Conmed 7550 Service manual

Service Manual

LIMITED WARRANTY

For a period of two years following the date of delivery,

CONMED Corporation warrants the CONMED Sys-

tem 7550 Electrosurgical Generator against any defects

in material or workmanship and will repair or replace (at

CONMED’s option) the same without charge, provided

that routine maintenance as specified in this manual has

been performed using replacement parts approved by

CONMED. This warranty is void if the product is used in

a manner or for purposes other than intended.

© 2006 CONMED Corporation

525 French Road

Utica, New York 13502 U.S.A.

U.S. Patent Numbers 4,437,464 - 4,569,345 - 4,617,927

- 4,727,874 - 4,848,335 - 4,961,739 - 5,152,762 5,626,575 and other patents pending.

For Technical Service or Return Authorization Phone:

303-699-7600 / 1-800-552-0138 Extension 5274

Fax 303-699-1628

For Customer Service or to order parts phone:

1-800-448-6506 / 315-797-8375 / Fax 315-735-6235

or contact your CONMED Representative.

European Authorized Representative

MDSS GmbH

Burckhardtstr 1

D - 30163 Hannover

Germany

The revision level of this manual is specified by the

highest revision letter found on either the inside front cover

or enclosed errata pages (if any).

Manual Number 60-7552-ENG Rev. D 10/06

Unit Serial Number_________________________________

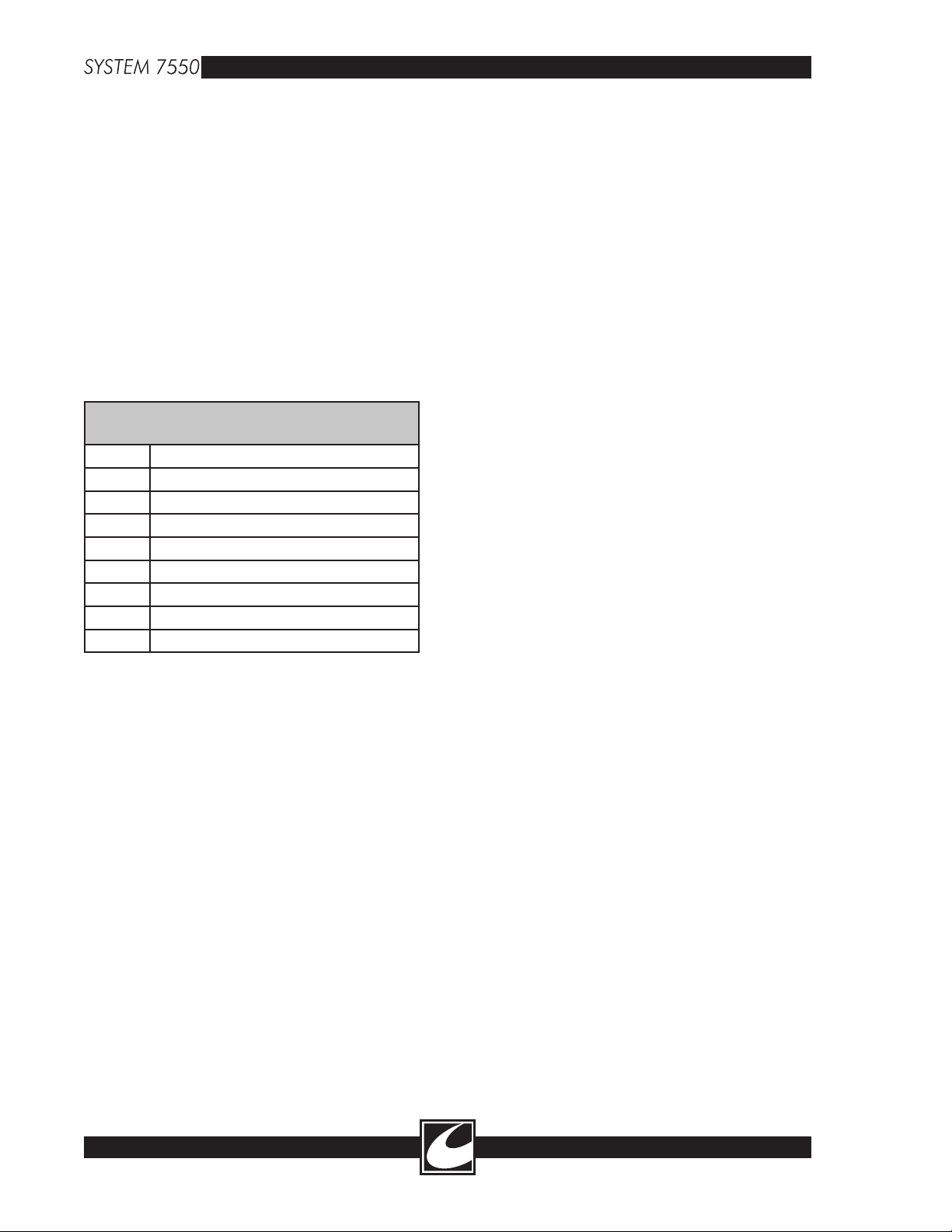

Table of Contents

& List of Illustrations

Section Title Page

1.0 General Information ...........Refer to Operator’s Manual (P/N 60-7551)

2.0 System Components .................................... Refer to Operator’s Manual

3.0 Operation .................................................... Refer to Operator’s Manual

4.0 Operator Service ......................................... Refer to Operator’s Manual

5.0 Technical Information ................................. Refer to Operator’s Manual

6.0 Circuit Descriptions .......................................................................... 6-1

6.1 Introduction ........................................................................................................ 6-1

6.2 Display Panel Assembly [A5] ............................................................................... 6-1

6.2.1 General Information ..........................................................................................................6-1

6.2.2 Mailbox [U19] ..................................................................................................................

6.2.3 Power Adjustments [U16 & U33] ..................................................................................

6.2.4 Activation Requests [U16 & U33] ....................................................................................

6.2.5 Mode Select Encoders [U31 & U32] ................................................................................

6.2.6 Display Drivers - Seven Segment

6.2.7 Indicator Driver [U34] .....................................................................................................

6.2.8 Firmware [U28 & U1] ......................................................................................................

6.2.9 RAM [U2 -6116] ..............................................................................................................

6.2.10 A/D Inputs [Control Microcontroller] ..............................................................................

6.2.11 A/D Inputs [Monitor Microcontroller] .............................................................................

6.2.12 EEPROM & Driver [U37, U27] ......................................................................................

6.2.13 D/A Converter [U12] .......................................................................................................

6.2.14 Keyboard Scanner [U5] ....................................................................................................

6.2.15 5V Monitoring [U29] .......................................................................................................

6.2.16 Output PIA [U21] ............................................................................................................

6.2.17 T_MON [U35] .................................................................................................................

[U14, U20, U39, U40, U41, & U17] ......................... 6-3

6.3 Power Control Assembly [A4] ............................................................................. 6-5

6.3.1 Power Control - Full Bridge Amplifier ..............................................................................6-6

6.3.2 RF Logic [U7 on the Power Control Assembly] ...............................................................

6.3.3 Power Control - I/O Signals ..............................................................................................6-8

6.3.4 ABC

™ Arc Sense ...............................................................................................................6-8

6.4 High Voltage Power Supply [A7] ........................................................................ 6-9

6.4.1 Power Supply Topology ....................................................................................................6-9

6.4.2 Phase Control Output ......................................................................................................

6.4.3 HVPS Isolation Components ..........................................................................................

6.4.4 HVPS Low Voltage Components ...................................................................................

6.5 HV/Flow Control Assembly [A1] ..................................................................... 6-11

6.5.1 Line Synchronization Circuit ...........................................................................................6-11

6.5.2 HV Regulation Control Loop .........................................................................................

6.6 Argon Flow Control [A1] ................................................................................. 6-13

6.6.1 Pneumatic Circuit ............................................................................................................6-13

6.6.2 Mass Flow Rate Regulation ............................................................................................

6.6.3 Smart Sense .....................................................................................................................

