Page 1

D Carousel Dryer - DC-1

Models 15, 25, 50, 75, and 100 with DC-1 Controls

Corporate Office: 412.312.6000 l Instant Access 24/7 (Parts and Service): 800.458.1960 l Parts and Service: 814.437.6861

USER GUIDE

UGD024/0304

www.conairnet.com

INTRODUCTION • Purpose of the User Guide • How the guide is organized • Your responsibilities as a user • ATTENTION:

Read this so no one gets hurt • How to use the lockout device • DESCRIPTION • What is the D Carousel Dryer? •

Typical applications • How it works • Specifications: D Dryer • INSTALLATION • Unpacking the boxes • Preparing for

installation • Mounting the dryer and hopper on a Processing Machine • Positioning the dryer on the floor; Mounting the

hopper on the throat • Mounting the dryer on the floor stand; Hopper on the throat • Mounting the dryer and hopper on

the mobile floor stand • Connecting the main power • Checking for proper air flow • Connecting the air hoses

•Connecting water hoses • Connecting the RTD probe • Mounting a loader on the hopper • OPERATION • How it works

• The DC-1 dryer control panel • D dryer DC-1 control functions • Control Function Description • To start drying • To stop

drying • Using the auto start countdown function • Setting high and low setpoint limits • MAINTENANCE

Page 2

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equipment and

the date you received it in the User Guide. Our service department uses this information, along with the manual number, to provide help for the specific equipment

you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists

together for documentation of your equipment.

Date:

Manual Number: UGD024/0304

Serial Number(s):

Model Number(s):

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors contained in this User Guide or

for incidental, consequential damages in connection with the furnishing, performance or use of

this information. Conair makes no warranty of any kind with regard to this information, including,

but not limited to the implied warranties of merchantability and fitness for a particular purpose.

Copyright 2004 l The Conair Group l All rights reserved

Page 3

Table of Contents

1-1 Introduction

Purpose of the User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How the guide is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using the D series as a central dryer . . . . . . . . . . . . . . . . . . . . . . 1-3

Your responsibilities as a user . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . . . . . . . . . . . . . . . . 1-4

How to use the lockout device . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2-1 Description

What is the D Carousel Dryer?. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How it works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Specifications: D Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3-1 Installation

Unpacking the boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Mounting the dryer and hopper on a Processing Machine . . . . . . . 3-6

Positioning the dryer on the floor; Mounting the hopper

on the throat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Mounting the hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Positioning the dryer on the floor . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Mounting the dryer on the floor stand; Hopper on the throat. . . . . 3-10

Mounting the dryer and hopper on the mobile floor stand . . . . . . 3-10

Connecting the main power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Table of Contents l i

Page 4

Checking for proper air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Connecting the air hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Connecting water hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Connecting the RTD probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Connecting the Optional Setback RTD. . . . . . . . . . . . . . . . . . . . . 3-16

Mounting a loader on the hopper . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4-1 Operation

The DC-1 dryer control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

D dryer DC-1 control functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Control function flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Control function descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

To start drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

To stop drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Using the auto start countdown function . . . . . . . . . . . . . . . . . . . 4-19

How to enable the auto start on the DC-1 control . . . . . . . . . . . . 4-19

How to disable the auto start on the DC-1 control . . . . . . . . . . . . 4-19

Setting high and low setpoint limits . . . . . . . . . . . . . . . . . . . . . . 4-20

5-1 Maintenance

Preventative maintenance checklist . . . . . . . . . . . . . . . . . . . . . . . 5-2

Cleaning the hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning the process filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cleaning the regeneration filter . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cleaning the aftercooler coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Cleaning the precooler coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Inspecting hoses and gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

ii l Table of Contents

Page 5

6-1 Troubleshooting

Before beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A few words of caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

DIAGNOSTICS

How to identify the cause of a problem . . . . . . . . . . . . . . . . . . . . 6-4

Shut down alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Passive alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Setback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

REPAIR

Replacing fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Checking heater solid state relays . . . . . . . . . . . . . . . . . . . . . . . 6-18

Checking or replacing temperature sensors. . . . . . . . . . . . . . . . . 6-19

Adjusting the limit switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Replacing the heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Replacing the desiccant tanks . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Refilling the desiccant tanks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

A Appendix

We’re Here to Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

How to Contact Customer Service . . . . . . . . . . . . . . . . . . . . . . . . A-1

Before You Call... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Equipment Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

B Appendix

Mounting the Dryer on a Floor Stand . . . . . . . . . . . . . . . . . . . . . . B-1

Mounting the Dryer and Hopper on a Mobile

Floor stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Table of Contents l iii

Page 6

C Appendix

Installing an aftercooler (optional) . . . . . . . . . . . . . . . . . . . . . . . . C-1

Cleaning the aftercooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

D Appendix

Installing the flow control (optional) . . . . . . . . . . . . . . . . . . . . . . . D-1

E Appendix

Installing a precooler (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Cleaning the precooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

F Appendix

Installing the dew point sensor (optional) . . . . . . . . . . . . . . . . . . . F-1

G Appendix

What is the MDC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

How conveying works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Specifications: MDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-4

Unpacking the boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Installing the MDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-9

Connecting conveying lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-10

Connecting the RTD probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Connecting the demand sensor . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Connecting the main power . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Connecting the water hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Mounting a loader on the hopper. . . . . . . . . . . . . . . . . . . . . . . . G-12

Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

iv l Table of Contents

Page 7

Table of Contents l v

The MDC control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

MDC control functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

To start drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

To stop drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

Using the auto start countdown function . . . . . . . . . . . . . . . . . . G-12

Setting the high setpoint limits . . . . . . . . . . . . . . . . . . . . . . . . . G-12

To start conveying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-13

To stop conveying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-14

Transporting the MDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-14

Preventative maintenance schedule . . . . . . . . . . . . . . . . . . . . . . G-15

Cleaning the hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-15

Cleaning the conveying lines . . . . . . . . . . . . . . . . . . . . . . . . . . . G-15

Cleaning the vacuum receiver . . . . . . . . . . . . . . . . . . . . . . . . . . G-16

Cleaning the dust collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-17

Cleaning the process filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-18

Cleaning the regeneration filter . . . . . . . . . . . . . . . . . . . . . . . . . G-18

Cleaning the aftercooler coils . . . . . . . . . . . . . . . . . . . . . . . . . . G-18

Cleaning the precooler coils . . . . . . . . . . . . . . . . . . . . . . . . . . . G-18

Inspect hoses and gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-18

Page 8

vi l Table of Contents

Page 9

Introduction

Purpose of the user guide . . . . . . . . . . . . . 1-2

How the guide is organized . . . . . . . . . . . . 1-2

Using the D series as a central dryer . . . . . . 1-3

Your responsibilities as a user . . . . . . . . . . 1-3

ATTENTION:

Read this so no one gets hurt . . . . . . . . 1-4

How to use the lockout device . . . . . . . . . . 1-5

SECTION

1

Introduction l 1-1

1

Introduction

Page 10

✐

Purpose of the User Guide

This User Guide describes the Conair D series of carousel dehumidifying

dryers and explains step-by-step how to install, operate, maintain and

repair this equipment.

Before installing this product, please take a few moments to read the User

Guide and review the diagrams and safety information in the instruction

packet. You also should review manuals covering associated equipment in

your system. This review won’t take long, and it could save you valuable

installation and operating time later.

How the Guide is Organized

Symbols have been used to help organize the User Guide and call your

attention to important information regarding safe installation and operation.

Symbols within triangles warn of conditions that could be hazardous to users or

could damage equipment. Read and take precautions before proceeding.

Numbers indicate tasks or steps to be performed by the user.

A diamond indicates the equipment’s response to an action performed by the user.

An open box marks items in a checklist.

A circle marks items in a list.

Indicates a tip. A tip is used to provide you with a suggestion that will help you with

the maintenance and operation of this equipment.

Indicates a note. A note is used to provide additional information about the steps

you are following throughout this manual.

1

◆

❒

•

✒

1-2 l Introduction

Page 11

Using the D Series as a Central

Dryer

This manual incorporates the information necessary to use the Conair D series

dryer as a central dryer. Throughout this manual, information particular to central dyer application of the D series dryer is called out by the following treatment.

Your Responsibility as a User

You must be familiar with all safety procedures concerning installation, operation and maintenance of this equipment. Responsible safety procedures include:

• Thorough review of this User Guide, paying particular attention

to hazard warnings, appendices and related diagrams.

•

Thorough review of the equipment itself, with careful attention

to voltage sources, intended use and warning labels.

