Page 1

GasTrac

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax:(412)-312-6001

Process Air Heater

UGD014/0497

Installation

Maintenance

Operation

Troubleshooting

Page 2

It’s a good idea to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Please keep this User Guide and all manuals, engineering

prints and parts lists together for documentation of your

equipment.

Date:

Manual Number: UGD014/0497

Serial number(s):

Model number(s):

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Please record your

equipment’s model and

serial number(s) and

the date you received it

in the spaces provided.

Copyright 1997

All rights reserved

THE CONAIR GROUP, INC.

Page 3

UGD014/0497 GasTrac Process Air Heater

TABLE OF

CONTENTS

I

NTRODUCTION . . . . . . . . . . . . . . . . . . .1-1

Purpose of the User Guide . . . . . . . . . . . . . . . . . . . . . . . . .1-2

How the guide is organized . . . . . . . . . . . . . . . . . . . . . . . .1-2

Your responsibilities as a user . . . . . . . . . . . . . . . . . . . . . .1-2

ATTENTION: Read this so no one gets hurt . . . . . . . . . . .1-3

How to use the lockout device . . . . . . . . . . . . . . . . . . . . . .1-5

DESCRIPTION . . . . . . . . . . . . . . . . . . . .2-1

What is the GasTrac? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How it works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Fuel train features and controls . . . . . . . . . . . . . . . . . . . . .2-6

Specifications: GasTrac . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Specifications: Exhaust flue . . . . . . . . . . . . . . . . . . . . . . . .2-9

Specifications: Main power supply . . . . . . . . . . . . . . . . . . .2-9

INSTALLATION . . . . . . . . . . . . . . . . . . . .3-1

Unpacking the boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Installing the GasTrac . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Replacing the host dryer’s process air heater . . . . . . . . . . .3-4

Installing the exhaust flue . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Connecting process air lines . . . . . . . . . . . . . . . . . . . . . . . .3-6

Connecting the gas supply . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Connecting the main power . . . . . . . . . . . . . . . . . . . . . . . .3-7

Installing the RTD probe . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

OPERATION . . . . . . . . . . . . . . . . . . . . . .4-1

GasTrac operating features . . . . . . . . . . . . . . . . . . . . . . . . .4-2

The GasTrac control . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

To start drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

To stop drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

MAINTENANCE . . . . . . . . . . . . . . . . . . . .5-1

Preventative maintenance checklist . . . . . . . . . . . . . . . . . .5-2

Cleaning the combustion air filter . . . . . . . . . . . . . . . . . . .5-3

Cleaning the electrical enclosure filters . . . . . . . . . . . . . . .5-3

Replacing the spark igniter . . . . . . . . . . . . . . . . . . . . . . . .5-4

Cleaning the ultraviolet flame detector . . . . . . . . . . . . . . . .5-6

Cleaning the burner sight glass . . . . . . . . . . . . . . . . . . . . .5-6

i

Page 4

GasTrac Process Air Heater UGD014/0497

TABLE OF

CONTENTS

T

ROUBLESHOOTING . . . . . . . . . . . . . . . .6-1

Before beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

A few words of caution . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

When an alarm occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

How to identify the cause of an alarm . . . . . . . . . . . . . . . .6-3

Temperature controller alarms . . . . . . . . . . . . . . . . . . . . . .6-4

Burner controller alarms . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Variable speed controller alarms . . . . . . . . . . . . . . . . . . . .6-10

Flue gas high temperature limit switch . . . . . . . . . . . . . . .6-14

Process high temperature limit switch . . . . . . . . . . . . . . .6-15

APPENDIX

Service/Warranty Information . . . . . . . . . . . . . . . .Appendix A

ii

Page 5

1-1

UGD014/0497 GasTrac Process Air Heater

● Purpose of the User Guide . . . .1-1

● How the guide is organized . . . .1-2

●Your responsibilities as a user .1-2

● ATTENTION: Read this so

no one gets hurt . . . . . . . . . . .1-3

● How to use the lockout device .1-5

INTRODUCTION

Page 6

GasTrac Process Air Heater UGD014/0497

1-2 INTRODUCTION

This User Guide describes the GasTrac process air heater and

explains step-by-step how to install, operate, maintain and

repair this equipment.

Before installing this product, please take a few moments to

read the User Guide and review the diagrams and safety information in the instruction packet. You also should review manuals covering associated equipment in your system. This

review won’t take long, and it could save you valuable installation and operating time later.

Symbols have been used to help organize the User Guide and

call your attention to important information regarding safe

installation and operation.

Symbols within triangles warn of conditions that could

be hazardous to users or could damage equipment.

Read and take precautions before proceeding.

Numbers within shaded squares indicate tasks or steps

to be performed by the user.

A diamond indicates the equipment’s response to an

action performed by the user.

An open box marks items in a checklist.

A shaded circle marks items in a list.

You must be familiar with all safety procedures concerning

installation, operation and maintenance of this equipment.

Responsible safety procedures include:

● Thorough review of this User Guide, paying particular

attention to hazard warnings, appendices and related

materials and diagrams.

● Thorough review of the equipment itself, with careful

attention to voltage sources, gas supply, intended use and

warning labels.

● Thorough review of instruction manuals for associated

equipment.

● Step-by-step adherence to instructions outlined in this

User Guide.

PURPOSE OF

THE USER

GUIDE

HOW THE

GUIDE IS

ORGANIZED

1

◆

❒

●

!

YOUR

RESPONSIBILITY

AS A USER

Page 7

UGD014/0497 GasTrac Process Air Heater

INTRODUCTION 1-3

We design equipment with the user’s safety in mind. You can

avoid the potential hazards identified on this machine by following the procedures outlined below and elsewhere in the

User Guide and related instructional materials.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

!

WARNING: Follow instructions carefully.

Incorrect installation, operation or maintenance of

this product can result in a fire, explosion or

other hazards causing property damage, severe

personal injury or loss of life.

Only licensed electrical/mechanical contractors, or

individuals experienced with the installation of natural gas piping, process air ducting, thermal insulation, exhaust ducting and regional codes for industrial gas appliances, should install the GasTrac.

The GasTrac should be maintained and repaired

by qualified technicians who are equipped with the

correct tools and are experienced in the maintenance and repair of industrial gas appliances.

Inspection and testing of gas supply piping,

exhaust ducting and the GasTrac gas controls and

safety features should be performed periodically to

ensure safe operation.

!

WARNING: If gas odor is detected...

❒ Open doors and/or windows to vent the gas.

❒ Do not touch electrical switches.

❒ Extinguish all open flames.

❒ Immediately have qualified personnel determine

the source of the gas leak and repair it.

!

WARNING: Do not store or place

aerosol, compressed gas or flammable

materials on or near this equipment.

The hot temperatures associated

with the drying process may

cause aerosols or other

flammable materials placed or

stored near the GasTrac to

explode.

!

Page 8

GasTrac Process Air Heater UGD014/0497

1-4 INTRODUCTION

WARNING: Hot surfaces.

Temperatures inside the GasTrac can

reach more than 800˚ F. Always shut

down the GasTrac and host dryer and

wait for them to cool before servicing. Do

not remove the safety guard covering the

GasTrac burner and heat exchanger.

WARNING: Disconnect and lock out

main power before servicing.

The GasTrac is connected to high voltage. Always disconnect and lock out the

main power source to the GasTrac before

servicing. Also disconnect and lock out

main power to the host dryer before servicing the GasTrac. Failure to disconnect

and lock out this voltage source could

result in severe personal injury.

WARNING: Shut off main gas supply

and purge heat exchanger and gas

lines before servicing.

If the fuel train, burner, ultraviolet sensor,

sight glass or ignition are to be serviced,

it is important that the GasTrac heat

exchanger and gas lines are purged of

natural gas. Failure to eliminate this

potential source of a gas leak could result

in severe damage, personal injury or loss

of life.

WARNING: Do not operate the

GasTrac with safety features disabled

or removed.

The GasTrac has been equipped with

numerous guards, controls and devices

to ensure safe operation.Never remove

or disable these devices to sustain production. Operating without these devices

could lead to hazardous conditions that

can damage the facility or cause severe

injury or loss of life.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

!

!

!

Page 9

UGD014/0497 GasTrac Process Air Heater

INTRODUCTION 1-5

CAUTION: Before performing maintenance

or repairs on this product, you should disconnect

and lock out electrical power sources to prevent

injury from unexpected energization or start-up. A

lockable device has been provided to isolate this

product from potentially hazardous electricity.

Lockout is the preferred method of isolating machines or

equipment from energy sources. Your Conair product is

equipped with the lockout device pictured below. To use the

lockout device:

Stop or turn off the equipment.

Isolate the equipment from

electrical power.

Turn the rotary disconnect

switch to Off, or O position.

Secure the device with an

assigned lock or tag.

The equipment is now locked out.

