Page 1

USER GUIDE

UGH041-0718

www.conairgroup.com

EP2 Series Portable Chillers

Portable and Remote Condenser Chillers 4 to 43 Tons

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 2

DISCLAIMER: Conair shall not be liable for errors contained in this User Guide or for incidental, consequential

Copyright 2018 l Conair l All rights reserved

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equipment and the date you

received it in the User Guide. Our service department uses this information, along with the manual

number, to provide help for the specific equipment you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists together for

documentation of your equipment.

Date:

Manual Number: UGH041-0718

Serial Number(s):

Model Number(s)

damages in connection with the furnishing, performance or use of this information. Conair makes no warranty

of any kind with regard to this information, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

Page 3

Table of Contents

Foreword .................................................................................................................................................................................................................. 1

Safety Guidelines .................................................................................................................................................................................................. 1

Pre-Installation ....................................................................................................................................................................................................... 2

Receiving Inspection ....................................................................................................................................................................................... 2

Unit Storage ........................................................................................................................................................................................................ 3

Installation - Chiller .............................................................................................................................................................................................. 3

Foundation .......................................................................................................................................................................................................... 3

Unit Location ...................................................................................................................................................................................................... 3

Rigging ................................................................................................................................................................................................................. 3

Chilled Process Fluid Piping ......................................................................................................................................................................... 3

Figure 1 – Recommended Overhead Piping ..................................................................................................................................... 3

Condenser Water Piping................................................................................................................................................................................ 3

Installation – Remote Condenser ................................................................................................................................................................... 4

Location ................................................................................................................................................................................................................ 4

Lifting ............................................................................................................................................................................................................... 4

Mounting Legs .................................................................................................................................................................................................. 4

Figure 2 - Mounting Remote Condenser Legs ................................................................................................................................ 5

Interconnecting Refrigerant Piping ........................................................................................................................................................... 5

Refrigeration Piping Design ......................................................................................................................................................................... 5

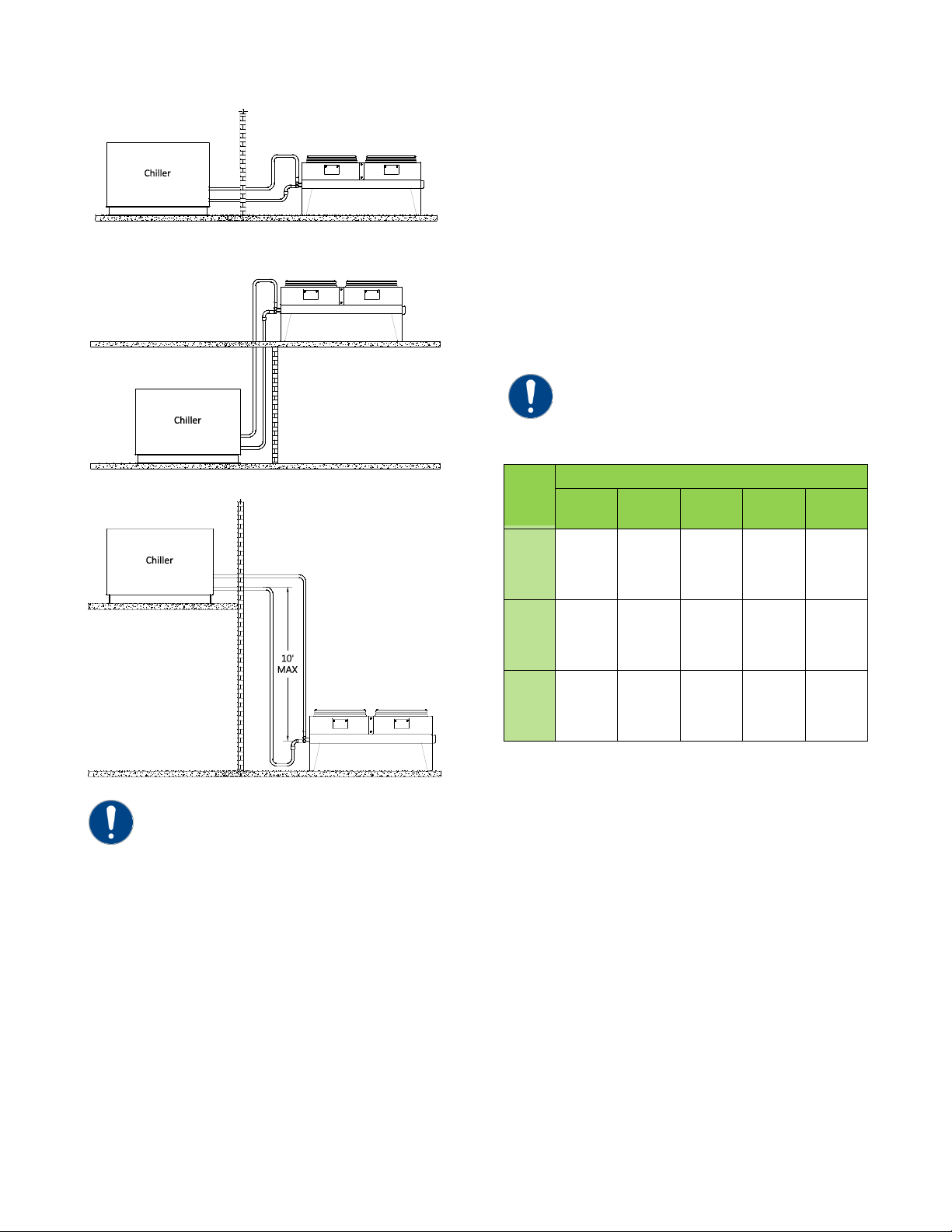

Figure 3 – Condenser Located at Chiller Level ................................................................................................................................. 6

Figure 4 – Condenser Located Above Chiller Unit ......................................................................................................................... 6

Figure 5 - Condenser Located Below Chiller Unit ........................................................................................................................... 6

Determining Equivalent Line Length ........................................................................................................................................................ 6

Table 1 – Equivalent Lengths of Elbows ............................................................................................................................................. 6

Liquid Line Sizing .............................................................................................................................................................................................. 6

Table 2 – Liquid Line Sizes for R410A .................................................................................................................................................. 7

Discharge (Hot Gas) Line Sizing .................................................................................................................................................................. 9

Figure 6 – Vertical Riser Traps ................................................................................................................................................................ 9

Figure 7 - Double Discharge Riser ........................................................................................................................................................ 9

Table 3 - Horizontal or Downflow Discharge Line Sizes for R410A (inches OD).............................................................. 10

Table 4 - Upflow Discharge Line Sizes for R410A (inches OD) ................................................................................................ 10

Calculating Refrigerant and Oil Charge ................................................................................................................................................. 11

Table 5 – Chiller & Condenser Refrigerant Charge ...................................................................................................................... 11

Table 6 - Field Piping R-410A Refrigerant Charges ..................................................................................................................... 11

Oil Charge Determination ........................................................................................................................................................................... 11

Setting Condenser Fan Controls............................................................................................................................................................... 11

Table 7 - Condenser Fan Pressure Settings (psig) ........................................................................................................................ 11

Installation - Electrical ....................................................................................................................................................................................... 12

Standard Controller Operation ...................................................................................................................................................................... 13

Table 8 - Operating Buttons ................................................................................................................................................................. 13

Table 9 - Temperature Displays ........................................................................................................................................................... 14

Table 10 - Operating Lights .................................................................................................................................................................. 14

Program Menu................................................................................................................................................................................................. 15

Table 11 - Controller Program Menu ................................................................................................................................................ 16

Table 12 – Controller Control Fault Logic ........................................................................................................................................ 17

SPI Communications (Optional) ............................................................................................................................................................... 17

Page 4

Table 13 - SPI Parameters ...................................................................................................................................................................... 18

Modbus RTU (Optional) ............................................................................................................................................................................... 18

Table 14 – Standard Controller Modbus RTU Option Parameters......................................................................................... 18

Optional PLC Operation ................................................................................................................................................................................... 20

System Initialization....................................................................................................................................................................................... 20

Figure 8 – Start-Up Splash Screen ...................................................................................................................................................... 20

Home - System Overview ............................................................................................................................................................................ 20

