Concordia Coffee 99277 Service Manual

Concordia

Model

2500s/i

Super

Automatic

Espresso

Machines

Technician’s Manual

Concordia Coffee Systems

1287 120th Avenue NE

Bellevue, WA 98005

(425) 453-2800

(800) 778-0990

(425) 453-2167 Fax

http://www.concordiacoffee.com

Technical Writer and Editor: Shana McKibbin

Technical Support: Andre Belyea, Gary Williams, Pete Oksendahl, Chris

Collier

Graphic Engineer: Scott Naito

Revision A

September, 2007

Welcome to Concordia Coffee Systems!

We are very pleased to have you join our team of professionals, united

in the common pursuit of excellence on behalf of our customers.

Concordia Coffee Systems is a leader in the design, development and

manufacture of fully automated espresso systems, serving thousands of

customers throughout the world. Our goal is to continuously achieve

the highest imaginable levels of quality, service, and technological

performance for our customers. We believe that it is the ability, talent

and spirit of people like you that will enable Concordia Coffee Systems

to reach this goal.

The basic objectives of Concordia Coffee Systems are:

Deliver quality and value to our customers through leadership

and excellence in everything that we do.

Provide a strong seamless network of service to all Concordia

Coffee Systems customers while, exceeding their expectations

from us.

Build value in our employees and agents through experience,

training and the provision of opportunities for success.

Build long term value in our Company.

Be strong contributing members of the communities in which

we conduct business.

You are an important part of our team. We want to do our best to help

you find your work with Concordia Coffee Systems satisfying, rewarding

and personally meaningful. The material in this manual has been

designed to be used as a training aid, reference resource and updated

library of Concordia Coffee Systems Policies and Procedures.

It is important that you keep your manual updated to reflect our

current revisions to ensure we have provided you with the tools

necessary to facilitate YOUR success!

Ray Ross

Vice President of Service and Customer Support

Concordia Coffee Systems

Revision Change Log

Replace Old

Section

With New

Section

Brief Description Date

2900-233

Revision

Table of Contents

Section 1 :: Model 2500s/i Overview.................................................1-1

Model 2500i Overview Diagram........................................................ 1-2

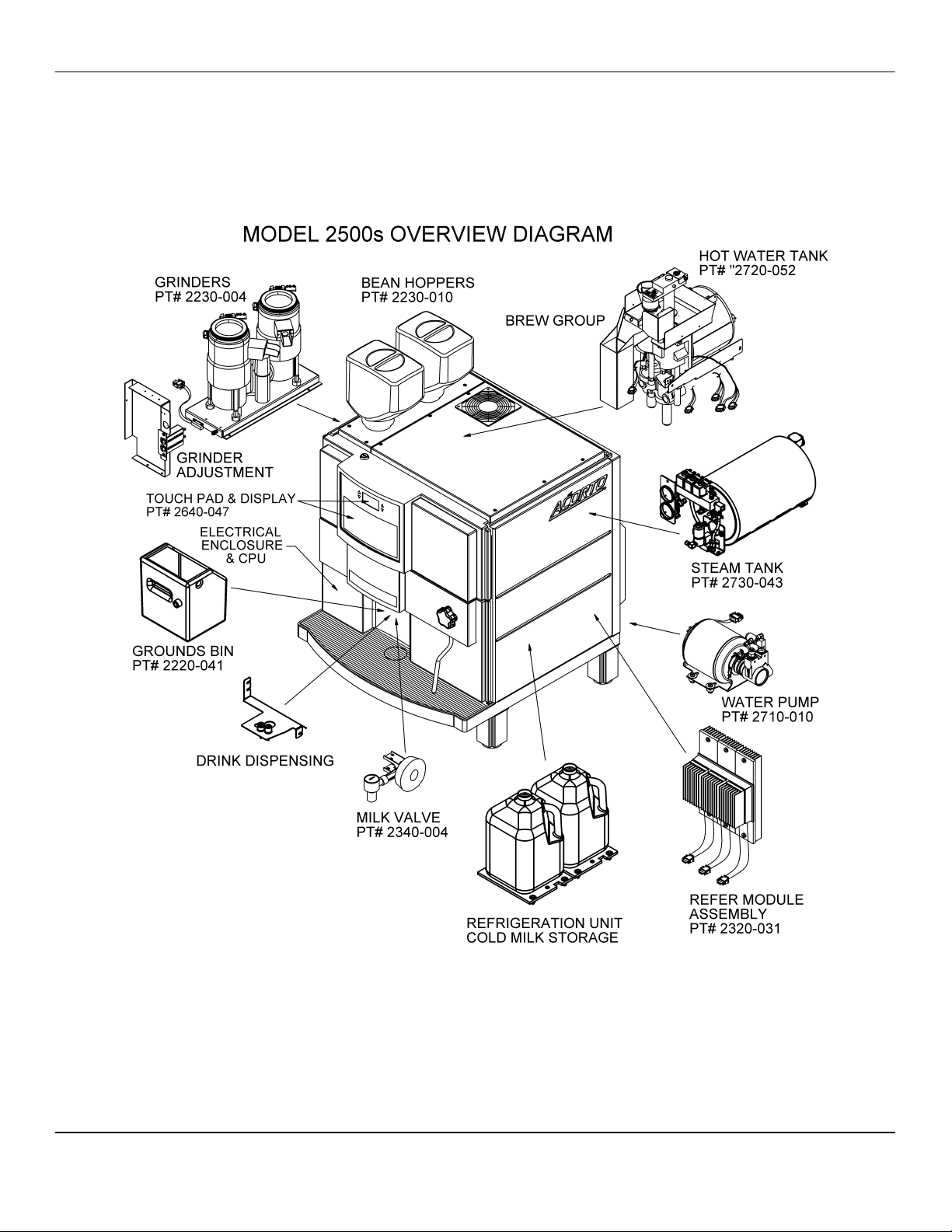

Model 2500s Overview Diagram ....................................................... 1-3

The Model 2500s/i Components....................................................... 1-4

Touch Pad................................................................ 1-4

Electrical Encosure ..................................................... 1-4

Bean Hoppers............................................................ 1-4

Water Pump.............................................................. 1-4

Hot Water Tank ......................................................... 1-4

Brew Group .............................................................. 1-4

Steam Tank .............................................................. 1-4

Refrigeration Unit....................................................... 1-4

Grounds Bin.............................................................. 1-4

Drink Dispensing......................................................... 1-4

Grinders and the Grinder Adjustment Assembly................... 1-4

Refer/Cooling Module Assembly...................................... 1-4

Milk Valve ................................................................ 1-4

Section 2 :: Installation and Removal................................................2-1

Installation Requirements.............................................................. 2-2