WARNING: Before removing lockout

devices and returning switches to the ON position,

make sure that all personnel are clear of the

machine, tools have been removed and all safety

guards reinstalled.

HOW TO USE

THE

LOCKOUT

DEVICE

I

O

1

2

3

4

!

Page 10

Page 11

2-1

UGD014/0497 GasTrac Process Air Heater

● What is the GasTrac? . . . . . . . . .2-1

●Typical applications . . . . . . . . . .2-2

● How it works . . . . . . . . . . . . . . .2-4

● Fuel train features

and controls . . . . . . . . . . . . .2-6

● Specifications: GasTrac . . . . . . .2-8

● Specifications: Exhaust flue . . .2-9

● Specifications: Main power

supply wire . . . . . . . . . . . . . .2-9

DESCRIPTION

Page 12

The GasTrac Process Air Heater is a stand-alone, gas-fired

heater designed to replace the electric process air heater in an

existing dehumidifying dryer or crystalizer. The GasTrac

allows plastics processors to convert existing electric equipment to a less-expensive gas source.

The GasTrac contains a metal-ceramic burner, heat exchanger,

combustion system and temperature controller to set and

maintain the temperature of the air entering a drying hopper.

The host dryer’s desiccant beds dry the air. The host dryer’s

process blower circulates air through the GasTrac heat

exchanger and the hopper.

The GasTrac’s temperature controller, ignition system and

burner safeguards communicate with the host dryer through a

RS-485 serial interface port.

The GasTrac can be used successfully in applications that

require:

● Drying of hygroscopic plastics at temperatures ranging

from 250˚ F to 350˚ F.

● Hot air drying of non-hygroscopic plastics.

● Process, or drying, air flow of 600 to 1800 cfm. Higher

or lower air flow ranges may be achieved, depending on

the model of the host dryer and the GasTrac selected.

● Central drying, using an existing electric dryer with a

single GasTrac or multiple GasTrac units.

The GasTrac has been designed and configured at the factory

for use with natural gas only. If you want to use a different gas

fuel source, such as propane, you must contact Conair.

WHAT IS THE

GASTRAC?

GasTrac Process Air Heater UGD014/0497

2-2 DESCRIPTION

TYPICAL

APPLICATIONS

Page 13

TYPICAL

APPLICATIONS

UGD014/0497 GasTrac Process Air Heater

DESCRIPTION 2-3

The GasTrac may be installed on a mezzanine or on the floor

between the host dryer and the drying hopper. You can use

flexible hose or pipe to deliver air between the host dryer, the

GasTrac and the drying hopper.

Mezzanine

installation

Floor

installation

Page 14

HOW IT WORKS

GasTrac Gas-Fired process Air Heater UGD014/0497

2-4 DESCRIPTION

ESC SEL

Combustion

Blower

RUN

MAN

234.0

250.0

SP2

OP1

OP2

REM

HOLD

2216

ESC SEL

The GasTrac has three interfaced controls that:

● Ignite the metal-ceramic burner and monitor the GasTrac

combustion circuit.

● Heat the dry air to the setpoint temperature.

● Monitor the air temperature as it enters the drying hopper.

● Automatically adjust the mixture of combustion air and

gas to maintain the setpoint temperature.

Temperature

RTD probe at

the hopper

inlet

The Temperature Controller

You enter the setpoint temperature in the Temperature Controller on the

main GasTrac control. The temperature controller monitors temperature at

the drying hopper inlet. When the actual temperature must increase or

decrease to maintain setpoint, this controller sends a 4 to 20 MA signal to

the variable speed controller.

Burner Controller

The Burner Controller is activated

when you press the RUN button on

the main GasTrac control. The burner

controller sends a signal to the spark

igniter, which fires the metal-ceramic

burner. This controller continues to

monitor the fuel train, combustion

blower and other combustion systems

for possible problems.

Variable Speed Controller

The Variable Speed Controller automatically adjusts the speed of the combustion

blower by varying the frequency and voltage of the signal. Increasing the speed

increases the air-to-fuel mixture and the heat output of the burner.

4 to 20 MA

signal

varying

frequency

Page 15

HOW IT WORKS

UGD014/0497 GasTrac Process Air Heater

DESCRIPTION 2-5

100

150

200

250

300

350

400

0

50

100

150

200

50

0

100

150

200

250

300

350

400

0

50

100

150

200

50

0

The Process Air Circuit

The Combustion Air Circuit

The process blower in the host

dryer sends dehumidified air into

the GasTrac heat exchanger.

The heated dry air exits

the GasTrac. The air is

blown by the host dryer

to the drying hopper.

The air is heated to the setpoint temperature

as it passes over and around the burner

cylinder and surrounding baffles.

The combustion blower

pulls ambient air into

the combustion circuit

through a filter.The air

is then blown to the

proportional gas mixer.

1a

2

Gas and air are mixed

in the proportion

needed to achieve the

setpoint temperature.

The GasTrac has two separate air circuits: the combustion air

circuit and the process air circuit.

Gas enters

the fuel train.

1b

The air/gas mixture

enters the burner,

where it is ignited

by a spark.

3

Combustion air flows through the burner

cylinder and the exhaust tube bundles.

4

Combustion

gases exhaust

through a flue.

5

3

1

2

Page 16

GasTrac Process Air Heater UGD014/0497

2-6 DESCRIPTION

The fuel train includes two automatic and manual safety gas

shutoff valves, four pressure switches, and a gas regulator and

governor to assure safe feeding of gas to the combustion burner. The four pressure switches monitor gas pressure and

process air flow. The GasTrac will automatically shut down if

a pressure switch senses an unsafe condition.

FUEL TRAIN

FEATURES AND

CONTROLS

GasTrac horizontal models

Combustion air filter

Zero Gas Governor

controls the gas feed to

the proportional mixer.

Manual burner

inlet gas shutoff valve

Proportional Mixer

Mixes air and gas in

the correct proportion

to produce the required

heat.

Combustion air

pressure switch

Primary automatic

safety shutoff valve

Secondary

automatic safety

shutoff valve

Process air

differential

pressure switch

Combustion air blower

Low gas

pressure switch

High gas

pressure switch

Gas inlet pressure gauge

Manual gas supply

shutoff valve

Regulated gas pressure gauge

Gas pressure regulator

Page 17

UGD014/0497 GasTrac Process Air Heater

DESCRIPTION 2-7

GasTrac upright models

Combustion air filter

Proportional Mixer

Mixes air and gas in

the correct proportion

to produce the required

heat.

FUEL TRAIN

FEATURES AND

CONTROLS

Combustion air blower

Gas inlet

pressure gauge

Manual gas supply

shutoff valve

Regulated gas pressure gauge

Gas pressure regulator

Zero Gas Governor

controls the gas feed to

the proportional mixer.

Manual burner

inlet gas shutoff valve

Primary automatic

safety shutoff valve

Secondary

automatic safety

shutoff valve

Process air

differential

pressure switch

High gas

pressure switch

Low gas pressure switch

Combustion air

pressure switch

Page 18

SPECIFICATIONS: GASTRAC

GasTrac Process Air Heater UGD014/0497

2-8 DESCRIPTION

H

W

D

Dimensions H W D Weight Air inlet/outlet

in./cm in./cm in./cm lbs/kg diameter in./cm

CGT700HH Horizontal Model 61/154.9 37/93.9 74/187.9 1115/505.7 12/30

CGT700HV Upright Model 67/170.2 39/99 64/162.6 1115/505.7 12/30

CGT500HH Horizontal Model 61/154.9 37/93.9 64/162.6 880/399.2 8/20.3

CGT500HV Upright Model 65/165.1 39/99 64/162.6 880/399.2 8/20.3

CGT350HH Horizontal Model 54/137.2 29/73.7 66/167.6 695/315.2 8/20.3

CGT350HV Upright Model 58/147.3 31/78.7 56/142.2 695/315.2 8/20.3

Remotable GasTrac control 3.5/8.9 12.5/31.7 6/15.2 — —

W

H

W

D

CGTHH horizontal model

CGTHV upright model

H

D

Remotable

GasTrac control

CGT700 models CGT500 models CGT350 models

General

Temperature range 250-350˚F / 122-177˚C 250-350˚F / 122-177˚C 250-350˚F / 122-177˚C

Maximum Flue Temperature 750˚F / 399˚C 750˚F / 399˚C 750˚F / 399˚C

Combustion blower 1.5 Hp Peripheral 1 Hp Peripheral 1 Hp Peripheral

Ignition source Spark igniter, interrupted Spark igniter, interrupted Spark igniter, interrupted

Burner type Metal-ceramic Metal-ceramic Metal-ceramic

Minimum burner capacity 150,000 BTU/hr 125,000 BTU/hr 90,000 BTU/hr

Maximum burner capacity 700,000 BTU/hr 500,000 BTU/hr 350,000 BTU/hr

Gas consumption 230 CFH @ 250˚F/1200 CFM 150 CFH @ 250˚F/800 CFM 105 CFH @ 250˚F/600 CFM

