Operator’s Manual

TM

E L E C T R O S U R G I C A L U N I T

LIMITED WARRANTY

For a period of two years following the date of delivery,

CONMED Corporation warrants the CONMED System

5000™ Electrosurgical Generator against any defects in

material or workmanship and will repair or replace (at

CONMED’s option) the same without charge, provided

that routine maintenance as specified in this manual has

been performed using replacement parts approved by

CONMED. This warranty is void if the product is used in

a manner or for purposes other than intended.

© 2007 CONMED Corporation

525 French Road

Utica, New York 13502 U.S.A.

U.S. Patent Nos. 4,961,739 - 5,152,762 - 5,626,575-

6,830,569 - 6,835,082 - 6,875,210 - 6,939,347 -

D477,082 - D477,408.

For Technical Service or Return Authorization Phone:

303-699-7600 / 1-800-552-0138 Extension 5274

Fax 303-699-1628

For Customer Service or to order parts phone:

1-800-448-6506 / 315-797-8375 / Fax 315-735-6235

or contact your CONMED Representative.

European Authorized Representative

MDSS GmbH

Schiffgraben 41

D - 30175 Hannover

Germany

The revision level of this manual is specified by the

highest revision letter found on either the inside front cover

or enclosed errata pages (if any).

Manual Number 60-8016-ENG Rev. N 11/07

Unit Serial Number_________________________________

TM

Table of Contents

& List of Illustrations

Section Title Page

1.0 General Information .........................................................................1-1

1.1 Cautions ...................................................................................................... 1-1

1.1.1 Cautions For Equipment Preparation ................................................................................1-2

1.1.2 Cautions For Patient Preparation .......................................................................................

1.1.3 Cautions For Use ..............................................................................................................

1.1.4 Cautions For Testing or Servicing .....................................................................................1-5

1.1.5 Electromagnetic Compatibility ..........................................................................................

1.1.5.1 EN/IEC 60601-1-2 Table 201 ...........................................................................................

1.1.5.2 EN/IEC 60601-1-2 Table 202 ...........................................................................................

1.1.5.3 EN/IEC 60601-1-2 Table 204 ...........................................................................................

1.1.5.4 EN/IEC 60601-1-2 Table 206 ...........................................................................................

1.2 Specifications .............................................................................................. 1-9

1.2.1 Mains Overcurrent Protection ...........................................................................................1-9

1.2.2 Mains Frequency Leakage .................................................................................................1-9

1.2.3 Regulatory Compliance ...................................................................................................

1.2.4 Operation ........................................................................................................................

1.2.5 Power Display Accuracy ..................................................................................................

1.2.6 Line Regulation ..............................................................................................................1-10

1.2.7 Environmental .................................................................................................................

1.2.8 Contact Quality Monitor .................................................................................................

1.2.9 Audio Specifications ........................................................................................................

1.2.10 Other Specifications ........................................................................................................

1.2.11 Operating Modes and Nominal Output Parameters .........................................................1-11

1.3 Explanation of Symbols ............................................................................. 1-12

1.3.1 Control Panel ..................................................................................................................1-12

1.3.2 Interior ............................................................................................................................

1.3.3 Output/Control Panel ......................................................................................................1-12

1.3.4 Rear Panel .......................................................................................................................1-13

1.4 Output Characteristic Curves .................................................................... 1-14

2.0 Installation and Operation ................................................................ 2-1

2.1 Initial Inspection ......................................................................................... 2-1

2.2 Installation .................................................................................................. 2-1

2.2.1 Installation Of Fuses .........................................................................................................2-1

2.3 Preliminary Checks .....................................................................................2-1

2.3.1 Preliminary Functional Testing ..........................................................................................2-1

2.3.2 Preliminary Performance Testing ......................................................................................

2.4 Controls, Displays and Connectors .............................................................2-3

2.4.1 Control Panel ....................................................................................................................2-3

2.4.2 Output Panel .....................................................................................................................

2.4.3 Rear Panel .........................................................................................................................

2.5 Set Up For Use ........................................................................................... 2-7

2.6 Oper

2.6.1 General ...........................................................................................................................2-10

2.6.2 Monopolar Pulse Cut ......................................................................................................2-10

ation .................................................................................................. 2-10

1-2

1-4

1-6

1-6

1-7

1-8

1-9

1-10

1-10

1-10

1-10

1-10

1-10

1-11

1-12

2-3

2-5

2-6

Section Title Page

2.6.3 Monopolar Pulse Coag ....................................................................................................2-11

2.6.4 Fluids Specialty Mode .....................................................................................................

2.6.5 Lap Specialty Mode .........................................................................................................

2.6.6 Programming ..................................................................................................................

2.6.6.1 Storing Programs ............................................................................................................

2.6.6.2 Using Programs ..............................................................................................................

