Page 1

Modbus®/TCP

Interface Configuration Quick Start

Page 2

Trademark Notices

Document Number: 2000477 Rev G

Comtrol, DeviceMaster, and PortVision are registered trademarks of Comtrol Corporation.

Concept is a trademark of Schneider Electric.

Modbus is a registered trademark of Schneider Electric.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

SIMATIC and Step7 are registered trademarks of Siemens AG.

Portions of SocketServer are copyrighted by GoAhead Software, Inc. Copyright © 2001. GoAhead Software,

Inc. All Rights Reserved.

Windows is a registered trademark of Microsoft Corporation in the United States and/or other countries.

Other product names mentioned herein may be trademarks and/or registered trademarks of their respective

owners.

Seventh Edition, July 15, 2013

Copyright © 2005-2013. Comtrol Corporation.

All Rights Reserved.

Comtrol Corporation makes no representations or warranties with regard to the contents of this document or

to the suitability of the Comtrol product for any particular purpose. Specifications subject to change without

notice. Some software or features may not be available at the time of publication. Contact your reseller for

current product information.

Page 3

Table of Contents

Overview...................................................................................................................................5

Comtrol Modbus Solutions .......................................................................................................................... 5

Locating the Latest Software and Documentation ............................................................................... 6

Modbus/TCP Installation Overview .......................................................................................................... 7

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters............................9

Prerequisites................................................................................................................................................... 9

Configuring Modbus/RTU Slaves ............................................................................................................. 10

Configuring Modbus/ASCII Slaves .......................................................................................................... 12

Configuring Modbus/RTU Master............................................................................................................ 14

Configuring Modbus/ASCII Master ......................................................................................................... 16

Configuring Read-Only Raw/ASCII Devices ..................................................................19

Prerequisites................................................................................................................................................. 19

Read-Only Raw/ASCII Serial Devices ..................................................................................................... 19

Embedded Web Page Configuration ........................................................................................................ 20

Modbus Raw Data Addressing ................................................................................................................. 25

Received Message Format ........................................................................................................................ 25

Read-Only Raw/ASCII Ethernet Devices ............................................................................................... 26

Embedded Web Page Configuration ........................................................................................................ 27

Modbus Addressing .................................................................................................................................. 33

Received Message Format ........................................................................................................................ 33

Configuring Read/Write Raw/ASCII Devices.................................................................35

Prerequisites................................................................................................................................................. 35

Read/Write Raw/ASCII Serial Devices.................................................................................................... 36

Embedded Web Page Configuration ........................................................................................................ 37

Modbus Addressing .................................................................................................................................. 46

Receive and Transmit Message Formats ................................................................................................ 46

Read/Write Raw/ASCII Ethernet Devices .............................................................................................. 47

Embedded Web Page Configuration ........................................................................................................ 48

Modbus Addressing .................................................................................................................................. 58

Receive and Transmit Message Formats ................................................................................................ 58

Filtering/Data Extraction Configuration .......................................................................61

PLC Filtering/Data Extraction ................................................................................................................. 63

Application Filtering/Data Extraction ................................................................................................... 65

Application Socket Configuration....................................................................................67

Alias Device ID Functionality ...........................................................................................71

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Table of Contents - iii

Page 4

Table of Contents

Troubleshooting and Technical Support........................................................................75

Troubleshooting Checklist ....................................................................................................................... 75

General Troubleshooting........................................................................................................................... 76

Daisy-Chaining DeviceMaster UP 2E/4-Port Units .............................................................................. 77

Technical Support ....................................................................................................................................... 78

iv - Table of Contents DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 5

Overview

This Quick Start is intended to help you quickly set-up serial or Ethernet devices. with the DeviceMaster UP.

You can use this document to locate software and installation documentation for the DeviceMaster UP to

quickly configure:

• Interfaces to serial Modbus/RTU and Modbus/ASCII slaves and masters

• Read-only devices such as barcode scanners and some RFID readers

• Read/write devices such as printers and some weigh scales

Comtrol Modbus Solutions

If you ordered the Modbus part number for your DeviceMaster UP, Modbus/TCP is loaded on the

DeviceMaster UP by default. You may want to review our other Modbus solutions to make sure that the

feature rich Modbus/TCP application is what you want to use. Optionally, Modbus Router or Modbus Server

may by more effective for your particular environment.

The Comtrol web site provides information about the differences between the three Modbus solutions:

• M

ODBUS/TCP

• M

ODBUS SERVER

• M

ODBUS ROUTER

In addition, the DeviceMaster UP product CD and ftp site also provide these documents for your reference.

The following links function if you are reading this document from the ftp site or CD.

Note: Optionally, open the CD and click Modbus. The main page (

links to these documents.

• Modbus Controller to Controller Communication

• Modbus Solution Examples

• Providing Read-Only Modbus Protection

• Resolving Modbus Device ID Conflicts

If Modbus Server or Modbus Router is a better solution, you can

corresponding documentation.

up_modbus_family_main.htm) provides

DOWNLOAD the appropriate firmware and

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Overview - 5

Page 6

Overview

Modbus/TCP Installation Overview

The DeviceMaster UP follows these installation steps.

Note: The

1. C

2. I

NSTALL PORTVISION DX from the CD or download and install the latest version.

3. C

4. Depending on the DeviceMaster UP model, do the following:

• Models without Modbus/TCP loaded, you must install the software assembly (.msi) from the CD or

• Models with Modbus/TCP loaded on the DeviceMaster UP, you should check to see if a later version of

Note: Models that have Modbus/TCP loaded on the DeviceMaster UP are identified in PortVision DX and

5. I

F NECESSARY, UPLOAD the Modbus/TCP firmware into the DeviceMaster UP using PortVision DX.

6. Configure serial or Ethernet TCP/IP characteristics using the DeviceMaster UP embedded web page

(Server Configuration).

• Modbus/RTU serial slave devices (Page 10

• Modbus/ASCII serial slave devices (Page 12

• Modbus/RTU serial master (Page 14

• Modbus/ASCII serial master (Page 16

• Read-only raw/ASCII serial devices (Page 19

• Read-only raw/ASCII Ethernet devices (Page 26

• Read/write raw/ASCII serial devices (Page 36

• Read/write raw/ASCII Ethernet devices (Page 47

7. Optionally, the DeviceMaster UPModbus/TCP User Guide provides detailed information about each web

page.

8. You may want to reference the P

User Guide.

9. Optionally, reference the

10. C

11. Verify any Ethernet TCP/IP devices are connected to the same subnet as the DeviceMaster UP.

BLUE CAPITALIZED links jump to external documents, which work while viewing from the ftp site or

from the CD.

ONNECT THE DEVICEMASTER UP to the network.

ONFIGURE THE DEVICEMASTER UP network settings using PortVision DX.

download and install the latest file, which contains the Modbus/TCP firmware and supporting files

required for Step 5.

Modbus/TCP is available for installation. Check the Modbus/TCP version in PortVision DX against the

web site to see if a later version is available. Typically, you should download and install the latest .msi

file and upload the latest version, which may include updates or enhancements.

the DeviceMaster UP is labeled accordingly.

)

)

)

)

)

)

)

)

ROGRAMMING INTERFACE chapter in the DeviceMaster UP Modbus/TCP

EXAMPLE PLC PROGRAMS in the DeviceMaster UP Modbus/TCP User Guide.

ONNECT any serial device or devices.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Overview - 7

Page 7

Overview

Locating the Latest Software and Documentation

You can use the links in this table to check for updated software or documentation.

Software and Documentation FTP

Use PortVision DX to manage Comtrol Ethernet-attached devices to:

• Scan the network for attached devices

• View networked devices in real-time

• Access product-specific network settings configurations

• Assign IP addresses and network settings to one or multiple

devices

• Upload the latest firmware or Bootloader

PortVision DX

(Windows)

Modbus/TCP Firmware

DeviceMaster UP Hardware

Installation and Configuration

Guide

• Save and load configuration files

• Access DeviceMaster UP configuration web pages

• Access Telnet/SSH sessions

• Remotely reboot devices

• Download technical documentation

• Enable event logging to assist in monitoring and troubleshooting

• Create shortcuts to quickly access your favorite applications

• Organize devices into folders and create multiple views

• Enter notes about a folder or device

This is the application that may or may not have been loaded on the

DeviceMaster UP depending on the model that was ordered.

You may need to use PortVision DX to load this firmware.

This contains hardware installation, configuration information, and

connector information.

This includes using PortVision DX to configure the IP address and if

necessary, how to update the firmware.

Modbus/TCP Interface

Configuration Quick Start

This document with web interface configuration procedures.

The User Guide contains detailed information about the Modbus/TCP

(application) firmware, which includes additional information about

Modbus/TCP User Guide

the web configuration interface for Modbus/TCP.

It also discusses the example PLC programs that were installed on

your system and provides a Programming Interface chapter.

This Guide discusses the data extraction and filtering processes in the

DeviceMaster UP are designed to off load as much work as possible

DeviceMaster UP Filtering and

Data Extraction Reference

from the PLC and/or application and provide a very simple and easy to

use interface for standard RFID and barcode data.

Guide

This functionality and interface is designed to save dozens, possibly

hundreds of lines of ladder logic in a typical PLC program.