675 CFH @ 350˚F/1800 CFM 465 CFH @ 350˚F/1200 CFM 325 CFH @ 350˚F/800 CFM

Gas pressure to regulator 10 - 20 inches of water / 2.49 - 4.98 kilopascals

Gas pressure from regulator 4 - 7 inches of water / 0.99 - 1.74 kilopascals

Gas heating value 1000 BTU/ft

3

Electrical

Available voltages / Total Amps

240 V/3 phase/60 Hz 4.8 A 2.5 A 2.0 A

380 V/3 phase/50 Hz 3.0 A 1.6 A 1.3 A

415 V/3 phase/50 Hz 2.7 A 1.5 A 1.2 A

480 V/3 phase/60 Hz 2.4 A 1.3 A 1.0 A

Total Kilowatts 1.9 kw 1.0 kw 0.8 kw

Emissions (all models)

Primary excess air 10% - 30%

Oxygen (O2) [Ideal 3%-4%] 2% - 5% acceptable range

Carbon Dioxide (CO2) 9% - 10.5%

Carbon Monoxide (CO) < 10 ppm corrected to 3% O

2

NOX < 20 ppm corrected to 3% O

2

Unburned hydrocarbons < 10 ppm corrected to 3% O

2

NOTE: Elevations 3000 feet above sea level must be specified at time of purchase.

All GasTrac models meet:

UL 372, UL 795, FM, CGA,

AGA, NFPA 54, NFPA 79,

NFPA 86 and IAS

Page 19

UGD014/0497 GasTrac Process Air Heater

DESCRIPTION 2-9

SPECIFICATIONS: MAIN POWER SUPPLY WIRE

The main power wire must be:

● Grounded and secured with a strain relief.

● Correctly sized for the current drawn.

Allowable ampacities of Copper Conductors

U.S.A. Canada European Community

75˚C insulation 90˚C insulation 70˚C insulation; 40˚C ambient air

Conductor 30˚C ambient air 40˚C ambient air Ground wire Conductor Maximum

Size AWG Maximum Full Load Amps Size AWG Size mm

2

Full Load Amps

14 15 13 14 2,5 16

12 20 17 12 4 23

10 30 27 10 6 29

8 43 47 10 10 40

NOTE: Local or regional electrical guidelines may have specifications that differ from the above national codes.

You should comply with the codes for your area.

SPECIFICATIONS: EXHAUST FLUE

The Conair GasTrac is classified under the National Fuel Gas Code [ANSI Z233.1]

as a Category III gas appliance. An exhaust flue is required to vent the combustion

gases produced by this appliance.The purchaser is responsible for installing an

exhaust flue that meets all local, regional and national codes in the installation area.

For you safety, Conair recommends that you consult a licensed mechanical contractor who is familiar with gas flue and ducting codes in your area.

GasTrac operating characteristics

Maximum flue temperature 750˚F / 399˚C

Minimum vent size (single unit installation) CGT350: 4 in. / 10.2 cm

CGT500: 6 in. / 15 cm

CGT700: 6 in. / 15 cm

Vent pressure at flue collar 1 to 2 in. water column

Installation recommendations

❒ Provide each GasTrac with a dedicated, vertical stack that exits the

building vertically through a rain-protected roof penetration. Limit any

horizontal ducting runs to 4 feet.

❒ Use a stainless steel, fabricated chimney flue.

❒Vent size should be 6 inches in diameter. If you connect multiple

GasTrac units to a stack manifold, adjust the stack size accordingly.

❒ Static pressure at the flue collar must not exceed 1 to 2 inches water

column.

❒ Install an induced draft fan between the GasTrac exhaust outlet and

stack ducting, if you have more than 1 to 2 inches water column pressure at the flue collar while the GasTrac is operating.

Page 20

Page 21

3-1

UGD014/0497 GasTrac Process Air Heater

● Unpacking the boxes . . . . . . . . .3-2

● Preparing for installation . . . . . .3-3

● Installing the GasTrac . . . . . . . .3-4

● Replacing the host dryer’s

process air heater . . . . . . . . .3-4

● Installing the exhaust flue . . . . .3-5

● Connecting process air lines . .3-6

● Connecting the gas supply . . . .3-6

● Connecting the main power . . .3-7

● Installing the RTD probe . . . . . .3-7

●Testing the installation . . . . . . . .3-8

INSTALLATION

Page 22

UNPACKING

THE

BOXES

GasTrac Process Air Heater UGD014/0497

3-2 INSTALLATION

Carefully remove the GasTrac and components

from their shipping containers.

Remove all packing material, protective paper, tape

and plastic. Be sure to examine packing material before

discarding. What looks like filler may contain parts, hardware or instructional materials.

Carefully inspect all components. Make sure you

have the correct model and all necessary hardware. Check

for any damage that may have occurred during shipping. If

you do find freight damage, you should immediately file a

damage claim against the delivering carrier.

Take a moment to record serial numbers, electri-

cal power and gas specifications in the blanks provided on

the back of the User Guide title page. This information

will be helpful if you ever need service or parts.

You are now ready to begin installation.

Follow all preparation steps beginning on the next page.

1

2

3

4

5

Optional Remote

Control Bracket

If you ordered the optional

bracket for mounting the

GasTrac control in a

remote location, see the

Appendix for installation

instructions.

Exhaust

flue elbow

Exhaust

flue Tee

1 “V” clamp

2 “V”

clamps

Temperature

probe (RTD)

Exhaust

flue Tee

Temperature

probe (RTD)

The GasTrac Process Air Heater arrives assembled. The RTD

temperature probe is packaged inside the electrical enclosure.

Depending on the model and options ordered, you also

should receive boxes containing V clamps and piping to

attach the GasTrac exhaust to a customer-installed flue.

CGT horizontal model

CGT upright model

Page 23

Select a location for the GasTrac. The location:

❒

Should be between the host dryer and the hopper.

For minimal heat loss, the GasTrac should be no more

than 10 feet from the drying hopper. The GasTrac control

must be within 10 feet of the drying hopper inlet, unless

optional cable extensions for the RTD temperature probe

have been purchased.

❒ Must allow for installation of an exhaust flue that

meets all local, regional and national codes. Ideally, each

GasTrac should have a dedicated vertical stack that exits

the building through a rain-protected roof penetration.

❒ Must provide minimum clearance for safe operation

and maintenance. For efficient combustion, you must not

obstruct air flow around the unit.

Install electrical power to the selected location.

The GasTrac requires a grounded, three-phase power

source. Check the GasTrac’s serial tag for the correct

amps, voltage and cycles for your model. All electrical

wiring should be completed by qualified personnel and

should comply with government codes in your region.

Install gas piping to the selected location.

Gas delivery piping should be sized to provide the rated

gas flow to the GasTrac at a delivery pressure of about 12

inches water column (about

1

/2psig). All gas piping

should be completed by qualified personnel and should

comply with government codes in your region.

PREPARING FOR

INSTALLATION

UGD014/0497 GasTrac Process Air Heater

INSTALLATION 3-3

WARNING: Follow instructions carefully.

Incorrect installation of this product can result in a

fire, explosion or other hazards causing proper ty

damage, severe personal injury or loss of life. Only

licensed electrical/mechanical contractors, or individuals experienced with the installation of natural

gas piping, process air ducting, thermal insulation

and exhaust ducting, should install the GasTrac.

!

1

3 feet

5 feet

2 feet

2 feet

3 ft.

18 inches

3 feet

5 feet

2 feet

2 feet

2

3

NOTE: For reliable longterm

performance, the gas supply

line should include:

❒

A water trap to collect

water condensing in the

gas line.

❒

An in-line, basket-type fil-

ter to collect rust, pipe

scale or welding slag.

Page 24

Move the GasTrac to the selected location.

Be sure to position the GasTrac so that you can easily:

❒ Connect the gas and main power supplies.

❒ Install the flue stack.

❒ Connect process air hoses or lines between the host

dryer, GasTrac and drying hopper.

Secure the GasTrac to the mounting surface.

We have provided 1 3/8-inch diameter holes in the base of

the GasTrac for bolting the unit to a mounting surface.

You must disconnect the host dryer’s process heater because

the GasTrac replaces it. You will need the wiring diagrams and

instruction manuals for your host dryer to determine which

wires to disconnect and which air lines to remove or reroute.

Disconnect and lock out power to the host

dryer.

If the dryer has been operating recently, wait for

the dryer too cool down before continuing to Step 2.

Disconnect the electrical wires between the host

dryer control and the process heating elements.

Disconnect and reroute the process air lines.

The host dryer’s process air outlet must be connected to

the GasTrac instead of the drying hopper. To reduce the

pressure drop in the process air circuit, you may need to

remove the process heater or reroute process air lines within the dryer to bypass the process heater. Refer to the manuals and diagrams that came with your dryer.