• Thorough review of instruction manuals for associated equipment.

•

Step-by-step adherence to instructions outlined in this User Guide.

Introduction l 1-3

1

Introduction

Central

This box will contain information or highlight system differences particular to the application of the D series dryer as a

central dryer.

Page 12

1-4 l Introduction

ATTENTION:

Read this so no one gets hurt

We design equipment with the user’s safety in mind. You can avoid the potential

hazards identified on this machine by following the procedures outlined below and

elsewhere in the User Guide.

WARNING: Improper installation, operation, or

servicing may result in equipment damage or

personal injury.

This equipment should be installed, adjusted, and serviced by qualified

technical personnel who are familiar with the construction, operation,

and potential hazards of this type of machine.

All wiring, disconnects, and fuses should be installed by qualified electrical technicians in accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate the equipment at power

levels other than what is specified on the machine serial tag and data

plate.

WARNING: Voltage hazard

This equipment is powered by three-phase alternating current,

as specified on the machine serial tag and data plate.

A properly sized conductive ground wire from the incoming power

supply must be connected to the chassis ground terminal inside the

electrical enclosure. Improper grounding can result in severe personal

injury and erratic machine operation.

Always disconnect and lock out the incoming main power source before

opening the electrical enclosure or performing non-standard operating

procedures, such as routine maintenance. Only qualified personnel

should perform troubleshooting procedures that require access to the

electrical enclosure while power is on.

Page 13

Introduction l 1-5

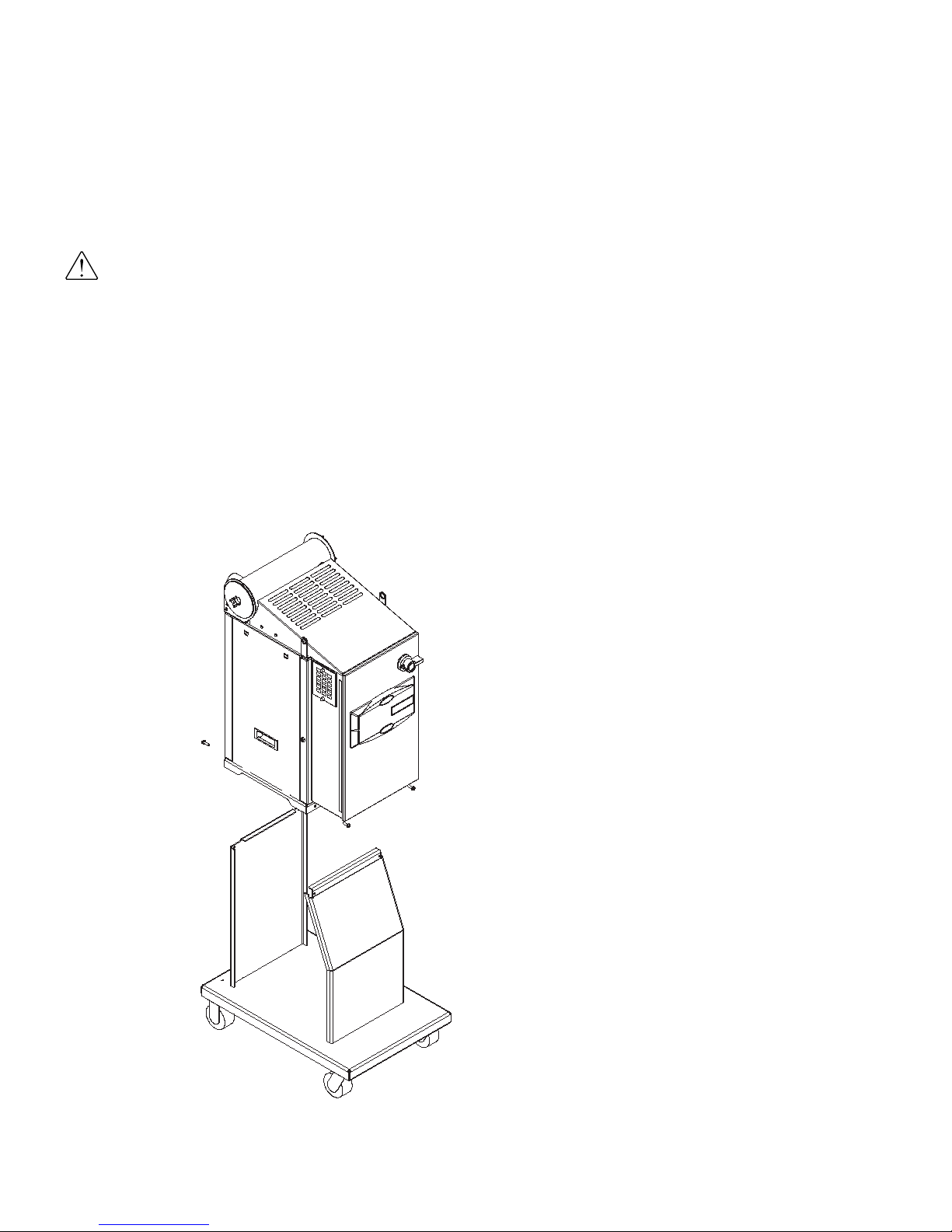

How to Use the Lockout Device

CAUTION: Before performing maintenance or repairs on this product, you should disconnect and lockout electri-

cal power sources to prevent injury from unexpected energization or start-up. A lockable device has been provided to isolate this product from potentially hazardous electricity.

Lockout is the preferred method of isolating machines or equipment from energy sources. Your Conair product

is equipped with the lockout device pictured below. To use the lockout device:

11

Stop or turn off the equipment.

22

Isolate the equipment from the electric power. Turn the rotary

disconnect switch to the OFF, or “O” position.

33

Secure the device with an assigned lock or tag. Insert a lock or tag

in the holes to prevent movement.

44

The equipment is now locked out.

WARNING: Before removing lockout devices and returning switches to

the ON position, make sure that all personnel are clear of the machine,

tools have been removed, and all safety guards reinstalled.

To turn the rotary disconnect back to the ON position:

11

Remove the lock or tag.

22

Turn the rotary disconnect switch to the ON or “I” position.

1

Introduction

Page 14

1-6 l Introduction

Page 15

Description

What is the D carousel dryer? . . . . . . . . . . 2-2

Typical applications . . . . . . . . . . . . . . . . . 2-2

How it works. . . . . . . . . . . . . . . . . . . . . . 2-4

Specifications: D dryer . . . . . . . . . . . . . . . 2-6

SECTION

2

2

Description

Description l 2-1

Page 16

What is the D Carousel Dryer?

The D carousel dehumidifying dryer produces hot, low-dew point air that removes

moisture from hygroscopic plastics. The dryer pulls warm, moist air from a drying

hopper and pumps it through dehumidifying desiccant. The dryer then heats the air

to the drying temperature you selected and circulates it through the material in the

hopper.

The dryer’s three-tank, closed-loop design ensures a continuous supply of hot,

dehumidified air while preventing contamination from moisture in the plant.

Typical Applications

2-2 l Description

The D dryer can be

mounted beside the

hopper on the throat of a

processing machine using

the optional diving board

support frame, or

positioned on the floor

near the machine using the

standard casters. Two

mobile floor stand designs

are also available.

Dryer on a floor stand; hopper on the

throat.

Dryer and hopper on the processing

machine throat using the optional

support frame.

Dryer on the floor; hopper on the throat.

Dryer and hopper on a mobile floor stand

(MDC version).

Page 17

Description l 2-3

2

Description

Central

Central

When supplied for central drying

applications, the D series dryer

is not equipped with a process

heater. Therefore, as a central

dryer, the D dryer will only supply dry air to the hoppers.

Typical Applications (continued)

The D carousel dryer can be used successfully in applications that require:

• A contamination-free drying environment.

• Drying temperatures within the ranges shown in the following table:

Model Drying Temperature Range

Low temperature (with precooler)* 100° - 150°F (38° - 66°C)

Standard 150° - 250°F (66° - 121°C)

High heat (with aftercooler) 150° - 375°F (66° - 191°C)

Low-high (with aftercooler & precooler)* 100° - 375°F (38° - 191°C)

*Note: See instruction on page 4-12 for setpoints over 150°F (66°C).

• Throughput rates of 15 to 100 lbs (6.8 to 37.3 kg) per hour (some materials

can be run at a higher rate).

• Dew points of -40°F (-40°C).

If you are drying material at temperatures over 250°F (121°C), you will need the

high-temperature package that includes an aftercooler. An aftercooler is standard

equipment on the High heat and Low-high models.

