Concordia Coffee 99702 Service Manual

A

scent Brewer

Technician’s Manual

Concordia Beverage Systems

1287 120th Avenue NE

Bellevue, WA 98005

USA

(425) 453-2800

(800) 778-0990

(425) 453-2167 Fax

http://www.concordiacoffee.com/

Technical Writer: Shana McKibbin

Technical Support: Gery Jaggars, Chris Collier, Brad Butler

Graphic Engineer: Seth Cope

Software: Allen Moore

Edition: October, 2014

2900-331x2

Revision Change Log

Replace

Old

Section

4 4

With New

Section

Brief Description Date

Updates to content in

Software section

November,

2014

XXX

Revision

B

TableofContents

Section 1 :: Ascent Brewer Overview..............................................................................1-1

Ascent Brewer External Machine Overview........................................................1-2

Ascent Brewer External Machine Components.............................1-3

Ascent Brewer Internal Machine Overview – Front View....................................1-4

Ascent Brewer Internal Machine Components – Front.................1-5

Internal Machine Overview – Rear View.............................................................1-6

Internal Machine Components – Rear ..........................................1-7

Removing a Side Panel ......................................................................................1-8

Removing the Back Panel...................................................................................1-9

Removing the Top Panel ..................................................................................1-10

Removing the Front Panel................................................................................1-11

Section 2 :: Installation....................................................................................................2-1

Technical Specifications and Site Requirements................................................2-2

Dimensions....................................................................................2-3

Installation...........................................................................................................2-4

Plumbing........................................................................................2-4

Water Supply.................................................................................2-4

Problems with Reverse Osmosis Water System...........................2-4

Additional Tasks Required at Installation............................................................2-5

Power Up the Machine..................................................................2-5

Install Bean Hoppers.....................................................................2-5

Section 3 :: Electrical.......................................................................................................3-1

Electrical System Overview ................................................................................3-2

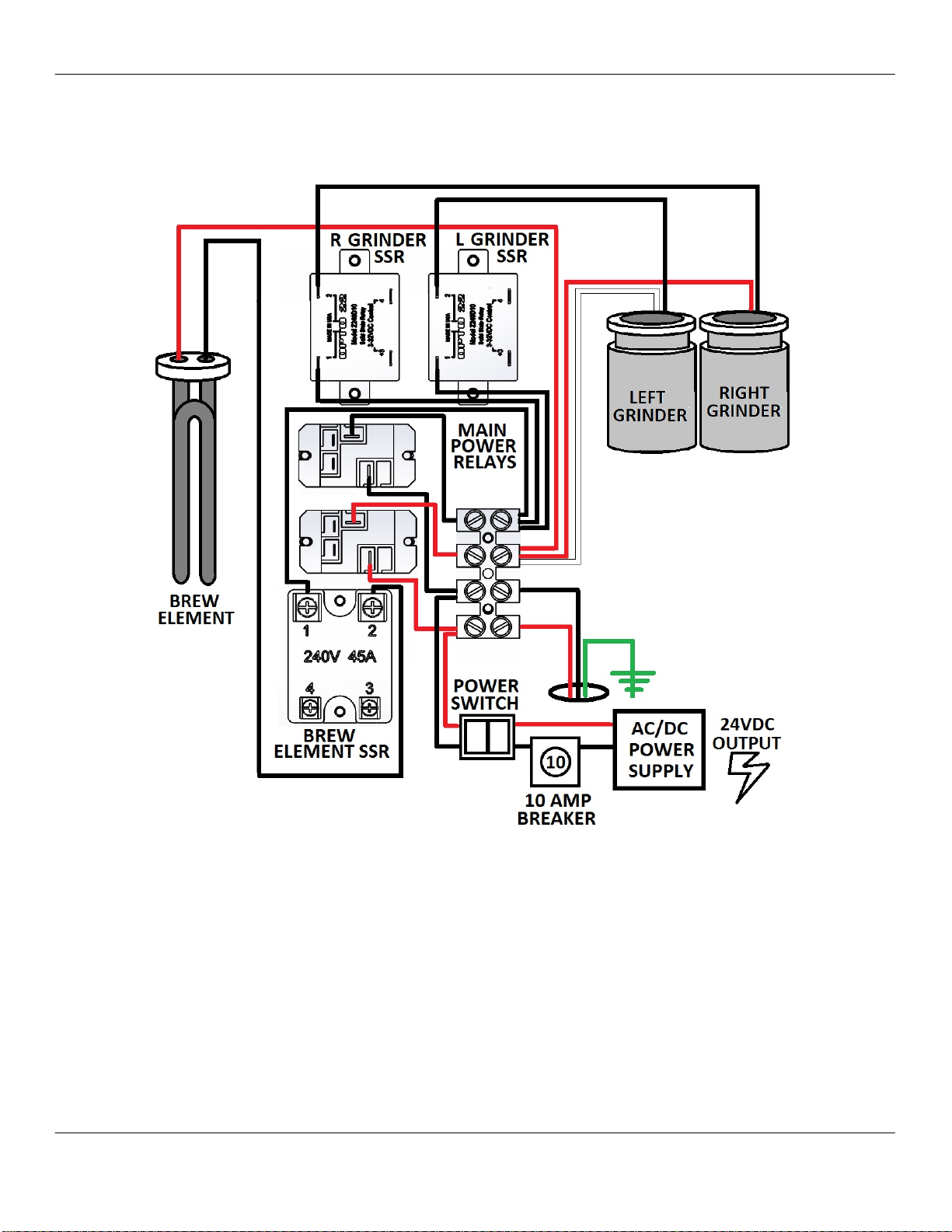

AC Block Diagram...............................................................................................3-3