INSTALLING THE

GASTRAC

GasTrac Process Air Heater UGD014/0497

3-4 INSTALLATION

WARNING:You are responsible for the

structural integrity of this installation.

If you are installing the GasTrac on a mezzanine,

the host dryer or another device, be sure that the

mounting surface can support the weight of the

GasTrac. See the specification tables for weights.

!

CAUTION: Use a suitable lifting device to

move the GasTrac.

The GasTrac models weigh up to 1,400 pounds.

Always use a for klift or other suitable lifting device

to move the unit.The GasTrac has been equipped

with forklift rails.

!

1

2

DISCONNECTING

THE

DRYER’S

PROCESS AIR

HEATER

1

2

3

Page 25

The GasTrac is a forced draft system, using a variable speed

combustion blower and a sealed combustion chamber. The temperature of combustion gases in the flue can reach 750˚ F.

Install the exhaust ducting and flue.

Consult government codes and a qualified mechanical contractor for detailed installation instructions and assistance.

See the

SPECIFICATIONS pages of this User Guide for GasTrac

operating characteristics and general recommendations.

Connect the flue to the GasTrac’s exhaust outlet.

Attach the T pipe to the GasTrac’s

exhaust outlet using the V clamp

provided. Connect the T pipe to the

exhaust flue. On an upright model,

you must attach the elbow to the

exhaust outlet before connecting

the T pipe and flue.

Insulate the flue and exhaust T assembly.

Exhaust flue and T temperatures can reach 750˚ F.

Install a condensate trap and drain.

Condensate occurs where flue gases cool below their dew

point. This condensate can be highly corrosive. Draining

and disposal should be done in compliance with applicable

safety and environmental codes in your area.

INSTALLING THE

EXHAUST FLUE

UGD014/0497 GasTrac Process Air Heater

INSTALLATION 3-5

WARNING: Do not operate the GasTrac

without a properly installed exhaust flue.

You must install an exhaust flue to vent the combustion gases produced by the GasTrac.The installation

should comply with government codes in your area

and be done by a qualified mechanical contractor

familiar with industrial flue and ducting systems.

!

1

2

3

4

T pipe

T pipe

V clamp

Elbow

Flue

Exhaust outlet

Condensate

drain

Flue

Condensate

drain

V clamp

Exhaust

outlet

TIP: A condensate trap

and drain can be made

by bending a piece of

stainless

steel tubing.

Secure the

drain to the

T pipe using

the appropriate

compression fitting.

Page 26

The process air lines carry dehumidified air from the host

dryer to the GasTrac, and from the GasTrac to the drying hopper. These air lines can be flexible hose or pipe. The air line

between the GasTrac and host dryer can be uninsulated. We

recommend an insulated air line between the GasTrac and the

drying hopper to minimize heat loss.

Connect the GasTrac process air inlet to the host

dryer’s process air outlet. Secure the air lines with

hose or pipe clamps.

Connect the GasTrac process air outlet to the drying hopper air inlet. Secure the air lines with hose or

pipe clamps.

CONNECTING

PROCESS AIR

LINES

GasTrac Process Air Heater UGD014/0497

3-6 INSTALLATION

NOTE: Do not allow

the flexible hoses to

kink or crimp.

1

2

CONNECTING

THE

GAS SUPPLY

WARNING: For your safety, we recommend that

these steps be completed by a qualified mechanical

contractor in compliance with all applicable natural

gas codes in your region.

!

Check all gas lines for leaks. Use a gas detecting

device or apply soapy water around pipe and fittings.

Purge the gas lines after pipe and fittings are known

to be free of leaks. The lines must be free of air, rust,

scale, pipe dope and welding slag.

Connect the gas supply line to the inlet on the

GasTrac fuel train. Make sure that a water trap and inline

basket filter has been installed on the supply line.

1

2

GAS INLET FITTING SIZES

Model NPT size

CGT350 3/4 in.

CGT500

3

/4in.

CGT700 1 in.

Process air

from dryer

Process air

to hopper

Process air

to hopper

Gas supply

inlet

Upright model

Horizontal model

3

Page 27

Open the GasTrac electrical enclosure.

Turn the disconnect dial on the GasTrac’s door

to the Off position. Turn the captive screw, and

swing the door open.

Insert the main power

wire through the knockout in

the electrical enclosure. Secure the wire with a rubber

compression fitting or strain relief.

Connect the power wires

to the three terminals

at the top of the disconnect holder.

Connect the ground wire to either grounding

point shown in the diagram.

CONNECTING

MAIN POWER

UGD014/0497 GasTrac Process Air Heater

INSTALLATION 3-7

4

CAUTION: Electrical hazard.

Always disconnect and lock out the main

power sources before making electrical

connections. Electrical connections should

be made only by qualified personnel.

IMPORTANT:

Always refer to

the wiring diagrams that came with

the GasTrac for the most accurate

information about electrical components and connections.

O

1

2

3

Honeywell

ESCSEL

INSTALLING THE

RTD PROBE

The RTD probe monitors the temperature of the drying air as

it enters the hopper. If the probe is not installed correctly, temperature readings will be inaccurate.

Insert the probe in the

delivery air inlet

of the

hopper. The end of the probe

must not touch the walls of

the inlet pipe. Most hoppers

provide a hole that is compatible with the probe’s

1

/8-inch

NPT compression fitting.

Plug the probe’s cable

into the GasTrac control

box. Coil any excess cable and

secure with a wire tie.

1

2

Page 28

You have completed the installation. Now its time to make

sure everything works. Qualified electrical and mechanical

personnel should be available during the systems check and

the installation test.

Check all electrical connections.

❒ Shut off power to the unit and verify that the GasTrac

and its burner controller are adequately grounded.

Inadequate grounding can cause controller error messages and nuisance alarms.

❒ With power off to the GasTrac and the host dryer, verify

that all terminal connections are tight and all new

wiring has adequate strain relief.

Check gas piping and ducting.

❒ Verify that the gas delivery piping is rigidly supported.

❒ Verify that exhaust gas ducting is secured, adequately

insulated and free of leaks.

Check the GasTrac fuel train for leaks.

Turn on the gas supply to the GasTrac. Open the primary

gas shutoff valve. Use a gas leak detection device or a

squirt bottle of soapy water to detect leaks around gas pipe

and fitting joints. Open the secondary gas shutoff valve,

and continue checking for leaks using the same procedure.

Start the host dryer.

Monitor the dryer during the first few minutes of operation

to verify that the start-up operating sequences are correct.

Turn on the gas supply to the GasTrac.

All manual shut-off valves in the gas supply line and the

GasTrac fuel train must be in the open position. Before

proceeding, use a detection device or soapy water to check

for gas leaks in the GasTrac fuel train.

Turn on main power to the GasTrac.

Turn the main disconnect dial to the I or ON

position.

If everything is installed correctly:

◆ The variable speed control’s display will

illuminate.

GAS AND

ELECTRICAL

SYSTEM

CHECKS

GasTrac Process Air Heater UGD014/0497

3-8 INSTALLATION

1

2

3

WARNING: Be sure lines are free of leaks.

To prevent accident or injury, all gas lines, including

the GasTrac’s factor y-mounted gas train, should be

checked for leaks before firing the burner.

TESTING THE

INSTALLATION

1

2

3

I

Page 29

Press the Power switch to ON.

◆ The Power ON/OFF switch illuminates.

◆ The temperature controller begins a 3-second self-test.

The display will flash between

STANDBY and the set-

point temperature.

◆ The Burner Controller begins a 10-second initiation,

which ends when the display indicates

STANDBY.

Set the drying temperature.

Press the the up or down arrow on the temperature controller until 250˚F appears in the lower display.

Press the RUN button.

◆ The green RUN light will illuminate after the Burner

Controller finishes initializing.

◆ The combustion blower will start and run for 90 sec-

onds to purge any residual gas from the burner.

◆ After the 90-second purge, the burner will ignite on low

fire (low blower speed) for about 15 seconds. The burner will alternate between high and low fire as required

to maintain the setpoint temperature.

Verify the combustion blower is rotating in the

correct direction.

The combustion blower uses three-phase blower. Hold a

strip of paper or piece of string near the blower inlet filter.

If the paper or string blows away from the filter, the blower is rotating in the wrong direction. Stop the GasTrac.

Disconnect and lock out the main power source. Reverse

any two incoming electrical leads on the blower and repeat

the test procedure.

Allow the actual temperature to reach setpoint.

Press the STOP button.

◆ The green RUN indicator light turns off.

◆ The gas inlet valves should close.

◆ The combustion blower should stop.

◆ The burner and temperature controllers should display

STANDBY.

Allow the actual temperature to reach setpoint.