2.6.7 Remote Power Control

2.6.7.1 Changing Monopolar Power Remotely ...........................................................................

..................................................................................................2-11

2-11

2-11

2-11

2-11

2-11

2-12

2.7 User Maintenance ..................................................................................... 2-12

2.7.1 General Maintenance Information ................................................................................... 2-12

2.7.2 Cleaning ..........................................................................................................................

2.7.3 Periodic Inspection ..........................................................................................................

2.7.4 Periodic Performance Testing ..........................................................................................

2-12

2-12

2-12

2.8 In Case of Difficulty .................................................................................. 2-12

2.8.1 Dispersive Electrode Alarm .............................................................................................2-12

2.8.1.1 Single Dispersive Electrode Alarm ...................................................................................

2.8.1.2 Dual Dispersive Electrode Alarm ....................................................................................

2.8.2 Acc Codes .......................................................................................................................

2.8.3 Err Codes ........................................................................................................................

2.8.4 If All Else Fails ................................................................................................................

2-12

2-13

2-13

2-13

2-13

2.9 Environmental Protection .........................................................................2-13

Figure/Title Page

Figure 1.1 Output Power vs. Power Setting ........................................................................................1-14

Figure 1.2 Display vs. Open Circuit Peak Voltage ...............................................................................

Figure 1.3 Load Regulation, Monopolar Pure Cut .............................................................................

Figure 1.4 Load Regulation, Monopolar Blend 1 ...............................................................................

Figure 1.5 Load Regulation, Monopolar Blend 2 ...............................................................................

Figure 1.6 Load Regulation, Monopolar Blend 3 ...............................................................................

Figure 1.7 Load Regulation, Monopolar Pinpoint Coag .....................................................................

Figure 1.8 Load Regulation, Monopolar Standard Coag ....................................................................

Figure 1.9 Load Regulation, Monopolar Spray Coag .........................................................................

Figure 1.10 Load Regulation, Bipolar Micro ......................................................................................

Figure 1.11 Load Regulation, Bipolar Macro .....................................................................................

Figure 1.12 Load Regulation, Lap Spray ............................................................................................

Figure 1.13 Load Regulation, Lap Standard .......................................................................................

Figure 2.1 Control Panel .......................................................................................................................

Figure 2.2 Output Panel .......................................................................................................................

Figure 2.3 Rear Panel ...........................................................................................................................

Figure 2.4 Accessory Schematics .........................................................................................................

Figure 2.5 Accessory Connections ......................................................................................................

1-14

1-15

1-15

1-16

1-16

1-17

1-17

1-18

1-18

1-19

1-19

1-20

2-4

2-6

2-7

2-14

2-14

TM

General Information

Section 1.0

This manual provides the set up and operating

instructions for the System 5000™ Electrosurgical

Unit (ESU). Electrosurgery can be dangerous

to patients, staff and other equipment if mis

used. Please understand and follow the warnings

and cautions that are included in this manual.

Technical specifications, performance characteristic

curves and user maintenance instructions are also

included.

The System 5000™ provides a broad range

of capabilities in a single, general-purpose

electrosurgical generator. This rugged ESU fulfills

the operational and safety needs of the modern

operating room by providing:

• Four monopolar cutting modes: Pure, Blend

1, Blend 2 and Blend 3.

• Three monopolar coagulation modes: Spray,

Standard and Pinpoint.

• Two bipolar modes: Micro and Macro

• Two specialty modes and a general surgery

mode:

• General Mode provides full power perfor

mance for open surgical procedures.

• Fluids Specialty Mode provides immediate

energy delivery for procedures performed

in a fluid medium.

• Laparoscopic Specialty Mode provides

optimal safety by limiting output voltage

and minimizing the potential harmful

effects of capacitive coupling.

• Pulse Cut Mode provides precise modulated

energy delivery for critical dissection.

• Pulse Coagulation Mode provides a modulated

waveform for unsurpassed precision and con

trol.

• Radio Frequency (RF) isolated and indepen

dent outputs.

• The proven Automatic Return Monitor

(A.R.M.™) contact quality monitoring system.

• Continuous microprocessor safety monitoring.

-

-

-

-

Features include:

• Dynamic Response Technology delivers opti

mal clinical effects in all operational modes

through the continuous synchronization of

current and voltage.

• Bipolar Output Meter provides visual and

audible feedback to surgeon during tubal liga

tions, vasectomies, and other procedures.

• ReadiPlug™ universal accessory receptacle

eliminates the need for foot-controlled adapters.

• Nine programmable memory settings provide

set-up convenience.

• Automatic programming restores the ESU to

the last settings used.

• Remote Power Control (PC) allows power set

ting changes using standard hand-controlled

pencils.

• Independent power setting available for all

modes.

• Ability to change power settings from the con

trol panel while the ESU is activated.

• Two handswitched receptacles and a separate

footswitched receptacle enable multiple acces

sory connections.

