Page 1

www.conairgroup.com

USER GUIDE

UGH050-0816

ESE Series Central Chillers

ESE Series Scroll Central Chillers

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 2

DISCLAIMER: Conair shall not be liable for errors contained in this User Guide or for incidental, consequential

Copyright 2016 l Conair l All rights reserved

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equi pment and the date you

received it in the User Guide. Our service department uses this information, along with the manual

number, to provide help for the specific equipment you installed.

Please keep this User Guide and all manuals, engine ering prints and parts lists together for

documentation of your equipment.

Date:

Manual Number: UGH050-0816

Serial Number(s):

Model Number(s)

damages in connection with the furnishing, performance or use of this information. Conair makes no warranty

of any kind with regard to this information, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 3

Page Intentionally Blank

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 4

Table of Contents

Foreword ............................................................................................................................................................................. 1

Safety Guidelines ............................................................................................................................................................... 2

General Data ....................................................................................................................................................................... 3

Table 1 – ESEW Series Single-Circuit Water-Cooled Condenser Chiller General Data (60 Hz) ............................................ 3

Table 2 – ESEW Series Dual-Circuit Water-Cooled Condenser Chiller General Data (60 Hz) ................................................ 4

Table 3 – ESER Series Single-Circuit Remote Air-Cooled Condenser Chiller General Data (60 Hz) ................................... 5

Table 4 – ESER Series Dual-Circuit Remote Air-Cooled Condenser Chiller General Data (60 Hz) ....................................... 6

Table 5 – Remote Air-Cooled Condenser General Data (60 Hz) ....................................................................................................... 7

Pre-Installation ................................................................................................................................................................... 8

Receiving Inspection ............................................................................................................................................................................................... 8

Unit Storage ............................................................................................................................................................................................................... 8

Installation - Chiller Mechanical ...................................................................................................................................... 9

Unit Location ............................................................................................................................................................................................................. 9

Rigging ......................................................................................................................................................................................................................... 9

Chilled Water Piping ............................................................................................................................................................................................... 9

Condenser Water Piping ....................................................................................................................................................................................... 9

Water Pressure Gauges ......................................................................................................................................................................................... 10

Master Temperature Sensor ................................................................................................................................................................................ 10

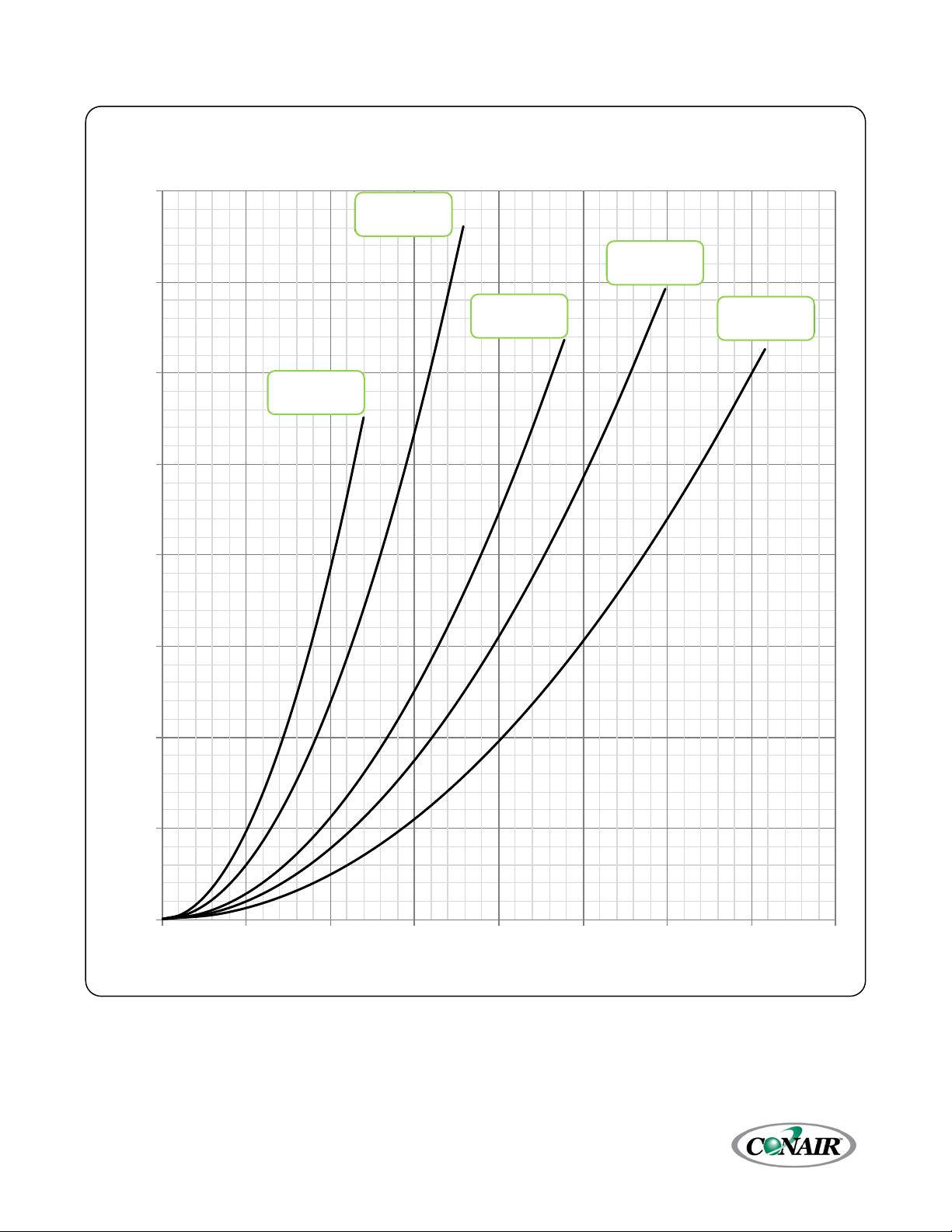

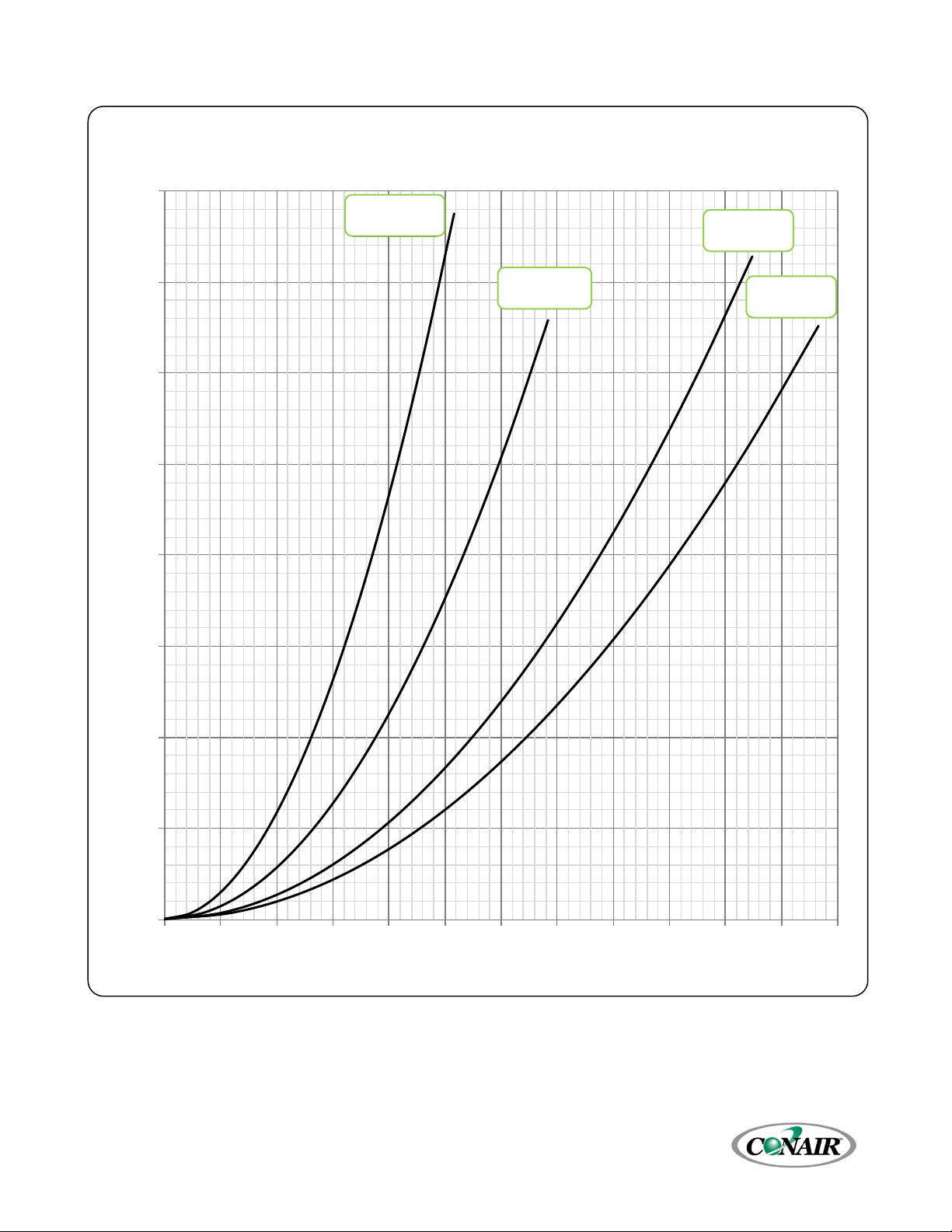

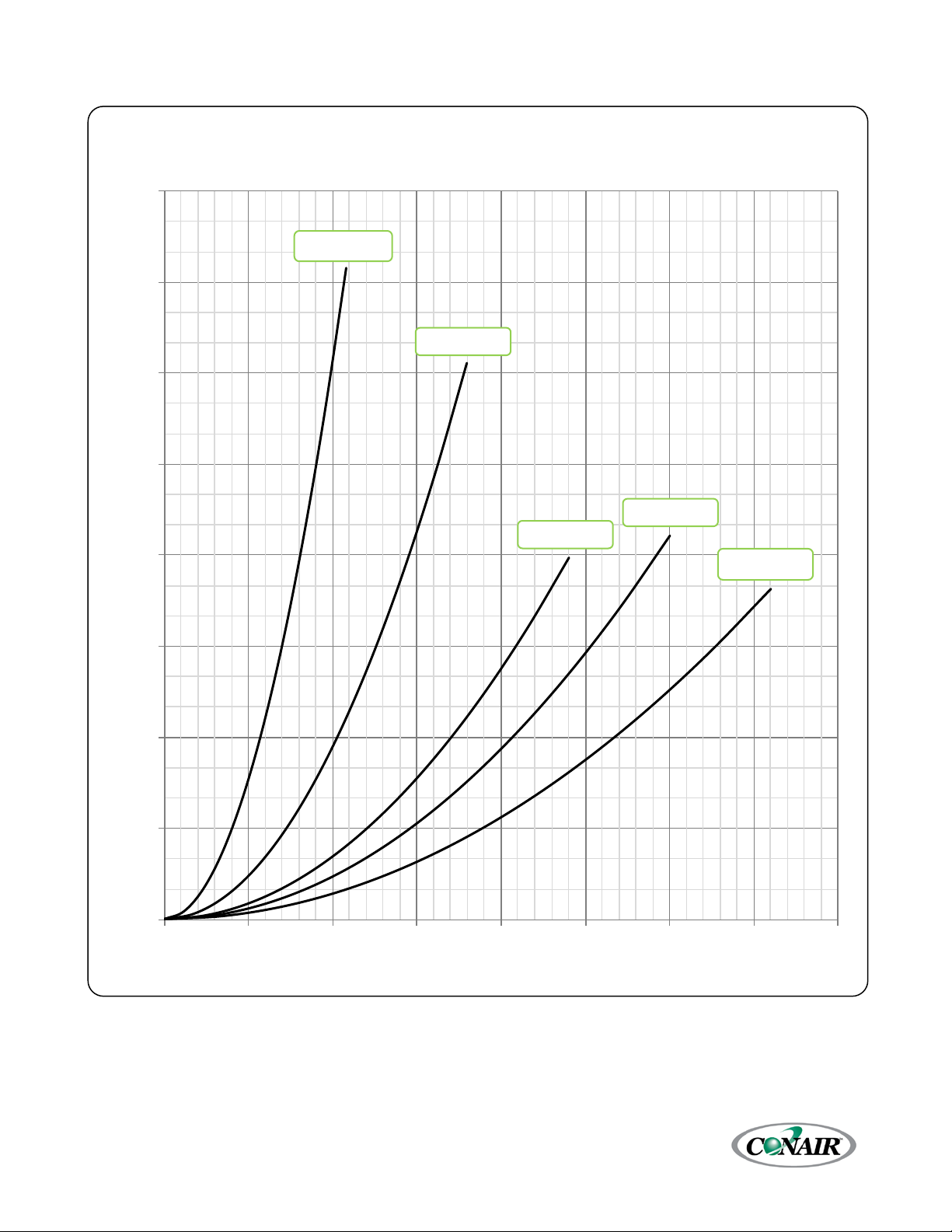

Figure 1 – Standard Flow Chiller Coolant Circuit Pressure Drop (10 through 30 Ton Single-Circuit Chillers) ............... 11

