acceptance: 10-150 ohms nominal

•Dual Foil alarm threshold: monitor set resistance +20% nominal

•Control error: 1710 Hz pulsating, 40-65 dbA

•Machine fault: 1000 Hz, 65 dbA continuous

DIMENSIONS:

•Size: 6" H (153mm) x 12" W (305mm) x 16" D (407mm)

•Weight: 20 lbs. (9.1 kg)

Note: Allow clearance of 2" (50mm) on each side and 3" (75mm) above for cooling.

SHIPPING & STORAGE:

Prior to shipment or storage, unit should be enclosed and sealed in polyethylene bag

and placed in original carton using original packing materials.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

MODE ACTIVATION MEANS ACTIVATION TONE COAG MODE

MONO CUT HAND OR FOOT 520 Hz EITHER

MONO COAG HAND OR FOOT 250 Hz MONOPOLAR

BIPOLAR COAG FOOT ONLY 250 Hz BIPOLAR

1-7

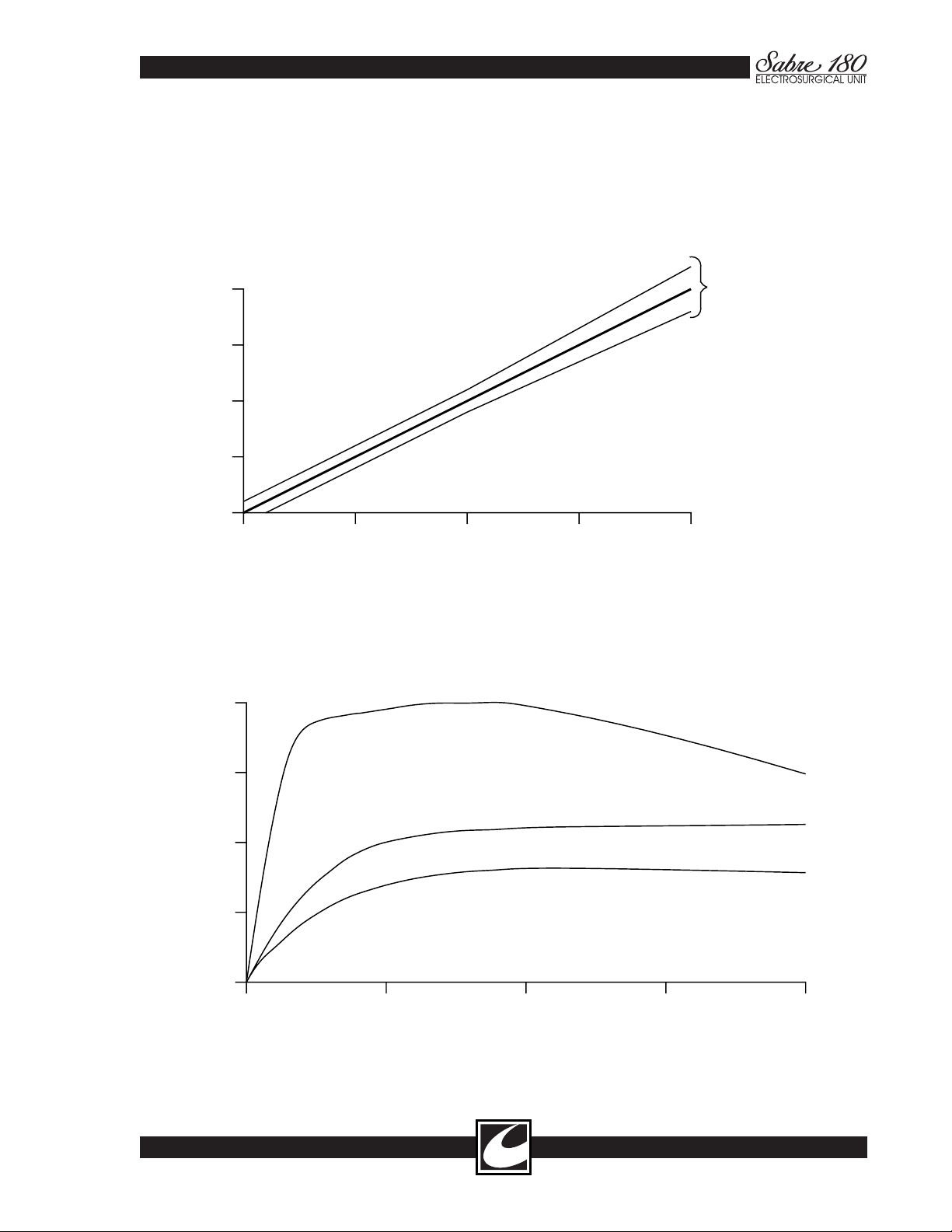

1.3 OUTPUT CHARACTERISTICS

Figure 1.1 illustrates output power delivered to rated load for all available modes. Section 1.2 specified rated

loads and maximum power for each mode, while Figures 1.2-1.6 illustrate output power delivered to a range

of load resistances for each mode.