Page 18

How It Works

The D carousel dryer achieves continuous, closed loop drying by passing air simultaneously through two heaters and three tanks of molecular sieve desiccant.

THE

PROCESS (DRYING) CYCLE

The process blower pulls moist air from the top of the drying hopper. The air passes through the process filter (and optional aftercooler, if installed) into the dryer’s

desiccant tank, where moisture is removed. The now dry air moves through the

process heater, where it is heated to the drying temperature selected by the operator. The hot, dry air is delivered to the hopper (after it passes through the optional

precooler, if installed) where a spreader cone evenly distributes the air through the

material.

The Cooling Cycle

A regenerated desiccant tank must be cooled before it is moved back into the

process cycle. The process blower pushes a small amount of air through the regenerated desiccant tank. The cooling air then passes through the optional aftercooler,

if installed, and repeats the circuit.

The Regeneration Cycle

The regeneration blower pulls air through the regeneration filter into the dryer’s

regeneration heater. The air is heated to 425°F (218°C) before it is pushed into the

“wet” desiccant tank. The hot air purges moisture from the desiccant. The moist air

is blown out the exhaust at the back of the dryer.

2-4 l Description

Central

THE PROCESS (DRYING) CYCLE

The process blower pulls moist air from the top of the drying hopper. The air passes through the process filter (and optional aftercooler, if installed) into the dryer’s desiccant tank, where moisture is

removed. The dry air is delivered to the hopper (after it passes

through the optional precooler, if installed) where a spreader cone

evenly distributes the air through the material.

Page 19

2

Description

How It Works (continued)

REGENERATION

AIR FILTER

DESICCANT

TANKS

BEDPLATE

REGENERATION

BLOWER

REGENERATION

HEATER

HIGH TEMP

SHUTOFF

REGENERATION

RTD

HOPPER

4 CURRENT METER

PROCESS

BLOWER

RETURN

AIR

FILTER

8 AFTERCOOLER

5 PROCESS FILTER STATUS

RETURN AIR

RTD

PROCESS

RTD

1 SET BACK TEMPERATURE

2 PROCESS CFM MONITOR

HIGH TEMP

SHUTOFF

PROCESS

HEATER BOX

10 ALARM HORN

10

4

9

9 FLOW CONTROL VALVE

11

7 PRECOOLER

11 ALARM LIGHTS

7

DRYER OPTIONS

1

3 PM1 / DEW POINT MONITOR

6

6 PHASE ROTATION PROTECTION

PROCESS

COOLING

REGENERATION

1

4

2

3

9

8

5

Description l 2-5

Central

The components identified by this type of box in the drawing are not supplied with the

D dryer when it is configured as a central dryer.

Page 20

2-6 l Description

Specifications: D Carousel

DEHUMIDIFYING DRYERS

D Small Series Carousel Dryers

MODEL D15 D25 D50 D75 D100

Performance characteristics (with full hopper)

Air flow {SCFM}

*

12 20 35 50 80

Air flow {ACFM @ 250°}

*

16 27 47 67 107

Drying temperature All models 100 - 375

°

F {38 - 191° C} with options

Dew point All models -40° F {-40° C}

Dimensions inches {cm}

A - Height 35.5 {90.2} 35.5 {90.2} 35.5 {90.2} 42.1 {107} 42.1 {107}

B - Overall width 17.3 {43.9} 17.3 {43.9} 17.3 {43.9} 22.0 {55.9} 22.0 {55.9}

C - Control width 15.7 {39.9} 15.7 {39.9} 15.7 {39.9} 15.7 {39.9} 15.7 {39.9}

D - Depth 24.8 {63.0} 24.8 {63.0} 24.8 {63.0} 30.3 {77.0} 30.3 {77.0}

Control depth 7.3 {18.5} 7.3 {18.5} 7.3 {18.5} 7.3 {18.5} 7.3 {18.5}

Outlet/inlet tube size OD 2.5 2.5 2.5 2.5 2.5

Weight lbs {kg}

Installed 225 {102} 225 {102} 240 {109} 310 {141} 340 {155}

Voltage†Total Amps

208 V/3 phase/60 Hz 6.6 7.5 10.1 18.2 NA

240 V/3 phase/60 Hz 5.7 6.5 8.8 15.8 25.3

400 V/3 phase/50 Hz 3.5 3.9 5.4 9.5 14

480 V/3 phase/60 Hz 2.8 3.2 4.4 7.9 11.7

575 V/3 phase/60 Hz 2.4 2.7 3.7 6.6 9.7

Total kilowatts kw {BTU/min} 2.2 {125} 2.5 {142} 3.4 {193} 6.1 {347} 9.0 {512}

Water requirements {for optional aftercooler or precooler}

Recommended temperature* 45

°

- 85°F 45°- 85°F

Water flow gal./min.{liters/min.} 1 {3.8} 2 {7.6}

Water connections NPT 1/2 inch NPT

SPECIFICATION NOTES:

*

SCFM stands for standard cubic feet per minute, referenced to a pre-specified pressure, temperature and relative humidity.In most

cases, SCFM is referenced to 14.7 PSIA 68° F and 0% relative humidity.ACFM stands for actual cubic feet per minute, and must be

supplied with a temperature reference, due to the change in air density with temperature.Because dryers operate at a relatively low

pressure the effects on air density are negligible.

†

Dryers running at 50 HZ will have 17% less airflow, and a 17% reduction in material throughput.

Specifications may change without notice. Consult a Conair representative for the most current information.

D

A

C

B

Page 21

Description l 2-7

2

Description

Specifications: D Carousel (continued)

7/16 inches {1.1 cm}

diameter

4 inches

{10.2 cm}

square

1 inch {2.5 cm}

diameter

3 inches {7.6 cm} square

6 inches

{15.2 cm}

square

7/16 inches {1.1 cm}

diameter

5 inches {12.7 cm} square

2 inches {5.1 cm}

diameter

Standard Base Plate

IB02

Optional Base Plate

IB01

(for mounting CH10

and CH14 hoppers

independent of dryer

only)

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

OPTIONAL HOPPERS AND MOUNTING BRACKET

MOUNTING PATTERNS

▲

▲

HOPPER MODEL CH10-0.5 CH10-1 CH10-1.5 CH14-2 CH14-3 CH14-4

Hopper / Mounting Frame Dimensions inches {cm}

A - Insulated hopper diameter 12.5 {13.8} 12.5 {31.8} 12.5 {31.8} 17 {43.2} 17 {43.2} 17 {43.2}

B - Overall height 32 {81.3} 43 {109.2} 54 {137.2} 45 {114.3} 56 {142.2} 67 {170.2}

C - Base plate, square 7.5 {19} 7.5 {19} 7.5 {19} 6.5 {16.5} 6.5 {16.5} 6.5 {16.5}

D - Width with insulated hopper 39 {99.1} 39 {99.1} 39 {99.1} 41 {104.1} 41 {104.1} 41 {104.1}

Volume ft3{liters} 0.5 {9.4} 1 {28.3} 1.5 {42.5} 2 {56.6} 3 {85} 4 {113.2}

Capacity lb {kg} @40 lb/ft

3

20 {9.0} 40 {18.1} 60 {27.2} 80 {36.3} 120 {54.4} 160 {72.5}

Mounting Frame Weight lb {kg} 30 {13.6} 30 {13.6} 30 {13.6} 35 {15.9} 35 {15.9} 35 {15.9}

Hopper Weight lb {kg}

Insulated 40 {18.1} 50 {22.7} 70 {31.7} 80 {36.32} 95 {43.1} 110 {48.9}

HOPPER MODEL CH18-4 CH18-6 CH24-8 CH24-12 CH24-15

Hopper / Mounting Frame Dimensions inches {cm}

A - Insulated hopper diameter 21 {53.3} 21 {53.3} 27 {68.58} 27 {68.58} 27 {68.58}