Figure 2 – Standard Flow Chiller Coolant Circuit Pressure Drop (40 through 80 Ton Single-Circuit Chillers) ............... 12

Figure 3 – Standard Flow Chiller Coolant Circuit Pressure Drop (20 through 160 ton Dual-Circuit Chillers) ................. 13

Figure 4 – Standard Flow Chiller Coolant Circuit Pressure Drop (80 through 160 ton Dual-Circuit Chillers) ................. 14

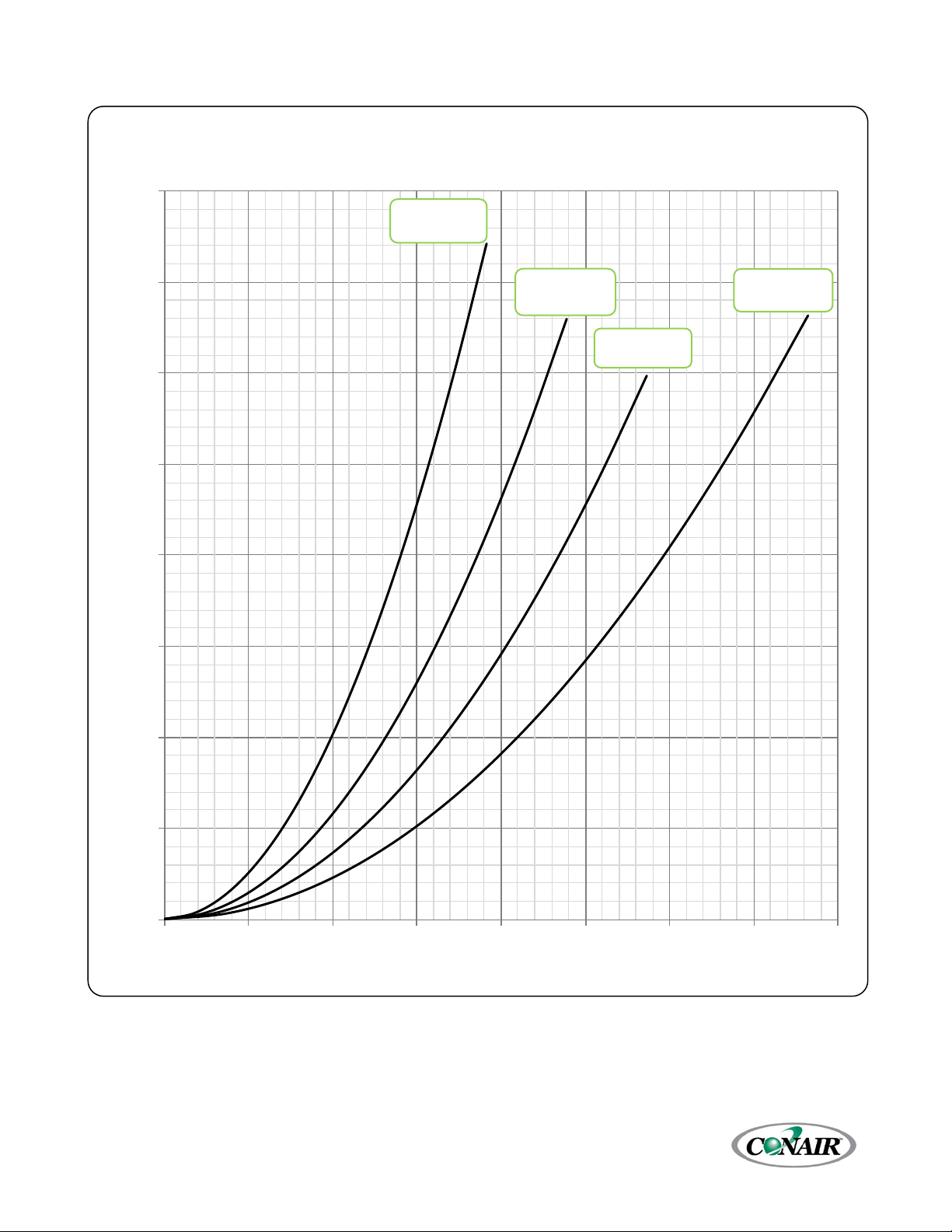

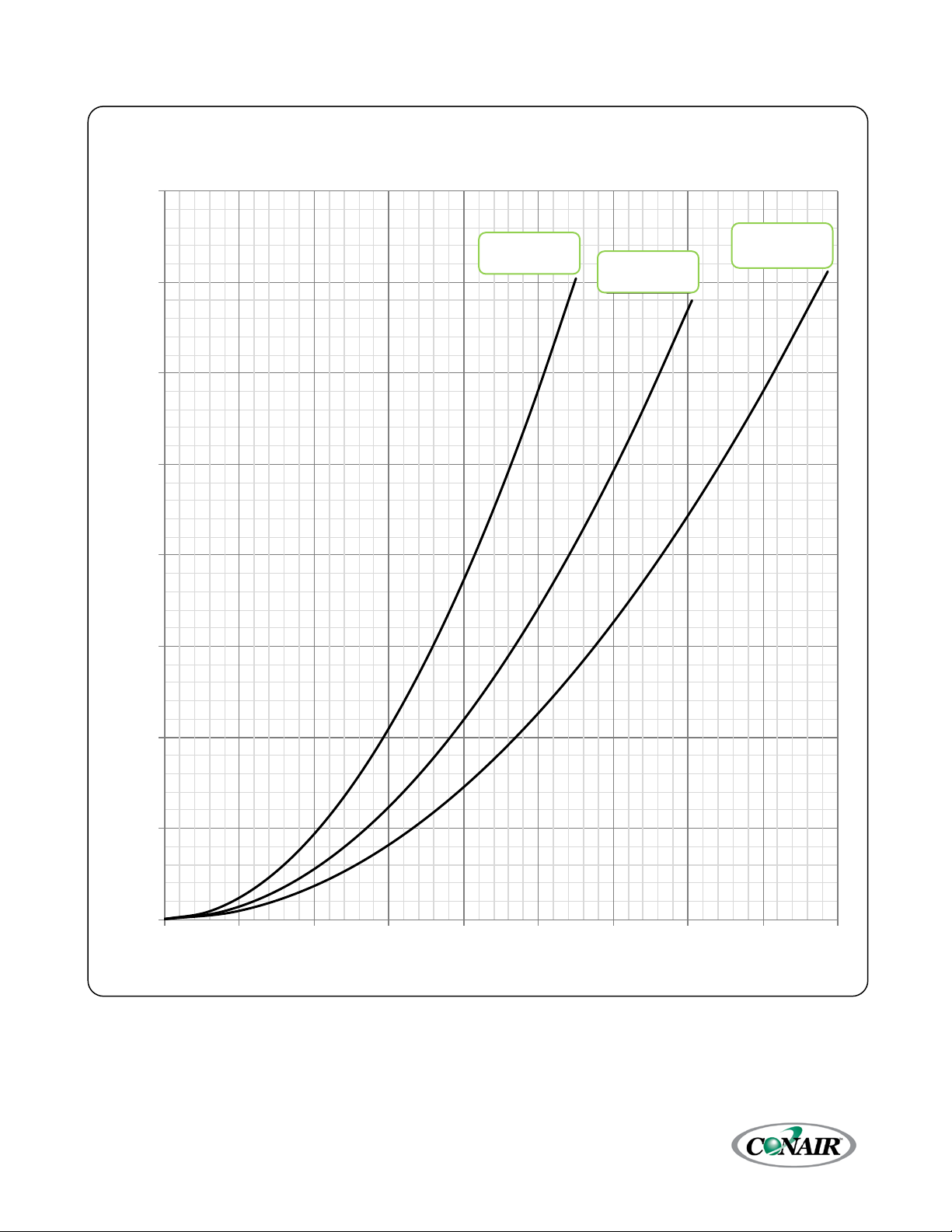

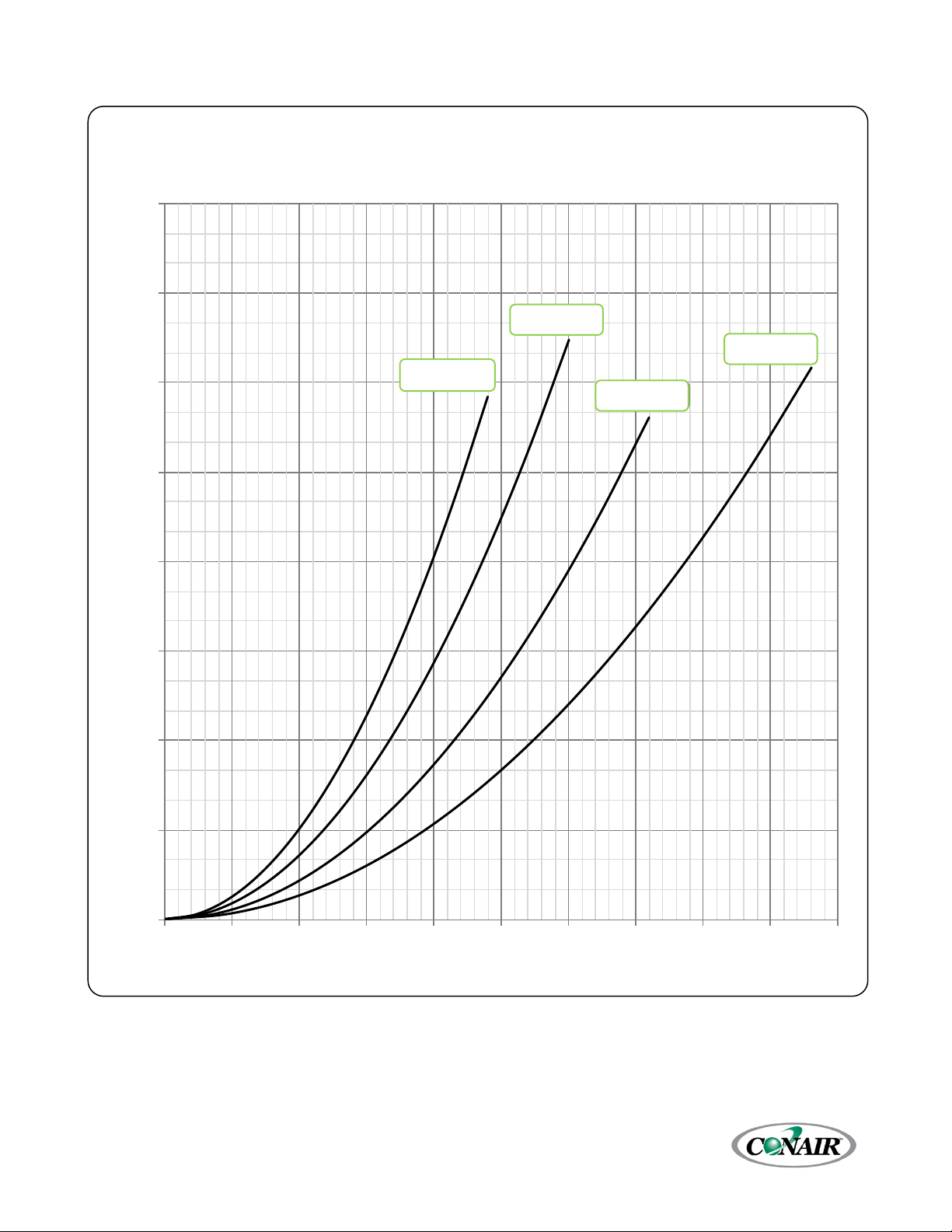

Figure 5 – High Flow Chiller Coolant Circuit Pressure Drop (10 through 25 ton Single-Circuit Chillers) ......................... 15

