Page 1

EtherNet/IP

Reference Manual

Page 2

Trademark Notices

Document Number: 2000589 Rev. A

Microsoft and Windows are registered trademarks of Microsoft Corporation.

Other product names mentioned herein may be trademarks and/or registered trademarks of their respective

owners.

First Edition, March 12, 2014

Copyright © 2013-2014. Comtrol Corporation.

All Rights Reserved.

Comtrol Corporation makes no representations or warranties with regard to the contents of this document or

to the suitability of the Comtrol product for any particular purpose. Specifications subject to change without

notice. Some software or features may not be available at the time of publication. Contact your reseller for

current product information.

Page 3

Table of Contents

Chapter 1. EtherNet/IP Interface .......................................................................................7

1.1. Introduction............................................................................................................................................. 7

1.1.1. Functionality Summary ................................................................................................................... 7

1.1.2. Data Type Definitions ...................................................................................................................... 8

1.1.3. Terms and Definitions ...................................................................................................................... 9

1.2. Data Transfer Methods ....................................................................................................................... 10

1.2.1. Receive Process Data Methods....................................................................................................... 10

1.2.1.1. Polling-PLC Requests Data .................................................................................................. 10

1.2.1.2. Write-to-Tag/File-IO-Link Master Writes Data Directly Into PLC Memory ..................... 10

1.2.1.3. Class 1 Connection (Input Only)-PLC and IO-Link Master Utilize an I/O Connection.... 11

1.2.2. Transmit Process Data Methods.................................................................................................... 11

1.2.2.1. PLC-Writes ........................................................................................................................... 11

1.2.2.2. Read-from-Tag/File-IO-Link Master Reads Data from PLC Memory ................................ 11

1.2.2.3. Class 1 Connection (Input and Output)-PLC and IO-Link Master Utilize an I/O Connection

12

1.3. Process Data Block Descriptions...................................................................................................... 13

1.3.1. Input Process Data Block Description........................................................................................... 13

1.3.1.1. Input Process Data Block-8 Bit Data Format...................................................................... 14

1.3.1.2. Input Process Data Block-16 Bit Data Format.................................................................... 14

1.3.1.3. Input Process Data Block-32 Bit Data Format.................................................................... 14

1.3.2. Output Process Data Block Description ........................................................................................ 15

1.3.2.1. Output Process Data Block-8 Bit (SINT) Data Format....................................................... 15

1.3.2.2. Output Process Data Block-16 Bit (INT) Data Format....................................................... 15

1.3.2.3. Output Process Data Block-32 Bit (DINT) Data Format .................................................... 16

Chapter 2. Functionality Descriptions............................................................................17

2.1. Event Handling ..................................................................................................................................... 17

2.1.1. Clear Event After Hold Time Process............................................................................................ 18

2.1.2. Clear Event in PDO Block Process ................................................................................................ 19

2.1.3. Clear Event Code in PDO Block and Clear Event After Hold Time Process-PDO Block First.. 20

2.1.4. Clear Event Code in PDO Block and Clear Event After Hold Time Process-Hold Time Expires ..

21

2.2. ISDU Handling ...................................................................................................................................... 21

2.2.1. ISDU Request/Response Structure................................................................................................ 22

2.2.1.1. Single ISDU Command Request .......................................................................................... 22

2.2.1.2. Multiple ISDU Command Structure .................................................................................... 23

2.2.2. ISDU Request Message Format-From PLC to IO-Link Master................................................... 25

2.2.2.1. Standard ISDU Request Command Format........................................................................ 25

2.2.2.2. Integer (16-Bit Word) ISDU Request Command Format.................................................... 26

2.2.3. ISDU Response Message Format................................................................................................... 27

2.2.3.1. Standard ISDU Response Command Format...................................................................... 27

2.2.3.2. Integer (16-Bit Word) ISDU Response Command Format.................................................. 28

2.2.4. ISDU Blocking and Non-Blocking Methods .................................................................................. 29

2.2.4.1. Single Command Blocking .................................................................................................... 29

2.2.4.2. Multiple Command Blocking ................................................................................................ 30

2.2.4.3. Single Command Non-Blocking............................................................................................31

2.2.4.4. Multiple Command Non-Blocking ........................................................................................ 32

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Table of Contents - 3

Page 4

Table of Contents

Chapter 3. EtherNet/IP CIP Object Definitions ............................................................33

3.1. IO-Link Port Information Object Definition (71 hex).................................................................. 33

3.1.1. Class Attributes .............................................................................................................................. 34

3.1.2. Instance Attributes......................................................................................................................... 35

3.1.3. Common Services............................................................................................................................ 36

3.1.4. Instance Attribute Definitions ....................................................................................................... 37

3.1.4.1. Attribute 1-Vendor Name .................................................................................................... 38

3.1.4.2. Attribute 2-Vendor Text ....................................................................................................... 38

3.1.4.3. Attribute 3-Product Name .................................................................................................... 38

3.1.4.4. Attribute 4-Product ID ......................................................................................................... 38

3.1.4.5. Attribute 5-Product Text ...................................................................................................... 38

3.1.4.6. Attribute 6-Serial Number .................................................................................................. 38

3.1.4.7. Attribute 7-Hardware Revision ........................................................................................... 38

3.1.4.8. Attribute 8-Firmware Revision ........................................................................................... 38

3.1.4.9. Attribute 9-Device PDI Length ............................................................................................ 39

3.1.4.10. Attribute 10-Device PDO Length ....................................................................................... 39

3.1.4.11. Attribute 11-PDI Data Block Length ................................................................................. 39

3.1.4.12. Attribute 12-PDO Data Block Length................................................................................ 39

3.1.4.13. Attribute 13-Input Assembly PDI Offset ........................................................................... 39

3.1.4.14. Attribute 14-Input Assembly PDO Offset .......................................................................... 39

3.1.4.15. Attribute 15-Output Assembly PDO Offset ....................................................................... 40

3.1.4.16. Attribute 16-Control Flags ................................................................................................. 40

3.2. PDI (Process Data Input) Transfer Object Definition (72 hex) ................................................. 41

3.2.1. Class Attributes .............................................................................................................................. 41

3.2.2. Instance Attributes......................................................................................................................... 41

3.2.3. Common Services............................................................................................................................ 41

3.2.4. Instance Attribute Definitions - Attribute 1 to 4-PDI Data Blocks ............................................. 41

3.3. PDO (Process Data Output) Transfer Object Definition (73 hex)............................................. 42

3.3.1. Class Attributes .............................................................................................................................. 42

3.3.2. Instance Attributes......................................................................................................................... 42

3.3.3. Common Services............................................................................................................................ 42

3.3.4. Instance Attribute Definitions - Attribute 1 to 4-PDO Data Blocks............................................ 42

3.4. ISDU Read/Write Object Definition (74 hex).................................................................................. 43

3.4.1. Class Attributes .............................................................................................................................. 43

3.4.2. Instance Attributes......................................................................................................................... 43

3.4.3. Common Services............................................................................................................................ 43

3.4.4. Object Specific Services .................................................................................................................. 44

3.4.5. Instance Attribute Definitions ....................................................................................................... 44

3.4.5.1. Attribute 1-ISDU Read/Write Response (Non-Blocking only) ............................................ 44

3.4.5.2. Attribute 2-ISDU Read/Write Request (Non-blocking only)............................................... 44

3.5. Identity Object (01hex, 1 instance)................................................................................................... 45

3.5.1. Class Attributes .............................................................................................................................. 45

3.5.2. Instance Attributes......................................................................................................................... 45

3.5.3. Status Word .................................................................................................................................... 46

3.5.4. Common Services............................................................................................................................ 46

3.6. Message Router Object (02 hex) ........................................................................................................ 48

3.6.1. Class Attributes .............................................................................................................................. 48

