Page 1

Operators Manual

Air Systems

2800 / 3350

3800 / 5250

P/N: 331815

S/N: 702575

AGCO-AMITY JV, LLC

17885 Highway 13

Wahpeton, ND 58075 (800)

688-3300

(701)

www.concordseeding.com

642-2621

Page 2

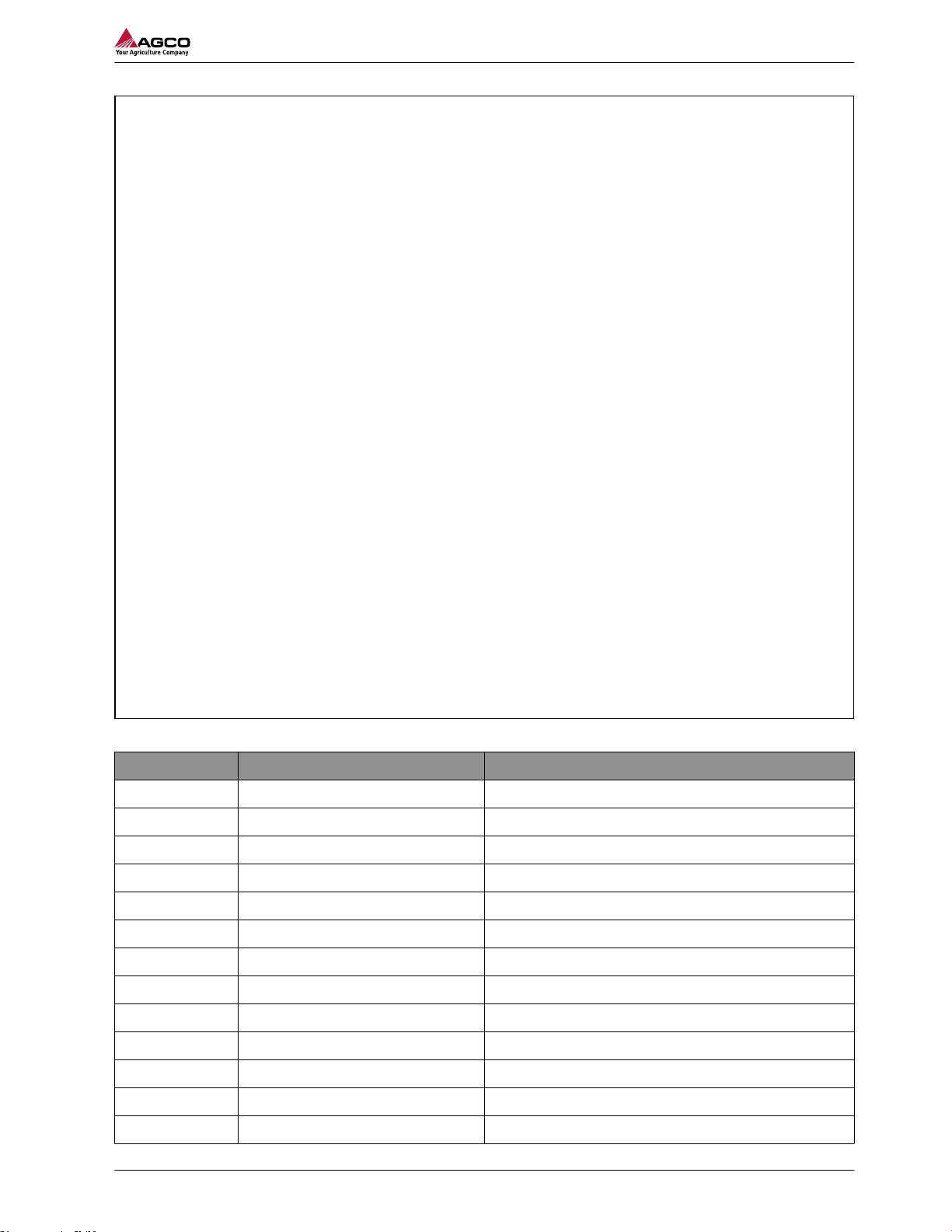

AMITY TECHNOLOGY, LLC LIMITED WARRANTY FOR NEW PRODUCTS

280/335/380/525 Bushel Air Carts

331815

1

1. General Provisions. This Warranty shall apply to the original purchaser of (1) any new and unused machine

manufactured by Amity Technology, LLC (“Amity”), and (2) any new and unused part which is manufactured

by Amity for use in an Amity machine, jointly referred to as “Products,” whether such Product is purchased

through a dealer or directly from Amity. Under this Warranty, Amity will repair or replace, as it chooses in its

sole discretion, any covered Product, or any component thereof, which Amity determines to be defective. This

Warranty shall be in effect for a period of twelve (12) months (“the Warranty Period”), beginning on the date of

delivery of the covered machine or part by the dealer or Amity to the purchaser (“the Warranty Start Date”). The

purchaser must pay the cost of transportation of a Product to be repaired or replaced to and from an authorized

Amity dealer. This Warranty may not be transferred from the original purchaser of a Product to any other

person. This Warranty does not give a purchaser the right to any relief other than repair or replacement of the

Product, and it specifically does not allow for consequential or incidental damages, exemplary or punitive

damages, or costs and fees.

2. Scope and Limitations of Warranty. With respect to machines, this Warranty is void if any part not supplied

by Amity is used in assembly or repair of the machine, or if the machine has been altered, abused or neglected,

as determined by Amity. With respect to parts, this Warranty is void if the part is used in any manner other than

that for which it is intended. This Warranty does not extend in any way to tires and any other component of a

Product warranted by another manufacturer, a copy of which warranty is provided herewith (“Third-Party

Warranties”). In the event Amity determines that a Product is not defective, or that any other provision of this

Paragraph 2 operates to limit the Warranty, this Warranty shall not apply and the purchaser shall be responsible

for transporting the Product from the authorized Amity dealer’s location within 10 days of notice by Amity.

3. Procedures for Obtaining Service. To secure Warranty service, a purchaser must (1) report the defect to an

authorized dealer and request repair within 45 days of the failure and within the Warranty Period; (2) present

evidence that this Warranty applies to the Product; (3) present evidence of the Warranty Start Date; and (4) bring

the Product to an authorized Amity dealer within a reasonable period of time after reporting the defect.

4. LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES. To the extent allowed by law,

neither Amity, its dealers, nor any company affiliated with Amity makes any warranties, representations, or

promises as to the quality, performance, or freedom from defect of any Product covered by this Warranty.

AMITY HEREBY WAIVES, TO THE EXTENT APPLICABLE, ANY AND ALL IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE. A PURCHASER’S ONLY REMEDIES IN CONNECTION WITH THIS

WARRANTY ARE THOSE SET FORTH ON THIS PAGE. IN NO EVENT WILL AMITY,

ITS DEALERS, OR ANY COMPANY AFFILIATED WITH AMITY BE LIABLE FOR

INCIDENTIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES.

Some states do not allow waivers of certain warranties, so the above waivers may not apply to you. You may

also have other rights which vary from state to state.

5. No Dealer Warranty. This is the exclusive warranty

applicable to Amity Products. No dealer has any authority

to make any other warranty, modify, limit, or expand the terms of this Warranty in any fashion, or make any

representation or promise on behalf of Amity.

6. Dispute Resolution. Any controversy or claim arising out of or relating to this Warranty must be settled by

arbitration in Fargo, North Dakota, at a time and location designated by the arbitrator, but not exceeding 30 days

after a demand for arbitration has been made, and may be conducted by electronic, video, or other technical

means. Arbitration will be conducted by the American Arbitration Association in accordance with its Rules of

Commercial Arbitration, and judgment upon the award rendered by the arbitrator may be entered in any court

having jurisdiction thereof. The arbitrator will have the authority to order Amity to undertake a repair or replace

any Product, at its election, if the arbitrator finds that this Warranty requires Amity to do so. The arbitrator will

not have the authority to impose any other remedy against Amity, including without limitation consequential or

incidental damages, exemplary or punitive damages, or costs and fees.