B - Overall height 48 {121.9} 68 {172.7} 64 {162.6} 79 {200.7} 90 {228.6}

C - Base plate, square 6.5 {16.5} 6.5 {16.5} 6.5 {16.5} 6.5 {16.5} 6.5 {16.5}

D - Width 47.63 {121.0} 47.63 {121.0} 47.63 {121.0} 50.63 {128.6} 50.63 {128.6}

Volume ft3{liters} 4 {113.3} 6 {169.9} 8 {226.5} 12 {339.8} 15 {424.8}

Capacity lb {kg} @40 lb/ft

3

160 {72.5} 240 {108.9} 320 {145.1} 480 {217.7} 600 {272.2}

Mounting Frame Weight lb {kg} 50 {22.7} 50 {22.7} 70 {31.7} 70 {31.7} 70 {31.7}

Hopper Weight lb {kg}

Insulated 145 {66} 165 {75} 210 {95} 235 {107} 255 {116}

D

B

A

C

Page 22

2-8 l Description

Page 23

Installation

Unpacking the boxes. . . . . . . . . . . . . . . . . 3-2

Preparing for installation. . . . . . . . . . . . . . 3-4

Mounting the dryer and hopper on a

processing machine . . . . . . . . . . . . . . 3-6

Positioning the dryer on the floor;

mounting the hopper on the throat . . . . . 3-8

Mounting the hopper. . . . . . . . . . . . . . . . . 3-9

Positioning the dryer on the floor . . . . . . . . 3-9

Mounting the dryer on the floor stand;

hopper on the throat . . . . . . . . . . . . . 3-10

Mounting the dryer and hopper on the mobile

floor stand . . . . . . . . . . . . . . . . . . . 3-10

Connecting the main power . . . . . . . . . . . 3-10

Checking for proper air flow . . . . . . . . . . . 3-12

Connecting the air hoses . . . . . . . . . . . . . 3-15

Connecting the water hoses . . . . . . . . . . . 3-15

Connecting the RTD probe . . . . . . . . . . . . 3-16

Connecting the Optional Setback RTD . . . . . 3-16

Mounting a loader on the hopper . . . . . . . . 3-17

Testing the installation . . . . . . . . . . . . . . 3-17

SECTION

3

3

Installation

Installation l 3-1

Page 24

3-2 l Installation

Unpacking the Boxes

The D carousel dryer comes in one to four boxes, depending on the model and

options ordered. The boxes could include (depends on options selected):

1 Carefully remove the dryer and components from their shipping containers,

and set upright. Note that the dryer is secured to its shipping container with

four bolts that pass through the bottom of the dryer frame. These bolts are

accessed by removing the side panels of the dryer.

2 Remove all packing material, protective paper, tape, and plastic, including any

inserted in the top section of the dryer. Be sure to remove the side panels from

the dryer and cut and remove three (3) tie wraps securing the bedplates. Also

cut and remove the tie wrap on the bedplate limit switch.

3 Carefully inspect all components to make sure no damage occurred during

shipping, and that you have all the necessary hardware.

Mounting

Hardware:

Floor stand option:

❒four 5/16-18 self-locking

bolts

❒four hose clamps

Support frame option:

❒eight 3/8-16 self-locking

bolts

❒four 5/16-18 self-locking

bolts

❒four hose clamps

NOTE: You must posi-

tion the dryer on the

floor or mount it to a

floor stand if your pro-

cessing machine throat

opening is 1 inch (2.54

cm) diameter or small-

er and requires a 3x3

inch (7.6x7.6 cm) or

smaller bolt pattern.

✐

RTD Probe

Hoses

D Carousel Dryer

Hopper

Support Frame

Mobile Floor Stand

Frame

with Casters

Slide Gate

Page 25

Installation l 3-3

Unpacking the Boxes (continued)

4 Take a moment to record serial numbers and electrical power specifications

in the blanks provided on the back of the the User Guide’s title page. The information will be helpful if you ever need service or parts.

5 You are now ready to begin installation.

Follow the preparation steps on the next page, then choose one of the four

mounting options:

• Dryer and hopper on the processing machine throat using the optional

support frame (see page 3-6).

• Dryer on the floor; hopper on the throat (see page 3-8).

• Dryer and hopper on a mobile floor stand (MDC mounting, see

Appendix B).

• Dryer on a floor stand; hopper on the throat (see Appendix B).

3

Description

Page 26

12 in. (30.48 cm)

needed to remove

optional aftercooler

coil for cleaning

3 in. (7.62 cm)

3 in. (7.62 cm)

Regeneration exhaust

high temperature

6 in. (15.24 cm)

6 in. (15.24 cm)

needed to change

filter

D-75 & D-100

Minimum

Clearance

6 in. (15.24 cm)

12 in. (30.48 cm)

needed to remove

optional aftercooler

coil for cleaning

3 in. (7.62 cm)

3 in. (7.62 cm)

Regeneration exhaust

high temperature

6 in. (15.24 cm)

needed to change

filter

D-15, D-25 & D-100

Minimum

Clearance

3-4 l Installation

Preparing for Installation

The D carousel dryer is easy to install if you plan the location and prepare the

mounting area properly.

1 Make sure the mounting area provides:

❒❒

A grounded power source supplying the correct current for your dryer

model. Check the dryer’s serial tag for the correct amps, voltage, phase, and

cycles. Field wiring should be completed by qualified personnel to the

planned location for the dryer. All electrical wiring should comply with your

region’s electrical codes.

❒❒

A source of water, if you have an aftercooler and / or precooler.

The D dryer’s optional aftercooler and precooler can use 1-2 gals./min. (3.8-

7.6 liters/min.) tower, city, or chiller water at temperatures of 40° to 85°F

(4° to 29°C). Pipe should be run to the planned dryer location. Use flexible

hose to connect the water pipes to the aftercooler and precooler. If the dryer

has an optional flow control, see Appendix D for connection information.

❒❒

Minimum clearance for safe operation and maintenance.

You should maintain 24 in. (61 cm) clearance on at least three sides of the

dryer. If the dryer is mounted with a hopper on a processing machine throat,

clearance between the dryer and hopper can be 4 in. (10.2 cm).

Page 27

Installation l 3-5

6 inches

(15.24 cm)

square

5 inches

(12.7 cm)

square

7/16 inches

(1.11 cm)

diameter

2 inches

(5.08 cm)

diameter

4 inches

(10.16 cm)

square

3 inches

(7.62 cm)

square

7/16 inches

(1.11 cm)

diameter

1 inch

(2.54 cm)

diameter

NOTE: If your mounting

surface does not match

the standard bolt patterns available, you will

need an adapter. You

can make an adapter

using the dimensions

provided or purchase

one from Conair.

❒❒

A mounting surface that will support the weight of the dryer, support

frame, and a fully-loaded hopper, or just the fully-loaded hopper. See the

specifications tables for weights and volumes.

❒❒

Material and conveying lines installed. If you plan to use vacuum or

compressed air loaders to fill the hopper, install conveying lines to the drying

hopper location.

2 Drill and tap mounting holes or make adapter.

Available discharge assemblies and slide gates fit mounting surfaces with

these bolt patterns and diameters.

3

Description

✐

Preparing for Installation (continued)

Page 28

Mounting the Dryer and Hopper on

a Processing Machine

WARNING: You are responsible for the structural integrity of this installation.

We recommend that you:

❒❒

Use bolts no smaller than 3/8 inch (M 10) when mounting the

hopper/dryer combination to the throat of a processing machine.

❒❒

Do not mount the hopper/dryer combination on a plate that swings

away or slides away from the processing machine throat. Either

remove the swing or slide plate, position the dryer on the floor, or

mount the dryer to an optional floor stand.

The dryer and hopper mount on a support frame / discharge assembly that bolts to

the throat of the processing machine, as pictured above.

CAUTION: To prevent accident and injury, lift the empty hopper and support frame

onto the throat of the processing machine using a hoist and the lifting lugs provided. After the hopper is mounted, then lift the dryer onto the support frame using a

hoist and the lifting lugs provided.

Tools for installation:

❒ Flathead screwdriver

❒ 9/16” and 1/2” wrench

❒ Hoist

NOTE: You must position the

dryer on the floor or mount it to

an optional floor stand if your

processing machine throat

requires the small discharge

assembly or a mounting plate

with less than a 3 x 3 in.

(7.6 x 7.6 cm) bolt pattern and

1 in. (2.54 cm) diameter open-

ing.

✐

3-6 l Installation

Page 29

3

Description

Mounting the Dryer and Hopper on

a Processing Machine (continued)

The drying hopper, slide gate, support frame, and discharge assembly may have

been shipped fully assembled. You can remove the hopper from the support frame,

if you find it easier to lift and bolt the frame and then the hopper to the throat of

the processing machine.

1 Lift the hopper, support frame, and discharge assembly onto the process-

ing machine throat. Use a hoist to lift the support frame and hopper. Position

the frame and discharge assembly so that its bolt holes line up with the holes

drilled in the throat. If hole patterns do not match, you can place a mounting

adapter between the throat and the support frame.

2 Bolt the frame and discharge assembly to

the throat. Using four 3/8 in. -16 (M 10)

self-locking bolts, fasten the support frame

and discharge assembly to the throat. The

bolts must be long enough to reach at least

1/2 in. (1.25 cm) into the processing

machine throat or mounting adapter after

passing through the discharge assembly and

support frame.