FIGURE 1.1 OUTPUT POWER VS. POWER SETTING

FIGURE 1.2 PURE CUT LOAD REGULATION

100

75

50

25

POWER OUTPUT,

WATTS TO RATED LOAD

0

0

25

100

50

POWER SETTING

75

SPECIFICATION

LIMITS

100

75

50

25

POWER OUTPUT, WATTS

0

0

500

1000

1500

LOAD RESISTANCE, OHMS

100W

50W

35W

2000

1-8

FIGURE 1.3 BLEND 1 CUT LOAD REGULATION

FIGURE 1.4 BLEND 2 CUT LOAD REGULATION

70

60

50

BLEND 1, 65W

40

30

20

10

POWER OUTPUT, WATTS

0

0

BLEND 1, 35W

500

70

1000

LOAD RESISTANCE, OHMS

1500

2000

60

50

40

30

20

10

POWER OUTPUT, WATTS

0

0

BLEND 2, 50W

500

LOAD RESISTANCE, OHMS

BLEND 2, 25W

1000

1500

2000

1-9

FIGURE 1.5 MONOPOLAR COAG REGULATION

FIGURE 1.6 BIPOLAR COAG REGULATION

100

80

60

40

20

POWER OUTPUT, WATTS

0

0

500

1000

LOAD RESISTANCE, OHMS

1500

80W

40W

2000

50

25

POWER OUTPUT, WATTS

0

10

50W

25W

10W

50

LOAD RESISTANCE, OHMS

100

500

1000

1-10

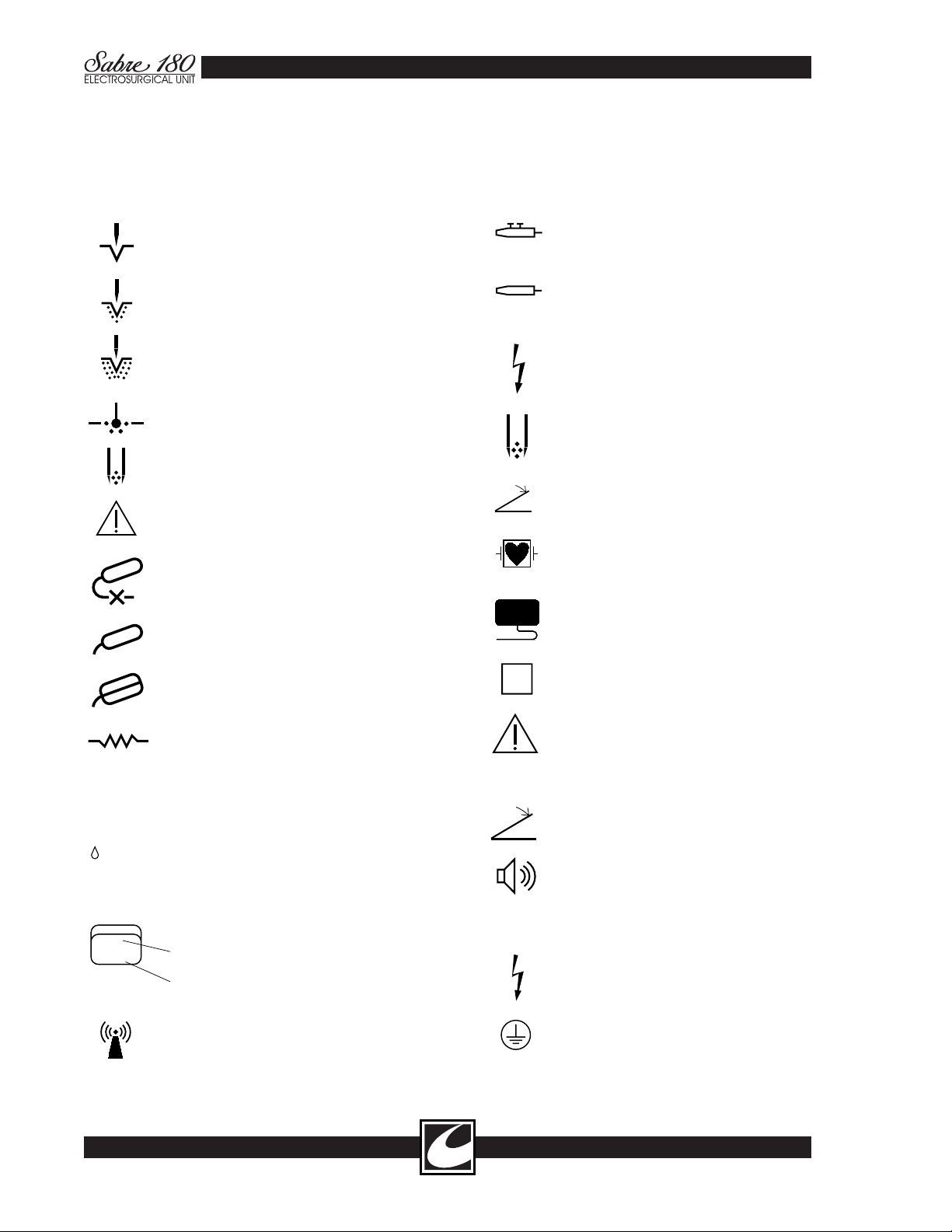

1.4 EXPLANATION OF SYMBOLS

CONTROL PANEL

PURE CUT - WAVEFORM WITH MINIMUM

THERMAL DAMAGE AND HEMOSTASIS

BLEND 1 - CUT WAVEFORM WITH

MODERATE HEMOSTASIS

BLEND 2 - CUT WAVEFORM WITH

HEAVY HEMOSTASIS

MONOPOLAR COAGULATION

BIPOLAR COAGULATION

MACHINE FAULT - UNIT HAS

DISABLED ITSELF. REFER TO

ACCOMPANYING DOCUMENTS

RETURN MONITOR ALARM MONOPOLAR OUTPUT IS DISABLED