Page 3

Table of contents

280/335/380/525 Bushel Air Carts

331815

2

280 / 335 / 380 / 525 Bushel Air Carts

1 Safety .....................................................................7

1.1 Introduction .........................................................9

1.1.1 Safety alert symbol ................................................9

1.1.2 Safety messages ..................................................9

1.1.3 Informational messages .............................................9

1.1.4 Safety signs ......................................................9

1.1.5 A word to the operator .............................................10

1.1.6 This manual .....................................................11

1.2 Operation ..........................................................12

1.2.1 Prepare for operation ..............................................12

1.2.2 General information ...............................................12

1.2.3 Personal protective equipment .......................................13

1.2.4 Seat instructions .................................................13

1.2.5 Shield and guards .................................................14

1.2.6 Exhaust warning .................................................14

1.2.7 Flying debris ....................................................15

1.2.8 Agricultural chemicals .............................................15

1.3 Travel on public roads ..............................................16

1.4 Maintenance .......................................................18

1.4.1 General maintenance information .....................................18

1.4.2 Fire prevention and first aid .........................................19

1.4.3 High pressure leaks ...............................................20

1.4.4 Tire safety ......................................................21

1.4.5 Replacement parts ................................................21

1.5 Marker lamps ......................................................22

1.6 Safety sign location .................................................23

2 Introduction ..............................................................37

2.1 Introduction ........................................................39

2.1.1 Units of measurement .............................................39

2.1.2 Replacement parts ................................................39

2.1.3 Intended use ....................................................39

2.1.4 Proper disposal of waste ...........................................39

2.2 Machine identification ..............................................41

2.2.1 Serial number plate ...............................................41

2.2.2 Serial number description ...........................................41

2.3 Air cart ............................................................43

2.4 Major components .................................................44

2.5 Two-bin operator manual ...........................................46

2.5.1 Operator manual storage ...........................................46

2.6 Three-bin operator manual ..........................................47

2.6.1 Operator manual storage ...........................................47

3 Operation .................................................................49

3.1 Ladder and railings .................................................51

3.1.1 Ladder and railings - two-bin model ....................................51

3.1.2 Ladder and railings - three-bin model ...................................51

3.2 Product bin lids .....................................................52

3.3 Auger ..............................................................53

Page 4

Table of contents

280/335/380/525 Bushel Air Carts

331815

3

3.3.1 Using the auger to load products ..................................... 53

3.3.2 Using the auger to unload products .................................... 55

3.3.3 Cleaning out the auger ............................................. 55

3.4 Ground drive ....................................................... 56

3.5 Hydraulic systems .................................................. 57

3.5.1 Air cart to drill hydraulic coupler ...................................... 57

3.5.2 Air cart to tractor hydraulic couplers ................................... 57

3.6 Hydraulic drive ..................................................... 59

3.7 Blower ............................................................. 60

3.7.1 Blower speed ................................................... 60

3.8 Selecting air stream ................................................ 61

3.9 Meters ............................................................. 62

3.9.1 Product meter adjustment .......................................... 62

3.9.2 Changing metering rolls - ground drive system ........................... 63

3.9.3 Changing metering rolls - hydraulic system .............................. 63

3.9.4 Meter roll options ................................................. 64

3.9.5 Meter adjustments ................................................ 64

3.10 Setting the application rate on a ground drive system ............... 66

3.11 Hydraulic drive calibration and operation ........................... 68

3.11.1 Preparing to calibrate a meter ....................................... 68

3.11.2 Priming the meter ............................................... 69

3.11.3 Taking a product sample for calibration ................................ 70

3.11.4 Entering accumulated weight on the virtual terminal ...................... 70

3.11.5 Manually setting the motor cal value for a variable rate system ............... 71

3.12 Rate charts ........................................................ 72

3.12.1 Fertilizer rate chart - 96 kg per cubic meter (60 lb per cubic foot) .............. 72

3.12.2 Barley rate chart ................................................. 74

3.12.3 Canola rate chart ................................................ 76

3.12.4 Soybean rate chart ............................................... 78

3.12.5 Wheat rate chart ................................................ 80

3.13 Raven system .......................................................82

3.13.1 Raven system overview .............................................82

3.13.2 Raven system hardware .......................... ..................82

3.14 Cart control system ................................................ 85

3.14.1 Virtual terminal - cart control system .................................. 85

3.14.2 Alarm and indicator icons .......................................... 85

3.14.3 Confirmation screen .............................................. 86

3.14.4 Main (home) screen .............................................. 87

3.14.5 Product bin alarms ............................................... 89

3.15 Profile set up ..................................................... 90

3.15.1 Profile Set Up (Ground Drive). ....................................... 96

3.15.2 Profile Set Up (Hydraulic Drive). ......................................105

3.15.3 Master Switch Operation. ..........................................114

3.15.4 Enabling Automatic Height Switch ....................................114

3.9.5.1 Shims ................................................... 64

3.9.5.2 Deflector block ............................................ 64

3.9.5.3 Meter door and cleanout door latches ........................... 65

3.9.5.4 Meter door tray ............................................ 65

3.13.2.1 Raven electronic control unit ..................................82

3.13.2.2 Virtual terminal ........................................... 82

3.13.2.3 Blower speed sensor ....................................... 82

3.13.2.4 Bin level sensor ........................................... 83

3.13.2.5 Meter box flow sensor ...................................... 83

3.13.2.6 Meter shaft speed sensor (ground drive) ......................... 83

3.13.2.7 Meter shaft speed sensor (hydraulic drive) ....................... 84

3.13.2.8 Ground speed sensor ...................................... 84

Page 5

Table of contents

280/335/380/525 Bushel Air Carts

331815

4

3.15.5 Manual Work Switch Operation ..................................... 114

3.15.6 Setting the automatic height switch operation ............................114

3.15.7 Customizing Product Tabs. ........................................115

3.15.8 Setting Test Speed ..............................................115

3.15.9 Refilling Product Bins. ............................................115

4 Maintenance .............................................................. 116

4.1 Lubrication points .................................................. 118

4.1.1 Lubrication and maintenance chart .................................... 118

4.1.2 Lubrication fitting locations .......................................... 118

4.2 Hydraulic motor maintenance ...................................... 120

4.3 Gear box maintenance ............................................. 121

4.3.1 Replacing the gearbox coupler shear pin ............................... 121

4.4 Wheel bearing maintenance ........................................ 122

4.5 Tires and wheels .................................................. 123

4.6 Storing the air cart ................................................ 124

5 Troubleshooting ......................................................... 113

5.1 Troubleshooting ................................................... 128

6 Specifications ............................................................ 117

6.1 Specifications ..................................................... 130

6.1.1 Specifications - two-bin model ...................................... 132

6.1.2 Specifications - three-bin model ..................................... 132

6.1.3 Conversion factors ............................................... 133

6.1.4 Formulas ...................................................... 134

6.2 Approximate tank fill percentages ...................................135

6.3 Maximum transport speed ......................................... 136

7 Index ............................................................... .....138

Page 6

Table of contents

280/335/380/525 Bushel Air Carts

331815

5

Page 7

Table of contents

280/335/380/525 Bushel Air Carts

331815

6

1. Safety

1.1 Introduction ..............................................................9

1.1.1 Safety alert symbol .....................................................9

1.1.2 Safety messages .......................................................9

1.1.3 Informational messages ..................................................9

1.1.4 Safety signs ...........................................................9

1.1.5 A word to the operator ..................................................10

1.1.6 This manual ..........................................................11

1.2 Operation ...............................................................12

1.2.1 Prepare for operation ...................................................12

1.2.2 General information ....................................................12

1.2.3 Personal protective equipment ............................................13

1.2.4 Seat instructions ......................................................13

1.2.5 Shield and guards ......................................................14

1.2.6 Exhaust warning ......................................................14

1.2.7 Flying debris .........................................................15

1.2.8 Agricultural chemicals ..................................................15

1.3 Travel on public roads ...................................................16

1.4 Maintenance ............................................................18

1.4.1 General maintenance information ..........................................18

1.4.2 Fire prevention and first aid ..............................................19

1.4.3 High pressure leaks ....................................................20

1.4.4 Tire safety ...........................................................21

1.4.5 Replacement parts .....................................................21

1.5 Marker lamps ...........................................................22

1.6 Safety sign location ......................................................23

Page 8

Table of contents

280/335/380/525 Bushel Air Carts

331815

7

Page 9

1.1 Introduction

280/335/380/525 Bushel Air Carts

331815

8

1.1.1 Safety alert symbol

The safety alert symbol means Attention! Become

Alert! Your Safety Is Involved!

Look for the safety alert symbol both in this

manual and on safety signs on this machine. The

safety alert symbol will direct your attention to

information that involves your safety and the

safety of others.

1.1.2 Safety messages

The words DANGER, WARNING or CAUTION are

used with the safety alert symbol. Learn to

recognize these safety alerts and follow the

recommended precautions and safety practices.

1. Safety

Fig. 1

DANGER:

Indicates an imminently hazardous

situation that, if not avoided, will

result in DEATH OR VERY SERIOUS

INJURY.

WARNING:

Indicates a potentially hazardous

situation that, if not avoided, could

result in DEATH OR SERIOUS

INJURY.

CAUTION:

Indicates a potentially hazardous

situation that, if not avoided, may

result in MINOR INJURY.

Fig. 2

1.1.3 Informational messages

The words important and note are not related to personal safety, but are used to give additional

information and tips for operating or servicing this equipment.

IMPORTANT: Identifies special instructions or procedures which, if not strictly observed, could result in

damage to or destruction of the machine, process, or its surroundings

NOTE: Identifies points of particular interest for more efficient and convenient repair or operation.

1.1.4 Safety signs

Keep signs clean by wiping off regularly. Use a mild soap and water solution if necessary.

WARNING:

Do not remove or obscure safety signs. Replace any safety signs that are not readable or

are missing. Replacement signs are available from your dealer in the event of loss or

damage. The actual location of the safety signs is illustrated at the end of this section.

Page 10

1. Safety

280/335/380/525 Bushel Air Carts

331815

9

If parts have been replaced or a used machine has been purchased, make sure all safety signs are present

and in the correct location and can be read. Illustrations of safety sign locations are located at the rear of

this section.