NOTE: If you removed the hopper from the support frame, lift the hopper onto the frame using

a hoist. Make sure the slide gate is positioned

in the recess on the bottom of the hopper base

plate. Align the bolt holes and fasten the base

plate to the discharge assembly using the four

3/8 in. -16 (M 10) self-locking bolts

provided.

3 Lift the dryer onto the support

frame using a hoist and the lifting

lugs provided. Align the four bolt

holes on the bottom of the dryer

with the four bolt holes on the top

of the support frame. Fasten the

dryer to the frame with 5/16 in. -18

bolts.

✐

Installation l 3-7

Page 30

Positioning the Dryer on the Floor;

Mounting the Hopper on the Throat

WARNING: You are responsible for the structural integrity of this installation.

We recommend that you:

• Use bolts no smaller than 3/8 in. (M 10) to mount the hopper on the throat of

a processing machine.

The hopper bolts to the throat of the processing machine, as pictured above.

The dryer can be positioned on the floor near the processing machine.

3-8 l Installation

Tools for installation:

❒ 9/16” wrench

❒ Flathead screwdriver

❒ Hoist

Page 31

Installation l 3-9

3

Description

Mounting the Hopper

CAUTION:

To prevent accident and injury, lift the empty hopper onto the throat of

the processing machine using a hoist and the lifting lugs provided. Also lift the dryer from

the shipping container using a hoist and the lifting lugs provided.

1 Lift the hopper onto the throat. Lift the hopper with a hoist, using the lifting

lugs provided. Make sure you align the bolt holes in the throat with the bolt

holes on the discharge assembly.

2 Bolt the hopper to the throat of

the machine. Using four 3/8 in.-16

(M 10) self-locking bolts, fasten

the support frame, discharge, and

slide gate to the throat. The bolts

must be long enough to reach at

least 1/2 in. (1.25 cm) into the

mounting adapter or processing

machine throat, after passing

through the discharge and slide

gate.

Positioning the

Dryer on the

Floor

1 Lift the dryer from the shipping

container using a hoist and the lifting

lugs provided.

2 Position the dryer on the floor near

the processing machine. Make sure

the location allows for the connection

of all hoses.

Page 32

3-10 l Installation

Mounting the Dryer on the Floor

Stand; Hopper on the Throat

For information about mounting the dryer on the floor stand and the hopper on the

throat, refer to Appendix B.

Mounting the Dryer and Hopper on

the Mobile Floor Stand

For information about mounting the dryer and hopper on the mobile floor stand,

refer to Appendix B.

Connecting the Main Power

CAUTION: Always disconnect and lock out the main power sources before making

electrical connections. Electrical connections should be made only by qualified

personnel.

1 Open the dryer’s electrical enclo-

sure. Turn the disconnect dial on the

dryer door to the Off or O position.

Lock out the main power (see Page

1-4 for complete lock out information). Turn the captive screw, and

swing the door open.

2

Insert the main power

wire

through the knockout in the side of

the enclosure. Secure the wire with

a rubber compression fitting or

strain relief.

Page 33

Installation l 3-11

3

Description

IMPORTANT: Always refer to the

wiring diagrams that came with

your dryer before making electrical connections.

3

Connect the power wires

to the three terminals at the top of the power discon-

nect holder.

4 Connect the ground wire to either grounding point as shown in the photo.

Connecting the Main Power (continued)

Page 34

Checking for Proper Air Flow

This step is only needed on 50, 75, and 100 models if the phase detection option

was not ordered with the dryer.

CAUTION: This step must be performed before the dryer’s air hoses are connected

to the hopper. Performing this step after the air hoses are connected could cause

damage to the dryer if the air flow direction is incorrect due to improper phase

connection. Material from the hopper can be pulled into the process heater,

causing permanent damage.

1 Turn on the main power to the dryer. Make sure the dryer’s disconnect dial is

in the ON position. This powers up the control and the display lights will illuminate.

2 Set the drying temperature. Press Setpoint Adjust ▲or ▼ buttons to set the

temperature.

3-12 l Installation

Set Point Actual

1 Process T emp.

2 Regen. T emp.

3 Return Air T emp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback T emp.(Pr ocess)

8 Setback Load Rate

9 PM1 Dewpoint

Shutdown Alarms

A1 Process High T emp.

A2 Process Loop Break

A3 Process Heater High T emp.

A4 Regen. Heater High T emp.

A5 Carousel Index Too Long

A6 Carousel Index Failure

A7 Return Air High T emp.

Passive Alarms

P1 Process T emp. Deviation

P3 Regen. T emp. De viation

P5 Return Air High T emp.

Auto Start

Desiccant Indexing

Set-Back Temp.

Process Blower

Process Pressure

Process Heater

Regen. Blower

Regen. Pressure

Regen. Heater

Central

When configured as a central dryer, the drying temperature can

not be set since there is no process heater in the system.

Page 35

Checking for Proper Air Flow (continued)

3 Press the START button. Hold your hand near the delivery

air outlet. You should feel air blowing out of the outlet.

4 Press the STOP button.

Start

Installation l 3-13

Stop

Moisture

exhaust

Delivery air outlet

(15, 25, and 50

models)

Return

Air Inlet

Delivery air

outlet (75 and

100 models)

Return

Air Inlet

Moisture

exhaust

CAUTION: Hot surface Do not place your hand on the delivery air outlet.

The outlet and the air can get hot enough to burn your hand.

3

Description

Page 36

Checking for Proper Air Flow (continued)

INSTALLATION NOTE: Models 50, 75, and 100

These models use a three-phase process blower. If the dryer shuts down and a Process

Loop Break shutdown alarm is indicated within the first few minutes of operation, check

for proper air flow.

If the air flow is reversed, the process blower is turning in the wrong direction.

Turn off and lock out the main power source. Open the electrical enclosure and

reverse any two leads connecting the main power supply to the dryer.

WARNING: All wiring, disconnects, and fuses should be installed by qualified

electrical technicians in accordance with electrical codes in your region. Always

maintain a safe ground. Do not operate the equipment at power levels other than

what is specified on the the machine serial tag and data plate.

✐

3-14 l Installation

Page 37

3

Description

Installation l 3-15

Connecting the Air Hoses

Using the two flexible hoses provided, connect the inlets and outlets of the drying hopper to the dryer. If you have positioned the dryer on the floor or mounted it to an optional floor stand, make sure the dryer is located no more than 5

feet (1.5 m) from the hopper to reduce heat loss.

If you ordered an insulated hose, it should be installed between the dryer outlet

and the hopper inlet.

If you have ordered an optional

aftercooler or precooler, see

Appendices C

and E.

1 Attach the hose to the return

air outlet at the top of the

hopper labeled “From Hopper”.

2 Attach the hose to the hopper’s

delivery air inlet labeled “To

Hopper”.

3

Secure hoses with clamps.

The hose clamp should be secured at

least 1/4 in. (0.64 cm) from the end of

the inlet or outlet tube.

Connecting the Water Hoses

The optional aftercooler, flow control, and precooler require a source of cooling

water and a discharge or return line. See Appendix C for information on installing

and connecting water hoses to the optional aftercooler. See Appendix D for information on installing and connecting water hoses to the optional flow control. See

Appendix E for information on installing and connecting water hoses to the optional precooler.

NOTE: Do not allow the

flexible hoses to kink or

crimp.

✐

Delivery air

outlet (75 and

100 models)

Return

Air Inlet

Delivery air outlet

(15, 25, and 50

models)

Return

Air Inlet

Page 38

Connecting the RTD Probe

The RTD probe monitors the temperature of the drying air as it enters the hopper.

If the probe is not installed correctly, temperature readings will be inaccurate.

1 Insert the probe at the inlet to the

hopper. The end of the probe must not

touch the walls of the inlet. The tip of the

probe should be approximately in the center of the tube. Tighten the nuts to lock the

probe in place.