Figure 9 – Chiller System Overview .................................................................................................................................................... 20

Table 15 – System Overview Functions ............................................................................................................................................ 21

Home – Full Screen ........................................................................................................................................................................................ 21

Figure 10 – Full Screen ............................................................................................................................................................................ 21

Menu 1 - Overview ........................................................................................................................................................................................ 21

Figure 11 – Menu 1 Screen .................................................................................................................................................................... 21

Menu 1 - Alarms Active ............................................................................................................................................................................... 22

Figure 12 – HMI Alarm Handler ........................................................................................................................................................... 22

Alarm Setup ...................................................................................................................................................................................................... 22

Figure 13 – Alarm Setup ......................................................................................................................................................................... 22

Menu 1 – Circuit Details Screen ................................................................................................................................................................ 22

Figure 14 – Circuit Details Screen ....................................................................................................................................................... 22

Circuit Details Screen – Interlocks ............................................................................................................................................................ 22

Figure 15 – Interlocks 1 Screen ............................................................................................................................................................ 22

Figure 16 – Interlocks 2 Screen ............................................................................................................................................................ 23

Menu 2 – Overview ........................................................................................................................................................................................ 23

Figure 17 – Menu 2 ................................................................................................................................................................................... 23

Menu 2 – Default ............................................................................................................................................................................................ 23

Figure 18 – Restore Factory Settings ................................................................................................................................................. 23

Figure 19 – Factory Settings Restored .............................................................................................................................................. 23

Menu 2 – Trending ........................................................................................................................................................................................ 24

Figure 20 – Trending Screen ................................................................................................................................................................. 24

Menu 2 – Logging .......................................................................................................................................................................................... 24

Figure 21 – Logging .................................................................................................................................................................................. 24

Modbus RTU (Optional) ............................................................................................................................................................................... 25

Table 16 – PLC Controller Modbus RTU Parameters ................................................................................................................... 25

Start-Up .................................................................................................................................................................................................................. 28

Step 1 - Connect Main Power ................................................................................................................................................................... 29

Step 2 - Fill Coolant Circuit ......................................................................................................................................................................... 29

System Fill Water Chemistry Requirements .................................................................................................................................... 29

Table 17 – Fill Water Chemistry Requirements .............................................................................................................................. 30

Table 18 - Recommended Glycol Solutions .................................................................................................................................... 30

Step 3 - Check Condenser .......................................................................................................................................................................... 30

Integral Air-Cooled Condenser Check .............................................................................................................................................. 30

Water-Cooled Condenser Check ......................................................................................................................................................... 30

Remote Air-Cooled Condenser Check .............................................................................................................................................. 30

Step 4 – Check Refrigerant Valves ........................................................................................................................................................... 30

Step 5 – Verify Freezestat Setting ............................................................................................................................................................ 30

Step 6 – Turn On Control Power .............................................................................................................................................................. 31

Step 7 – Establish Coolant Flow ................................................................................................................................................................ 31

Step 8 – Intial Unit Operation .................................................................................................................................................................... 31

Preventive Maintenance ................................................................................................................................................................................... 32

Once a Week .................................................................................................................................................................................................... 32

Page 5

Once a Month .................................................................................................................................................................................................. 32

Every Three Months ....................................................................................................................................................................................... 32

Preventive Maintenance Checklist ............................................................................................................................................................... 33

General Troubleshooting ................................................................................................................................................................................. 34

Drawings................................................................................................................................................................................................................. 35

Page 6

Page Intentionally Blank

Page 7

General Warning

Electricity Warning

Sharp Element Warning

Hot Surface Warning

Flammable Material Warning

Explosive Material Warning

General Mandatory Action

Wear Eye Protection

Wear Protective Gloves

Wear Ear Protection

Disconnect Before Carrying Out Maintenance or

Connect an Earth Terminal to Ground

Foreword

The portable chiller is a packaged unit that typically

includes a refrigeration circuit, coolant reservoir, and

pumping system in a cabinet. The purpose is to

provide cooling water or coolant.

This manual is to serve as a guide for installing,

operating, and maintaining the equipment. Improper

installation, operation, and maintenance can lead to

poor performance and/or equipment damage. Use

qualified installers and service technicians for all

installation and maintenance of this equipment.

This manual is for our standard product. The

information in this manual is general in nature. Unitspecific drawings and supplemental documents are

included with the equipment as needed. Additional

copies of documents are available upon request.

Due to the ever-changing nature of applicable

codes, ordinances, and other local laws pertaining to

the use and operation of this equipment, we do not

reference them in this manual.

The equipment uses a hydro fluorocarbon (HFC),

trade named R-410A, as a chemical refrigerant for

heat transfer purposes. This chemical is sealed and

tested in a pressurized system containing ASME

coded vessels; however, a system failure will release

it. Refrigerant gas can cause toxic fumes if exposed

to fire. Place these units in a well-ventilated area,

especially if open flames are present. Failure to

follow these instructions could result in a hazardous

condition. We recommend the use of a refrigerant

management program to document the type and

quantity of refrigerant in the equipment. In addition,

we recommend only licensed and EPA certified

service technicians work on our refrigeration circuits.

Safety Guidelines

Observe all safety precautions during installation,

start-up, and service of this equipment. The

following is a list of symbols used in this manual and

their meaning.

Repair

1

Page 8

WARNING: Any use or misuse of this equipment

WARNING: Vent all refrigerant relief valves in

oxygen and cause suffocation.

WARNING: This equipment contains hazardous

WARNING: This equipment contains refrigerant under

damage.

WARNING: This equipment may contain fan blades or

protective shields are securely in place.

WARNING: The exposed surfaces of motors, refrigerant

hands.

CAUTION: Disconnect and lock out incoming power

maintenance.

CAUTION: Wear eye protection when installing,

against any sparks, debris, or fluid leaks.

CAUTION: The equipment will exceed 70 dBA sound

proximity to the chiller.

CAUTION: Wear protective gloves when installing,

against any sparks, debris, or fluid leaks.

Only qualified personnel should install, start-up, and

service this equipment. When working on this

equipment, observe precautions in this manual as

well as tags, stickers, and labels on the equipment.

outside of the design intent may cause injury or harm.

accordance to ANSI/ASHRAE Standard 15, Safety Code

for Mechanical Refrigeration. Locate this equipment in

a well-ventilated area. Inhalation of refrigerant can be

hazardous to your health and the accumulation of

refrigerant within an enclosed space can displace

voltages that can cause severe injury or death.

pressure. Accidental release of refrigerant under

pressure can cause personal injury and or property

other sharp edges. Make sure all fan guards and other

piping, and other fluid circuit components can be very

hot and can cause burns if touched with unprotected

before installing, servicing, or maintaining the

equipment. Connecting power to the main terminal

block energizes the entire electric circuitry of the unit.

Shut off the electric power at the main disconnect

before opening access panels for repair or

maintaining, or repairing the equipment to protect

pressure at 1 meter distance and 1 meter elevation

when operating. Wear ear protection as required for

personal comfort when operating or working in close

maintaining, or repairing the equipment to protect

Pre-Installation

Receiving Inspection

When the unit arrives, verify the information on the

unit nameplate agrees with the order

acknowledgement and shipping papers. Inspect the

equipment for any visible damage and verify all

items shown on the bill of lading are present. If

damage is evident, document it on the delivery

receipt by clearly marking any item with damage as

“unit damage” and notify the carrier. Do not install

damaged equipment without getting the equipment

repaired.

Shipping damage is the responsibility of the carrier.

To protect against possible loss due to damage

incurred during shipping and to expedite payment

for damages, it is important to follow proper

procedures and keep records. Photographs of

damaged equipment are excellent documentation

for your records.

Start unpacking the unit, inspect for concealed

damage, and take photos of any damage found.

Once received, equipment owners have the

responsibility to provide reasonable evidence that

the damage did not occur after delivery. Photos of

the equipment damage while the equipment is still

partially packed will help in this regard. Refrigerant

lines can be susceptible to damage in transit. Check

for broken lines, oil leaks, damaged controls, or any

other major component torn loose from its

mounting point.

Record any signs of concealed damage and file a

shipping damage claim immediately with the

shipping company. Most carriers require concealed

damages be reported within 15 days of receipt of

the equipment.