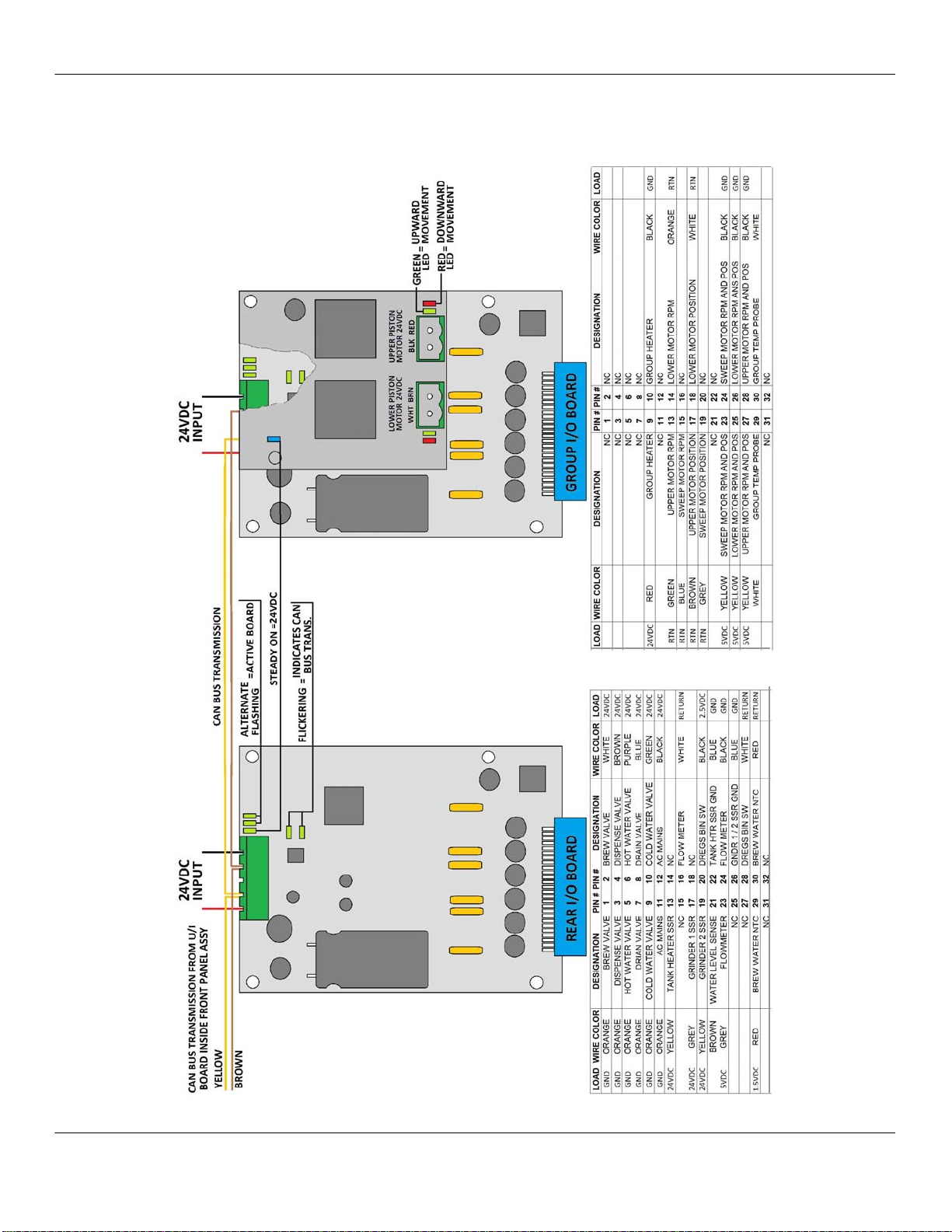

I/O Harness Board Diagram................................................................................3-4

DC Power Supply Diagram.................................................................................3-5

Section 4 :: Software.......................................................................................................4-1

Software Overview..............................................................................................4-2

Software Menu Categories............................................................4-2

Accessing the Software Menu.......................................................4-2

Accessing Different User Access Levels.......................................4-2

Resetting the User Access Level ..................................................4-2

Scrolling in the Menu.....................................................................4-3

Accessing a Sub-Category............................................................4-3

Changing a Value..........................................................................4-3

Exiting a Sub-Category .................................................................4-3

Exiting the Main Menu...................................................................4-3

Check Beverage Statistics ............................................................4-3

User Interface Test..............................................................................................4-4

Menu Shortcuts...................................................................................................4-4

Software Quick Reference Table........................................................................4-5

Updating Software...............................................................................................4-7

Installing or Updating Software.....................................................4-7

Calibration...........................................................................................................4-8

Coffee Extraction and Temperature Parameters ..........................4-8

Beverage Temperatures................................................................4-8

Section 5 :: Plumbing......................................................................................................5-1

The Water System ..............................................................................................5-2

Hydraulics Diagram.......................................................................5-2

Water Supply.......................................................................................................5-3

Line Pressure ................................................................................5-3

Water Inlet.....................................................................................5-3

Water Pump...................................................................................5-3

Removing the Water Pump Assembly ..........................................5-4

Flowmeter......................................................................................5-5

Removing the Flowmeter ..............................................................5-6

Pressure Regulator .......................................................................5-7

Removing the Pressure Regulator................................................5-7

Hot Water Tank Assembly ..................................................................................5-8

Level Probe ...................................................................................5-8

Heating Element............................................................................5-8

Hi Temperature Limit Switch.........................................................5-8

Pressure Relief Valve....................................................................5-8

Expansion Valve............................................................................5-9

Temperature Probe.......................................................................5-9

Removing the Hot Water Tank....................................................5-10

Water Valves.....................................................................................................5-12

Brew and Hot Water Valve Assembly.........................................5-12

Removing/Replacing a Valve......................................................5-13

Section 6 :: Coffee System .............................................................................................6-1

Coffee System Overview ....................................................................................6-2

Grinder Overview................................................................................................6-3

Upper and Lower Grinder Burrs....................................................6-4

Replacing Bean Grinder Burrs/Blades..........................................6-4

Grounds Chute..............................................................................6-4

Removing a Bean Grinder.............................................................6-5

Brew Group.........................................................................................................6-6

Brew Group Components..............................................................6-7

Removing the Brew Group............................................................6-8

Bean Hoppers...................................................................................................6-10

Filling a Bean Hopper..................................................................6-10

Removing a Bean Hopper...........................................................6-10

Inserting a Hopper Stopper.........................................................6-10

Replacing a Bean Hopper...........................................................6-10

Dispense Valve Assembly...........................................................6-11

Drain Valve Assembly.................................................................6-11

Section 7 :: Cleaning and Maintenance..........................................................................7-1

Machine Maintenance.........................................................................................7-2

Concordia Cleaning Products........................................................7-2

Cleaning Timer....................................................................................................7-2

Daily Cleaning Procedures .................................................................................7-3

Perform the Brew Clean Cycle......................................................7-3

Empty the Grounds Bin.................................................................7-4

Clean the Drain Grate and the Drain Tray ....................................7-4

Clean Exterior Surfaces ................................................................7-4

Clean the Product Nozzle..............................................................7-4

Refill Consumables .......................................................................7-4

Monthly Cleaning Procedure...............................................................................7-4

Clean the Bean Hoppers...............................................................7-4

Preventive Maintenance .....................................................................................7-5

PM Kits..........................................................................................7-5

Section 8 :: Messages.....................................................................................................8-1

Troubleshooting Display Messages....................................................................8-2

Section 9 :: Troubleshooting...........................................................................................9-1

Troubleshooting Quick Reference Guide............................................................9-2

Machine Failure.............................................................................9-2

Coffee System...............................................................................9-2

Section 10 :: Parts Lists & Diagrams ............................................................................10-1

Recommended Tools List.................................................................................10-2

Standard Tools............................................................................10-2

Parts Lists and Diagrams............................................................10-3

Diagram 1: Machine Overview....................................................10-4

Diagram 1, Parts List: Machine Overview...................................10-5

Diagram 2: Single Grinder Assembly..........................................10-6

Diagram 2, Parts List: Single Grinder Assembly.........................10-7

Diagram 3: Double Grinder Assembly.........................................10-8

Diagram 3, Parts List: Double Grinder Assembly........................10-9

Diagram 4: Group Upper and Lower Piston Assembly.............10-10

Diagram 4, Parts List: Group Upper and Lower Piston Assembly10-

11

Diagram 5: Water Pump Assembly...........................................10-12

Diagram 5, Parts List: Water Pump Assembly..........................10-13

Diagram 6: Hot Water Tank Assembly......................................10-14

Diagram 6, Parts List: Hot Water Tank Assembly.....................10-15

Diagram 7: Product Nozzle Assembly.......................................10-16

Diagram 7, Parts List: Product Nozzle Assembly......................10-17

Diagram 8: Front Panel Assembly ............................................10-18

Diagram 8, Parts List: Front Panel Assembly ...........................10-19

Diagram 9: Electrical Enclosure................................................10-20