6 - Overview DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 8

Overview

8 - Overview DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 9

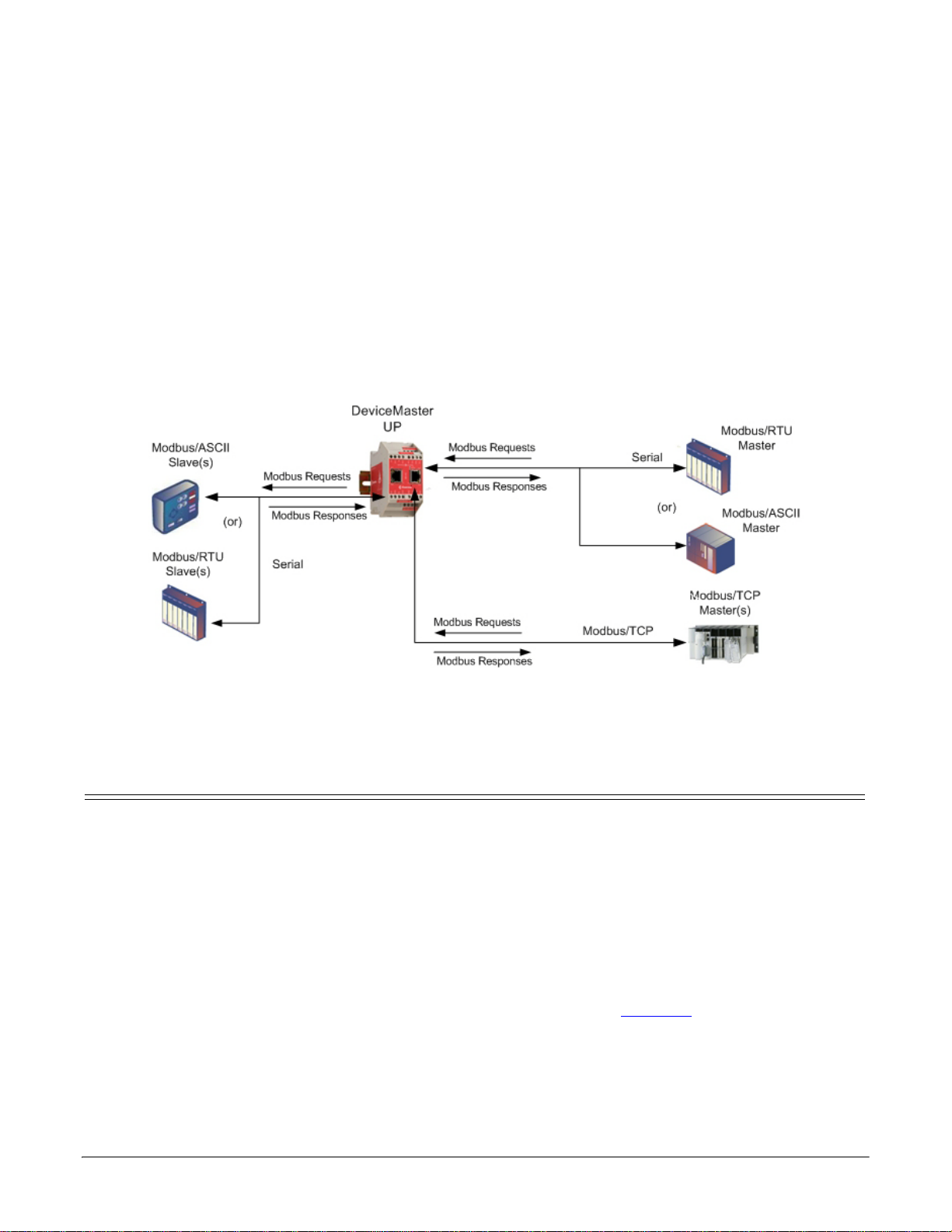

Configuring Modbus/RTU and Modbus/ASCII Slaves

Modbus Master(s) to Modbus Slave(s)

and Masters

For pure Modbus devices, the DeviceMaster UP supports:

• Modbus/RTU serial slaves

• Modbus ASCII serial slaves

• Modbus/RTU serial masters

• Modbus/ASCII serial masters

• Modbus/TCP masters

Note: All masters can communicate to all slaves.

Prerequisites

Before you can configure the serial ports for this mode, make sure that you have done the following:

• Installed the hardware

• Installed PortVision DX

• Configured the DeviceMaster UP IP address using PortVision DX

• If necessary, uploaded the latest Modbus/TCP firmware using PortVision DX

Note: The DeviceMaster UP provides an Modbus/TCP interface, which may or may not have the Modbus/

TCP firmware loaded (depending on the model you purchased). Models that have Modbus/TCP loaded

on the DeviceMaster UP are identified in PortVision DX and the DeviceMaster UP is labeled

accordingly.

If you need to perform any of these procedures or locate the latest files, see Overview

on Page 5.

Modbus/TCP Quick Start: 2000477 Rev. G Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters - 9

Page 10

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

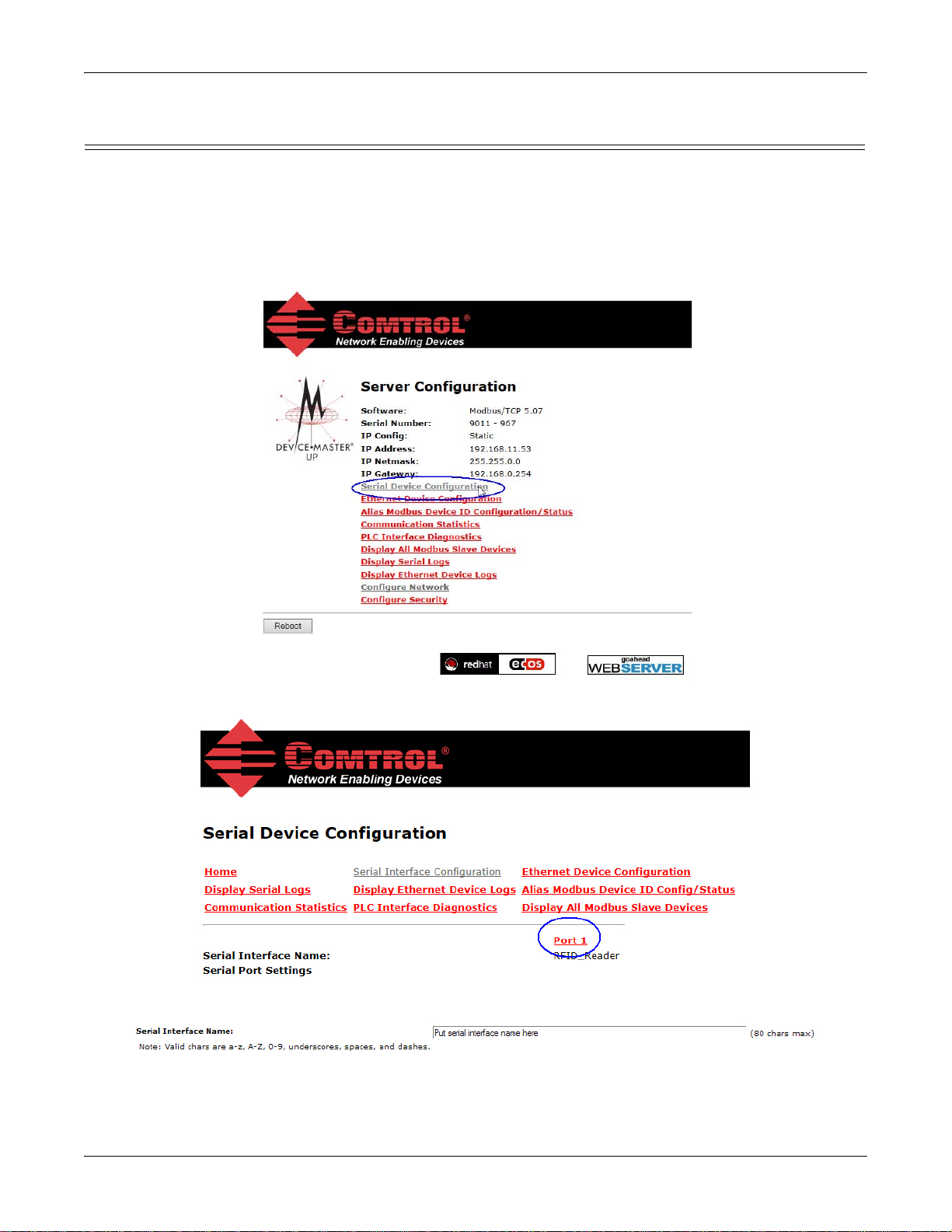

Configuring Modbus/RTU Slaves

Use the following procedure to configure a serial interface to Modbus/RTU slave(s).