• Simultaneous activation in non-contact

monopolar coagulation modes.

• Channeled accessory receptacles direct plugs

into position, making attachments less cum

bersome.

• Illuminated receptacles for greater visibility.

• Integrated operating room control system

capability.

• Integrated interface for activation of smoke

evacuators and similar devices.

-

-

1.1 Cautions

This equipment, in conjunction with connected

accessories, is intended to produce high-frequency

electrical energy for the controlled destruction of

tissue.

-

-

-

-

1-1

Safe and effective electrosurgery is dependent not

only on equipment design, but also on factors

under the control of the operator. It is important

that the instructions supplied with this equipment

be read, understood and followed in order to

ensure safe and effective use of the equipment.

1.1.1 Cautions For Equipment Preparation

• Use only accessories that comply with the rel

evant regulatory standards for your location

and meet the requirements of Section 1.2,

Section 1.4, and Figure 2.4. Use of other

accessories may result in increased emissions

or decreased immunity of the ESU.

• Reusable accessory cables should be periodically function and safety tested in accordance

with the original manufacturer’s instructions.

• Visually inspect all accessories before each use

to verify the integrity of insulation and the

absence of obvious defects. In particular, elec

trode cables and endoscopic accessories should

be checked for damage to the insulation.

• The System 5000™ is equipped to connect

three monopolar accessories at one time for

the convenience of the surgical staff. Unused

accessories should be stowed in a safe, electri

cally insulated place such as a non-conductive

holster, isolated from the patient. CONMED

recommends accessories not be connected

unless needed.

• Never connect more than one accessory at

a time to any one receptacle, not including

the dispersive electrode receptacle when the

appropriate CONMED adapter is used.

• Use only a hospital grade, 3-prong, power

cord rated to meet the specifications in

Section 1.2 and all of the requirements for

safe grounding of the ESU. The user should

verify that the power receptacle with which

this ESU is used is properly grounded, cor

rectly polarized and of the proper frequency

per Section 1.2. Do not use ground cheater

plugs or extension cords.

• Do not place liquid containers on top of

the ESU. Wipe spilled liquids off the ESU

immediately. To preclude inadvertent entry of

liquids, do not operate this ESU except in its

normal position.

• Do not stack other devices or equipment on

top of or adjacent to the System 5000™.

The CONMED Stacking Adapter (Cat. No.

-

-

60-8030-001) allows two System 2500™ or

System 5000™ units to be stacked in a safe

manner.

• Confirm all accessories are properly connected

to the appropriate receptacles before powering

the ESU.

• Potentially hazardous conditions may exist

when accessories of similar connector types

are combined. Be certain accessories are

appropriate for the type of generator output

used. Use only CONMED Electrosurgery

footswitches. Confirm bipolar leads are

connected only to the bipolar receptacles.

Connecting bipolar accessories to monopolar

outputs may result in patient injury.

• Do not reuse disposable (single use) accesso

ries.

• Do not use cords as handles as damage to the

-

-

insulation and increased risk of burns or other

injury may result.

• A failure in the ESU could cause an unintend

ed increase in output power. Verify that the

ESU is functioning correctly prior to use.

• Prior to use, verify that devices connected

to the Activation Relay Connector function

properly in a manner that is synchronized

with ESU power delivery.

• Equipment connected to the Serial Interface

Connector must be approved by CONMED

and must be connected in accordance with

instructions accompanying the equipment.

Verify proper operation prior to ESU use.

1.1.2 Cautions For Patient Preparation

• Electrosurgery should NEVER be performed

in the presence of flammable anesthetics,

flammable prep solutions or drapes, oxidiz

ing gases such as Nitrous Oxide (N

oxygen-enriched environments. The risk of

igniting flammable gases or other materials is

inherent in electrosurgery and cannot be elim

inated by device design. Precautions must

be taken to restrict flammable materials and

substances from the electrosurgical site. They

may be present in the form of an anesthetic,

life support, skin preparation agent, produced

by natural processes within body cavities or

originate in surgical drapes, tracheal tubes or

other materials. There is a risk of pooling

of flammable solutions in body depressions

such as the umbilicus and in body cavities,

O) or in

2

-

-

-

-

1-2

such as the vagina. Any fluid pooled in these

areas should be removed before the high fre

quency surgical equipment is used. Due to

the danger of ignition of endogenous gases,

the bowel should be purged and filled with

nonflammable gas prior to abdominal surgery.

To avoid the risk of tracheal fires, never use

electrosurgery to enter the trachea during tra

cheotomy procedures.

• The System 5000™ mobile pedestal is made of

nonconductive plastic, that can hold a static

charge. It should not be used in a flammable

environment, as described above.

• Only non-flammable agents should be used for

cleaning and disinfection wherever possible.