Replace any safety signs that can not be read, are damaged, or are missing. Clean the machine surface

thoroughly with a mild soap and water solution before replacing signs. Replacement safety signs are

available from your dealer.

1.1.5 A word to the operator

It is your responsibility to read and understand the

safety section in this manual and the manual for all

attachments before operating this machine.

Remember you are the key to safety. Good safety

practices not only protect you, but also the people

around you.

Study the content in this manual and make the

content a working part of your safety program.

Keep in mind that this safety section is written

only for this type of machine. Practice all other

usual and customary safe working precautions,

and above all remember - safety is your

responsibility. You can prevent serious injury or

death.

Fig. 3

This safety section is intended to point out some

of the basic safety situations that may be

encountered during the normal operation and

maintenance of your machine. This section also

suggests possible ways of dealing with these

situations. This section is not a replacement for

other safety practices featured in other sections of

this manual.

Personal injury or death may result if these

precautions are not followed.

Learn how to operate the machine and how to use

the controls properly.

Do not let anyone operate the machine without

instruction and training.

For your personal safety and the personal safety of

others, follow all safety precautions and

instructions found in the manuals and on safety

signs affixed to the machine and all attachments.

Use only approved attachments and equipment.

Make sure your machine has the correct

equipment needed by the local regulations.

WARNING:

An operator should not use alcohol or

drugs which can affect their alertness

or coordination. An operator on

prescription or 'over the counter'

drugs needs medical advice on

whether or not they can properly

operate machines.

Page 11

1. Safety

280/335/380/525 Bushel Air Carts

331815

10

CAUTION:

If any attachments used on this

equipment have a separate Operator

Manual, see that manual for other

important safety information.

1.1.6 This manual

This manual covers general safety practices for this machine. The operator manual must always be kept

with the machine.

Right-hand and left-hand, as used in this manual, are determined by facing the direction the machine will

travel when in use.

The photos, illustrations, and data used in this manual were current at the time of printing, but due to

possible in-line production changes, your machine can vary slightly in detail. The manufacturer reserves the

right to redesign and change the machine as necessary without notification.

WARNING:

In some of the illustrations and photos used in this manual, shields or guards may have

been removed for clarity. Never operate the machine with any shields or guards removed.

If the removal of shields or guards is necessary to make a repair, they must be replaced

before operation.

Page 12

1. Safety

280/335/380/525 Bushel Air Carts

331815

11

1.2 Operation

1.2.1 Prepare for operation

Read and understand all operating instructions and precautions in this manual before operating or servicing

the machine.

Make sure you know and understand the positions and operations of all controls. Make certain all controls

are in neutral and the park brake is applied before starting the machine.

Make certain all people are well away from your area of work before starting and operating the machine.

Check and learn all controls in an area clear of people and obstacles before starting your work. Be aware of

the machine size and have enough space available to allow for operation. Never operate the machine at

high speeds in crowded places.

Emphasize the importance of using correct procedures when working around and operating the machine.

Do not let children or unqualified persons operate the machine. Keep others, especially children, away

from your area of work. Do not permit others to ride on the machine.

Make sure the machine is in the proper operating condition as stated in the Operator Manual. Make sure

the machine has the correct equipment required by local regulations.

1.2.2 General information

When parking, park the machine and the tractor on

a solid level surface. put all controls in neutral and

apply the tractor park brake. Stop the tractor

engine and take the key with you.

Make sure the tractor and implement are in the

proper operating condition according to the

operator manuals. Make sure the tractor brakes

and the machine brakes are adjusted correctly.

The tractor must have enough weight and braking

capacity, especially when operating on roads and

terrain that is not even. Use a tractor of

recommended size and weight to tow the

machine. See the machine specifications for the

minimum tractor size and weight.

Tractor must be equipped with rollover protective

structure (ROPS) and a seat belt. use seat belt

during operation.

Do not dismount from moving machinery.

Always operate the machine with the terminal

turned on.

Never start the tractor with the PTO engaged or

terminal turned on.

Stay off slopes too steep for operation.

Where possible avoid operating the machine near

ditches, embankments, and holes. Reduce ground

speed when operating on rough, slippery, or

muddy surfaces and when turning or crossing

slopes.

Fig. 4

Be aware of the size of the machine and have

enough space available to allow for operation.

Page 13

Always lower the machine when not in use and

280/335/380/525 Bushel Air Carts

331815

12

relieve the pressure in the hoses and cylinders.

Do not stand between the tractor and the

implement to install the hitch pin when the tractor

engine is running.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

Watch for overhead wires or other obstructions

when raising the markers, and when moving the

machine with the markers raised.

1.2.3 Personal protective equipment

1. Safety

Fig. 5

Wear all personal protective equipment (PPE) and

protective clothing issued to you or called for by

job conditions and country/local regulations. PPE

includes, but is not limited to, equipment to

protect eyes, lungs, ears, head, hands and feet

when operating, servicing, or repairing equipment.

Always keep hands, feet, hair, and clothing away

from moving parts. Do not wear loose clothing,

jewelry, watches, or other items that could

entangle in moving parts. Tie up long hair that can

also entangle in moving parts.

1.2.4 Seat instructions

Securely fasten the seat belt before operating the

machine. Always remain seated and have the seat

belt fastened while operating the machine.

Replace the seat belts when they become worn or

broken.

Never wear a seat belt loosely or with slack in the

belt system. Never wear the seat belt in a twisted

condition or pinched between the seat structural

members.

Fig. 6

When using the instructional seat, if equipped,

securely fasten the seat belt. The instructional seat

is to be used only to train new operators or

diagnose a problem. The instructional seat is only

intended for short periods of use. Extra riders,

especially children, are not permitted on the

machine.

Fig. 7

Page 14

1. Safety

280/335/380/525 Bushel Air Carts

331815

13

When the instructional seat is used the machine

must be driven at a slower speed and on level

ground. Avoid quick starts, stops, and sharp turns.

Avoid driving on highways or public roads.

1.2.5 Shield and guards

All shields and guards must be in the correct

operating position and in good condition.

Do not open, remove, or reach around shields

while the engine is operating. Entanglement in

rotating belts and components can cause serious

injury or death. Stay clear of rotating components.

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in rotating

drive shafts can cause serious injury or death. Stay

clear of rotating components.

Fig. 8

Make sure rotating guards turn freely.

1.2.6 Exhaust warning

Never operate the engine in a closed building

unless the exhaust is vented outside.

Do not tamper with or modify the exhaust system

with unapproved extensions.

Fig. 9

Fig. 10

Page 15

1. Safety

280/335/380/525 Bushel Air Carts

331815

14

1.2.7 Flying debris

WARNING:

Be careful when operating along the

side of a road or building. Rocks or

other debris can be thrown from the

machine during operation possibly

resulting in injury.

Never stand near the machine during operation.

Debris can be thrown from the machine during

operation possibly resulting in injury.

Fig. 11

1.2.8 Agricultural chemicals

Agricultural chemicals can be very hazardous. Improper use of fertilizer, fungicides, herbicides, insecticides

and pesticides can injure people, plants, animals, soil and other people's property.

Always read and follow all manufacturers' instructions before opening any chemical container.

Even if you think you know the instructions, read and follow instructions each time you use a chemical.

Use the same precautions when adjusting, servicing, cleaning or storing the machine as used when

installing chemicals into the hoppers or tanks.

Inform anyone who comes in contact with chemicals of the potential hazards involved and the safety

precautions required.

Stand upwind and away from smoke from a chemical fire.

Store or dispose of all unused chemicals only in a manner as specified by the chemical manufacturer.

Page 16

1. Safety

280/335/380/525 Bushel Air Carts

331815

15

1.3 Travel on public roads

Make sure you understand the speed, brakes,

steering, stability, and load characteristics of this

machine before you travel on public roads.

Use good judgment when traveling on public

roads. Maintain complete control of the machine at

all times. Never coast down hills.

The maximum speed of farm equipment is

governed by local regulations. Adjust travel speed

to maintain control at all times.

Familiarize yourself with and obey all road

regulations that apply to your machine. Consult

your local law enforcement agency for local

regulations regarding movement of farm

equipment on public roads. Use head lamps,

flashing warning lamps, tail lamps and turn signals,

day and night, unless prohibited by local law.

Make sure all the flashers are operating prior to

driving on the road. Make sure reflectors are

correctly installed, in good condition, and wiped

clean. Make sure the Slow Moving Vehicle (SMV)

emblem is clean, visible, and correctly mounted on

the rear of the machine.

Fig. 12

Lock brake pedals together (if equipped with dual

brake pedals) so both wheel brakes will be applied

at the same time.

Raise implements to transport position and lock in

place. Place all implements into narrowest

transport configuration.

Disengage the power take-off and differential lock.

With towed implements, use a proper hitch pin

with a clip retainer and safety transport chain.

Be aware of other traffic on the road. Keep well

over to your own side of the road and pull over,

whenever possible, to let faster traffic pass.

Be aware of the overall width, length, height, and

weight of the machine. Be careful when

transporting the machine on narrow roads and

across narrow bridges.