TESTING THE

INSTALLATION

UGD014/0497 GasTrac Process Air Heater

INSTALLATION 3-9

RUN

MAN

235.0

250.0

SP2

OP1

OP2

REM

HOLD

2216

5

6

4

4

5

6

7

6

8

9

10

BURNER START UP NOTE:

If the burner fails to ignite

and the red alarm light illuminates, there may still be air

in the gas lines. Check the

burner controller display. If

the alarm LED is illuminated,

press the reset button on the

front of the electrical enclosure. If not, refer to the

T

ROUBLESHOOTING

section of

the User Guide and the

burner controller manual.

Page 30

Page 31

4-1

UGD014/0497 GasTrac Process Air Heater

● GasTrac operating features . . . .4-2

●The GasTrac control . . . . . . . . . .4-3

●To start dr ying . . . . . . . . . . . . . .4-4

●To stop drying . . . . . . . . . . . . . .4-5

OPERATION

Page 32

GASTRAC

OPERATING

FEATURES

GasTrac Process Air Heater UGD014/0497

4-2 OPERATION

ESC SEL

Cooling Exhaust Filter

Prevents contaminants

from entering the electrical enclosure through

the exhaust vent.

The GasTrac Control

This is the primary operating control.You

turn the GasTrac on or off, enter the setpoint drying temperature and start or stop

the GasTrac using this remotable control. A

green light indicates the GasTrac is running.

A red light indicates an alarm condition.

Main Power

Disconnect Switch

Turn the lockable dial to

provide or disconnect

electrical power to the

GasTrac.

The OPERATING section introduces the GasTrac operating fea-

tures and explains how to use the primary GasTrac control to

start and stop drying. For detailed information about the

Temperature, Burner and Variable Speed Controllers, see the

manufacturer’s manuals in the instruction packet.

Electrical Enclosure

Cooling Fan and Filter

Draws outside air

through the enclosure

to cool electrical components.

Process High Temperature

Limit Switch

Shuts down the GasTrac when

the process, or drying, temperature exceeds 450˚F.

Flue Gas High Temperature

Limit Switch

Shuts down the GasTrac

when the combustion exhaust

temperature exceeds 800˚F.

High Temperature Limit

Switch Reset Button

Push to reset the flue gas and

process high temperature limit

switches.

Burner Controller

The Burner Controller is activated

when you press the RUN button

on the main GasTrac control. The

burner controller sends a signal to

the spark igniter, which fires the

metal-ceramic burner.This controller continues to monitor the

fuel train, combustion blower and

other combustion components for

possible problems.

Variable Speed Controller

The Variable Speed Controller automatically adjusts the speed of the combustion

blower by var ying the frequency and voltage of the signal. Increasing the speed

increases the air-to-fuel mixture and the

heat output of the burner.

Page 33

UGD014/0497 GasTrac Process Air Heater

OPERATION 4-3

THE GASTRAC

CONTROL

RUN

MAN

235.0

250.0

SP2

OP1

OP2

REM

HOLD

2216

The GasTrac control is the primary operator interface. This

control may have been mounted in a remote location.

Run Button

Push to start

the GasTrac.

Emergency Stop Button

Push to shutdown the

GasTrac during an emergency. Pull to restore

power before restarting.

Alarm Light

An illuminated light Indicates the

GasTrac has shutdown on an

alarm condition. The Troubleshooting section will help you

identify and correct the problem.

Run Light

An illuminated

light indicates

the GasTrac is

operating.

Power On/Off

This switch sends power to

the burner controller, the

GasTrac control and the

process and safeguard relay

devices The switch illuminates when power is ON.

Temperature Controller

OP1: Indicates the variable frequency controller output is active.

SP2: Indicates the controller will control to setpoint #2 when in automatic mode.

MAN: Indicates the controller is being manually operated by the operator.

Actual

temperature

Setpoint

temperature

Page button

Press to select parameter lists during setup and configuration of the controller.

Scroll button

Press to scroll through parameter lists to select a parameter to modify.

Down button

Press to decrease a value or scroll down through a list.

Up button

Press to increase a value or scroll up through a list.

See the Eurotherm Temperature

Controller manual in the instruction

packet for a full description of alarm

messages, programming modes and

parameters.

Stop Button

Push to stop

the GasTrac.

2216

OP1

OP2

234.0

SP2

REM

250.0

RUN

HOLD

MAN

Page 34

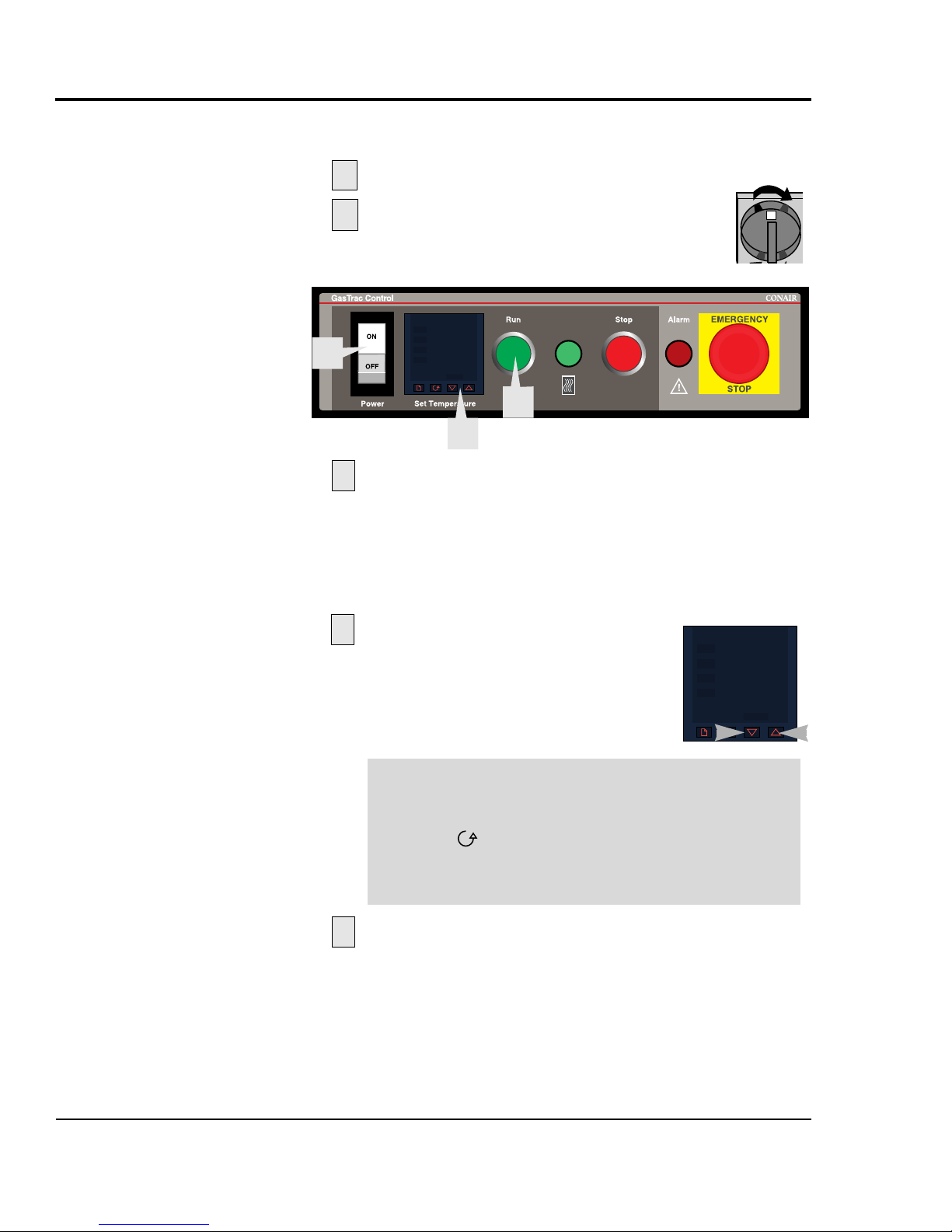

The temperature controller is factory configured to start and

operate in automatic mode.

Start the host dryer.

Turn the main power disconnect to

the

I or ON position.

◆ The variable speed controller turns on.

Press the Power switch to ON.

◆ The Power ON/OFF switch illuminates.

◆ The temperature controller begins a 3-second self-test.

The display will flash between

STANDBY and the setpoint

temperature.

◆ The Burner Controller begins a 10-second initiation,

which ends when the display indicates

STANDBY.

Set the drying temperature.

Press the the up or down arrow on the

temperature controller until the recommended drying temperature appears in

the lower display.

Press the RUN button.

◆ The green RUN light will illuminate after the Burner

Controller finishes initializing.

◆ The combustion blower will start and run for 90 sec-

onds to purge any residual gas from the burner.

◆ After the purge, the burner will ignite on low fire (low

blower speed) for about 15 seconds. The burner will

alternate between high and low fire as required to maintain the setpoint temperature.

TO START

DRYING

GasTrac Process Air Heater UGD014/0497

4-4 OPERATION

1

2

3

4

5

4

5

3

NOTE: The temperature units were set at the

factory in ˚F or ˚C, as specified in the order.