6.7 Full Bridge Amplifier [A8] ................................................................................ 6-15

6-1

6-1

6-2

6-2

6-3

6-3

6-3

6-3

6-4

6-4

6-4

6-5

6-5

6-5

6-5

6-7

6-9

6-10

6-11

6-12

6-14

6-15

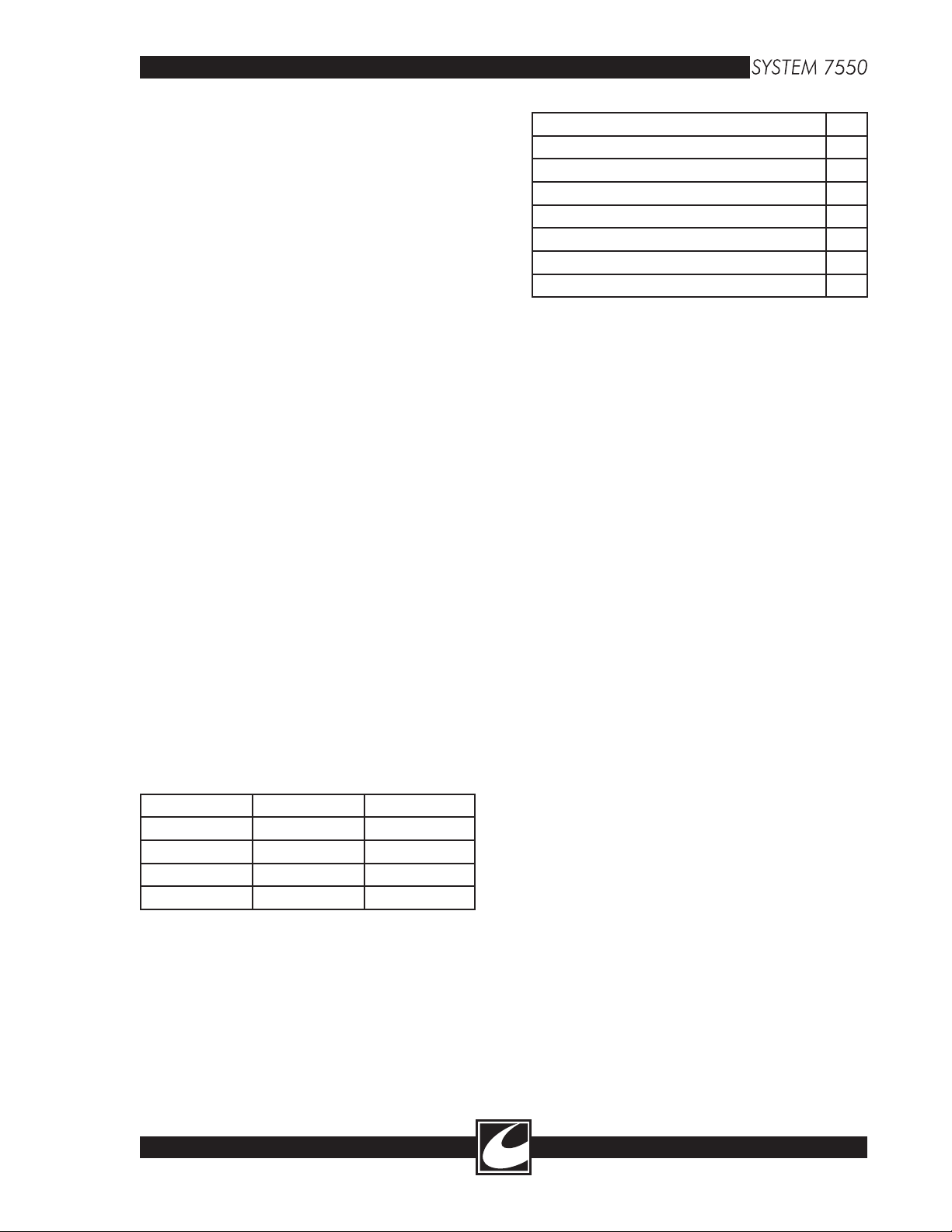

Section Title Page

6.8 Single-Ended Amplifier [A9] ............................................................................. 6-16

6.9 RF Output Assembly/Component

6.10 Low Voltage Power Supply [A6] .......................................................................

6.11 HS/A.R.M. Assemb

6.11.1 Handsense Circuit ...........................................................................................................6-18

6.11.2 Aspen Return Monitor (A.R.M.) ....................................................................................

6.11.3 RF Leakage Monitor .......................................................................................................

6.11.4 Transformer Select Relays ................................................................................................

6.11.5 Arc Sense Transformer ....................................................................................................

ly [A11] ............................................................................. 6-18

s [A10] ......................................................... 6-17

6-18

6-19

6-20

6-20

6-20

7.0 Maintenance/Checkout ...................................................................... 7-1

7.1 Introduction ........................................................................................................ 7-1

7.2 Cleaning .............................................................................................................. 7-1

7.3 Generator & Mobile Storage Assembly ................................................................ 7-1

7.4 Access to Circuits & Factory Settings .................................................................. 7-2

7.5 Default Settings (Factory Settings) ...................................................................... 7-2

7.6 AC Mains Frequency & Voltage .......................................................................... 7-2

7.7 Initial Setup & Test ............................................................................................. 7-3

7.7.1 Accessory Connections ......................................................................................................7-3

7.7.2 Display Panel Testing ........................................................................................................7-3

7.7.3 Activation Testing .............................................................................................................7-5

7.7.4 RF Output Power Checks .................................................................................................7-5

7.7.5 Argon Flow Testing .......................................................................................................... 7-6

7.7.6 Remote Power Control Testing .........................................................................................7-6

7.7.7 Return Monitor (A.R.M. - Aspen Return Monitor) .......................................................... 7-7

7.8 Pulsed Cut Mode ................................................................................................. 7-8

7.9 RF Leakage Test .................................................................................................. 7-8

7.10 Final Checks ........................................................................................................ 7-8

7.11 Mobile Storage Pedestal (Cart) ............................................................................ 7-8

8.0 Calibration ........................................................................................8-1

8.1 Introduction ........................................................................................................ 8-1

8.2 Equipment List ...................................................................................................

8.2.1 Standard Equipment List ..................................................................................................8-1

8.2.2 Optional Calibration Equipment List ................................................................................

8.2.3 Test Leads & Adaptors ......................................................................................................

8.3 Calibration Set-Up .............................................................................................. 8-1

8.4 A.R.M. Calibration (HS/A.R.M. Assembly - A11) ............................................

8.4.1 10 Ohm A.R.M. Calibration ............................................................................................. 8-1

8.4.2 150 Ohm A.R.M. Calibration ...........................................................................................

8.5 High Voltage Calibration (HV/Flow Control Assembly - A1) ............................. 8-2

8.5.1 HV RAMP Calibration ..................................................................................................... 8-2

8.5.2 High Voltage Adjust .........................................................................................................

8.5.3 HV_MON Adjust .............................................................................................................

8.6 Argon Flow Calibration (HV/Flow Control Assembly - A1) ............................... 8-2

8.6.1 dP Calibration (Differential Pressure) ................................................................................8-2

8.6.2 PABS Calibration (Absolute Pressure) ...............................................................................

8.6.3 Flow Rate Calibration (Optional) .....................................................................................

8.6.4 FMON Calibration ...........................................................................................................

8.7 Power Calibration ................................................................................................ 8-3

8.7.1 Filter Calibration - Full Bridge Modes (Optional) .............................................................8-3

8.7.2 Cut Power Calibration (Power Control Assembly - A4) ....................................................

8-1

8-1

8-1

8-1

8-2

8-2

8-2

8-2

8-2

8-3

8-3

Section Title Page

8.7.3 Pinpoint Coag Calibration (Power Control Assembly - A4) ..............................................8-3

8.7.4 Spray Coag Calibration (Power Control Assembly - A4) ...................................................

8.7.5 Bipolar Calibration (Power Control Assembly - A4) .........................................................

8.7.6 ABC Calibration (Power Control Assembly - A4) .............................................................

8.7.7 ABC Over Voltage Calibration (Power Control Assembly - A4) [Optional] .....................

8-3

8-4

8-4

8-4

8.8 EEPROM Calibration ......................................................................................... 8-4

8.8.1 Spray Coag PW_MEA Loading ........................................................................................8-4

8.8.2 ABC PW_MEA Loading ...................................................................................................

8.8.3 A.R.M. Max Voltage Loading ...........................................................................................

8-4

8-4

8.9 IEC RF Leakage Measurement [Optional] .......................................................... 8-5

Appx. A Mnemonic List ................................................................................. A-1

Appx. B Troubleshooting Gu

Introduction ........................................................................................................ B-1

Control Microcontroller Failure Codes and Troubleshooting Tips ........................B-2

Monitoring Microcontroller Failure Codes and Troubleshooting Tips ..................B-3

Additional Troubleshooting Tips (Non-Error Code Related) ............................... B-5

Error Storage and Retrieval ................................................................................. B-7

Error Display Configuration .............................................................................................B-7

Example Error ...................................................................................................................B-8

ide .....................................................................B-1

Appx. C Schematics & BOMs ........................................................................ C-1

Bill of Material: Chassis & Cart ........................................................................... C-1

Bill of Material: HV/Flow Control PCB Assembly ..............................................C-2

Bill of Material: Power Control PCB Assembly ...................................................C-4

Bill of Material: Display PCB Assembly .............................................................. C-5

Bill of Material: LV Power Supply PCB Assembly .............................................C-10

Bill of Material: HV Output PCB Assembly ......................................................C-11

Bill of Material: FB Amplifier PCB Assembly ....................................................C-12

Bill of Material: SE Amplifier PCB Assembly .................................................... C-13

Bill of Material: RF Output PCB Assembly .......................................................C-14

Bill of Material: ARM/Handsense PCB Assembly .............................................C-15

Figure/Title Page

Figure 6.1 RF Drive Signals ....................................................................................................... 6-8

Figure 6.2 Line Sync/RAM ......................................................................................................