3.6.2. Instance Attributes......................................................................................................................... 48

3.6.3. Common Services............................................................................................................................ 48

3.7. Connection Manager Object (06 hex)............................................................................................... 49

3.7.1. Class Attributes Object (06 hex) .................................................................................................... 49

3.7.2. Instance Attributes (02 hex) .......................................................................................................... 49

3.7.3. Common Services Object (06 hex) .................................................................................................. 49

4 - Table of Contents IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 5

Table of Contents

3.8. Port Object (F4 hex-1 instance)......................................................................................................... 50

3.8.1. Class Attributes .............................................................................................................................. 50

3.8.2. Instance Attributes......................................................................................................................... 51

3.8.3. Common Services............................................................................................................................ 51

3.9. TCP Object (F5 hex-1 instance) ......................................................................................................... 52

3.9.1. Class Attributes .............................................................................................................................. 52

3.9.2. Instance Attributes......................................................................................................................... 52

3.9.3. Common Services............................................................................................................................ 54

3.10. Ethernet Link Object (F6 hex-1 instance) .................................................................................... 54

3.10.1. Class Attributes ............................................................................................................................ 54

3.10.2. Instance Attributes....................................................................................................................... 55

3.10.3. Common Services.......................................................................................................................... 55

3.11. PCCC Object (67 hex-1 instance) .................................................................................................... 56

3.11.1. Instances ....................................................................................................................................... 56

3.11.2. Common Services.......................................................................................................................... 56

3.11.3. Message Structure Execute_PCCC: Request Message ............................................................... 56

3.11.4. Message Structure Execute_PCCC: Response Message ............................................................. 57

3.11.5. Supported PCCC Command Types .............................................................................................. 57

3.12. Assembly Object (For Class 1 Interface) ....................................................................................... 58

3.12.1. Class Attributes ............................................................................................................................ 58

3.12.2. Instance Definitions...................................................................................................................... 58

3.12.3. Instance Attributes....................................................................................................................... 59

3.12.4. Common Services.......................................................................................................................... 59

3.12.5. Instance Attribute Definitions: Attribute 3-Request/Write Data .............................................. 60

3.12.6. Instance Attribute Definitions: Attribute 4-Data Length .......................................................... 60

3.12.7. Overview of Assembly Interface .................................................................................................. 60

3.12.8. Grouping of Assembly Instances.................................................................................................. 61

Chapter 4. IO-Link Port Configuration...........................................................................63

4.1. IO-Link Settings Configuration Page .............................................................................................. 63

4.1.1. Editing IO-Link Settings................................................................................................................ 64

4.1.2. IO-Link Settings Parameters......................................................................................................... 64

4.2. EtherNet/IP Settings Configuration Page ...................................................................................... 65

4.2.1. Editing EtherNet/IP Settings ........................................................................................................ 66

4.2.2. EtherNet/IP Settings Parameters ................................................................................................. 67

Chapter 5. Using the Diagnostics Pages .........................................................................73

5.1. IO-Link Port Diagnostics .................................................................................................................... 73

5.2. EtherNet/IP Diagnostics ..................................................................................................................... 76

Chapter 6. ControlLogix Family - Example PLC Programs .......................................81

6.1. Import the PLC program into RSLogix 5000 ................................................................................. 81

6.2. Configure the Controller .................................................................................................................... 81

6.3. Add the EtherNet/IP Module Interface ........................................................................................... 83

6.4. Configure the Ethernet Module ........................................................................................................ 85

6.5. Example PLC Program Operation ................................................................................................... 90

6.6. User Defined Data Structures ........................................................................................................... 93

6.6.1. User Defined Structure Example 1................................................................................................ 94

6.6.2. User Defined Structure Example 2................................................................................................ 94

6.6.3. User Defined Structure Example 3................................................................................................ 95

6.6.4. User Defined Structure Example 4................................................................................................ 95

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Table of Contents - 5

Page 6

Table of Contents

6.7. Example PLC Program Tag Definitions.......................................................................................... 96

6.7.1. PrtN_DeviceInformation Definition .............................................................................................. 98

6.7.2. PrtN_RxPdiData Definition ........................................................................................................... 99

6.7.3. PrtN_MiscISDUReqs .................................................................................................................... 100

6.7.4. PrtN_MiscISDUResp .................................................................................................................... 101

6.7.5. Using Other ISDU Request/Response Command Formats ........................................................ 101

Chapter 7. SLC/PLC-5/MicroLogix Interface ...............................................................103

7.1. Requirements ...................................................................................................................................... 103

7.2. PLC-5 and SLC 5/05 PLC Requirements........................................................................................104

7.2.1. SLC 5/05 ........................................................................................................................................ 104

7.2.2. PLC-5............................................................................................................................................. 104

7.3. PLC-5 and SLC Messages .................................................................................................................. 105

7.4. Process Data (PDI and PDO) Access via PCCC Messages ........................................................107

Chapter 8. Troubleshooting and Technical Support .................................................109

8.1. Troubleshooting.................................................................................................................................. 109

8.2. Contacting Technical Support ........................................................................................................ 110

8.3. Using Log Files.................................................................................................................................... 111

8.3.1. View a Log File ............................................................................................................................. 111

8.3.2. Clear a Log File............................................................................................................................. 111

8.3.3. Export a Log File .......................................................................................................................... 112