To see which temperature unit was set:

Press the button once. F or C will be displayed.

To change the temperature unit:

See the Eurotherm Temperature Controller manual

235.0

250.0

RUN

HOLD

MAN

2216

OP1

OP2

SP2

REM

OP1

OP2

234.0

SP2

REM

250.0

MAN

RUN

HOLD

I

2216

Page 35

UGD014/0497 GasTrac Process Air Heater

OPERATION 4-5

TO STOP

DRYING

Press the red STOP button.

◆ The green indicator light turns off.

◆ The gas inlet valves should close.

◆ The combustion blower should stop.

Press the ON/OFF switch to OFF.

◆ The burner control turns off.

◆ The temperature controller turns off.

Turn the main power disconnect off.

◆ The variable speed control display remains

lit for a brief period. Then it becomes blank.

Turn the host dryer off after at least 2 minutes.

1

2

3

4

1

2

IMPORTANT: Do not shut down the host dr yer before

stopping the GasTrac.

After stopping the GasTrac, allow the host dryer’s

process blower to continue running for a minimum of 2

minutes.This prevents excessive heat from building up

in the GasTrac.

O

CAUTION:Voltage present

Some voltage will be present in the variable speed drive for a brief period after

power has been turned off.When the voltage is gone, the variable speed control

display will become blank.

235.0

250.0

RUN

HOLD

MAN

2216

OP1

OP2

SP2

REM

Page 36

Page 37

5-1

UGD014/0497 GasTrac Process Air Heater

● Maintenance checklist . . . . . . . .5-2

● Cleaning the combustion

air filter . . . . . . . . . . . . . . . . . . .5-3

● Cleaning the electrical

enclosure filters . . . . . . . . . . . .5-3

● Replacing the spark igniter . . . .5-4

● Cleaning the ultraviolet

flame detector . . . . . . . . . . . . .5-6

● Cleaning the burner

sight glass . . . . . . . . . . . . . . . .5-6

MAINTENANCE

Page 38

PREVENTATIVE

MAINTENANCE

CHECKLIST

GasTrac Process Air Heater UGD014/0497

5-2 MAINTENANCE

Routine maintenance will ensure optimum operation and performance of the GasTrac. We recommend the following maintenance schedule and tasks.

● Weekly, or as often as needed

❒ Clean the GasTrac combustion air filter.

You may need to clean the filter more often than

weekly. Frequency depends on the amount of dust

in your facility’s air.

❒ Clean the GasTrac electrical enclosure filters.

You may need to clean the filters more often than

weekly. Frequency depends on the amount of dust

in your facility’s air.

● Monthly

❒ Inspect air hoses and hose connections.

Check for damage, kinks or loose hose clamps.

Replace any hoses that show signs of damage or

wear. Reposition and tighten loose hose clamps.

❒ Inspect and test safety controls.

Fuel safety shutoff valves, combustion safeguards

and temperature and pressure switches should be

inspected and tested by trained personnel.

❒ Inspect the burner sight glass.

Clean the sight glass, if needed. Replace the sight

glass if you see cracks or any other defect.

● Every six months

❒ Inspect the GasTrac metal-ceramic burner.

While the unit is fired, look through the sight glass

at the burner. The burner surface should be glowing

orange with an even flame. Blue flames, flames

projecting from the burner surface, or cracks or

dark spots on the burner surface indicate damage.

You may need to replace the burner.

❒ Inspect piping, wiring and electrical connections.

Check for leaks, corrosion and loose connections.

Replace any component that shows signs of damage or wear. Tighten loose connections.

● Annually

❒ Replace the spark igniter.

To assure optimum performance, you should

replace the spark igniter once a year.

❒ Clean the ultraviolet flame detector lens.

Use alcohol and a soft cloth.

Page 39

You must clean the combustion air intake filter periodically. A

clogged filter reduces air flow through the combustion circuit,

which reduces burner efficiency and heat output.

Stop the GasTrac.

Press the red STOP

button, then press the

rocker switch to

OFF.

Disconnect and lock out main power.

Remove the filter shroud.

Remove the wing nut and washer

that holds the shroud in place.

Lift the shroud up and off.

Remove the filter.

Remove the wing nut and washer

that holds the filter in place. Lift

the filter up and off.

Clean the filter.

Vacuum or blow dirt and debris

from the filter using vacuum or

low-pressure compressed

air. When using compressed air, blow from

inside the filter toward

the outside.

Reassemble .

Repeat steps 3 and 4 in

reverse order to replace

the filter.

CLEANING THE

COMBUSTION

FILTER

UGD014/0497 GasTrac Process Air Heater

MAINTENANCE 5-3

1

2

3

NOTE: Replace any

filter that has cracked

end gaskets or is

torn, worn or clogged

with so much dirt that

it cannot be cleaned.

4

5

3

4

CLEANING THE

ELECTRICAL

ENCLOSURE

FILTERS

Periodically, you should clean the filters covering the

cooling fan inlet and outlet on the electrical enclosure.

Remove the the thumb

screws and filters.

Clean the filters.

Use vacuum or low-pressure compressed air to remove loose debris.

Wash the filters in warm, soapy

water, then rinse and air dry.

Replace torn or worn filters.

Reassemble.

6

1

2

3

OP1

OP2

SP2

REM

235.0

250.0

RUN

HOLD

MAN

2216

ESCSEL

Page 40

The spark igniter should be replaced at least once a year to

assure trouble-free operation. You should replace the igniter

before the annual period, if you inspect it and find:

● The spark gap is less than 0.125 inch. The gap should

be between 0.07 and 0.09 inch.

● The igniter insulation is cracked

● The spark electrodes are warped or taper to a needle-

like shape.

Do not operate the GasTrac with a worn or damaged spark

igniter. A badly burned or warped igniter can cause burner

ignition failure.

Stop the GasTrac.

Press the red STOP

button, then press the

rocker switch to

OFF.

Disconnect and lock out main power.

Remove the igniter wire.

Pull the wire boot, not the wire,

away from the spark igniter. If the

wire or its boot is cracked, you

should replace it.

Remove the spark igniter.

Use a 7⁄8 inch spark

plug socket and ratchet

to loosen the igniter.

Pull the igniter straight

out of the GasTrac. Do

not allow the spark

igniter to touch the

burner surface.

REPLACING THE

SPARK IGNITER

GasTrac Process Air Heater UGD014/0497

5-4 MAINTENANCE

1

2

3

IMPORTANT: When

removing or inserting the

spark igniter, do not allow

the igniter electrode or

grounding rod to touch the

burner.You could damage

the burner surface.

3 4

4

TIP: Before removing the spark igniter for inspection,

use a felt tip marker to mark the position of the igniter

in its threaded hole. By

indexing the position,

you will able to return

the igniter to the correct

position after inspection.

The igniter must be

installed so that the

ground rod is 180˚

away from the

burner surface.

WARNING:

Hot surfaces

Allow the GasTrac

to cool before

removing the burner guard to perform

maintenance

OP1

OP2

SP2

REM

235.0

250.0

RUN

HOLD

MAN

2216

Page 41

Mark the position of the grounding rod on the

new spark igniter, using a felt tip marker. This index mark

must end up 180˚ away from the burner surface when the

spark igniter is inserted and tightened. The electrode

should be closest to the burner surface.

Coat the threads of the igniter with a high-temper-

ature conductive anti-seize compound.

Carefully insert the igniter into GasTrac.

Insert the igniter straight into the threaded fitting. Do not

bend the electrode, and do not allow the spark igniter to

touch the burner surface.

Screw the igniter into the threaded fitting.

Tighten by hand

first. Then use a

socket and ratchet

to tighten the

igniter one turn or

a partial turn until

the index mark on

the igniter is 180˚

away from the

burner surface.

Push the boot and wire onto the spark igniter.

Push until you feel the boot snap into place.

UGD014/0497 GasTrac Process Air Heater

MAINTENANCE 5-5

Electrode

Grounding rod

5

REPLACING THE

SPARK IGNITER

180˚

WARNING: Do not over tighten the spark igniter.

You could damage the porcelain insulator.

6

7

8

9

Page 42

A dirty ultraviolet flame detector may fail to recognize burner

ignition, which will cause the GasTrac to alarm and shut down

automatically.

Stop the GasTrac.

Press the red STOP button, then press the rocker switch to

OFF.

Disconnect and lock out main power.

Remove the flame detector.

Loosen the mounting nut while holding the flame detector, then pull the

detector away from the viewing hole.

Clean the viewing hole lens.

Use a soft cloth or cotton swab

moistened with alcohol.

Replace the flame detector.

Align the detector over the

viewing hole, and thread the silver

mounting nut onto the coupling.

Hand tighten first. Then use a

wrench to tighten the nut an

additional quarter turn.