Diagram 9, Parts List: Electrical Enclosure...............................10-21

Diagram 10: Upper Piston Assembly........................................10-22

Diagram 10, Parts List: Upper Piston Assembly.......................10-23

Diagram 11: Grinder Chute Assembly ......................................10-24

Diagram 11, Parts List: Grinder Chute Assembly.....................10-25

Diagram 12: Grounds Bin..........................................................10-26

Diagram 12, Parts List: Grounds Bin.........................................10-27

Section 11 :: Index ........................................................................................................11-1

Section 12 :: Service Bulletins ......................................................................................12-1

Service Bulletins................................................................................................12-2

Page Intentionally Left Blank

Section 1 :: Ascent Brewer

Overview

1. External Machine Overview

2. Internal Machine Overview – Front View

3. Internal Machine Overview – Rear View

4. Side Panel Removal Instructions

5. Back Panel Removal Instructions

6. Top Panel Removal Instructions

7. Front Panel Removal Instructions

TECHNICAL SUPPORT

Section 1: Ascent Brewer Overview 3035-001A

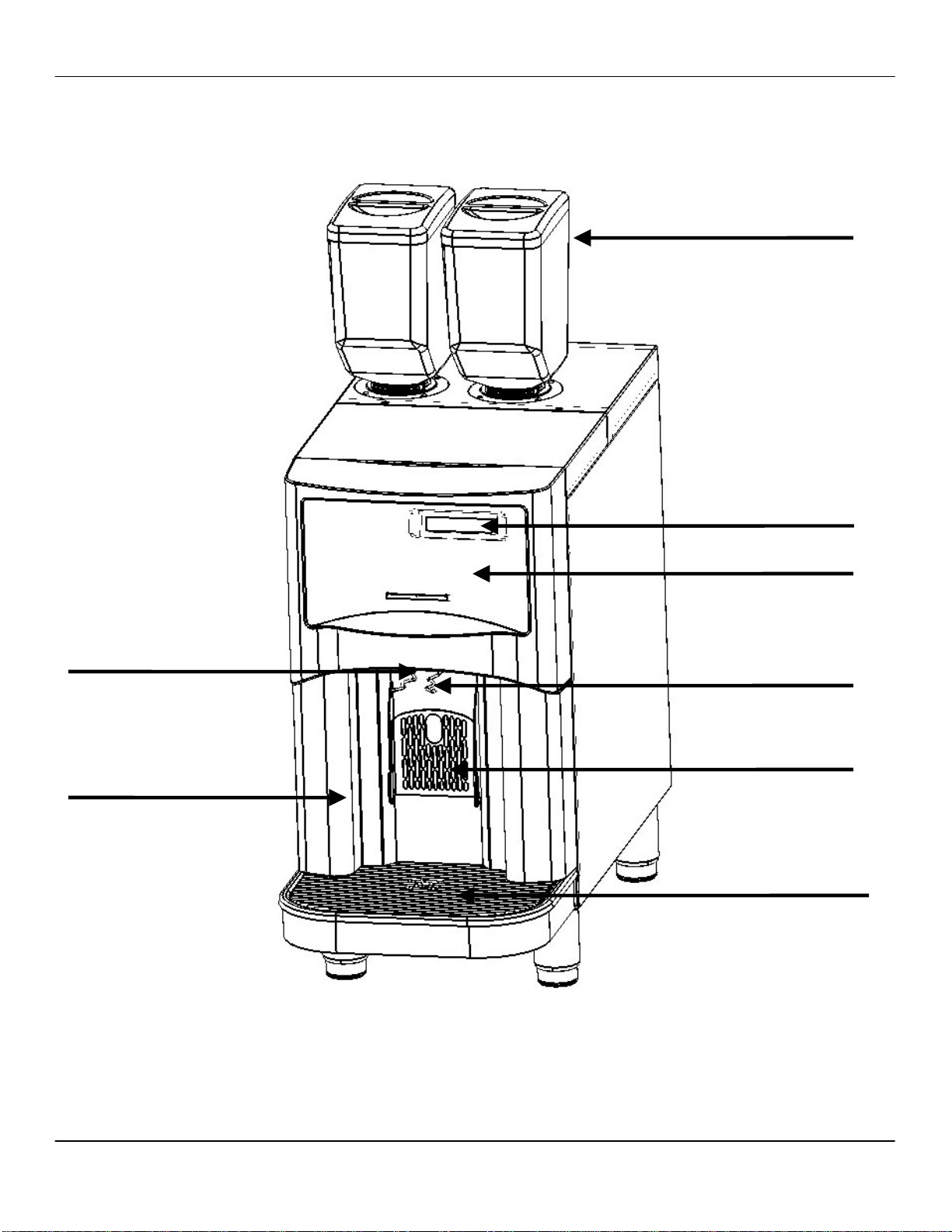

Ascent Brewer External Machine Overview

Bean Hoppers

Display

Product Nozzle

Grounds Bin

Front Panel

Carafe Hooks

Cup Shelf

Drain Grate and Drain Tray

1-2 Concordia Ascent Technical Support Manual

2900-331

3035-001A Section 1: Ascent Brewer Overview

Ascent Brewer External Machine Components

Power Switch

NOT SHOWN

The power switch is located on the back, upper left side of the machine.

Bean Hoppers

Each bean hopper holds approximately two pounds of beans.

Touch Pad

A touch pad provides a user-friendly interface for selecting and pouring

beverages. It also provides access to brew system statistics and service

functions.

Product Nozzle

Finished beverages are poured through the product nozzle and into the

cup or bulk-fill container.

Front Panel

The front panel provides access to the interior of the machine, for

cleaning, maintenance, and service.

Grounds Bin

A grounds bin is attached to the back of the bottom of the lower front of

the machine. The grounds bin holds used coffee grounds.

Carafe Hook

The carafe hook provides stability for a coffee carafe, while it is being

filled.

Cup Shelf

For use when pouring an individual beverage. The cup shelf folds up for

when a carafe or To Go Container is being filled.

Drain Grate and Drain Tray

The metal drain grate and the hard-plastic drain tray direct excess amd

waste liquid into the drain.