Page 17

Watch for overhead wires and other obstructions.

280/335/380/525 Bushel Air Carts

331815

16

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

1. Safety

Fig. 13

Page 18

1. Safety

280/335/380/525 Bushel Air Carts

331815

17

1.4 Maintenance

1.4.1 General maintenance information

Before doing any unplugging, lubricating, servicing,

cleaning, or adjusting:

• Park the machine on a solid level surface.

• Disengage the tractor power take-off.

• Make sure all controls are in the neutral

position and apply the park brake.

• Make sure all implements and attachments

have been lowered to the ground.

• Stop the engine and take the key with you.

• Look and Listen! Make sure all moving parts

have stopped.

• Put blocks in front of and behind the wheels of

the machine before working on or under the

machine.

Do not leave the tractor or implement unattended with the engine running.

Do not pull crop or any other object from the machine while the machine engine is running. Moving parts

can pull you in faster than you can move away.

Fig. 14

Check all nuts and bolts periodically for tightness, especially wheel mounting hardware.

Do not attempt to service or adjust the machine until all moving parts have stopped.

Be aware of the size of parts when doing service work. Never stand under or near a part being moved with

lifting equipment.

After unplugging, lubricating, servicing, cleaning, or adjusting the machine make sure all tools and

equipment have been removed.

Make sure electrical connectors are clean and free of dirt or grease before connecting.

Check for loose, broken, missing, or damaged parts. Make sure the machine is in good repair. Make sure

all guards and shields are in position.

Always raise implement, shut off tractor engine, apply the parking brake, shift to park position (or neutral)

remove the key and install the cylinder stops channels before working around the machine.

Avoid working under the machine. However, if it becomes unavoidable to do so, make sure the machine is

securely blocked and the cylinder lockup channels are in position.

When working around discs, be careful to not get cut on sharp edges.

Never service, check or adjust drive chains or belts

while the engine is running.

Fig. 15

Page 19

Do not operate the machine with the drive shaft

280/335/380/525 Bushel Air Carts

331815

18

shields open or removed. Entanglement in rotating

drive shafts can cause serious injury or death.

Stay clear of rotating components.

Make sure rotating guards turn freely.

A loose yoke can slip off a shaft and result in injury

to persons or damage to the machine.

When installing a quick disconnect yoke, the

spring activated locking pins must slide freely and

be seated in the groove on the shaft. Pull on the

driveline to make sure the quick disconnect yoke

can not be pulled off the shaft.

Remove spilled oil, antifreeze or fuel immediately

from the steps, platform, and other access areas.

Keep all access areas clean and free of

obstructions.

1. Safety

Fig. 16

1.4.2 Fire prevention and first aid

Be prepared for emergencies.

Keep a first aid kit handy for treatment of minor

cuts and scratches.

Always carry one or more fire extinguishers of the

correct type. Check fire extinguishers regularly as

instructed by the manufacturer. Make sure fire

extinguishers are properly charged and in

operating condition.

Due to the nature of the crops this machine will

operate in, the risk of fire is of concern. Use a

water type fire extinguisher or other water source

for a fire in crop.

For fires involving anything other than crop, such

as oil or electrical components, use a dry chemical

fire extinguisher with an ABC rating.

Mount fire extinguishers within easy reach of

where fires can occur.

Frequently remove accumulated crop material

from the machine and check for overheated

components. Check the machine daily for any

noises that are not normal. Such noises could

indicate a failed component that can cause excess

heat.

Fig. 17

Fig. 18

Page 20

1. Safety

280/335/380/525 Bushel Air Carts

331815

19

If any flame cutting, welding, or arc welding is to

be done on the machine or attachments, make

sure to clear any crop material or debris from

around the area. Make sure the area below the

work area is clear of any flammable material as

falling molten metal or sparks can ignite the

material.

If fire occurs stand upwind and away from smoke

from the fire.

Fig. 19

1.4.3 High pressure leaks

Fluid leaking from the hydraulic system or the fuel

injection system under high pressure can be very

hard to see. The fluid can go into the skin causing

serious injury.

Fluid injected into the skin must be surgically

removed within a few hours. If not removed

immediately, serious infection or reaction can

develop. Go immediately to a doctor who knows

about this type of injury.

Use a piece of cardboard or wood to search for

possible leaks. Do not use your bare hand. Wear

leather gloves for hand protection and safety

goggles for eye protection.

Relieve all pressure before loosening any hydraulic

lines. Relieve the pressure by lowering raised

equipment, shutting off accumulator valve, if

equipped, and shutting off the engine. Tighten all

connections securely before applying pressure.

Fig. 20

Fig. 21

Page 21

1.4.4 Tire safety

280/335/380/525 Bushel Air Carts

331815

20

Check tires for cuts, bulges, and correct pressure.

Replace worn or damaged tires. When tire service

is needed, have a qualified tire mechanic service

the tire. Tire changing can be very hazardous and

must be done by qualified tire mechanic using

proper tools and equipment. See the

Specifications Section for the correct tire size.

Tire explosion and/or serious injury can result from

over inflation. Do not exceed the tire inflation

pressures. See the Specifications Section for the

correct tire pressure.

Do not inflate a tire that is seriously under inflated

or has been run flat. Have the tire checked by

qualified tire mechanic.

Do not weld on the rim when a tire is installed.

Welding will make an air/gas mixture that can

cause an explosion and burn with high

temperatures. This danger applies to all tires,

inflated or deflated. Removing air or breaking the

bead is not enough. The tire must be completely

removed from the rim prior to welding.

1. Safety

Fig. 22

1.4.5 Replacement parts

Where replacement parts are necessary for

periodic maintenance and servicing, genuine

replacement parts must be used to restore your

equipment to original specifications.

The manufacturer will not accept responsibility for

installation of unapproved parts and/or accessories

and damages as a result of their usage.

Fig. 23

Page 22

1. Safety

280/335/380/525 Bushel Air Carts

331815

21

1.5 Marker lamps

The machine is equipped with marker lamps and

reflectors that must be used when transporting

the machine on public roads.

The front of the machine is equipped with two

amber lamps (1) located at the front.

The rear of the machine is equipment with a bar

that has marker lamps (2) mounted at each end.

Each lamp contains a yellow lens pointing toward

the front and a red lens pointing toward the rear.

The machine is equipped with yellow reflectors

mounted on the front and sides of the machine

and red and orange reflectors mounted on the rear

that must be visible when transporting the

machine on public roads. See the safety sign

location information for the location of these

reflectors.

Fig. 24

Page 23

1.6 Safety sign location

280/335/380/525 Bushel Air Carts

331815

22

Two-bin model

1. Safety

Fig. 25

Item Reference number Description

1 997661 Reflector, red

2 997662 Reflector, orange

3 997663 Reflector, yellow

4 9971018 Speed sign, 20 mph - North American models

5 997861 Safety sign, read manual

6 997857 Safety sign, fasten safety chain

7 997853 Safety sign, unhitching hazard

8 997859 Safety sign, engine off

9 997863 Safety sign, high voltage

10 997867 Safety sign, fluid under pressure

11 997840 Safety sign, chemical hazard

9971009 Speed sign, 30 km/h - Non-North American models

Page 24

1. Safety

280/335/380/525 Bushel Air Carts

331815

23

Item Reference number Description

12 700732049 Safety sign-exploding parts read manual

13 9971011 Safety sign, moving part hazard

14 997841 Safety sign, crushing hazard

15 9971015 Safety sign, fall off hazard

16 700731523 Safety sign, safety sign-hot surface, hand

Most of the safety signs on this machine have two

panels with few or no words. The hazard panel (A)

depicts the hazard and the consequence of

encountering the hazard. The avoidance panel (B)

depicts the action required to avoid the hazard.

Reflector, red (1)

Reflector, orange (2)

Fig. 26

Fig. 27

Fig. 28

Page 25

Reflector, yellow (3)

24

North American models, safety sign, speed sign

(4)

Do not exceed the maximum speed of 20 mph

1. Safety

Fig. 29

Non-North American models, safety sign, speed

sign (4)

Do not exceed the maximum speed of 30 kph.

Safety sign, read manual (5)

Hazard (A) - General safety alert

Avoidance (B) - Read and understand the

Operator’s Manual before operating the

equipment. Follow safety and operating

instructions.

Fig. 30

Fig. 31

Fig. 32

Page 26

1. Safety

25

Safety sign, fasten safety chain (6)

Hazard (A) - Loss of machine control

Avoidance (B) - Install the safety chains when

attaching the implement to the tractor. Read the

Operator Manual for safety information and

operating instructions before operating the

machine.

Safety sign, unhitching hazard (7)

Hazard (A) - Negative tongue weight will cause

immediate elevation of the tongue.

Avoidance (B) - Stay clear of the tongue when

disconnecting the implement form the tractor.

Read the Operator Manual for safety information

and operating instructions before operating the

machine.

Fig. 33

Safety sign, engine off (8)

Hazard (A) - General safety alert

Avoidance (B) - Shut off engine and remove the

key before performing maintenance or repair work.

Safety sign, high voltage (9)

Hazard (A) - Electrical shock hazard - risk of

personal injury and component damage

Avoidance (B) - Keep sufficient distance away

from electrical power lines.