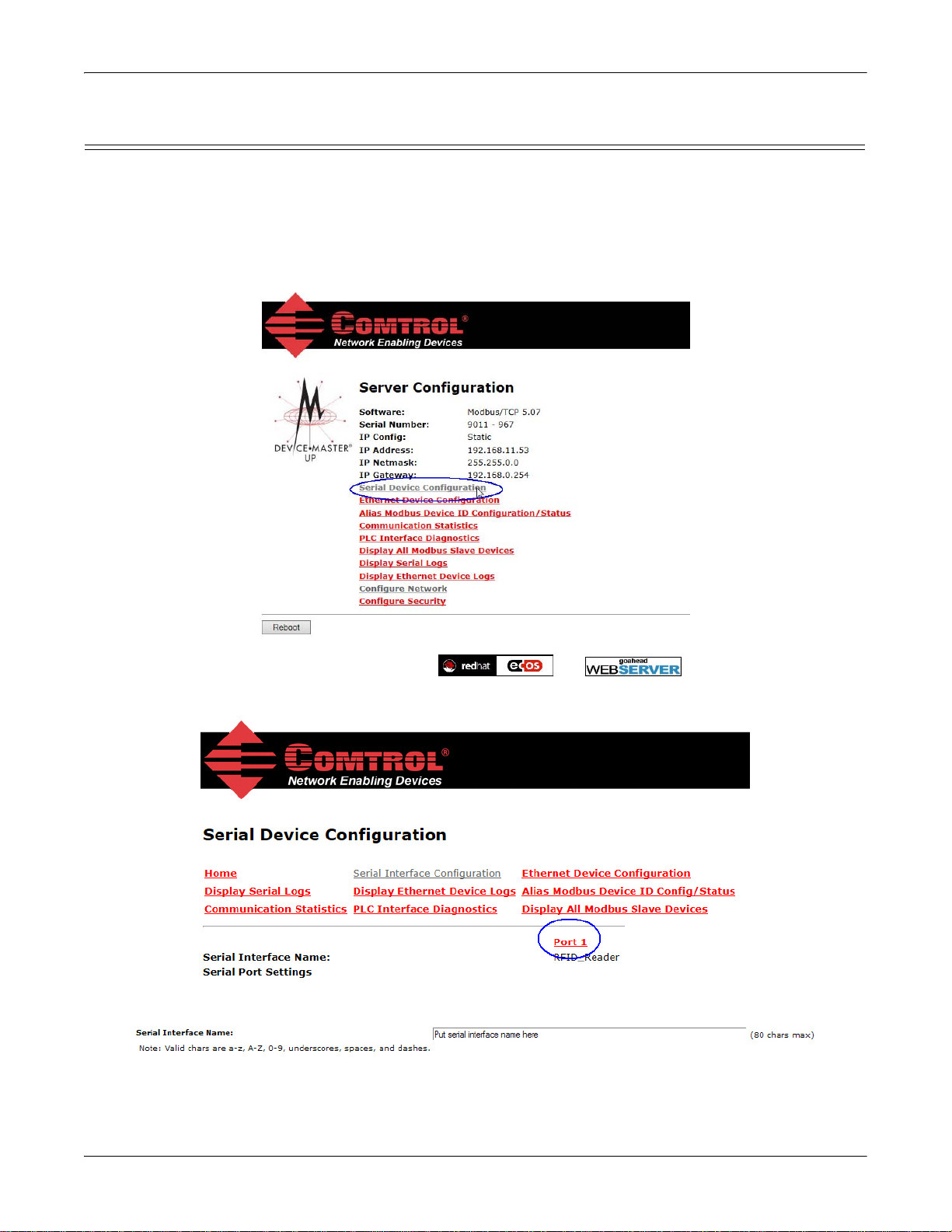

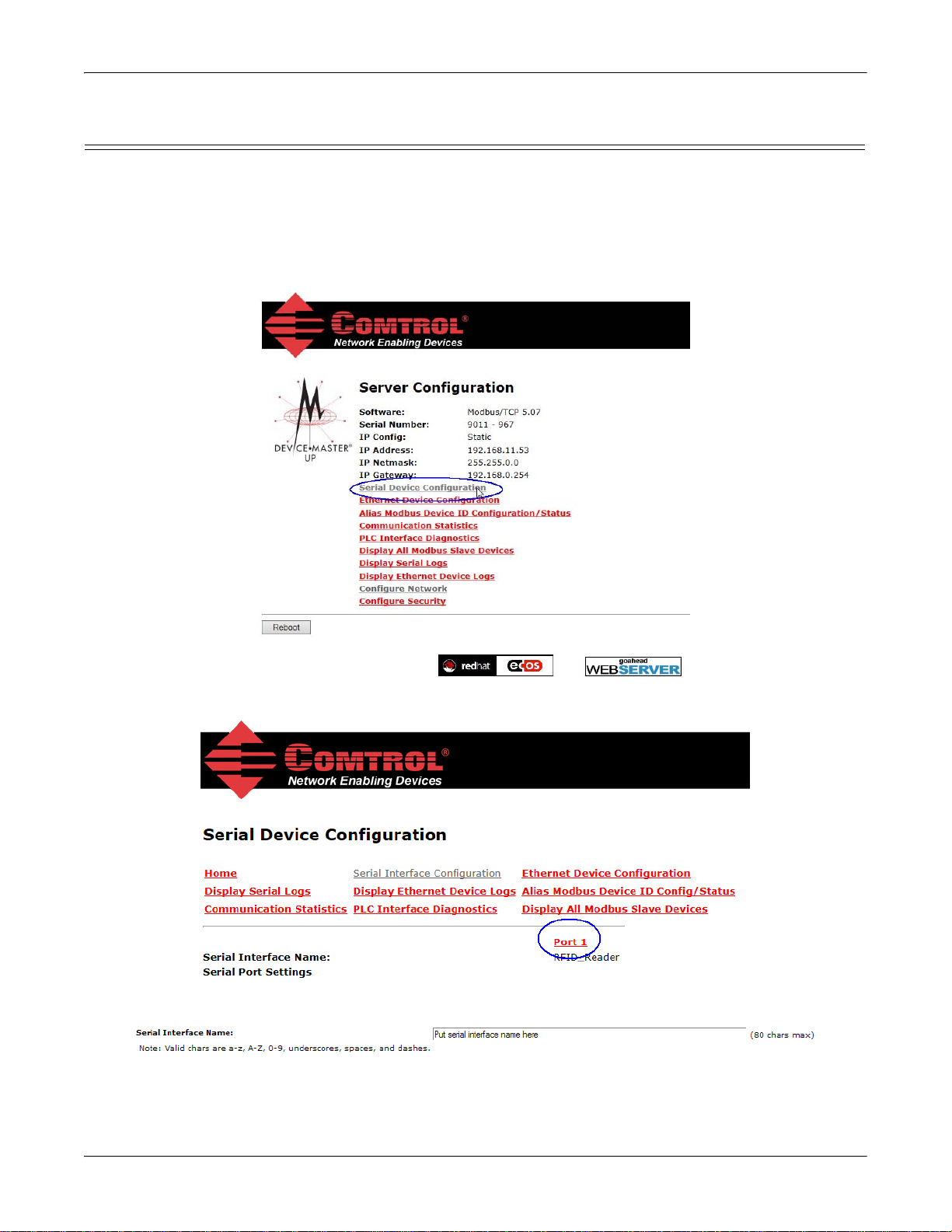

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Serial Device Configuration link to open the Serial Device Configuration page.

3. Click Port N for the port you want to configure, where N is the port number.

4. If desired, provide a Serial Interface Name.

10 - Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters Modbus/TCP Quick Start: 2000477 Rev. G

Page 11

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

5. Set up the Serial Configuration for your device.

6. Configure the serial port for Modbus/RTU-to-Slaves operation. Under General Protocol Settings:

a. Set Serial Port Protocol to Modbus/RTU-to-Slaves.

b. Enable Discard Rx Packets With Errors.

c. Under Modbus Slave and Raw-Data Device Settings, set the Device Response Timeout value or leave at

the default.

d. 2/4-port models only

: Under Modbus Slaves Only, enable Lost Device Search Enable if you want the

DeviceMaster UP to search for a lost Modbus slave device on other Modbus/RTU and/or Modbus/

ASCII slave ports that also have this option enabled.

7. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

Note: If necessary, see Filtering/Data Extraction Configuration

on Page 61 or Application Socket

Configuration on Page 67 for additional configuration procedures.

Modbus/TCP Quick Start: 2000477 Rev. G Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters - 11

Page 12

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

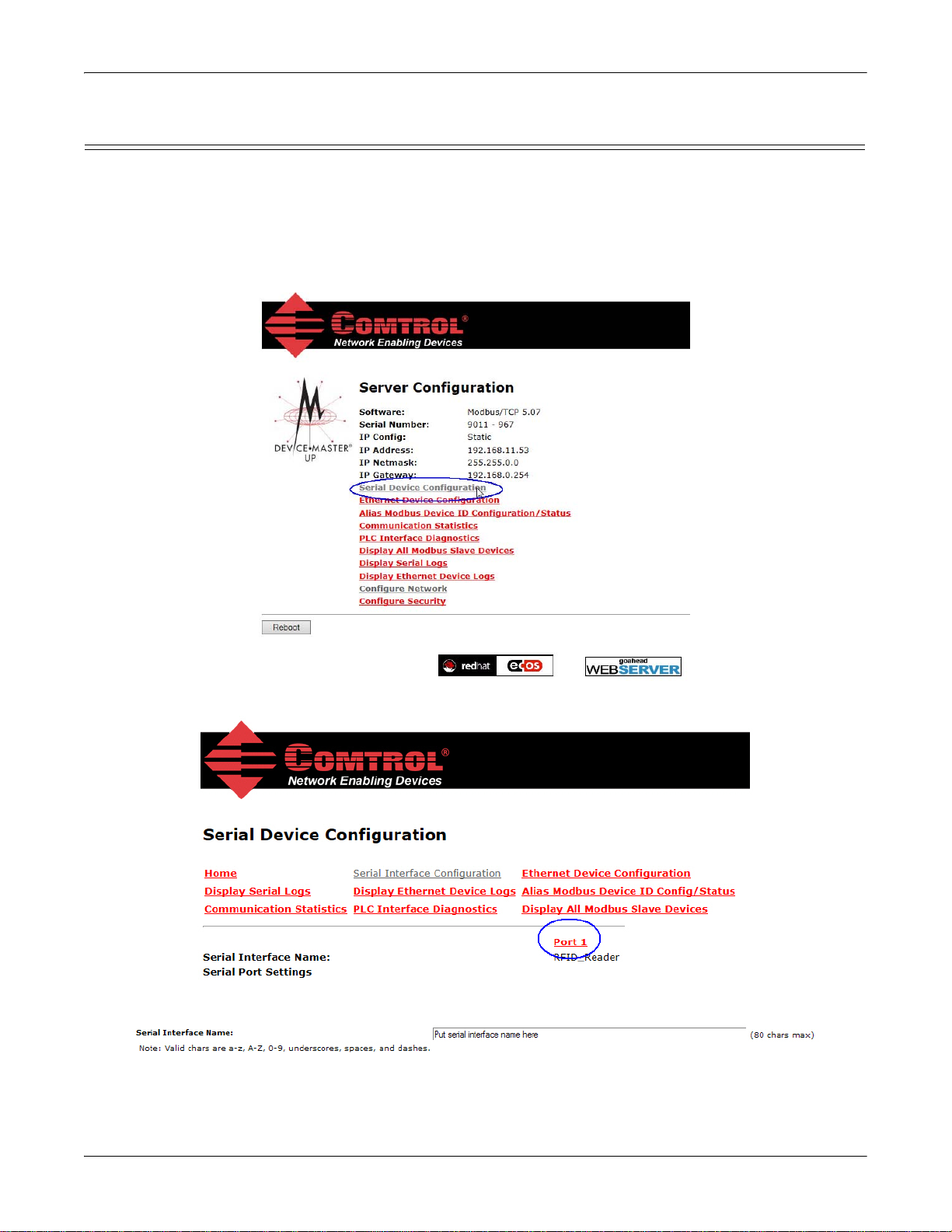

Configuring Modbus/ASCII Slaves

Use the following procedure to configure a serial interface to Modbus/ASCII slave(s).

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Serial Device Configuration option to open the Serial Device Configuration page.

3. Click Port N for the port you want to configure, where N is the port number.

4. If desired, provide a Serial Interface Name.

12 - Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters Modbus/TCP Quick Start: 2000477 Rev. G

Page 13

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

5. Set up the Serial Configuration for your device.

6. Configure the serial port for Modbus/ASCII-to-Slaves operation. Under General Protocol Settings:

a. Set Serial Port Protocol to Modbus/ASCII-to-Slaves.

b. Enable Discard Rx Packets With Errors.

c. Under Modbus Slave and Raw-Data Device Settings, set the Device Response Timeout value or leave at

the default.

d. 2/4-port models only: Under Modbus Slaves Only, enable Lost Device Search Enable if you want the

DeviceMaster UP to search for a lost Modbus slave device on other Modbus/RTU and/or Modbus/

ASCII slave ports that also have this option enabled.

7. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

Note: If necessary, see Filtering/Data Extraction Configuration

on Page 61 or Application Socket

Configuration on Page 67 for additional configuration procedures.

Modbus/TCP Quick Start: 2000477 Rev. G Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters - 13

Page 14

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

Configuring Modbus/RTU Master

Use the following procedure to configure a serial interface to Modbus/RTU master.

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Serial Device Configuration option to open the Serial Device Configuration page.

3. Click Port N for the port you want to configure, where N is the port number.

4. If desired, provide a Serial Interface Name.

14 - Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters Modbus/TCP Quick Start: 2000477 Rev. G

Page 15

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

5. Set up the Serial Configuration for your device.

6. Configure the serial port for Modbus/RTU-to-Master operation. Under General Protocol Settings:

a. Set Serial Port Protocol to Modbus/RTU-to-Master.

b. Enable Discard Rx Packets With Errors.

7. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

Note: If necessary, see Filtering/Data Extraction Configuration

on Page 61 or Application Socket

Configuration on Page 67 for additional configuration procedures.

Modbus/TCP Quick Start: 2000477 Rev. G Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters - 15

Page 16

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

Configuring Modbus/ASCII Master

Use the following procedure to configure a serial interface to Modbus/ASCII master.

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Serial Device Configuration option to open the Serial Device Configuration page.

3. Click Port N for the port you want to configure, where N is the port number.

4. If desired, provide a Serial Interface Name.

16 - Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters Modbus/TCP Quick Start: 2000477 Rev. G

Page 17

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

5. Set up the Serial Configuration for your device.

6. Configure the serial port for Modbus/ASCII-to-Master operation. Under General Protocol Settings:

a. Set Serial Port Protocol to Modbus/ASCII-to-Master.

b. Enable Discard Rx Packets With Errors.

7. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

Note: If necessary, see Filtering/Data Extraction Configuration

on Page 61 or Application Socket

Configuration on Page 67 for additional configuration procedures.