Chillers with an integral water-cooled or air-cooled

condenser ship with a full refrigerant charge. Chillers

designed for use with a remote air-cooled condenser

and the remote condensers themselves ship with a

nitrogen holding charge. Check the remote

condenser for signs of leaks prior to rigging. This will

ensure no coil damage has occurred after the unit

left the factory. The condenser ships with the legs

removed. Mount the legs to the condenser using the

provided nuts, bolts, and washers.

2

Page 9

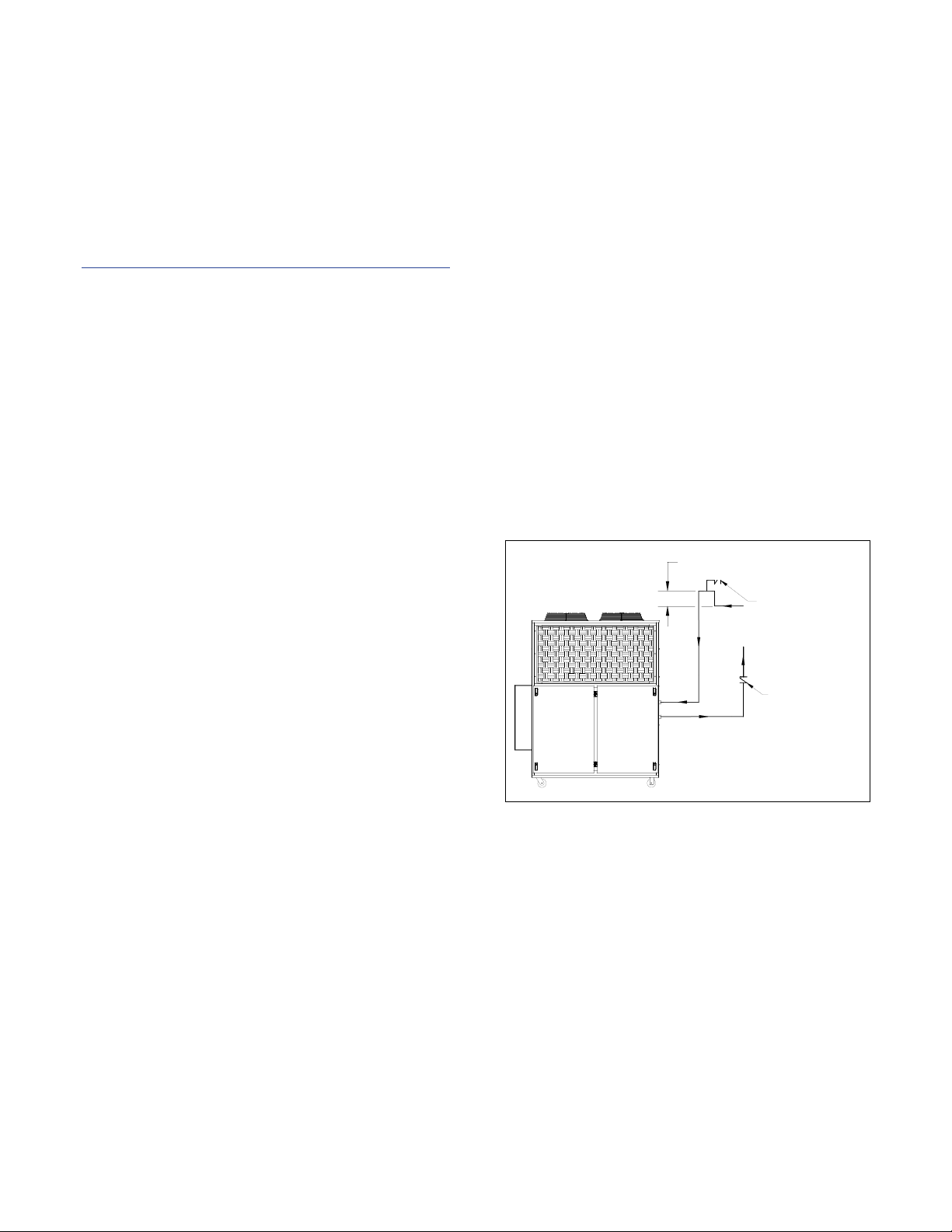

NOTE:

If piping is above chiller and exceeds 90 feet in total

length, install an inverted P-trap and vacuum break

valve in return line and add a check valve to the

supply line.

Check valve

1/2 inch vacum break valve

12 inches above highest

point in piping system

12 inches above highest point

in the piping system

½ inch vacuum

break valve

Check valve

Unit Storage

When storing the unit it is important to protect it

from damage. Blow out any water from the unit;

cover it to keep dirt and debris from accumulating or

getting in, and store in an indoor sheltered area that

does not exceed 145°F.

Installation - Chiller

Foundation

Install the chiller on a rigid, non-warping mounting

pad, concrete foundation, or level floor suitable to

support the full operating weight of the equipment.

When installed the equipment must be level within

¼ inch over its length and width.

Unit Location

The unit is available in many different configurations

for various environments. Refer to the proposal and

order acknowledgement document for the

equipment to verify the specific design conditions in

which it can operate.

To ensure proper airflow and clearance space for

proper operation and maintenance allow a minimum

of 36 inches of clearance between the sides of the

equipment and any walls or obstructions. Avoid

locating piping or conduit over the unit to ensure

easy access with an overhead crane or lift to lift out

heavier components during replacement or service.

In addition, ensure the condenser and evaporator

refrigerant pressure relief valves can vent in

accordance with all local and national codes.

Air-cooled chillers use the surrounding air for

cooling the condenser and require free passage of

air in and out of the chiller and provision for remove

of the warm air from the area.

Rigging

The chiller has a frame to facilitate easy movement

and positioning with a crane or forklift. Follow

proper rigging methods to prevent damage to

components. Avoid impact loading caused by

sudden jerking when lifting or lowering the chiller.

Use pads where abrasive surface contact may occur.

Chilled Process Fluid Piping

Proper insulation of chilled process fluid piping is

crucial to prevent condensation. The formation of

condensation adds a substantial heat load to the

chiller.

The importance of properly sized piping cannot be

overemphasized. See the ASHRAE Handbook or

other suitable design guide for proper pipe sizing. In

general, run full size piping out to the process and

reduce pipe size at connections as needed. One of

the most common causes of unsatisfactory chiller

performance is poor piping system design. Avoid

long lengths of hoses, quick disconnect fittings, and

manifolds wherever possible as they offer high

resistance to water flow. When manifolds are

required, install them as close to the use point as

possible. Provide flow-balancing valves at each

machine to assure adequate water distribution in the

entire system. Typically, when piping is overhead

with a total run length over 90 feet there should be a

valve in the supply line and an inverted P trap with a

vacuum break valve installed as shown in Figure 1.

Figure 1 – Recommended Overhead Piping

All standard portable chillers include an internal

coolant pump and reservoir. Nominal coolant flow

rates assume a 10°F rise across the evaporator at

50°F set point and 85°F entering condenser water for

water-cooled chillers or 95°F entering air for integral

air-cooled or remote air-cooled condenser chillers.

Condenser Water Piping

(Water-Cooled Condenser Chillers Only)

The performance of a water-cooled condenser is

dependent on the flow and temperature of the

cooling water used. Insufficient cooling of the

condenser will result in the reduction of cooling

capacity of the chiller and under extreme conditions

may result in the chiller shutting down due to high

3

Page 10

refrigerant pressure. Allowing the condenser to plug

up from contaminants in the condenser water

stream adversely affects performance. In order to

reduce maintenance costs and chiller downtime, a

water treatment program is highly recommended for

the condenser cooling water. Contact our Customer

Service Department for assistance in the proper

procedure for cleaning out any plugged condenser.

The nominal water-cooled condenser is designed for

85°F condenser cooling water supply. Under normal

operation there will be about a 10°F rise through the

condenser resulting in 95°F exiting water. To ensure

proper water flow through the condenser, ensure the

condenser water pump provides at least 25 psi or

water at a flow rate of 3 gpm per ton of chiller

capacity.