Fig. 34

Fig. 35

Fig. 36

Page 27

Safety sign, fluid under pressure (10)

26

Hazard (A) - Injection hazard into skin - escaping

fluid under high pressure

Avoidance (B) - Shut off engine, remove key, and

relieve pressure before performing maintenance or

repair work. Refer to the Operator Manual for

proper service procedures.

Safety sign, chemical hazard (11)

Hazard (A) - Chemical injestion hazard, lungs -

opening the cover.

Avoidance (B) - Refer to the Operator’s Manual

and the chemical manufacturer’s instructions.

1. Safety

Fig. 37

Safety sign, thrown or flying object hazard (12)

Hazard (A) - Thrown or flying object hazard.

Avoidance (B) - Keep a safe distance. Read the

Operator Manual for safety information and

operating instructions before operating the

machine.

Safety sign, moving part hazard (13)

Hazard (A) - Shearing hazard - finger shearing

hazard - rotating components.

Avoidance (B) - Do not open, remove, or reach

around shields while the engine is operating.

Fig. 38

Fig. 39

Fig. 40

Page 28

1. Safety

27

Safety sign, crushing hazard (14)

Hazard (A) - Crushing hazard - risk of personal

injury.

Avoidance (B) - Keep a safe distance from the

machine while engine and machine are operating.

Read the Operator Manual for safety information

and operating instructions before operating the

machine.

Safety sign, fall off hazard (15)

Hazard (A) - Falling off hazard.

Avoidance (B) - Do not ride on the machine when

it is operating or moving.

Fig. 41

Safety sign, hot surface, hand,(16)

Hazard (A) - Hand and finger burn hazard - hot

surfaces.

Avoidance (B) - Stay clear and do not touch hot

surfaces.

Fig. 42

Fig. 43

Page 29

Three-bin model

28

1. Safety

Fig. 44

Item Reference number Description

1 997661 Reflector, red

2 997662 Reflector, orange

3 997663 Reflector, yellow

4 9971009 Speed sign, 30 km/h

5 997861 Safety sign, read manual

6 997857 Safety sign, fasten safety chain

7 997853 Safety sign, unhitching hazard

8 997859 Safety sign, engine off

9 997863 Safety sign, high voltage

10 997867 Safety sign, fluid under pressure

11 997840 Safety sign, chemical hazard

12 700732049 Safety sign-exploding parts read manual

13 9971011 Safety sign, moving part hazard

Page 30

1. Safety

29

Item Reference number Description

14 997841 Safety sign, crushing hazard

15 9971015 Safety sign, fall off hazard

16 700731523 Safety sign, safety sign-hot surface, hand

17 65329 SMV Emblem

Most of the safety signs on this machine have two

panels with few or no words. The hazard panel (A)

depicts the hazard and the consequence of

encountering the hazard. The avoidance panel (B)

depicts the action required to avoid the hazard.

Fig. 45

Reflector, red (1)

Reflector, orange (2)

Fig. 46

Fig. 47

Page 31

Reflector, yellow (3)

30

North American models, safety sign, speed sign

(4)

Do not exceed the maximum speed of 20 mph

1. Safety

Fig. 48

Non-North American models, safety sign, speed

sign (4)

Do not exceed the maximum speed of 30 kph.

Safety sign, read manual (5)

Hazard (A) - General safety alert

Avoidance (B) - Read and understand the

Operator’s Manual before operating the

equipment. Follow safety and operating

instructions.

Fig. 49

Fig. 50

Fig. 51

Page 32

1. Safety

31

Safety sign, fasten safety chain (6)

Hazard (A) - Loss of machine control

Avoidance (B) - Install the safety chains when

attaching the implement to the tractor. Read the

Operator Manual for safety information and

operating instructions before operating the

machine.

Safety sign, unhitching hazard (7)

Hazard (A) - Negative tongue weight will cause

immediate elevation of the tongue.

Avoidance (B) - Stay clear of the tongue when

disconnecting the implement form the tractor.

Read the Operator Manual for safety information

and operating instructions before operating the

machine.

Fig. 52

Safety sign, engine off (8)

Hazard (A) - General safety alert

Avoidance (B) - Shut off engine and remove the

key before performing maintenance or repair work.

Safety sign, high voltage (9)

Hazard (A) - Electrical shock hazard - risk of

personal injury and component damage

Avoidance (B) - Keep sufficient distance away

from electrical power lines.

Fig. 53

Fig. 54

Fig. 55

Page 33

Safety sign, fluid under pressure (10)

32

Hazard (A) - Injection hazard into skin - escaping

fluid under high pressure

Avoidance (B) - Shut off engine, remove key, and

relieve pressure before performing maintenance or

repair work. Refer to the Operator Manual for

proper service procedures.

Safety sign, chemical hazard (11)

Hazard (A) - Chemical injestion hazard, lungs -

opening the cover.

Avoidance (B) - Refer to the Operator’s Manual

and the chemical manufacturer’s instructions.

1. Safety

Fig. 56

Safety sign, thrown or flying object hazard (12)

Hazard (A) - Thrown or flying object hazard.

Avoidance (B) - Keep a safe distance. Read the

Operator Manual for safety information and

operating instructions before operating the

machine.

Safety sign, moving part hazard (13)

Hazard (A) - Shearing hazard - finger shearing

hazard - rotating components.

Avoidance (B) - Do not open, remove, or reach

around shields while the engine is operating.

Fig. 57

Fig. 58

Fig. 59

Page 34

1. Safety

33

Safety sign, crushing hazard (14)

Hazard (A) - Crushing hazard - risk of personal

injury.

Avoidance (B) - Keep a safe distance from the

machine while engine and machine are operating.

Read the Operator Manual for safety information

and operating instructions before operating the

machine.

Safety sign, fall off hazard (15)

Hazard (A) - Falling off hazard.

Avoidance (B) - Do not ride on the machine when

it is operating or moving.

Fig. 60

Safety sign, hot surface, hand,(16)

Hazard (A) - Hand and finger burn hazard - hot

surfaces.

Avoidance (B) - Stay clear and do not touch hot

surfaces.

Fig. 61

Fig. 62

Page 35

SMV Emblem (17)

34

1. Safety

Fig. 63

Page 36

1. Safety

35

Page 37

Table of contents

36

2. Introduction

2.1 Introduction .............................................................39

2.1.1 Units of measurement ..................................................39

2.1.2 Replacement parts .....................................................39

2.1.3 Intended use .........................................................39

2.1.4 Proper disposal of waste ................................................39

2.2 Machine identification ...................................................41

2.2.1 Serial number plate ....................................................41

2.2.2 Serial number description ................................................41

2.3 Air cart .................................................................43

2.4 Major components ......................................................44

2.5 Two-bin operator manual ................................................46

2.5.1 Operator manual storage ................................................46

2.6 Three-bin operator manual ...............................................47

2.6.1 Operator manual storage ................................................47

Page 38

Table of contents

37

Page 39

2. Introduction

38

2.1 Introduction

CAUTION:

In some of the illustrations used in this Operator Manual, panels or guards may have been

removed for clarity. Never operate the tractor with these panels and guards removed. If

the removal of a shield is necessary to make a repair, it must be replaced before

operation.

CAUTION:

Read this book in its entirety prior to operating machine. Use only genuine replacement

parts for repairs and/or replacement.

This manual gives the operator the proper instructions needed for operation and maintenance. Read,

understand, and follow these instructions for best machine performance and life. With proper maintenance

and operation procedures, the machine will have better over all performance. Use normally available tools

for maintenance on this machine.

All operators must read and understand this manual before operating this machine. Where possible,

operators who have not operated the machine must receive instruction from an operator who has operated

this machine. Your dealer can give instruction in machine operation. Keep this manual with the machine for

future reference. If the original manual is damaged, order a replacement from your dealer.

See your dealer in for any service problems and adjustments. The dealer is equipped for all service work

and to help with specific applications of the tractor in local conditions.

Left-hand and right-hand are determined by facing the direction the machine will travel when in use.

2.1.1 Units of measurement

Measurements are given in metric units followed by the equivalent in US units. Hardware sizes are given

in millimeters for metric hardware and inches for US hardware.

2.1.2 Replacement parts

To receive prompt efficient service, remember to have the following information:

Correct part description and part number

Model number of the machine

Serial number of the machine

2.1.3 Intended use

This machine is designed solely for use in customary agricultural operations.

Do not use this machine for any application or purpose other than those described in this manual. The

manufacturer accepts no liability for damage or injury resulting from misuse of this machine.

Compliance with the conditions of operation, service and repair as specified by the manufacturer constitute

essential elements for the intended use of this machine.

This machine should be operated, serviced and repaired only by qualified persons familiar with its

characteristics and familiar with the relevant safety rules and procedures.

All generally recognized safety regulations and road traffic regulations must be obeyed at all times.

Any unauthorized modifications performed on this machine will relieve the manufacturer of all liability for

any resulting damage or injury.