Modbus/TCP Quick Start: 2000477 Rev. G Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters - 17

Page 18

Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters

18 - Configuring Modbus/RTU and Modbus/ASCII Slaves and Masters Modbus/TCP Quick Start: 2000477 Rev. G

Page 19

Configuring Read-Only Raw/ASCII Devices

Serial Read-Only Device Communications

This chapter contains these subsections:

• Prerequisites (below)

• Read-Only Raw/ASCII Serial Devices (below)

•

Read-Only Raw/ASCII Ethernet Devices on Page 26

Prerequisites

Before you can configure the ports, make sure that you have done the following:

• Installed the hardware

• Installed PortVision DX

• Configured the DeviceMaster UP IP address using PortVision DX

• If necessary, uploaded the latest Modbus/TCP firmware using PortVision DX

Note: The DeviceMaster UP provides a Modbus/TCP interface, which may or may not have the Modbus/TCP

If you need to perform any of these procedures or locate the latest files, see

firmware loaded (depending on the model you purchased). Models that have Modbus/TCP loaded on

the DeviceMaster UP are identified in PortVision DX and the DeviceMaster UP is labeled accordingly.

Overview on Page 5.

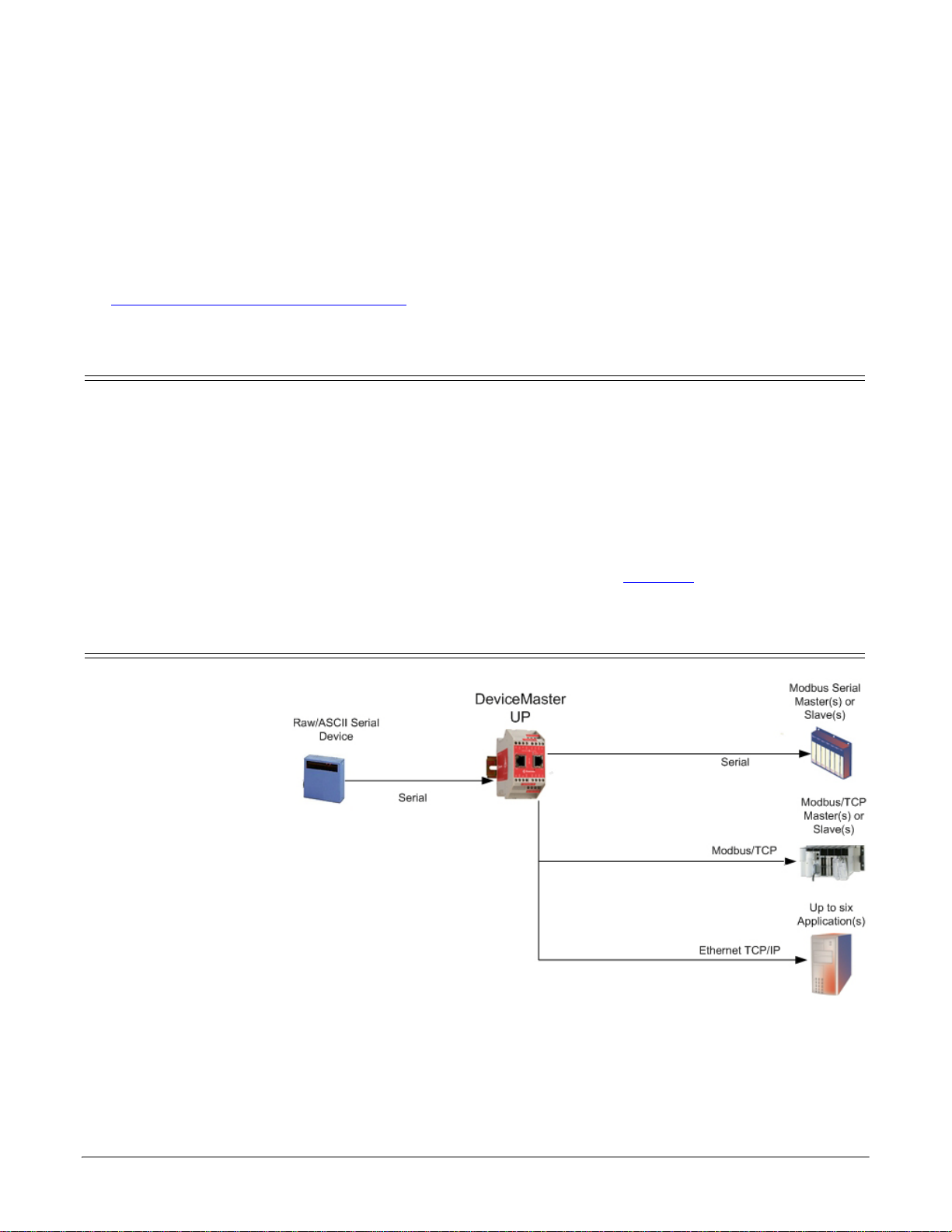

Read-Only Raw/ASCII Serial Devices

Read-only raw/ASCII serial

devices use the Serial

Device Configuration page

to:

• Allow connections

between a serial device,

such as a barcode

scanner or RFID

reader, to PLC(s) and/

or application(s).

• Provide an optional

filtering mechanism for

string, RFID, and

barcode data.

The PLC and application

can both communicate to

the serial device, but they

cannot communicate

directly to each other.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 19

Page 20

Configuring Read-Only Raw/ASCII Devices

Embedded Web Page Configuration

Use the following procedure to configure read-only raw/ASCII serial devices.

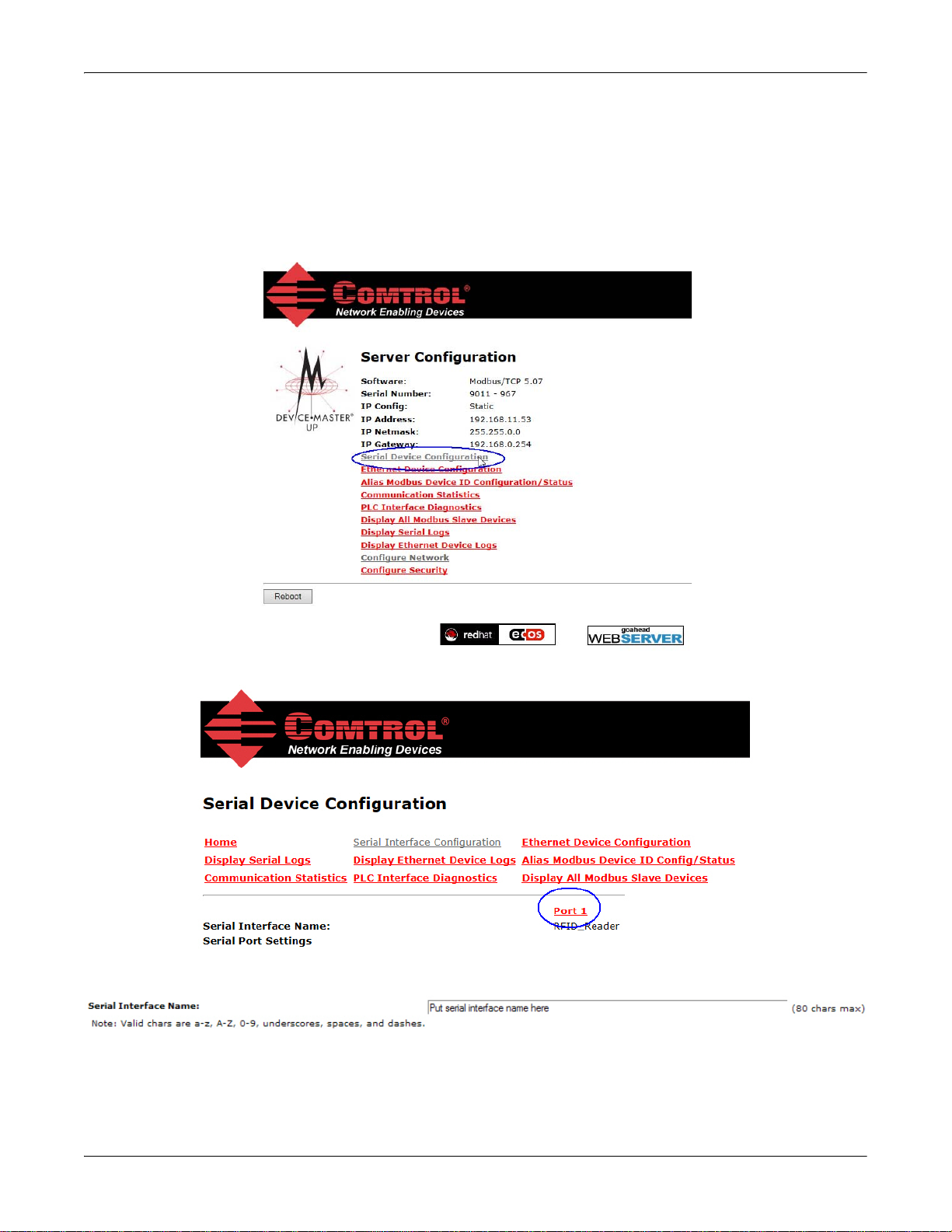

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Serial Device Configuration option to open the Serial Device Configuration page.

3. Click Port N for the port you want to configure, where N is the port number.

4. If desired, provide a Serial Interface Name.

20 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 21

Configuring Read-Only Raw/ASCII Devices

5. Set the Serial Configuration for your device.

6. Set the General Protocol Settings:

a. Set Serial Port Protocol to Raw-Data.

b. Enable Discard Rx Packets With Errors.

7. Set the Message Transfer mode, by setting the Raw-Data Message Transfer Mode to Data-Stream.

8. Set up the serial packet

identification (Serial Packet ID

Settings (Raw Data Only).

• Set the STX (Start of

transmission) Rx Detect in

decimal format.

• Set the ETX (End of

transmission) Rx Detect in

decimal format.

• Enable the S trip Rx STX/ETX

option if you do not want the

STX and ETX bytes returned

to the PLC or application(s).

Note: Refer to your device's User Manual for the Start and End of Transmission byte(s) settings. You may

also be able to use the Serial Interface Logs page to determine these settings.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 21

Page 22

Configuring Read-Only Raw/ASCII Devices

You can use the Master Receive Transfer method only if your PLC can

operate as a Modbus/TCP slave, Modbus/RTU serial slave, or Modbus/

ASCII serial slave.

You can use the Slave Receive

Transfer method only if your PLC can operate as a Modbus/TCP master,

Modbus/RTU serial master, or Modbus/ASCII serial master.

9. Configure the Modbus/TCP and/or Serial Modbus Master Settings for your environment using one of the

following settings:

• Master Receive Transfer mode (recommended) writes data directly into the memory of a Modbus/

TCP slave or serial Modbus slave attached to this gateway. This requires the least amount of PLC

programming, requires the least amount of PLC overhead, and provides minimal latency.

Go to Step 10

on Page 23 to configure Master Receive Transfer mode.

• Slave Receive Transfer mode requires the PLC to poll for received data. This method is provided for

PLC programmers who prefer polling for data or those who have PLCs that can only operate in master

mode.

Go to Step 11

on Page 24 to configure Slave Receive Transfer mode.

22 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 23

Configuring Read-Only Raw/ASCII Devices

10. Master Receive Transfer Mode Only

Use the following procedure to configure Master Receive Transfer mode.