SINGLE FOIL - USED WITH ELECTRODES

THAT DO NOT MONITOR CONTACT QUALITY

DUAL FOIL - SETS MONITOR TO USE

ELECTRODES THAT DO MONITOR

CONTACT QUALITY

RESISTANCE - IN DUAL FOIL MODE,

INDICATES RELATIVE RESISTANCE

OF RETURN ELECTRODE CONTACT

WITH THE PATIENT

OUTPUT PANEL

HANDSWITCHED OUTPUT - CONNECTION

FOR HANDSWITCHED MONOPOLAR

ACCESSORIES

FOOTSWITCHED OUTPUT - CONNECTION

FOR FOOTSWITCHED MONOPOLAR

ACCESSORIES

HIGH VOLTAGE CAUTION EQUIPMENT HAS HIGH VOLTAGE OUTPUT

CAPABLE OF CAUSING PHYSIOLOGICAL

EFFECTS

BIPOLAR OUTPUT - CONNECTION FOR

BIPOLAR ACCESSORIES

FOOTSWITCHED BIPOLAR OUTPUT

TYPE CF - PATIENT CONNECTIONS ARE

ISOLATED FROM EARTH AND RESIST THE

EFFECTS OF DEFIBRILLATOR DISCHARGE

RETURN ELECTRODE - CONNECTION FOR

MONOPOLAR DISPERSIVE ELECTRODE

RF ISOLATED - PATIENT

CONNECTIONS ARE ISOLATED FROM

F

EARTH AT HIGH FREQUENCY

CONSULT ACCOMPANYING DOCUMENTS

PRIOR TO PLACING EQUIPMENT

IN SERVICE

REAR PANEL

IPX1

TOP COVER

DRIP PROOF - ENCLOSURE PROTECTED

AGAINST VERTICALLY FALLING WATER

DROPS WHEN EQUIPMENT IS IN A

POSITION OF NORMAL USE

POWER SWITCH

I

O

POWER ON - POWER SWITCH

POSITION TO TURN EQUIPMENT ON

POWER OFF - POWER SWITCH

POSITION TO TURN EQUIPMENT OFF

THIS EQUIPMENT INTENTIONALLY SUPPLIES

NON-IONIZING RF ENERGY FOR

PHYSIOLOGICAL EFFECT.