Figure 6 – High Flow Chiller Coolant Pressure Drop (30 through 50 ton Single-Circuit Chillers) ....................................... 16

Figure 7 – High Flow Chiller Coolant Pressure Drop (20 through 50 ton Dual-Circuit Chillers) .......................................... 17

Figure 8 – High Flow Chiller Coolant Pressure Drop (60 through 100 ton Dual-Circuit Chillers) ........................................ 18

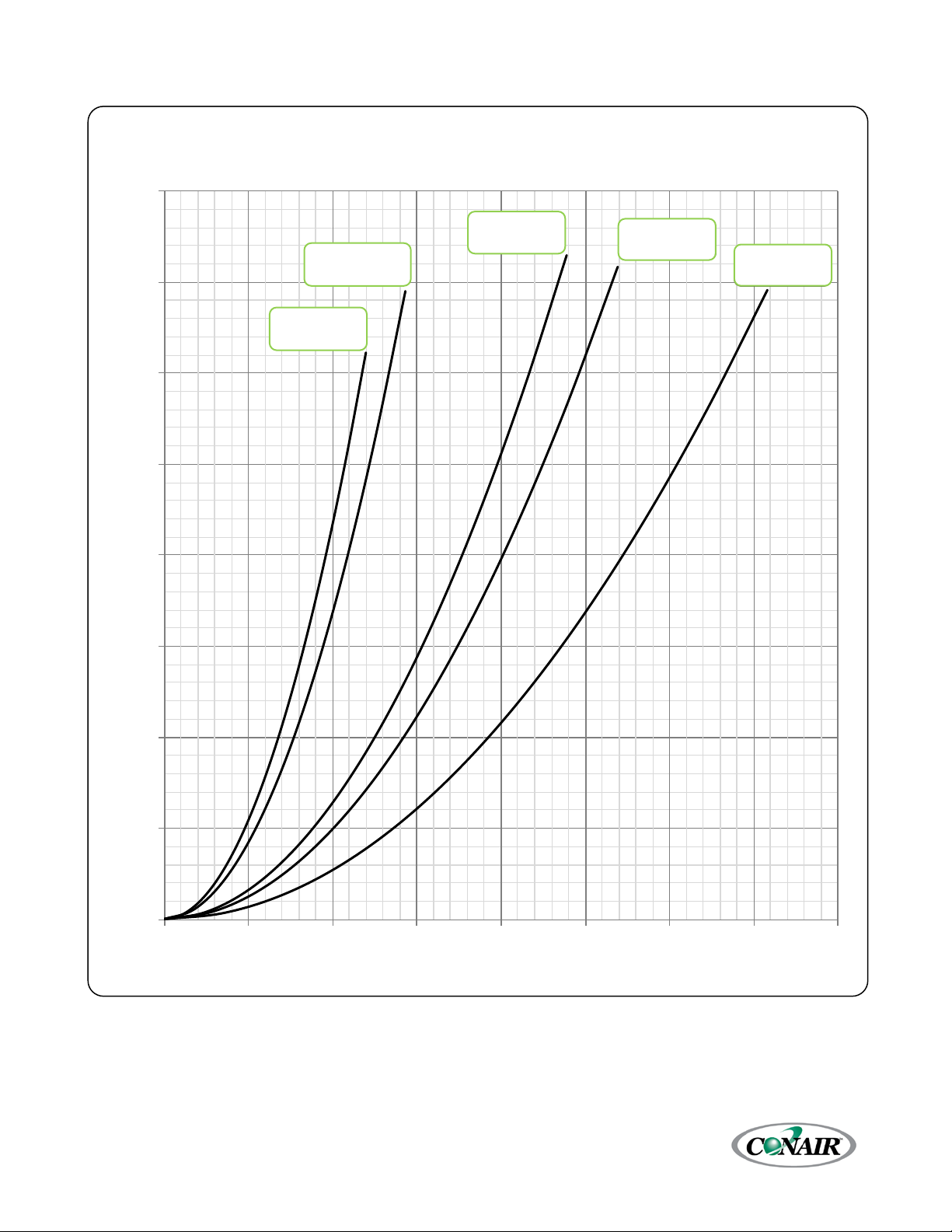

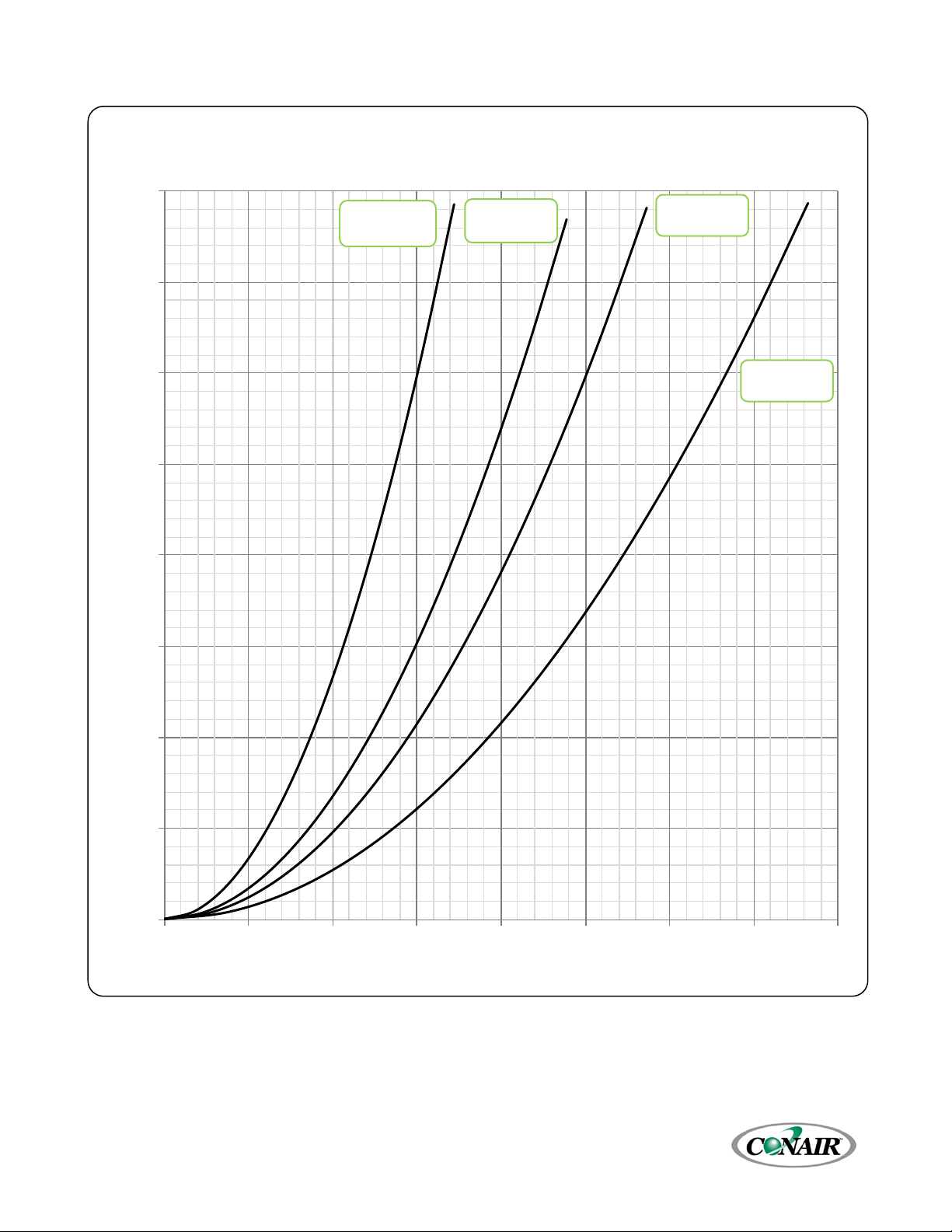

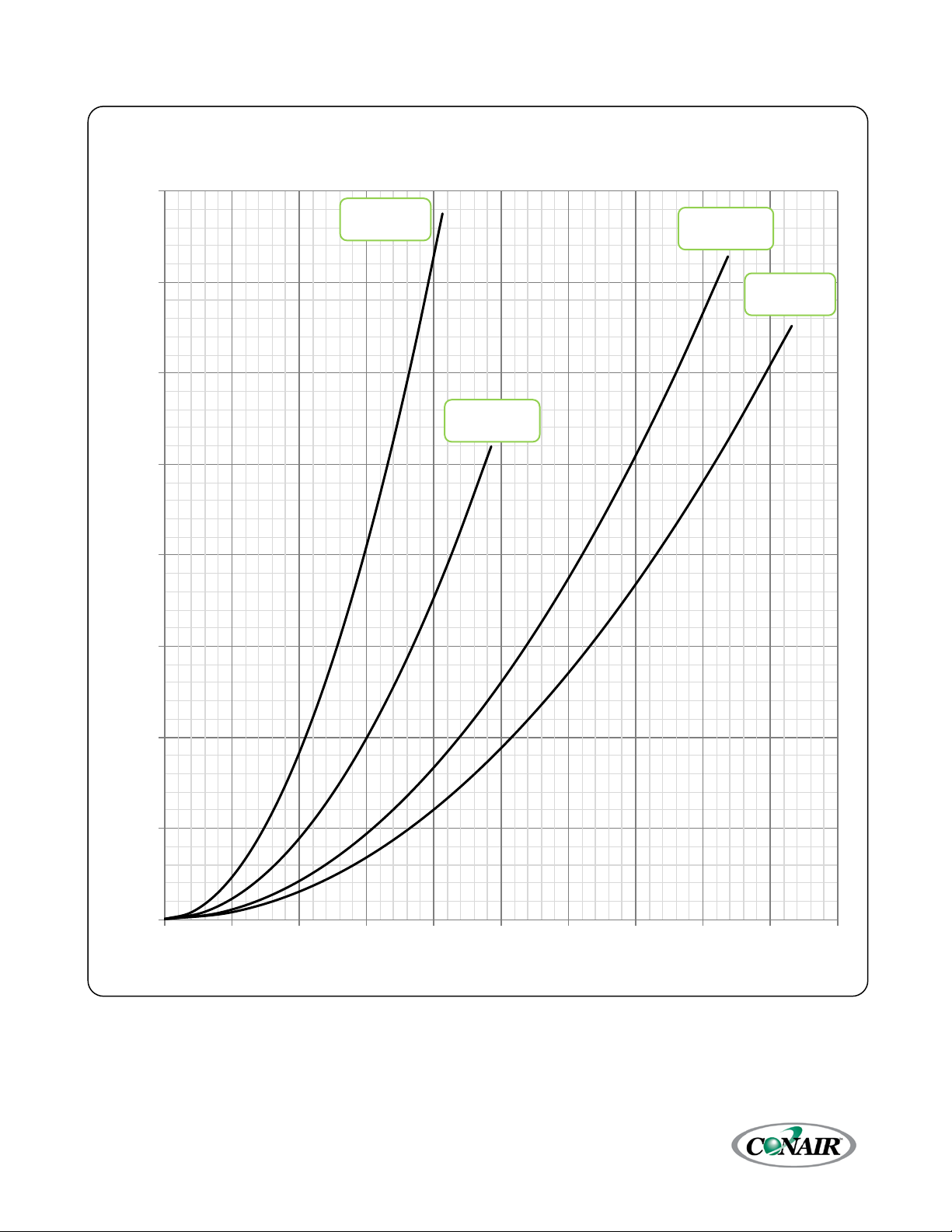

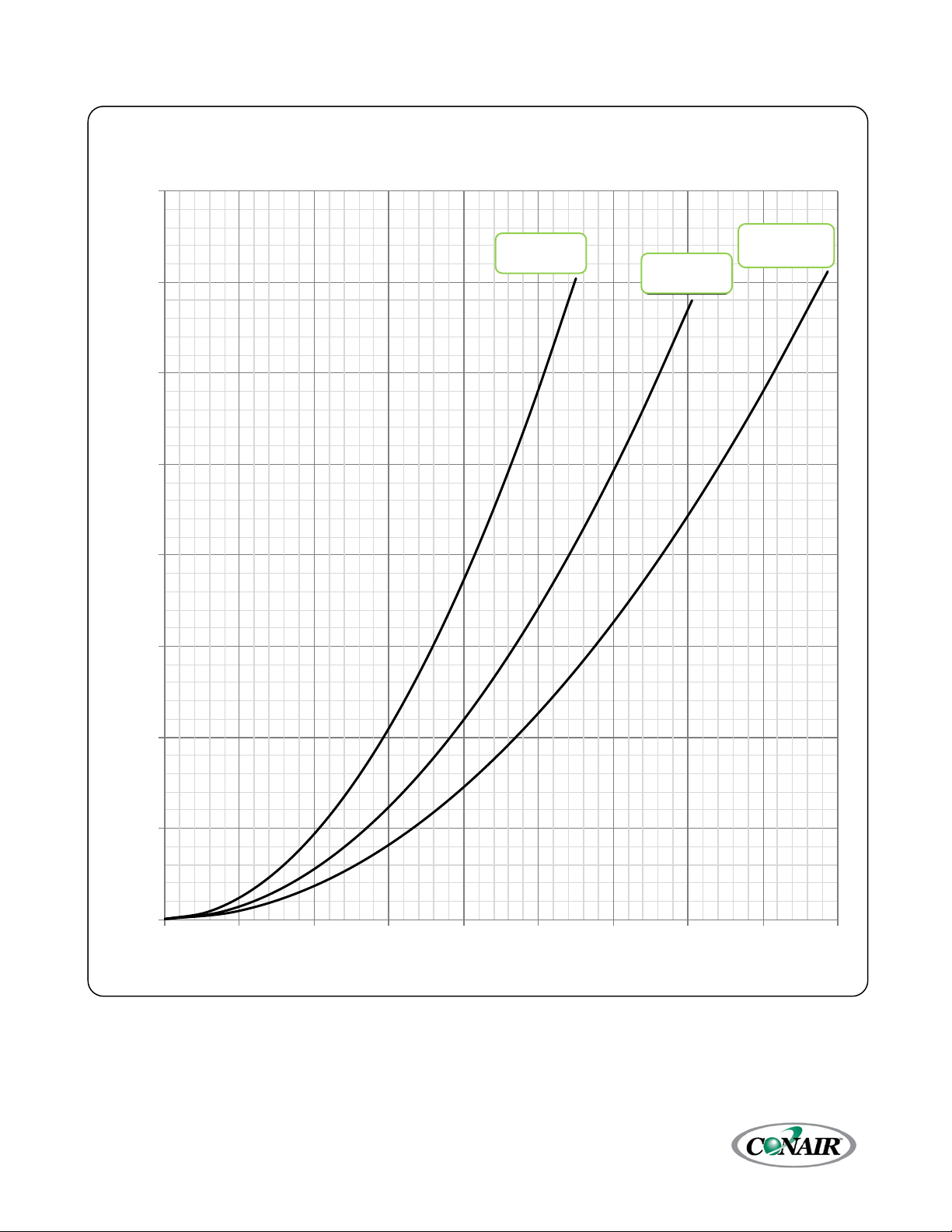

Figure 9 – Condenser Water Circuit Pressure Drop (10 through 30 ton Single-Circuit Chillers) ......................................... 19

Figure 10 – Condenser Water Circuit Pressure Drop (40 through 80 ton Single-Circuit Chillers) ....................................... 20

Figure 11 – Condenser Water Circuit Pressure Drop (20 through 60 ton Dual-Circuit Chillers) .......................................... 21

Figure 12 – Condenser Water Circuit Pressure Drop (80 through 160 ton Dual-Circuit Chillers) ....................................... 22

Installation - Remote Air-Cooled Condenser ................................................................................................................ 23

Location ....................................................................................................................................................................................................................... 23

Mounted Legs and Lifting (10 ton Single-Circuit and 20-ton Dual-Circuit Units) ......................................................................... 24

Mounted Legs and Lifting (all except 10 ton Single-Circuit and 20-ton Dual-Circuit Units)..................................................... 25

Interconnecting Refrigerant Piping .................................................................................................................................................................. 26

Refrigeration Piping Design ................................................................................................................................................................................ 26

Figure 13 – Condenser Located with No Elevation Difference .......................................................................................................... 27

Figure 14 – Condenser Located above Chiller Unit................................................................................................................................ 27

Figure 15 - Condenser Located Below Chiller Unit ................................................................................................................................ 28

Determining Equivalent Line Length ................................................................................................................................................................ 28

Table 6 – Equivalent Lengths of Fittings ..................................................................................................................................................... 29

Liquid Line Sizing ..................................................................................................................................................................................................... 29

Table 7 – Liquid Line Sizes for R410A .......................................................................................................................................................... 30

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 5

Discharge (Hot Gas) Line Sizing ......................................................................................................................................................................... 32

Figure 16 – Vertical Riser Traps ...................................................................................................................................................................... 32

Figure 17 - Double Discharge Riser.............................................................................................................................................................. 33

Table 8 – Discharge Line Sizes for Chiller (inches OD) ......................................................................................................................... 33

Table 9 - Upflow Discharge Line Sizes for R410A (inches OD) .......................................................................................................... 34

Calculating System Refrigerant and Oil Charge .......................................................................................................................................... 34

Table 10 – Combined Chiller and Remote Condenser Summer Refrigerant Charge ............................................................... 34

Table 11 - Field Piping R-410A Refrigerant Charge per 100 Feet of Run (Lbs.) ......................................................................... 34

Oil Charge Determination .................................................................................................................................................................................... 35

Setting Condenser Fan Controls ........................................................................................................................................................................ 35

Table 12 - Condenser Fan Pressure Settings (psig) ............................................................................................................................... 35

Installation - Electrical ...................................................................................................................................................... 36

Table 13 – ESEW & ESER Single-Circuit Chiller Electrical Data (60 Hz) .......................................................................................... 37

Table 14 – ESEW & ESER Single-Circuit Chiller with Standard Flow Pump Set Electrical Data (60 Hz) ............................. 38

Table 15 – ESEW & ESER Single-Circuit Chiller with High Flow Pump Set 1 Electrical Data (60 Hz) .................................. 39

Table 16 – ESEW & ESER Single-Circuit Chiller with High Flow Pump Set 2 Electrical Data (60 Hz) .................................. Error! Book

Table 17 – ESEW & ESER Dual-Circuit Chiller Electrical Data (60 Hz) ............................................................................................. 40

Table 18 – ESEW & ESER Dual-Circuit Chiller with Standard Flow Pump Set Electrical Data (60 Hz) ................................ 41

Table 19 – ESEW & ESER Dual-Circuit Chiller with High Flow Pump Set 1 Electrical Data (60 Hz) ..................................... 42

Table 20 – ESEW & ESER Dual-Circuit Chiller with High Flow Pump Set 2 Electrical Data (60 Hz) ..................................... Error! Book

Table 21 – Single-Circuit Remote Condenser Electrical Data (60 Hz) ............................................................................................. 43

Table 22 – Dual-Circuit Remote Condenser Electrical Data (60 Hz) ................................................................................................ 44

General Control Operation ............................................................................................................................................... 45

System Initialization ................................................................................................................................................................................................ 45

Figure 18 – Start-Up Splash Screen .............................................................................................................................................................. 45

Home - System Overview ................................................................................................................................................. 46

System Overview ...................................................................................................................................................................................................... 46

Figure 19 – ESEW System Overview ............................................................................................................................................................. 46

Figure 20 – ESER System Overview ............................................................................................................................................................... 46

Table 23 – System Overview Functions ....................................................................................................................................................... 46

Home – Full Screen ............................................................................................................................................................ 47

Figure 21 – Full Screen ...................................................................................................................................................................................... 47

Warnings ..................................................................................................................................................................................................................... 47

Figure 22 – Warning Screen ............................................................................................................................................................................ 47

Home – Pump Control (Optional) ................................................................................................................................... 48

Pump Control Screen (Optional) ....................................................................................................................................................................... 48

Figure 23 – Pump Control Screen ................................................................................................................................................................. 48

Pump VFD Control Screen (Optional) .............................................................................................................................................................. 48

Figure 24 – Pump VFD Control Screen ....................................................................................................................................................... 48

Menu 1 - Overview ............................................................................................................................................................ 49

Figure 25 – Menu 1 Screen .............................................................................................................................................................................. 49