Each condenser has a two-way condenser waterregulating valve. The condenser water-regulating

valve controls the amount of water allowed to pass

through the condenser in order to maintain proper

refrigeration pressures in the circuit.

To prevent damage to the condenser and/or waterregulating valve, the water pressure should not

exceed 150 psig.

Installation – Remote Condenser

Chillers designed for use with a remote air-cooled

condenser include a factory-selected remote

condenser. The remote air-cooled condenser

typically ships separately from a different location

than the chiller.

Location

The remote air-cooled condenser is for outdoor use.

Locate the remote condenser in an accessible area.

The vertical air discharge must be unobstructed. The

vertical air discharge must be unobstructed. Allow a

minimum of 48 inches of clearance between the

sides and ends of the condenser and any walls or

obstructions. For installations with multiple

condensers, allow a minimum of 96 inches between

condensers placed side-by-side or 48 inches for

condensers placed end-to-end.

When locating the condenser it is important to

consider access to the components to allow for

proper maintenance and servicing of the unit. Avoid

locating piping or conduit over the unit to ensure

easy access with an overhead crane or lift to lift out

heavier components during replacement or service.

Proper ventilation is another important

consideration when locating the condenser. In

general, locate the unit in an area that will not rise

above 110°F.

Install the unit on a firm, level base no closer than its

width from walls or other condensers. Avoid

locations near exhaust fans, plumbing vents, flues, or

chimneys. Fasten the mounting legs at their base to

the steel or concrete of the supporting structure. For

units mounted on a roof structure, the steel support

base holding the condenser should be elevated

above the roof and attached to the building.

Avoid areas that can create a “micro-climate” such as

an alcove with east, north, and west walls that can be

significantly warmer than surrounding areas. The

condenser needs to have unrestricted airways so it

can easily move cool air in and heated air away.

Consider locating the condenser where fan noise

and vibration transmission into nearby workspaces is

unlikely.

The unit ships on its side with the legs removed to

reduce shipping dimensions and provide more

protection to the coil from possible damage caused

by impact loading over rough roads and transit

conditions.

Lifting

Use only qualified personnel using the proper

equipment when lifting and positioning the

condenser. Lifting brackets or holes are at the

corners for attaching lifting slings. Use spreader bars

when lifting to apply the lifting force vertically.

Under no circumstances use the coil headers or

return bends in the lifting or moving of the

condenser.

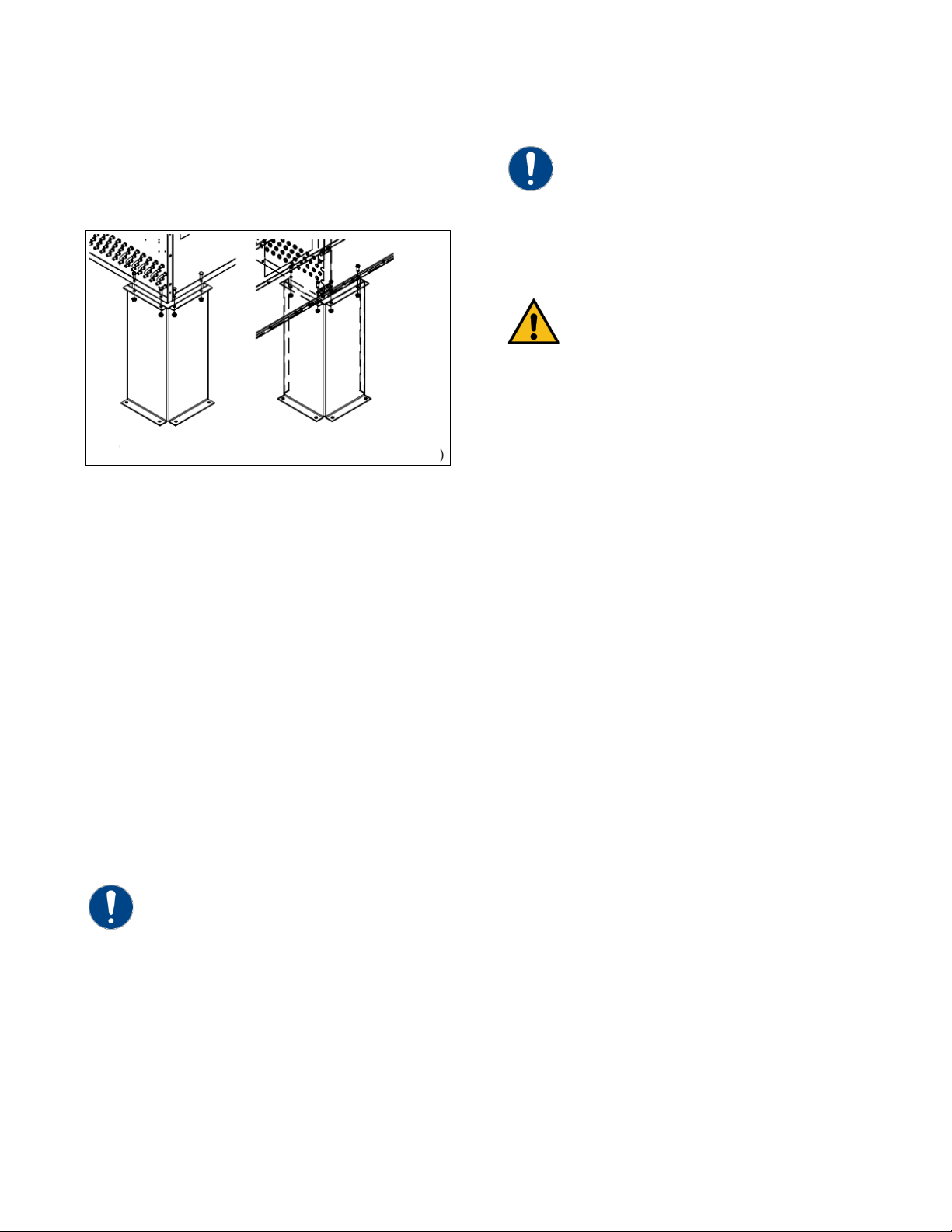

Mounting Legs

Assemble the corner legs to the bottom flanges on

the unit side panels and end panels using the

hardware provided and the matching mounting

hole-patterns. All corner legs are the same. For units

that are longer than three fans, assemble the center

leg. Remove two bolts from the bottom flange of the

unit side panels that match the hole-pattern on the

4

Page 11

CAUTION: Only use refrigerant grade copper tubing

for sizes 5/8” ODS or smaller.

CAUTION: Do not use soft solders. For copper-to-

brazing.

WARNING: The POE oil contained within the

installing the interconnecting refrigerant tubing.

Center Leg

(Right-hand Side Facing Header)

top flanges of both legs. Attached the center legs

using the hardware provide at the center-divider

panel location. Replace the bolts removed from the

side panels to secure the leg assembly to the bottom

flanges of the condenser side panels.

Figure 2 - Mounting Remote Condenser Legs

Interconnecting Refrigerant Piping

The chiller and remote condenser ship with a

nitrogen holding charge. Evacuation of this charge is

required before charging with refrigerant. The chiller

is for use only with the air-cooled condenser

provided with the unit. The following section covers

the required piping between the chiller and the

provided air-cooled condenser.

The discharge and liquid lines leaving the chiller

have caps. These line sizes do not necessarily reflect

the actual line sizes required for the piping between

the chiller and the air-cooled condenser.

Refrigerant piping size and piping design have a

significant impact on system performance and

reliability. All piping should conform to the

applicable local and state codes.

ASTM B280 and isolate the refrigeration lines from

building structures to prevent transfer of vibration. All

copper tubing must have a pressure rating suitable for

R-410A: tubing that is 3/4” OD or larger must be Type

K rigid tubing. ACR annealed tubing coil may be used

Do not use a saw to remove end caps. This might

allow copper chips to contaminate the system. Use a

tube cutter or heat to remove the caps. When

sweating copper joints it is important to evacuate all

refrigerant present and flow dry nitrogen through

the system. This prevents the formation of toxic

gases, corrosive acids, and scale.

copper joints use a copper-phosphorus braze alloy

(BCuP per the American Welding Society) with 5%

(BCuP-3) to 15% (BCuP-5) silver content. Only use a

high silver content brazing alloy (BAg per AWS) for

copper-to-brass or copper-to-steel joints such as a

45% (BAg-5) silver content. Only use oxy-acetylene

compressor is hygroscopic and has the ability to

absorb water vapor from the atmosphere. Take

necessary steps to prevent an open system from

exposure to the atmosphere for extended periods while

Refrigeration Piping Design

The system is configurable in any of the

arrangements as shown in Figure 3, Figure 4, and

Figure 5. The configuration and its associated

elevation, along with the total distance between the

chiller and the air-cooled condenser are important

factors in determining the liquid line and discharge

line sizes. This will also affect the field refrigerant

charges. Consequently, it is important to adhere to

certain physical limitations to ensure the system

operates as designed.