FOOTSWITCH CONNECTOR

ACTIVATION TONE VOLUME

A4 ASSEMBLY

CAUTION - THIS CIRCUITRY

SUPPORTS PEAK VOLTAGES GREATER

THAN 1000V

PROTECTIVE EARTH (GROUND)

This section contains initial installation, preliminary checks and operating instructions for the

Sabre 180.

2.1 INITIAL INSPECTION

Unpack the unit upon receipt and physically

inspect it for any obvious damage that may have

occurred during shipment. We recommend that

this inspection be performed by a qualified biomedical engineer or other person thoroughly

familiar with electrosurgical devices. If the unit is

found to be damaged, notify the carrier and your

Conmed representative immediately. Retain original packing material for future storage or shipment.

2.2 INSTALLATION

The unit may be placed on any stable cart or

table.

CAUTION: Since the unit depends on natural

convection of air for cooling, it should not be

installed in a cabinet or similar enclosure. If

mounted on a shelf, allow a two inch clearance on either side and three inches above the

unit to permit free circulation of cooling air.

The power cordset of the unit should be connected to a properly polarized and grounded power

source whose voltage and frequency characteristics are compatible with those listed on the nameplate of this unit.

2.3 PRELIMINARY CHECKS

Prior to initial use of this unit in clinical service it

is recommended that its performance be tested in

accordance with the tests described in the Sabre

180 Service Manual. Results of that testing

should be compared to the results tabulated on

the factory Test Data Sheet that is supplied with

each unit. This data should be retained for future

reference and comparison.

2.3.1 Preliminary Functional Testing

The following checks are recommended upon initial installation of the equipment and prior to

each use of the instrument to avoid unnecessary

delays in surgery. See Figures 2.1 - 2.3 for location of controls and connectors.

1. Ensure that the Power Switch is OFF.

2. Connect the power cordset to the unit's mains

inlet on the rear panel and to a properly grounded

and polarized mating power receptacle.

3. Connect a two-treadle monopolar foot switch

to the connector on the rear panel of the unit.

4. Connect a handcontrol (hand-switchable pencil) to the appropriate connector on the output

panel.

5. Make no connection to the Dispersive

Electrode (Patient Plate) connector at this time.

6. Set the Power Switch to the ON position.

Within one second the machine should respond

by:

a) Sounding each of the four tones in ascending

order over a one second interval.

b) During that interval, displaying "8"s on all five

digital displays.

c) Illuminating all mode activation and error

indicators and all ten resistance indicator bars.

d) After the fourth tone is complete, the machine

should sound two beeps indicating a return fault.

Power and mode selections will change to powerup defaults (see Section 2.6.5 for default option

selection).

Installation & Operation

Section 2.0

2-1

2-2

7. Control Panel Checks:

a) Rotate the CUT and COAG power controls

CW and CCW at least one revolution (36 steps),

verifying that the associated power display

changes in one watt steps for each click of its control.

(NOTE: Displays will not decrement below zero

or increment above maximum rated power for the

selected mode.)

b) Using the MODE pushbuttons, step through

each CUT and COAG mode, verifying that the

associated mode selection indicator illuminates.

Set power to zero in each mode. Leave COAG

mode in monopolar.

(NOTE: Units not equipped with the Bipolar

option do not have COAG mode controls or

indicators).

c) Using the PAD pushbutton, verify that the

SINGLE and DUAL indicators toggle back and

forth. Verify that the RESISTANCE bar graph is

dark in SINGLE mode and that all bars are flashing in DUAL mode. Verify that a "two-beep"

alarm sounds after each mode change.

d) Verify that the MACHINE indicator is dark

and that the RETURN MONITOR indicator is

lit in both SINGLE and DUAL modes.