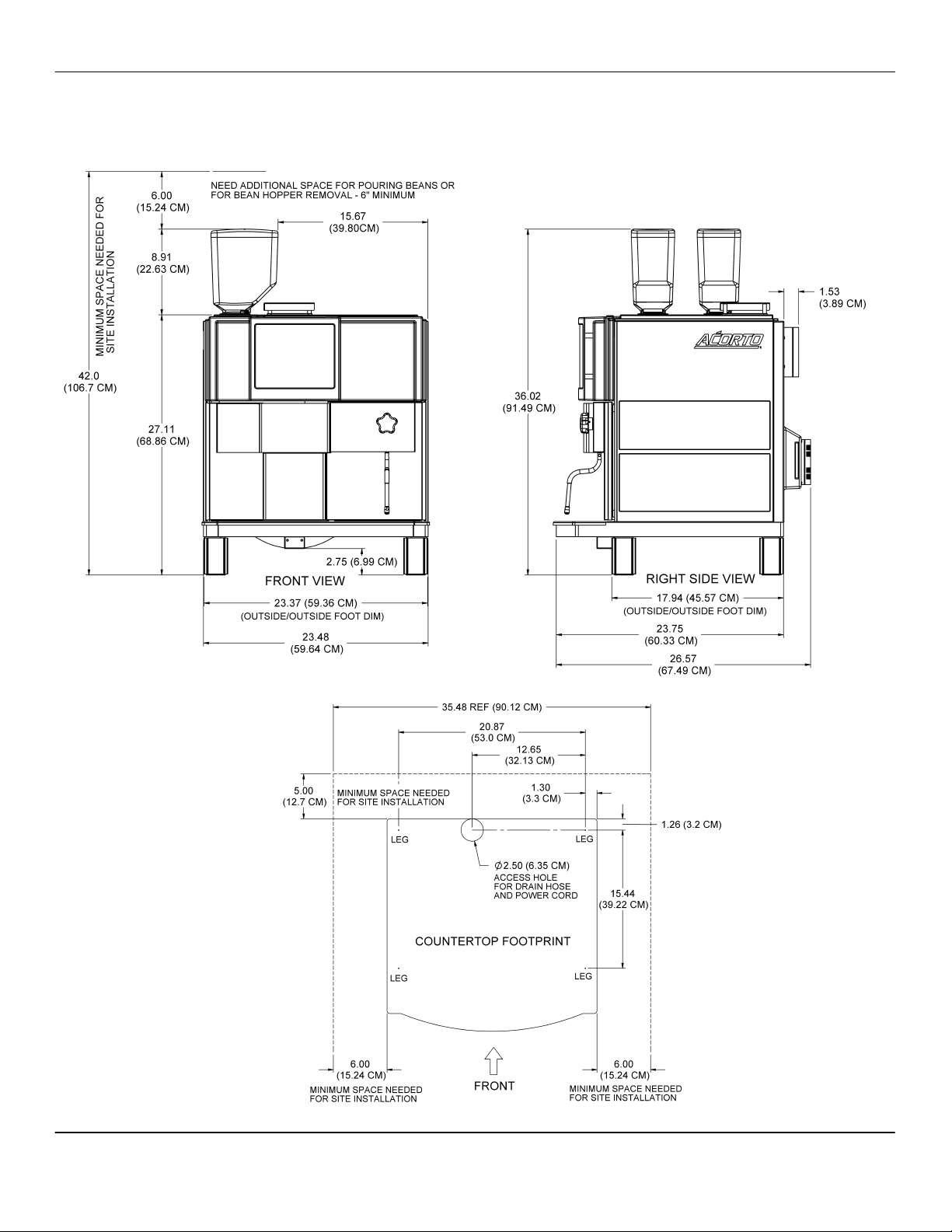

Dimensions................................................................................ 2-3

Installation ............................................................................... 2-4

Placing the Unit......................................................... 2-4

Ambient Temperature.................................................. 2-4

Configuring the Machine for Supply Voltage........................ 2-4

Espresso Machine Electrical Settings ................................ 2-4

Setting the DC Jumper Plug........................................... 2-5

Configuring Transformer Auxiliary Connector #1 .................. 2-6

Connecting the Drain................................................... 2-7

Connecting the Water Supply......................................... 2-8

Problems with Reverse Osmosis Water System..................... 2-8

Connecting the Water Treatment System........................... 2-9

Starting the Machine...................................................................2-10

Consumables ............................................................................2-10

Calibration...............................................................................2-10

Customer Training......................................................................2-10

Installation Checklist ..................................................................2-11

Removal Procedures ...................................................................2-12

Cumulative Drink Total ...............................................2-12

Clean Refrigerator.....................................................2-12

Clean Brew Group & Grinders........................................2-12

Run Daily Clean Cycles................................................2-12

Disconnect Water Supply & Drain Tanks ...........................2-12

Preparation for Shipping..............................................2-13

Packaging for Shipment...............................................2-13

Section 3 :: Electrical .................................................................. 3-1

Electrical Block Diagram ............................................................... 3-2

Fuses....................................................................................... 3-3

Backplane................................................................................. 3-4

AC Drawer Assembly .................................................................... 3-5

Transformer .............................................................................. 3-6

Transformer Diagrams.................................................. 3-6

Operating Voltage....................................................................... 3-7

AC Voltage ............................................................... 3-7

DC Voltage ............................................................... 3-7

Valves..................................................................... 3-7

Diodes..................................................................... 3-7

Electrical Enclosure Fan ............................................... 3-8

Power Into the Machine ................................................................ 3-9

Power into DC Power Supply Board .................................. 3-9

Power into AC Components ..........................................3-10

Setting the DC Jumper Plug (J1) .................................... 3-10

Set Transformer Auxiliary Connector #1 ...........................3-11

DC Power Supply Board LEDs .........................................................3-12

Solid State Relays......................................................3-13

Jumper Plug Connector Detail........................................................3-14

Jumper Plug 1 ..........................................................3-14

Jumper Plug 2 ..........................................................3-15

Jumper Plug 3 ..........................................................3-15

Jumper Plug 6 ..........................................................3-16

Jumper Plug 7 ..........................................................3-16

Jumper Plug 8 ..........................................................3-17

Jumper Plug 10.........................................................3-17

Jumper Plug 9 ..........................................................3-18

Heater Element Wiring Diagrams ....................................................3-19

Section 4 :: Software...................................................................4-1

Software Overview...................................................................... 4-2

Main Menu Categories.................................................. 4-2

The Service Switch...................................................... 4-3

Navigating the Menu System .......................................... 4-3

Accessing the Main Menu .............................................. 4-4

Accessing a Submenu................................................... 4-4

Exiting the Menu System............................................... 4-4

Modifying a Value....................................................... 4-4

Accessing Cumulative Drink Statistics............................... 4-5

Software Quick Reference Table...................................................... 4-6

CPU Board ...............................................................................4-11

CPU and LEDs...........................................................4-11

Calibration Overview ..................................................................4-13

Espresso Extraction....................................................4-13

The Extraction Goal ................................................... 4-13

Espresso Extraction & Temperature Parameters..................4-13

Espresso Extraction Time.............................................4-13

Temperatures...........................................................4-13

How to Calibrate Espresso ............................................................4-14

Step 1: Verify Factory Settings ......................................4-14

Step 2: Use Fresh Espresso Roast Coffee Beans................... 4-14

Step 3: Adjust the Coffee Grind Texture...........................4-15

Step 4: Ask Customer to Approve Extraction......................4-16

Step 5: Coffee Powder Dose and Water Volume are adjustable per

customer request ......................................................4-16

Espresso Extraction Pre-Treatment Options .......................................4-17

Pre-Treatment Options ...............................................4-17

Setting Milk and Water Timings ......................................................4-19

Latte Milk Timing ......................................................4-19

Double/Triple Latte Milk Timing ....................................4-19

Cappuccino Foamed Milk Timing ....................................4-19

Cappuccino Boost Delay ..............................................4-19

Cappuccino Coffee Delay.............................................4-19

Section 5 :: Plumbing...................................................................5-1

Water System ............................................................................ 5-2

2500s & 2500i Hydraulics Diagram ................................... 5-2

Water Supply............................................................................. 5-3

Water Filtering .......................................................... 5-3

Water Pump and Motor................................................................. 5-4

Water Pressure Gauge.................................................. 5-4

Changing Pump Pressure............................................... 5-5

Expansion Valve......................................................... 5-5

Flowmeter................................................................................ 5-5

Check Water Flow Message............................................ 5-6

Water Tank............................................................................... 5-6

Temperature/Level Probe............................................. 5-6

Level Probe .............................................................. 5-6

Temperature Probe..................................................... 5-7

Heating Elements ....................................................... 5-7

High Temperature Limit Switch ...................................... 5-7

Pressure Relief Valve................................................... 5-7

Drain Valve............................................................... 5-8

Valves ..................................................................................... 5-8

Brew Valve............................................................... 5-8

Hot Water Valve......................................................... 5-8

Water Level Sensors..................................................................... 5-9

The Steam System....................................................................... 5-9

Steam Tank Fill Valve .................................................5-10

Steam Tank .............................................................5-10

Water Level Probes....................................................5-10

Pressure Gauge.........................................................5-11

Heating Elements ......................................................5-11

Pressure Relief Valve..................................................5-11

High Temperature Limit Switch .....................................5-11

Steam Valves............................................................................5-12

Latte Steam Valve .....................................................5-12

Cappuccino Steam Valve..............................................5-12

Steam Wand Valve (if present) ...................................... 5-12

Captive Water Purge System.........................................5-13

Post Steam Valve.......................................................5-13

Air Purge Process ......................................................5-13

Section 6 :: The Coffee System.......................................................6-1

Coffee System Overview ............................................................... 6-2

The Espresso Path....................................................... 6-2

Grinders................................................................................... 6-3