Concordia Ascent Technical Support Manual 1-3

2900-331

Section 1: Ascent Brewer Overview 3035-001A

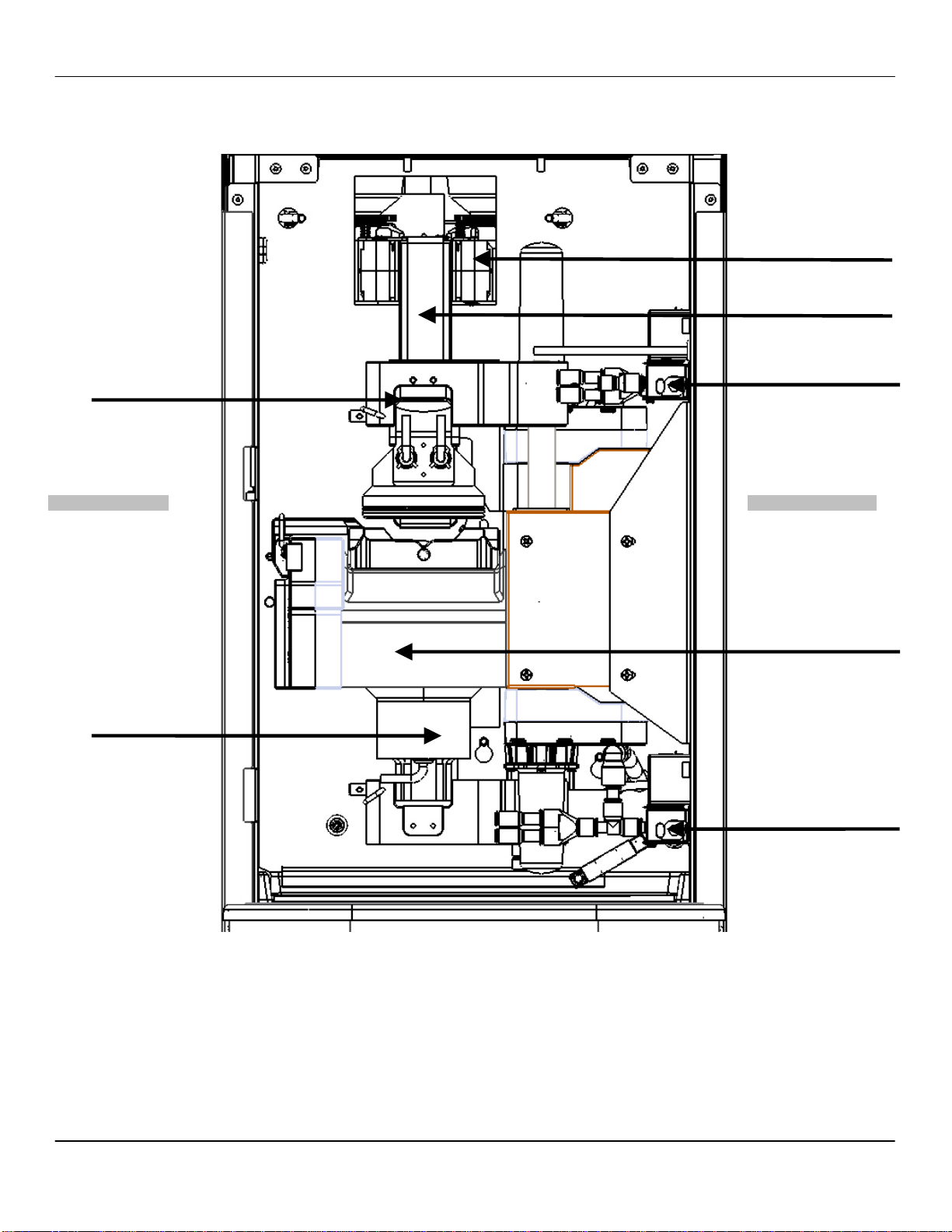

Ascent Brewer Internal Machine Overview – Front View

Grinders

Grounds Chute

Upper Piston

LEFT OF MACHINE RIGHT OF MACHINE

Lower Piston

Dispense Valve

Brew Group

Brew + Hot Water Valves

1-4 Concordia Ascent Technical Support Manual

2900-331

3035-001A Section 1: Ascent Brewer Overview

Ascent Brewer Internal Machine Components – Front

Grinders

Each bean grinder is calibrated to grind beans according to preprogrammed recipes for each type of bean.

Grounds Chute

A grounds chute is located between the grinder and the brew group.

Once the grinder has ground the coffee beans, the coffee grounds are

directed down the grounds chute into the brew chamber where water is

introduced to brew the coffee.

The coffee powder is pressed between the pistons and water is

introduced to brew coffee.

Dispense Valve

The dispense valve controls the flow of coffee to the product nozzle.

Brew Group

The brew group assembly collects ground coffee from the grinders,

brews and dispenses coffee, then discards the used coffee grounds into

the grounds bin.

Brew and Hot Water Valves

The brew valve controls the water flow to the brew group.

The hot water valve is used for dispensing hot water into the cup.

Lower Piston

Hot water passes through the lower piston, into the brew chamber, and

then through the ground coffee during a beverage pour.

Upper Piston

Once the coffee is brewed in the brew chamber, the brewed coffee

passes through the upper piston microscreen, through the dispense

valve, and then to the product nozzle. When coffee is ground and

delivered into the brew chamber, the left piston moves up to pack the

coffee against the upper piston.

Concordia Ascent Technical Support Manual 1-5

2900-331

Section 1: Ascent Brewer Overview 3035-001A

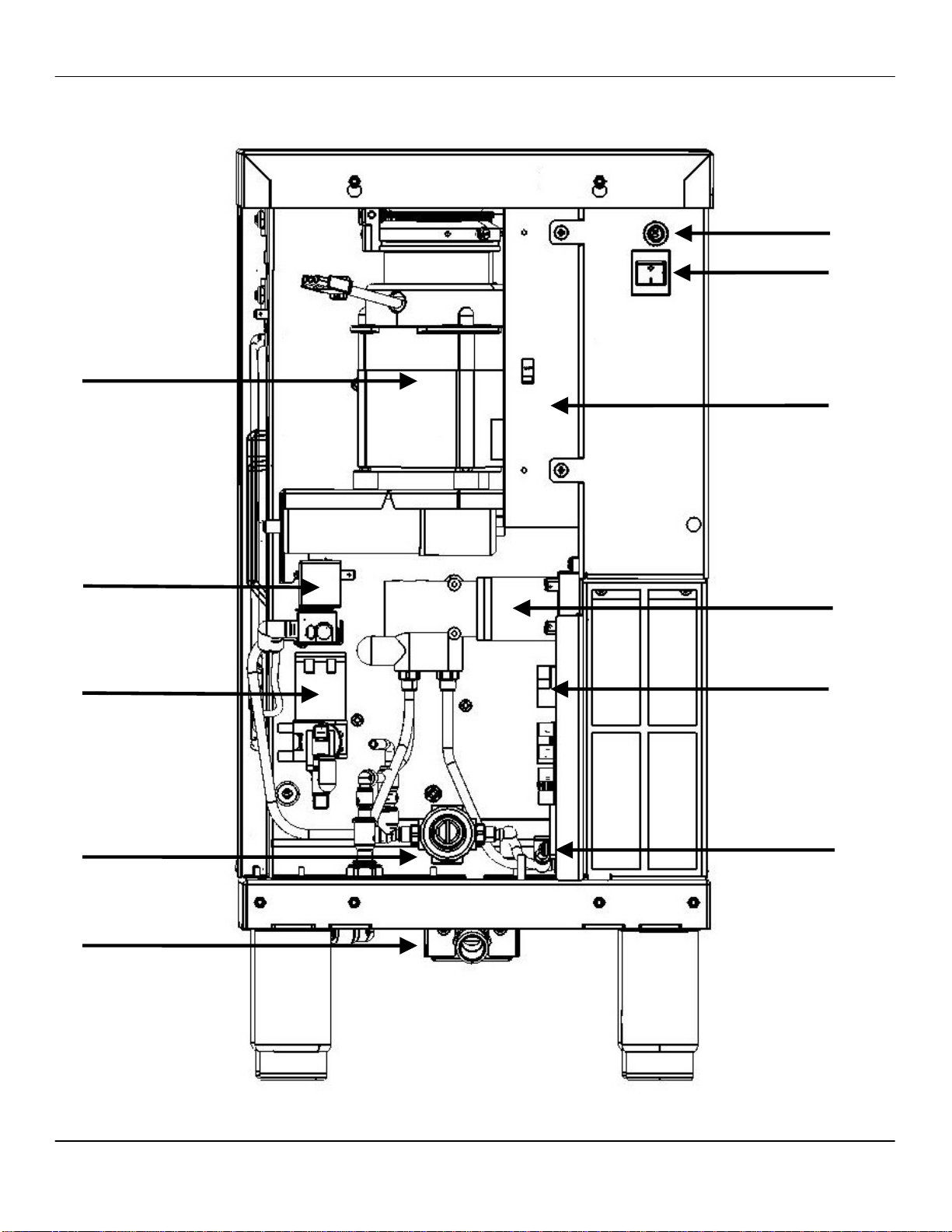

Internal Machine Overview – Rear View

Main Power

Circuit Breaker

Power Switch

Grinders

DC Power

Cold Water Valve

Drain Valve

Pressure Regulator

Drain

Water Pump

AC Control

System

Flowmeter

1-6 Concordia Ascent Technical Support Manual

2900-331

3035-001A Section 1: Ascent Brewer Overview

Internal Machine Components – Rear

Hot Water Tank

NOT SHOWN

The hot water tank stores and heats water used to brew the coffee.