Table 24 – Menu 1 Functions .......................................................................................................................................................................... 50

Menu 1 - Alarms................................................................................................................................................................. 51

Alarms Active ............................................................................................................................................................................................................. 51

Figure 26 – HMI Alarm Handler ..................................................................................................................................................................... 51

Alarm History ............................................................................................................................................................................................................. 51

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 6

Figure 27 – Alarm History ................................................................................................................................................................................. 51

Alarm Setup ............................................................................................................................................................................................................... 52

Figure 28 – Alarm Setup ................................................................................................................................................................................... 52

Alarm Glycol ............................................................................................................................................................................................................... 52

Figure 29 – Alarm Setup ................................................................................................................................................................................... 52

Menu 1 – Metric Units/Imperial Units ............................................................................................................................ 53

Menu 1 - Compressor Data .............................................................................................................................................. 53

Compressor Data Screen ...................................................................................................................................................................................... 53

Figure 30 – Circuit Data Screen (Water-Cooled Condenser Chiller) ................................................................................................ 53

Figure 31 – Circuit Data Screen (Remote Air-Cooled Condenser Chiller) ..................................................................................... 54

Compressor Data Screen – Interlocks .............................................................................................................................................................. 54

Figure 32 – Interlocks ......................................................................................................................................................................................... 54

Figure 33 – Critical Interlocks .......................................................................................................................................................................... 55

Figure 34 – Refrigeration Interlocks ............................................................................................................................................................. 55

Menu 1 – Modbus/BAS ..................................................................................................................................................... 56

Modbus RTU/BAS Setup Screen ........................................................................................................................................................................ 56

Figure 35 – Modbus Setup Screen ................................................................................................................................................................ 56

Figure 36 – Modbus Word Data Screen ..................................................................................................................................................... 56

Figure 37 – Modbus Bit Data Screen ........................................................................................................................................................... 56

Menu 1 – EXV1 Expansion Valve Setup .......................................................................................................................... 57

EXV1 Expansion Valve Setup Screen ................................................................................................................................................................ 57

Figure 38 – EXV1 Expansion Valve Setup Screen .................................................................................................................................... 57

Table 25 – EXV1 Setup Parameters............................................................................................................................................................... 57

Menu 1 – EXV2 Hot Gas Bypass Setup ............................................................................................................................ 58

EXV2 Hot Gas Bypass Setup Screen (Optional)............................................................................................................................................ 58

Figure 39 – EXV2 Hot Gas Bypass Screen .................................................................................................................................................. 58

Table 26 – EXV2 Setup Parameters............................................................................................................................................................... 58

Menu 1 – Water Regulating Valve (WRV) Setup .......................................................................................................... 59

WRV Water Regulating Valve Setup Screen ................................................................................................................................................. 59

Figure 40 – WRV Setup Screen....................................................................................................................................................................... 59

Table 27 – WRV Setup Parameters ............................................................................................................................................................... 59

Menu 1 – Compressor Staging/PID ................................................................................................................................. 60

Compressor Staging Setup Screen ................................................................................................................................................................... 60

Figure 41 – Compressor Staging Setup Screen ....................................................................................................................................... 60

Table 28 – Compressor Staging Setup Parameters ................................................................................................................................ 60

Compressor Staging Graph Screen .................................................................................................................................................................. 61

Figure 42 – Compressor Staging Graph Screen ...................................................................................................................................... 61

Table 29 – Compressor Staging Graph Parameters ............................................................................................................................... 61

Compressor Staging Local Screen .................................................................................................................................................................... 62

Figure 43 – Compressor Staging Local Screen ........................................................................................................................................ 62

Table 30 – Compressor Staging Local Parameters ................................................................................................................................. 62

Menu 1 – Inputs/Outputs ................................................................................................................................................. 63

Inputs / Outputs Screens ...................................................................................................................................................................................... 63

Figure 44 – Digital Inputs Screen .................................................................................................................................................................. 63

Figure 45 – Digital Outputs Screen .............................................................................................................................................................. 63

Figure 46 – Analog Inputs Screen ................................................................................................................................................................. 63

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 7

Figure 47 – Analog Outputs Screen ............................................................................................................................................................. 63

Menu 1 – Temperature Offsets ........................................................................................................................................ 64

RTD Temperature Offset Adjustment .............................................................................................................................................................. 64

Figure 48 – RTD Temperature Offsets Screen .......................................................................................................................................... 64

Menu 1 – Process Control ................................................................................................................................................. 65

Leaving/Entering Sensor Selection ................................................................................................................................................................... 65

Figure 49 – Process Control Screen .............................................................................................................................................................. 65