General design considerations are:

1. The total distance between the chiller and the

air-cooled condenser must not exceed 200

actual feet or 300 equivalent feet. Keep the

distance as short as possible.

2. Liquid line risers must not exceed 15 feet in

height from the condenser liquid line

connection.

3. Discharge line risers cannot exceed an elevation

difference greater than 100 actual feet without a

minimum of 2% efficiency decrease.

4. To form a proper liquid seal at the condenser,

immediately drop at least 15 inches down from

the liquid outlet before routing the piping to the

chiller. Make the drop leg before any bends or

angles connecting to the remainder of the liquid

connection piping.

5

Page 12

Caution: Liquid line sizing for each chiller capacity is

Handbook or other suitable design guide.

CAUTION: When calculating the equivalent length, do

must be considered.

Line

Size OD

Equivalent Lengths of Refrigerant Pipe (feet)

90°

Standard

90°Long

Radius

90°

Street

45°

Standard

45°

Street ⅞ 2.0

1.4

3.2

0.9

1.6

1⅛

2.6

1.7

4.1

1.3

2.1

1⅜

3.3

2.3

5.6

1.7

3.0

1⅝

4.0

2.6

6.3

2.1

3.4

2⅛

5.0

3.3

8.2

2.6

4.5

2⅝

6.0

4.1

10.0

3.2

5.2

3⅛

7.5

5.0

12.0

4.0

6.4

3⅝

9.0

5.9

15.0

4.7

7.3

4⅛

10.0

6.7

17.0

5.2

8.5

Figure 3 – Condenser Located at Chiller Level

Figure 4 – Condenser Located Above Chiller Unit

Figure 5 - Condenser Located Below Chiller Unit

the same pressure loss. See the ASHRAE

Refrigeration Handbook for more information.

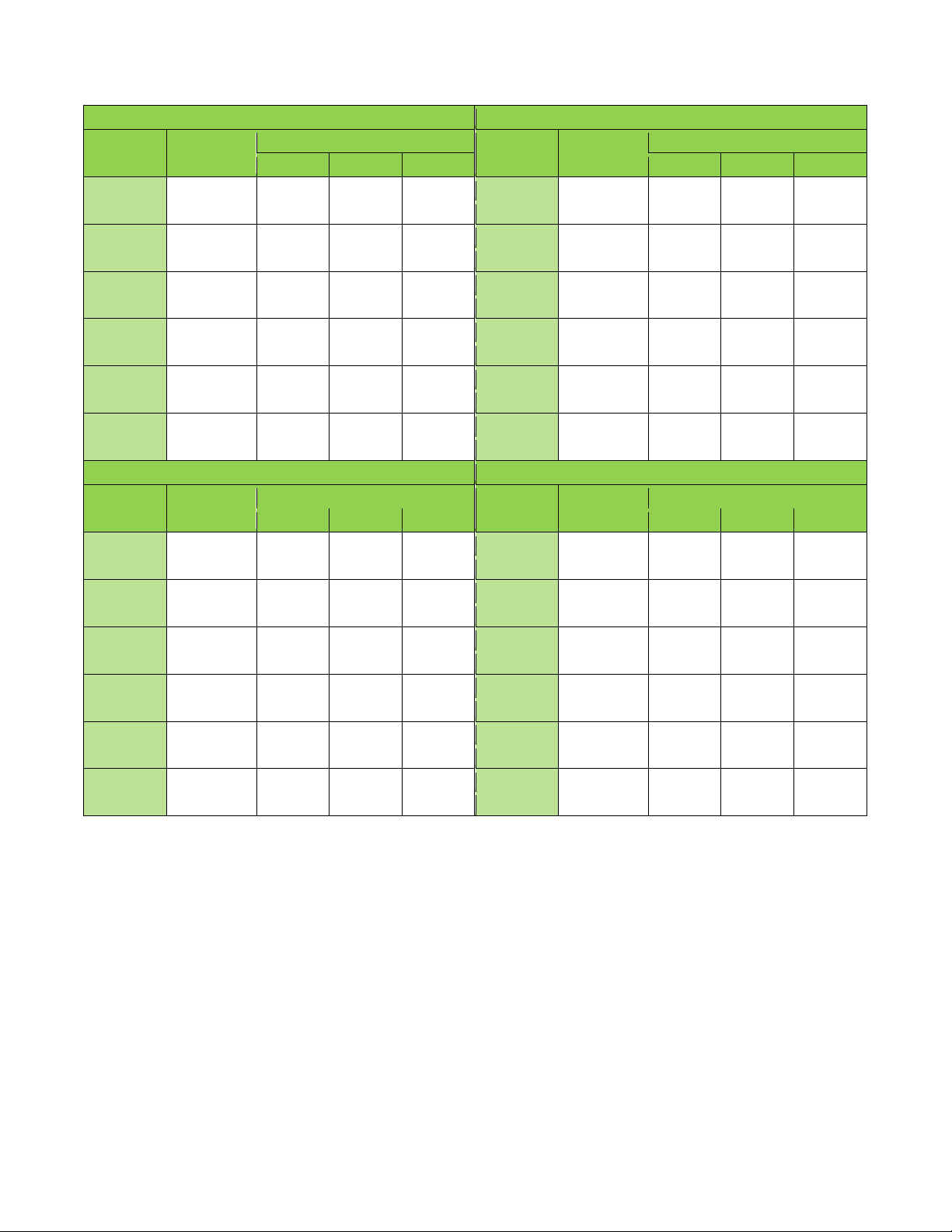

Follow these steps when calculating line size:

1. Start with an initial approximation of equivalent

length by assuming that the equivalent length of

pipe is 1.5 times the actual pipe length.

2. Determine approximate line sizes by referring to

Table 2 for liquid lines, Table 3 and Table 4 for

the discharge lines.

3. Check the line size by calculating the actual

equivalent length using the equivalent lengths

as shown in Table 1.

not include piping of the chiller unit. Only field piping

Table 1 – Equivalent Lengths of Elbows

(in)

shown in Table 2. These line sizes are listed per circuit

and apply where leaving water temperature (LWT) is

40°F or higher. For applications where the LWT is

below 40°F, size lines using the ASHRAE Refrigeration

Determining Equivalent Line Length

To determine the appropriate size for field installed

liquid and discharge lines, it is first necessary to

establish the equivalent length of pipe for each line.

The equivalent length is the approximate friction loss

from the combined linear run of pipe and the

equivalent feet of elbows, valves, and other

components in the refrigeration piping. The sum

total is the equivalent length of pipe that would have

Liquid Line Sizing

The liquid line diameter should be as small as

possible while maintaining acceptable pressure drop.

This is necessary to minimize refrigerant charge. The

total length between the chiller unit and the aircooled condenser must not exceed 200 actual feet

or 300 equivalent feet. It is best to pipe the liquid

line so that there is an immediate drop of at least 15

inches at the condenser outlets to make a liquid seal.