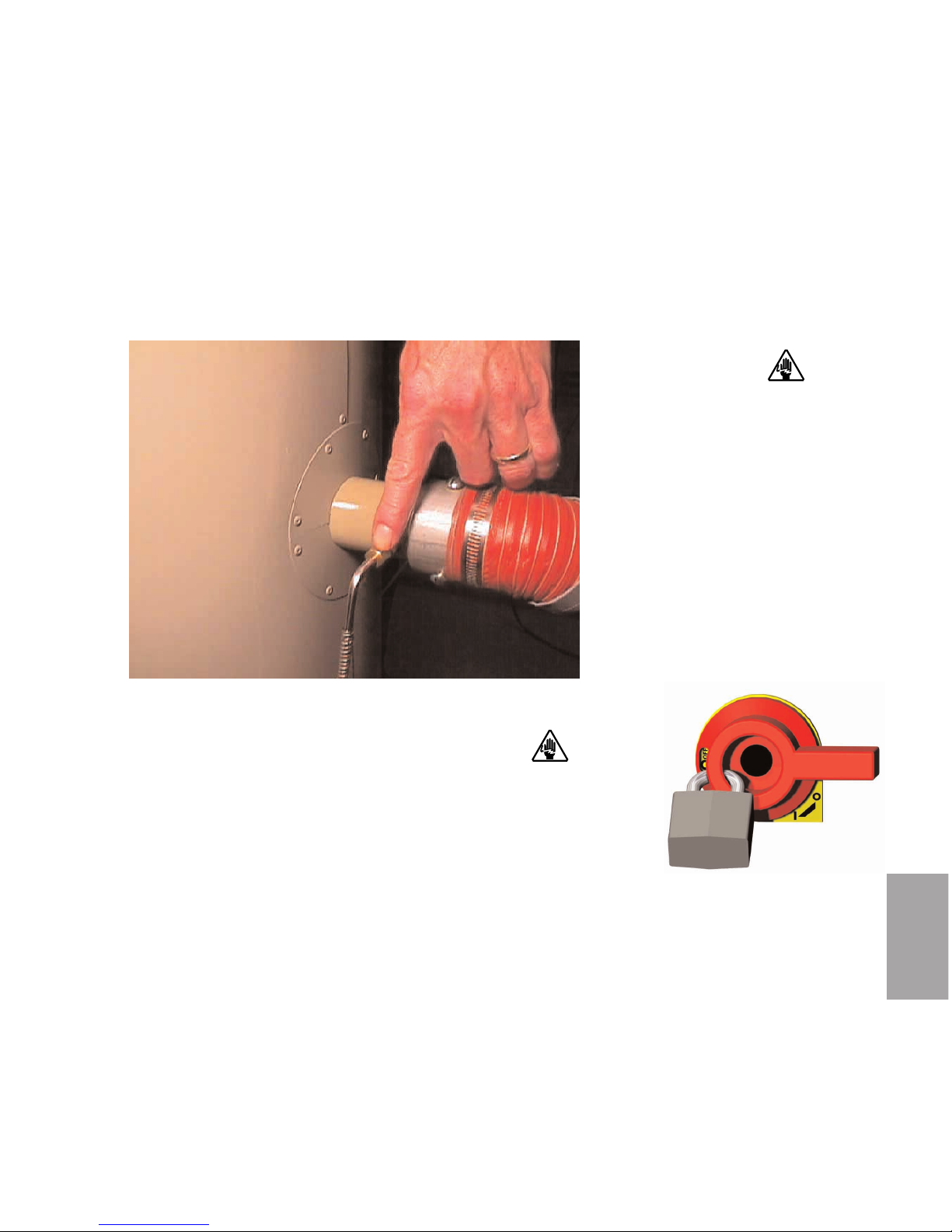

2 Plug the probe’s

cable into the receptacle on the left side

of the electrical

enclosure. Hand

tighten the connector.

Coil any excess cable

and secure it with a

wire tie.

Connecting the Optional Setback

RTD

1 Insert the probe in the hopper outlet at the top of the hopper. The end of the

probe must not touch the walls of the inlet. The tip of the probe should be

approximately in the center of the tube. Tighten the nuts to lock the probe in

place.

2 Plug the probe’s cable into the receptacle on the left side of the electrical

enclosure. Hand tighten the connector. Coil any excess cable and secure it

with a wire tie.

3-16 l Installation

Central

When configured as

a central dryer, monitoring the drying air

temperature is not

necessary since there

is no process heater

in the system.

Therefore, installation and connection

of this RTD probe is

not applicable.

Process RTD

Setback RTD

(Optional)

Page 39

3

Description

Installation l 3-17

Mounting a Loader on the Hopper

If you have a Conair loader or vacuum receiver, you can

use the flange and mounting clips provided on the top of

the hopper. Refer to the manuals that came with your

receiver or loader for detailed installation instructions.

Testing The Installation

You have completed the installation. Now it’s time to make

sure everything works.

1 Make sure there is no material in the hopper. If you

have mounted a loader or vacuum receiver on the hopper, disconnect the material inlet hose at the source.

2 Turn on the main power to the dryer. Make sure the

dryer’s disconnect dial is in the ON position. This powers up the control and the display lights will illuminate.

3 Set the drying temperature. Press the Setpoint Adjust ▲or ▼ buttons to set

the temperature.

(continued)

Central

When configured as a central dryer, the drying temperature can

not be set since there is no process heater in the system.

Set Point Actual

1 Process T emp.

2 Regen. T emp.

3 Return Air T emp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback T emp.(Pr ocess)

8 Setback Load Rate

9 PM1 Dewpoint

Shutdown Alarms

A1 Process High T emp.

A2 Process Loop Break

A3 Process Heater High T emp.

A4 Regen. Heater High T emp.

A5 Carousel Index Too Long

A6 Carousel Index Failure

A7 Return Air High T emp.

Passive Alarms

P1 Process T emp. Deviation

P3 Regen. T emp. De viation

P5 Return Air High T emp.

Auto Start

Desiccant Indexing

Set-Back Temp.

Process Blower

Process Pressure

Process Heater

Regen. Blower

Regen. Pressure

Regen. Heater

Page 40

Testing The Installation(continued)

4 Press the START button.

If everything is installed correctly:

• The green light on the start button will illuminate.

• The process and regeneration blowers turn on.

• The process and regeneration heaters turn on.

• If the desiccant tanks are not in their correct position, the carousel will

turn clockwise and stop in the correct position.

5 Press the STOP button.

If everything is installed correctly:

• The blowers will continue running as needed to cool the heaters.

6 The test is over. If the dryer performed the normal operating sequences as out-

lined, you can load the hopper and begin operation. If it did not, refer to the

T

ROUBLESHOOTING

section of the User Guide.

Stop

Start

3-18 l Installation

Central

• The regeneration heater turns on.

Page 41

SECTION

4

4

Operation

Operation

T he DC-1 dryer control panel . . . . . . . . . . . 4-2

D dryer DC-1 control functions . . . . . . . . . . 4-3

Control function flow chart . . . . . . . . . . . . 4-3

Control function descriptions . . . . . . . . . . . 4-5

To start drying . . . . . . . . . . . . . . . . . . . . 4-17

To stop drying . . . . . . . . . . . . . . . . . . . . 4-18

Using the auto start countdown function . . . 4-19

How to enable the auto start on the DC-1

conrtol . . . . . . . . . . . . . . . . . . . . . . 4-19

How to disable the auto start on the DC-1

control . . . . . . . . . . . . . . . . . . . . . . 4-19

Setting high and low setpoint limits . . . . . . 4-20

Operation l 4-1

Page 42

The DC-1 Dryer Control Panel

4-2 l Operation

Set Point Actual

1 Process T emp.

2 Regen. T emp.

3 Return Air T emp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback T emp.(Pr ocess)

8 Setback Load Rate

9 PM1 Dewpoint

Shutdown Alarms

A1 Process High T emp.

A2 Process Loop Break

A3 Process Heater High T emp.

A4 Regen. Heater High T emp.

A5 Carousel Index Too Long

A6 Carousel Index Failure

A7 Return Air High T emp.

Passive Alarms

P1 Process T emp. Deviation

P3 Regen. T emp. De viation

P5 Return Air High T emp.

Auto Start

Desiccant Indexing

Set-Back Temp.

Process Blower

Process Pressure

Process Heater

Regen. Blower

Regen. Pressure

Regen. Heater

Start and Stop

Buttons

Press Start to start the dryer.

Press Stop to stop the dryer.

Increment/

Decrement Buttons

Used to increase or

decrease values.

Acknowledge

Alarm Button

Press once to silence the

optional audible alarm and

display alarm messages.

Press again to clear the

alarm.

Actual

Display

Shows the actual

temperature value.

Set Point

Display

Shows the set

point value.

Menu List

Numbers 1, 2, 3, and 4 are standard items that will

always be present. Numbers 5, 6, 7, 8, and 9 are

screens associated with options. If the option is not

installed the screen will not be displayed.

Alarm

Codes

See

“Troubleshooting”

Section 6 for a

more complete

listing of alarm

codes.

Scroll Button

Press to scroll

through the

closed loop menu

list. Pressing the

scroll button

moves you down

the list.

Menu

Number

Display

Displays the

menu number

corresponding to

what is shown in

the set point and

actual displays.

Can also display

letters for alarm

and setup screens.