2.1.4 Proper disposal of waste

Improper disposal of waste can pollute the environment and ecology. A few examples of potentially

harmful equipment waste can include, but not limited to, items such as oil, fuel, coolant, brake fluid, filters,

battery chemicals, tires, etc.

Page 40

2. Introduction

39

Use leak proof containers when draining fluids. Do not use food or beverage containers to collect waste

fluids, as food or beverage container(s) may mislead someone into drinking from them.

Do not pour or spill waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth's atmosphere. Government

regulations may require a certified air conditioning service center to recover and recycle used air

conditioning refrigerants.

Inquire with local environmental or recycling center on the proper way to recycle or dispose waste.

Page 41

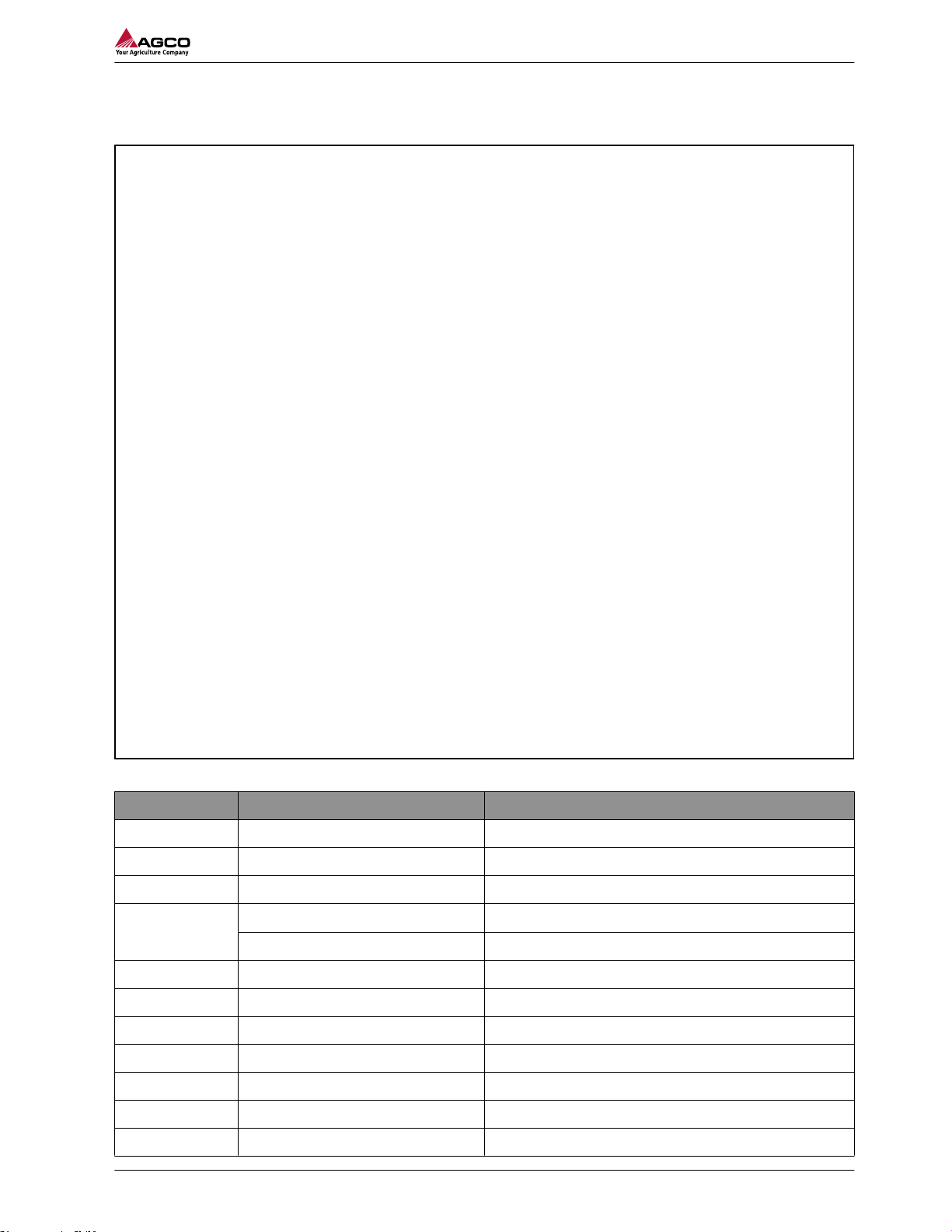

2.2 Machine identification

40

Each machine is identified by a model and a serial number.

Record these numbers in the spaces given.

Give the model number and serial number to your dealer when parts or service are required.

Machine model number:

Machine serial number:

Date of delivery:

Dealer name:

Dealer address:

Dealer telephone number:

Dealer e-mail address:

Dealer fax number:

2. Introduction

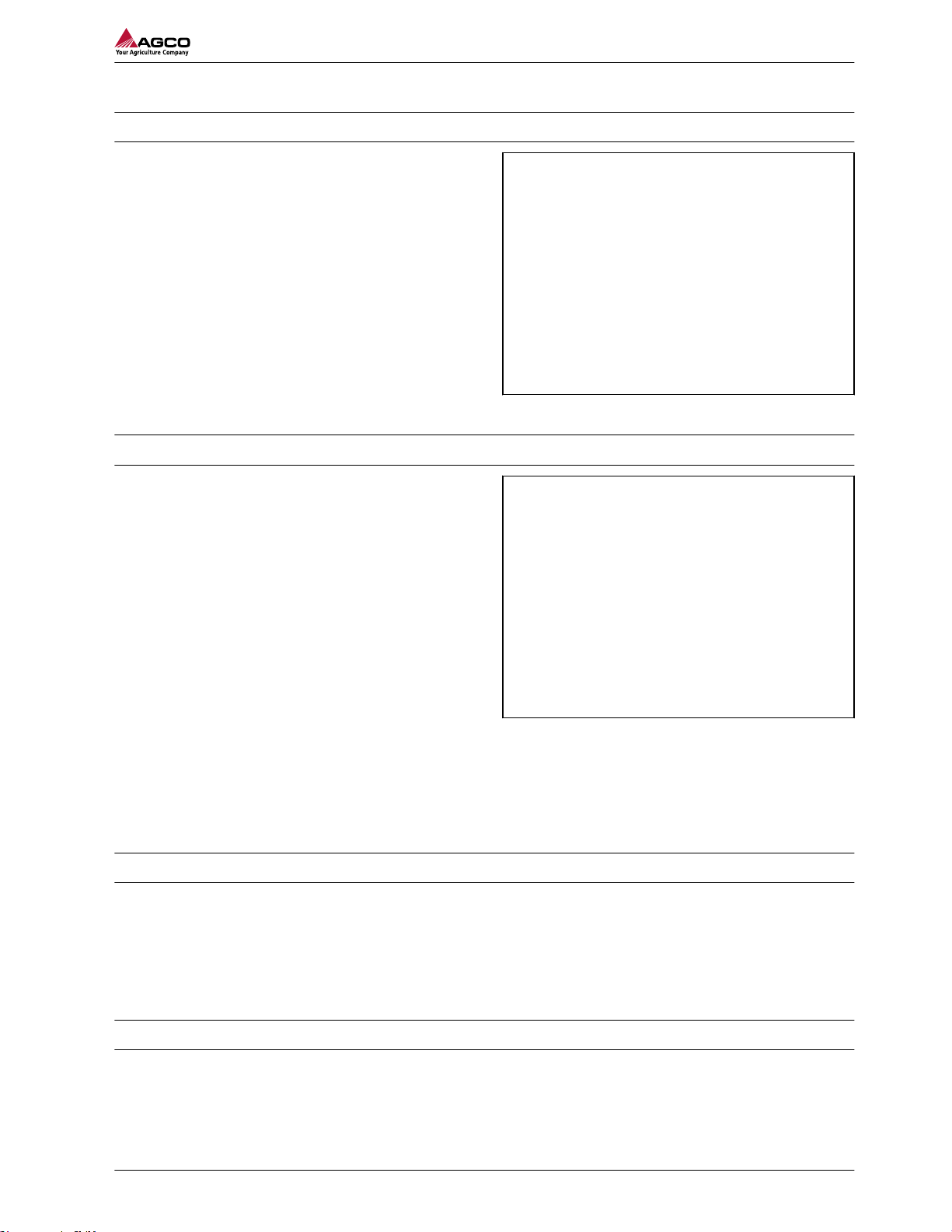

2.2.1 Serial number plate

For two-bin models, the serial number plate (1) is

located on the rear hopper support.

For three-bin models, the serial number plate (1) is

located on the frame.

Fig. 1

Fig. 2

2.2.2 Serial number description

Description of the serial number for model year 2010 and up.