• Exercise care when relocating the ESU to

avoid electrostatic charge buildup in the pres

ence of flammable materials, as there is a risk

of igniting these materials if a spark should

occur.

• This ESU is equipped with the Automatic

Return Monitor (A.R.M.™), which monitors

the quality of the dispersive electrode con

nection. When a correctly functioning single

dispersive electrode is connected to the ESU,

A.R.M.™ verifies the connections between the

ESU, the dispersive electrode cable and the

dispersive electrode. It DOES NOT verify

that a single dispersive electrode is in contact

with the patient. When using a dual disper

sive electrode, A.R.M.™ confirms the total

resistance is within the preset safety range.

Proper application and visual inspection of the

dispersive electrode is required for safe opera

tion.

• The use and proper placement of a dispersive

electrode is a key element in safe and effec

tive electrosurgery. Follow manufacturer’s

directions and recommended practices for the

preparation, placement, use, surveillance and

removal of any dispersive electrode supplied

for use with this electrosurgical unit.

• Apply the dispersive electrode over a well-vas

cularized muscle mass that is thoroughly clean

and dry. Clean and clip site, as necessary, to

provide adequate electrical connection and per

hospital policy. Avoid placement over scar tis

sue, bony prominences or other areas where

pressure points on small areas might develop.

• Because of the risk of burns, needles should

never be used as a dispersive electrode for

-

-

-

-

-

-

-

-

electrosurgery. The entire area of the disper

sive electrode should be placed so that the

entire conductive area is in firm contact with

an area of the patient’s body that has a good

blood supply and is as close to the operative

site as possible. In general, electrosurgical

current paths should be as short as possible

and should run either longitudinally or in a

diagonal direction to the body, not laterally

and under no circumstances lateral to the tho

rax.

• Dispersive electrodes and probes of monitor

ing, stimulating and imaging devices can

provide paths for high frequency currents

even if they are battery powered, insulated

or isolated at 50/60 Hz. The risk of burns

can be reduced but not eliminated by placing

the probes as far away as possible from the

electrosurgical site and the dispersive elec

trode. Protective impedances incorporated

in the monitoring leads may further reduce

the risk of these burns. Needles should not

be used as monitoring electrodes during

electrosurgical procedures.

• When high frequency surgical equipment

and physiological monitoring equipment are

used simultaneously on the same patient, all

monitoring electrodes should be placed as far

as possible from the surgical site and disper

sive electrode. Needle monitoring electrodes

are not recommended. Monitoring systems

incorporating high frequency current limiting

devices are recommended whenever possible.

• The active electrode should not be used in the

vicinity of electrocardiograph electrodes.

• Heat applied by thermal blankets or other

sources is cumulative with the heat pro

duced at the dispersive electrode (caused by

electrosurgical currents). Choosing a disper

sive electrode site that is remote from other

heat sources may minimize risk of a patient

injury.

• Electrosurgery, by its nature produces signifi

cant levels of electromagnetic interference

(EMI) when the ESU is activated. This EMI

may damage or impair the function of other

-

electronic equipment in the operating room,

especially equipment that makes contact

with the patient. Adverse effects can only be

mitigated by use of equipment specifically

designed to tolerate electrosurgical interfer

-

-

-

-

-

-

-

-

-

1-3

ence. Cables subject to flexing should be

inspected frequently for shielding integrity.

• Other equipment in the operating room,

including portable or mobile communica

tions equipment, may produce EMI, which

can affect the function of the ESU. Adverse

effects can only be mitigated by use of equip

ment with EMI characteristics proven below

recognized limits. In the event of suspected

interference from other equipment, discon

tinue use of the ESU until the problem can be

remedied.

• The patient should not be allowed to come

into contact with metal items that are ground

ed or have an appreciable capacitance to earth.

Examples of this would be operating tables,

supports, etc.

• Jewelry and other metallic items can cause

localized burns if they make contact with

grounded items and should be removed from

the patient prior to use of electrosurgery.

• Skin to skin contacts, such as between the arm

and body of a patient or between the legs and

thighs, should be avoided by the insertion of

dry gauze.

• The use of electrosurgery on patients with

cardiac pacemakers, AICDs, neurostimulators

or other active implants is potentially hazard

ous. The implant may be irreparably dam

aged and/or the high frequency energy of the

electrosurgical output may interfere with the

function of the implant. Ventricular fibrilla

tion may occur. Precautions should be taken

to ensure the patient’s well-being is main

tained in the event of such interaction. The

manufacturers of the implants should be con

sulted for advice before operating on a patient

with an implant. These precautions also apply

to operating room personnel with similar

implants.

• To minimize the possibility of cardiac pace

maker interference, place the dispersive elec

trode such that the electrosurgical current

path does not intersect the path of the pace

maker or leads.