Figure 6.3

Flow Diagram ......................................................................................................... 6-14

Figure 6.4 Resistance vs. Bargraph ...........................................................................................

Figure 7.1 Test Adapters ............................................................................................................

Figure 7.2 Test Analyzer C

onnections ...................................................................................... 7-10

Figure 3.1 RAMP Flat Spot .......................................................................................................

Figure 3.2 IEC Method RF L

eakage Test Setup ......................................................................... 8-5

Figure B-1 Signal Status for a Handcontrol 1, Cut Activation Request .....................................

®

Figure B-2 Signal Status for ABC

Activation ........................................................................ B-10

Figure C-1a Assembly Location Diagram ..................................................................................

Figure C-1b Pneumatic Assembly ..............................................................................................

Figure C-2 Interconnect Diagram .............................................................................................

Figure C-3 A1 HV/Flow Control PCB .....................................................................................

Figure C-4a A1 HV/Flow Control PCB Schematic, Sheet 1 (of 2) ...........................................

Figure C-4a A1 HV/Flow Control PCB Schematic, Sheet 2 (of 2) ...........................................

Figure C-5 A

Figure C-6 A4

Figure C-7 A

Figure C-8a A

Figure C-8b A

Figure C-8c A

Figure C-8d A

Figure C-9 A

Figure C-10 A

Figure C-11 A

Figure C-12 A

Figure C-13 A

Figure C-14 A

Figure C-15 A

Figure C-16 A

Figure C-17 A

Figure C-18 A

Figure C-19 A

Figure C-20 A

4 Power Control PCB ...........................................................................................C-4

Power Control PCB Schematic ..........................................................................C-4

5 Display PCB ......................................................................................................C-5

5 Display PCB Schematic, Sheet 1 (of 4) ............................................................C-6

5 Display PCB Schematic, Sheet 2 (of 4) ...........................................................C-7

5 Display PCB Schematic, Sheet 3 (of 4) ............................................................ C-8

5 Display PCB Schematic, Sheet 4 (of 4) ...........................................................C-9

6 LV Power Supply PCB ....................................................................................C-10

6 LV Power Supply PCB Schematic .................................................................C-10

7 HV Output PCB ........................................................................................... C-11

7 HV Output PCB Schematic ..........................................................................C-11

8 FB Amplifier PCB .........................................................................................C-12

8 FB Amplifier PCB Schematic ........................................................................C-12

9 SE Amplifier PCB .........................................................................................C-13

9 SE Amplifier PCB Schematic .........................................................................C-13

10 RF Output PCB .......................................................................................... C-14

10 RF Output PCB Schematic .........................................................................C-14

11 A.R.M./Handsense PCB ..............................................................................C-15

11 A.R.M./Handsense PCB Schematic .............................................................C-15

6-11

6-19

7-9

8-2

B-9

C-1

C-1

C-1

C-2

C-2

C-3

Circuit Descriptions

Section 6.0

6.1 Introduction

The information on the System 7500™ circuits

identifies specific signals and I/O ports that help

identify the appropriate signal levels. The text

uses the word SET for high and

low. To locate the assemblies within the System

7500™, refer to Figure C-1. Use the system inter

connect (Figure C-2) to identify wiring harness

terminations and individual signals within a har

ness.

CLEAR for

-

6.2 Display Panel Assembly [A5]

6.2.1 General Information

The System 7500™ has two 80C550 microcon

trollers with one dedicated to system control and

the other dedicated to system monitoring. The

control microcontroller (U15) sets the system

enables and control limits, while the monitor

microcontroller (U22) monitors system perfor

mance and sets “inhibits” when an error is detect

ed. Both of these devices have “on-board” A/D

converters, and each device independently moni

tors separate analog signals. The address, data

and control buses of both microcontrollers are

isolated by a device called the “mailbox”, U19, a

dual port RAM that allows two-way data transfer

between the two microcontrollers.

On the schematic, the signal labels will have either

a “C” or “M” attached. The “C” is for the con

troller logic (U15) or control microcontroller and

the “M” is for the monitor logic (U22) or moni

tor microcontroller interface. The schematic for

the display panel (Figure C-8) is on four separate

sheets. Sheet 1 is the schematic for the displays

and drivers only; sheet 2 shows all the connec

tors that are on this assembly along with some

discrete non-logic circuitry; sheet 3 is the control

microcontroller logic; and sheet 4 is the monitor

microcontroller logic.

This assembly has several programmable logic

devices to interface signals to the data bus for

both the control and monitor microcontrollers.

During the discussion when two reference desig

-

-

-

-

-

-

-

-

nators are listed together it means the logic func

tions are the same and can be interchanged.

6.2.2 Mailbox [U19]

A dual port logic device that allows data transfer

between the two microcontrollers. All system

-

setups and messages are communicated through

the mailbox between the two microcontrollers.

When data is loaded by either microcontroller, a

bit labeled DA (data available) is

the other microcontroller that it has mail. Once

the data is read from the mailbox, another bit

labeled DC (data cleared) is

the sender that the mail has been retrieved. Each

microcontroller has independent access to the

mailbox and the mailbox is the only component

that connects the two data buses. Each instruc

tion sent through the mailbox requires two bytes

of information with the first byte (command byte)

identifying the instruction and the second byte

(data byte) containing the data for the instruction.

6.2.3 Power Adjustments [U16 & U33]

(C for controller; M for monitor) Power adjust

ments on the System 7500™ are made by rotat

ing the power control encoders. The mnemon

ics for the power encoders are: CT - CUT; CG

- COAG; BP - BIPOLAR; BM - ABC™. Each

encoder is a two bit counter (i.e.; CT0 & CT1)

where the two counts are used to identify the

direction of rotation. The logic devices (U16

& U33) store the previous count and compare

it to the new count in order to recognize if the

count is increasing or decreasing, which defines

if the encoder is rotated clockwise or counterclockwise. Each “click” of the encoder is a count

and the number of counts are stored within

U16 & U33 until the microcontroller reads the

port. The microcontroller reads each encoder

port independently and if an encoder has been

rotated, the count will be greater than zero. The

data the micro will see is a number (0 to 32) rep

resenting the number of “clicks” the encoder has

been rotated and a separate bit that signifies the

direction of the count, either up or down. The

microcontroller then takes this count and adds or

SET to inform

CLEARED to inform

-

-

-

-

-

-

6-1

subtracts it to the existing power value.

The control microcontroller reads and controls

power change requests, however the monitor

microcontroller also looks at the encoders to verify

the change is valid. If the two microcontrollers

disagree on the direction (up or down), number

of counts, or which encoder is rotating, the power

will not be changed; i.e. the change request is

ignored.

6.2.4 Activation Requests [U16 & U33]

Activation requests are “looked at” by both micro

controllers, and if the two do not agree on an acti

vation request, an error code (Err 303 or Err 307)

will be displayed.

Activation Requests: Handcontrol or

Footcontrol

H2CT Handcontrol 2, Cut, Active Low

H2CG Handcontrol 2, Coag, Active Low

H1CT Handcontrol 1, Cut, Active Low

H1CG Handcontrol 1, Coag, Active Low

HIP Handcontrol, Bipolar, Active Low

FCT Footcontrol, Cut, Active High

FCG Footcontrol, Coag, Active High

FBIP Footcontrol, Bipolar, Active High

FAB Footcontrol, ABC™, Active High

Note: HABC Handcontrol is activated at

handcontrol 2 and is a result of H2CT * H2CG *

HABC_DR, which is an output of U16.

6.2.5 Mode Select Encoders [U31 & U32]

Blend Level (BL) and Argon Flow (FL) rate is

adjusted by the same type of encoders as used for

power adjustments. The logic within U31 & U32

for these two encoders is the same as for power

adjustment and the discussion for power adjust

-

ment applies here.

These logic devices have I/O ports also, and the

following text provides a brief description of each

port signal.

U31: Port B (PB0 - PB7) Inputs for Control

Microcontroller

LPSW: Low Pressure Switch

SET when the argon tank pressure is less than

240 psi. Low Tank warning is illuminated.