8. Depress the Cut treadle of the foot switch.

The Return Alarm tone should sound and the

RETURN lamp should remain lit. While holding the Cut treadle, rotate the Volume Control

over its full range and verify that there is no significant change in sound level. Release the Cut

footswitch. The tone should stop and the

RETURN MONITOR should remain lit.

9. Depress the Coag foot switch. The Return

Alarm should sound and the RETURN MONITOR should remain lit.

10. On units equipped with Bipolar, select BIPOLAR COAG. Depress the Coag foot switch.

Verify that the Coag indicator illuminates and the

Coag activation tone sounds. While depressing

the Coag treadle, turn the Coag Power Control

clockwise. The power should increase from zero

to 5 watts. Turn the Coag Power Control counterclockwise and the power should decrease to

zero watts.

11. Release the Coag foot switch. The unit

should silence. Then, select MONOPOLAR

COAG.

12. Select SINGLE PAD MODE. Connect a

non-monitoring dispersive electrode to the Patient

Plate connector; verify that the Return lamp and

bar graph extinguish.

13. Depress the Cut foot switch. The yellow

CUT indicator lamp should illuminate and the

Cut tone should sound. While Cut is activated,

rotate the VOLUME control (rear panel) over its

full range, verifying that the tone volume varies

accordingly. Set the volume to a comfortable yet

audible level.

(NOTE: At minimum volume, the activation

tones should remain audible.)

14. While continuing to press the Cut treadle of

the foot switch, depress the Coag treadle. A pulsating alarm tone will sound. Release the Cut

treadle, continue to press the Coag treadle and

confirm that the sound changes to the Coag tone,

and the blue Coag indicator is illuminated until

the Coag treadle is also released.

15. Activate, one at a time, the Cut and Coag

handswitch controls verifying proper actuation of

each mode.

15a. While depressing the Coag treadle (or

handswitch), turn the Coag Power Control clockwise. The power should increase from zero to 5

watts. Turn the Coag Power Control counterclockwise and the power should decrease to zero

watts.

15b. While depressing the Cut treadle (or

handswitch), turn the Cut Power Control clockwise. The power should increase from zero to 5

watts. Turn the Cut Power Control counterclockwise and the power should decrease to zero watts.

16. While the single foil electrode remains

connected, select DUAL PAD mode. Verify a

2-3

return alarm and that the bar graph remains dark.

Press MONITOR SET and verify that RETURN

MONITOR remains lit and a "two-beep" alarm

sounds.

17. Replace the single foil electrode with an

A.R.M. compatible dual-foil monitoring electrode. While the electrode remains open to the

air, press MONITOR SET. Verify that RETURN

MONITOR remains lit, a two-beep alarm sounds

and that all RESISTANCE bar segments are

flashing.

18. Gradually apply the dual foil electrode to

well-perfused, relatively hair-free skin surface,

such as the medial forearm or posterior calf. As

electrode contact area increases, verify that the

RESISTANCE bar graph segments darken from

right to left.

19. With the dual foil electrode fully applied,

verify that a portion of the RESISTANCE bar

graph remains flashing. Press MONITOR SET,

and verify that the RETURN MONITOR goes

out and that the RESISTANCE bar graph stops

flashing.

20. Gradually peel the dual foil electrode until a

RETURN alarm occurs. Verify that over 2/3rd

of the electrode remains in contact with the skin

at the onset of the alarm. Continue peeling the

electrode slowly, verifying the RESISTANCE bar

graph progressively illuminates.

2.3.2 Preliminary Performance Testing

After the unit passes the Preliminary Functional

Tests of Paragraph 2.3.1, preliminary performance

testing may be conducted. Such testing is best

carried out by use of an electrosurgical generator

tester, as described in Section 4 of the Sabre 180

Service Manual. If such a tester is available, note

that the power display will most accurately indicate the power available to a 500 ohm

(Monopolar) and the 50 ohm (Bipolar) noninductive resistor. However, the indicated power to

any such load in the 300-500 ohm (40-80

Bipolar) range should be within 15% of that indicated on the digital display.