1.1.3 Cautions For Use

• Safe and effective electrosurgery is dependent

not only on equipment design, but also on

factors under the control of the operator. It

is important that the instructions supplied

-

-

with this equipment be read, understood and

followed in order to ensure safe and effective

use of the equipment. Only properly quali

fied and trained operators should perform

electrosurgery. The operator and their sup

port personnel must be diligent in assuring

-

-

-

-

-

-

-

-

-

-

that the ESU is properly configured and that

proper settings are used. The ESU must be

located to assure the operator or their support

personnel can readily verify the settings.

• PLEASE NOTE: Federal law (U.S.A.)

requires that all health care facilities must

report to the manufacturer of a medical

device, any death or serious injury or illness

to a patient related to the use of a medical

device. Serious injuries or illness involving

the use of a medical device must be reported

to the manufacturer of the device (or to the

FDA if the manufacturer of the device is not

known) within 10 working days of the inci

dent. Summary reports of such injuries must

also be submitted directly to the FDA twice

a year. Patient deaths related to the use of a

medical device must be reported to the manu

facturer and the FDA. For further informa

tion, please contact the Regulatory Affairs

Department of CONMED Electrosurgery at

800-552-0138, 303-699-7600 or FAX 303699-9854.

• Do not use monopolar electrosurgery on small

appendages, as in circumcision or finger sur

gery, as it can cause thrombosis and other

unintended injury to tissue proximal to the

surgical site. Should the surgeon decide that

the bipolar electrosurgical technique is accept

able for circumcision, do not apply the bipolar

electrosurgical current directly to circumcision

clamps.

• Apparent low power output or failure of the

electrosurgical equipment to provide the

expected effect at otherwise normal settings

may indicate faulty application of the disper

sive electrode, failure of an electrical lead or

excessive accumulation of tissue on the active

electrode. Do not increase power output

before checking for obvious defects or misap

plication of the dispersive electrode. Check

for effective contact of the dispersive electrode

to the patient anytime the patient is moved

after initial application of the dispersive elec

trode.

-

-

-

-

-

-

-

-

-

-

1-4

• Studies have shown that smoke generated during electrosurgical procedures may be harmful

to surgical personnel. These studies recom

mend using a surgical mask and adequate ven

tilation of the smoke using a surgical smoke

evacuator or other means.

• In the event that the system resets due to a

power interruption or low voltage, check the

contact of the dispersive electrode prior to

resuming electrosurgery.

• If a dispersive electrode or A.R.M.™ alarm is

sounded intraoperatively, physically confirm

proper dispersive electrode attachment to the

patient and confirm that the display falls with

in the set range. Smooth the dispersive elec

trode surface with hand to ensure electrode

contact to patient skin. Replace the dispersive

electrode if necessary.

• Simultaneous activation can be used in both

Standard and Spray monopolar coagulation

modes. Caution should be used as the output

from either active electrode may change as a

result of activation of a second output or end

ing activation of an output. Power sharing is

unlikely to be equal because of differences in

electrode to tissue distance and other factors.

This unequal power sharing can be enough

to stop power delivery to one electrode if the

second electrode is close to tissue and the first

electrode is somewhat above the tissue. The

motion or deactivation of one electrode can

cause the other electrode to start delivering

power when it had been too far away from

tissue to arc before the first electrode change.

Simultaneous activation can also increase

leakage currents, which can be hazardous to

the patient. It is recommended that a second

electrosurgical generator be used when it is

necessary to perform simultaneous operation.

• The cables to the surgical electrodes (active,

bipolar or dispersive electrodes) should be

positioned in such a way that contact with the

patient or other leads is avoided.

• Confirm the desired specialty mode is selected

prior to use to ensure output characteristics

are suitable for the intended procedure.

• Confirm the desired bipolar mode is selected

prior to use to ensure output characteristics

are suitable for the intended procedure.

-

-

• The output power selected should be as low

as possible and activation times should be as

short as possible for the intended purpose.

-

-

-

• The clinical use of electrosurgery is intermit

tent in nature. This ESU should not be acti

vated continuously for extended periods of

time.

• When uncertain of the proper setting for the

power level in a given procedure, start with a

low setting and increase as required.

• Confirm that Pulse Cut Mode is properly

selected prior to activation to ensure that

improper application does not result in

patient injury. Set the monopolar coag power

to 0 when using Pulse Cut to ensure that an

accidental activation of coag does not cause

patient injury. Listen for the distinct Pulse

Cut Activation Tone during activation to con

firm that Pulse Cut is indeed active.

• Observe all caution and warning symbols

printed on the ESU.

• The operating room staff should never contact

electrosurgical electrodes (either active or dis

persive) while the RF output of the ESU is

energized.

• The electrodes of recently activated accessories may be hot enough to burn the patient

or ignite surgical drapes or other flammable

material.

• Do not ignore unexpected tones. Check to

determine the cause of the tone, otherwise

injury can occur.

• Temporarily unused active electrodes should

be stored in an electrically insulated holster.