FDEV: Flow Deviance

SET if an occlusion occurs to the argon flow.

A_T: Active Mode or Target Mode

ABC™ mode and used for tone selection only.

A_T SET, tone is 500 Hz and ABC™ is active

- A_T CLEARED, tone is 250 Hz and

ABC™ is in the Target mode.

BRN_OUT: Brown Out

Holds high for at least 6 seconds when power

fails and is used to identify a temporary power

loss. The user settings are returned following

a temporary power loss.

-

-

Tone_A: Tone Signal

Mode Activation and Alarms. Square wave sig

nal with frequency between 250 Hz to 1KHz

for audible tone.

KB_DA: Keyboard Data Available

SET when a front panel switch is pressed, cleared

when the device is read.

U31: Port C (PC0 - PC6) Outputs from

Control Microcontroller

ABC>80: ABC™ Power is Greater than 80W

SET when ABC™ power is set to greater than

CLEARED when ABC™ power is 80W

80W.

or less.

RFEN: RF Enable

SET to enable the RF drive for all activations.

FB_EN: Full Bridge Enable

CLEARED when activation for Cut, Blend,

Pinpoint, & Bipolar occurs.

OV_TST: Over Voltage Test

Test pin that allows the control microcontroller

to test and verify the ABC™ over voltage

circuit is operational. During Power-On SelfTest (POST), this signal is clocked for a dura

-

tion of about 7mS.

Alarm: Tone for alarms

1KHz signal tone for alarm - volume cannot be

adjusted.

Tone_B: Tone, Mode

Signal for all Tones except alarm tones. Volume

can be adjusted.

U32: Port B (PB0 - PB7) Monitor Inputs

This port has the switch for setting the system

defaults. The switch is located on the back side of

the Display PCB for accessibility. Default settings

are with the switch in the “OFF” position (off

= high on the input pin of U32). To change a

default setting, move the appropriate switch to the

6-2

“ON” position. To verify the selection, turn the

power off for at least 10 seconds, and then restore

power.

1-TEST-RUN (Default: RUN MODE)

TEST mode allows the system to be operated

without error detection and shut down. This

mode can be changed anytime while the system is in standby. Test mode can be selected

before the unit is powered on, however the

“store” button must be held down until an

“Err 1” is displayed. Test mode is to be used

only for system level testing.

2-SIN-DUAL PAD (Default: DUAL PAD)

SIN is for single foil return electrodes.

3-ZERO-LAST (Default: LAST SETTING)

When ZERO is selected, all power levels will

default to zero when the system is powered

on. Last setting only applies to power levels

of the default modes.

4-SPRAY-PPT (Default: PINPOINT COAG)

Spray Coagulation can be selected as a default

mode.

5-NON_SIM-SIM (Default: SIMULTANEOUS)

When the switch is set for non-simultaneous

activation, dual activation will not occur for

coag modes.

6-GAS TEST (for testing purposes only)

Allows the ABC™ mode to be tested without

argon gas connected. Can only be set after

the unit has been powered on and completed

initialization.

U32 - PORT C: Outputs from Monitor

This port has three (3) active outputs only and the

outputs are used solely to inhibit internal circuits

when a system fault is detected.

GAS_En: Gas Enable

SET to enable argon gas flow - CLEAR inhibits

argon gas flow. Drives the solenoid valve that

is part of the argon flow control manifold.

HV_INH: High Voltage Inhibit

SET inhibits the HV to the amplifiers.

RF_INH: RF Drive Inhibit

CLEAR inhibits the RF Drive to the amplifiers.

6.2.6 Display Drivers - Seven Segment [U14,

U20, U39, U40, U41, & U17]

Converts Hex to Seven-Segment. The hex value

on bits 0-3 drive the “ones” digit; the hex value

on bits 4-7 drive the “tens” digit; and the hex

value on the address (A0, A1) is used to drive

the “hundreds” digit. The displays are common

anode, therefore each segment is illuminated with

an active low on the drivers. The digits are mul

tiplexed, allowing only one digit to be on at any

one time for each section.

6.2.7 Indicator Driver [U34]

All indicators on the display panel with the excep

tion of the numeric displays are driven with this

logic device in a 4x7 matrix. The outputs labeled

S0-S3 are multiplexed at a 25% duty cycle and

these outputs are converted to 15V at U38 &

U42, which provide drive current for all LED

indicators. U9 and U10 sink the current for the

indicators. The monitor microcontroller loads

4- eight bit registers, with each bit dedicated to a

specific display panel indicator. The outputs S0S3 are “send” and the outputs labeled R0-R7 are

“receive”. All the send and receive outputs are

active high at a 25% duty cycle.

6.2.8 Firmware [U28 & U1]

The firmware or program for the control

microcontroller is stored in U1 and the program

for the monitor microcontroller is stored in U28.

6.2.9 RAM [U2 -6116]

U2 is the external RAM for the con

trol microcontroller only and the monitor

microcontroller only uses internal RAM.

6.2.10 A/D Inputs [Control Microcontroller]

Only four of the 8 internal A/D inputs are uti

lized, and three of these inputs are for the A.R.M.

(Aspen Return Monitor).

2VARM: A voltage that represents the resistance of

the patient plate.

ARM_10: Calibration limit for 10 ohms. (See

A.R.M. cal)

ARM_150: Calibration limit for 150 ohms (See

A.R.M. cal)

FMEA: Back pressure monitoring for argon gas

flow. The control microcontroller monitors this

signal as a means of detecting occlusions or special

accessories with small orifice sizes.

When the monitor microcontroller senses an error

at ARM_10 or ARM_150, it will display an error

code to identify which input has the fault. These

are fatal errors that require the system to be reset

-

-

-

-

6-3

when they occur. An error for 2VARM is a return

electrode fault and occurs when the resistance

measured on the return electrode is not within

specified limits for either a single or dual foil

return electrode. An error code is not displayed,

however the “red” indicator for a return electrode

fault is illuminated.

In many cases, intermittent or continuous alarms

associated with these signals can be rectified

by going through the calibration procedure for

A.R.M.

FMEA has an idle voltage of one-half of the value

ABS. When testing or troubleshooting, use

of P

the calibration procedure for P

the value of F

MEA when no argon flow is occur-

ABS to determine

ring. This voltage increases with flow. A voltage

that exceeds 3.3V in all flow modes will set a flow

alarm by illuminating the “red” Flow Fault indica

tor.

6.2.11 A/D Inputs [Monitor Microcontroller]

Seven of the eight available inputs are used for

monitoring system signals. A failure with any one

of the inputs will be displayed as an error code.

HV_MON: High Voltage Power Supply Monitoring

This A/D input is 200mV±40mV when the

system is in the idle mode. The resolution is

20mV/V or 20mV for every volt on the +DC

& -DC terminals of the High Voltage power

supply. Calibrated for 1V with 50V on the

High Voltage Power Supply.

IMEA: Current Measure

A ratio of the output current that is applied to

the patient when Cut, Blend, Pinpoint or

Bipolar modes are used. Used in conjunction

with the HV_MON to determine the output

power.

F_MON: Flow Monitor

The current through the flow control valve rep

resents the flow rate. A flow rate that exceeds

requested flow by more than 2 SLPM will

set an alarm and inhibit both RF Output and

argon flow. This signal is calibrated for 2V

with a flow setting of 4 SLPM.

PW_MEA: Pulse Width Measure

Spray and ABC™ modes only. A DC average of

the RF Drive pulse width to the single ended

amplifier. In ABC™, the voltage increases as

the power increases if a load is connected to

the ABC™ output. In Spray, the voltage is

constant for all dial settings.

FB_MON: Full Bridge Monitoring

Cut, Blend, Pinpoint and Bipolar modes only.

A DC average of the full bridge RF Drive.

With Cut activated, FB_MON is approxi

mately 2.85V and for each blend, the voltage

is about 225mV less than the previous blend

or cut mode.

10V Reference:

The 10V reference is monitored and must be

4.46V±.2V.

15V Supply:

The system 15V for control circuits is moni

tored. This voltage is used for op amps,

relays and flow control valves. This voltage

-

must be 3.72V±.5V.

6.2.12 EEPROM & Driver [U37, U27]

The EEPROM (U37) is used to store user set

tings and these settings are recalled when the unit

is first powered on or if a 5 second brown out

occurs. On power-up, power settings will be the

last settings for the default modes. Included in

the EEPROM are the calibration limits for ABC™

and SPRAY PW_MEA settings. A failure detected

with the EEPROM during system initialization

will default all power settings to “0”. A failure

detected with the PW_MEA stored data will

inhibit the system from being used until the prob

-

lem is corrected.

U27 is a parallel-to-serial interface device.