Double Grinder Assembly.............................................. 6-3

Grinder Calibration..................................................... 6-3

Grinder Adjustment Panel............................................. 6-4

Coffee Powder Channel................................................ 6-5

Removing a Grinder .................................................... 6-5

Replacing Grinder Burrs/Blades ...................................... 6-5

Setting Grinder Adjustment Indicator to Mid-Scale ............... 6-6

Bean Hoppers ............................................................................ 6-7

Directions for Filling Bean Hopper ................................... 6-7

Inserting the Hopper Stopper ......................................... 6-7

Section 7 :: Milk System and Refrigeration Unit ................................... 7-1

Milk System Overview................................................................... 7-2

Milk Delivery System Overview........................................................ 7-2

The Milk Delivery System Components............................................... 7-3

Milk Valve Assembly .................................................... 7-3

Milk Valve Solenoid and Plunger...................................... 7-3

Nozzle and Anti-Splatter Shield ...................................... 7-4

Air-Gate Valve Assembly ............................................................... 7-4

Air-Gate Valve........................................................... 7-4

Air Vent Needle ......................................................... 7-4

Connection of Milk Valve Assembly and Air-Gate Valve .......... 7-4

Alt Milk Valve ............................................................................ 7-4

The Latte Pour Process ................................................ 7-5

The Cappuccino Pour Process......................................... 7-5

Understanding the Relationship between Steam Temperature and Milk

Temperature ............................................................................. 7-5

Troubleshooting and Repair........................................... 7-6

The Milk Delivery System............................................................... 7-7

Placing Milk in the Machine ........................................... 7-7

Checking the Refrigeration Unit Temperature..................... 7-7

The Refrigeration Unit.................................................................. 7-8

Refrigeration Cooling Module Assembly.............................................. 7-9

Cold Sink Deflector ....................................................7-10

Fans.......................................................................................7-11

Interior Circulation Fan Assembly...................................7-11

Temperature Probe Assembly........................................7-11

Exterior Cooling Module Fan Assembly .............................7-12

Milk Weight Trays.......................................................................7-13

Adjusting the Milk Weight Tray......................................7-14

Milk Level Sensors......................................................7-15

Auto Milk Select........................................................ 7-15

Troubleshooting and Repair...........................................................7-16

Section 8:: Brew Group ................................................................8-1

The Brew Group ......................................................................... 8-2

Hall-Effect Sensors...................................................................... 8-3

Piston Movement ........................................................................ 8-4

Group Initialization ..................................................................... 8-5

Measuring Coffee Powder Dose........................................................ 8-5

Motors..................................................................................... 8-6

Right Motor .............................................................. 8-6

Left Motor................................................................ 8-6

Pistons..................................................................................... 8-7

Left Piston ............................................................... 8-7

Right Piston.............................................................. 8-8

Piston Removal Procedures............................................................ 8-9

Left Piston Removal Procedure....................................... 8-9

Right Piston Removal Procedure...................................... 8-9

Gearbox Removal and Installation...................................................8-10

Gearbox Removal ......................................................8-10

Gearbox Installation...................................................8-10

Section 9 :: Cleaning and Maintenance..............................................9-1

Daily Maintenance of the Concordia Espresso Machine............................ 9-2

Importance of Cleaning................................................ 9-2

Concordia Cleaning Products.......................................... 9-2

Performing Daily Cleaning............................................. 9-2

Auto-Rinse ............................................................... 9-3

Preventive Maintenance................................................................ 9-3

PM Kits.................................................................... 9-3

Preventive Maintenance Checklist ................................... 9-4

Section 10 :: Concordia Procedures.................................................10-1

Concordia Coffee Systems Service Call Process ...................................10-2

Arrival to Site...........................................................10-2

Machine Repair.........................................................10-2

Hold for Parts Procedures ............................................10-2

Departing from Site....................................................10-2

Required Immediately for Call Closeout ...........................10-2

Complete Call Protocol................................................................10-3

Machine Appearance ..................................................10-3

Milk Valve ...............................................................10-3

Brew Group .............................................................10-3

Water Tank .............................................................10-3

Water Pump.............................................................10-3

Steam Tank .............................................................10-3

Refrigeration Unit......................................................10-3

Espresso Extraction....................................................10-3

Milk Pour ................................................................10-3

Service Call Checklist..................................................................10-4

Parts Return Policy.....................................................................10-5

Return Material Tag ...................................................10-6

Return Material Authorization Form................................10-7

Form: Return Material Authorization............................... 10-8

Section 11 :: Customer Service and Training ......................................11-1

Training the Customer.................................................................11-2

Customer Training Includes ..........................................11-2

Quick Reference Guide................................................11-2

Filling Machine with Beans and Milk ................................11-2

Making a Drink..........................................................11-2

Serial Number ..........................................................11-2

Accessing Programming Menu........................................11-3

Cleaning .................................................................11-3

Ordering Cleaning Supplies...........................................11-3

Troubleshooting Tips..................................................11-3

Calling Concordia for Assistance.....................................11-3

Concordia Coffee Systems’ Value-Added Service..................................11-4

Value-Added Service ..................................................11-4

G.U.E.S.T. ...............................................................................11-5

Greet the Customer ...................................................11-5

Understand your Customer...........................................11-6

Empathize with your customer ...................................... 11-7

Solve the Problem .....................................................11-8

Train the Customer....................................................11-8

Section 12 :: Messages ................................................................12-1

Troubleshooting Display Messages ...................................................12-2

Section 13 :: Troubleshooting........................................................13-1

Troubleshooting Quick Reference Guide............................................13-2

Machine Failure ........................................................13-2

Milk System .............................................................13-4

Troubleshooting Trees.................................................................13-5

Section 14 :: Parts List & Diagrams .................................................14-1

Recommended Tools List..............................................................14-2

Standard Tools .........................................................14-2

Concordia Stocked Tools.............................................. 14-2

Consumables............................................................14-2

Recommended Van Stock .............................................................14-3

Parts List and Diagrams................................................................14-5

Diagram 1: Overview ..................................................14-6

Diagram 1, Parts List: Overview.....................................14-7

Diagram 2: Chassis..................................................... 14-8

Diagram 2, Parts List: Chassis........................................14-9

Diagram 3: Doors, 2500i ............................................ 14-10

Diagram 3, Parts List: Doors, 2500i ............................... 14-11

Diagram 4, Doors, 2500s............................................ 14-12

Diagram 4, Parts List: Doors, 2500s............................... 14-13

Diagram 5: Front Panel 2500i ...................................... 14-14

Diagram 5, Parts List: Front Panel 2500i......................... 14-15

Diagram 6: Front Panel 2500s...................................... 14-16

Diagram 6, Parts List: Front Panel 2500s......................... 14-17

Diagram 7: Top Panel ............................................... 14-18

Diagram 7, Parts List: Top Panel .................................. 14-19

Diagram 8: Grinder Assembly ...................................... 14-20

Diagram 8, Parts List: Grinder Assembly......................... 14-21

Diagram 9: Grinder Adjustment ................................... 14-22

Diagram 9, Parts List: Grinder Adjustment...................... 14-23

Diagram 10: Group Upper and Lower Piston Assy............... 14-24

Diagram 10, Parts List: Group Upper & Lower Piston Assy.... 14-25

Diagram 11: Group Drive System.................................. 14-26

Diagram 11, Parts List: Group Drive System..................... 14-27

Diagram 12: Milk Valve Assembly.................................. 14-28

Diagram 12, Parts List: Milk Valve Assembly .................... 14-29

Diagram 13: Product Delivery, 2500i ............................. 14-30

Diagram 13, Parts List: Product Delivery, 2500i ................ 14-31

Diagram 14: Product Delivery, 2500s ............................. 14-32

Diagram 14, Parts List: Product Outlet 2500s ................... 14-33

Diagram 15: Refer Module Assembly.............................. 14-34

Diagram 15, Parts List: Refer Module Assembly................. 14-35

Diagram 16: Refer Cooling Fan Assembly ........................ 14-36

Diagram 16, Parts List: Refer Cooling Fan Assembly ........... 14-37

Diagram 17: Steam Tank, Front ................................... 14-38

Diagram 17, Parts List: Steam Tank, Front ...................... 14-39

Diagram 18: Steam Tank, Rear .................................... 14-40

Diagram 18, Parts List: Steam Tank, Rear ....................... 14-41

Diagram 19: Steam Wand........................................... 14-42

Diagram 19, Parts List: Steam Wand.............................. 14-43

Diagram 20: Water Pump........................................... 14-44

Diagram 20, Parts List: Water Pump.............................. 14-45

Diagram 21: Water Tank............................................ 14-46

Diagram 21, Parts List: Water Tank............................... 14-47

Diagram 22: Water/Steam Gauge Assembly ..................... 14-48

Diagram 22, Parts List: Water/Steam Gauge Assembly........ 14-49

Section 15: Index.......................................................................15-1