6 - Table of Contents IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 7

Chapter 1. EtherNet/IP Interface

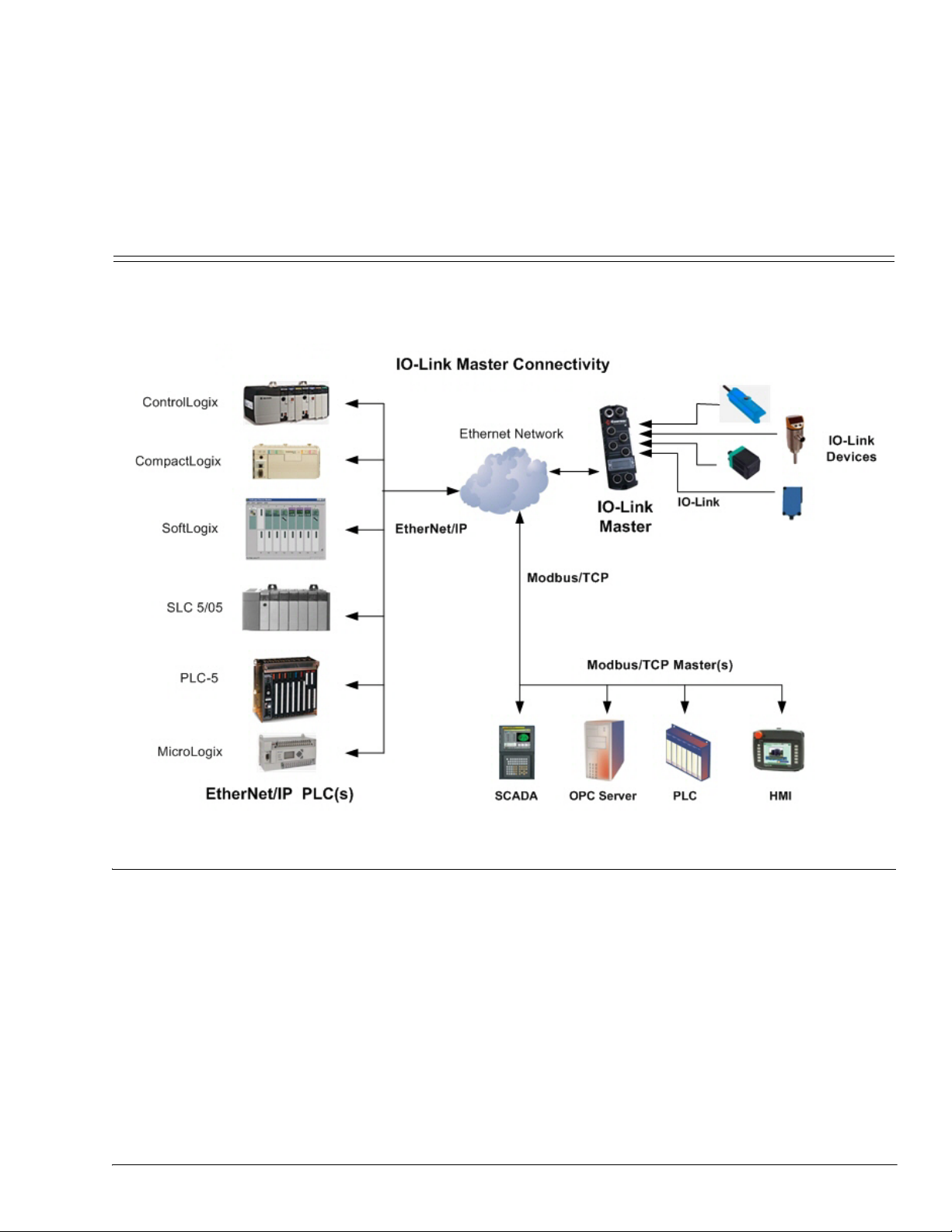

1.1. Introduction

This section is intended to describe the EtherNet/IP and Modbus/TCP interfaces provided by the IO-Link

Master.

These interfaces provide the ability to retrieve port and device status information, input and output process

data and access to IO-Link device ISDU (SPDU) data blocks.

1.1.1. Functionality Summary

The EtherNet/IP interface consists of:

• Input Process Data blocks that include:

- Port communication status

- PDI valid status

- Auxiliary Input status (pin 2 of IO-Link connector)

- The active event code (zero if no active event)

- The input process data received from the port. This may be

• IO-Link mode: IO-Link device input process data

• I/O Input mode: Input bit status

• I/O Output mode: Output bit status (configurable option)

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 1. EtherNet/IP Interface - 7

Page 8

Data Type Definitions

• Output Process Data blocks that include:

- The active event code to clear ((configurable option)

- The output process data to be sent to the port. This may be

• IO-Link mode: IO-Link device output process data

• I/O Output mode: Output bit status

• ISDU (ISDU) interface:

- Provides single and nested batch read/write capabilities

- Requires use of MSG instructions

- Provides both blocking and non-blocking message capabilities

• Blocking message responses are not returned until all the ISDU command(s) have completed.

• Non-blocking messages return immediately. The PLC must then request the ISDU command(s)

response status until a valid response is returned.

• Web based configuration and diagnostic pages:

- IO-Link interface configuration and diagnostics

- EtherNet/IP interface configuration and diagnostics

• EtherNet/IP interface support for ControlLogix, SLC, MicroLogix, and PLC-5 PLC families.

• Modbus/TCP slave interface.

• Example PLC programs to aid the PLC programmer.

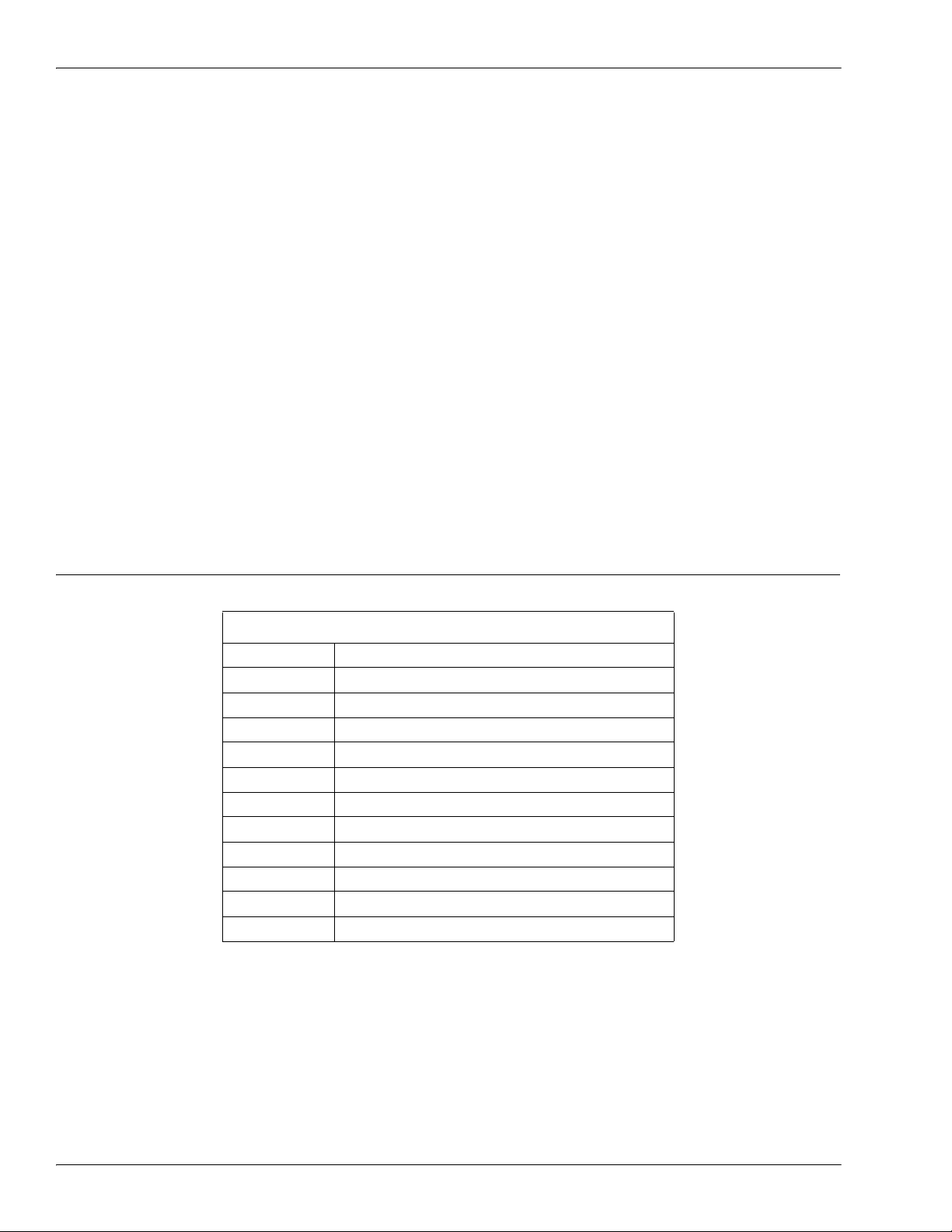

1.1.2. Data Type Definitions

The following data type definitions apply.

BOOL Boolean; TRUE if = 1; False if = 0

USINT Unsigned Short Integer (8 bit)

CHAR Character (8 bit)

SINT Short Integer (8 bit)

UINT Unsigned Integer (16 bit)

INT Signed Integer (16 bit)

UDINT Unsigned Double Integer (32 bit)

DINT Signed Double Integer (32 bit)

STRING Character String (1 byte per character)

BYTE Bit String (8 bit)

WORD Bit String (16 bits)

DWORD Bit String (32 bits)

Data Type Definitions

8 - Chapter 1. EtherNet/IP Interface IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 9

1.1.3. Terms and Definitions

This section uses the following terms and definitions.

Term Definition

Otherwise called implicit messaging, is a method of communication

between EtherNet/IP controllers and devices that:

Class 1

Class 3

EtherNet/IP

Ethernet TCP/IP

Ethernet UDP/IP

IO-Link Master

Multicast

Point-to-Point

PDI data

(Process Data

Input)

PDO data

(Process Data

Output)

ISDU

ISDU

Class 1

• Uses Ethernet UDP messages.