The EEPROM is loaded serially, however the

PCF8584 allows the control microcontroller to

load the serial data from the parallel data bus.

6.2.13 D/A Converter [U12]

The D/A converter is used to control the follow

-

ing:

•High Voltage (V

•Output Power (P

•Maximum voltage at each dial setting (I

CON)

CON)

LIM)

for Cut, Blend, Pinpoint, & Bipolar Modes

•Argon Flow Rate (V

GAS).

Each of these signals should be zero volts in the

idle mode and increase as the power or flow

increases. The voltages listed below are the maximum limits at full power settings.

6-4

VCON = 9V when HVDC is 200V (0V-9V)

PCON = 8.8V at full dial cut (0V - 8.8V)

ILIM = 3.8V at full dial cut (0V - 3.8V)

VGAS = 6.2V at 10 SLPM (.15v to 6.2V)

6.2.14 Keyboard Scanner [U5]

The 74C922 allows a 4X4 matrix keyboard to

be connected. When a Front Panel switch is

pressed, the location of the switch is latched into

the device and the signal KB_DA (keyboard data

available) is

SET. Only one switch press is stored

and gets cleared after the device is read.

6.2.15 5V Monitoring [U29]

U29 is a microcontroller supervisory device that

automatically sets the “RST” when the 5V sup

ply is less than 4.5V. A short interruption of the

mains power will cause a system reset to occur.

On the input of U29 (pin 1) is a comparator

(U35) that will cause a reset to occur if the 5V

exceeds 5.7V. The pin “RST” is active high and

“/RST” is active low.

6.2.16 Output PIA [U21]

Dedicated output PIA for the control

microcontroller to latch control logic to system

functions. This device has three (3) output ports

and each will be described briefly.

PORT A: CON_D0 - CON_D7

Dedicated for mode identification to the Power

Control Assembly. When a mode activation

occurs, the controller latches a Hex count into this

register and the magnitude of the count identi

fies to the RF Logic FPGA which mode is being

requested.

Cut: 39h Blend 1: 37h Blend 2: 35h

Blend 3: 33h Blend 4: 31h Blend 5: 29h

Blend 6: 27h Blend 7: 25h Blend 8: 23h

Blend 9: 21h Bipolar: 6Fh PPT: 43h

Spray: 82h ABC™: C3h

PORT B: OUTPUT RELAY SELECT

These outputs connect to a relay driver (U23)

on this PCB Assembly. Upon an activation, hex

counts are latched into this register for relay clo

sure dependent on mode and method of RF acti

-

-

vation.

Handcontrol 1 - Cut or PPT. Coag 31h

Handcontrol 1 - Spray Coag

Handcontrol 2 - Cut or PPT. Coag

Handcontrol 2 - Spray Coag

Argon Beam Coagulation

Bipolar A0h

Footcontrol - Cut or PPT. Coag

Footcontrol - Spray

51h

32h

52h

08h

34h

54h

PORT C: CIRCUIT ENABLES

The following signals are

SET during activation as

shown:

PSRQT: Power Supply Request

Enables the high voltage power supply circuit -

Enabled for all mode activations.

PC_EN: Power Control Enable

Enables the Power Control Circuit to inter

face with the HV Control Circuit for Power

Control when Cut, Blend, Bipolar or Pinpoint

modes are activated.

LVT_EN: Low Voltage Triac Enable

Enables the low voltage triac (125V) when Cut,

Blend or Bipolar are activated.

HVT_EN: High Voltage Triac Enable

Enables the high voltage triac (185V) when

Pinpoint, Spray, or ABC™ are activated.

AR_EN: Argon Enable

Enables the flow control circuit when ABC™ is

activated.

6.2.17 T_MON [U35]

The monitor microcontroller verifies that for every

activation of RF Output, a tone is generated.

T_MON is a signal with the same frequency as

the tone generated.

6.3 Power Control Assembly [A4]

This assembly controls output power of all modes

and has the driver logic for both RF Amplifiers.

It is important to remember that this system has

two separate RF Amplifiers and each amplifier

operates in a different manner. The amplifier

against the back wall is called Full Bridge (FB)

and is used for Cut, Pinpoint, Blend, and Bipolar

Modes. The other amplifier is against the side

wall and is only activated for Spray and ABC™

modes. This discussion will focus on each ampli

fier independently.

-

6-5

6.3.1 Power Control - Full Bridge Amplifier

Output power in the Full Bridge modes is con

trolled by monitoring the output voltage and

current, multiplying the two together and the

product of the operation is power. The measured

power is then compared to the requested power

and if the power is greater than requested power,

the power control circuit reduces the HVDC. If

the power is less than the requested power, then

the power control circuit increases the HVDC.

The power control loop encompasses several

assemblies, however we will only focus on the cir

cuits of the Power Control Assembly. For this dis

cussion, it is important to refer to the schematic

(Figure C-6). The RF Output can be constant

current, power regulated or a fixed output voltage,

all depending on the RF load.

The inputs labeled V

SN (voltage sense) and ISN

(current sense) are ratios of the RF output voltage

and current that is delivered to the patient. U1 &

U3 are RMS-to-DC converters that convert both

signals to a DC level so they can be monitored

and controlled. The DC level is then connected

to the input of a unity gain amplifier (U2). U2

is used to control both voltage and current lim

its outside of the load regulation range. For the

time, we will focus on the simpler aspect of this

circuit, and cover the limits later in the discussion.

Power regulation can be seen on the load curves

that are within this manual. (See Figure 5.1.10,

Pure Load Curves) Using Pure Cut as our mode

for discussion, the output power is regulated

between 300 ohms to 1K ohms. When the RF

load is between 300 ohms and 1K ohms, the

outputs of the amplifiers connected to U1 & U3

are negative, or the diodes D4 & D3 are reverse

biased. The DC value of the RMS-to-DC con

verters is passed around the amplifier to the cath

-

odes of D4 & D3, where they are buffered by the

unity gain amplifiers, U2.

U12 is a multiplier that multiplies the measured voltage (V

SN) and measured current (ISN)

together for a product term called POWER

(P=VI). On the output of U12 is an amplifier

(U10) with a potentiometer (RA5) in the feed

back. This potentiometer is used to calibrate the

gain of the loop and it is this potentiometer that is

adjusted for Pure Cut calibration. The output of

the amplifier (U10) is called measured power and

the measured power is compared to the requested

power P

CON at V10D. The difference of the

two is called P

ERR (Power Error), a signal that

can increase or decrease the HVDC for power

control. When the signal is positive, the HVDC

is reduced and when negative, the HVDC is

increased.

Digressing back to the outputs of the RMS-toDC converters for a moment, the DC value of the

output voltage and current are both connected to

the inverting input of the unity gain amplifiers.

As long as the load is within the defined limits

for power regulation (300 ohms - 1K ohms), the

measured value will exceed the reference level or

-

the level on the non-inverting inputs. The output

of the amplifier is then negative, reverse biasing

D3 & D4 diodes, and the output of the RMS-DC

converters is passed through the 2.7 ohm resis

-

tors.

The signal called I

When the output current is less than this refer

ence, the I

LIM value is used as the multiplier with

the measured voltage. I

LIM is actually a reference.

-

LIM is dependent on the

dial setting, however for each dial setting it is

fixed and becomes a fictitious representation for

the output current. I

LIM is multiplied against the

measured voltage and the product is compared to

the requested power. With a fixed current being

compared to a fixed power setting, the result is a

fixed voltage on the RF output. For loads that

are greater than the loads for power regulation

(R>1K ohms in cut), the RF output voltage is

fixed (V=P/I).

On U2-3 (V

LIM) is a reference voltage that is

really a fictitious value for the output voltage. For

heavy loads (R<300 ohms in Cut), the output

voltage is less than this reference so the value is

multiplied against the measured output current.

The product of the two is then compared to the

requested power. With a fixed voltage (reference)

and a fixed power setting, the output current is

fixed (I=P/V). The resistance for power regula

tion drops with power setting, meaning at full

power the load is 300 ohms but at 100 watts, the

load is 100 ohms.

Calibration of the Power Control circuit is set in

Pure Cut initially by adjusting RA5. This poten

tiometer calibrates the loop gain for accurate

power monitoring and control. Blend modes are

a direct function of Pure Cut and do not need to

be calibrated, however Bipolar and Pinpoint do

require calibration. Bipolar is calibrated by adjust

-

ing RA6 and Pinpoint is calibrated by adjusting

6-6

RA7. The signal labeled PCON (power control) is

driven from the DAC on the Display PCB and is

the control voltage for output power. The range

CON is 0V-9V.

for P

IMEA is a ratio of the output current measured,

scaled from 0V to 4V maximum. I

MEA allows the

monitor microcontroller to monitor the output

current. Too much output current will cause RF

to be inhibited and an error code displayed.