Section 16: Service Bulletins.........................................................16-1

Section 1 :: Model 2500s/i

Overview

1. Model 2500i Overview Diagram

2. Model 2500s Overview Diagram

3. The Model 2500s/i Components

TECHNICAL SUPPORT

Section 1: Model 2500s/i Overview 3025-001A

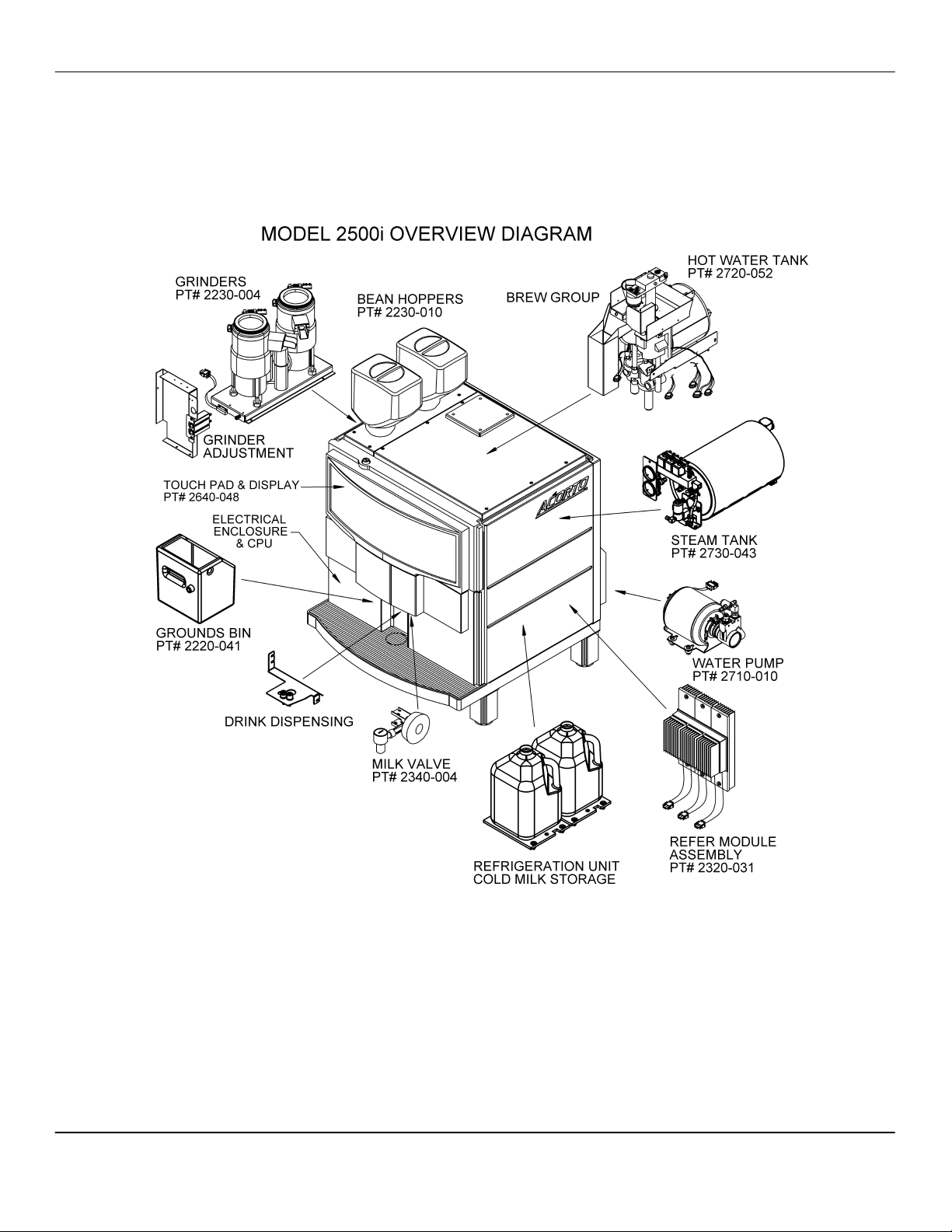

Model 2500i Overview Diagram

1-2 Concordia 2500s/i Technical Support Manual

2900-233

3025-001A Section 1: Model 2500s/i Overview

Model 2500s Overview Diagram

Concordia 2500s/i Technical Support Manual 1-3

2900-233

Section 1: Model 2500s/i Overview 3025-001A

The Model 2500s/i Components

Touch Pad

The touch pad provides a user interface for selecting and pouring

drinks.

Electrical Encosure

The electrical enclosure houses the CPU, AC board, and DC board.

Bean Hoppers

Each bean hopper holds approximately 2lbs of whole beans, and feeds

the beans to the grinders.

Water Pump

The water pump regulates the water pressure to 140psi during the

espresso extraction process.

Hot Water Tank

The hot water tank stores and heats the water used to brew espresso.

Brew Group

The brew group assembly precisely brews espresso, and automatically

discards the used coffee into the grounds bin.

Steam Tank

The steam tank provides steam used for steaming the milk, and for

units utilizing a steam wand.

Refrigeration Unit

The on-board refrigeration unit holds two 1-gallon milk containers.

Grounds Bin

The grounds bin catches used coffee pucks.

Drink Dispensing

The product outlet dispenses freshly brewed espresso while the

patented milk valve froths the milk.

Grinders and the Grinder Adjustment Assembly

The grinders are calibrated to grind beans according to the customer’s

desired recipe.

Refer/Cooling Module Assembly

The refer/cooling module assembly regulates the temperature inside

the refrigeration unit.

Milk Valve

Steam, air, and milk are mixed in the milk valve.

1-4 Concordia 2500s/i Technical Support Manual

2900-233

Section 2 :: Installation and

Removal

1. Installation Requirements

2. Dimensions

3. Installation

4. Starting the Machine

5. Consumables

6. Calibration

7. Customer Training

8. Installation Checklist

9. Removal Procedures

TECHNICAL SUPPORT

Section 2: Installation and Removal 3025-002A

Installation Requirements

Installation site must meet specified requirements to ensure proper

machine operation.

Foot Print/Dimensions

Weight 245lb (111.13kg)

Counter Space

Electrical

Water

Water Treatment System

Drain

Ambient Air Temperature Maximum ambient temp: 90°F

23.48”W x 25.32”D x 36”H (23.48cm x

64.31cm x 91.44cm)

36”W x 29”D x 42”H (91.44cm x 73.66cm x

106.68cm)

Located within two (2) meters of machine

Single Phase:

200-240vac, 30amp dedicated circuit

NEMA L14-30 Receptacle

Three Phase:

200-240vac, 20amp, three phase dedicated

circuit

NEMA L15-30 receptacle

High Leg:

200-240vac, 30amp, high leg dedicated

circuit

International machines are shipped without a

power plug. A plug must be attached at the

time of installation and meet with all local

electrical codes.

Minimum: 30psi; Maximum: 100psi (min: 2

bar, max 7 bar)

25 gallons per hour (95 liters per hour)

Cold water source with female ¼” NPT

fitting with shutoff valve

Located within five (5) feet of machine

A fresh water bypass is required for sites

with a reverse osmosis filter system.

All machines are shipped with the Scalex

Water Treatment System which includes two

combination carbon filters and water

softening cartridges.

25”H x 11”W x 5.25”D

Connection for ¾” drain dose

Indirect drain required

Located within five (5) feet of machine

2-2 Concordia 2500s/i Technical Support Manual

2900-233

3025-002A Section 2: Installation and Removal

Dimensions

Concordia 2500s/i Technical Support Manual 2-3

2900-233

Section 2: Installation and Removal 3025-002A

Installation

Installation includes machine set-up; connection to the water,

electrical and drain supplies; calibration; and customer training. If

more than one visit is required to complete the installation due to an

unprepared site, return visits are billable to the customer.