Page 42

2. Introduction

41

Fig. 3

(1) Beginning symbol

(2) World manufacturer code

(3) Brand code

(4) Model identifier (model number)

(5) Check letter (0 or used if model identifier is

five digits)

(6) Model year code (A=2010, B=2011, C=2012,

and on)

(7) Plant code

(8) Family code

(9) Unit number for the year

(10) Ending symbol

Page 43

2. Introduction

42

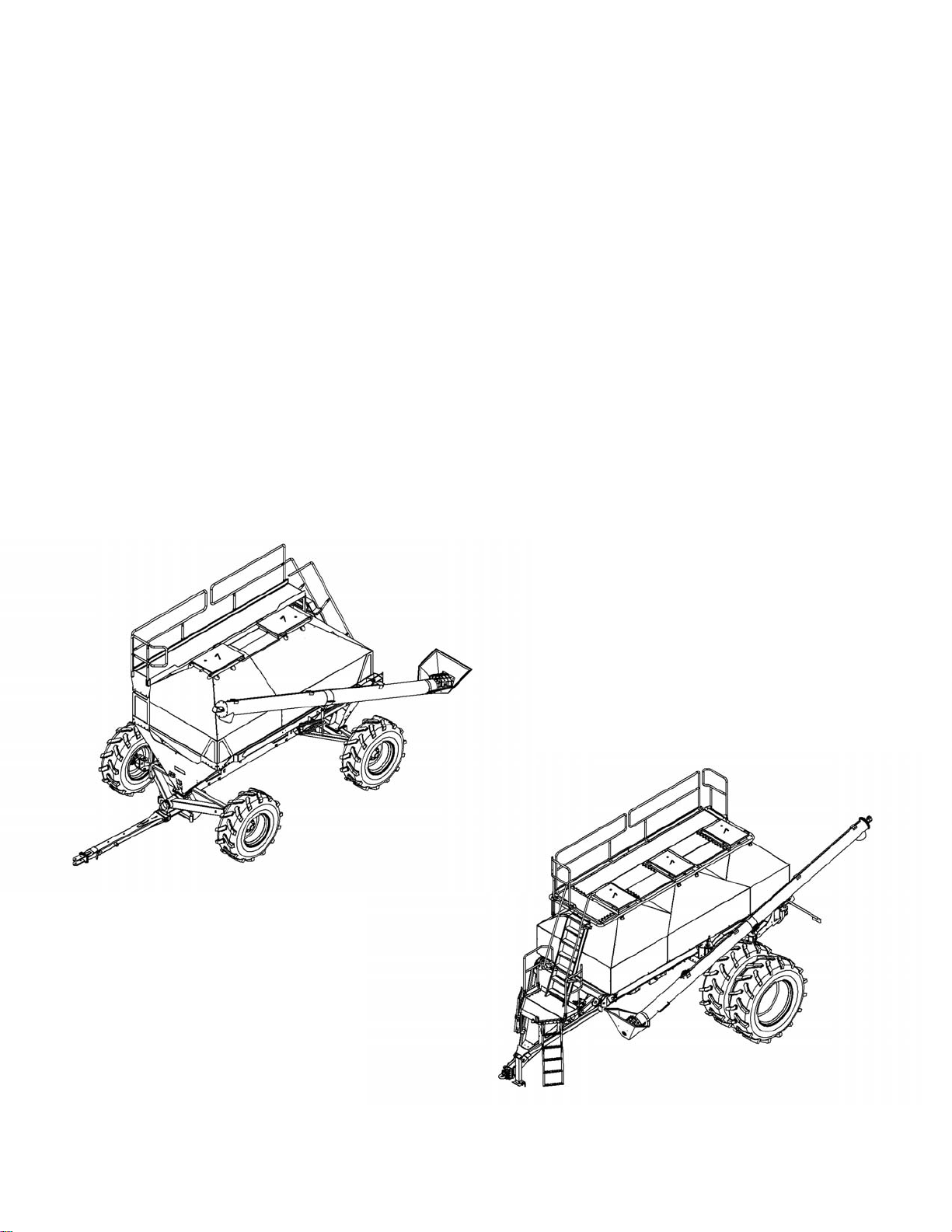

2.3 Air cart

The tanks on the air cart are made of stainless steel to prevent corrosion damage from granular fertilizer.

There are two basic models available that each have two size options:

• Two-bin model - 280 and 335 bushels

• Three-bin model - 380 and 525 bushels

Page 44

2. Introduction

43

2.4 Major components

Fig. 4

The major components for the 3-bin model are shown. The major components for the 2-bin model are in

similar locations.

(1) Front hitch

(2) Ladder

(3) Railer

(4) Auger

(5) Product bin lid

(6) Product bin

(7) Rear hitch

Page 45

Manual holder location

44

For the two-bin model, the manual holder (1) is

located as shown.

For the three-bin model, the manual holder (1) is

located as shown.

2. Introduction

Fig. 5

Fig. 6

Page 46

2. Introduction

45

2.5 Two-bin operator manual

2.5.1 Operator manual storage

The Operator Manual is located in the container (1)

on the machine.

Fig. 7

Page 47

2.6 Three-bin operator manual

46

2.6.1 Operator manual storage

The Operator Manual is located in the container (1)

on the machine.

2. Introduction

Fig. 8

Page 48

2. Introduction

47

Page 49

Table of contents

48

3. Operation

3.1 Ladder and railings ......................................................51

3.1.1 Ladder and railings - two-bin model .........................................51

3.1.2 Ladder and railings - three-bin model ........................................51

3.2 Product bin lids ..........................................................52

3.3 Auger ...................................................................53

3.3.1 Using the auger to load products ..........................................53

3.3.2 Using the auger to unload products .........................................55

3.3.3 Cleaning out the auger ..................................................55

3.4 Ground drive ............................................................56

3.5 Hydraulic systems .......................................................57

3.5.1 Air cart to drill hydraulic coupler ...........................................57

3.5.2 Air cart to tractor hydraulic couplers ........................................57

3.6 Hydraulic drive ..........................................................59

3.7 Blower ..................................................................60

3.7.1 Blower speed ........................................................60

3.8 Selecting air stream .....................................................61

3.9 Meters ..................................................................62

3.9.1 Product meter adjustment ...............................................62

3.9.2 Changing metering rolls - ground drive system ................................63

3.9.3 Changing metering rolls - hydraulic system ...................................63

3.9.4 Meter roll options ......................................................64

3.9.5 Meter adjustments .....................................................64

3.9.5.1 Shims ........................................................64

3.9.5.2 Deflector block .................................................64

3.9.5.3 Meter door and cleanout door latches ................................65

3.9.5.4 Meter door tray .................................................65

3.10 Setting the application rate on a ground drive system ....................66

3.11 Hydraulic drive calibration and operation ................................68

3.11.1 Preparing to calibrate a meter ............................................68

3.11.2 Priming the meter ....................................................69

3.11.3 Taking a product sample for calibration .....................................70

3.11.4 Entering accumulated weight on the virtual terminal ...........................70

3.11.5 Manually setting the motor cal value for a variable rate system ....................71

3.12 Rate charts .............................................................72

3.12.1 Fertilizer rate chart - 96 kg per cubic meter (60 lb per cubic foot) ...................72

3.12.2 Barley rate chart ......................................................74

3.12.3 Canola rate chart .....................................................76

3.12.4 Soybean rate chart ....................................................78

3.12.5 Wheat rate chart .....................................................80

3.13 Raven system ............................................................. 82

3.13.1 Raven system overview .................................................. 82

3.13.2 Raven system hardware .................................................. 82

3.13.2.1 Raven electronic control unit ......................................... 82

3.13.2.2 Virtual terminal ................................................82

3.13.2.3 Blower speed sensor ............................................82

3.13.2.4 Bin level sensor ................................................83

3.13.2.5 Meter box flow sensor ...........................................83

3.13.2.6 Meter shaft speed sensor (ground drive) ..............................83

3.13.2.7 Meter shaft speed sensor (hydraulic drive) ............................84

Page 50

Table of contents

49

3.13.2.8 Ground speed sensor ...........................................84

3.14 Cart control system .....................................................85

3.14.1 Virtual terminal - cart control system .......................................85

3.14.2 Alarm and indicator icons ...............................................85

3.14.3 Confirmation screen ...................................................86

3.14.4 Main (home) screen ...................................................87

3.14.5 Product bin alarms ....................................................89

3.15 System set up ..........................................................90

3.15.1 System settings screen ................................................90

3.15.2 Work switch operation .................................................91

3.15.3 Selecting the external work switch operation mode ............................92

3.15.4 Manual work switch operation ...........................................92

3.15.5 Setting the automatic work switch operation .................................92

3.15.6 Dry product/bin settings ................................................92

3.16 Advanced setup ........................................................94

3.17 Sensor types ...........................................................96

Page 51

3.1 Ladder and railings

50

3.1.1 Ladder and railings - two-bin model

The air cart is equipped with a ladder and railings

for access to the top of the tanks. Always make

sure the railings are fastened in the raised position

when operating the air system. The railings can be

lowered for storage or servicing, if required.

To lower the railings:

1. Use a ladder that is of the correct height, when

put on the ground to reach the top of the

machine, to remove the top bolt from each of

the legs on the railing sections.

2. Rotate the railing section down so that the

railing sections are next to the air system.

3. Install the bolts in the holes for storage.

WARNING:

Falling hazard. Personal injury or

death can occur. Do not stand on the

top of the machine when raising or

lowering the railings. Read and follow

the instructions in the operator's

manual for the movement of the

railings.