Menu 1 – Pumps Setup ..................................................................................................................................................... 66

Pump Setup Screen ................................................................................................................................................................................................. 66

Figure 50 – Pump Setup Screen ..................................................................................................................................................................... 66

Table 31 – Pump Setup Parameters ............................................................................................................................................................. 66

Menu 1 – Tank Setup ......................................................................................................................................................... 67

Tank Setup Screen ................................................................................................................................................................................................... 67

Figure 51 – Tank Setup Screen ....................................................................................................................................................................... 67

Menu 1 – Counters ............................................................................................................................................................. 68

Counters Screens ..................................................................................................................................................................................................... 68

Figure 52 – Counters 1 Screen ....................................................................................................................................................................... 68

Figure 53 – Counters 2 Screen ....................................................................................................................................................................... 68

Figure 54 – Counters 3 Screen ....................................................................................................................................................................... 68

Menu 2 - Overview ............................................................................................................................................................ 69

Figure 55 – Menu 2 ............................................................................................................................................................................................. 69

Table 32 – Menu 2 Functions .......................................................................................................................................................................... 69

Menu 2 – Hardware Options Selected ............................................................................................................................ 70

Hardware Options Screen .................................................................................................................................................................................... 70

Figure 56 – Hardware Options Screen ........................................................................................................................................................ 70

Menu 2 - Date/Time .......................................................................................................................................................... 71

Menu 2 – System Menu .................................................................................................................................................... 71

Menu 2 – Defaults .............................................................................................................................................................. 71

Figure 57 – Restore Factory Settings ........................................................................................................................................................... 71

Figure 58 – Factory Settings Restored ........................................................................................................................................................ 72

Menu 2 – Remote Setpoint Setup ................................................................................................................................... 72

Figure 59 – Remote Setpoint Setup Screen .............................................................................................................................................. 72

Menu 2 – Remove SD Storage ......................................................................................................................................... 73

Menu 2 – Trending ............................................................................................................................................................ 73

Figure 60 – Trending Screen ........................................................................................................................................................................... 73

Menu 2 – Remote Mode ................................................................................................................................................... 73

Menu 2 – PLC Link Setup .................................................................................................................................................. 74

PLC Link (Master/Slave) Setup Screen ............................................................................................................................................................. 74

Figure 61 – PLC Link Setup Screen ............................................................................................................................................................... 74

Figure 62 – PLC Link Word Data Screen ..................................................................................................................................................... 74

Figure 63 – PLC Link Bit Data Screen ........................................................................................................................................................... 74

Menu 2 – Touch Calibration ............................................................................................................................................. 75

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 8

Start-Up ............................................................................................................................................................................... 75

Step 1 - Connect Main Power ............................................................................................................................................................................. 75

Step 2 - Fill Coolant Circuit .................................................................................................................................................................................. 76

System Fill Water Chemistry Requirements .............................................................................................................................................. 76

Table 33 – Fill Water Chemistry Requirements ........................................................................................................................................ 77

Table 34 - Recommended Glycol Solutions .............................................................................................................................................. 77

Step 3 - Check Condenser .................................................................................................................................................................................... 77

Water-Cooled Condenser Check ................................................................................................................................................................... 77

Remote Air-Cooled Condenser Check ........................................................................................................................................................ 77

Step 4 – Check Refrigerant Valves .................................................................................................................................................................... 77

Step 5 – Verify Freezestat Setting ..................................................................................................................................................................... 78

Step 6 – Turn On Control Power ........................................................................................................................................................................ 78

Step 7 – Establish Coolant Flow ......................................................................................................................................................................... 78

Step 8 – Intial Unit Operation ............................................................................................................................................................................. 78

Low-Ambient Start-Up (Remote Condensers) ......................................................................................................................................... 78

Preventive Maintenance ................................................................................................................................................... 79

Once a Week ............................................................................................................................................................................................................. 79

Once a Month ........................................................................................................................................................................................................... 80

Once Every Three Months .................................................................................................................................................................................... 80

Once a Year ................................................................................................................................................................................................................ 80

Cleaning the Operator Interface ...................................................................................................................................... 81

General Troubleshooting .................................................................................................................................................. 82

Preventive Maintenance Checklist .................................................................................................................................. 83

Drawings ............................................................................................................................................................................. 83

Warranty Information ....................................................................................................................................................... 84

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 9

Page Intentionally Blank

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 10

Foreword

The central chiller contains on or more refrigeration

circuits intended to chiller or cool a process fluid. As

an option, a process fluid reservoir and pumping

system is available to create a complete packaged

chiller system.

The intent of this manual is to serve as a guide for

placing our central chiller in service and operating

and maintaining it properly. Improper installation

can lead to poor equipment performance or severe

equipment damage. Failure to follow the installation

instructions may result in damage not covered by

your warranty. It is extremely important that a

qualified refrigeration installation contractor perform

all installation line sizing and piping. Please supply

these instructions to your authorized refrigeration

contractor. This manual is for our standard product

line with supplements as required to accommodate

any special items provided for a specific application.

The written information contained in this manual, as

well as various drawings, are intended to be general

in nature. Unit specific drawings are included with

the equipment for troubleshooting and servicing of

the unit. Additional copies of drawings are available

upon request. We strive to maintain an accurate

record of all equipment during the course of its

useful life.

Due to the ever-changing nature of applicable

codes, ordinances, and other local laws pertaining to

the use and operation of this equipment we do not

reference them in this manual. There is no substitute

for common sense and good operating practices

when placing any mechanical equipment into

operation. We encourage all personnel to familiarize

themselves with this manual's contents. Failure to do

so may unnecessarily prolong equipment down time.

The chiller uses chemical refrigerants for heat

transfer purposes. This chemical is sealed and tested

in a pressurized system containing ASME coded

vessels; however, a system failure will release it.

Refrigerant gas can cause toxic fumes if exposed to

fire. Place these units in a well-ventilated area,

especially if open flames are present.

Failure to follow these instructions could result in a

hazardous condition. The standard refrigerant used

in these units is a hydro fluorocarbon (HFC) trade

named R-410A. We strongly recommend a

refrigerant management program be implemented

which includes a survey of all equipment to

document the type and quantity of refrigerant in

each machine. In addition, we recommend only

licensed and EPA certified service technicians work

on our refrigeration circuits. Follow good piping

practices and the information in this manual to

ensure successful installation and operation of this

equipment. We are not responsible for liabilities

created by substandard piping methods and

installation practices external to the chiller.

We trust your equipment will have a long and useful

life. If you should have any questions, please contact

the Conair Service Department specifying the serial

number and model number of the unit as indicated

on the nameplate.

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

1

Page 11

General Warning

High Voltage Warning

Sharp Element Warning

Hot Surface Warning

Flammable Material Warning

Explosive Material Warning

General Mandatory Action

Wear Eye Protection

Wear Protection Gloves

Wear Ear Protection

Disconnect Before Carrying Out Maintenance or

Connect an Earth Terminal to Ground

WARNING: Any use or misuse of this equipment

harm.

WARNING: Vent all refrigerant relief valves in

displace oxygen and cause suffocation.

WARNING: This equipment contains hazardous

WARNING: This equipment contains refrigerant

property damage.

WARNING: This equipment may contain fan

in place.

WARNING: The exposed surfaces of motors,

CAUTION: Disconnect and lock out incoming

opening access panels for repair or maintenance.

CAUTION: Wear eye protection when installing,

protect against any sparks, debris, or fluid leaks.

CAUTION: The chiller will exceed 70 dBA sound

chiller.

CAUTION: Wear protective gloves when

or fluid leaks.

Safety Guidelines

Observe all safety precautions during installation,

start-up, and service of this equipment. The

following is a list of symbols used in this manual and

their meaning.

outside of the design intent may cause injury or

accordance to ANSI/ASHRAE Standard 15, Safety

Code for Mechanical Refrigeration. This

equipment should be located within a wellventilated area. Inhalation of refrigerant can be

hazardous to your health and the accumulation

of refrigerant within an enclosed space can

voltages that can cause severe injury or death.

under pressure. Accidental release of refrigerant

under pressure can cause personal injury and or

blades or other sharp edges. Make sure all fan

guards and other protective shields are securely

Repair

Only qualified personnel should install, start-up, and

service this equipment. When working on this

equipment, observe precautions in literature, and on

tags, stickers, and labels located on the equipment.

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

2

refrigerant piping, and other fluid circuit

components can be very hot and can cause burns

if touched with unprotected hands.

power before installing, servicing, or

maintaining the equipment. Connecting power to

the main terminal block energizes the entire

electric circuitry of the unit. A power supply

provides 24 VDC control power. Electric power at

the main disconnect should be shut off before

maintaining, or repairing the equipment to

pressure at 1 meter distance and 1 meter

elevation when operating. Wear ear protection

as required for personnel comfort when

operating or working in close proximity to the

installing, maintaining, or repairing the

equipment to protect against any sparks, debris,

Page 12

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

010S

015S

020S

025S

030S

040S

050S

060S

080S

General

Cooling Capacity tons

1

Set Point Range °F

Process In/Out (in.)-Standard

3 3 4

Process In/Out (in.)-High Flow

4 4

Condenser Water In/Out (in.)

3 4 4

Refrigerant Charge (lbs of

R410A)

70 80

Min Unloaded Capacity ton

with HGBP Option ton

A - Length inches {mm}

68 {1727}

68 {1727}

68 {1727}

68 {1727}

72 {1829}

100 {2540}

100 {2540}

100 {2540}

105 {2667}

B - Width inches {mm}

24 {610}

24 {610}

24 {610}

24 {610}

24 {610}

24 {610}

30 {762}

30 {762}

30 {762}

C- Height inches {mm}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

Ship Weight lbs {kg}

1200 {544}

1300 {590}

1400 {635}

1500 {680}

1600 {726}

1800 {816}

2000 {907}

2200 {998}

2400 {1089}

Operating Weight lbs {kg}

1400 {635}

1500 {680}

1600 {726}

1700 {771}

1800 {816}

2000 {907}

2200 {998}

2400 {1089}

2600 {1179}

MCA @ 460/3/60 amps

2

22

34

42

53

62

71

86

124

165

Reservoir Capacity gal {l}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

450 {1703}

450 {1703}

(Process/Chiller)

5D/1.5A

5D/1.5A

5D/1.5A

5D/1.5A

7.5D/2A

10D/2A

10D/3A

10D/3A

15D/3A

Process Connection Size inch

1½

1½ 2 2

2½

2½ 3 3

4

D - Length inches {mm}

84 {2134}

84 {2134}

84 {2134}

96 {2438}

96 {2438}

96 {2438}

96 {2438}

108 {2743}

108 {2743}

E - Width inches {mm}

72 {1829}

72 {1829}

76 {1930}

76 {1930}

76 {1930}

92 {2337}

92 {2337}

95 {2413}

100 {2540}

F - Height inches {mm}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

Ship Weight lbs {kg}

Operating Weight lbs {kg}

MCA @ 460/3/60 amps

2

Reservoir Capacity gal {l}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

650 {2461}

650 {2461}

Pump Models

(Process/Chiller)