Placing the Unit

Verify counter is stable and capable of supporting at least 300lbs.

The machine height is 36”. A recommended 6” minimum additional

space is needed for pouring beans and for bean hopper removal.

Ambient Temperature

The maximum temperature of the area around a machine is 90°F. The

refrigeration unit cannot maintain a proper temperature in a location

with an ambient temperature greater than 90°F.

Do not place machine next to any equipment that exhausts hot air.

Configuring the Machine for Supply Voltage

Before connecting machine to the electrical supply, check and verify

the incoming power supply. The following chart displays the required

voltages.

2500s/ i Equipped with 4 p rong 220 volt plug

LEG 1 120VAC

TO NEUTRAL

NEUTRAL

NEUTRAL

LEG 2 120VAC

TO NEUTRAL

NEMAL14-30R

Receptacle

GROUND

Espresso Machine Electrical Settings

Prior to connecting the machine to the power source, verify all the

settings are correct. The DC jumper plug and transformer must be

properly configured.

WARNING: Failure to properly set the DC jumper plug and the

transformer connector may result in machine malfunction, short

circuit, blown fuses, overheating, or damage to the circuit boards.

Required Receptacle Voltages

Connections Voltage

L1 to Ground 110vac -120vac

L2 to Ground 110vac - 120vac

L1 to Neutral 110vac - 120vac

L2 to Neutral 110vac - 120vac

L1 to L2 200vac - 240vac

Ground to Neutral 0vac

2-4 Concordia 2500s/i Technical Support Manual

2900-233

3025-002A Section 2: Installation and Removal

Setting the DC Jumper Plug

1. Measure the source voltage at the wall outlet (refer to the chart on

the previous page) and record the value in the Comments section

of the Installation Checklist

2. Remove the electrical enclosure cover to access the DC power

supply board

CAUTION: ESD protection required

3. Remove the DC power supply board using the white ejector lever

4. Using the voltage table, configure the jumper plug to the source

voltage

Jumper Plug is located on DC Power Supply Board

200 VAC

208 VAC

220-240 VAC

L2

5. Insert the jumper plug into the jumper connection located on the

DC power supply board

6. Re-install the DC power supply board

IMPORTANT: Ensure the board is fully seated by firmly pressing

the board into the connector on the backplane.

7. Re-install the electrical enclosure cover and verify the display

cable is not stressed, pinched or cut when the front panel is

lowered

50-60Hz

200 VAC

208 VAC

220-240 VAC

L2

Concordia 2500s/i Technical Support Manual 2-5

2900-233

Section 2: Installation and Removal 3025-002A

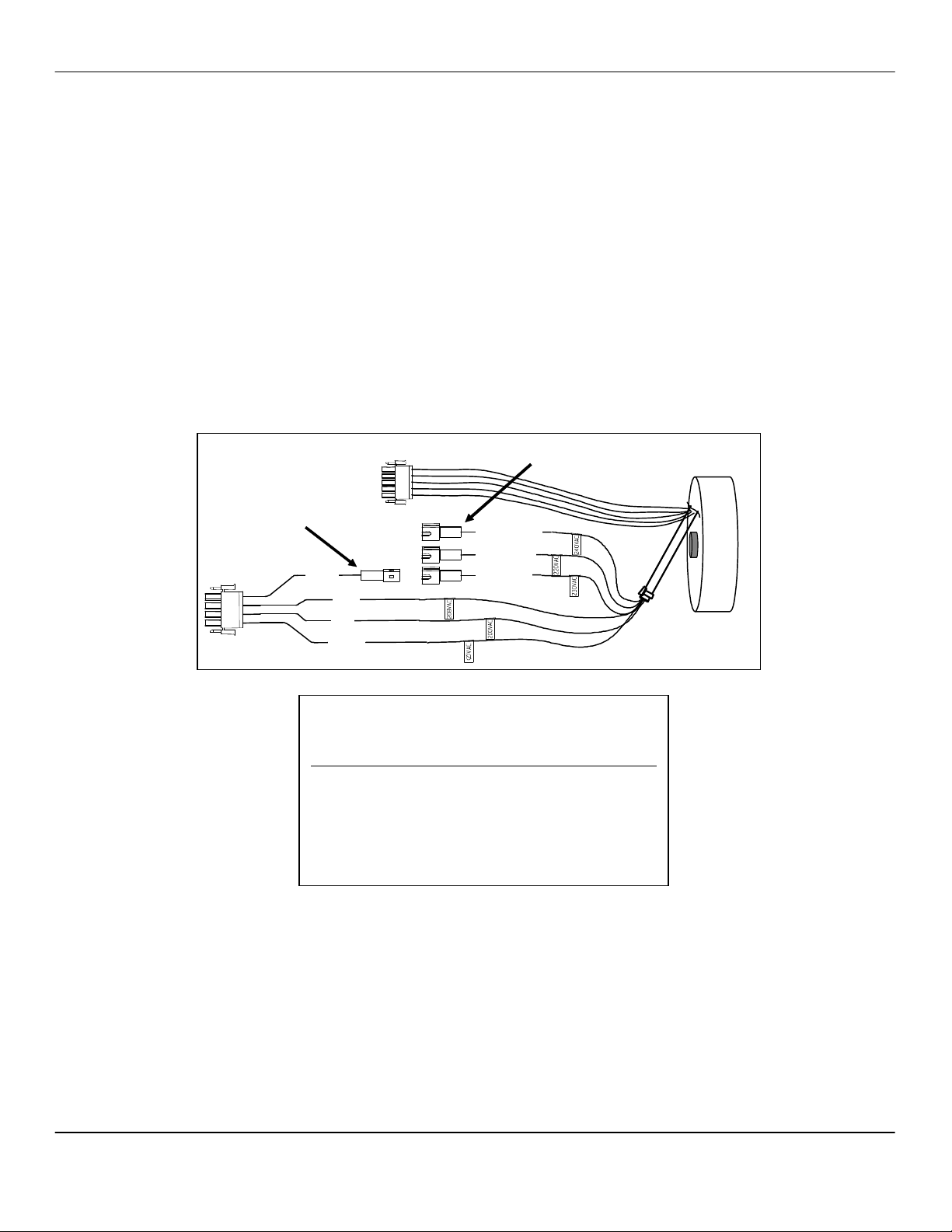

Configuring Transformer Auxiliary Connector #1

If the source voltage is between 200 – 214vac, no adjustment is

necessary.

If the source voltage is between 215 – 244vac, you must set the

auxiliary connector on the transformer.