Main Power Circuit Breaker

The main power circuit breaker protects the machine if there is an

electrical malfunction (i.e. overload) or a short circuit.

Power Switch

The power switch controls power to the machine.

DC Power

The DC power area houses all the components that provide DC voltage

for the machine.

Water Pump

The water pump pumps water at 25gph during the extraction process.

AC Control System

The AC control system houses all the components that provide AC

voltage for the machine.

Flowmeter

The flowmeter measures the water flowing throughout the system.

Drain

The drain transports excess and waste water away from the machine,

and ensures its appropriate disposal.

Pressure Regulator

The pressure regulator regulates the water pressure to the brew

chamber during the drink cycle.

Drain Valve

The drain valve controls the flow of waste water to the drain.

Cold Water Valve

OPTIONAL

The cold water valve provides water used for iced coffee beverages.

Concordia Ascent Technical Support Manual 1-7

2900-331

Section 1: Ascent Brewer Overview 3035-001A

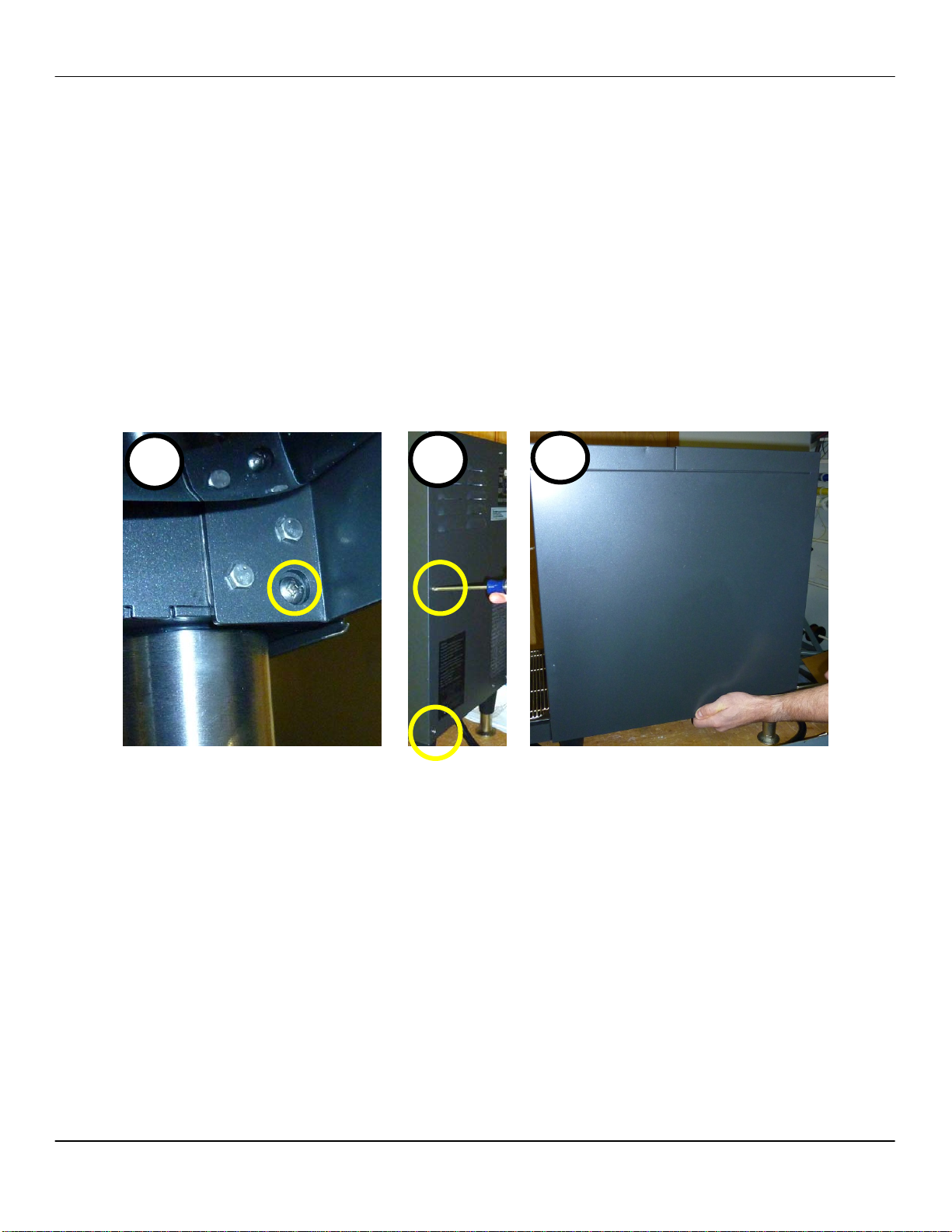

Removing a Side Panel

NOTE: This procedure describes how to remove the right side panel.

This procedure can be applied to both the right and left side panels.

NOTE: The right and left side panels are not interchangeable, so if

you’ve removed both panels and are having a difficult time reinstalling a

panel, try installing it on the other side of the machine.

1. Loosen one screw on the bottom of the machine, next to the right

front machine leg. See photo below.

2. Remove the middle screw on the back panel. See photo below.

3. Hold the bottom of the side panel as you remove the final screw,

as it will start to slide down as soon as the final screw is

removed. See photo below.

To reinstall this component, reverse the removal instructions.

1

2

1-8 Concordia Ascent Technical Support Manual

2900-331

3035-001A Section 1: Ascent Brewer Overview

Removing the Back Panel

1. Remove the right and left side panels. See page 1-8.

2. Remove four screws on the back panel. See photo below.

3. To remove the rear panel, lift the edge of the top panel, and then

tilt the top of the back panel towards you. See photo below.

4. Remove the back panel.

To reinstall this component, reverse the removal instructions.

3

2

Concordia Ascent Technical Support Manual 1-9

2900-331

Section 1: Ascent Brewer Overview 3035-001A

Removing the Top Panel

1. Remove the bean hoppers.

2. Remove two screws on the top of the back panel. Use a #2

Philips screwdriver. See photo below.

3. Raise the front panel assembly.

4. Remove the screws on top of the machine. See photo below.

5. Lift and remove the top panel.

To reinstall this component, reverse the removal instructions.