• Is cyclic in nature. Input and/or output data is exchanged between

the controllers and devices at regular time intervals.

Otherwise called explicit messaging, is a method of communication

between EtherNet/IP controllers and devices that:

• Uses Ethernet TCP/IP messages.

• By itself is not cyclic in nature. The controller and devices must send

individual messages to each other.

An Ethernet based industrial communication protocol utilized to

communicate between controllers, often times PLCS, and devices.

Standard Ethernet communications protocol utilizing socket

communication interfaces that guarantees delivery to the intended

device.

Standard Ethernet communications protocol utilizing socket

communication interfaces that does not guarantee delivery. The data

may or may get to the intended device.

IO-Link gateway that provides communication between IO-Link devices

and Ethernet protocols such as EtherNet/IP and Modbus/TCP.

Multicast addressing involves Ethernet devices sending messages to each

other using a multicast address. Multicast addressing:

• Uses a specified IP address range designated for multicast

communication.

• Allows either one or multiple devices to receive the same messages.

Point-to-Point, otherwise called unicast, addressing involves Ethernet

devices sending messages directly to each other using their own IP

addresses. Messages are sent to only one device.

Process data received from an IO-Link device or I/O interface that can be

provided to external controllers such as PLCs, HMIs, SCADA, and OPC

Servers.

Process data received from external controllers such as PLCs, HMIs,

SCADA, and OPC Servers and sent to an IO-Link device or I/O interface.

Note: IO-Link devices may or may not support PDO data.

Service Process Data Unit. Otherwise called ISDU, refers to the Service

Data units on IO-Link devices that are used for information, status and

configuration settings.

Indexed Service Data Unit. Otherwise called ISDU, refers to the Service

Data units on IO-Link devices that are used for information, status and

configuration settings.

Otherwise called implicit messaging, is a method of communication

between EtherNet/IP controllers and devices that:

• Uses Ethernet UDP messages.

• Is cyclic in nature. Input and/or output data is exchanged between

the controllers and devices at regular time intervals.

Terms and Definitions

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 1. EtherNet/IP Interface - 9

Page 10

Data Transfer Methods

1.2. Data Transfer Methods

The IO-Link Master provides a selection of process data transfer methods and a number of options to

customize the process data handling.

• 1.2.1. Receive Process Data Methods

• 1.2.2. Transmit Process Data Methods on Page 11

1.2.1. Receive Process Data Methods

The IO-Link Master supports the following receive process data methods:

• 1.2.1.1. Polling-PLC Requests Data

• 1.2.1.2. Write-to-Tag/File-IO-Link Master Writes Data Directly Into PLC Memory

• 1.2.1.3. Class 1 Connection (Input Only)-PLC and IO-Link Master Utilize an I/O Connection

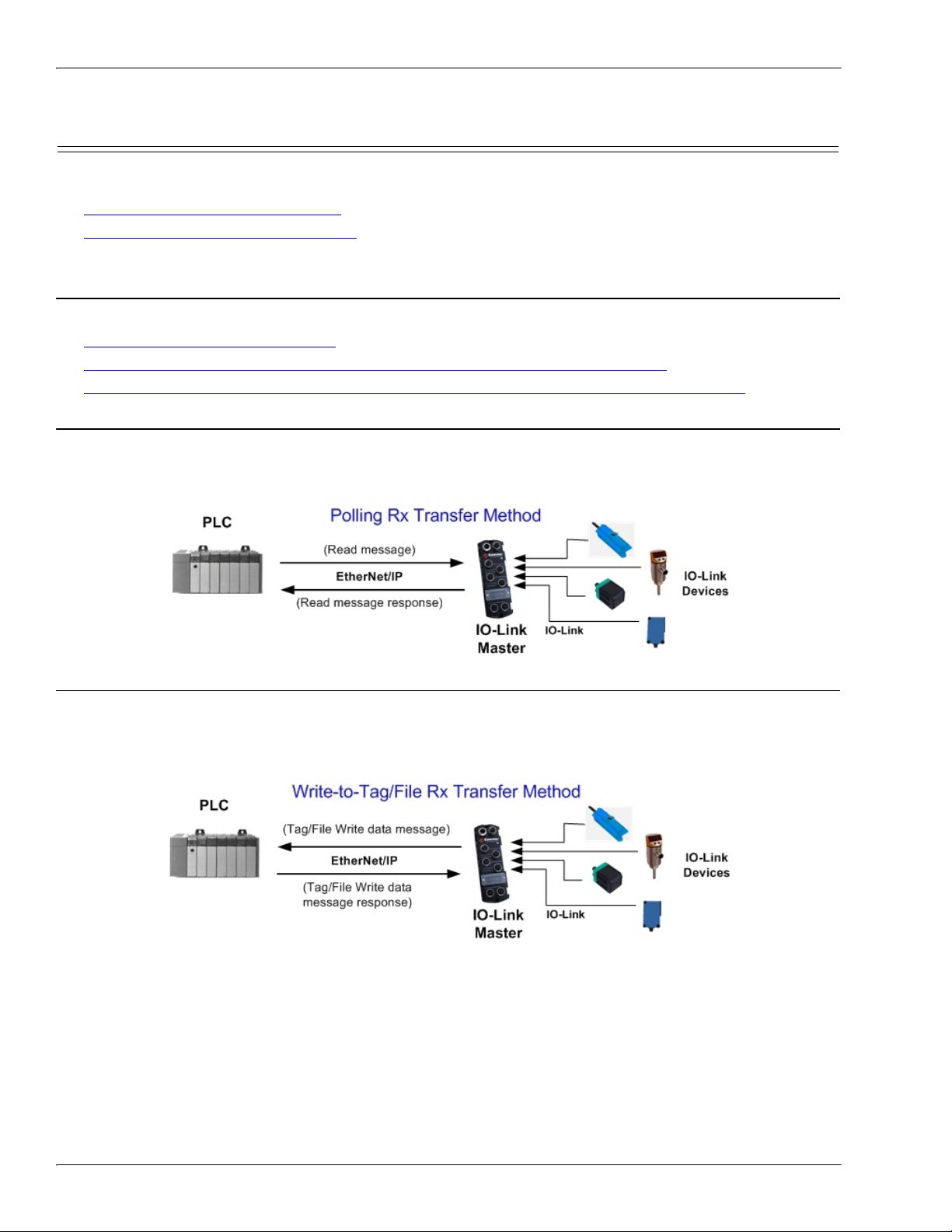

1.2.1.1. Polling-PLC Requests Data

Also called Slave-Mode for some industrial protocols, the polling method requires the controller to request

data from the IO-Link Master via messages. The IO-Link Master does not respond until it receives a request

for data.

1.2.1.2. Write-to-Tag/File-IO-Link Master Writes Data Directly Into PLC Memory

Also called Master-Mode for some industrial protocols, the Write-to-Tag/File method requires the IO-Link

Master to send messages that write data directly into a tag or file on the PLC. The IO-Link Master sends

changed data to the PLC immediately and, optionally, can be configured to also send “heartbeat” update

messages at a regular time interval.