1. Remove the machine back panel

2. Locate the power supply transformer and connectors

3. Using the voltage table, configure the auxiliary transformer

connector #1 to the appropriate transformer connector #2, #3,

or #4

4. Reinstall the back panel and proceed with the machine

installation

Transformer is accessible from the back of the machine

CONNECTO RS #2, #3, #4

AUXILIARY

CONNECTOR #1

WHITE

1

BLUE

RED

BROWN

2

3

4

ORANGE 240V

GREEN 220V

WHITE 230V

TRANSFORMER

VOLTAGE TABLE

SOURCE JUMPER PLUG CONNECTOR

VOLTAGE RANGE SETTING SETTING

200 – 204 200 NO ADJUSTMENT

205 – 214 208 NO ADJUSTMENT

215 – 224 220-240 #3 GREEN WIRE

225 – 234 220-240 #4 WHITE WIRE

235 – 244 220-240 #2 ORANGE WIRE

2-6 Concordia 2500s/i Technical Support Manual

2900-233

3025-002A Section 2: Installation and Removal

Y

Y

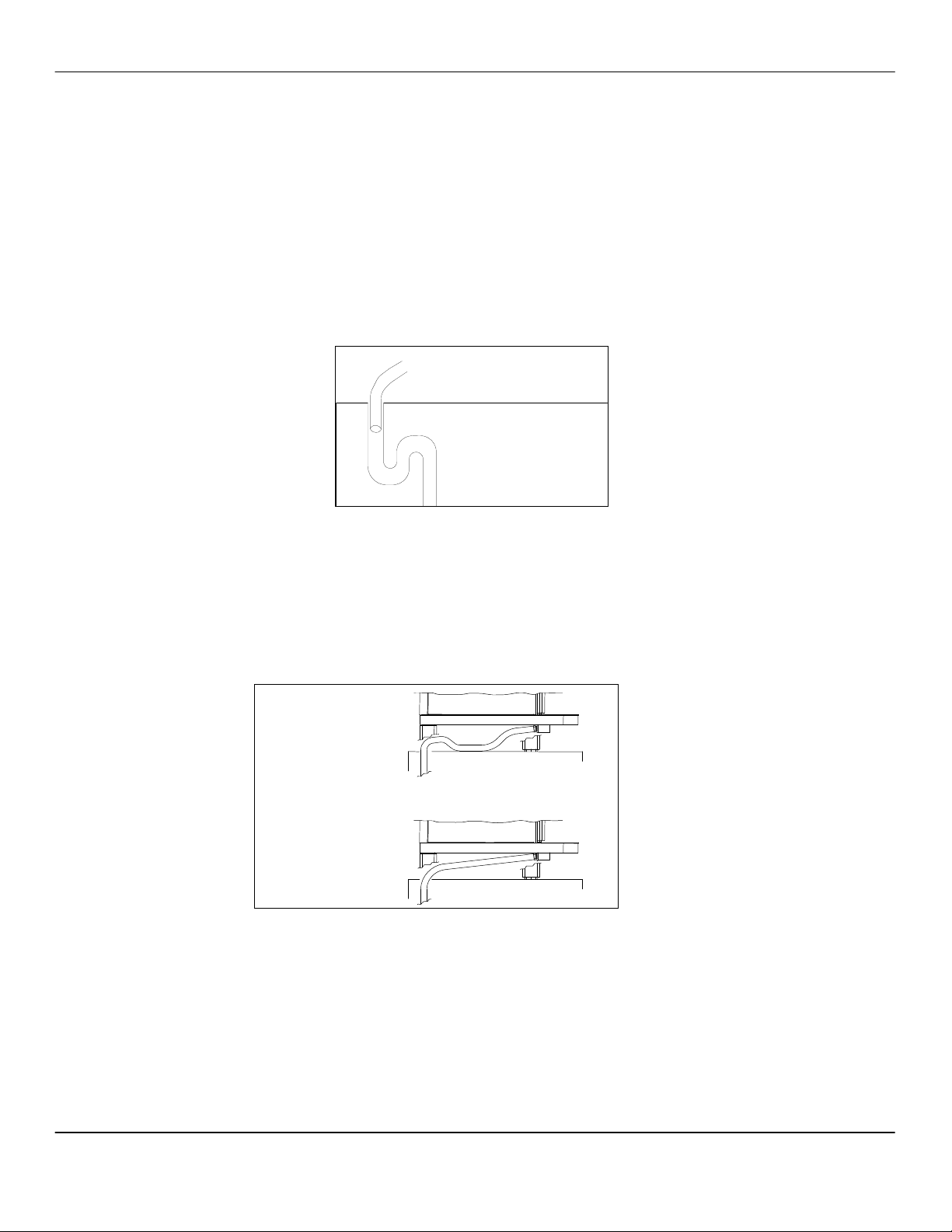

Connecting the Drain

Only a qualified plumber, complying with all local codes and

requirements, can install the drain.

The following requirements must be met:

Connection for a ¾” drain hose

Drain must be located within five (5) feet of machine

An indirect drain is required to ensure waste water does not

travel up hose

Indirect Drain

DRAIN HOSE FROM MACHINE

DRAIN

The minimum rate of fall required is one inch per foot. When installing

the drain hose, it is important the drain hose has a continuous rate of

fall.

If the drain has any l ow spots or any horizon tal runs as it travels f rom

the machine to the drain, the water and other waste from the machine

will back up and cause the drain hose and/or the drain tray to clog.

Connecting Drain

WRONG

INCORRECTL

INSTALLED DRAIN

RIGHT

CORRECTL

INSTALLED DRAIN

Concordia 2500s/i Technical Support Manual 2-7

2900-233

Section 2: Installation and Removal 3025-002A

Connecting the Water Supply

To ensure proper operation of the machine, the following requirements

must be met:

Cold water source with a shutoff valve and female ¼” NPT

fitting

Minimum 30psi

Maximum 100psi

Water source must be located within five (5) feet of machine

All machines must be installed with a Scalex Water Treatment

System

If the location has a reverse osmosis filter system, a freshwater

bypass is required

Problems with Reverse Osmosis Water System

A fresh water bypass is required for sites with a reverse osmosis filter

system. Machine water level sensors are inoperative when used with

this system.

2-8 Concordia 2500s/i Technical Support Manual

2900-233

3025-002A Section 2: Installation and Removal

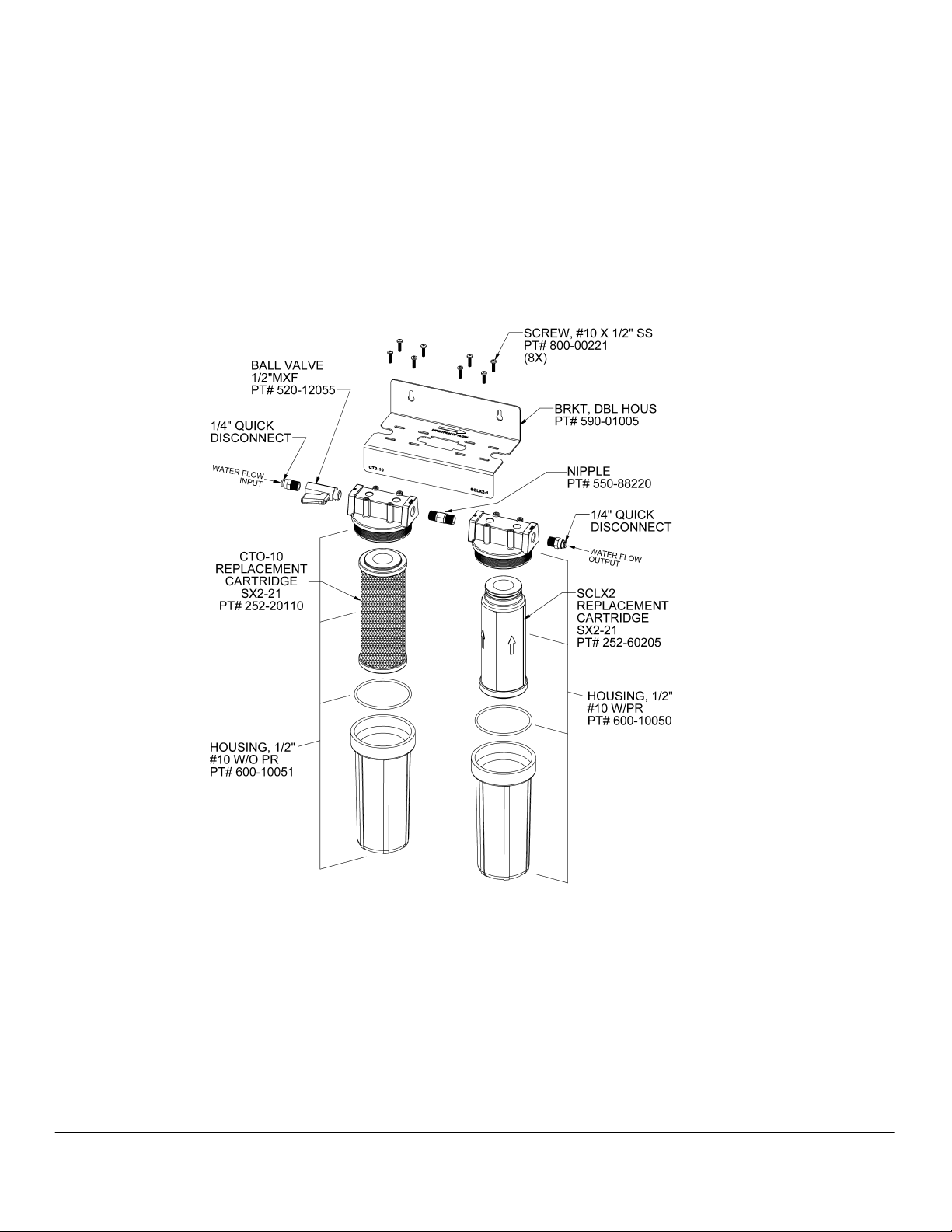

Connecting the Water Treatment System

All machines are installed with a Scalex Water Treatment System. Wall

space must be available and located within five (5) feet of machine.