2

4

1-10 Concordia Ascent Technical Support Manual

2900-331

3035-001A Section 1: Ascent Brewer Overview

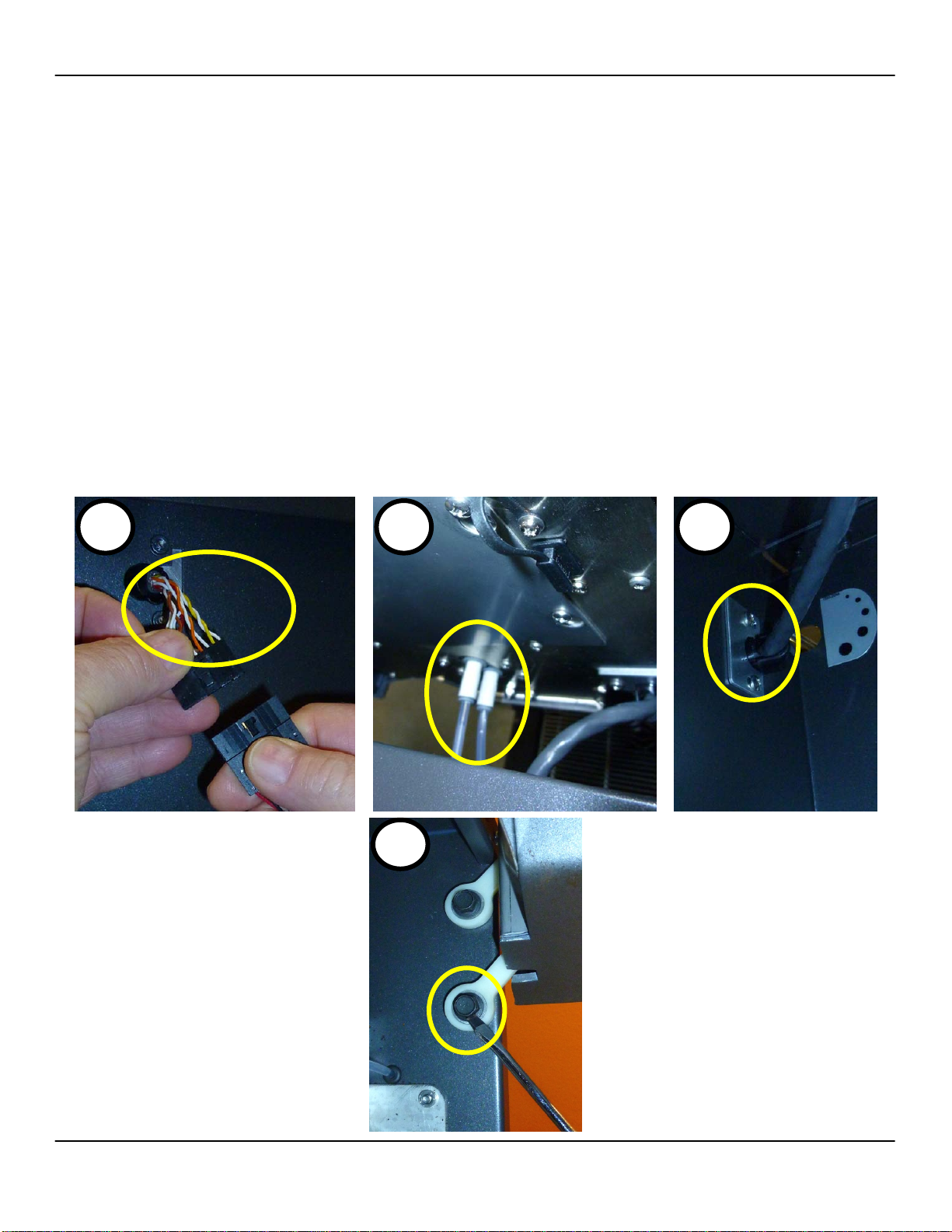

Removing the Front Panel Removing the Front Panel

1. Turn the power to the machine off. 1. Turn the power to the machine off.

2. Remove the left side panel. See page 1-8. 2. Remove the left side panel. See page 1-8.

3. Disconnect the front panel interface cable. See photo below. 3. Disconnect the front panel interface cable. See photo below.

4. Disconnect the two tubes connected to the back of the front

4. Disconnect the two tubes connected to the back of the front

panel. Press the collar down on each tube, to release. See

panel. Press the collar down on each tube, to release. See

photo below.

photo below.

5. Remove the two screws holding the front panel interface cable,

5. Remove the two screws holding the front panel interface cable,

on the inside of the machine. See photo below.

on the inside of the machine. See photo below.

6. Pull the power wires through the opening on the side panel. 6. Pull the power wires through the opening on the side panel.

NOTE: Avoid forcibly pulling the wires, to avoid damage. NOTE: Avoid forcibly pulling the wires, to avoid damage.

7. Remove four bolts (two on each side). See photo below. 7. Remove four bolts (two on each side). See photo below.

8. Remove the front panel. 8. Remove the front panel.

To reinstall this component, reverse the removal instructions. To reinstall this component, reverse the removal instructions.

NOTE: When reinstalling the panel, tighten the lower bolts (one on each

NOTE: When reinstalling the panel, tighten the lower bolts (one on each

side) to ensure that there is enough resistance. The front panel should

side) to ensure that there is enough resistance. The front panel should

not be hard to press down, nor should it slide down if not held open, and

not be hard to press down, nor should it slide down if not held open, and

the front panel should be level on both sides when it is raised.

the front panel should be level on both sides when it is raised.

3 5

4

Concordia Ascent Technical Support Manual 1-11

2900-331

Section 1: Ascent Brewer Overview 3035-001A

Page Intentionally Left Blank

1-12 Concordia Ascent Technical Support Manual

2900-331

Section 2 :: Installation

1. Technical Specifications and Site

Requirements

2. Installation

3. Additional Tasks Required at Installation

TECHNICAL SUPPORT

Section 2: Installation 3035-002A

Technical Specifications and Site Requirements

To ensure the site is ready, the customer is required to complete and

return a pre-installation checklist. The customer is required to have

electrical, water, and a drain located within a specified distance from the

machine.

Technical Specifications

Weight: 125lbs/57kg

Operating Environment: 40-90°F/13-29°C

Compliance:

FCC: Pending

UL Listed Pending

NSF Certified Pending

CE Compliant Pending

CSA Compliant Pending

RoHS Compliant Pending

Location Requirements

Locate indoors only

Overall Space

13” W x 27” D x 34” H

33cm W x 69cm D x 86cm H

Drain

Connection for 3/4” ID drain dose

Indirect drain required

Located within five feet (1.5 meters) of machine

Power and Water Requirements

Power

Located within five feet (1.5 meters) of machine

208Vac, 30amp

Water

Cold water source with a female 3/8” tube fitting and a

shut-off valve located behind the machine.

Water Pressure

Minimum: 25psi; Maximum: 100psi

25 gallons per hour (95 liters per hour)

A fresh water bypass is required for sites with a reverse

osmosis filter system.

Water Treatment System

A water treatment system must be used with the Ascent

Brewer.