10 - Chapter 1. EtherNet/IP Interface IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 11

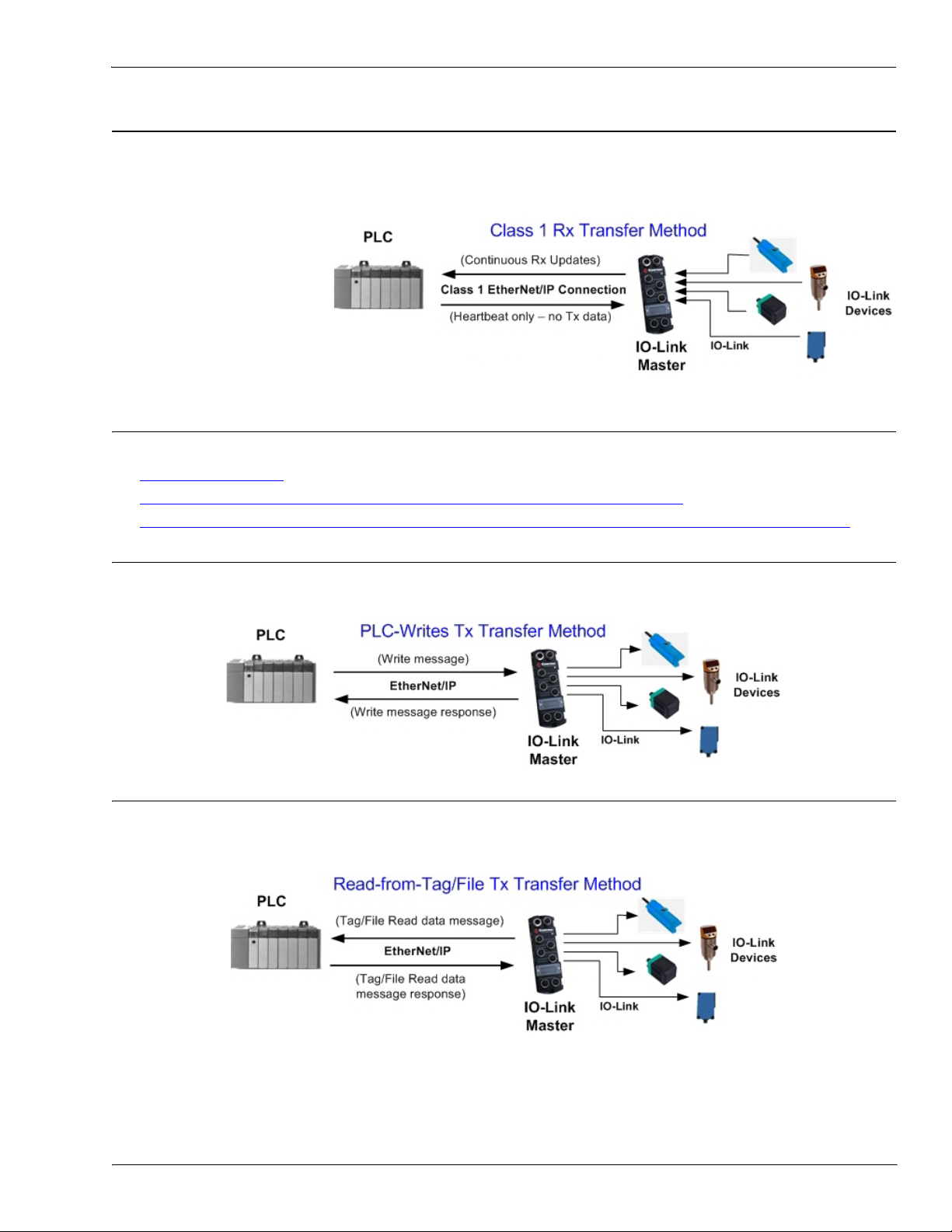

Class 1 Connection (Input Only)-PLC and IO-Link Master Utilize an I/O Connection

1.2.1.3. Class 1 Connection (Input Only)-PLC and IO-Link Master Utilize an I/O Connection

Also called I/O Mode for some industrial protocols, the Class 1 connection method requires the IO-Link

Master and PLC to connect to each via an I/O connection. For EtherNet/IP, a connection over UDP must first

be created. Once the connection is established, the IO-Link Master continually sends input data to the PLC at

a PLC configurable rate.

1.2.2. Transmit Process Data Methods

The IO-Link Master supports the following transmit process data methods:

• 1.2.2.1. PLC-Writes

• 1.2.2.2. Read-from-Tag/File-IO-Link Master Reads Data from PLC Memory

• 1.2.2.3. Class 1 Connection (Input and Output)-PLC and IO-Link Master Utilize an I/O Connection

1.2.2.1. PLC-Writes

Also called Slave-Mode for some industrial protocols, the PLC-Writes method requires the PLC to send data

to the IO-Link Master via write messages.

1.2.2.2. Read-from-Tag/File-IO-Link Master Reads Data from PLC Memory

Also called Master-Mode for some industrial protocols, the Read-from-Tag/File method requires the IO-Link

Master to read data from a tag or file on the PLC. In this method, the IO-Link Master requests data from the

PLC at configurable time intervals.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 1. EtherNet/IP Interface - 11

Page 12

Class 1 Connection (Input and Output)-PLC and IO-Link Master Utilize an I/O Connection

1.2.2.3. Class 1 Connection (Input and Output)-PLC and IO-Link Master Utilize an I/O Connection

Also called I/O Mode for some industrial protocols, the Class 1 connection method requires the IO-Link

Master and PLC to connect to each via an I/O connection. For EtherNet/IP, a connection over UDP must first

be created. Once the connection is established, the PLC and IO-Link Master continually exchange data at a

configurable rate.

12 - Chapter 1. EtherNet/IP Interface IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 13

Process Data Block Descriptions

1.3. Process Data Block Descriptions

This subsection discusses the following:

• 1.3.1. Input Process Data Block Description

• 1.3.2. Output Process Data Block Description on Page 15

1.3.1. Input Process Data Block Description

The Input Process Data Block format is dependent on the configured PDI Data Format. The following tables

describe the Input Process Data Block in the possible formats.