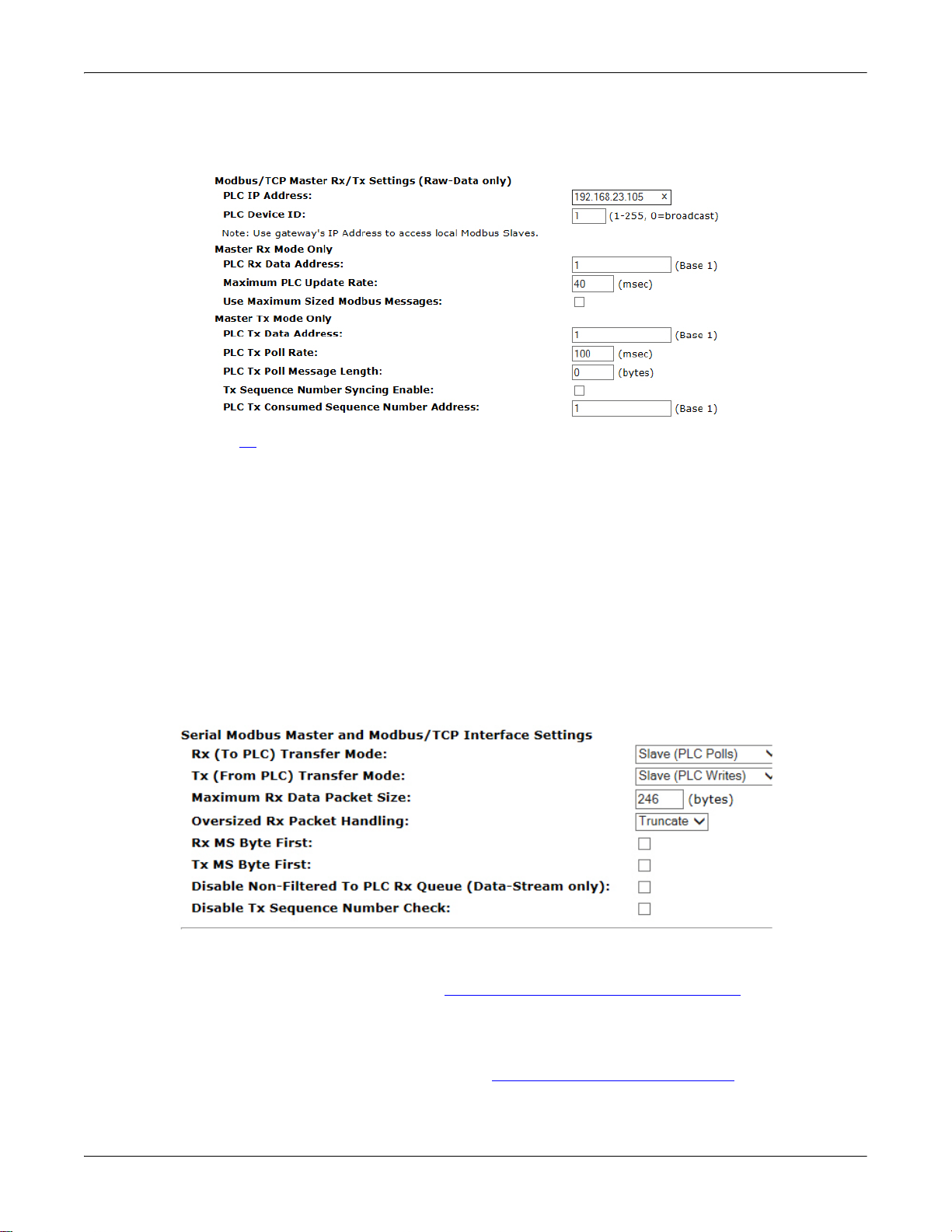

Under Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only):

a. Set Rx (To PLC) Transfer Mode to Master (Write to PLC).

b. Set Tx (From PLC) Transfer Mode to either Slave (PLC Writes) or Off.

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. For writing to

a Modbus/TCP slave or Modbus serial slave, this can be a maximum of 1,518 bytes.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received during the Maximum PLC Update Rate time period, only

the last received data packet will be sent to the PLC.)

Under Modbus/TCP Master Rx/Tx Settings (Raw-Data Only):

g. Enter the PLC IP Address:

• For Modbus/TCP slaves, set the PLC IP Address to that of your PLC in xxx.xxx.xxx.xxx format.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC IP Address to that of this

DeviceMaster UP in xxx.xxx.xxx.xxx format.

Note: The Modbus serial slave must be attached to one of the serial ports on this DeviceMaster UP

chassis.

h. Enter the PLC Device ID:

• For Modbus/TCP slaves, set the PLC Device ID to that of your PLC. This is typically 1.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC Device ID to that of the serial slave

device.

Note: This must be a unique device id attached to this DeviceMaster UP chassis.

i. Set the PLC Rx Data Address to the PLC memory address where you want to place the received data

message. This address is Base 1, which means the address starts at 1 (or 400001 for some PLCs). If

your address range is Base 0, or starts at zero, you will need to add one to your address.

j. Set the Maximum PLC Update Rate to the fastest rate your PLC can reliably receive and process data.

This is typically longer than the scan rate. The default of 40 milliseconds is usually sufficient, but

your system may require a longer time period.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 23

Page 24

Configuring Read-Only Raw/ASCII Devices

k. Set the Use Maximum Sized Modbus Messages option if you are receiving messages over 196 bytes, your

PLC can receive messages larger than 200 bytes, and you want to decrease latency and network

usage.

Note: Go to Step 12

on Page 24 to complete configuration.

11. Slave Receive Transfer Mode Only:

Use the following procedure to configure Slave Receive Transfer mode.

Under Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only):

a. Set Rx (To PLC) Transfer Mode to Slave (PLC Polls).

b. Set Tx (From PLC) Transfer Mode to either Slave (PLC Writes) or Off.

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. This can be a

maximum of 246 bytes in Slave Rx mode.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received between received data requests, only the last received

data packet will be returned.)

12. Set up the filtering/data extraction settings:

• If no filtering/data extraction is required, leave all filtering/data extraction settings to defaults (off).

• If filtering/data extraction is required, see

Filtering/Data Extraction Configuration on Page 61.

13. Set up the application socket interface settings:

• If no application socket interface is required, leave all application socket interface settings at defaults

and the application Enable option in not selected.

• If an application socket interface is required, see

Application Socket Configuration on Page 67.

14. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

24 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 25

Configuring Read-Only Raw/ASCII Devices

Modbus Raw Data Addressing

The serial port receive data addresses used for polling:

Serial Port

Raw/ASCII

Serial Port 1 Serial Port 2 Serial Port 3 Serial Port 4 Access Rule

Addressing

Unit ID 255 (FF Hex) 255 (FF Hex) 255 (FF Hex) 255 (FF Hex) N/A

Receive Data

Address

1000 (Base 0)

1001 (Base 1)

2000 (Base 0)

2001 (Base 1)

3000 (Base 0)

3001 (Base 1)

4000 (Base 0)

4001 (Base 1)

Read Only

Received Message Format

If all is set up correctly, the data packets will be written into the PLC memory space starting at the specified

memory location. The first word received is the sequence number. This is incremented with each new data

packet. The next word is the length, which indicates the number of data bytes received. The rest is data.

The format of received serial data sent to or returned to the PLC:

Name Data Type Data Value(s)

Receive (DeviceMaster UP to PLC)

message data.

Structure of:

Produced data sequence

Data length (in bytes)

Data array

WORD

WORD

Array of

WORD

0-65535 (

FFFF Hex)

1-1024 (Master Rx Mode)

0-246 (Slave Rx Mode)

0-65535

Access

Rule

Get

General requirements:

• The memory area must be defined in 16 bit words and large enough to handle the largest serial packet

plus two words for the produced sequence number and data length parameters.

•The Maximum Rx Data Packet Size must be set large enough to accept the largest possible packet.

• For large received data packets over 246 bytes (This may be less for your PLC):

The Rx (To PLC) Transfer Mode must be set to Master (Write to PLC).

- The data will automatically be placed in continuous memory.

- All data will have been transferred to the PLC when the sequence number is updated.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 25

Page 26

Configuring Read-Only Raw/ASCII Devices

Ethernet TCP/IP Read-Only device Communications

Caution

Read-Only Raw/ASCII Ethernet Devices

Read-only raw/ASCII Ethernet devices use the Ethernet Device Configuration page to:

• Allow connections between devices that communicate over Ethernet TCP/IP, such as a barcode scanner,

RFID reader, or weigh scale, and a PLC and/or application.

• Provide an optional filtering mechanism for string, RFID, and barcode data.

• Provide support for only Raw/ASCII type data.

Verify that you have an actual Ethernet device in which to connect to and that the Ethernet device supports

Ethernet TCP socket connections.

Do not use this configuration page for serial devices.

26 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 27

Configuring Read-Only Raw/ASCII Devices

Embedded Web Page Configuration

Use the following procedure to configure read-only Ethernet devices.

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Ethernet Device Configuration option to open the Ethernet Device Configuration page.

Note: The Ethernet device must be a target Ethernet device such as a barcode scanner, RFID reader,

weigh scale, or some other device that is to be connected to a PLC and/or application.

3. Click Socket N for the port that you want to configure, where N is the Socket number.

4. If desired, enter an Ethernet Interface Name.

5. Click Enable under Device TCP Connection Configuration and configure the settings for your environment

using one of the following procedures.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 27

Page 28

Configuring Read-Only Raw/ASCII Devices

Connect Mode Set Up

Listen Mode Set Up

Listen and Connect Modes Set Up

• If your Ethernet TCP/IP device requires

another device to connect to it, configure

the socket port on the DeviceMaster UP to

Connect mode:

- Leave Listen unselected.

-Set Connect To Mode to Connect-Always.

- Set the Connect Port to the socket port

number of your Ethernet device.

- Set the Connect IP Address to the IP

address of your Ethernet device.

Do not enter the IP address of the

DeviceMaster UP or PLC here.

-Set Disconnect Mode to Never.

• If your Ethernet TCP/IP device is

configured to connect to another device,

configure the socket port on the

DeviceMaster UP to Listen mode:

-Select Listen.

- Use the default Listen Port on the

DeviceMaster UP of 8xxx or designate

your own.

-Set Connect To Mode to Never.

-Set Disconnect Mode to Never.

- Configure your Ethernet device to

connect to the DeviceMaster UP at the DeviceMaster UP IP address and Listen Port.

• If you do not know if your device will connect

to another Ethernet device, but do know

your device’s socket port and IP address, you

can do the following to enable both the Listen

and Connect modes:

-Select Listen.

- Use the default Listen Port on the

DeviceMaster UP of 8xxx or designate

your own.

-Set Connect To Mode to Connect-Always.

-Set the Connect Port to the port number

of your Ethernet device.

- Set the Connect IP Address to the IP address of your Ethernet device.

Do not enter the IP address of the DeviceMaster UP or PLC here.

-Set Disconnect Mode to Never.

- Optionally configure your Ethernet device to connect to the DeviceMaster UP at the DeviceMaster

UP IP address and Listen Port.