Central

Menu List

Numbers 2, 3, and 4 are standard items that will

always be present. Number 9 is a screen associated

with an option. If the option is not installed, the

screen will not be displayed.

Page 43

D Dryer DC-1 Control Functions

Dryer functions are values that you can set or monitor. Press the Scroll button until

the function you want to set or monitor appears in the LED display.

Note: Grey shaded screens denote optional functions. If the options were not purchased

with the dryer, those screens will not appear. All options can be purchased and installed

in the field.

Control Function Flow Chart

The following flow chart provides a quick summary of the control functions. For

an explanation of each control function, see Control Function Description.

Operation l 4-3

4

Operation

✐

Page 44

4-4 l Operation

POWER ON

screen #

1

Pr up

5 sec

2

d25

5 sec

3

C v00 09.5

1 sec

4

d v00 01.0

1 sec

5

1 250 250

Process Temp Default Screen

6

2 425 425

Regen Temp

7

3 100 100

Return Air Temp

8

416On

Auto Start

9

5 10 -----

Load Time (MDC)

10

6 150 120

Activate Setback Temp (Option)

11

7 145 250

Setback Temp Process (Option)

12

857

Setback Load Rate (Option)

13

9-30-40

Dewpoint Monitor or PM1 (Options)

14

00

Password Screen

754 755 756

15

C10C01

28

Hoff 1

44

A1P3

16

C 400 C02

29

H

off 2

44

A1A1

17

CoffC03

30

Hoff 3

44

A1A5

18

C 425 C04

31

Hoff 4

44

A1A4

19

CoffC05

32

Hoff 5

44

A1P1

20

C10C06

33

Hoff 6

44

A1P5

21

CtimC07

34

Hoff 7

44

A1A1

22

C20C08

35

Hoff 8

44

A1A7

23

CoffC09

36

Hoff 9

44

A1A2

24

CoffC10

37

Hoff 10

44

A1A6

25

CoffC11

38

Hoff 11

26

CoffC12

39

Hoff 12

27

CoffC13

40

Hoff 13

41

Hoff 14

42

Hoff 15

43

Hoff 16

Setup

Access Code

Test Mode

Access Code

Alarm

History

Access Code

Central

5

1

CNT

DRY

Central

When supplied for central

drying applications, these

control functions are not

available.

Page 45

Once power is turned on, this screen is displayed for 5 sec. while the control does

some self-checking.

Once power is turned on and screen 1 is

displayed for 5 sec., this screen is displayed for another 3 sec. It shows the

dryer model number for which the control

is configured.

After the model number is displayed, this

screen flashes for 1 sec. and displays the

control board software version.

After the control versions is shown, the

screen flashes again for 1 sec. and displays

the display board software version.

This is the DEFAULT screen. It shows the

process air temperature setpoint and actual

temperature measured at the inlet to the

drying hopper. The + / - buttons can be

used to change the setpoint. Holding the +

/ - buttons in will cause the number to

ramp up faster the longer the button is

held. The display will return to the default

screen from anyplace in the menu structure

if nothing is done after 10 min.

Indicates configuration as a central dryer.

Shows the regeneration air setpoint and

actual temperature. The setpoint can not be

changed from this screen; it is shown only

as a reference.

4

Operation

Operation l 4-5

Screen

SCREEN 1

SCREEN 2

SCREEN 3

SCREEN 4

SCREEN 5 (Default Screen)

SCREEN 5 (Default Screen)

SCREEN 6

Pr

Function

Control Function Descriptions

up

d

25

v00

09.5

C

v00

01.0

d

250

250

1

425

425

2

CNT

DRY

1

Central

Page 46

Screen

SCREEN 7

SCREEN 8

SCREEN 9 (MDC Option)

100

Function

Control Function Descriptions

(continued)

This screen shows the actual return air

temp measured at the inlet to the process

blower. If the optional aftercooler flow

control is installed, a setpoint will be displayed on this screen as well. The + / buttons can be used to change the set

point. Holding the + / - buttons in will

cause the number to ramp up faster the

longer the button is held.

This screen is used to set the dryer to auto

start. The dryer must be on but not running to set auto start. The value shown is

the countdown time setpoint. It is

adjustable from 0.1 hrs. to 150 hrs. Once

the countdown time is set, press the RUN

button. The display will show ON to tell

the operator that the auto start is ON and

counting. The auto start LED on the display also flashes green when the auto start

is armed and counting down. The LED

will turn solid green when the dryer starts.

The dryer will begin operating when the

control has finished counting down.

This screen shows the amount of time the

conveying blower will run. Based on the

position of the demand sensor in the material receiver, this time may need adjusted.

The time should be set for the time it takes

to satisfy the demand sensor + 1 sec. If

the MDC tries to load 3 times without satisfying the demand signal the dryer will

display a passive alarm. The range for this

time setting is 5 to 20 sec.

100

3

16

On

4

10

-----

5

4-6 l Operation

Central

When supplied for

central drying applications, this function

is not available.

Page 47

Screen

SCREEN 10 (Setback

Temperature Option)

SCREEN 11 (Setback Options)

SCREEN 12 (Setback Load Rate

Option)

Function

Control Function Descriptions

(continued)

If the dryer has the setback on temperature

option installed, this is the temperature

setpoint for the air at the outlet of the drying hopper. When this setpoint is reached,

the dryer will automatically change the

process setpoint to the setpoint shown on

Menu number 7, Screen 11. When the

temperature at the outlet of the hopper

drops below the setpoint (menu number 6)

by the value shown under C07, screen 22,

the dryer will return to the normal drying

setpoint.

If the dryer has the setback on temperature

option installed, this is the temperature setpoint to which the process air will revert

once the air at the outlet of the hopper has

reached its setpoint. (Menu number 6)

If the dryer has the optional setback on

load rate option, this screen shows the

number of load dumps per hour, setpoint

and actual. When the actual drops below

the setpoint the dryer will go into setback

mode. When the actual goes above the setpoint, the dryer will return to the normal

process temperature.

150

120

6

145

250

7

5

7

8

Operation l 4-7

4

Operation

Central

When supplied for

central drying applications, these functions

are not available.

Page 48

Screen

SCREEN 13 (PM1 and/or DEWPOINT MONITOR Options)

SCREEN 14

Function

Control Function Descriptions

(continued)

If the dryer has the dewpoint monitor

option installed, this screen will show the

actual dewpoint of the process delivery air

measured after the desiccant tank in the

process position but before the process

heater. If the Power Miser 1 (PM1) option

is installed, there will also be a setpoint

shown on this screen. Although the dryer

is capable of producing dewpoints much

lower than -40

°F (-40°C), the minimum

sensor range is -40°F (-40°C). The PM1

option (when set to index on dewpoint)

will monitor the dewpoint of the process

air and not index a new tank into the

process position until the dewpoint reaches

the entered setpoint. After the normal

regeneration cycle is complete, the regeneration heaters and regeneration blower

will turn off and wait for the dewpoint to

reach setpoint before turning on again.

This saves energy by only regenerating

when you need to if your material is not

that wet. The maximum time it will wait

to index is 2 hr.

This is the password entry screen that

gives the user access to the Set Up, Test

Mode, and Alarm History screens and also

password protected control functions. The

user can get to the non-password protected

control functions through this screen by

pressing the scroll button and the - button

at the same time. This works only if you

are on menu #1 . (default screen). The

access codes are as follows:

Set Up Screens 754

Test Mode Screens 755

Alarm History Screens 756

To exit the password section, enter 500 and

press scroll.

-30

-40

9

0

0

4-8 l Operation

Page 49

Screen

Screens 15-27 require access

code 754.

SCREEN 15 (Set up Screen)

SCREEN 16 (Set up Screen)

SCREEN 17 (Set up Screen)

SCREEN 18 (Set up Screen)

SCREEN 19 (Set up Screen)

Function

Control Function Descriptions

(continued)

This is the process deviation temperature

screen. The range is 5 - 20°F (-15.0 -

-6.7°C). This is the deviation temperature

band around the set point. If the dryer

goes outside this band, the dryer will display a passive alarm (P1).

This is the process high temperature

screen. This is the high temperature limit.

If the process temperature reaches this setpoint, the dryer will shutdown on alarm

A1.

This is the process heater autotune screen.

The autotune function can be turned on by

pressing the + key. Once the + key is

pressed, the screen will show On and then

start the autotune process. This may take a

minute or so to complete. When finished,

the display will read "don". The new PID

values are automatically saved.

This is a regeneration temperature screen.

This is the regeneration heater autotune

screen. The autotune function can be

turned on by pressing the + key. Once the

+ key is pressed, the screen will show On

and then start the autotune process. This

may take a minute or so to complete.