The unused active electrode should never

be placed on the patient. This is especially

important for laparoscopic procedures.

• Ensure that the footswitches are not inadver

tently depressed in order to prevent acces

sories from being unintentionally activated.

Place footswitches in locations that necessi

tate deliberate action in order to activate the

footswitch. Use caution when selecting the

correct footswitch to activate.

1.1.4 Cautions For Testing or Servicing

• Service should not be attempted without refer

ence to the System 5000™ service manual

(Catalog Number 60-8017-ENG).

-

-

-

-

-

-

-

-

1-5

• This electrosurgical unit should be tested by

a Hospital Qualified Biomedical Technician

on a periodic basis to ensure proper and safe

operation. It is recommended that examina

-

tion of the ESU be performed at least yearly.

• Refer all servicing to a Hospital Qualified

Biomedical Technician. Your CONMED sales

representative will be happy to assist you in

getting your equipment serviced.

• High voltages are developed within the ESU

that are accessible when the top cover is

removed. These voltages are potentially dan

gerous and should be treated with extreme

caution.

• The high voltage DC power supply in the

System 5000™ is equipped with a bleeder

resistor to dissipate the charge on the filter

capacitor. However, it takes several seconds

after power is removed to bleed that charge

down to a safe level. It is recommended that

at least thirty (30) seconds be allowed to

elapse before touching or attempting to per

form any maintenance involving the power

supply or power amplifier.

• Never remove or install any parts with the

power cord connected to AC mains.

• Avoid contact with the output leads when the

ESU is activated. Periodically inspect the

test leads used for the output connections for

obvious defects.

• Although this ESU will withstand momentary

short circuits on the output, prolonged short

circuits may damage the ESU. Short-circuit

ing the output should be avoided since it is

neither necessary nor desirable.

• Since the clinical use of electrosurgical units

is intermittent in nature with duty cycles on

the order of 10%, this ESU is not designed

to operate for extended periods of continu

ous output. When testing, it is recommended

that duty cycles be limited to 10 seconds

-

activation with delays of 30 seconds between

activations.

• Activating the System 5000™ in other than its

normal operating position impairs the heat

dissipation capability of the heat sink.

• Ensure that the two top cover screws are tight

ened and always perform a power-up check to

confirm a normal power-up sequence before

returning the ESU to service.

• Improperly connecting test equipment can

cause electric shock and destruction of equip

-

ment.

• Turn unit off and wait until storage capacitors

have discharged before connecting test equip

-

ment.

• Loss of power supply isolation can cause elec

trical shock. When servicing the high voltage

power supply, assume internal isolation is

compromised until verified otherwise.

1.1.5 Electromagnetic Compatibility

Following are guidance and manufacturer’s declarations regarding electromagnetic compatibility for the

System 5000™.

1.1.5.1 EN/IEC 60601-1-2 Table 201

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions

The System 5000™ Electrosurgical Unit is intended for use in the electromagnetic environment specified below. The

customer or the end user of the System 5000 Electrosurgical Unit should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/

Flicker emissions

IEC 61000-3-3

Group 2 The System 5000 Electrosurgical Unit must emit electromagnetic

energy in order to perform its intended function. Nearby elec

tronic equipment may be affected.

Class A The System 5000 Electrosurgical Unit is suitable for use in all

establishments, other than domestic establishments and those

Class A

Complies

directly connected to the public low-voltage power supply net

work that supplies buildings used for domestic purposes.