5D/1.5A

7.5D/1.5A

10D/1.5A

10D/1.5A

10D/2A

15D/2A

15D/3A

20D/3A

25D/3A

Process Connection Size

inches

2

2½

2½ 3 3 4 4 4 6

D - Length inches {mm}

84 {2134}

84 {2134}

84 {2134}

84 {2134}

120 {3048}

132 {3353}

132 {3353}

132 {3353}

132 {3353}

E - Width inches {mm}

72 {1829}

72 {1829}

72 {1829}

76 {1930}

76 {1930}

92 {2337}

92 {2337}

92 {2337}

92 {2337}

F - Height inches {mm}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

Operating Weight lbs {kg}

MCA @ 460/3/60 amps

2

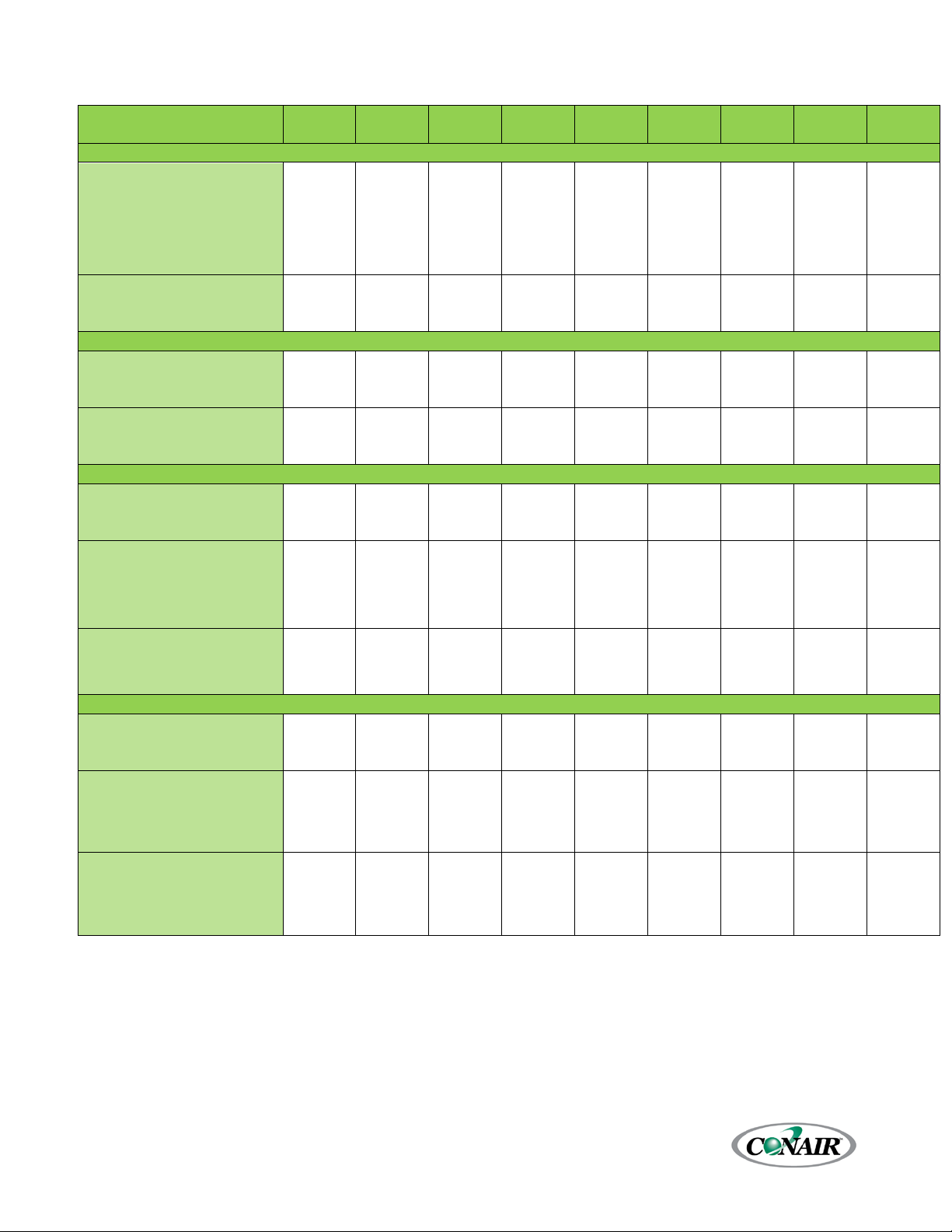

General Data

Table 1 – ESEW Series Single-Circuit Water-Cooled Condenser Chiller General Data (60 Hz)

Model

10.9 16.1 22.1 27.3 32.6 42.2

20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80

1½ 1½ 2 2 2½ 2½

2 2½ 2½ 3 3 4

1½ 2 2 2½ 2½ 3

10 30 30 35 40 50

5.5 8.1 11.1 13.7 16.2 21.0

2.7 4.0 5.5 6.8 8.1 10.5

53.3

20 to 80

25.9

13.0

Dimensions, Weights, Amps (Chiller Only)

Dimensions, Weights, Amps (Chiller with Standard Flow Reservoir Option , 10°F ∆T Process, 10°F ∆T Chiller)

Pump Models

68.4

20 to 80

33.9

17.0

86.2

20 to 80

N/A

100

42.6

21.3

2600 {1179} 2700 {1225} 2900 {1315} 3200 {1451} 3900 {1769} 4100 {1860} 4700 {2132} 5100 {2313} 5400 {2449}

4900 {2223} 5000 {2268} 5100 {2313} 5500 {2495} 6200 {2812} 6400 {2903} 7000 {3175} 7400 {3357} 7800 {3538}

32 43 50 62 75 86

104

Dimensions, Weights, Amps (Chiller with High Flow Reservoir Option 1, 5°F ∆T Process, 10°F ∆T Chiller)

Ship Weight lbs {kg}

1

Cooling capacity when cooling water with 50°F {10°C} set point, 60°F {16°C} return, 85°F {29°C} condenser water, R-410A

refrigerant.

2

MCA is Minimum Circuit Amps (for wire sizing), complie with NEC, Section 430-24.

2800 {1270} 2900 {1315} 3100 {1406} 3400 {1542} 4100 {1860} 4300 {1950} 4900 {2223} 5350 {2427} 5650 {2563}

5960 {2699} 6050 {2744} 6150 {2790} 6550 {2971} 7250 {3289} 7450 {3379} 8050 {3651} 9050 {4105} 9450 {4286}

32 46 57 68 78 91

109

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

3

141

153

188

201

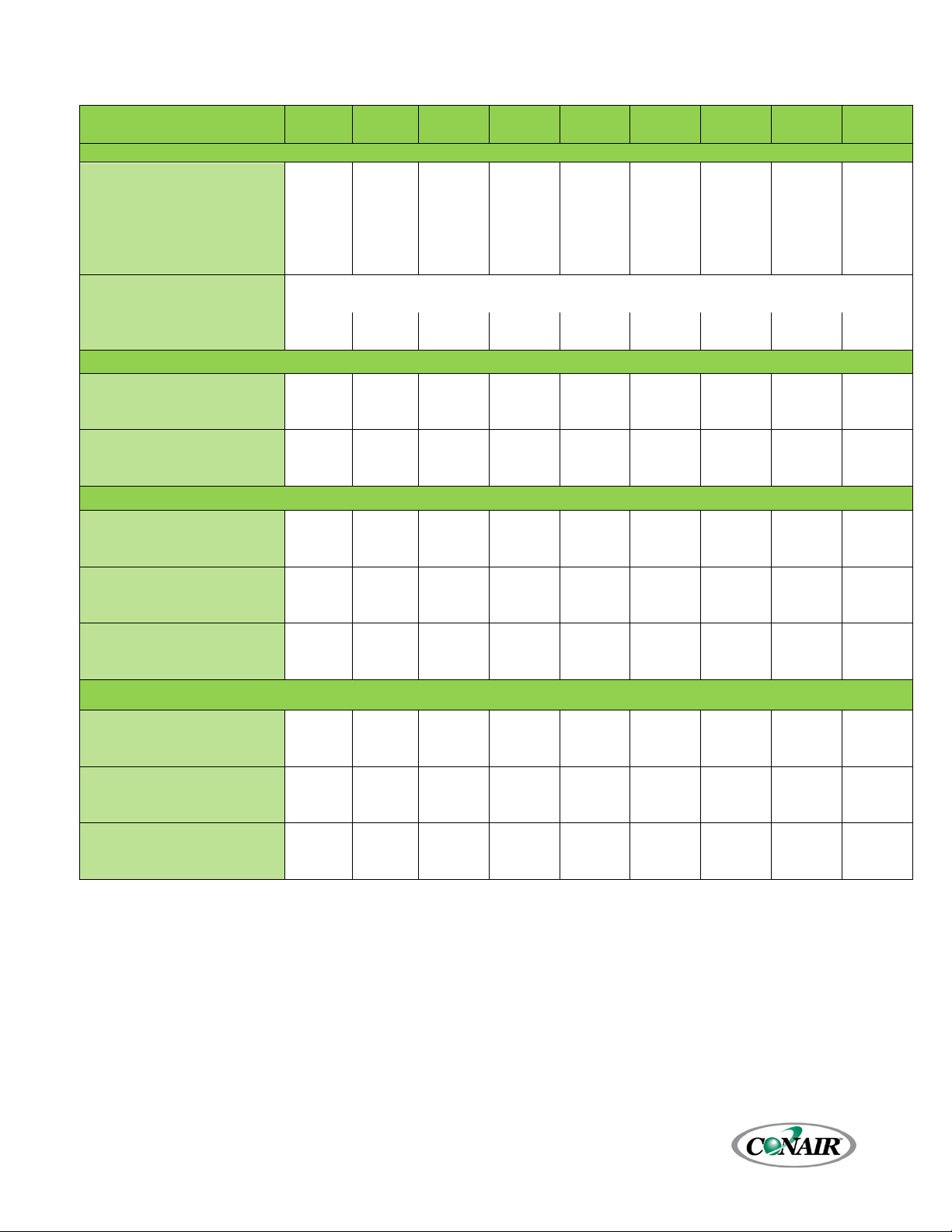

Page 13

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

ESEW-

020D

030D

040D

050D

060D

080D

0100D

0120D

0160D

General

Cooling Capacity tons

1

Set Point Range °F

Process In/Out (in.)-Standard

Process In/Out (in.)-High Flow

Condenser Water In/Out

inches

Refrig Charge/Cir (lbs of R410A)

Mini Unloaded Capacity ton

Dimensions, Weights, Amps (Chiller Only)

A - Length inches {mm}

75 {1905}

75 {1905}

80 {2032}

80 {2032}

85 {2159}

115 {2921}

115 {2921}

118 {2997}

125 {3175}

B - Width inches {mm}

56 {1422}

56 {1422}

56 {1422}

56 {1422}

56 {1422}

56 {1422}

56 {1422}

56 {1422}

56 {1422}

C- Height inches {mm}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

Ship Weight lbs {kg}

2500 {1134}

2600 {1179}

2800 {1270}

3000 {1361}

3200 {1451}

3600 {1633}

4000 {1814}

4400 {1996}

4800 {2177}

Operating Weight lbs {kg}

2700 {1225}

2800 {1270}

3000 {1361}

3200 {1451}

3400 {1542}

3800 {1724}

4200 {1905}

4600 {2087}

5000 {2268}

MCA @ 460/3/60 amps

2

42

63

76

99

115

131

161

232

311

Dimensions, Weights, Amps (Chiller with Standard Flow Reservoir Option , 10°F ∆T Process, 10°F ∆T Chiller)

Reservoir Size gal {l}

Pump Models (Process/Chiller)

Process Connection Size inch

78 {1981}

78 {1981}

78 {1981}

90 {2286}

90 {2286}

1053

1103

1103

1103

F - Height inches {mm}

Ship Weight lbs {kg}

10450

{4740}

MCA @ 460/3/60 amps

2

Dimensions, Weights, Amps (Chiller with High Flow Reservoir Option 1, 5°F ∆T Process, 10°F ∆T Chiller)

Reservoir Size gal {l}

Pump Models (Process/Chiller)

10D/1.5A

Process Connection Size inch

78 {1981}

78 {1981}

78 {1981}

90 {2286}

90 {2286}

1053

{26746}

1103

{28016}

1103

{28016}

1103

{28016}

F - Height inches {mm}

76 {1930}

76 {1930}

76 {1930}}

76 {1930}

76 {1930}

90 {2286}

90 {2286}

90 {2286}

Operating Weight lbs {kg}

7450 {3379}

7650 {3470}

7750 {3515}

8050 {3651}

9350 {4241}

9500 {4332}

11000

11400

11800

MCA @ 460/3/60 amps

2

Table 2 – ESEW Series Dual-Circuit Water-Cooled Condenser Chiller General Data (60 Hz)

21.7 32.1 44.3 54.7 65.2 84.5 106.7 136.9 172.5

20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80

2 2½ 2½ 3 3 4 4 4 6

2½ 3 4 4 4 6 6 6 N/A

2 2½ 3 3 4 4 4 6 6

10 30 30 35 40 50 70 80 100

5.5 8.0 11.1 13.7 16.2 20.9 25.9 33.9 42.6

with HGBP Option ton

2.7 4.0 5.5 6.8 8.1 10.5 13.0 16.9 21.3

275 {1041} 275 {1041} 275 {1041} 275 {1041} 450 {1703} 450 {1703} 700 {2650} 700 {2650} 1000 {3785}

5D/1.5A 7.5D/2A 10D/2A 10D/3A 10D/3A 15D/3A 15D/5A 20D/7.5F 25D/10E

2 2½ 2½ 3 3 4 4 4 6

D - Length inches {mm}

E - Width inches {mm}

108 {2743} 108 {2743} 108 {2743} 120 {3048} 132 {3353} 132 {3353} 132 {3353} 144 {3658} 144 {3658}

{26746}

{28016}

{28016}

75 {1905} 75 {1905} 75 {1905} 75 {1905} 75 {1905}} 75 {1905} 75 {1905} 75 {1905} 90 {2286}

4100 {1860} 4300 {1950} 4400 {1996} 4700 {2132} 5400 {2449} 5600 {2540} 6200 {2812} 6600 {2994} 7000 {3175}

Operating Weight lbs {kg}

6400 {2903} 6600 {2994} 6700 {3039} 7000 {3175} 7700 {3493} 7900 {3583} 8500 {3856} 8900 {4037}

51 76 93 117 133 154 187 269 356

400 {1514} 400 {1514} 400 {1514} 400 {1514} 650 {2461} 650 {2461} 1000 {3785} 1000 {3785} 1000 {3785}

10D/2A 15D/2A 15D/3A 20D/3A 25D/3A 30D/5A 40D/7.5F 40D/10E

2½ 3 4 4 4 6 6 6 6

D - Length inches {mm}

108 {2743} 108 {2743} 108 {2743} 120 {3048} 132 {3353} 132 {3353} 144 {3658} 144 {3658} 144 {3658}

E - Width inches {mm}

Ship Weight lbs {kg}

1

Cooling capacity when cooling water with 50°F {10°C} set point, 60°F {16°C} return, 85°F {29°C} condenser water, R-410A

refrigerant.