GasTrac Process Air Heater UGD014/0497

5-6 MAINTENANCE

CLEANING THE

ULTRAVIOLET

FLAME

DETECTOR

RUN

MAN

235.0

250.0

SP2

OP1

OP2

REM

HOLD

2216

WARNING:

Hot surfaces

Allow the GasTrac

to cool before

removing the burner guard to perform

maintenance

1

2

3

4

5

CLEANING THE

BURNER SIGHT

GLASS

WARNING:

Hot surfaces

Allow the GasTrac

to cool before

removing the burner guard to perform

maintenance

A dirty sight glass prohibits inspection or viewing of the

metal-ceramic burner during operation.

Stop the GasTrac. Disconnect and lock out

main power.

Remove the screws on the

sight glass bracket.

Clean the sight glass.

Use a clean soft cloth or cotton swab

moistened with alcohol.

Coat the screw threads with

a high-temperature anti-seize compound.

Replace the sight glass.

Tighten the screws in the bracket

to hold the glass in place.

1

2

3

4

5

Page 43

6-1

UGD014/0497 GasTrac Process Air Heater

● Before beginning . . . . . . . . . . . .6-2

● A few words of caution . . . . . . .6-2

● When an alarm occurs . . . . . . . .6-3

● How to identify the cause

of an alarm . . . . . . . . . . . . . . . .6-3

●Temperature controller

alarms . . . . . . . . . . . . . . . . . . . .6-4

● Burner controller alarms . . . . . .6-7

● Variable speed controller

alarms . . . . . . . . . . . . . . . . . . .6-10

● Flue gas high temperature

limit switch . . . . . . . . . . . . . . .6-14

● Process high temperature

limit switch . . . . . . . . . . . . . . .6-15

TROUBLESHOOTING

Page 44

BEFORE

BEGINNING

GasTrac Process Air Heater UGD014/0497

6-2 TROUBLESHOOTING

You can avoid most problems by following the recommended

installation and maintenance procedures outlined in this Users

Guide. If you do have a problem, this section will help you

determine what caused it and tell you how to fix it.

Before you begin troubleshooting:

❒ Find the wiring and assembly diagram you

received with your GasTrac. These diagrams will note any

custom features such as special wiring or alarm capabilities not covered in the User Guide.

❒ Find the instruction manuals and diagrams that

were shipped with the GasTrac and your host dryer.

❒ Find any installation diagrams or notes which may

have been generated at the time the GasTrac was

installed.

A FEW WORDS

OF

CAUTION

WARNING: The GasTrac should be maintained

and repaired by qualified technicians who are

equipped with the correct tools and are experienced in the maintenance and repair of industrial

gas appliances.

WARNING: Hot surfaces.

Temperatures inside the GasTrac can reach more

than 800˚ F. Always shut down the GasTrac and

host dryer and wait for them to cool before servicing.

WARNING: Disconnect and lock out main

power before servicing.

The GasTrac is connected to high voltage.

Always disconnect and lock out the main power

source to the GasTrac before servicing. Also disconnect and lock out the main power to the host

dryer before servicing the GasTrac. Failure to disconnect and lock out this voltage source could

result in severe personal injury.

WARNING: Shut off main gas supply and

purge heat exchanger and gas lines before

servicing.

Failure to eliminate this potential source of a gas

leak could result in severe damage, personal

injury or loss of life.

Page 45

When there is a problem with the GasTrac the alarm light will

illuminate and the GasTrac will shutdown.

WHEN AN

ALARM OCCURS

UGD014/0497 GasTrac Process Air Heater

TROUBLESHOOTING 6-3

HOW TO

IDENTIFY THE

CAUSE OF AN

ALARM

RUN

MAN

235.0

250.0

SP2

OP1

OP2

REM

HOLD

2216

Alarm light

The single alarm may be caused by any one of five major

control components or another device within the GasTrac.

Check the controllers for alarm messages.

Causes of the more probable alarm messages can be

found in this section of the User Guide. If you don’t find

the alarm message here, then see the manufacturer’s manual for that particular controller. These manuals can be

found in the instruction packet that came with your

GasTrac.

Check the limit switches for contact closure.

Possible causes of switch failure can be found in this

section of the User Guide.

Check the GasTrac electrical and gas systems.

These checks should be performed only by trained electrical and gas technicians equipped with the proper tools.

Control components and indications of failure:

●

Temperature controller

Displays a flashing alarm message.

●

Burner controller

Displays a flashing alarm message.

●

Variable speed controller

Displays a flashing alarm message.

●

Process outlet high temperature limit switch

Ver ify switch contact closure.

●

Flue gas high temperature limit switch

Ver ify switch contact closure.

1

2

3

Page 46

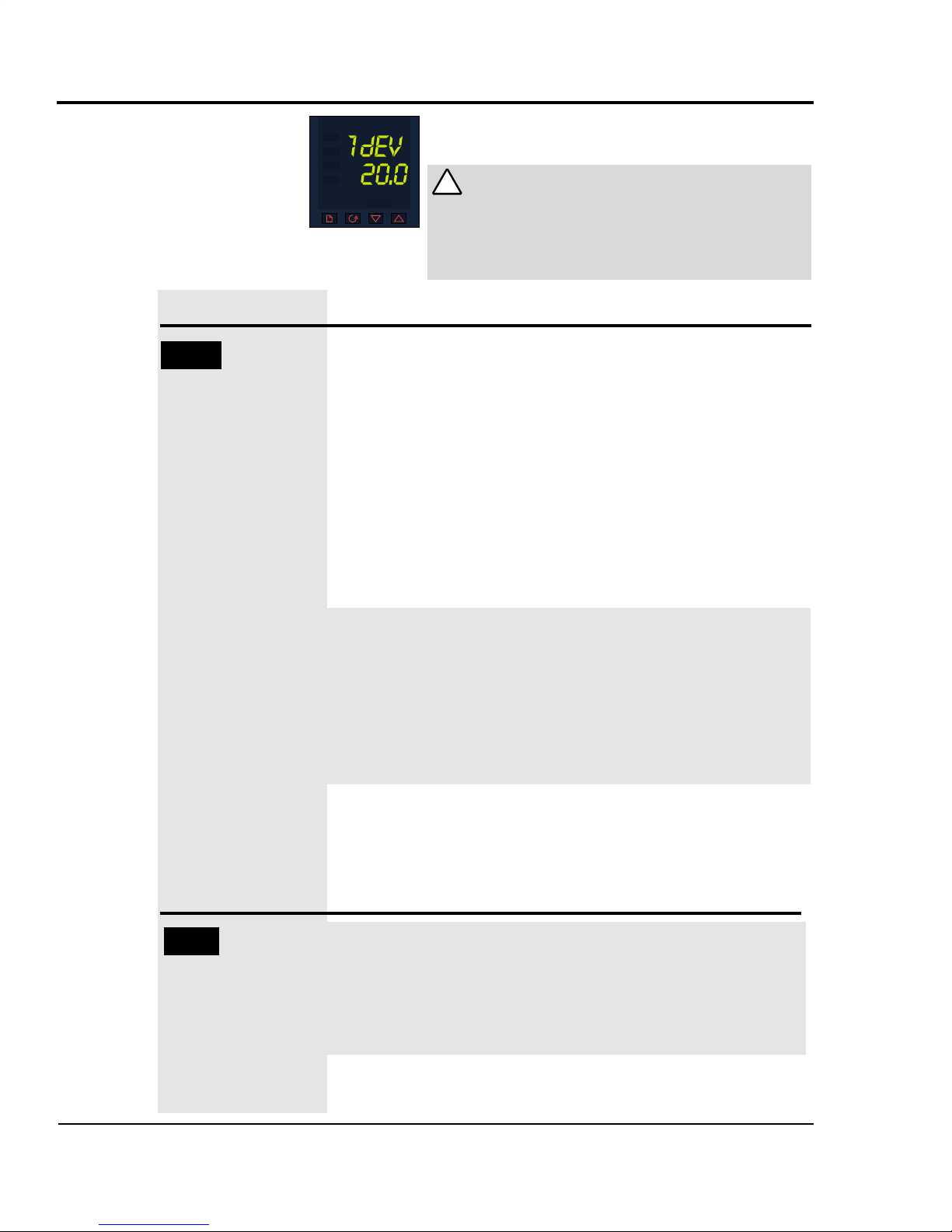

TEMPERATURE

CONTROLLER

ALARMS

GasTrac Process Air Heater UGD014/0497

6-4 TROUBLESHOOTING

Alarm

Deviation

Band

The drying, or

process circuit, temperature is higher or

lower than the setpoint alarm band

allows.

Sensor

Break

The sensor input for

RTD temperature

probe has failed.

Possible cause

Is something blocking or

restricting the flow of

drying, or process, air?

Is the RTD temperature

probe installed correctly?

Is the temperature range

for the deviation band too

narrow?

Is the RTD temperature

probe connection loose or

incorrectly installed?

Is the RTD temperature

probe damaged?