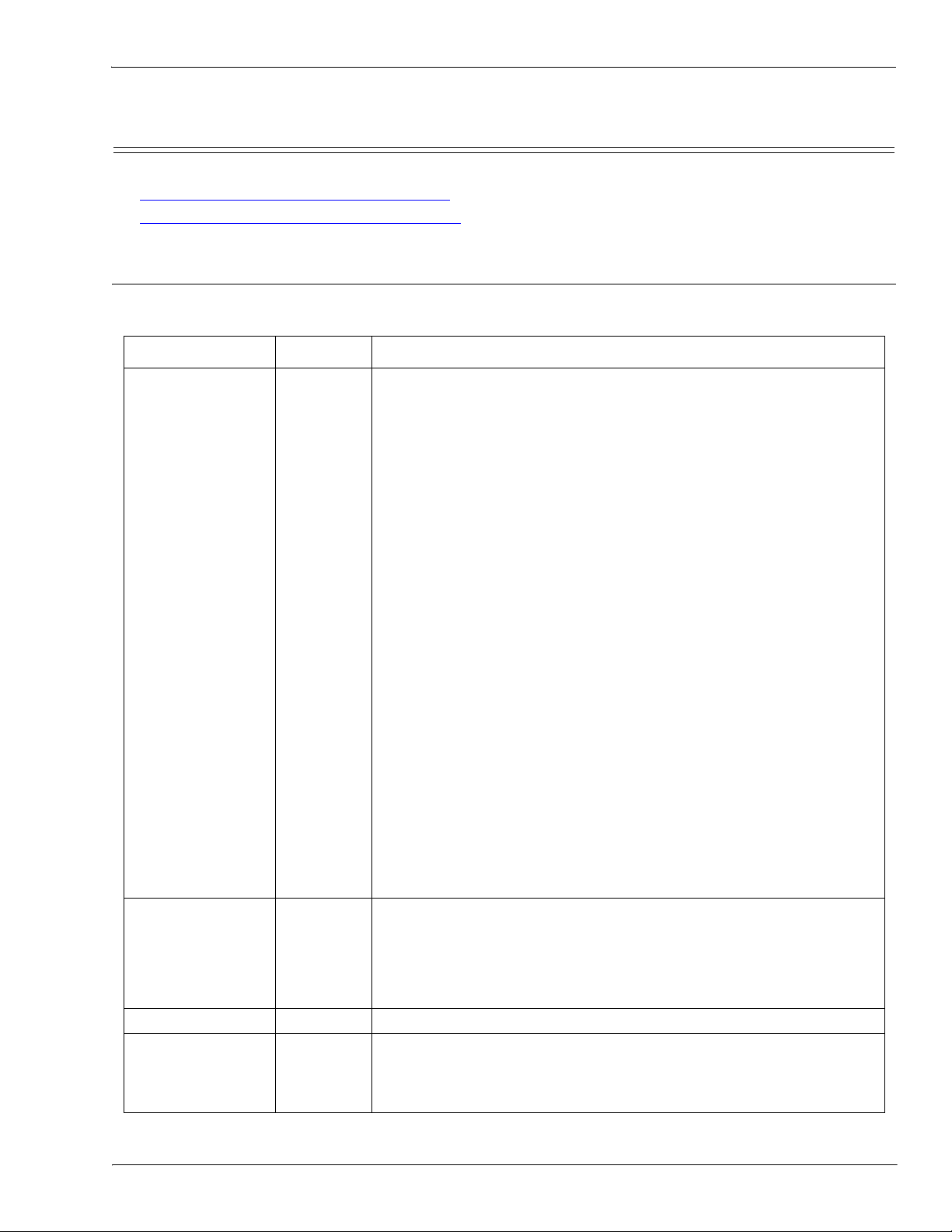

Parameter Name Data Type Description

The status of the IO-Link device.

Bit 0 (0x01):

0 = IO-Link port communication initialization process is inactive

1 = IO-Link port communication initialization process is active

Bit 1 (0x02):

0 = IO-Link port communication is not operational

1 = IO-Link port communication is operational

Bit 2 (0x04):

0 = IO-Link input process data is not valid.

1 = IO-Link input process data is valid.

Bit 3 (0x08):

0= No fault detected

Port Status BYTE

1= Fault detected

• A minor communication fault is indicated by the Operational

status bit being set to 1. A minor communication fault results

from:

- A temporary loss of communication to the IO-Link device.

- A recoverable IO-Link Master software or hardware fault.

• A major communication fault is indicated by the Operational

bit being set to 0.

- An unrecoverable loss of communication to the IO-Link

device.

- An unrecoverable IO-Link Master software or hardware

fault.

Bits 4-7: Reserved (0)

Auxiliary I/O:

Bit 0: The status of the Pin 2 auxiliary bit.

Auxiliary I/O BYTE

Event Code INT 16-bit event code received from the IO-Link device.

PDI Data

Default Length = 32

bytes

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 1. EtherNet/IP Interface - 13

Array of up

to 32

BYTEs

0 = off

1 = on

Bits 1-7: Reserved (0)

The PDI data as received from the IO-Link device. May contain from 0

to 32 bytes of PDI data. The definition of the PDI data is device

dependent.

Note: Length is configurable using the web page interface.

Page 14

Input Process Data Block-8 Bit Data Format

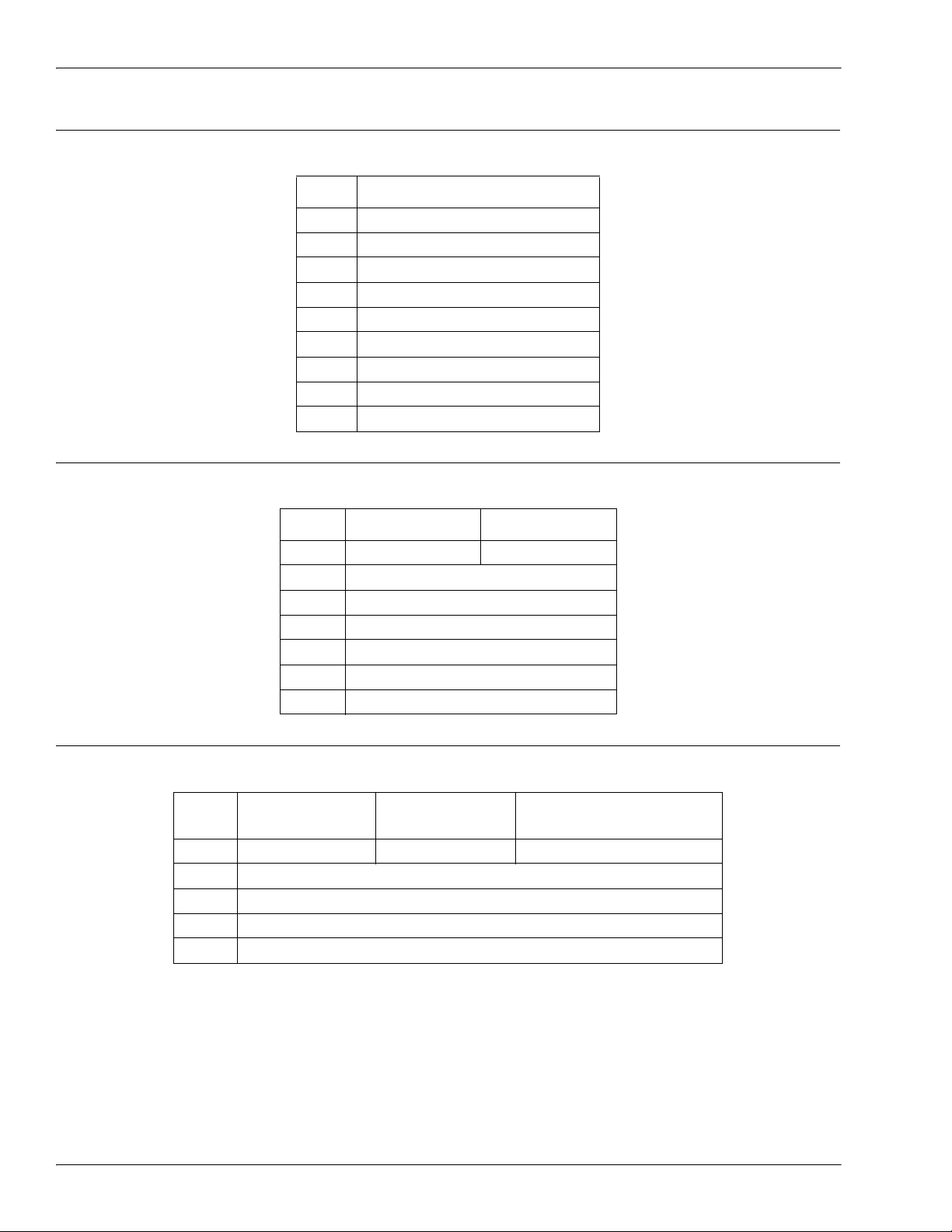

1.3.1.1. Input Process Data Block-8 Bit Data Format

The following table provides detailed information about the Input Process Data Block-8 Bit data format.

Byte Bit 7 Bit 0

0Port Status

1 Auxiliary I/O

2Event Code LSB

3Event Code MSB

4 PDI Data Byte 0

5 PDI Data Byte 1

.. ..

.. ..

N+3 PDI Data Byte (N-1)

1.3.1.2. Input Process Data Block-16 Bit Data Format

The following table provides detailed information about the Input Process Data Block-16 data format.

Word Bit 15 Bit 8 Bit 7 Bit 0

0 Port Status Auxiliary I/O

1Event Code

2 PDI Data Word 0

3 PDI Data Word 1

.. ..

.. ..

N+1 PDI Data Word (N-1)

1.3.1.3. Input Process Data Block-32 Bit Data Format

The following table provides detailed information about the Input Process Data Block-32 Bit data format.

Long

Word

Bit 31 Bit 24 Bit 23 Bit 16 Bit 15 Bit 0

0 Port Status Auxiliary I/O Event Code

2 PDI Data Long Word 0

3 PDI Data Long Word 1

.. ..