-

-

1-6

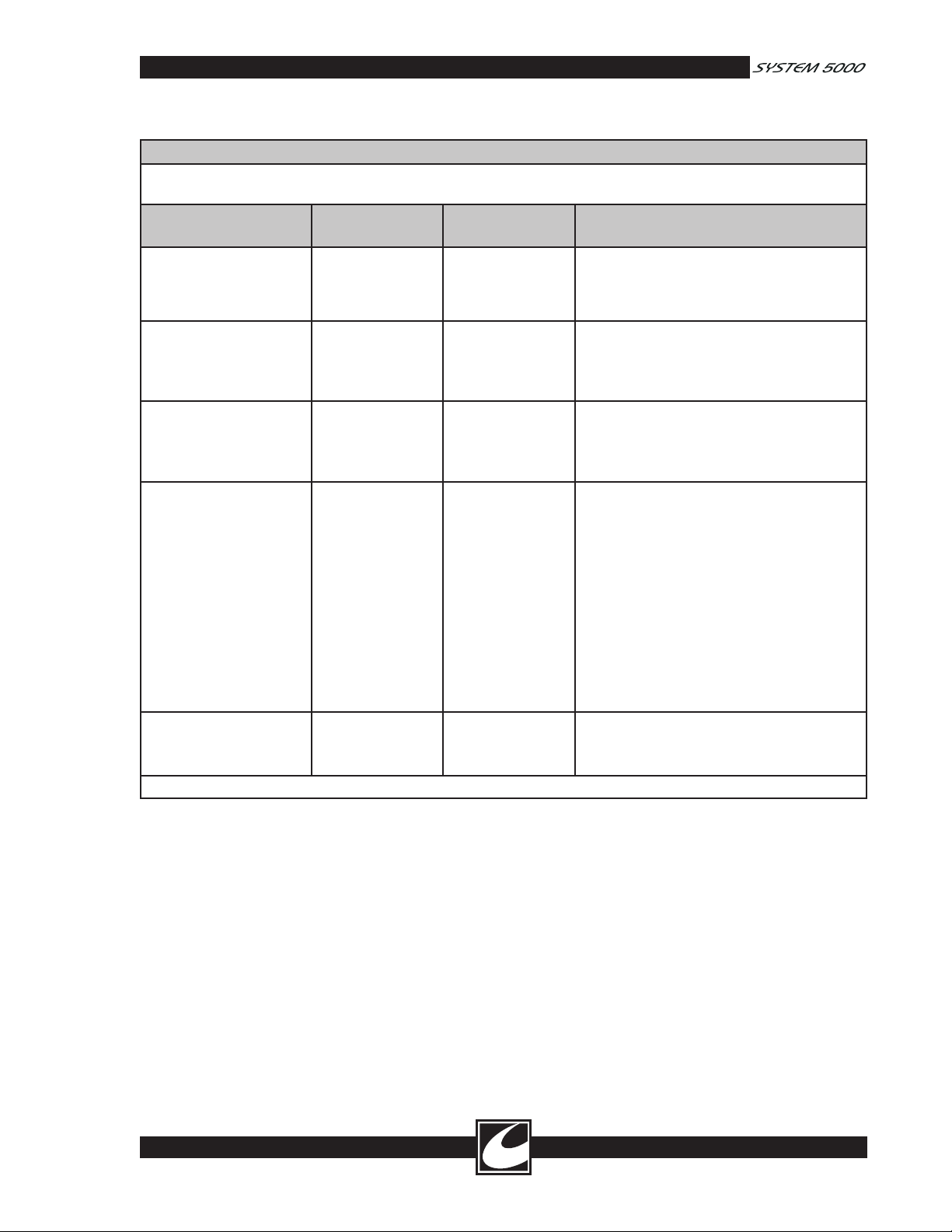

1.1.5.2 EN/IEC 60601-1-2 Table 202

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

The System 5000™ Electrosurgical Unit is intended for use in the electromagnetic environment specified below. The

customer or the end user of the System 5000 Electrosurgical Unit should assure that it is used in such an environment.

Immunity Test IEC60601 test

level

Electromagnetic discharge

(ESD)

IEC 61000-4-2

Electrical fast transient/

burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short inter

ruptions and voltage

variations on power sup

ply input lines

IEC 61000-4-11

Power frequency (50/60

Hz) magnetic field

IEC 61000-4-8

NOTE UT is the a.c. mains voltage prior to application of the test level.

±6 kV contact

±8 kV air

±2 kV for power

supply lines

±1 kV for input/

output lines

±1 kV differential

mode

±2 kV common

mode

-

<5 % UT

(>95 % dip in UT)

-

for 0.5 cycle

40 % UT

(60 % dip in UT)

for 5 cycles

70 % UT

(30 % dip in UT)

for 25 cycles

<5 % UT

(>95 % dip in UT)

for 5 sec

3 A/m 3 A/m Power frequency magnetic fields should be at

Compliance

level

±6 kV contact

±8 kV air

±2 kV for power

supply lines

±1 kV for input/

output lines

±1 kV differential

mode

±2 kV common

mode

<5 % UT

(>95 % dip in UT)

for 0.5 cycle

40 % UT

(60 % dip in UT)

for 5 cycles

70 % UT

(30 % dip in UT)

for 25 cycles

<5 % UT

(>95 % dip in UT)

for 5 sec

Electromagnetic environment -

guidance

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic mate

rial, the relative humidity should be at least

30%.

Mains power quality should be that of a typi

cal commercial or hospital environment.

Mains power quality should be that of a typical commercial or hospital environment.

Mains power quality should be that of a typi

cal commercial or hospital environment. If

the user of the System 5000 Electrosurgical

Unit requires continued operation during

power mains interruptions, it is recommended

that the System 5000 Electrosurgical Unit be

powered from an uninterruptible power sup

ply or a battery.

levels characteristic of a typical location in a

typical commercial or hospital environment.