2

MCA is Minimum Circuit Amps (for wire sizing), complies with NEC, Section 430-24

3

To keep the shipping dimensions within a 102” width for standard flatbed shipping, the condenser inlet manifold is removed

for shipment.

4300 {1950} 4500 {2041} 4600 {2087} 4900 {2223} 5650 {2563} 5850 {2654} 6500 {2948} 6900 {3130} 7300 {3311}

{4990}

{5171}

59 79 98 122 145 168 207 294 375

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

4

{28016}

90 {2286}

{5352}

Page 14

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

010S

015S

020S

025S

030S

040S

050S

060S

080S

General

Cooling Capacity tons

1

Set Point Range °F

Process In/Out (in.)-Standard

Process In/Out (in.)-High Flow

Refrigerant Discharge Line inch

Refrigerant Liquid Line inch

Refrigerant Charge (lbs of

R410A)

with HGBP Option ton

A - Length inches {mm}

68 {1727}

68 {1727}

68 {1727}

68 {1727}

72 {1829}

102 {2591}

102 {2591}

102 {2591}

105 {2667}

B - Width inches {mm}

24 {610}

24 {610}

24 {610}

24 {610}

24 {610}

24 {610}

30 {762}

30 {762}

30 {762}

C- Height inches {mm}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

Ship Weight lbs {kg}

1200 {544}

1300 {590}

1400 {635}

1500 {680}

1600 {726}

1800 {816}

2000 {907}

2200 {998}

2400 {1089}

Operating Weight lbs {kg}

1300 {590}

1400 {635}

1500 {680}

1600 {726}

1700 {771}

1900 {862}

2100 {953}

2300 {1043}

2500 {1134}

MCA @ 460/3/60 amps

2

22

34

42

53

62

71

86

124

165

Reservoir Capacity gal {l}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

275 {1041}

450 {1703}

450 {1703}

Pump Models (Process/Chiller)

5D/1.5A

5D/1.5A

5D/1.5A

5D/1.5A

7.5D/2A

10D/2A

10D/3A

10D/3A

15D/3A

Process Connection Size inch

1½

1½ 2 2

2½

2½ 3 3

4

D - Length inches {mm}

84 {2134}

84 {2134}

84 {2134}

96 {2438}

96 {2438}

96 {2438}

96 {2438}

108 {2743}

108 {2743}

E - Width inches {mm}

64 {1626}

64 {1626}

64 {1626}

76 {1930}

76 {1930}

92 {2337}

92 {2337}

96 {2438}

98 {2489}

F - Height inches {mm}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

Ship Weight lbs {kg}

Operating Weight lbs {kg}

MCA @ 460/3/60 amps

2

Reservoir Capacity gal {l}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

400 {1514}

650 {2460}

650 {2460}

Pump Models (Process/Chiller)

5D/1.5A

7.5D/1.5A

10D/1.5A

10D/1.5A

10D/2A

15D/2A

15D/3A

20D/3A

25D/3A

Process Connection Size inch

2

2½

2½ 3 3 4 4 4 6

D - Length inches {mm}

84 {2134}

84 {2134}

84 {2134}

96 {2438}

96 {2438}

96 {2438}

96 {2438}

108 {2743}

108 {2743}

E - Width inches {mm}

64 {1626}

64 {1626}

64 {1626}

76 {1930}

92 {2337}

92 {2337}

92 {2337}

96 {2438}

98 {2489}

F - Height inches {mm}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

Ship Weight lbs {kg}

Operating Weight lbs {kg}

MCA @ 460/3/60 amps

2

Table 3 – ESER Series Single-Circuit Remote Air-Cooled Condenser Chiller General Data (60 Hz)

10 14.9 20.4 25.2

20 to 80 20 to 80 20 to 80 20 to 80

1½ 1½ 2 2

2 2½ 2½ 3

⅞ 1⅛ 1⅛ 1⅜

⅝ ⅞ ⅞ 1⅛

30.1 38.9 48.9 63.6 78.7

20 to 80 20 to 80 20 to 80 20 to 80 20 to 80

2½ 2½ 3 3 4

3 4 4 4 N/A

1⅜ 1⅝ 1⅝ 1⅝ 2⅛

1⅛ 1⅛ 1⅛ 1⅜ 1⅝

Varies based on refrigerant system piping

Min Unloaded Capacity ton

5.0 7.4 10.0 12.5

2.5 3.7 5.0 6.2

14.8 19.1 23.6 30.9 38.5

7.4 9.6 11.8 15.5 19.3

Dimensions, Weights, Amps (Chiller Only)

Dimensions, Weights, Amps (Chiller with Standard Flow Reservoir Option , 10°F ∆T Process, 10°F ∆T Chiller)

2600 {1179} 2700 {1225} 2900 {1315} 3200 {1451} 3900 {1769}

4900 {2223} 5000 {2268} 5100 {2313} 5500 {2495} 6200 {2812} 6400 {2903} 7000 {3175} 7400 {3357} 7800 {3538}

32 43 50 62

4100 {1860} 4700 {2132} 5100 {2313} 5400 {2449}

75 86 104 141 188

Dimensions, Weights, Amps (Chiller with High Flow Reservoir Option 1, 5°F ∆T Process, 10°F ∆T Chiller)

2800 {1270} 2900 {1315} 3100 {1406} 3400 {1542} 4100 {1860} 4300 {1950} 4900 {2223} 5350 {2427} 5650 {2563}

5950 {2699} 6050 {2744} 6150 {2790} 6550 {2971} 7250 {3289} 7450 {3379} 8050 {3651} 9050 {4105} 9450 {4286}

1

Cooling capacity when cooling water with 50°F {10°C} set point, 60°F {16°C} return, 95°F {35°C} condenser air, R-410A

refrigerant.

2

MCA is Minimum Circuit Amps (for wire sizing).

32 46 57 68

78 91 109 153 201

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

5

Page 15

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

ESER-

020D

030D

040D

050D

060D

080D

0100D

0120D

0160D

General

Cooling Capacity tons

1

Set Point Range °F

Process In/Out (in.)-Standard

Process In/Out (in.)-High Flow

Refrig Discharge Line/Circuit

inches

Refrig Liquid Line/Circuit

inches

R410A)

Min Unloaded Capacity ton

with HGBP Option ton

A - Length inches {mm}

75 {1905}

75 {1905}

80 {2032}

80 {2032}

89 {2261}

105 {2667}

105 {2667}

110 {2794}

125 {3175}

B - Width inches {mm}

48 {1219}

48 {1219}

48 {1219}

48 {1219}

48 {1219}

48 {1219}

48 {1219}

48 {1219}

52 {1321}

C- Height inches {mm}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

69 {1753}

Ship Weight lbs {kg}

2500 {1134}

2600 {1179}

2800 {1270}

3000 {1361}

3200 {1451}

3600 {1633}

4000 {1814}

4400 {1996}

4800 {2177}

Operating Weight lbs {kg}

2700 {1225}

2800 {1270}

3000 {1361}

3200 {1451}

3400 {1542}

3800 {1724}

4200 {1905}

4600 {2087}

5000 {2268}

MCA @ 460/3/60 amps

2

42

63

76

99

115

131

161

232

311

Reservoir Size gal {l}

275 [1041}

275 {1041}

275 {1041}

275 {1041}

450 {1703}

450 {1703}

700 {2650}

700 {2650}

1000 {3785}

Pump Models

(Process/Chiller)

5D/1.5A

7.5D/2A

10D/2A

10D/3A

10D/3A

15D/3A

15D/5A

20D/7.5F

20D/10E

Process Connection Size inch

6

D - Length inches {mm}

108 {2743}

108 {2743}

108 {2743}

120 {3048}

132 {3353}

132 {3353}

132 {3353}

144 {3658}

144 {3658}

E - Width inches {mm}

74 {1880}

74 {1880}

74 {1880}

74 {1880}

74 {1880}

92 {2337}

102 {2591}

102 {2591}

102 {2591}

F - Height inches {mm}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

75 {1905}

Ship Weight lbs {kg}

6800 {3084}

Operating Weight lbs {kg}

9100 {4128}

MCA @ 460/3/60 amps

2

356

400 {1514}

400 {1514}

400 {1514}

400 {1514}

650 {2461}

650 {2461}

1000 {3785}

1000 {3785}

1000 {3785}

Pump Models

(Process/Chiller)

10D/1.5A

10D/2A

15D/2A

15D/3A

20D/3A

25D/3A

30D/5A

40D/7.5F

40D/10E

D - Length inches {mm}

108 {2743}

108 {2743}

108 {2743}

120 {3048}

132 {3353}

132 {3353}

132 {3353}

144 {3658}

144 {3658}

E - Width inches {mm}

74 {1880}

74 {1880}

74 {1880}

74 {1880}

74 {1880}

92 {2337}

102 {2591}

102 {2591}

102 {2591}

F - Height inches {mm}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

76 {1930}

90 {2286}

90 {2286}

90 {2286}

90 {2286}

Operating Weight lbs {kg}

7250 {3289}

7350 {3334}

7450 {3379}

7850 {3561}

9150 {4150}

9350 {4241}

10800

11200

11160

MCA @ 460/3/60 amps

2

Table 4 – ESER Series Dual-Circuit Remote Air-Cooled Condenser Chiller General Data (60 Hz)

20.4 29.9 40.7 50.5 60.2 77.8 97.7 127.2 157.5

20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80 20 to 80

2 2½ 2½ 3 3 4 4 4 6

2½ 3 4 4 4 6 6 6 N/A

⅞ 1⅛ 1⅛ 1⅜ 1⅜ 1⅝ 1⅝ 1⅝ 2⅛

⅝ ⅞ ⅞ 1⅛ 1⅛ 1⅛ 1⅛ 1⅜ 1⅝

Refrig Charge/Cir (lbs of

Varies based on refrigeration system piping

5.0 7.3 10.0 12.5 14.7 19.1 23.6 30.9 38.5

2.5 3.7 5.0 6.2 7.4 9.6 11.8 15.5 19.3

Dimensions, Weights, Amps (Chiller Only)

Dimensions, Weights, Amps (Chiller with Standard Flow Reservoir Option , 10°F ∆T Process, 10°F ∆T Chiller)

2 2½ 2½ 3 3 4 4 4

3900 {1769} 4000 {1814} 4200 {1905} 4500 {2041} 5200 {2359} 5400 {2449} 6000 {2722} 6400 {2903}

6200 {2812} 6300 {2858} 6400 {2903} 6800 {3084} 7500 {3402} 7700 {3493} 8300 {3765} 8700 {3946}

51 76 93 117 133 154 187 269

Dimensions, Weights, Amps (Chiller with High Flow Reservoir Option 1, 5°F ∆T Process, 10°F ∆T Chiller)

Reservoir Size gal {l}

Process Connection Size inch

Ship Weight lbs {kg}

1

Cooling capacity when cooling water with 50°F{10°C} set point, 60°F {16°C} return, 95°F {35°C} condenser air, R-410A

refrigerant.

2

MCA is Minimum Circuit Amps (for wire sizing), complies with NEC, Section 430-24.