6. Set up the Message Transfer Settings, by setting the Message Transfer Mode to Data-Stream.

28 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 29

Configuring Read-Only Raw/ASCII Devices

7. Set up the Socket Packet Identification.

a. Set the Rx Timeout Between Packets. Set to zero to stream data with the Rx STX/ETX Detect settings set

to none. For normal settings, typical values are 10 to 50 ms.

b. Set the STX (Start of transmission) Rx Detect in decimal format.

c. Set the ETX (End of transmission) Rx Detect in decimal format.

d. Enable the Strip Rx STX/ETX option if you do not want the STX and ETX bytes returned to the PLC or

application.

Note: Refer to your device's User Manual for the Start and End of Transmission byte(s) settings. You may

also be able to use the Ethernet Device Interface Logs page to determine these settings.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 29

Page 30

Configuring Read-Only Raw/ASCII Devices

You can use the Master Receive Transfer method only if your PLC can operate as a

Modbus/TCP slave, Modbus/RTU serial slave, or Modbus/ASCII serial slave.

You can use the Slave Receive Transfer method only if your PLC can operate as a

Modbus/TCP master, Modbus/RTU serial master, or Modbus/ASCII serial master.

8. Configure the Modbus/TCP and/or Serial Modbus Master Settings for your environment using one of the

following methods.

• Master Receive Transfer mode (recommended) writes data directly into the memory of a Modbus/

TCP slave or serial Modbus slave attached to this gateway. This requires the least amount of PLC

programming, requires the least amount of PLC overhead, and provides minimal latency.

Go to Step 9

on Page 31 to configure Master Receive Transfer mode.

• Slave Receive Transfer mode requires the PLC to poll for received data. This method is provided for

PLC programmers who prefer polling for data or those who have PLCs that can only operate in master

mode.

Go to Step 10

on Page 32 to configure Slave Receive Transfer mode.

30 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 31

Configuring Read-Only Raw/ASCII Devices

9. Master Receive Transfer Mode Only:

Use the following procedure to configure Master Receive Transfer mode.

Under Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only):

a. Set Rx (To PLC) Transfer Mode to Master (Write to PLC).

b. Set Tx (From PLC) Transfer Mode to either Slave (PLC Writes) or Off.

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. For writing to

a Modbus/TCP slave or Modbus serial slave, this can be a maximum of 1,518 bytes.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received during the Maximum PLC Update Rate time period, only

the last received data packet will be sent to the PLC.)

Under Modbus/TCP Master Rx/Tx Settings (Raw-Data Only):

g. Enter the PLC IP Address:

• For Modbus/TCP slaves, set the PLC IP Address to that of your PLC in xxx.xxx.xxx.xxx format.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC IP Address to that of this

DeviceMaster UP in xxx.xxx.xxx.xxx format.

Note: The Modbus serial slave must be attached to one of the serial ports on this DeviceMaster UP

chassis.

h. Enter the PLC Device ID:

• For Modbus/TCP slaves, set the PLC Device ID to that of your PLC. This is typically 1.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC Device ID to that of the serial slave

device.

Note: This must be a unique device id attached to this DeviceMaster UP chassis.

i. Set the PLC Rx Data Address to the PLC memory address where you want to place the received data

message. This address is Base 1, which means the address starts at 1 (or 400001 for some PLCs). If

your address range is Base 0, or starts at zero, you will need to add one to your address.

j. Set the Maximum PLC Update Rate to the fastest rate your PLC can reliably receive and process data.

This is typically longer than the scan rate. The default of 40 milliseconds is usually sufficient, but

your system may require a longer time period.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 31

Page 32

Configuring Read-Only Raw/ASCII Devices

k. Set the Use Maximum Sized Modbus Messages option if you are receiving messages over 196 bytes, your

PLC can receive messages larger than 200 bytes, and you want to decrease latency and network usage

l. Go to Step 11

on Page 32 to complete configuration.

10. Slave Receive Transfer Mode Only:

Use the following procedure to configure the Slave Receive Transfer mode.

Under Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only):

a. Set Rx (To PLC) Transfer Mode to Slave (PLC Polls).

b. Set Tx (From PLC) Transfer Mode to either Slave (PLC Writes) or Off.

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. This can be a

maximum of 246 bytes in Slave Rx Mode.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received between received data requests, only the last received

data packet will be returned.)

11. Set up the Filtering/Data Extraction Configuration settings:

• If no filtering/data extraction is required, leave all filtering/data extraction settings to defaults (off).

• If filtering/data extraction is required, see

32 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Filtering/Data Extraction Configuration on Page 61.

Page 33

Configuring Read-Only Raw/ASCII Devices

12. Set up the Application TCP Connection Configuration settings:

• If no application socket interface is required, leave all application socket interface settings at defaults

and the application Enable option is not selected.

• If an application socket interface is required, see

Application Socket Configuration on Page 67.

13. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

Modbus Addressing

The receive data addresses used for polling are as follows:

Socket Port Raw/

ASCII Addressing

Socket Port 1Socket Port 2Socket Port 3Socket Port

4

Access Rule

Unit ID 254 (FF Hex) 254 (FF Hex) 254 (FF Hex) 254 (FF Hex) N/A

Receive Data Address

1000 (Base 0)

1001 (Base 1)

2000 (Base 0)

2001 (Base 1)

3000 (Base 0)

3001 (Base 1)

4000 (Base 0)

4001 (Base 1)

Read Only

Received Message Format

If all is set up correctly, the data packets will be written into the PLC memory space starting at the specified

memory location. The first word received is the sequence number. This is incremented with each new data

packet. The next word is the length, which indicates the number of data bytes received. The rest is data.

The format of received socket data sent to the PLC:

Name Data Type Data Value(s)

Receive (DeviceMaster UP to PLC)

message data.

Structure of:

Produced data sequence

Data length (in bytes)

Data array

WORD

WORD

Array of

WORD

0-65535 (FFFF Hex)

1-2048 (Master Rx Mode)

0-246 (Slave Rx Mode)

0-65535

Access

Rule

Get

General requirements:

• The memory area must be defined in 16 bit words and large enough to handle the largest serial packet

plus two words for the produced sequence number and data length parameters.

•The Maximum Rx Data Packet Size must be set large enough to accept the largest possible packet.

For large received data packets over 246 bytes (This may be less for your PLC):

-The Rx (To PLC) Transfer Mode must be set to Master (Write to PLC).

- The data will automatically be placed in continuous memory.

- All data will have been transferred to the PLC when the sequence number is updated.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read-Only Raw/ASCII Devices - 33

Page 34

Configuring Read-Only Raw/ASCII Devices

34 - Configuring Read-Only Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 35

Configuring Read/Write Raw/ASCII Devices

This section discusses the following:

• Prerequisites

•

Read/Write Raw/ASCII Serial Devices on Page 36

•

Read/Write Raw/ASCII Ethernet Devices on Page 47

Prerequisites

Before you can configure the ports, make sure that you have done the following:

• Installed the hardware

• Installed PortVision DX

• Configured the DeviceMaster UP IP address using PortVision DX

• If necessary, uploaded the latest Modbus/TCP firmware using PortVision DX

Note: The DeviceMaster UP provides a Modbus/TCP interface, which may or may not have the Modbus/TCP

If you need to perform any of these procedures or locate the latest files, see

firmware loaded (depending on the model you purchased). Models that have Modbus/TCP loaded on

the DeviceMaster UP are identified in PortVision DX and the DeviceMaster UP is labeled accordingly.

Overview on Page 5.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 35

Page 36

Configuring Read/Write Raw/ASCII Devices

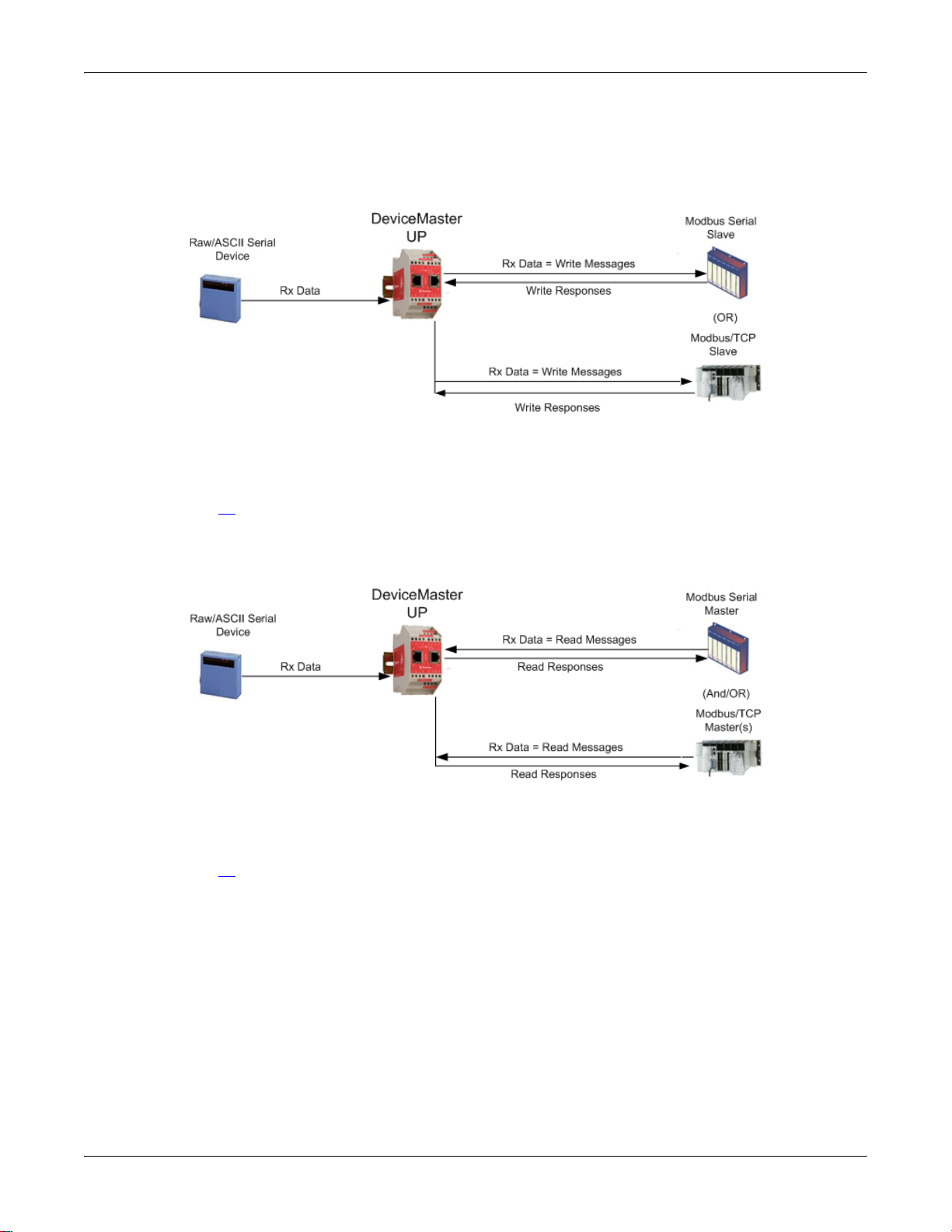

Serial Read/Write Device Communications

Read/Write Raw/ASCII Serial Devices

Read/write raw/ASCII serial devices use the Serial Device Configuration page to:

• Allow connections between a serial device, such as a barcode scanner or RFID reader, and a PLC and/or

application(s).