Dimensions: 25”H x 11” W x 5.25” D

Mount the system as close as possible to the machine

Flush the cartridge for five minutes prior to connecting to

machine

Scalex Water Treatment System

Concordia 2500s/i Technical Support Manual 2-9

2900-233

Section 2: Installation and Removal 3025-002A

Starting the Machine

1. Ensure the jumper plug has been set appropriately and, if

necessary, the transformer auxiliary connector

2. Ensure the electrical cord is plugged in and twist-locked

3. Ensure water is supplied to the unit

4. Ensure drain is supplied to the unit

5. Start the unit by turning on the main power switch located

behind the grounds bin door

6. Warm-up will take 10-15 minutes

NOTE: The grounds bin must be in place and all doors must be

closed.

7. Fill the bean hoppers with fresh, whole, espresso-roast beans

8. Place fresh milk in the refrigerator and ensure the milk pickup

tubes are correctly inserted into the milk containers

Consumables

At the time of installation, the customer is required to have on hand:

• 5lb whole espresso-roast beans

• 3lb decaffeinated espresso-roast beans

• 2 gallons of milk

• Large and small cups

Calibration

Complete calibration of espresso, milk timings, and water timings is

required at the time of installation. Calibrate the machine to customer

specifications, and any customer-specific recipe provided at the time

of installation.

Refer to Section 4: Software, for complete calibration instructions.

Customer Training

Complete customer training is required at the time of installation.

Refer to Section 11: Customer Service and Training Section, for

complete customer training instructions.

2-10 Concordia 2500s/i Technical Support Manual

2900-233

3025-002A Section 2: Installation and Removal

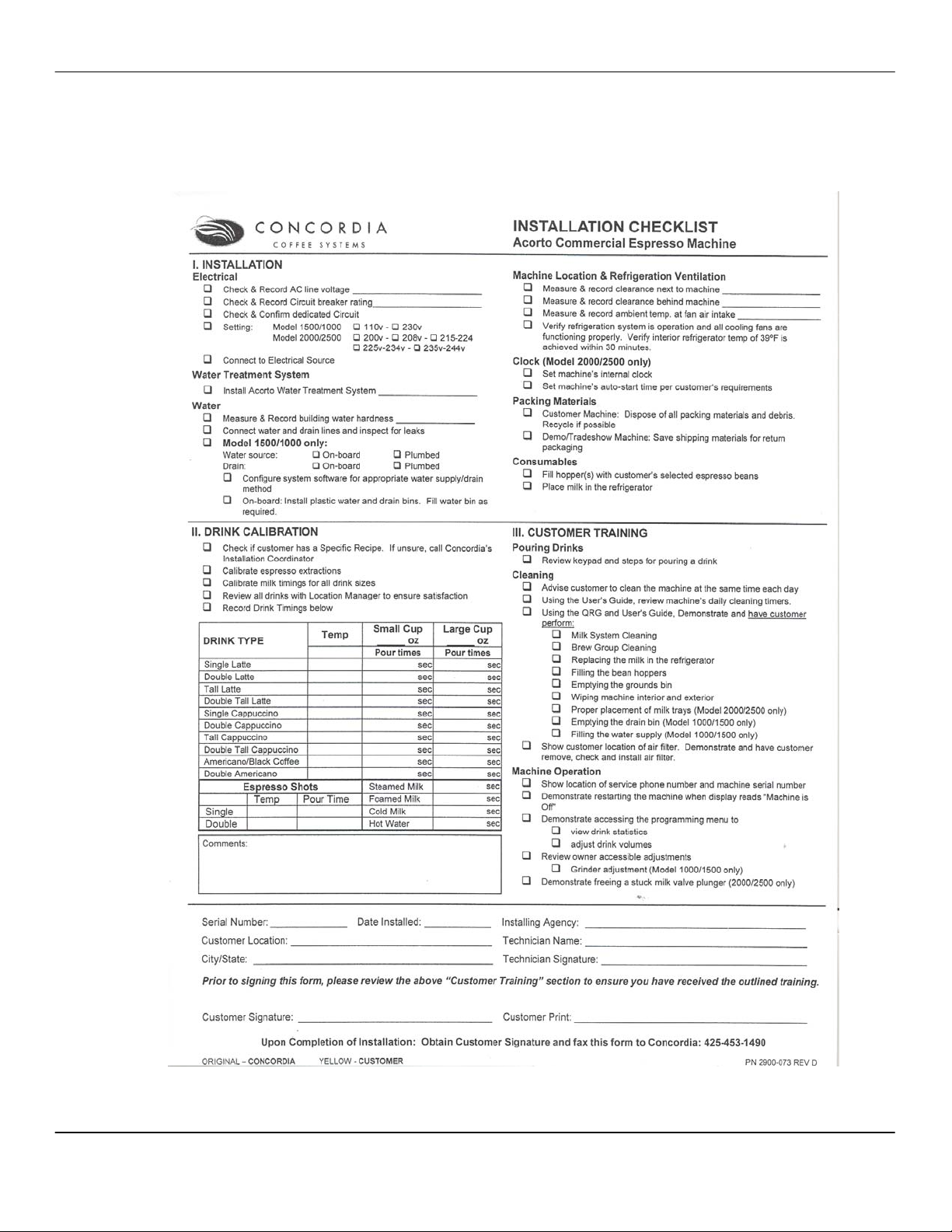

Installation Checklist

The installation checklist must be completed and faxed to Concordia

within 24 hours of installation.

Concordia 2500s/i Technical Support Manual 2-11

2900-233

Section 2: Installation and Removal 3025-002A

Removal Procedures

The de-install procedure below must be performed prior to shipping a

machine.

You will be billed for parts and labor to restore the machine if the

removal procedure is not followed.

Cumulative Drink Total

A. Obtain and record the CUMULATIVE DRINK TOTAL on the

service invoice

Clean Refrigerator

A. Remove milk from the refrigeration unit

B. Clean the interior of refrigeration unit, and the milk weight

trays

Clean Brew Group & Grinders

A. Remove beans from the grinders

B. Clear ground beans from the grinder assembly by running three

double espressos per grinder assembly

C. Remove sediment and buildup from the brew group and

grounds chute

D. Clean any coffee grounds from the machine, with a brush

and/or vacuum

E. Clean the product nozzle

F. Clean the grounds bin and bean hoppers

Run Daily Clean Cycles

A. Run MILK CLEAN cycle

B. Run SHUTDOWN CLEAN cycle

Disconnect Water Supply & Drain Tanks

A. Turn off the main power switch and unplug the machine

B. Disconnect the water supply line

C. Disconnect the water gauge line from the gauge

D. Drain the water tank

E. Drain the steam tank

F. Leave the tank drain valves open

G. Restore the water line to the gauge

H. Clean and dry all interior and exterior surfaces (refrigeration

unit, brew group area, drain tray, etc.)

I. Store the bean hoppers and lids inside the refrigeration unit

J. Ensure the Operator’s Manual and Quick Reference Guide are

included with the unit

2-12 Concordia 2500s/i Technical Support Manual

2900-233

3025-002A Section 2: Installation and Removal

K. Coil the power cord, water supply line, and drain hose with Ty-

Coil the power cord, water supply line, and drain hose with Tywraps®

wraps®

Preparation for Shipping Preparation for Shipping

Follow steps 1-5 of Removal Procedures, in addition to the steps

Follow steps 1-5 of Removal Procedures, in addition to the steps

below.

below.

A. If Demo Machine: Remove, drain, clean, dry, and pack the

A. If Demo Machine: Remove, drain, clean, dry, and pack the

water filtration system for shipping. Discard the filter

water filtration system for shipping. Discard the filter

cartridges, collect all cleaning supplies and include with

cartridges, collect all cleaning supplies and include with

machine.

machine.

B. If the machine is shipping to an alternate location, call

B. If the machine is shipping to an alternate location, call

Concordia for additional shipping requirements.

Concordia for additional shipping requirements.