N PDI Data Long Word (N-1)

14 - Chapter 1. EtherNet/IP Interface IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 15

1.3.2. Output Process Data Block Description

The contents of the Output Process Data Block are configurable.

Parameter Name Data Description

Output Process Data Block Description

Event to Clear

(Configurable option)

INT

If included, allows clearing of 16-bit event code received in

the PDI data block via the PDU data block.

Default: Not included

The PDO data written to the IO-Link device. May contain

PDO Data

Default Length = 32 bytes

Array of up

to 32 BYTEs

from 0 to 32 bytes of PDO data. The definition and length

of the PDO data is device dependent.

Note: Length is configurable via web page interface.

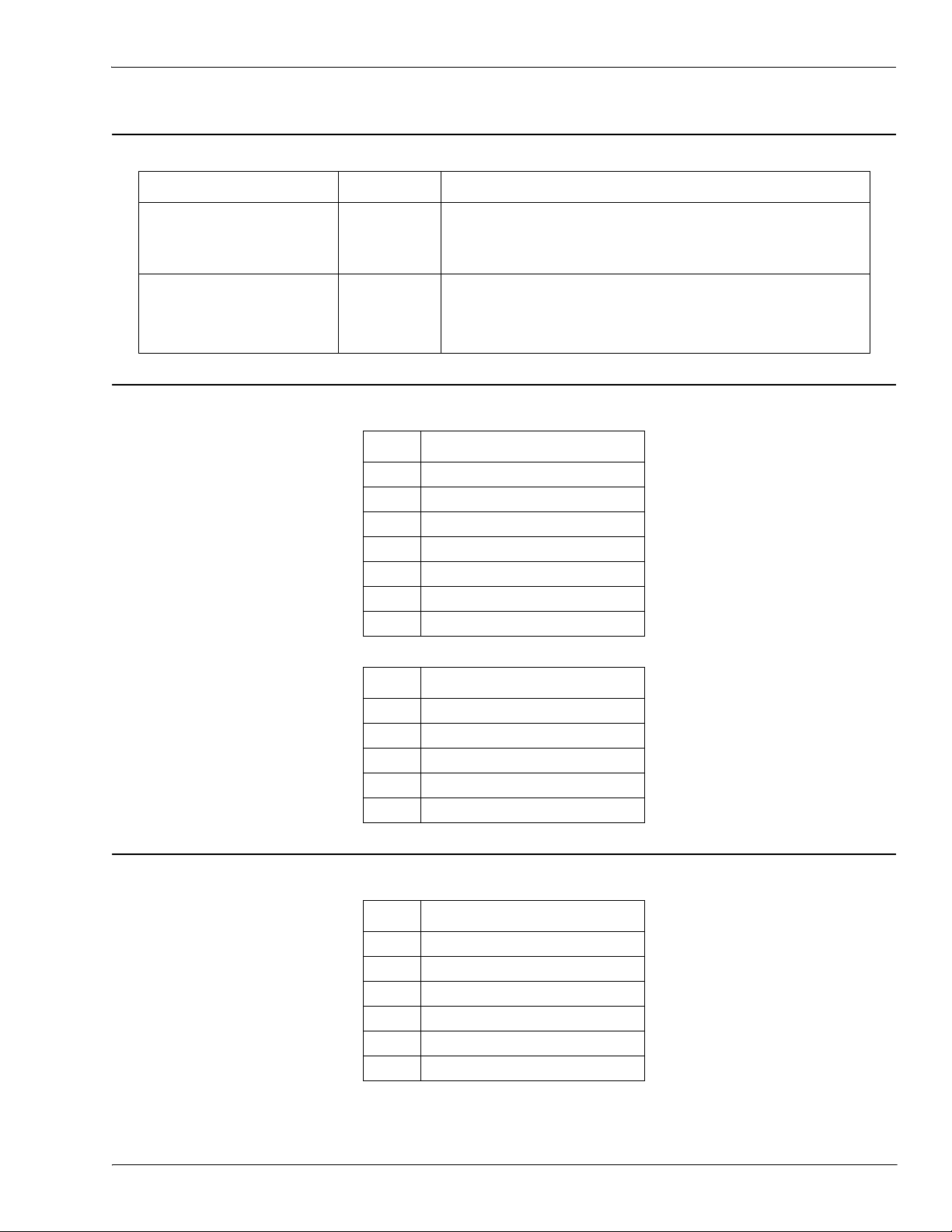

1.3.2.1. Output Process Data Block-8 Bit (SINT) Data Format

With the Include Event to Clear option selected:

Byte Bit 7 Bit 0

0 Event Code LSB

1 Event Code MSB

2 PDO Data Byte 0

3 PDO Data Byte 1

.. ..

.. ..

N+1 PDO Data Byte (N-1)

Without the Event to Clear option selected:

Byte Bit 7 Bit 0

0 PDO Data Byte 0

1 PDO Data Byte 1

.. ..

.. ..

N-1 PDO Data Byte (N-1)

1.3.2.2. Output Process Data Block-16 Bit (INT) Data Format

With the Include Event to Clear option selected:

Word Bit 15 Bit 0

0 Event Code

1 PDO Data Word 0

2 PDO Data Word 1

.. ..

.. ..

N PDO Data Word (N-1)

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 1. EtherNet/IP Interface - 15

Page 16

Output Process Data Block-32 Bit (DINT) Data Format

Without the Event to Clear option selected:

Word Bit 15 Bit 0

0 PDO Data Word 0

1 PDO Data Word 1

.. ..

.. ..

N-1 PDO Data Word (N-1)

1.3.2.3. Output Process Data Block-32 Bit (DINT) Data Format

With the Include Event to Clear option selected:

Long Word Bit 31 Bit 16 Bit 15 Bit 0

0 0 Event Code

1 PDO Data Long Word 0

2 PDO Data Long Word 1

.. ..

.. ..

N - 1 PDO Data Long Word (N-1)

Without the Event to Clear option selected:

Long Word Bit 31 Bit 0

0 PDO Data Long Word 0

1 PDO Data Long Word 1

.. ..

.. ..

N - 1 PDO Data Long Word (N-1)

16 - Chapter 1. EtherNet/IP Interface IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 17

Chapter 2. Functionality Descriptions

This appendix discusses the following:

• 2.1. Event Handling

• 2.2. ISDU Handling on Page 21

2.1. Event Handling

The IO-Link Master event handling is designed to provide real-time updates of event codes received directly

from the IO-Link device. The IO-Link event code:

• Is included in the second 16-bit word of the Input Process Data (PDI) block.

- An active event is indicated by a non-zero value.

- Inactive or no event is indicated by a zero value.

• Two methods are provided to clear an event:

- Enable the Clear Event After Hold Time option.

• The IO-Link Master keeps, or holds, the active event code in the PDI block until the configured Active

Event Hold Time has passed.

• The IO-Link Master then clears the event code in the PDI block and waits until the Clear Event Hold

Time has passed before including another event code in the PDI block.

- Enable the Clear Event In PDO Block option.

• The IO-Link Master monitors the PDO block received from the PLC.

• The IO-Link Master expects the first entry of the PDO block to indicate an event code to be cleared.

• If there is an active event code in the PDI block and the PDO block both contain the same event

code, the event code is cleared in the PDI block.

• The IO-Link Master then clears event code in the PDI block and waits until the Clear Event Hold

Time has passed before including another event code in the PDI block.

• The two methods can be used separately or together to control clearing of events.

The next subsections illustrate the event clearing process for the various event configurations.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 17

Page 18

Clear Event After Hold Time Process

2.1.1. Clear Event After Hold Time Process

This illustrates clearing the event after the hold time process.