• Provide an optional filtering mechanism for string, RFID, and barcode data.

Note: The PLC and application(s) can both communicate to the serial device, but they cannot communicate

directly to each other.

36 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 37

Configuring Read/Write Raw/ASCII Devices

Embedded Web Page Configuration

Use the following procedure to configure read/write raw/ASCII serial devices.

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Serial Device Configuration option to open the Serial Device Configuration page.

3. Click Port N for the port that you want to configure, where N is the port number.

4. If desired, provide a Serial Interface Name.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 37

Page 38

Configuring Read/Write Raw/ASCII Devices

5. Set up the Serial Configuration for your device.

6. Select the Modbus/TCP communication method and set up the Modbus/TCP Interface settings under

General Protocol Settings:

a. Set Serial Port Protocol to Raw-Data.

b. Enable Discard Rx Packets With Errors.

7. Set the Raw-Data Message Transfer mode:

• Selecting Data-Stream enables asynchronous communication to the device.

- Transmit data is sent immediately from all Modbus and active Application interfaces.

- Received data will be returned to the Modbus interface and all active Application interfaces.

-If Data-Stream is selected, the rest of the options in this section are not applicable.

• Selecting Command/Response enables synchronous communications with the device.

- Transmit data will expect one or more responses.

- Responses will only be returned to the transmit message originator.

If Command/Response is selected:

- Set the Response Timeout to a valid timeout period for your device.

-The Cmd/Resp Age Time will set the time at which old responses to the Modbus interface are

discarded.

-The Cmd/Resp Expected Responses Per Command indicates the number of responses expected per

transmitted message. This is typically 1.

-Set the Cmd/Resp Mode Response To Modbus/TCP Based On option to:

- IP-Address if there is only one Modbus/TCP interface per IP-Address communicating to this

port. This is typically used for PLC or single OPC Server/SCADA systems.

- TCP-Connection if there is more than one Modbus/TCP interface per IP-Address

communicating to this port. This typically is required for multiple OPC Server/ SCADA

systems running on the same computer.

38 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 39

Configuring Read/Write Raw/ASCII Devices

8. Set up the serial packet identification (Serial Packet ID Settings (Raw Data Only).

• Set the STX (Start of transmission) Rx Detect in decimal format.

• Set the ETX (End of transmission) Rx Detect in decimal format. Refer to your serial device's User Manual

for these settings.

•Enable the Strip Rx STX/ETX option if you do not want the STX and ETX bytes returned to the PLC or

application.

• If desired, set the STX (Start of transmission) Tx Append in decimal format. This will append the STX

byte(s) to transmitted messages from the PLC or application.

• If desired, set the ETX (End of transmission) Tx Append in decimal format. This will append the ETX

byte(s) to transmitted messages from the PLC or application.

9. Configure the Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only) settings for your

environment using one of the following methods.

• PLC Master/DeviceMaster UP Slave mode. You can use the PLC Master/DeviceMaster UP Slave

method only if your PLC can operate as a Modbus/TCP master, Modbus/RTU serial master, or Modbus/

ASCII serial master. Go to Step 10

on Page 40 for configuration procedures.

• PLC Slave/DeviceMaster UP Master mode. You can use the PLC Slave/DeviceMaster UP Master

method only if your PLC can operate as a Modbus/TCP slave, Modbus/RTU serial slave, or Modbus/

ASCII serial slave. Go to Step 11

on Page 41 for configuration procedures.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 39

Page 40

Configuring Read/Write Raw/ASCII Devices

• Dual Master – Write mode. You can use Dual Master - Write method only if your PLC can operate as

a Modbus master and slave simultaneously. Go to Step 12

on Page 43 for configuration procedures.

• Dual Master – Read mode. You can use Dual Master - Read method only if your PLC can operate as

a Modbus master and slave simultaneously. Go to Step 13

on Page 44 for configuration procedures.

10. PLC Master/DeviceMaster UP Slave Mode Only:

Use the following procedure to configure PLC Master/DeviceMaster UP Slave mode.

a. Set Rx (To PLC) Transfer Mode to Slave (PLC Polls).

b. Set Tx (From PLC) Transfer Mode to Slave (PLC Writes).

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. This can be a

maximum of 246 bytes in Slave Rx Mode.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set Tx MS Byte First if you want to transmit data most significant byte first.

g. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received between received data requests, only the last received

data packet will be returned.)

40 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 41

Configuring Read/Write Raw/ASCII Devices

h. Set the Disable Tx Sequence Number Check option if you want to disable the transmit sequence number

checking.

• If selected, the transmit sequence number checking is disabled. All transmit messages will be

transmitted if the sequence number has been incremented or not.

• If not selected, the sequence number is checked and the message will only be transmitted if the

sequence number has been incremented.

i. Go to Step 14

on Page 45 to complete configuration.

11. PLC Slave/DeviceMaster UP Master Mode Only:

Use the following procedure to configure PLC Slave/DeviceMaster UP Master mode.

Under the Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only) section:

a. Set Rx (To PLC) Transfer Mode to Master (Write to PLC).

b. Set Tx (From PLC) Transfer Mode to Master (Poll the PLC).

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. This can be a

maximum of 1518 bytes in Master Rx Mode.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set Tx MS Byte First if you want to transmit data most significant byte first.

g. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received during the Maximum PLC Update Rate time period, only

the last received data packet will be returned.).

Under the Modbus/TCP Master Rx/TX Settings (Raw-Data Only) section:

h. Enter the PLC IP Address:

• For Modbus/TCP slaves, set the PLC IP Address to that of your PLC in xxx.xxx.xxx.xxx format.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC IP Address to that of this

DeviceMaster UP in xxx.xxx.xxx.xxx format.

Note: The Modbus serial slave must be attached to one of the serial ports on this DeviceMaster UP

chassis.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 41

Page 42

Configuring Read/Write Raw/ASCII Devices

i. Enter the PLC Device ID:

• For Modbus/TCP slaves, set the PLC Device ID to that of your PLC. This is typically 1.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC Device ID to that of the serial slave

device.

Note: This must be a unique device id attached to this DeviceMaster UP chassis.

j. Set the PLC Rx Data Address to the PLC memory address where you want to place the received data

message. This address is Base 1, which means the address starts at 1 (or 400001 for some PLCs). If

your address range is Base 0, or starts at zero, you will need to add one to your address.

k. Set the Maximum PLC Update Rate to the fastest rate your PLC can reliably receive and process data.

This is typically longer than the scan rate. The default of 40 milliseconds is usually sufficient, but

your system may require a longer time period.

l. Set the Use Maximum Sized Modbus Messages option if you are receiving messages over 196 bytes, your

PLC can receive messages larger than 200 bytes, and you want to decrease latency and network

usage.

m. Set the PLC Tx Data Address to the PLC memory address at which to request the transmit data

message. This is Base 1, which means the address starts at 1 (or 400001 for some PLCs). If your

address range is Base 0, or starts at zero, you will need to add one to your address.

n. Set the PLC Tx Poll Rate to the rate at which you would like the DeviceMaster UP to poll for transmit

messages. If Tx Sequence Number Syncing is disabled, this rate must be faster than the rate at which

you wish to transmit data. If not, transmit messages will be lost.

o. Set the PLC Tx Poll Message Length to the length in bytes of your longest transmit data packet plus

four bytes for the sequence number and length parameters at the start of the transmit message

(maximum of 250 bytes). Any additional bytes requested will be left unused.

p. If you wish to enable synchronization of the transmit data messages between the PLC and the

DeviceMaster UP:

-Enable Tx Sequence Number Syncing Enable.

- Set the PLC Tx Consumed Sequence Address to the PLC memory address at which you wish the

DeviceMaster UP to write the transmit consumed sequence number. This memory address must

point to a 16-bit word and, like the other address definitions, is base 1. When the Tx Produced

Sequence Number (at the PLC Tx Data Address) and this consumed sequence number are equal, the

DeviceMaster UP has transmitted the last message and is ready for the next transmit message.

Note: Go to Step 14

42 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

on Page 45 to complete configuration.

Page 43

Configuring Read/Write Raw/ASCII Devices

12. Dual Master – Write Mode Only:

Use the following procedure to configure Dual Master – Write mode.

Under the Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only) section:

a. Set the Rx (To PLC) Transfer Mode to Master (Write to PLC).

b. Set the Tx (From PLC) Transfer Mode to Slave (PLC Writes).

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. This can be a

maximum of 1518 bytes in Master Rx Mode.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set Tx MS Byte First if you want to transmit data most significant byte first.

g. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received during the Maximum PLC Update Rate time period, only

the last received data packet will be returned.)

h. Set the Disable Tx Sequence Number Check option if you want to disable the transmit sequence number

checking.

• If selected, the transmit sequence number checking is disabled. All transmit messages will be

transmitted if the sequence number has been incremented or not.

• If not selected, the sequence number is checked and the message will only be transmitted if the

sequence number has been updated.

Under the Modbus/TCP Master Rx/TX Settings (Raw-Data Only) section:

i. Set the PLC IP Address to that of your PLC in xxx.xxx.xxx.xxx format.

j. Set the PLC Device ID to that of your PLC. This is typically 1.

k. Set the PLC Rx Data Address to the PLC memory address where you want to place the received data

message. This address is Base 1, which means the address starts at 1 (or 400001 for some PLCs). If

your address range is Base 0, or starts at zero, you will need to add one to your address.

l. Set the Maximum PLC Update Rate to the fastest rate your PLC can reliably receive and process data.

This is typically longer than the scan rate. The default of 40 milliseconds is usually sufficient, but

your system may require a longer time period.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 43

Page 44

Configuring Read/Write Raw/ASCII Devices

m. Set the Use Maximum Sized Modbus Messages option if you are receiving messages over 196 bytes, your

PLC can receive messages larger than 200 bytes, and you want to decrease latency and network

usage.

Note: Go to Step 14

on Page 45 to complete configuration.

13. Dual Master – Read Mode Only:

Use the following procedure to configure Dual Master – Read mode.

Under the Serial Modbus Master and Modbus/TCP Settings (Raw-Data Only) section:

a. Set the Rx (To PLC) Transfer Mode to Slave (PLC Polls).

b. Set the Tx (From PLC) Transfer Mode to Master (Poll the PLC).

c. Set the Maximum Rx Data Packet Size to that of the largest expected receive data packet. This can be a

maximum of 246 bytes in Slave Rx Mode.

d. Set the Oversized Rx Packet Handling to either Truncate or Drop, depending how you want to handle

oversized received packets.

e. Set Rx MS Byte First if you want to receive data most significant byte first.

f. Set Tx MS Byte First if you want to transmit data most significant byte first.

g. Set the Disable Non-Filtered To PLC Rx Queue option if you only want to receive the last received data

packet. (If two or more packets are received between received data requests, only the last received

data packet will be returned.)

44 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 45

Configuring Read/Write Raw/ASCII Devices

Under the Modbus/TCP Master Rx/TX Settings (Raw-Data Only) section:

h. Enter the PLC IP Address:

• For Modbus/TCP slaves, set the PLC IP Address to that of your PLC in xxx.xxx.xxx.xxx format.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC IP Address to that of this

DeviceMaster UP in xxx.xxx.xxx.xxx format.