If no tester is convenient, the availability of

therapeutic current may be ascertained subjectively by attempting to cut and coagulate on surrogate tissue such as a piece of meat or fresh fruit, a

wet bar of soap or a sponge moistened in saline.

Although not recommended, a last resort verification of available power can be made by drawing

arcs between active and dispersive electrodes or

between the tips of a bipolar forceps. Such a test

will not damage the unit if not carried out for

more than a few seconds, however one should

expect that the electrodes may be damaged due to

the extreme temperatures generated by the arc.

2-4

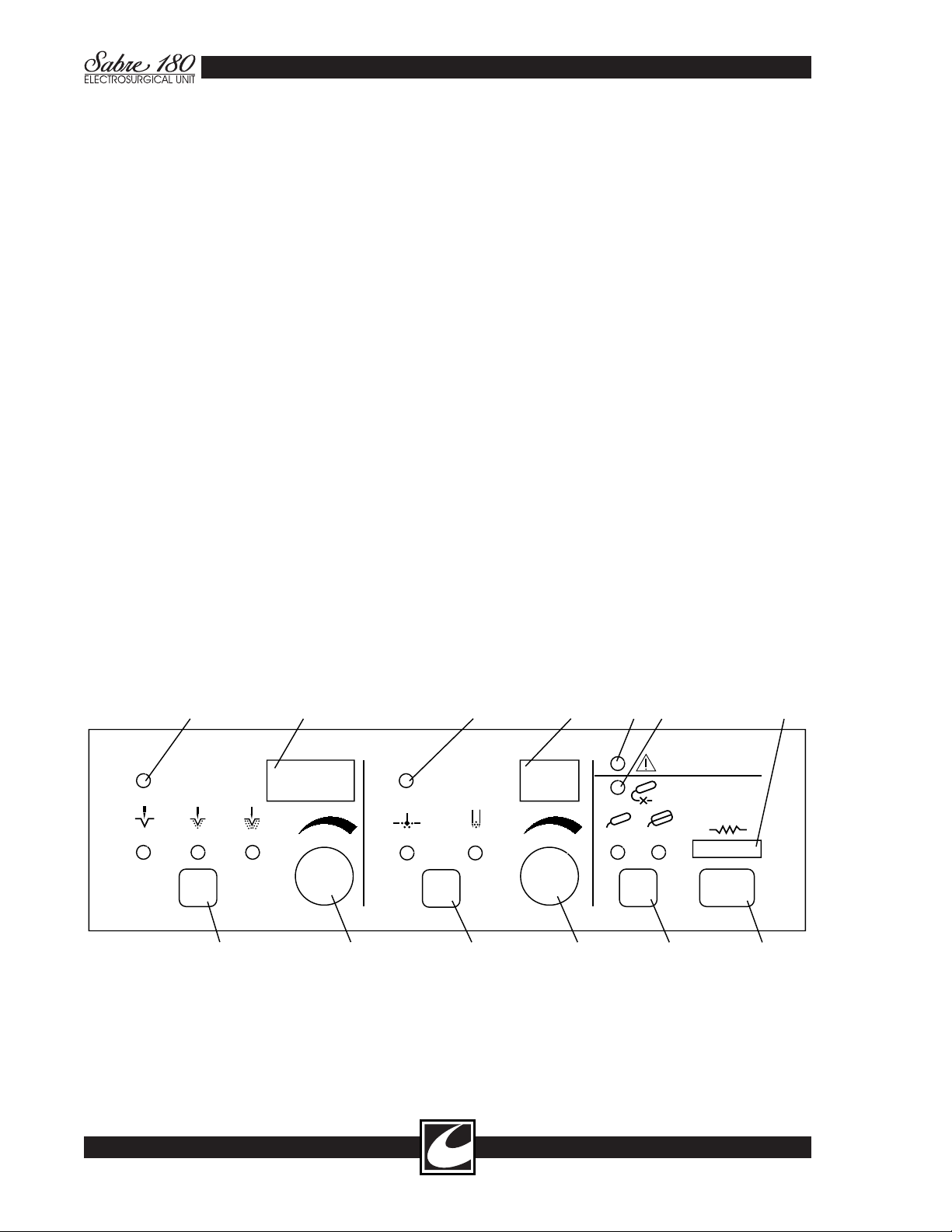

2.4 CONTROLS, DISPLAYS AND

CONNECTORS

(1) CUT ACTIVATION INDICATOR - Lit

when a cutting output is present.