25 gallons per hour (95 liters per hour)

2-2 Concordia Ascent Technical Support Manual

2900-331

3035-002A Section 2: Installation

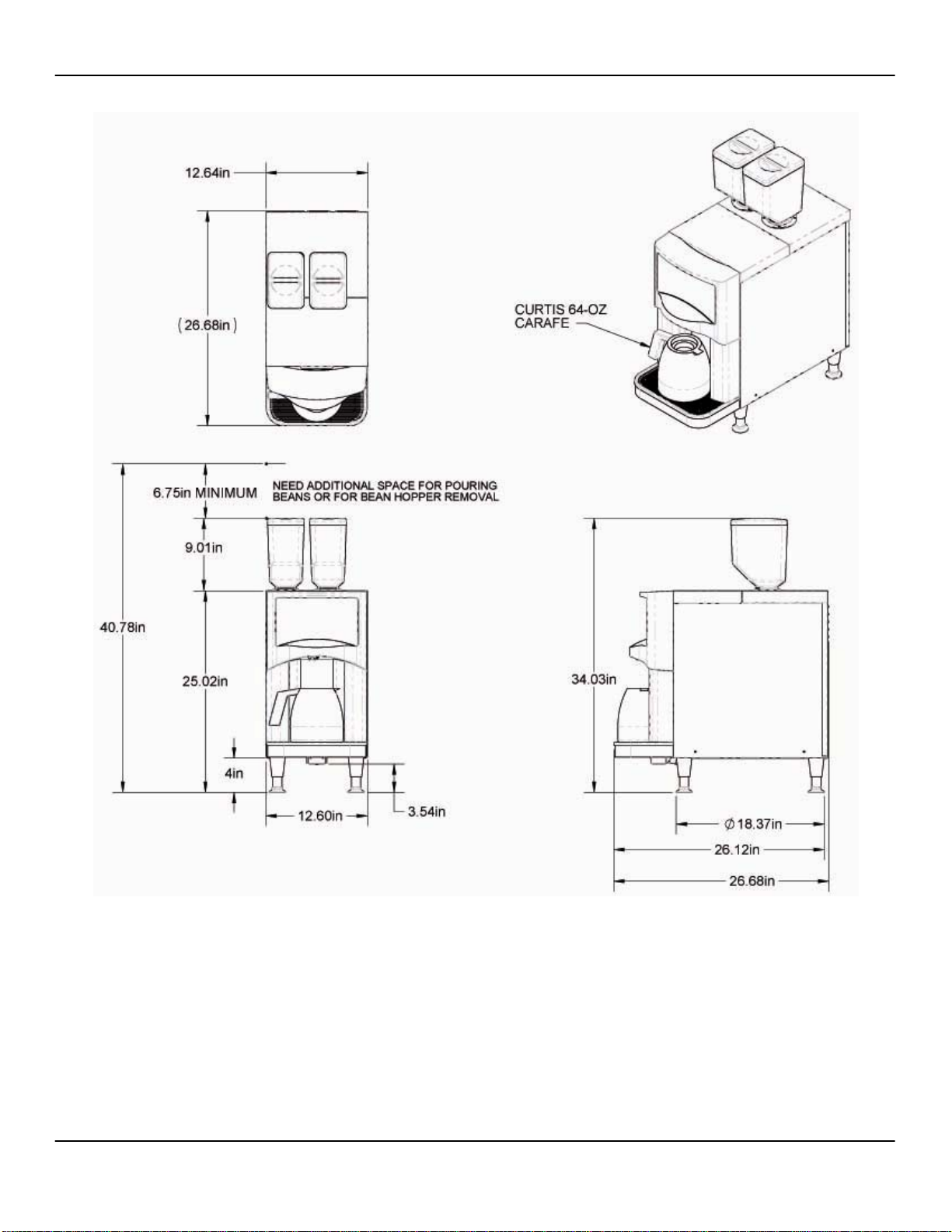

Dimensions

Concordia Ascent Technical Support Manual 2-3

2900-331

Section 2: Installation 3035-002A

Installation

Plumbing

Only a qualified plumber complying with all local codes and requirements

can install the drain at the site. You are responsible for connecting the

machine to the drain.

The following requirements must be met:

• Drain accommodating a 3/4" (1.9cm) ID drain hose

• Drain must be located within five feet (1.5 meters) of machine

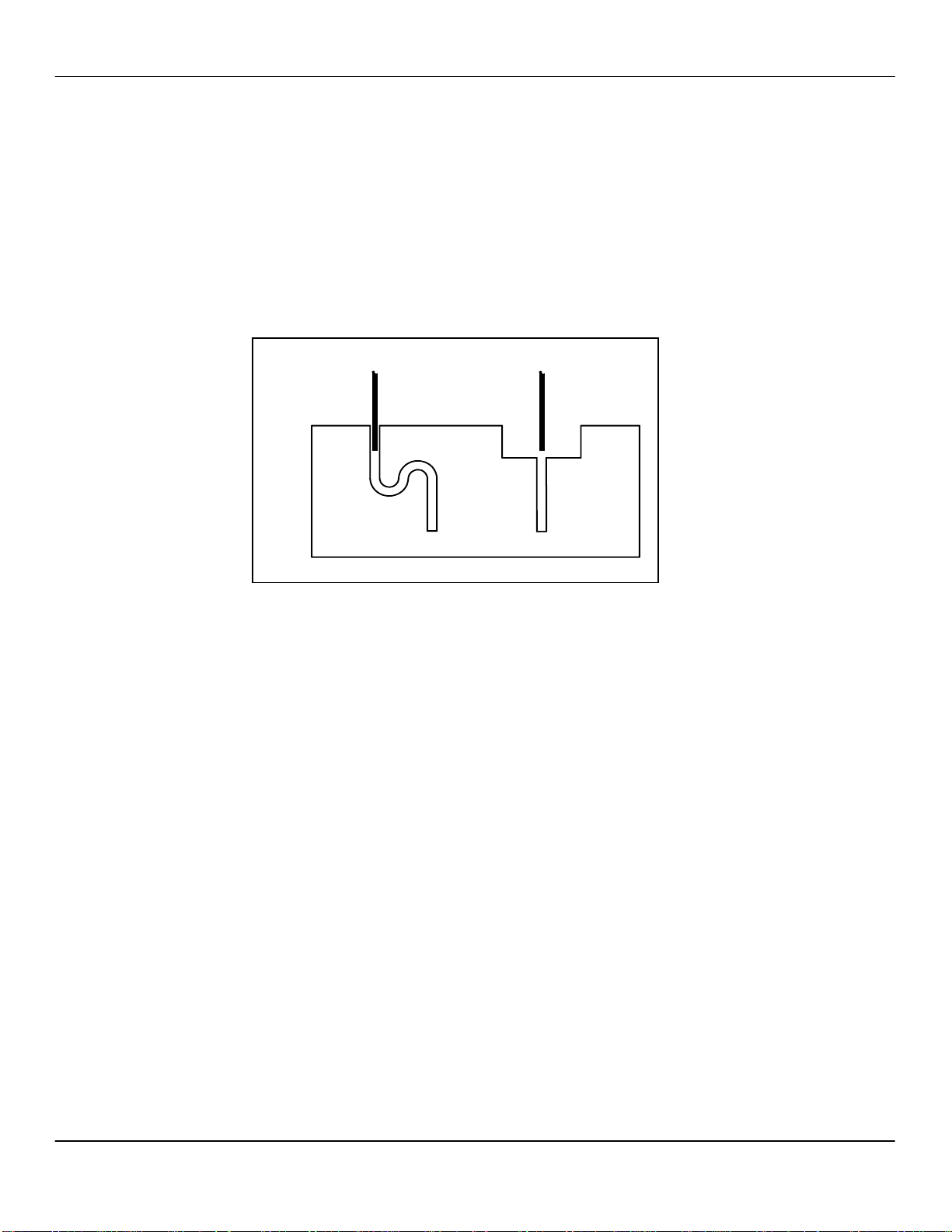

Approved Drain Configurations

DRAIN HOSE

FROM MACHINE

INDIRECT

DRAIN

DRAIN HOSE

FROM MACHINE

FLOOR SINK

DRAIN

The minimum rate of fall required is 1” (2.54cm) per foot, and the drain

hose must have a continuous rate of fall. Ensure the drain hose is

connected to the machine drain port.