FB_EN is “cleared” by the control microcontroller

anytime that Cut, Blend, Bipolar, or Pinpoint are

activated. This signal enables the power control

circuit when cleared. With FB_EN set, an offset

is placed on the non-inverting input of the differ

ential amplifier, causing P

ERR to be greater than 0

-

volts, which in the event of a failure, would force

the HVDC to be low. P

ERR was covered earlier

but as a reminder, this signal is the difference

between the measured output power and request

ed power. When P

ERR is positive, the HVDC

-

is decreased and when negative the HVDC is

increased.

6.3.2 RF Logic [U7 on the Power Control

Assembly]

U7 is an FPGA, programmable logic device that

is used to develop the RF amplifier drive signals

for all modes. This device will be described with

respect to the I/O only. Listed below is a brief

description of the I/O on U7.

COND0 - COND7 (Control Microcontroller

Inputs)

The hex count on these inputs select which

RF amplifier will be driven and sets the

right drive signals for the mode. The eight

signals are latched into U7 when an activa

tion request is made. (See display panel

description for hex values as related to modes

requested.)

RF_CLK (RF Clock - input)

A 1MHz clock for RF drive timing. Runs con

-

tinuously.

RF_INH (RF inhibit - input from monitor

microcontroller)

When CLEARED (low), RF is inhibited.

CLEARED when no activation is requested or

if a failure is detected.

FB_EN (Full Bridge Enable - input from control

microcontroller)

CLEARED when Cut, Blend, Pinpoint or

Bipolar modes are requested. A

CLEARED is

required to enable output power control.

OV_TST (Over voltage test - input from control

microcontroller)

A test pin used only to test the ABC™ Over

Voltage circuit during system initialization by

a series of pulses that simulate an ABC™ over

voltage condition. After the test is conducted,

the signal is latched low.

A/T (Active/Target - output to control

microcontroller)

ABC™ mode only - A high occurs when ABC™

is in the ACTIVE mode; a low occurs when

ABC™ is in the TARGET Mode. For tone

control only as the two modes have distinctive

tones.

BM>80 (Beam greater than 80W - from control

microcontroller)

SET when ABC™ power is greater than 80W.

An internal limit in U7 for switching from

active to target mode.

RFEN: (RF Enable - input from control

microcontroller)

SET to enable RF Drive to the amplifiers.

RST: (Reset - from system reset signal)

A SET causes internal latches to CLEAR.

CT_PCON: (Cut Power Control voltage select)

SET when Cut or Blend modes are activated .

Switches Pcon for Cut.

CG_PCON: (Coag Power Control voltage select)

SET when Pinpoint is activated. Switches Pcon

for Pinpoint.

BP_P

CON: (Bipolar Power Control voltage select)

SET when Bipolar is activated. Switches Pcon

for Bipolar.

SE_PCON: (PCON for Spray & ABC™ active

select)

SET for Spray or ABC™ active only. Switches in

Pcon for Spray and ABC™ active.

BM_BST: (ABC™ Booster voltage control level)

SET to enable Boost Pcon.

BM_TAR: (ABC™ Target voltage control level)

SET to enable Target Pcon.

6-7

SP_PCON: (Scaler to calibrate Spray power)

SET for Spray activation to rescale SE_Pcon for

Spray calibration and control.

T_RLY:

Tank Relay selects either the Spray or ABC™

transformer primary. set when Spray is acti

vated.

XSLO:

Transformer Sense input must be low. If the

harness from the Handsense PCB to the

Power Control PCB is not connected or broken, this signal is pulled up and will inhibit

single ended operation.

A_SNS:

Arc Sense - A pulsed signal that pulses high any

time the ABC™ output exceeds a reference

level. Four or more pulses indicates an open

circuit on ABC™ and less than four pulses

indicates the ABC™ output is loaded.

ABC_OV: ABC™ Over Voltage

Pulses if the ABC™ output exceeds 3500 Vpk

and 192 consecutive pulses will cause ABC™

to be inhibited. If a failure occurs that

latches ABC™ in the Active Mode, this signal

will inhibit RF at power levels greater than

approximately 45W.

SE_EN: Single Ended drive control.

When this signal goes low, it allows C10 to start

charging up and RF drive to the Single Ended

Amplifier occurs.

SE_PW: Single Ended Pulse Width -

RF drive to the Single Ended Amplifier starts

when SE_EN goes low and stays on until this

signal transitions high. When this signal tran

sitions high, RF drive is terminated for one

cycle.

FB1 & FB2 DRV: (Full Bridge drive)

RF drive for the Full Bridge Amplifier. The full

bridge amplifier requires two drive signals

that are 180° out of phase with each other.

The rate is 461KHz and the duty cycle of the

signal varies with the mode requested. These

signals are active in Cut, Blend, Bipolar, and

Pinpoint.

FB1 & FB2 RST: (Full Bridge Drive Reset)

Reset signals for the amplifier drive transformers

6-8

on the full bridge amplifier. The FB1 RST

follows the FB1 DRV and has pulse duration

of about 200nS. FB2 RST follows FB2 DRV

and has a pulse duration of about 200nS.

SE_DRV: (Single Ended Drive)

RF drive for the single ended amplifier. This

signal is active when Spray and ABC™ modes

-

are active.

-

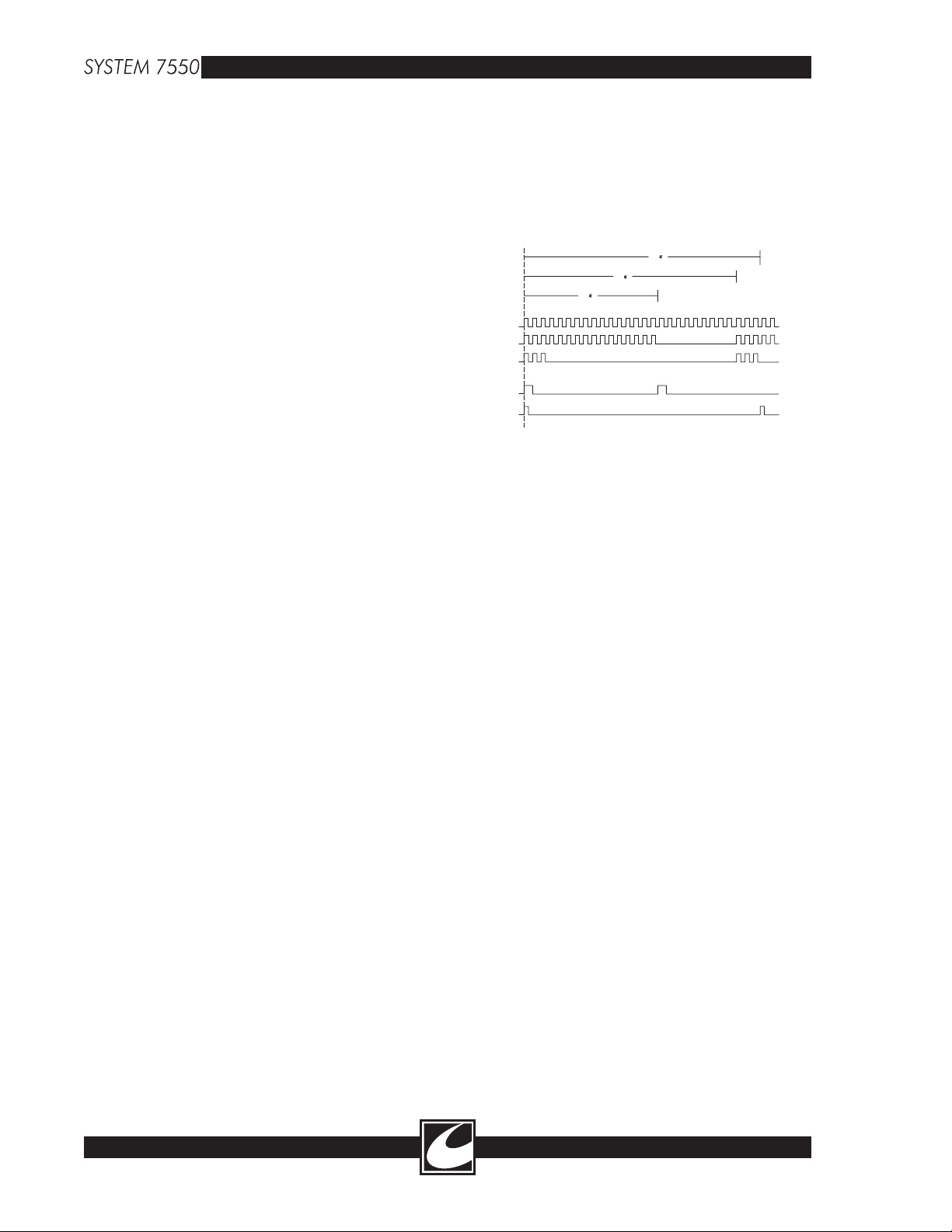

Figure 6.1 RF Drive Signals

6.3.3 Power Control - I/O Signals

The following signals are in addition to those

described for U7.