Liquid line risers in the system will require an

additional 0.5 psig pressure drop per foot of vertical

rise. When it is necessary to have a liquid line riser,

make the vertical run immediately after the

condenser before any additional restrictions. The

liquid line risers must not exceed 10 feet in height

from the condenser liquid line connection. The liquid

line does not require pitching. Install a pressure tap

6

Page 13

5 Ton Circuit (R410A) Liquid Line Size (Inch OD)

7½ Ton Circuit (R410A) Liquid Line Size (Inch OD)

Up Flow (Feet of Run)

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

1/2

1/2

1/2

1/2

25

5/8

5/8

5/8

5/8

50

1/2

1/2

1/2

5/8

50

5/8

5/8

5/8

5/8

75

1/2

1/2

1/2

5/8

75

5/8

5/8

5/8

3/4

100

1/2

1/2

5/8

5/8

100

5/8

5/8

5/8

3/4

125

1/2

1/2

5/8

3/4

125

5/8

5/8

3/4

3/4

150

1/2

5/8

5/8

3/4

150

5/8

5/8

3/4

7/8

175

5/8

5/8

5/8

3/4

175

5/8

5/8

3/4

7/8

200

5/8

5/8

5/8

3/4

200

5/8

3/4

3/4

7/8

225

5/8

5/8

5/8

3/4

225

5/8

3/4

3/4

7/8

250

5/8

5/8

5/8

3/4

250

5/8

3/4

3/4

7/8

275

5/8

5/8

3/4

3/4

275

3/4

3/4

3/4

7/8

300

5/8

5/8

3/4

7/8

300

3/4

3/4

3/4

7/8

10 Ton Circuit (R410A) Liquid Line Size (Inch OD)

15 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Horizontal or

Up Flow (Feet of Run)

Equivalent

Horizontal or

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

3/4

3/4

3/4

3/4

25

7/8

7/8

7/8

7/8

50

3/4

3/4

3/4

3/4

50

7/8

7/8

7/8

7/8

75

3/4

3/4

3/4

3/4

75

7/8

7/8

7/8

7/8

100

3/4

3/4

3/4

7/8

100

7/8

7/8

7/8

1 1/8

125

3/4

3/4

3/4

7/8

125

7/8

7/8

7/8

1 1/8

150

3/4

3/4

3/4

7/8

150

7/8

7/8

7/8

1 1/8

175

3/4

3/4

3/4

7/8

175

7/8

7/8

7/8

1 1/8

200

3/4

3/4

7/8

1 1/8

200

7/8

7/8

1 1/8

1 1/8

225

3/4

3/4

7/8

1 1/8

225

7/8

7/8

1 1/8

1 1/8

250

3/4

3/4

7/8

1 1/8

250

7/8

7/8

1 1/8

1 1/8

275

3/4

3/4

7/8

1 1/8

275

7/8

7/8

1 1/8

1 1/8

300

3/4

7/8

7/8

1 1/8

300

7/8

7/8

1 1/8

1 1/8

valve at the condenser to facilitate measuring

pressure for service.

Liquid lines do not typically require insulation.

However, if exposing the lines to solar heat gain or

temperatures exceeding 110 °F, there is a negative

Table 2 – Liquid Line Sizes for R410A

Equivalent

Length (Ft)

Horizontal or

Down Flow

effect on sub-cooling. In these situations, insulate

the liquid lines.

Equivalent

Length (Ft)

Horizontal or

Down Flow

Length (Ft)

Down Flow

Length (Ft)

Down Flow

7

Page 14

20 Ton Circuit (R410A) Liquid Line Size (Inch OD)

25 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Horizontal or

Up Flow (Feet of Run)

Equivalent

Horizontal or

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

1 1/8

1 1/8

1 1/8

1 1/8

25

1 1/8

1 1/8

1 1/8

1 1/8

50

1 1/8

1 1/8

1 1/8

1 1/8

50

1 1/8

1 1/8

1 1/8

1 1/8

75

1 1/8

1 1/8

1 1/8

1 1/8

75

1 1/8

1 1/8

1 1/8

1 1/8

100

1 1/8

1 1/8

1 1/8

1 1/8

100

1 1/8

1 1/8

1 1/8

1 1/8

125

1 1/8

1 1/8

1 1/8

1 1/8

125

1 1/8

1 1/8

1 1/8

1 1/8

150

1 1/8

1 1/8

1 1/8

1 1/8

150

1 1/8

1 1/8

1 1/8

1 3/8

175

1 1/8

1 1/8

1 1/8

1 1/8

175

1 1/8

1 1/8

1 1/8

1 3/8

200

1 1/8

1 1/8

1 1/8

1 3/8

200

1 1/8

1 1/8

1 1/8

1 3/8

225

1 1/8

1 1/8

1 1/8

1 3/8

225

1 1/8

1 1/8

1 1/8

1 3/8

250

1 1/8

1 1/8

1 1/8

1 3/8

250

1 1/8

1 1/8

1 1/8

1 3/8

275

1 1/8

1 1/8

1 1/8

1 3/8

275

1 1/8

1 1/8

1 1/8

1 3/8

300

1 1/8

1 1/8

1 1/8

1 3/8

300

1 1/8

1 1/8

1 3/8

1 3/8

30 Ton Circuit (R410A) Liquid Line Size (Inch OD)

35 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Horizontal or

Up Flow (Feet of Run)

Equivalent

Horizontal or

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

1 1/8

1 1/8

1 1/8

1 1/8

25

1 3/8

1 3/8

1 3/8

1 3/8

50

1 1/8

1 1/8

1 1/8

1 1/8

50

1 3/8

1 3/8

1 3/8

1 3/8

75

1 1/8

1 1/8

1 1/8

1 1/8

75

1 3/8

1 3/8

1 3/8

1 3/8

100

1 1/8

1 1/8

1 1/8

1 3/8

100

1 3/8

1 3/8

1 3/8

1 3/8

125

1 1/8

1 1/8

1 1/8

1 3/8

125

1 3/8

1 3/8

1 3/8

1 3/8

150

1 1/8

1 1/8

1 1/8

1 3/8

150

1 3/8

1 3/8

1 3/8

1 3/8

175

1 1/8

1 1/8

1 1/8

1 3/8

175

1 3/8

1 3/8

1 3/8

1 3/8

200

1 1/8

1 1/8

1 1/8

1 3/8

200

1 3/8

1 3/8

1 3/8

1 5/8

225

1 1/8

1 1/8

1 3/8

1 3/8

225

1 3/8

1 3/8

1 3/8

1 5/8

250

1 1/8

1 1/8

1 3/8

1 5/8

250

1 3/8

1 3/8

1 3/8

1 5/8

275

1 1/8

1 1/8

1 3/8

1 5/8

275

1 3/8

1 3/8

1 3/8

1 5/8

300

1 1/8

1 1/8

1 3/8

1 5/8

300

1 3/8

1 3/8

1 3/8

1 5/8

Table 2 – Liquid Line Sizes for R410A (continued)

Length (Ft)

Length (Ft)

Down Flow

Down Flow

Length (Ft)

Length (Ft)

Down Flow

Down Flow

8

Page 15

40 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Horizontal or

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

25

1 3/8

1 3/8

1 3/8

1 3/8

50

1 3/8

1 3/8

1 3/8

1 3/8

75

1 3/8

1 3/8

1 3/8

1 3/8

100

1 3/8

1 3/8

1 3/8

1 3/8

125

1 3/8

1 3/8

1 3/8

1 3/8

150

1 3/8

1 3/8

1 3/8

1 5/8

175

1 3/8

1 3/8

1 3/8

1 5/8

200

1 3/8

1 3/8

1 3/8

1 5/8

225

1 3/8

1 3/8

1 3/8

1 5/8

250

1 3/8

1 3/8

1 3/8

1 5/8

275

1 3/8

1 3/8

1 3/8

1 5/8

300

1 3/8

1 3/8

1 3/8

1 5/8

Note: Discharge line sizing shown in Table 3and Table

guide.

Table 2 – Liquid Line Sizes for R410A (continued)

Length (Ft)

Down Flow

Discharge (Hot Gas) Line Sizing

The discharge line sizes depend on the velocity

needed to obtain sufficient oil return. It is very

important to minimize line length and restrictions to

reduce pressure drop and maximize capacity.

Upflow hot gas risers need to have a trap at the

bottom and reverse trap at the top. In addition, a

trap and reverse trap arrangement needs to be

spaced every 15 feet in the rise for oil management

(see Figure 6).

The discharge lines should pitch downward, in the

direction of the hot gas flow, at the rate of ½ inch

per each 10 foot of horizontal run. If the chiller unit

is below the condenser, loop the discharge line to at

least 1 inch above the top of the condenser. Install a

pressure tap valve at the condenser to facilitate

measuring pressure for service. Take careful

consideration in the design of the discharge gas

riser.