When finished the display will read "don".

The new PID values are automatically

saved.

400

C02

C

off

C03

C

425

C04

C

10

C01

C

off

C05

C

Operation l 4-9

4

Operation

Central

When supplied for

central drying applications, these functions are not available.

Page 50

Screen

Screens 15-27 require access

code 754.

SCREEN 20 (Set up Screen)

MDC Option

SCREEN 21 (Set up Screen)

SCREEN 22 (Set up Screen)

Setback Temperature Option

Function

Control Function Descriptions

(continued)

This screen shows the time delay setting

for the conveying blower on the MDC.

This is the minimum time the MDC will

wait before starting another load cycle.

This screen shows how the dryer is set to

index the bedplates, on Time "tim"or

Dewpoint "dew". To have the selection for

indexing on Dewpoint, the PM1 option

must be installed. By pressing the + or keys, the setting can be changed. When the

dryer is set to index on Dewpoint, it will

index on time (20 min.) for the first 3

indexes so that the desiccant tanks have

time to dry out. Then it will index on dewpoint. The regeneration cycle will still be

20 min. If at the end of the 20 min. regeneration cycle the process dewpoint is still

below the setpoint the dryer will turn off

the regeneration blower and heater and

wait for the process dewpoint to reach its

setpoint. If, however, the process dewpoint stays below setpoint for 2 hrs., the

dryer will index automatically.

This screen is the Setback Temperature

Band screen. This temperature is the

amount the return air out of the hopper has

to drop below the activate setback temperature before the original process temperature is restored. For example, if the activate setback temperature was 180

°F

(82.2°C) and the dryer was in setback. The

actual temperature measured at the outlet

to the hopper would have to drop below

160

°F (71°C)to restore the original process

setpoint.

tim

C07

C

20

C08

C

10

C06

C

4-10 l Operation

Central

When supplied for

central drying applications, this function

is not available.

Central

When supplied for

central drying applications, this function

is not available.

Page 51

Screen

Screens 15-27 require access

code 754.

SCREEN 23 (Set up Screen)

Aftercooler Flow Control Option

SCREEN 24 (Set up Screen)

Setback Temperature Option

SCREEN 25 (Set up Screen)

Setback Load Rate Option

Function

Control Function Descriptions

(continued)

This screen is the Aftercooler Flow

Control Enable screen. By pressing the +

or - keys, the setting can be changed. With

this off or disabled, the dryer will not open

the flow control valve and try and control

the return air temperature. There will also

be no set point value on Menu number 3,

Screen 7.

This screen shows the setting of the setback option. It can be set to Off or On.

"Off" turns the setback mode off, and the

dryer will not change the process set point.

"On" tells the control the dryer should go

into setback when the hopper outlet temperature reaches its set point. Menu 6

Screen 10.

This screen shows the setting of the setback load rate option. It can be set to Off

or On. “Off” turns the setback load rate

function off, and the dryer will not change

the process set point. The "On" setting

tells the dryer to go into setback when the

load rate gets to its set number of loads per

hour Menu 8, Screen 12.

(continued next page)

off

C11

C

off

C09

C

off

C10

C

Operation l 4-11

4

Operation

Central

When supplied for

central drying applications, these functions

are not available.

Page 52

Screen

Screens 15-27 require access

code 754.

SCREEN 26 (Set up Screen)

Precooler Option

WARNING: The precooler must NOT

be installed in the process line for

temperature setpoints above 150°F

(65.5°C). The precooler hosing will

absorb too much heat and will result

in poor process temperature control.

SCREEN 27 (Set up Screen)

Precooler Flow Control Option

WARNING: The precooler must NOT

be installed in the process line for

temperature setpoints above 150°F

(65.5°C). The precooler hosing will

absorb too much heat and will result

in poor process temperature control.

Screen 28-43 require access

code 755.

SCREEN 28 (Test Mode Screen)

Function

Control Function Descriptions

(continued)

This screen shows how the precooler is set

to operate. If it is set to "Off" the control

assumes the precooler is not installed in

the process line and will not control well

below 150

°F (65.5°C). If the screen is set

to "On" the control will assume the precooler is connected in the process line and

will only allow setpoints from 100 to

150

°F (37.8 to 65.5°C). The control will

also assume that the water flow rate is set

manually with a ball valve and make no

attempt to control water flow. The precooler option must be installed for this

screen to appear.

This screen shows how the precooler flow

control is set to operate. The precooler

flow control option must be installed for

this screen to appear. If the screen is set to

"On", the control will assume the precooler is installed in the process line and will

only allow setpoints from 100 to 150

°F

(37.8 to 65.5

°C). It will also assume the

water flow solenoid valve is piped in the

water line and the dryer control will regulate water flow to control temperature.

This is the Test Mode screen for the

process blower. By pressing the + or keys, the setting can be changed. When

set to "On", the process blower output will

be turned on for 3 sec. and then shut off

automatically.

off

C13

C

off

1

H

off

C12

C

4-12 l Operation

Central

When supplied for

central drying applications, these functions are not available.

Page 53

Screen

Screen 28-43 require access

code 755.

SCREEN 29 (Test Mode Screen)

SCREEN 30 (Test Mode Screen)

SCREEN 31 (Test Mode Screen)

SCREEN 32 (Test Mode Screen)

SCREEN 33 (Test Mode Screen)

Function

Control Function Descriptions

(continued)

This is the Test Mode screen for the

process heater. By pressing the + or keys, the setting can be changed. When

set to "On", the process heater output will

be turned on for 3 sec. and then shut off

automatically.

Note: The isolation contactor will not be

pulled in so no electricity will go the heater.

The solid state relay contacts should close.

This is the Test Mode screen for the regeneration blower. By pressing the + or keys, the setting can be changed. When

set to "On", the regeneration blower output

will be turned on for 3 sec. and then shut

off automatically.

This is the Test Mode screen for the regeneration heater. By pressing the + or - keys,

the setting can be changed. When set to

"On", the regeneration heater output will

be turned on for 3 sec. and then shut off

automatically.

Note: The isolation contactor will not be

pulled in so no electricity will go the heater.

The solid state relay contacts should close.

This is the Test Mode screen for the bed

drive motor. By pressing the + or - keys,

the setting can be changed. When set to

"On", the bed drive motor output will be

turned on until the limit switch makes the

next valley, and then shut off automatically.

This Test Mode screen is not used in the

current program.

(continued)

off

3

H

off

2

H

✐

off

5

H

off

4

H

✐

Operation l 4-13

4

Operation

off

6

H

Page 54

Screen

Screen 28-43 require access

code 755.

SCREEN 34 (Test Mode Screen)

SCREEN 35 (Test Mode Screen)

SCREEN 36 (Test Mode Screen)

SCREEN 37 (Test Mode Screen)

SCREEN 38 (Test Mode Screen)

Function

Control Function Descriptions

(continued)

This is the Test Mode screen for the isolation contactor. By pressing the + or - keys,

the setting can be changed. When set to

"On", the isolation contactor output will be

turned on for 3 sec. and then shut off automatically.

This is the Test Mode screen for the alarm

output (horn and or red light). By pressing

the + or - keys, the setting can be changed.

When set to "On", the alarm output will be

turned on for 3 sec. and then shut off automatically.

Note: The alarm light on the membrane

switch will not come on. If the optional

alarm horn or red light is not installed,

nothing will happen.

This is the Test Mode screen for the precooler flow control valve. By pressing the

+ or - keys the setting can be changed.

When set to "On" the precooler flow control valve output will be turned on for 3

sec and then shut off automatically.

Note: If the optional precooler flow control

valve is not installed, nothing will happen.

This is the Test Mode screen for the aftercooler flow control valve. By pressing the

+ or - keys, the setting can be changed.

When set to "On", the aftercooler flow

control valve output will be turned on for

3 sec. and then shut off automatically.

Note: If the optional aftercooler flow control

valve is not installed, nothing will happen.

This screen is not used in the current program.

off

8

H

off

7

H

off

10

H

off

9

H

✐

✐

4-14 l Operation

✐

off

11

H

Page 55

Screen

Screen 28-43 require access

code 755.

SCREEN 39 (Test Mode Screen)

SCREEN 40 (Test Mode Screen)

SCREEN 41 (Test Mode Screen)

SCREEN 42 (Test Mode Screen)

SCREEN 43 (Test Mode Screen)

Function

Control Function Descriptions

(continued)

This is the Test Mode screen for the MDC

conveying blower. By pressing the + or keys, the setting can be changed. When

set to "On", the conveying blower output

will be turned on for 3 sec. and then shut

off automatically.