PW_MEA: Pulse Width Measured

An average DC voltage of the Spray and ABC™

drive cycles. The Monitor microcontroller

verifies that the measured pulse width is cor

-

rect for the power setting.

FB_MON: Full Bridge Monitor

An average DC voltage of the Full Bridge

Amplifier drive to allow the monitor

microcontroller a means of verifying the duty

cycle of the RF drive.

IMEA: Current Measured

The monitor microcontroller verifies that the

-

output current is within limits.

6.3.4 ABC™ Arc Sense

ABC™ has two modes - Active and Target. The

active mode is enabled when a load is sensed and

only in the active mode will the power control dial

have any effect on the output voltage or power.

When a load is not present, the target mode is

enabled where the RF Output voltage is fixed and

the repetition rate increased. The Target mode

also has two modes - Target Pulses and Booster

Pulses.

The ABC™ mode is quite similar to Spray in the

sense that the output is a damped sinusoidal wave

form. The waveform is heavily damped when a

heavy load is on the output and lightly damped

with a light load. The degree of dampening is

used to determine if a load is present or not.

Refer to Figure C-6 and locate the input labeled

+ASEN. This signal is a ratio of the primary

current on the ABC™ output transformer. ASEN

is compared to a reference voltage at U15-3 and

each peak of the damped waveform that exceeds

this reference level will cause the output of U15

to switch high at the same frequency as the output

(570KHz). If the output of U15 has four pulses

for one cycle (1 cycle is 35uS active/60uS target),

the logic within U7 assumes a load is not pres

ent and the system remains in the Target mode.

However, if less than four pulses are detected for

one cycle, the logic within U7 assumes a load is

present and switches to the active mode.

Staying with the signal ASEN, it is also connected

to a comparator (U16). This comparator is

used for ABC™ over-voltage detection. Without

going into significant detail, if the output of U16

pulses 192 consecutive cycles, the logic within U7

assumes the system has locked up in the active

mode and the RF is inhibited. Note that the

inverting input of this comparator has a potenti

ometer (RA9). This potentiometer allows calibra

tion of the over voltage limit, and should ABC™

fail to initiate, it may be necessary to refer to the

calibration section for this adjustment.

The target and booster pulses are a means of lim

iting RF leakage by controlling both the output

voltage and repetition rate when the output is not

loaded. Both modes are fixed outputs, meaning

the power setting has no influence on the output

voltage. The resistor ladder (R24, RA4, R17,

& R19) sets the limits for both the target and

booster modes. Target has 1032 pulses with a

peak voltage of approximately 1800Vpk, and then

the booster is switched in. The booster mode has

32 pulses with a peak voltage of 6000Vpk and

these pulses are used to ionize the argon gas to

assist with initiation. When a load is not detected

during the booster pulses, then the target/booster

cycle is repeated until a load is sensed. The volt

age level of each mode is selected by U4 with

BM_TAR for target and BM_BST for booster.

These two signals should toggle on and off when

ABC™ is activated without a load on the output.

When a load is sensed, SE_P

CON is set and now

the power setting determines the pulse width and

the logic reduces the repetition rate from 60uS to

35uS. Output power is controlled by pulse width

and the pulse width controller is U5 and Q2. For

the start of each cycle of ABC™, Q2 is turned off

and this allows C10 to charge linearly. When the

charge of C10 exceeds the P

CON voltage on U5-3,

the output of U5 switches high and terminates the

pulse time.

Now is a good time to bring up Spray. Spray

Coagulation and ABC™ are quite similar, only

Spray is lower power and does not have the target

modes. The output power in spray is controlled

by HVDC, and the pulse width in spray is fixed

at about 1.3uS. Calibration of Spray is performed

by adjusting RA3, which simply scales P

down for a pulse width that will correct the out

CON

-

put power to match the dial setting.

6.4 High Voltage Power Supply [A7]

The High Voltage Power Supply (HVPS) provides variable regulated DC voltage and current

to the RF amplifiers which converts this energy

into high frequency surgical current. The HVPS

is contained on two separate circuit board assem

blies.

The High Voltage output assembly contains the

-

power devices and capacitive filters which provide

the high voltage output. The HV/Flow Control

assembly generates the control signals required

to regulate the high voltage output and performs

other high voltage related tasks. This section will

be specific to the high voltage assembly and the

control circuit for the high voltage will follow.

6.4.1 Power Supply Topology

The HVPS is a phase controlled type power sup

ply. With this topology, output voltage is con

trolled by varying the phase angle at which the

AC mains sinusoidal waveform is permitted to

conduct. Typically, a triac or SCR in series with

the incoming AC line is off during the rise of the

mains sinusoidal waveform. Following the peak

of the waveform, a trigger is asserted at the gate

allowing the triac or SCR to turn on and the

line voltage present at the triggered phase angle

is available to charge filter capacitors commonly

used with these topologies. The phase angle trig

gering sequence occurs for each subsequent half

cycle of the sinusoidal waveform.

6.4.2 Phase Control Output

Referring to the High Voltage Output schematic

(Figure C-12), the line isolated AC voltage enters

the printed circuit assembly at J1-1 (AC Hi), J1-3

-

-

-

-

6-9

(AC Lo), and J1-4 (AC Com). We should note

that these AC signals are isolated from AC Mains

by means of an isolation transformer located in

the generator assembly. The AC signals are trans

former taps with AC Lo rated for 125V and AC

Hi rated for 185V with a nominal voltage input.

Referring once again to the schematic, Q3 & Q7

are triacs that are triggered by opto couplers U1

or U4 when the HVPS is enabled. Q3 is selected

when Spray, Pinpoint or ABC™ modes are acti

vated and Q7 is selected for Pure Cut, Blend, and

Bipolar modes. The resistor and capacitor that

are connected from MT2 & MT1 are snubbers for

switching energy and the remaining discrete com

ponents contribute to the generation of the trigger

pulse. The trigger pulse from the opto couplers

(U1 & U4) occurs at phase angles of approxi

mately 80° to 170° of the AC waveform.

Following the triacs are two separate bridge recti

fiers (B1 & B2). The rectified signal from the

bridges is then filtered by C13 & C14 which

results in a DC voltage. Resistor R18 is a bleed

resistor that will dissipate the energy from the

filter capacitors. The schematic shows two test

points (TP1 & TP2) that are labeled +HV and

-HV. The voltage on these two test points is the

regulated DC and is referred to as HVDC.

Connecting an oscilloscope to the +HV and -HV

test points would show a voltage with 120 Hz

ripple, and the magnitude of the ripple depends

on the load. A heavy load on the output means a

high ripple rate on the HVDC test points. These

test points have easy access and are a good place

to connect a DVM when troubleshooting a system

that does not have any RF Output. A system

failure detected by the monitor microcontroller

and some hardware circuits will typically inhibit

the HVDC as a means of shutting down the RF

output.

The high voltage triacs (U1 & U4) of this assem

bly are only enabled when the system is activated

for RF output, otherwise the voltage at TP1 &

TP2 is an idle voltage of 10V. Referring on the

schematic to TP1, a 33 ohm resistor and a fuse are

shown in series with a

sistor is switched on following each RF deactiva

tion to dump the charge from the filter capacitors

(C13 & C14) and bring the HVDC back to, or

near, idle voltage.

The fuse would be the weak link of this power

supply. Each time an activation request is termi

MOSFET, Q8. This tran-

-

-

-

-

-

-

-

-

nated, the voltage on HVDC is dumped through

this fuse. If the fuse opens up, then the only

means of discharging the HVDC is through the

bleed resistor R18.

6.4.3 HVPS Isolation Components

Digressing momentarily, this assembly has three

optically isolated triac drivers, one opto coupler,

and two isolation “sense” transformers. These

components isolate the High Voltage Output cir

cuit from the High Voltage Control circuit. The

System 7500™ has two intermediate circuits that

are both isolated from ground (chassis ground)

and both are also isolated from each other. When

using a voltmeter or oscilloscope on these cir

cuits, it is imperative that the ground reference be

connected to “-HV” of this circuit or the signal

ground of the control or low voltage circuit. The

signal grounds of the control circuit are not com

mon to the -HV ground of this circuit.