-

-

-

-

1-7

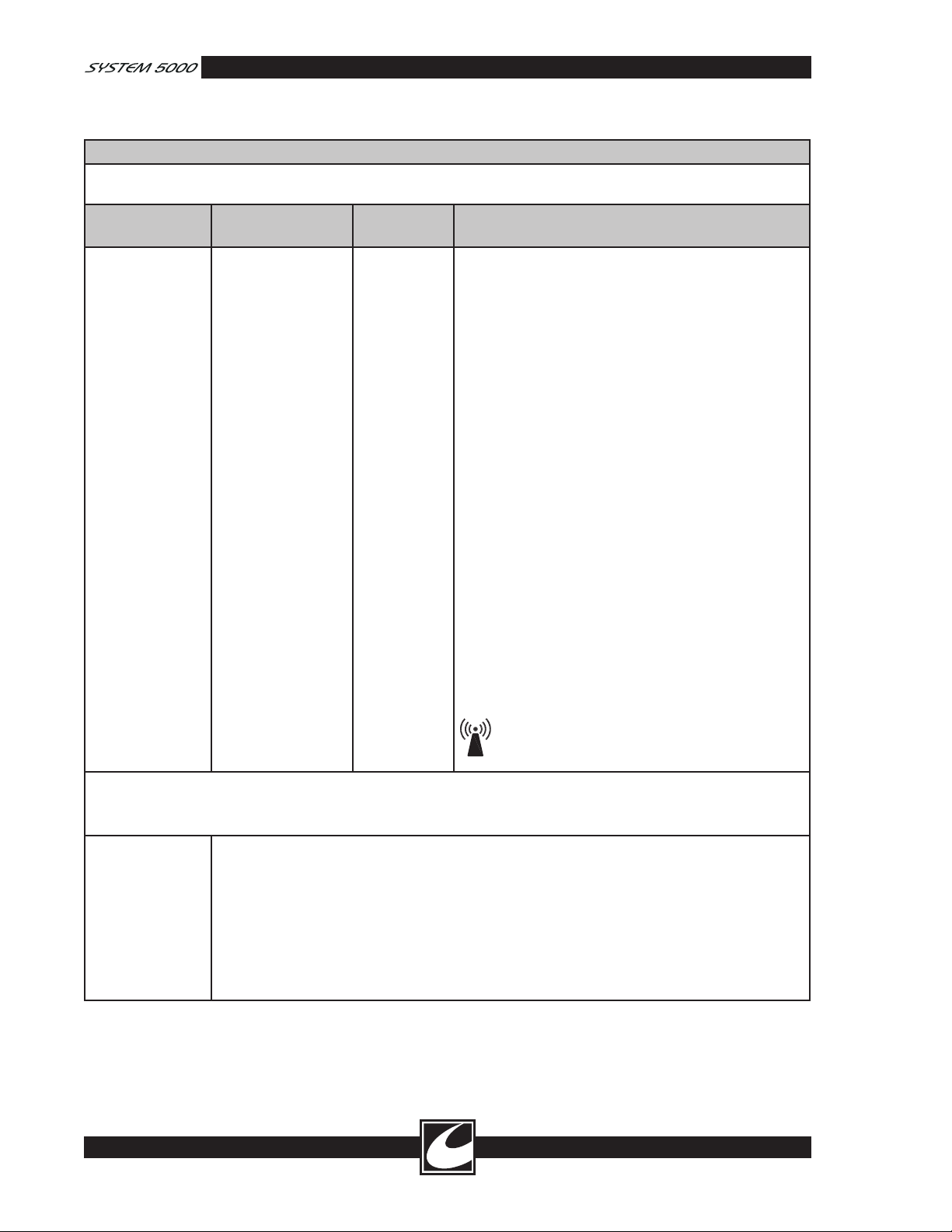

1.1.5.3 EN/IEC 60601-1-2 Table 204

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

The System 5000™ Electrosurgical Unit is intended for use in the electromagnetic environment specified below. The

customer or the end user of the System 5000 Electrosurgical Unit should assure that it is used in such an environment.

Immunity Test IEC60601 test

level

Compliance

level

Electromagnetic environment - guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the System

5000™ Electrosurgical Unit, including cables, than the

recommended separation distance calculated from the

equation applicable to the frequency of the transmitter.

Recommended separation distance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

a

b

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) tele

phones and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast

cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due

to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured

field strength in the location in which the System 5000™ Electrosurgical Unit is used exceeds the

applicable RF compliance level above, the System 5000™ Electrosurgical Unit should be observed

to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as reorienting or relocating the System 5000™ Electrosurgical Unit.

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than [v1] V/m.

3 Vrms

3 V/m

d = 1.2√P

d = 1.2√P 80 MHz to 800 MHz

d = 2.3√P 800 MHz to 2.5 GHz

where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and

tance in meters (m).

Field strengths from fixed RF transmitters, as determined

by an electromagnetic site survey,

compliance level in each frequency range.

Interference may occur in the vicinity of equipment

marked with the following symbol:

d is the recommended separation dis-

a

should be less than the

b

-

1-8

Loading...

Loading...