(2) CUT POWER SETTING - Displays power

setting of selected cut mode.

(3) COAG ACTIVATION INDICATOR - Lit

when monopolar or bipolar coag output is

present.

(4) COAG POWER SETTING - Displays

power setting of selected coag mode.

(5) MACHINE INDICATOR - Lit when an

internal fault has disabled unit. Accompanied by

diagnostic code in power setting windows (2),

(4).

(6) RETURN MONITOR INDICATOR - Lit

when monopolar output is disabled due to a fault

in the return electrode circuit.

(7) RESISTANCE BAR GRAPH- Indicates relative resistance at dual foil monitoring return

electrode.

(8) MONITOR SET PUSHBUTTON - In dual

foil mode, stores present monitor resistance and

clears return monitor alarm (6).

(9) PAD SELECTION - Selects whether return

monitor is to operate with SINGLE foil (nonmonitoring) or DUAL foil (contact quality monitoring) return electrodes.

(10) COAG POWER CONTROL - Adjusts

coag power setting (4) of selected coag mode

(11). Does not affect the non-selected mode.

(11) COAG MODE SELECTION

•MONOPOLAR - Coag hand or foot switch

activates coag output at appropriate monopolar

active output.

•BIPOLAR - Coag foot switch activates bipolar

output. Cut hand or foot switch will operate

as in monopolar mode.

(12) CUT POWER CONTROL - Adjusts cut

power setting (2) of selected cut mode (13).

(13) CUT MODE SELECTION - Selects degree

of hemostasis of monopolar cut waveform as

indicated by associated indicator lamps.(1)

FIGURE 2.1 CONTROL PANEL

1

2

6

3

4

5

7

CUT

PURE

BLEND 1

MODE

13

WATTS

BLEND 2

COAG

MONOPOLAR

MODE

12

WATTS

BIPOLAR

11

10

SINGLE

MACHINE

RETURN MONITOR

DUAL

PAD

9

MONITOR

SET

8

2-5

(1) HANDSWITCHED MONOPOLAR

ACTIVE JACK - Accepts industry-standard

handswitching monopolar active accessories.

Output is delivered only when handswitch controls are operated. See below for connections.

(2) FOOTSWITCHED MONOPOLAR

ACTIVE JACK - Accepts Bovie #12 monopolar

active accessories and adapters. Output is delivered only when foot switch is operated.

(3) BIPOLAR OUTPUT - Accepts Conmed

bipolar plugs and bipolar cords with 1/4" banana

plugs. The small hand switch pin is unused.

Output is delivered only in BIPOLAR COAG

mode when coag footswitch is depressed.

(4) RETURN ELECTRODE JACK - Accepts

Industry standard ARMTM2-pin dispersive electrode cord plugs. Proper connection is required

for monopolar operation.

(5) POWER SWITCH - Controls AC power on

(1) and off (O).

(6) RETURN ELECTRODE ADAPTER Provides for use of CONMED Bioplus single full

dispersive electrodes when connected to return

electrode jack (4).

FIGURE 2.2 OUTPUT PANEL

HANDSWITCHED ACTIVE CONNECTIONS

1

HAND CONTROL

2

FOOT CONTROL

3

BIPOLAR

4

CUT

COAG

5

I

O

F

6

RF

2-6

(1) MAINS INLET - Accepts AC power cordset.

(2) MAINS FUSES - Overload protection on AC

input.

CAUTION: Replace only with Type T (SLOBLO) 5 x 20mm fuses with ratings as marked.

(3) FOOT SWITCH CONNECTOR - Accepts

Aspen dual treadle foot switch such as Cat. No.

60-5104-001. See below for connections.

(4) VOLUME CONTROL - Sets volume of activation tones over specified range. Does not affect

alarm tone volume.

FIGURE 2.3 REAR PANEL

FOOTSWITCH CONNECTIONS

1

2

TYPE

T

3

V

A

U.S. PATENT NOS. 4,569,345 - 4,617,927 4,848,335 - 4,961,739 AND PATENT PEND.

4

CUT

A

COAG

C

B

D

Loading...

Loading...