Solution

❒ Check the process filter in

the host dryer. Clean or replace

the filter if it is clogged or

damaged.

❒ Check the process air hoses

for leaks, crimps, blockage or

loose connections. Remove

obstructions. Repair leaks or

loose connections.

❒ Check the process air blower in the host dryer. If it is not

running correctly, see the

dryer’s manual.

Make sure the sensing end of

the RTD probe is positioned

near the center of the process

air line at the hopper inlet.

Temperature readings will be

incorrect if the sensing end is

too close to the wall of the

inlet hose or pipe.

Increase the deviation band

5˚F at a time. The default setting is 20˚F. To avoid nuisance

alarms, do not adjust this band

more than necessary.

❒ Verify that the RTD temperature probe is installed.

❒ Check for a loose RTD connection at the GasTrac control

or the process air inlet of the

hopper.

Replace the RTD temperature

probe.

1dEV

S.br

The Temperature Controller will flash an alarm

message in the upper or lower display window.

WARNING: The GasTrac should be tested and repaired only by qualified technicians

equipped with the correct tools and trained in

the maintenance and repair of electrical systems and industrial gas appliances.

RUN

MAN

SP2

OP1

OP2

REM

HOLD

2216

!

Page 47

UGD014/0497 GasTrac Process Air Heater

TROUBLESHOOTING 6-5

Alarm

Loop

Break

The actual drying

temperature did not

approach the setpoint within the loop

break time. There

may be a problem in

the combustion or

process air circuit.

Power

Failure

The line voltage to

the Temperature

Controller is too low.

Possible cause

Is something blocking or

restricting the flow of

drying, or process, air?

Is the GasTrac combustion air filter dirty?

Is the Variable Speed

Controller operating correctly?

Is the setpoint correct?

Is the GasTrac being supplied with the correct

voltage?

Is there a loose or faulty

connection in the electrical circuit?

Solution

❒ Check the process filter in

the host dryer. Clean the filter,

or replace it if it is damaged.

❒ Check the process air hoses

for leaks, crimps, blockage or

loose connections. Remove

obstructions. Repair leaks or

loose connections.

❒ Check the process air blower in the host dryer. If it is not

running correctly, see the

dryer’s manual.

Clean the combustion air filter.

Replace the filter if it is torn or

too clogged with dirt to clean.

Check the Variable Speed

Controller for error or alarm

messages. See the Variable

Speed Controller pages in this

TROUBLESHOOTING section and in

the Allen-Bradley controller

manual.

Make sure the setpoint is within the range specified for your

GasTrac unit.

Check the main power supply

to the GasTrac and the electrical circuits supplying power to

the control panel and the temperature controller.

L.br

TEMPERATURE

CONTROLLER

ALARMS

Pwr.F

The Temperature Controller will flash an alarm

message in the upper or lower display window.

WARNING: The GasTrac should be tested and repaired only by qualified technicians

equipped with the correct tools and trained in

the maintenance and repair of electrical systems and industrial gas appliances.

RUN

MAN

SP2

OP1

OP2

REM

HOLD

2216

!

Page 48

GasTrac Process Air Heater UGD014/0497

6-6 TROUBLESHOOTING

Alarm

The ROM self test

failed.

The RAM self test

failed.

Watchdog Failure

Keyboard failure.

Input Circuit Failure

Possible cause

The temperature controller is defective.

The temperature controller is defective.

The temperature controller is defective.

A button on the temperature controller keypad is

stuck or was pressed during power up.

The temperature controller is defective.

Solution

Replace the temperature controller, or return it to the factory for repair.

Replace the temperature controller, or return it to the factory for repair.

Replace the temperature controller, or return it to the factory for repair.

Switch the power to the

GasTrac control off and the on

using the

POWER ON/OFF

switch. Do not touch any buttons on the temperature controller.

Replace the temperature controller, or return it to the factory for repair.

TEMPERATURE

CONTROLLER

ALARMS

The Temperature Controller will flash an alarm

message in the upper or lower display window.

WARNING: The GasTrac should be tested and repaired only by qualified technicians

equipped with the correct tools and trained in

the maintenance and repair of electrical systems and industrial gas appliances.

RUN

MAN

SP2

OP1

OP2

REM

HOLD

2216

Err1

Err2

Err3

Err4

Err5

!

Page 49

BURNER

CONTROLLER

ALARMS

UGD014/0497 GasTrac Process Air Heater

TROUBLESHOOTING 6-7

When there is a problem related to the

burner or ignition, the burner controller

displays a fault code and illuminates an

alarm light. To restart the GasTrac after a

burner controller alarm:

Press the GasTrac

STOP button.

Press the burner

RESET button.

Press the GasTrac

RUN button.

Alarm

Flame did not occur

within the 4-second

flame establishing

period.

WARNING:

The GasTrac

should be tested

and repaired only

by qualified technicians equipped

with the correct

tools and trained in

the maintenance

and repair of electrical systems and

industrial gas

appliances.

Possible cause

Is the spark igniter providing a spark?

Is there a problem with

the gas supply?

Is the lens of the ultraviolet sensor dirty?

Is negative pressure in

the building affecting static pressure of the combustion exhaust flue?

Is the burner controller

defective?

Solution

Restart the GasTrac while watching through the sight glass. If you

don’t see a spark during the 4second ignition period:

❒ Verify there is power supplied

to the transformer during the

ignition period.

❒ Check the wire and connec-

tions between the transformer

and spark igniter.

❒ Check the spark igniter.

Replace if damaged.

If the burner fails to light even

though you can see a spark:

❒ Verify that the gas supply is

on and that the gas shutoff

valves are open during the

ignition period.

❒ Restart the GasTrac 4 or 5

times to purge any air that may

be in the gas lines.

❒ Verify that the gas pressure

regulator is set to supply the

correct pressure.

If the burner ignites and then

goes out, check

the lens for dirt.

Clean if necessary.

Verify that the static pressure of

the combustion exhaust flue is 1

to 2 inches of water column. If

not, you may need to add a draft

fan to the flue to create the correct static pressure.

If none of the solutions above can

resolve the problem, you may

need to replace the burner controller.

1

2

3

LOCKOUT #16

*Flame Out Timer*

!

Page 50

GasTrac Process Air Heater UGD014/0497

6-8 TROUBLESHOOTING

Alarm

The main flame

failed after

RUN was

pushed and the

flame had been

established for at

least 10 seconds.

WARNING:

The GasTrac

should be tested

and repaired only

by qualified technicians equipped

with the correct

tools and trained in

the maintenance

and repair of electrical systems and

industrial gas

appliances.

Possible cause

Are the gas shutoff valves

open?

Did the ultraviolet flame

detector fail to send an

adequate signal?

Are the safety pressure

switches malfunctioning

or detecting incorrect

pressures?

Is the gas pressure regulator adjusted correctly?

Solution

❒ Verify that the manual gas

shutoff valves are open.

❒ Verify that the automatic gas

shutoff valves remain open

after burner ignition. If

automatic shutoff valves are

not opening, check the solenoid electrical connections.

During operation, the flame

signal should fluctuate

between 1.25V and 5V D.C.

❒ Verify that the ultraviolet

flame detector lens is clean.

❒ Check for blockage in the

cooling air line between the

ultraviolet sensor and combustion air blower. The temperature at the sensor must

be less than 215˚F.

❒ The sensor or flame amplifi-

er may need to be replaced.

Reset the GasTrac, press

RUN

and check the LED lights on

the process air, combustion air,

low gas and high gas pressure

switches during the 90-second

purge cycle. If a light is not

green, check for leaks, blockage or other problems that

could interfere with air or gas

flow detected by that switch.

Make sure the gas pressure

regulator is adjusted to supply

the pressure outlined in the

S

PECIFICATIONS pages.

BURNER

CONTROLLER

ALARMS

When there is a problem related to the

burner or ignition, the burner controller

displays a fault code and illuminates an

alarm light. To restart the GasTrac after a

burner controller alarm:

Press the GasTrac

STOP button.

Press the burner

RESET button.

Press the GasTrac

RUN button.

1

2

3

LOCKOUT #17

*Main Flame Fail*

!

Page 51

BURNER

CONTROLLER

ALARMS

UGD014/0497 GasTrac Process Air Heater

TROUBLESHOOTING 6-9

Alarm

OR

WARNING:

The GasTrac

should be tested

and repaired only

by qualified technicians equipped

with the correct

tools and trained in

the maintenance

and repair of electrical systems and

industrial gas

appliances.

Possible cause

Is the combustion blower

intake filter clogged?

Are the safety pressure

switches malfunctioning

or detecting incorrect

pressures?

Did the airflow interlock

fail closed?

Solution

Clean the filter. Replace the

filter if it is worn, torn or so

clogged with dirt that it can’t

be cleaned.

Reset the GasTrac, press

RUN

and check the LED lights on

the process air, combustion air,

low gas and high gas pressure

switches during the 90-second

purge cycle. If a light is not