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

2½ 3 4 4 4 6 6 6 6

4100 {1860} 4200 {1905} 4400 {1996} 4700 {2132} 5450 {2472} 5650 {2563} 6300 {2858} 6700 {3039} 7100 {3221}

{4899}

{5080}

{5262}

59 79 98 122 145 168 207 294 375

6

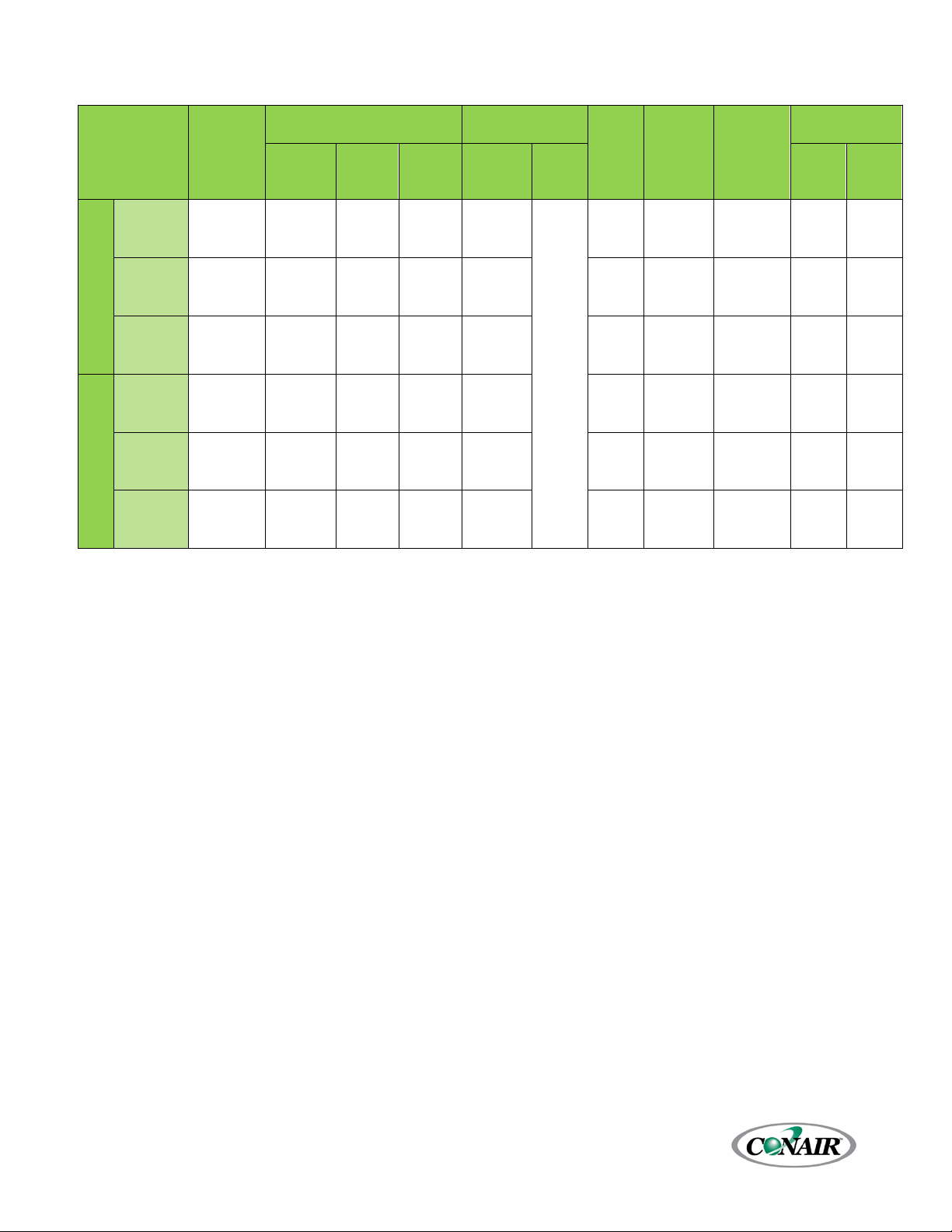

Page 16

Chiller

Dimensions inches {mm}

Weights lbs {kg}

Total

Sound

MCA @

Refrig Lines

(in)

Inlet

Circuit

Outlet

Circuit

KCM014

Operating weight varies base on system refrigeration charge

and operating conditions

14,400

53

KCL023

24,000

63

KCL030

22,600

63

KCL037

20,600

63

KCL045

33,900

64

KCL056

30,900

64

KCL068

42,400

65

KCL095

51,800

66

KCL110

62,100

67

KCM034

28,400

55

KCL047

47,900

65

KCL060

45,200

65

KCL074

41,200

65

KCL090

67,800

67

KCL112

61,800

67

KCL137

84,800

68

KCL190

103,500

69

KCL224

124,200

70

Table 5 – Remote Air-Cooled Condenser General Data (60 Hz)

Model

Single-Circuit

Dual-Circuit

1

One condenser is required per chiller; dual-circuit chillers use one remote condenser that has two refrigeration circuits.

2

Sound pressure level at 30 feet.

3

MCA is Minimum Circuit Amps (for wire sizing) as provided by the remote condenser manufacturer.

Model

Used

1

With

ESER-010S 83 {2108} 43 {1092} 48 {1219} 415 {188}

ESER-015S 113 {2870} 45 {1143} 54 {1372} 670 {304}

ESER-020S 113 {2870} 45 {1143} 54 {1372} 720 {327}

ESER-025S 113 {2870} 45 {1143} 54 {1372} 800 {363}

ESER-030S 168 {4267} 45 {1143} 54 {1372} 1075 {488}

ESER-040S 168 {4267} 45 {1143} 54 {1372} 1200 {544}

ESER-050S 223 {5664} 45 {1143} 54 {1372} 1475 {669}

ESER-060S 278 {7061} 45 {1143} 54 {1372} 1950 {885}

ESER-080S 333 {8458} 45 {1143} 54 {1372} 2300 {1043}

ESER-020D 83 {2108} 83 {2108} 48 {1219} 830 {376}

ESER-030D 113 {2870} 87 {2210} 54 {1372} 1275 {578}

ESER-040D 113 {2870} 87 {2210} 54 {1372} 1350 {612}

ESER-050D 113 {2870} 87 {2210} 54 {1372} 1525 {692}

ESER-060D 168 {4267} 87 {2210} 54 {1372} 2050 {930}

ESER-080D 168 {4267} 87 {2210} 54 {1372} 2275 {1032}

ESER-0100D 223 {5664} 87 {2210} 54 {1372} 2800 {1270}

ESER-0120D 278 {7061} 87 {2210} 54 {1372} 3700 {1678}

ESER-0160D 333 {8458} 87 {2210} 54 {1372} 4400 {1996}

L W H Ship Oper

Air

Flow

(cfm)

Pressure

Level

(dBA)2

460/3/60

(amps)

2.6

7.0

7.0

7.0

10.1

10.1

16.0

16.0

21.0

4.9

16.0

16.0

16.0

21.0

21.0

24.8

36.0

46.0

3

Per

1⅜ 1⅛

2⅛ 1⅜

2⅛ 1⅝

2⅛ 1⅝

2⅝ 1⅝

2⅝ 2⅛

2⅝ 2⅛

3⅛ 2⅝

3⅛ 2⅝

1⅝ 1⅛

2⅛ 1⅜

2⅛ 1⅝

2⅛ 1⅝

2⅝ 1⅝

2⅝ 2⅛

2⅝ 2⅛

3⅛ 2⅝

3⅛ 2⅝

Per

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

7

Page 17

Pre-Installation

Receiving Inspection

When the unit arrives, verify it is the correct unit by

comparing the information that appears on the unit

nameplate with that which appears on the order

acknowledgement and shipping papers. Inspect the

equipment condition for any visible damage and

verify all items shown on the bill of lading are

present. If damage is evident, properly document it

on the delivery receipt and clearly mark any item

with damage as “unit damage” and notify the carrier.

In addition, make note of the specific damage and

notify Conair’s Service Department.

Shipping damage is the responsibility of the carrier.

To protect against possible loss due to damage

incurred during shipping and to expedite payment

for damages, it is important to follow proper

procedures and keep records. Photographs of

damaged equipment are excellent documentation

for your records.

Start unpacking the unit, inspect for concealed

damages, and take photos of any damages found.

Once received, equipment owners have the

responsibility to provide reasonable evidence that

the damage did not occur after delivery. Photos of

the equipment damage while the equipment is still

partially packed will help in this regard. Refrigerant

lines can be susceptible to damage in transit. Check

for broken lines, oil leaks, damaged controls, or any

other major component torn loose from its

mounting point.

Record any signs of concealed damage and file a

shipping damage claim immediately with the

shipping company. Most carriers require concealed

damages be reported within 15 days of receipt of

the equipment. In addition to notifying the carrier,

notify Conair’s Service Department.

Water-cooled chillers ship with a full refrigerant

charge while remote condenser chillers ship with a

nitrogen holding charge. Remote air-cooled

condensers ship separately with a 350-psi dry

nitrogen gas charge. Check the remote condenser

for signs of leaks prior to rigging. This will ensure no

coil damage has occurred after the unit left the

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

factory. The condenser ships with the legs removed.

Mount the legs to the condenser using the provided

nuts, bolts, and washers.

Unit Storage

If the chiller is stored prior to installation, it is

important to protect it from damage. Blow out any

water or fluid from the evaporator and water-cooled

condenser circuits to protect the unit from damage

from freezing. Close any open refrigerant valves.

Cover the equipment to keep dirt and debris from

accumulating on it. Units charged with refrigerant

should not be stored in areas warmer than

145°F (62.8°C).

8

Page 18

Installation - Chiller Mechanical

Unit Location

The chiller is available in many different

configurations to meet various environments. Please

refer to the proposal and order acknowledgement

for this equipment to verify the specific

environmental design conditions for your chiller.

Allow a minimum of 48 inches (1219mm) of

clearance between the remote condenser and any

walls or obstructions. For installations with multiple

condensers, allow a minimum of 96 inches (2438mm)

between condensers placed side-by-side or 48

inches (1219mm) for condensers placed end-to-end.

In all cases, install the equipment on a rigid surface

suitable to support the full operating weight of the

unit. Level all equipment to ensure proper operation.

When installed the equipment must be level within

¼ inch over its length and width.

Serviceability is an important factor to consider when

deciding on the location of the chiller. Do not

compromise this feature by locating it in an

inaccessible area. When locating the chiller it is

important to consider accessibility to the

components to allow for proper maintenance and

servicing of the unit. In general, allow a minimum of

36 inches (914mm) of clearance around all sides and

above the unit. There should be no piping or conduit

located over the unit. This will ensure easy access

with an overhead crane or lift for heavier

components should they need to be replaced or

serviced.

Proper ventilation is another important

consideration when locating the unit. Locate the unit

is an area that will not rise above 110°F (43.3°C).

In addition, ensure the condenser and evaporator

refrigerant pressure relief valves can vent in

accordance with all local and national codes.

Rigging

The chiller has a structural steel frame with forklift

slots to facilitate easy movement and positioning.

Follow proper rigging methods to prevent damage

to components. Avoid impact loading caused by

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

sudden jerking when lifting or lowering the chiller.

Use pads where abrasive surface contact may occur.

Use the frame supporting the unit for positioning it

with a crane or a forklift.

Chilled Water Piping

Proper insulation of chilled water piping is crucial to

prevent condensation. The formation of

condensation on chiller water piping, the state

change of the water from gas to liquid, adds a

substantial heat load to the system and becomes an

additional burden for the chiller.

The importance of properly sized piping between

the chiller and process cannot be overemphasized.

Reference the current edition of the ASHRAE

Fundamentals Handbook or other suitable design

guide for proper pipe sizing. In general, run full size

piping out to the process and then reduce the pipe

size to match the connections on the process

equipment. One of the most common causes of

unsatisfactory chiller performance is poor piping

system design. Avoid long lengths of hoses, quick

disconnect fittings, and manifolds wherever possible

as they offer high resistance to water flow. When

manifolds are required, install them as close to the

use point as possible. Provide flow-balancing valves

at each machine to assure adequate water

distribution in the entire system.

Condenser Water Piping

(Water-Cooled Condenser Chillers Only)

The performance of a condenser is dependent on

maintaining the proper flow and temperature of

water through the heat exchanger. Insufficient water

flow or high condenser water supply temperature

will result in the reduction of cooling capacity of the

chiller. Extreme conditions will eventually result in