Check the oil-level sight glass in the compressor to

ensure it is at the appropriate level to verify there is

no trapping of oil in the piping. The chiller is

equipped with hot-gas bypass capacity control and

the gas in the upflow discharge lines may have

problems moving the oil against gravity when

completely unloaded if a single rise system is used.

We recommend a double riser system to ensure

proper oil return under low load operation. See

Figure 7 and Table 4 for double riser constructions.

Figure 6 – Vertical Riser Traps

Figure 7 - Double Discharge Riser

4 are listed per circuit and apply where leaving water

temperature (LWT) is 40°F or higher. For applications

where LWT is below 40°F, size lines using the ASHRAE

Refrigeration Handbook or other suitable design

9

Page 16

Total Equivalent Length (Ft)

25

50

75

100

125

150

175

200

225

250

275

300 5 5/8

5/8

5/8

5/8

3/4

3/4

3/4

3/4

3/4

3/4

3/4

7/8

7.5

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

10

7/8

7/8

7/8

7/8

7/8

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

15

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

20

7/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

25

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

30

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

35

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

40

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

Total Equivalent Length (Ft)

25

50

75

100

125

150

175

200

225

250

275

300

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

B – 1/2

B – 1/2

B – 1/2

B – 1/2

B – 5/8

B – 5/8

B – 5/8

B – 5/8

B – 5/8

B – 5/8

B – 5/8

B – 3/4

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 3/8

A – 1/2

A – 1/2

B – 3/4

B – 3/4

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 1 1/8

B – 1 1/8

A – 3/8

A – 3/8

A – 3/8

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 5/8

A – 5/8

B – 3/4

B – 7/8

B – 7/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 3/8

B – 1 3/8

A – 3/8

A – 3/8

A – 3/8

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 1/2

A – 5/8

A – 5/8

B – 7/8

B – 7/8

B – 7/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 3/8

B – 1 3/8

A – 1/2

A – 1/2

A – 1/2

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

B – 7/8

B – 7/8

B – 7/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 3/8

B – 1 3/8

B – 1 3/8

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

B – 1 1/8

B – 1 1/8

B – 1 1/8

B – 1 3/8

B – 1 3/8

B – 1 3/8

B – 1 3/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

A – 3/4

B – 1 3/8

B – 1 3/8

B – 1 3/8

B – 1 3/8

B – 1 3/8

B – 1 3/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

B – 1 5/8

Table 3 - Horizontal or Downflow Discharge Line Sizes for R410A (inches OD)

Circuit

Tons

Table 4 - Upflow Discharge Line Sizes for R410A (inches OD)

Circuit

Tons

5

7.5

10

15

20

25

30

35

40

10

Page 17

Total Combined Chiller and Condenser

R410A) 5 7.6

7.5

11.1

10

15.3

15

22.2

20

30.2

25

37.2

30

44.3

35

51.9

40

59.4

Line Size OD

Lbs of R410A per 100 Foot of Line Length

Discharge Line

Liquid Line

3/8

0.4

3.7

1/2

0.7

6.8

5/8

1.1

11

3/4

1.6

16.4

7/8

2.2

22.8

1 1/8

3.6

36.7

1 3/8

5.6

57.4

1 5/8

7.9

81.2

2 1/8

13.9

142.1

2 5/8

21.4

219.5

Number of Fan Stages

1 2 3

4

Max Speed

410

410

410

410

Min Speed

320

320

320

320

Fan On

400

400

370

Fan Off

340

340

305

Fan On

435

385

Fan Off

375

325

Fan On

400

Fan Off

340

Calculating Refrigerant and Oil Charge

To determine the approximate charge, first refer to

Table 12 and establish the required charge for the

condenser and chiller. Then refer to Table 13 to

determine the charge required for the field-installed

piping per circuit. The approximate charge per circuit

is therefore the sum of the values from Table 12 and

Table 13.

Table 5 – Chiller & Condenser Refrigerant Charge

Circuit Capacity

(tons)

Summertime Refrigerant Charge (lbs of

Oil level should be checked after the chiller has run

for 15 minutes.

Setting Condenser Fan Controls

Depending on the number of condenser fans

present there will be different fan cycling pressure

control setting requirements. It is important that

these settings be correct in order to maintain proper

capacity control and operation of the system. Each

refrigerant circuit has a separate head-pressure

control circuit. Refer to Table 7 for the proper

pressure settings.

Table 7 - Condenser Fan Pressure Settings (psig)

Stage

Number

Stage 1

Stage 2

Stage 3

Setting

Table 6 - Field Piping R-410A Refrigerant Charges

(inches)

Oil Charge Determination

The chiller is factory charged with the amount of oil

required by the chiller only and not the total system.

The amount of oil required is dependent upon the

amount of refrigerant added to the system for the

field-installed piping. Use the following to determine

the amount of oil needed for the system.

Pints of Oil = Pounds of refrigerant in system / 100

Stage 4

To do this, open the remote condenser control

panel, remove the cover from the pressure control

module, and make sure everything is set as shown

below.

11

Page 18

WARNING: This equipment contains hazardous

WARNING: This equipment contains refrigerant under

damage.

WARNING: This equipment may contain fan blades or

protective shields are securely in place.

WARNING: The exposed surfaces of motors, refrigerant

hands.

CAUTION: Disconnect and lock out incoming power

maintenance.

CAUTION: Wear eye protection when installing,

against any sparks, debris, or fluid leaks.

CAUTION: Wear protective gloves when installing,

against any sparks, debris, or fluid leaks.

CAUTION: Wire the unit ground in compliance with

CAUTION: The unit requires the main power to remain

24 hours prior to initial startup.

Installation - Electrical

All wiring must comply with local codes and the

National Electric Code. Minimum circuit amps (MCA)

and other unit electrical data are on the unit

nameplate. A unit specific electrical schematic ships

with the unit. Measure each leg of the main power

supply voltage at the main power source. Voltage

must be within the voltage utilization range given on

the drawings included with the unit. If the measured

voltage on any leg is not within the specified range,

notify the supplier and correct before operating the

unit. Voltage imbalance must not exceed two

percent. Excessive voltage imbalance between the

phases of a three-phase system can cause motors to

overheat and eventually fail. Voltage imbalance is

determined using the following calculations:

%Imbalance = (Vavg – Vx) x 100 / Vavg

Vavg = (V1 + V2 + V3) / 3

Vx = phase with greatest difference from Vavg

For example, if the three measured voltages were

442, 460, and 454 volts, the average would be:

(442 + 460 + 454) / 3 = 452

The percentage of imbalance is then:

(452 – 442) x 100 / 452 = 2.2 %

This exceeds the maximum allowable of 2%.

There is a terminal block for main power connection

to the main power source. The main power source

should be connected to the terminal block through

an appropriate disconnect switch. There is a separate

lug in the main control panel for grounding the unit.

Check the electrical phase sequence at installation

and prior to start-up. Operation of the compressor

with incorrect electrical phase sequencing will result

in mechanical damage to the compressors. Check

the phasing with a phase sequence meter prior to

applying power. The proper sequence should read

“ABC” on the meter. If the meter reads “CBA”, open

the main power disconnect and switch two line leads

on the line power terminal blocks (or the unit

mounted disconnect). Do not interchange any load

leads that are from the unit contactors or the motor

terminals.

voltages that can cause severe injury or death.

pressure. Accidental release of refrigerant under

pressure can cause personal injury and or property

other sharp edges. Make sure all fan guards and other

piping, and other fluid circuit components can be very

hot and can cause burns if touched with unprotected

before installing, servicing, or maintaining the

equipment. Connecting power to the main terminal

block energizes the entire electric circuitry of the unit.

Electric power at the main disconnect should be shut

off before opening access panels for repair or

maintaining, or repairing the equipment to protect

maintaining, or repairing the equipment to protect

local and national codes.

connected during off-hours to energize the

compressor’s crankcase heater. Disconnect main

power only when servicing the chiller. The crankcase

heater should remain on when the compressor is off to

ensure liquid refrigerant does not accumulate in the

compressor crankcase. Connect main power at least

12

Page 19

Button

Description of Operation

Start

Depressing the Start button will start the pump and enable the compressor. The compressor (and condenser fans if the

The Start button also performs an “Enter” function while in the programming menu.