The triacs are fired when the cathode of the triac

drivers are pulled to signal ground. The diode of

these drivers is common with, and controlled by,

the HV Control circuit. A short pulse of current

through the diode of the triac driver switches on

the gate of the triac at a phase angle that is greater

than 80°. The triac will remain on until the AC

signal is at approximately zero volts.

The optocoupler (U5) is controlled by the HV

Control Circuit and it switches on Q8 when the

cathode of the diode is pulled low. When U5 is

energized, the emitter goes high which switches

on Q9; switches off Q10; allowing approximately

14V to switch on the gate of Q8. Pulling the

cathode of U5 back high switches off U5, allow

ing Q9 to be switched off and Q10 to pull the

charge from the gate of Q8 and switch it off.

Following each RF activation (system is unkeyed),

Q8 is switched on for approximately 100mS to

allow R33 to dissipate the energy stored in the

filter capacitors.

The two sense transformers (T1 & T2) transfer a

proportional ratio of the HVDC across the isola

tion barrier to the HV Control circuit. T1 pro

vides what is called the HV sense for control and

T2 provides the HV sense for monitoring. Both

circuits and transformers are the same and the

ratio of voltage transferred is the same. The pur

pose for the monitoring circuit is a means of veri

fying the controlling circuit is operating properly.

-

-

-

-

-

-

-

-

6-10

6.4.4 HVPS Low Voltage Components

The NPN transistor, Q6, provides the supply

voltage for the low voltage components on this

assembly. The voltage source for Q6 is the AC

LO, where R26 limits the current and the zener

diode (12V) sets the voltage on the cathode of

D6 at about 10V. This 10V is used to provide

the supply voltage to U3 & U2 of this assembly.

The monitoring circuit will test for this 10V, and

should a failure occur where this voltage is too

high or too low, the system activation will be ter

-

minated.

The sense transformers are driven at about 40

KHz by U3 & U2 with the outputs Q and /Q

out of phase by 180°. The sense transformers are

set up for a center tapped push-pull drive signal.

When the top transistors (Q1 & Q5) are ON,

they pull current from the center tap to ground

which produces a signal on the secondary. The

top transistors then switch OFF and the lower

transistors (Q4 & Q2) switch ON, reversing the

current through the primary and reversing the

polarity on the output.

6.5 HV/Flow Control Assembly [A1]

The HV/FLOW Control assembly provides two

unrelated unit functions. High Voltage Power

Supply (HVPS) control and Argon Flow manage

ment circuits are both on this assembly. The sche

matics (Figures C-4a and C-4b) for this assembly

are on two pages with the high voltage control

schematic and the argon flow control schematic

on separate sheets for clarity.

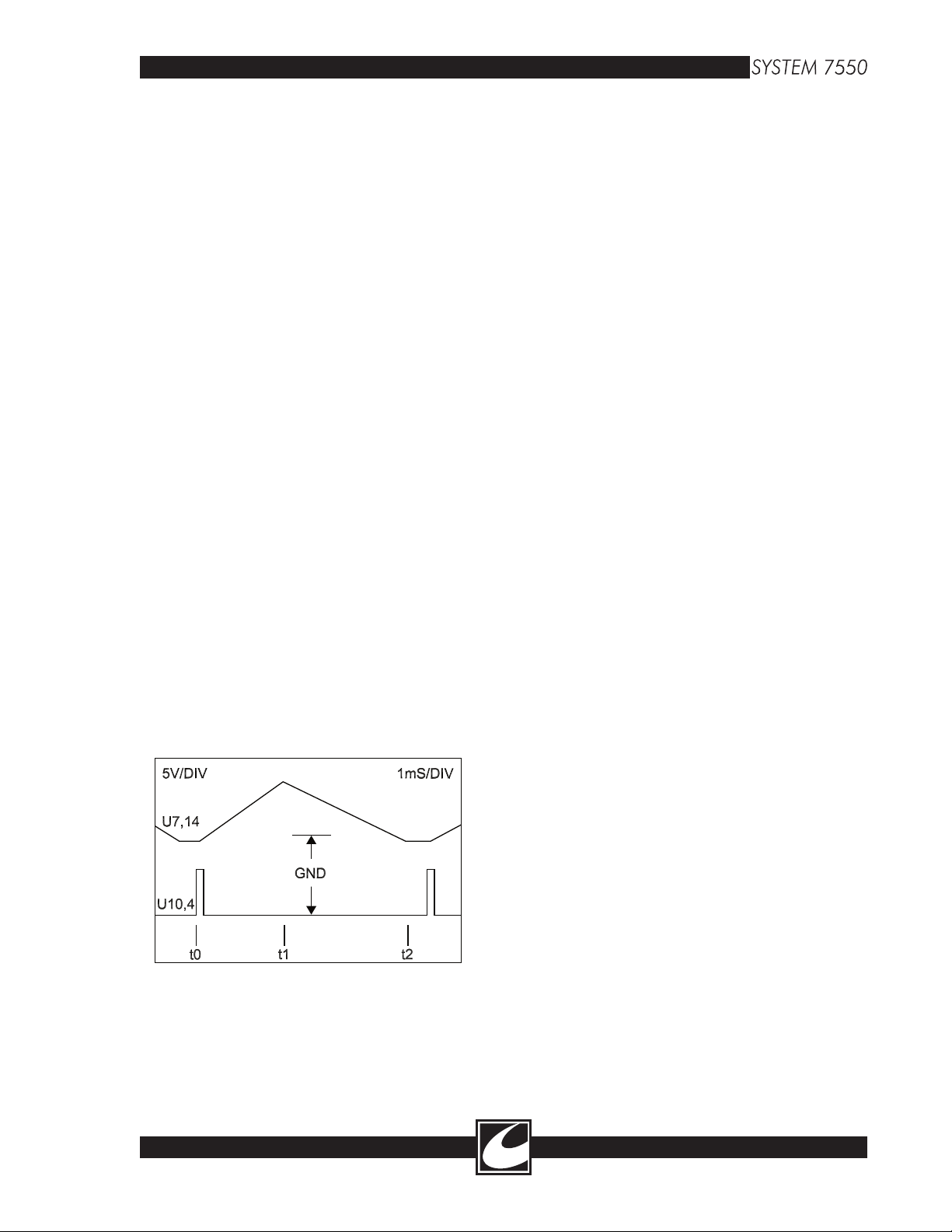

Figure 6.2 Line Sync/RAM

The HVPS that is controlled by this circuit has a

variable DC voltage (HVDC) that is dependent

on the dial setting and the load. Power regulation

of the System 7500™ is accomplished by control

ling the HVDC where each power setting results

-

in a specific DC voltage at light loads (R

L>1K

ohms), and then the DC voltage will be reduced

for heavier loads (R

L<1K ohms) for power regu-

lation. The HVPS & HV Control circuit make

up a control loop, and a control circuit loop by

nature feeds on itself such that one action in the

loop results in another action, which results in

another action, etc.

6.5.1 Line Synchronization Circuit

For this section, refer to Figure C-4a. The high

voltage power supply (HVPS) is phase controlled

and must be synchronized with the AC line volt

age. The synchronization is accomplished by the

zero crossing detector (U5-7) that is driven by

F_LN (J3-13), a replica of the AC Line Voltage

which comes from the low voltage line transform

er secondary. The sine wave of F_LN is converted

to a square wave at U5-7 and this results in a

50µS pulse at U10-4.

The lower trace of Figure 6.2 shows the 50µS

trigger pulse that is synchronized with zero cross

ing. The upper trace represents a ramping wave

-

form that is ultimately used to initiate the HVPS

triac trigger. The generation of the “cyclic ramp”

waveform is accomplished with a circuit loop.

The components of the loop will be covered in the

-

-

next few paragraphs.

To provide a simple description of this circuit, we

will start at the voltage divider with the switch, S1

(RA7, R66, R67, & R68). The switch (S1) is set

for either 50Hz or 60Hz operation. To the right

of S1 is a precision clamp (U7B & U7C) with

diodes on the outputs. The outputs of the preci

sion clamps, if viewed with an oscilloscope, are a

square wave with a rate of “Line Frequency x 2”

or 120Hz when the line frequency is 60 Hz.

A precision clamp will control the anode of the

output diode to the lowest voltage on the two

inputs. With 0V on the inverting (-) input, the

anode of the output diode will be 0V and when

the inverting input switches high (5V), then the

anodes of the output diodes have the same voltage

as S1-C (3V @ 60 Hz or 2.5V @ 50 Hz).

Following the precision clamp is a differential

amplifier (U7A) with a gain of .9 on the noninverting input (U7-3), and unity gain on the

inverting input (U7-2). The differential amplifier

controls the direction of charge on the RAMP so

that when the output of the differential amplifier

is positive (3.2V), the RAMP discharges or ramps

6-11

Loading...

Loading...