Note: The Modbus serial slave must be attached to one of the serial ports on this DeviceMaster UP

chassis.

i. Enter the PLC Device ID:

• For Modbus/TCP slaves, set the PLC Device ID to that of your PLC. This is typically 1.

• For Modbus/RTU or Modbus/ASCII serial slaves, set the PLC Device ID to that of the serial slave

device.

Note: This must be a unique device id attached to this DeviceMaster UP chassis.

j. Set the PLC Tx Data Address to the PLC memory address at which to request the transmit data

message. This is Base 1, which means the address starts at 1 (or 400001 for some PLCs). If your

address range is Base 0, or starts at zero, you will need to add one to your address.

k. Set the PLC Tx Poll Rate to the rate at which you would like the DeviceMaster UP to poll for transmit

messages. If Tx Sequence Number Syncing is disabled, this rate must be faster than the rate at which

you wish to transmit data. If not, transmit messages will be lost.

l. Set the PLC Tx Poll Message Length to the length in bytes of your longest transmit data packet plus

four bytes for the sequence number and length parameters at the start of the transmit message

(maximum of 250 bytes). Any additional bytes requested will be left unused.

m. If you wish to enable synchronization of the transmit data messages between the PLC and the

DeviceMaster UP:

•Enable Tx Sequence Number Syncing Enable.

• Set the PLC Tx Consumed Sequence Address to the PLC memory address at which you wish the

DeviceMaster UP to write the transmit consumed sequence number. This memory address must

point to a 16-bit word and, like the other address definitions, is base 1. When the Tx Produced

Sequence Number (at the PLC Tx Data Address) and this consumed sequence number are equal, the

DeviceMaster UP has transmitted the last message and is ready for the next transmit message.

14. Set up the filtering/data extraction settings:

• If no filtering/data extraction is required, leave all filtering/data extraction settings to defaults (off).

• If filtering/data extraction is required, see

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 45

Filtering/Data Extraction Configuration on Page 61.

Page 46

Configuring Read/Write Raw/ASCII Devices

15. Set up the application socket interface settings:

• If no application socket interface is required, leave all application socket interface settings at defaults

and the application Enable option is not selected.

• If an application socket interface is required, see

Application Socket Configuration on Page 67.

16. Scroll to the bottom of the page, verify that Reset Port and Save in Flash are selected, and click Submit.

Modbus Addressing

The DeviceMaster UP serial port data addressing used for slave modes:

Serial Port Raw/

ASCII Addressing

Serial Port 1 Serial Port 2 Serial Port 3 Serial Port 4 Access Rule

Unit ID 255 (FF Hex) 255 (FF Hex) 255 (FF Hex) 255 (FF Hex) N/A

Receive Data Address

Transmit Data

Address

1000 (Base 0)

1001 (Base 1)

1300 (Base 0)

1301 (Base 1)

2000 (Base 0)

2001 (Base 1)

2300 (Base 0)

2301 (Base 1)

3000 (Base 0)

3001 (Base 1)

3300 (Base 0)

3301 (Base 1)

4000 (Base 0)

4001 (Base 1)

4300 (Base 0)

4301 (Base 1)

Read Only

Read/Write

Receive and Transmit Message Formats

The format of received serial data messages sent to or returned from the PLC:

Name Data Type Data Value(s) Access Rule

Receive (DeviceMaster UP to PLC)

message data.

Structure of:

Produced data sequence

Data length (in bytes)

Data array

WORD

WORD

Array of

0-65535 (FFFF Hex)

1-1024 (Master Rx Mode)

0-246 (Slave Rx Mode)

0-65535

Read

WORD

General requirements:

• The memory area must be defined in 16 bit words and large enough to handle the largest serial packet

plus two words for the produced sequence number and data length parameters.

•The Maximum Rx Data Packet Size must be set large enough to accept the largest possible packet.

For large received data packets over 246 bytes (This may be less for your PLC):

•The Rx (To PLC) Transfer Mode must be set to Master (Write to PLC).

• The data will automatically be placed in continuous memory.

• All data will have been transferred to the PLC when the sequence number is updated.

The format of the transmit serial data received from the PLC:

Name Data Type Data Value(s) Access Rule

Transmit (PLC to DeviceMaster UP)

message data.

Structure of:

Produced data sequence

Data length (in bytes)

Data array

WORD

WORD

Array of

0-65535 (FFFF Hex)

1-236 (Slave Mode)

1-246 (Master Mode)

0-65535

Read/Write

WORD

46 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 47

Configuring Read/Write Raw/ASCII Devices

Transmit messages have the following characteristics:

• All data is transferred in 16 bit words.

• If operating in Tx (From PLC) Transfer Mode of Master (Poll the PLC): The sequence number must be

incremented when there is new data to transmit.

• If operating in Tx (From PLC) Transfer Mode of Slave (PLC Writes): The sequence number must be

incremented when there is new data to transmit only if the Disable Tx Sequence Number Check is not

selected.

• The data length field indicates the number of valid bytes contained in this message.

• The actual length of the message received from a PLC may contain extra, unused data.

• Unused data is ignored.

• A request for transmit data returns the last transmit data message.

Read/Write Raw/ASCII Ethernet Devices

Read/write raw/ASCII

Ethernet devices use the

Ethernet Device

Configuration page to:

• Allow connections

between an Ethernet

device, such as a

barcode scanner, RFID

reader, or weigh scale,

and a PLC and/or an

application.

• Raw/ASCII data is the

only supported data

type.

• The Ethernet device

must support Ethernet

TCP socket

connections.

Note: The PLC and

applications can

both communicate to the Ethernet device, but they cannot communicate directly to each other.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 47

Page 48

Configuring Read/Write Raw/ASCII Devices

Embedded Web Page Configuration

Use the following procedure to configure read/write Ethernet devices.

1. Access the Server Configuration web page by entering the DeviceMaster UP IP address in your web

browser or by highlighting the DeviceMaster UP in PortVision DX and clicking Webpage.

Note: If the browser does not display the web page correctly, clear the browser history and refresh the

DeviceMaster UP web page.

2. Click the Ethernet Device Configuration option to open the Ethernet Device Configuration page.

Note: The Ethernet device must be a target Ethernet device such as a barcode scanner, RFID reader,

weigh scale, or some other device that is to be connected to a PLC and/or application.

3. Click Socket N for the port that you want to configure, where N is the Socket number.

4. If desired, enter an Ethernet Interface Name.

48 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 49

Configuring Read/Write Raw/ASCII Devices

Connect Mode Set Up

Listen Mode Set Up

Listen and Connect Modes Set Up

5. Click Enable under Device TCP Connection Configuration and configure the settings for your environment

using one of the following procedures.

• If your Ethernet TCP/IP Device requires

another device to connect to it, configure

the socket port on the DeviceMaster UP to

Connect mode:

- Leave Listen unselected.

- Set Connect To Mode to Connect-Always.

- Set the Connect Port to the socket port

number of your Ethernet device.

- Set the Connect IP Address to the IP

Address of your Ethernet device.

Do not enter the IP address of the

DeviceMaster UP or PLC here.

- Set Disconnect Mode to Never.

• If your Ethernet TCP/IP Device is

configured to connect to another device,

configure the socket port on the

DeviceMaster UP to Listen mode:

-Select Listen.

- Use the default Listen Port on the

DeviceMaster UP of 8xxx or designate

your own.

- Set Connect To Mode to Never.

- Set Disconnect Mode to Never.

- Configure your Ethernet device to

connect to the DeviceMaster UP at the

DeviceMaster UP IP address and Listen Port.

• If you do not know if your device will connect

to another Ethernet device, but do know

your device’s socket port and IP address, you

can do the following to enable both the Listen

and Connect modes:

-Select Listen.

- Use the default Listen Port on the

DeviceMaster UP of 8xxx or designate

your own.

- Set Connect To Mode to Connect-Always.

- Set the Connect Port to the port number

of your Ethernet device.

- Set the Connect IP Address to the IP address of your Ethernet device.

Do not enter the IP address of the DeviceMaster UP or PLC here.

- Set Disconnect Mode to Never.

- Optionally configure your Ethernet device to connect to the DeviceMaster UP at the DeviceMaster

UP IP Address and Listen Port.

DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G Configuring Read/Write Raw/ASCII Devices - 49

Page 50

Configuring Read/Write Raw/ASCII Devices

6. Set the Message Transfer mode:

• Selecting Data-Stream will enable asynchronous communication to the device.

- Transmit data will be sent immediately from all Modbus and active Application interfaces.

- Received data will be returned to the Modbus interface and all active Application interfaces.

-If Data-Stream is selected, the rest of the options in this section are N/A (not applicable).

• Selecting Command/Response will enable synchronous communications with the device.

- Transmit data will expect one or more responses.

- Responses will only be returned to the transmit message originator.

If Command/Response is selected:

- Set the Cmd/Resp Response Timeout to a valid timeout period for your device.

-The Cmd/Resp Age Time will set the time at which old responses to the Modbus interface are

discarded.

-The Cmd/Resp Expected Responses Per Command indicates the number of responses expected per

transmitted message. This is typically 1.

- Set the Cmd/Resp Mode Response To Modbus/TCP Based On option to:

- IP-Address if there is only one Modbus/TCP interface per IP-Address communicating to this

port. This is typically used for PLC or single OPC Server/SCADA systems.

- TCP-Connection if there is more than one Modbus/TCP interface per IP-Address

communicating to this port. This typically is required for multiple OPC Server/ SCADA

systems running on the same computer.

7. Set up the Socket Packet Identification.

a. Set the Rx Timeout Between Packets. Set to zero to stream data with the Rx STX/ETX Detect settings set

to none. For normal settings, typical values are 10 to 50 ms.

b. Set the STX (Start of transmission) Rx Detect in decimal format.

c. Set the ETX (End of transmission) Rx Detect in decimal format.

d. Enable the S trip Rx STX/ETX option if you do not want the STX and ETX bytes returned to the PLC or

application.

Note: Refer to your device's User Manual for the Start and End of Transmission byte(s) settings.

50 - Configuring Read/Write Raw/ASCII Devices DeviceMaster UP Modbus/TCP Quick Start: 2000477 Rev. G

Page 51

Configuring Read/Write Raw/ASCII Devices

Note: You can use the PLC Master/DeviceMaster UP Slave method

only if your PLC can operate as a Modbus/TCP master, Modbus/RTU

serial master, or Modbus/ASCII serial master.

Note: You can use the PLC Slave/DeviceMaster UP Master method only if your

PLC can operate as a Modbus/TCP slave, Modbus/RTU serial slave, or

Modbus/ASCII serial slave.

Note: You can use the Dual Master - Write method only if your PLC can

operate as a Modbus master and slave, simultaneously.

You may also be able to use the Ethernet Device Interface Logs page to determine these settings.

8. Configure the Modbus/TCP Settings for your environment using one of the following methods.

• PLC master/DeviceMaster UP Slave mode, go to Step 9

on Page 52 for configuration procedures.