Stop

Depressing the Stop button will shut off the compressor, pump, condenser fans (if the chiller is air-cooled), and clear all

also performs a “Cancel” function while in the programming menu.

Alarm Silence /

When an alarm condition is present, the alarm light is on and red. The first Alarm Silence/Reset button press will silence

immediately go into a new alarm state.

Compressor

Press and hold the Compressor Running Hours Button to display the amount of time that each compressor in the system

hours is in units of hundreds so a display value

is not disturbed while displaying the running hours.

Pump Running

Press and hold the Pump Running Hours Button to display the amount of time the pump has run. The running hours

running hours is in units of hundreds so a display value of 10 would mean

running hours.

Standard Controller Operation

The chiller includes a controller to perform all

control functions directly from the front panel. When

Control Power is applied, the controller initiates a

diagnostic test of each indicating light and display

segments by briefly lighting each sequentially. As

part of this initial diagnostic test, the program

revision level displays for a moment. After the initial

diagnostic sequence is completed, the controller is

ready for operation.

Table 8 - Operating Buttons

chiller is air-cooled) will start only if the microprocessor is calling for cooling because the actual To Process temperature

is higher than the Set Point temperature. If the Autostart feature is enabled the Autostart signal will have precedence

over the Start Button. See the

fault signals. If the Autostart feature is enabled and an Autostart signal is present, the Stop button will not stop the

chiller. See the

Alarm Reset

Running Hours

Hours

the alarm horn (optional), open the remote alarm contact (optional), and the alarm light changes from red to yellow. The

alarm horn and/or remote alarm contact remain disabled until a subsequent alarm occurs. A second press of the Alarm

Silence/Reset button resets the state from Alarm to Normal Operation. The High Refrigerant Pressure and Pump

Overload require a mechanical safety manual reset before the control board reset. If the fault is still present, the unit will

has run. The Set Point window will show which compressor’s usage is being displayed (for units with two compressors).

The running hours show in the process display window. Display of running

of 10 would mean 1,000 hours. The running hours show while holding the button. For units with two compressors, the

display will toggle between the two compressors every three seconds. The hours show while holding the button. Control

show in the process display window. Display of

1,000 hours. The running hours will show while holding the button. Control is not disturbed while displaying the pump

Program Menu section for instructions on how to enable or disable the Autostart feature.

Program Menu section for instructions on how to enable or disable the Autostart feature. The Start button

13

Page 20

Button

Description of Operation

Pump Test

With the chiller stopped, pressing this button briefly engages the pump to test its operation. The pump will not run if

second time. The pump will shut down after one minute of operation.

Display/Program

The Display/Program button will change the temperature displayed in the Process screen from Supply to Return. When

Menu section for more detail.

Up

The Up button raises the set point temperature. Pressing the Up button and releasing it increases the set point

various alarms and set point values when the unit in the programming mode.

Down

The Down button decreases the set point temperature. Pressing the Down button and releasing it decreases the set point

adjusts various alarms and set point values when the unit is in the programming mode.

Display

Description of Operation

Set Point

The Set Point display normally shows the set point temperature. A decimal point in the lower right corner of this display

indicates the temperature unit of measure is set to °F, no decimal point indicates the temperature unit of measure is set to

and programming information.

Process

The Process Temperature display normally shows supply temperature. A decimal point in the lower right corner of the

button press. This display also shows alarm codes and programming information.

Light

Description of Operation

Control Power

The Control Power light is green when 24VDC control voltage is present.

Autostart Signal

The Autostart Signal light is green when closed (run), yellow when open (stop), and unlit if this feature is disabled. This

introduce any external voltage to the Autostart contacts, as this will result in damage to the controller.

Pump

The Pump light is solid green when the pump is running and flashes red if the pump motor overload trips.

Hot Gas Bypass

The Hot Gas Bypass light will pulse or light solidly when the chiller is operating at partial load and the hot gas bypass

temperature may begin to drop below the Set Point temperature, eventually cycling off compressor(s).

Compressor #1

The Compressor #1 light is solid green when Compressor #1 is running, flashes red if a compressor overload or fault

chiller rises above the Set Point by an amount

section for instructions on how to adjust PS1 and nS1.

Table 8 – Operating Buttons (continued)

there are any active alarms. The pump shuts down by either pressing the Stop button or pressing the Pump Test button a

the display is set to supply temperature, there will be an orange indicating light in the lower right corner of the Process

temperature display. When the display is set to return temperature, there will be no orange indicating light in the lower

right corner of the Process temperature display. To toggle the process temperature display from supply to return

temperature, press and release the Display/Program button. The display will return to the default Supply temperature

automatically after 5 seconds without a button press. In addition to switching between the supply and return process

temperature displays, the Display/Program button will initiate and navigate through the program menu. See the

temperature by one degree. Pressing the Up button and holding it increases the set point temperature until reaching the

maximum allowable set point temperature. In addition to adjusting the set point temperature, the Up button adjusts

temperature by one degree. Pressing the Down button and holding it decreases the set point temperature until reaching

the minimum allowable set point temperature. In addition to adjusting the set point temperature, the Down button

Table 9 - Temperature Displays

Program

°C. See the Program Menu section to change the temperature scale units of measure. This display also shows alarm codes

display indicates the temperature displayed is the supply temperature, no decimal point indicates the temperature

displayed is the return temperature. To change the display from supply to return temperature, press and release the

Display/Program button. The display will return to the default Supply temperature automatically after 5 seconds without a

Table 10 - Operating Lights

feature allows starting and stopping of the unit by a remote contact closure. From the factory, the Autostart feature is

disabled. See the

valve opens. The light stays on for longer periods of time when the chiller is under smaller loads. If the light stays off the

chiller is under full load. If the light stays on the chiller is fully unloaded. If this condition persists, the To Process

occurs, and is solid red if the controller is attempting to start the compressor before the anti-recycle timer has timed out.

Compressor #1 is enabled when the temperature of the coolant leaving the

equal to the control parameter PS1 (Compressor #1 Positive Spread). PS1 is equal to 2 °F by default. The compressor is

disabled if the temperature of the coolant leaving the chiller drops below the Set Point by an amount equal to the control

parameter nS1 (Compressor #1 Negative Spread). The parameter nS1 is set to 4 °F by default. See the

Program Menu section for instructions on how to enable or disable the Autostart feature. Do not

Program Menu

14

Page 21

Light

Description of Operation

Compressor #2

The Compressor #2 light is solid green when Compressor #2 is running, flashes red if a compressor overload or fault

chiller rises above the Set Point by an amount

section for instructions on how to adjust PS2 and nS2.

Temperature Limit

The Temperature Limit light flashes yellow if a high or low temperature limit warning occurs and flashes red if a high or

Pushing the Alarm Reset

button will reset this alarm.

Electrical Phase

Error

The Electrical Phase Error light flashes red when a line voltage problem exists (loss of phase, phase reversal, or phase

imbalance). This safety stops all compressors and pumps. Pushing the Alarm Reset button will reset this alarm.

Low Flow

The Low Flow light is red if the flow through the chiller is too low. This safety is defeated for 5 seconds after starting the

the safety and restarts the chiller.

Freezestat

The Freezstat light is red if the coolant leaving the chiller drops below the Freezestat Limit (FLS) setting. This safety stops

to adjust FLS.

Reservoir Level

The Low Reservoir Level light is red when the water level in the reservoir drops below the lower limit of the float switch.

coolant level in the reservoir has risen about the lower limit of the float switch.

Compressor

The Compressor Recycle light is yellow when the number of compressor starts per hour exceeds the number allowed. This

yellow whenever there is a wait period before a compressor can start.

High Refrig

The High Refrigerant Pressure light is red when the compressor discharge refrigerant pressure exceeds the setting of the

refrigerant pressure safety.

Low Refrig

The Low Refrigerant Pressure light is red when the compressor suction pressure drops below the setting on the low

Reset button resets the fault if the compressor suction pressure is above the setting of the low refrigerant pressure safety.

Program Mode

The Program Mode LED flashes yellow when the control system is in the programming menu.