3. Operation

Fig. 1

3.1.2 Ladder and railings - three-bin model

The air cart is equipped with a ladder and railings

for access to the top of the tanks. Always make

sure the railings are fastened in the raised position

when operating the air cart. The railings can be

lowered for storage or servicing, if required.

To lower the railings:

1. Use a ladder that is of the correct height, when

put on the ground to reach the top of the

machine, to remove the spring pins.

2. Fold down the side railings over the top of the

tank.

3. Fold down the front and rear hand rails over the

side rails.

4. Install the spring pins for storage.

WARNING:

Falling hazard. Personal injury or

death can occur. Do not stand on the

top of the machine when raising or

lowering the railings. Read and follow

the instructions in the operator's

manual for the movement of the

railings.

Fig. 2

Page 52

3. Operation

51

3.2 Product bin lids

The product bin lids on the air cart compartments

must be correctly closed and sealed for the meters

to supply product correctly.

Periodically check the product bin lids for correct

adjustment and inspect the seal for damage.

To determine whether the product bin lid is

adjusted correctly, watch the product bin lid as the

latch is opened. The product bin lid must tilt a little

toward the latch end. A pull on the latch handle is

required to over-center the latch.

To adjust the hinge end of the product bin lid,

loosen or tighten the jam nuts (1) on the hold

down bar.

To adjust the latch, loosen or tighten the nuts (2)

on the toggle U-bolt.

In the off season, release the latch to relieve

pressure on the gasket.

Fig. 3

Page 53

3.3 Auger

52

The air cart is equipped with an auger (1) for

loading and unloading the product bins. The auger

is mounted in a swing arm. A flexible discharge

hose is mounted on one end. This hose can be

moved from one compartment to another without

moving the hopper. The swing arm also enables

the auger to be turned around to unload and clean

out the compartments.

The hydraulic drive for the auger is supplied with

oil from the blower hydraulics. A diverter valve in

rear of the machine supplies oil to the auger. The

diverter valve can be switched with the blower

running. The diverter valve at the rear of the

machine selects either the fan or auxiliary (auger

and/or winch) function. Push the knob in to run the

blower. Pull the knob out to run the auger or

winch.

The auger has a three position variable speed valve

to run the auger forward, rearward, or to stop.

3. Operation

Fig. 4

3.3.1 Using the auger to load products

Procedure

Park the machine on a solid, level surface.

1.

Apply the park brake.

2.

For the two-bin models, put the auger on the

3.

ground to correctly load the material:

a) Drop the front bracket lock pin (1) just far

enough to release the small pivot arm (2).

Do not remove the pins for the long arm.

b) On the inner arm and the outer arm, pull

down the spring loaded pin into the

detent position.

c) Remove the auger from the rear clamp

assembly.

For the three-bin models only, put the auger

4.

in the operating position:

Fig. 5

Fig. 6

Page 54

3. Operation

53

a) Drop the lock pin (6) in the neutral

position.

b) On the inner arm and the outer arm, pull

down the spring loaded pin into the

detent position.

c) Remove the auger from the clamp.

d) Pull the inner arm into position, by

swinging the hopper away from the air

cart.

e) Release the detent pin on the inner arm

and lock into place.

f) Pull down the outer arm pin so the auger

is free to move from the inner arm.

Put the hopper on the ground:

5.

° For two-bin models, put the hopper in a

position vertical to the center line of the

tanks with the discharge end of the auger

between the compartment covers. From

this position the discharge end of the

auger can move between compartments

without moving the hopper.

° For three-bin models, put the hopper on

the ground in a position perpendicular to

the center tank lid. From this position the

discharge end of the auger can be moved

between compartments without moving

the hopper.

Put the auger over the lid of the desired tank

6.

to be filled.

Push the divert valve knob in to run the

7.

blower. Pull the diverter valve out to run the

auger or winch.

On three-bin models, put the spring loaded

8.

pin into the detent position before moving to

a different compartment or damage can

occur.

Page 55

3.3.2 Using the auger to unload products

54

Procedure

Swing the inner arm far enough away from the machine to let the hopper fit in front of the wheels.

1.

See the information for inner arm position.

Put the hopper (1) under the meter for the

2.

desired compartment.

For rear tank on three-bin models, the outer

arm will have to swing more than 180

degrees to reach the meter.

Close the metering slide (2).

3.

Remove the product meter door (3).

4.

Open the metering slide to control flow from

5.

the compartment.

Removing the pointer lets the gate open

without changing the rate setting.

Fig. 7

3.3.3 Cleaning out the auger

3. Operation

Procedure

Park the machine on a solid, level surface.

1.

Apply the park brake, stop the engine, and take the key with you.

2.

If desired, put a catch pan under the auger.

3.

Put the hopper (1) upside down to empty.

4.

If desired, put a catch pan under the auger.

5.

Run the auger rearward until the auger tube

6.

is empty.

Fig. 8

Page 56

3. Operation

55

3.4 Ground drive

On air carts equipped with ground drive a

magnetic clutch disengages the drive. The

magnetic clutch uses electrical power to hold the

engaged position. The clutch is turned on and off

by the control system either automatically when

the drill is raised and lowered, or manually by

pressing a manual master work switch on the

virtual terminal in the tractor cab. The clutch

requires no service.

When roading long distances, remove the drive

chain at the drive wheel. This will extend the life of

the chain and the sprocket.

Fig. 9

Page 57

3.5 Hydraulic systems

56

3. Operation

The hydraulic system on the air carts includes:

• Blower control circuit

• Auger control circuit

• Hydraulic meter drive control circuit

A group of control valves enables all three circuits

to be operated by one hydraulic remote on the

tractor. This system was designed to function

under a maximum hydraulic pressure of 19 995

kPa (2900 psi).

Fan with

hydraulic

drive

Fan speed Flow Pressure

3000 rpm 49.2 l/min (13

4000 rpm 60.6 l/min (16

5000 rpm 70 l/min (18.5

6000 rpm 79.5 l/min (21

Fan only 10cc fan motor

Fan speed Flow Pressure

10cc fan motor with 5 gal

meter priority

8174 to 11 721

gal/min)

gal/min)

gal/min)

gal/min)

kPa (1200 to

1700 psi)

11 032 to 4

479 kPa (1600

to 2100 psi)

13 790 to 17

237 kPa (2000

to 2500 psi)

16 547 to19

995 kPa (2400

to 2900 psi)

3000 rpm 30.3 l/min (8

gal/min)

4000 rpm 39.7 l/min (10.5

gal/min)

5000 rpm 51 l/min (13.5

gal/min)

6000 rpm 60.6 l/min (16

gal/min)

6895 to 10 342

kPa (1000 to

1500 psi)

9653 to 13 100

kPa (1400 to

1900 psi)

12 411 to 15

858 kPa (1800

to 2300 psi)

15 168 to 18

616 kPa (2200

to 2700 psi)

3.5.1 Air cart to drill hydraulic coupler

The couplers connecting the air cart to the drill/implement are (3/4 inch) #12 ISO 7241 Series B, high-flow

couplers. Using the high-flow couplers reduces the pressure drop across the coupler and enables the

operator to easily disconnect the air cart from the drill/implement. Make sure the pressure line on the tank

is connected to the pressure line on the drill.

The blower motor case drain line has a (5/8 inch) #10 ISO 7241 Series B coupler. The smaller size helps to

tell the difference between this coupler and other larger couplers.

IMPORTANT:

Be sure that the case drain line on the blower motor is not connected to pressure. Damage to the shaft

seal or motor will result.

3.5.2 Air cart to tractor hydraulic couplers

The couplers connecting the blower pressure and the return lines from the air cart to the tractor are #8 (1/2 inch)

ISO 5675 (Pioneer) tip coupler to a #10 (5/8 inch) female ORB.

Page 58

3. Operation

57

A #8 ISO 16028 (at-face) coupler tip to a #6 (3/8 inch) female ORB on the air cart connects the case drain line to the tractor.

The case drain line must be connected or the blower motor will be damaged. If a case drain return port is

not available on your tractor, contact your dealer.

A (3/4 inch) #12 ISO 7241-1 Series A low-pressure return tip is included with all implements. The lowpressure return tip is also available through Service Parts.

If your tractor has a low-pressure port available, the low-pressure return tip can be used on the 3/4 inch

blower return line. Using the low-pressure return tip can remove the pressure drop caused by the 1/2 inch

Pioneer tip and the hydraulic valve of the tractor on the return side. The low-pressure return tip can also be

used on the case drain line, if the 3/8 inch at face port is not available.

Do not install a tee tting connecting the blower return line and the blower case drain lines together. The

blower case line must always be connected to a direct return to the hydraulic reservoir or blower motor

failure will result.

The hydraulic line with the label pressure must be used to operate the blower. A check valve is installed in

the blower circuit to protect the motor from the too much pressure in the return line and prevents

cavitation during shutdown.

NOTE:

The 3/4 inch low pressure return tip is not compatible with the 3/4 inch high ow ttings used at the front

of the cart. The connectors look similar, but the connectors are not compatible.

Page 59

3. Operation

58

3.6 Hydraulic drive

Air systems equipped with the hydraulic drive option use electric-over-hydraulic (EOH) technology to