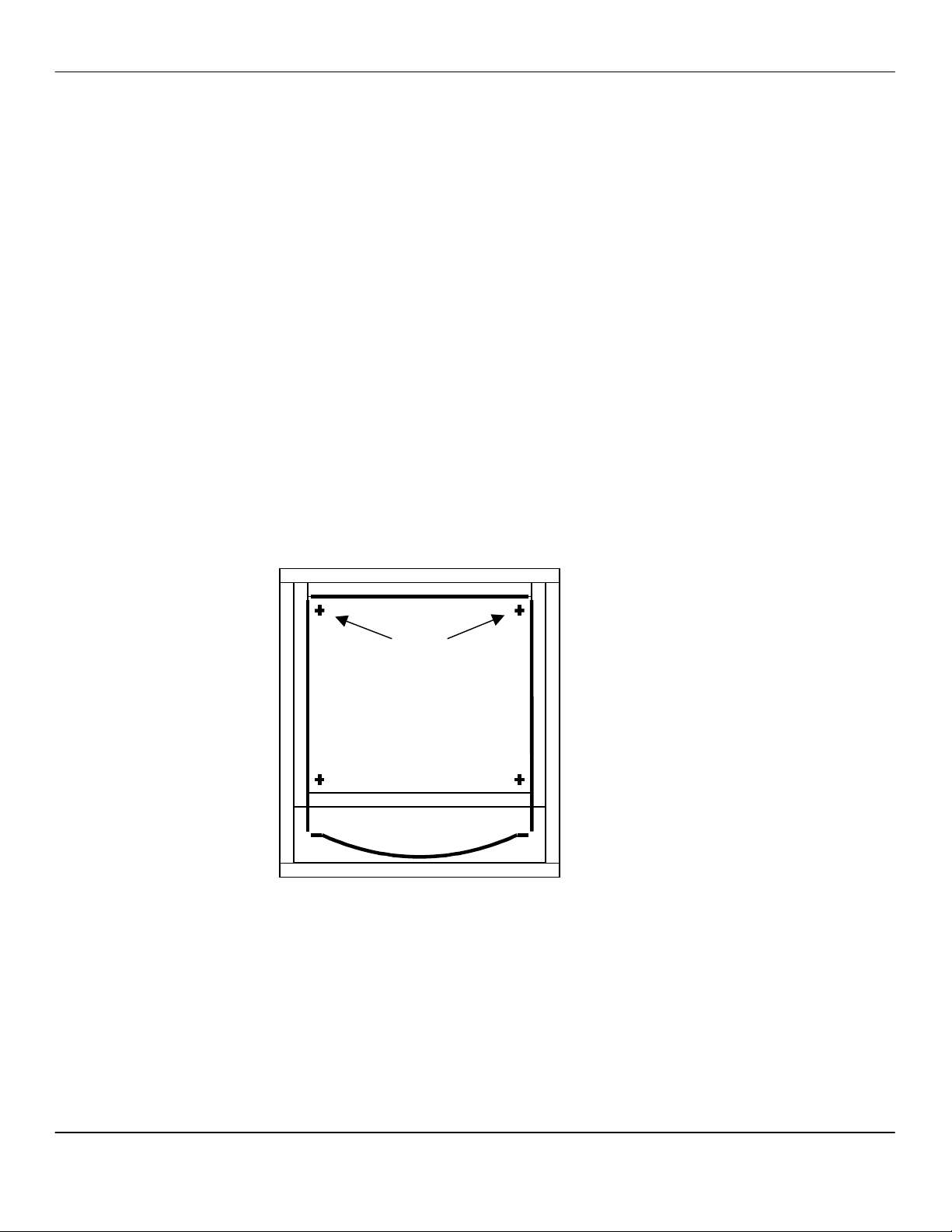

Packaging for Shipment Packaging for Shipment

Ship the machine using Concordia-supplied pallet and shipping supplies. Ship the machine using Concordia-supplied pallet and shipping supplies.

If necessary, contact Concordia to request a shipping kit. If necessary, contact Concordia to request a shipping kit.

A. Place clean machine on shipping pallet. Ensure the machine

A. Place clean machine on shipping pallet. Ensure the machine

feet are within framework.

feet are within framework.

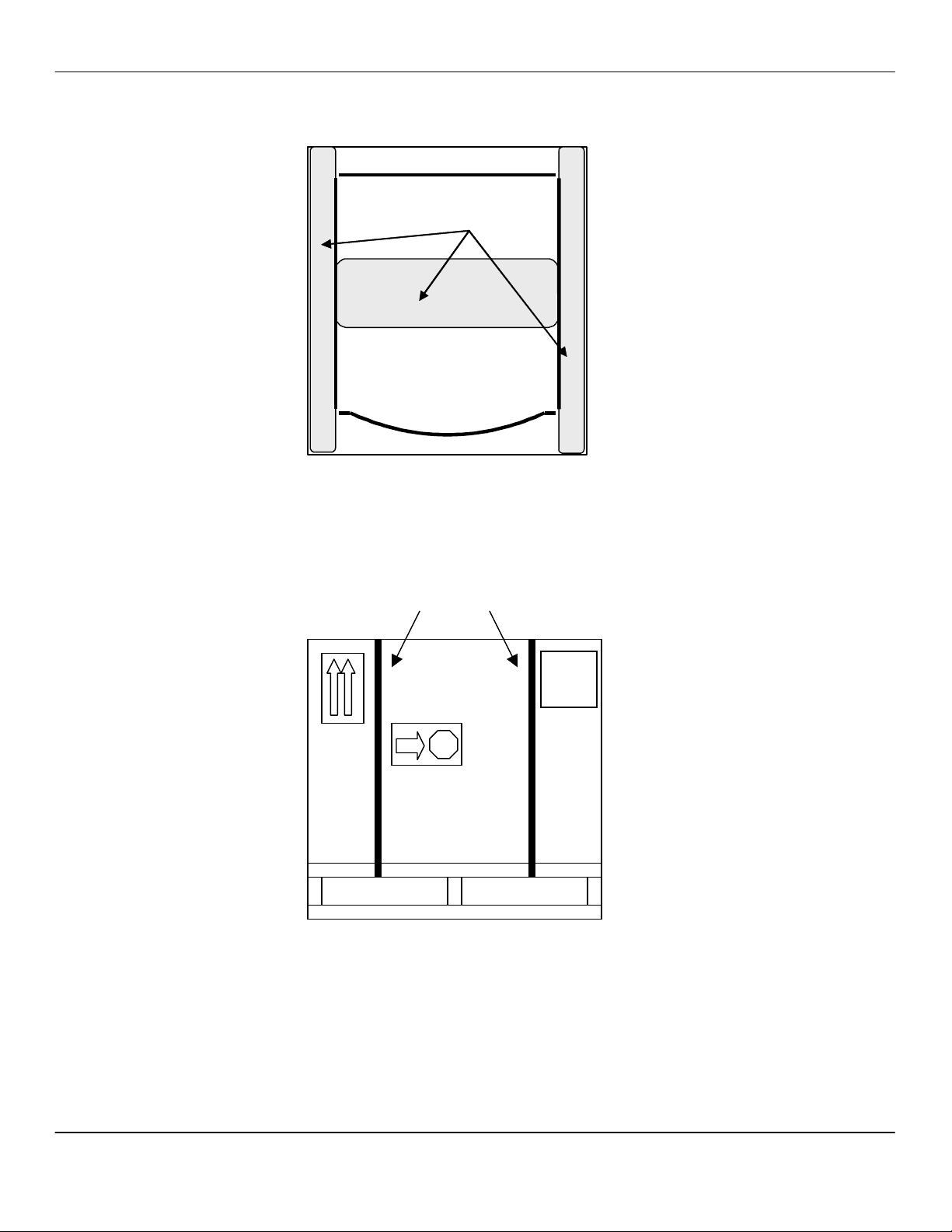

Top View

FEET

FRONT

B. Place box over the machine B. Place box over the machine

C. Place the foam inserts into the top of the box C. Place the foam inserts into the top of the box

Concordia 2500s/i Technical Support Manual 2-13

2900-233

Section 2: Installation and Removal 3025-002A

Top

View

FOAM

SINSERT

FRONT

D. Place labeling on the box. Place the DO NOT STACK label on

the top of the box. Place the banding straps on each side of the

the top of the box. Place the banding straps on each side of the

box (refer to diagram below), through the holes in the pallet

box (refer to diagram below), through the holes in the pallet

and strapped down with the clips to hold the machine in place.

and strapped down with the clips to hold the machine in place.

g on the box. Place the DO NOT STACK label on

BANDING STRAPS

FRAGILE

Side View

2-14 Concordia 2500s/i Technical Support Manual

2900-233

Loading...

Loading...