If the drain has any low spots or any horizontal runs as it travels from the

machine to the drain, water and other waste from the machine will back

up and cause the drain hose and/or the drain tray to clog.

NOTE: When water and drain lines are connected, check for leaks.

Water Supply

To ensure proper operation of the machine, the following requirements

must be met:

• Cold water source with a shut-off valve and female 1/4" or 3/8”

fitting

• Water pressure: minimum 25psi; maximum 100psi

• Water source must be located within five feet (1.5 meters) of

machine

Problems with Reverse Osmosis Water System

A fresh water bypass is required for sites with a reverse osmosis filter

system. The machine water level sensors are inoperative when used

with this system.

2-4 Concordia Ascent Technical Support Manual

2900-331

3035-002A Section 2: Installation

Additional Tasks Required at Installation

Power Up the Machine

1. Ensure the electrical cord is plugged in.

2. Ensure water is supplied to unit and the water inlet valv e is open.

3. Ensure the unit is connected to a drain.

4. Ensure that the grounds bin is in place and the top panel is

closed.

5. Start the unit by turning on the main power switch located on

back left side of the Brewer.

6. Warm-up takes approximately 10 minutes.

NOTE: The grounds bin must be fully pushed into the machine.

Install Bean Hoppers

1. Install both bean hoppers.

2. Fill each bean hopper with the coffee beans associated with that

bean hopper button on the operator panel.

NOTE: The left bean hopper holds decaffeinated coffee beans

and the right bean hopper holds regular coffee beans.

IMPORTANT: Ensure the hopper stoppers are removed, so that the

beans are delivered to the grinder.

Concordia Ascent Technical Support Manual 2-5

2900-331

Section 2: Installation 3035-002A

Page Intentionally Left Blank

2-6 Concordia Ascent Technical Support Manual

2900-331

Section 3 :: Electrical

1. Electrical System Overview

2. AC Block Diagram

3. I/O Harness Board Schematic

4. DC Power Supply Schematic

TECHNICAL SUPPORT

Section 3: Electrical 3035-003A

Electrical System Overview

Machine Operating Voltage

The minimum electrical requirements must be met to ensure proper

operation of machine:

• 208Vac

• Single Phase: 30amp dedicated circuit

• NEMA 14-30/30amp four-prong 250Vac plug

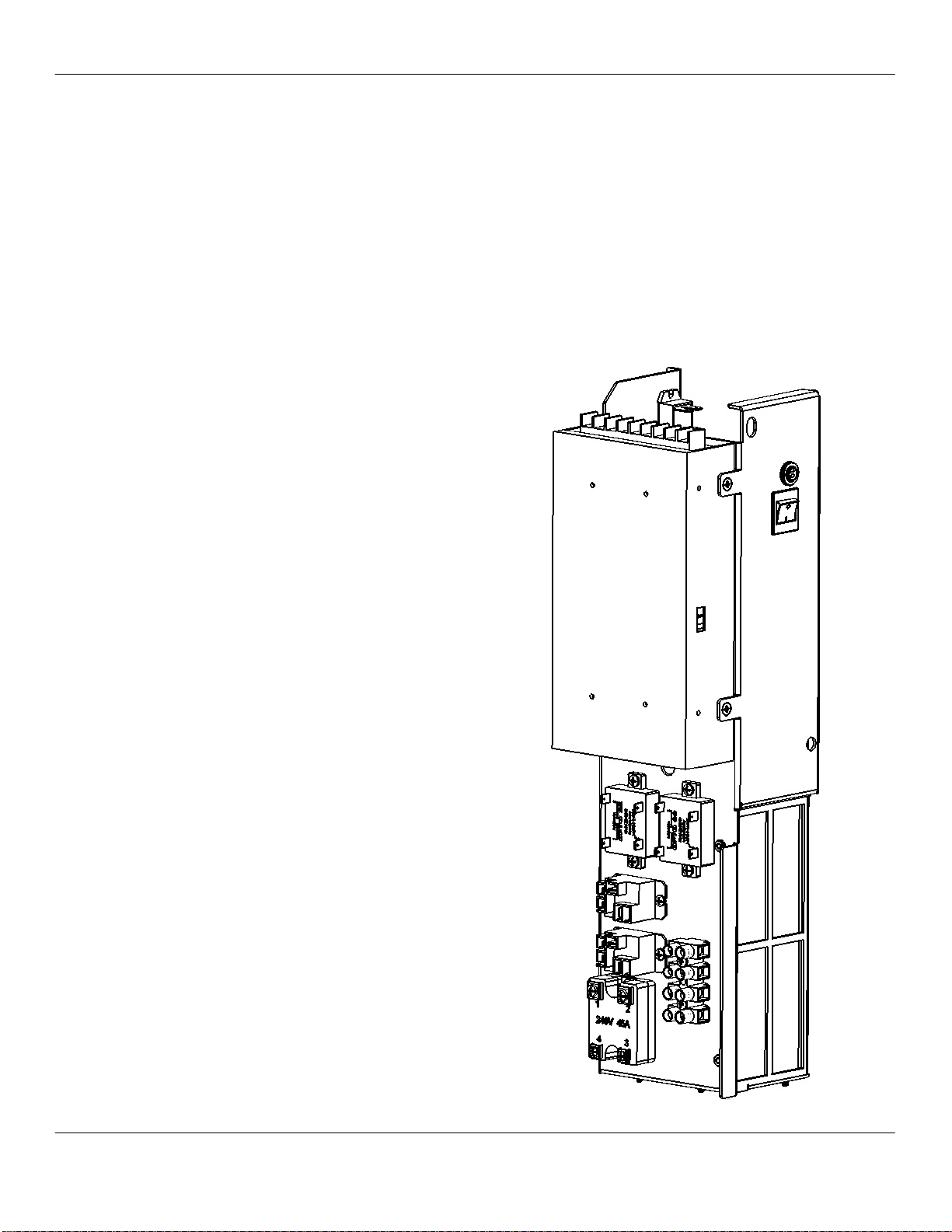

Electrical Tower

Located in the back of the machine behind the left grinder, the electrical

tower houses:

• Power Switch

• Circuit Breaker

• DC Power Supply

• Rear Input/Output Control Board

• A/C Power Relays

• Hot Water Heater Solid State Relay

• Grinder Solid State Relays

• Water Pump Relay

3-2 Concordia Ascent Technical Support Manual

2900-331

3035-003A Section 3: Electrical

AC Block Diagram

Concordia Ascent Technical Support Manual 3-3

2900-331

Section 3: Electrical 3035-003A

Section 3: Electrical 3035-003A

I/O Harness Board Diagram

3-4 Concordia Ascent Technical Support Manual

3-4 Concordia Ascent Technical Support Manual

2900-331

2900-331

Loading...

Loading...