18 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 19

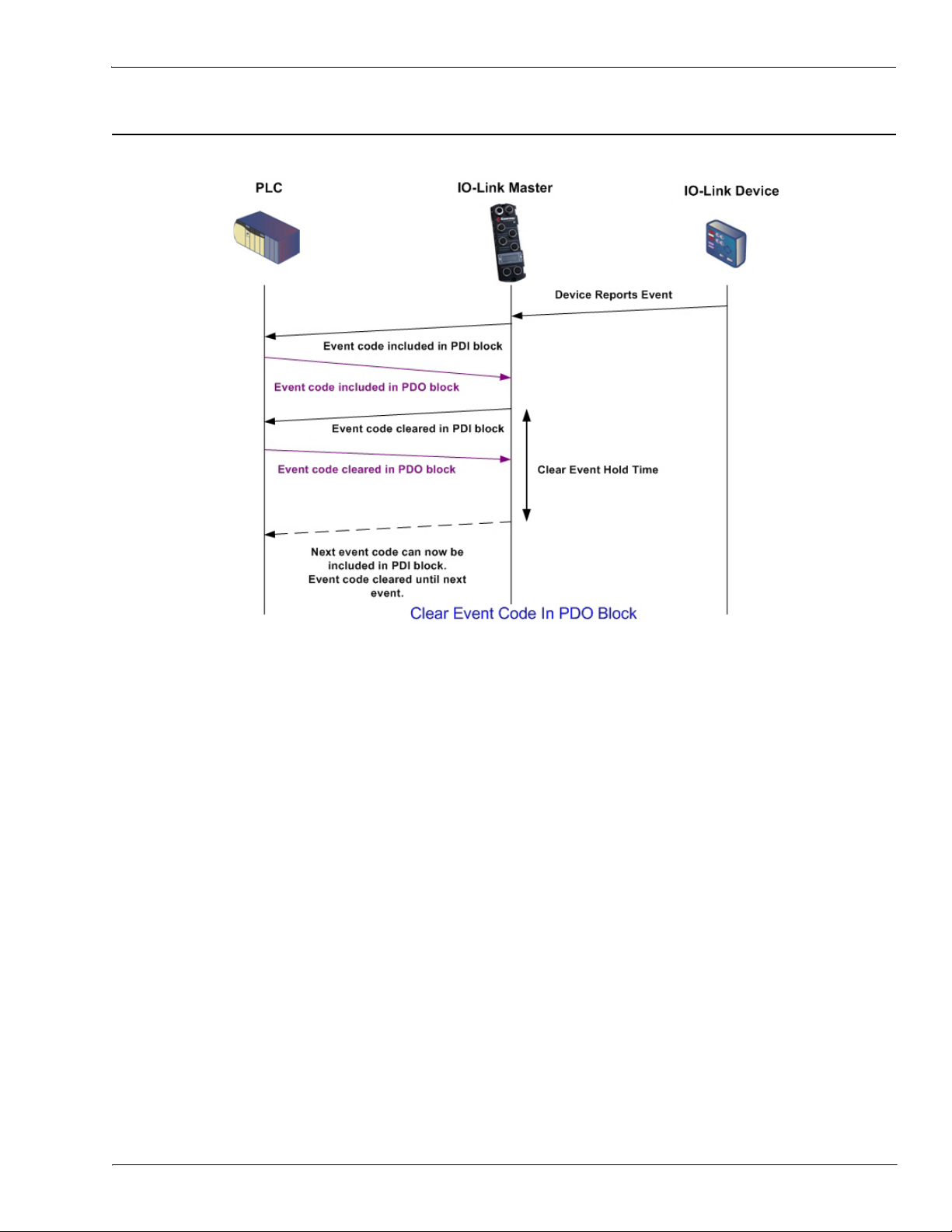

2.1.2. Clear Event in PDO Block Process

This illustrates clearing the event in the PDO block process.

Clear Event in PDO Block Process

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 19

Page 20

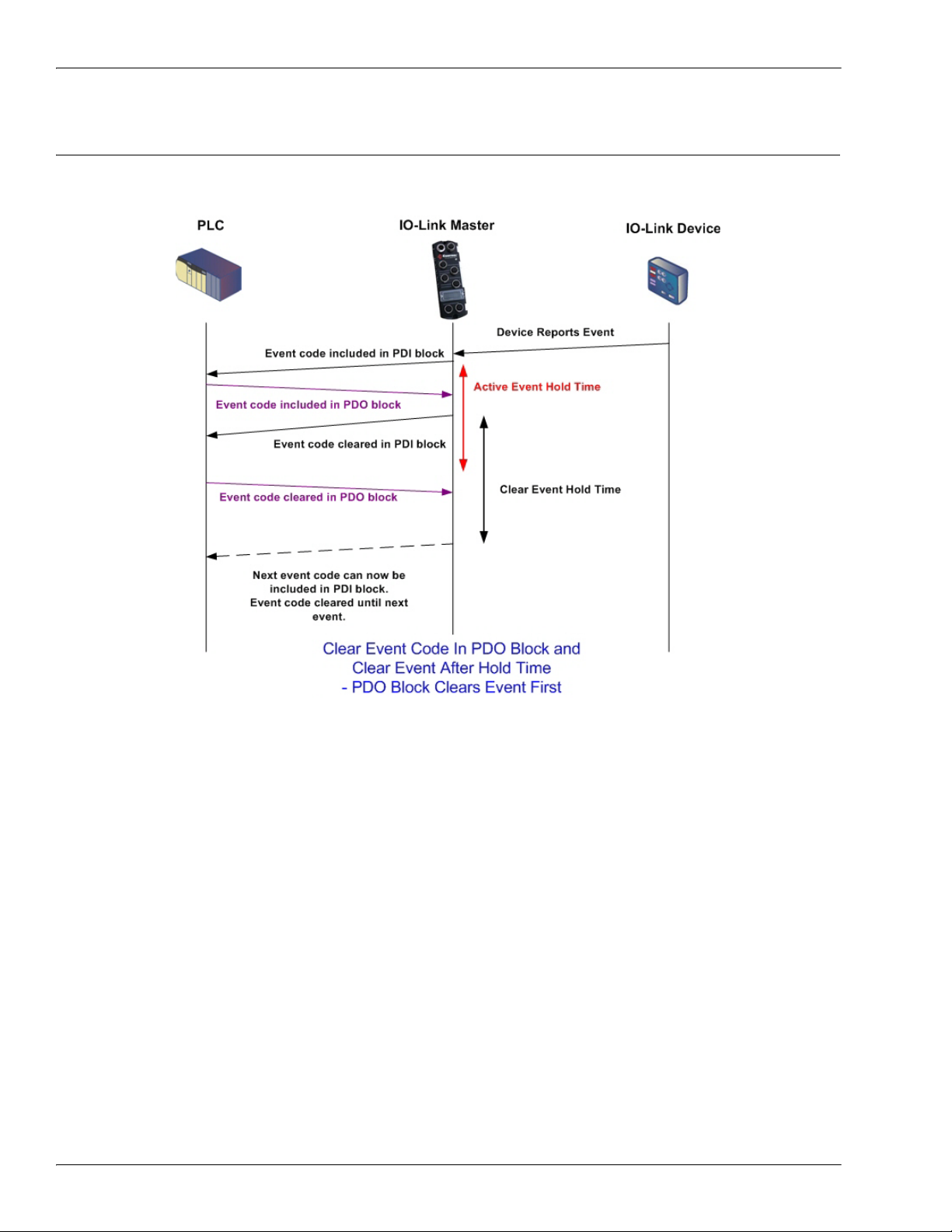

Clear Event Code in PDO Block and Clear Event After Hold Time Process-PDO Block First

2.1.3. Clear Event Code in PDO Block and Clear Event After Hold Time ProcessPDO Block First

This illustrates clearing the event code in the PDO block and clearing the event after the hold time process

with the PDO block first.

20 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 21

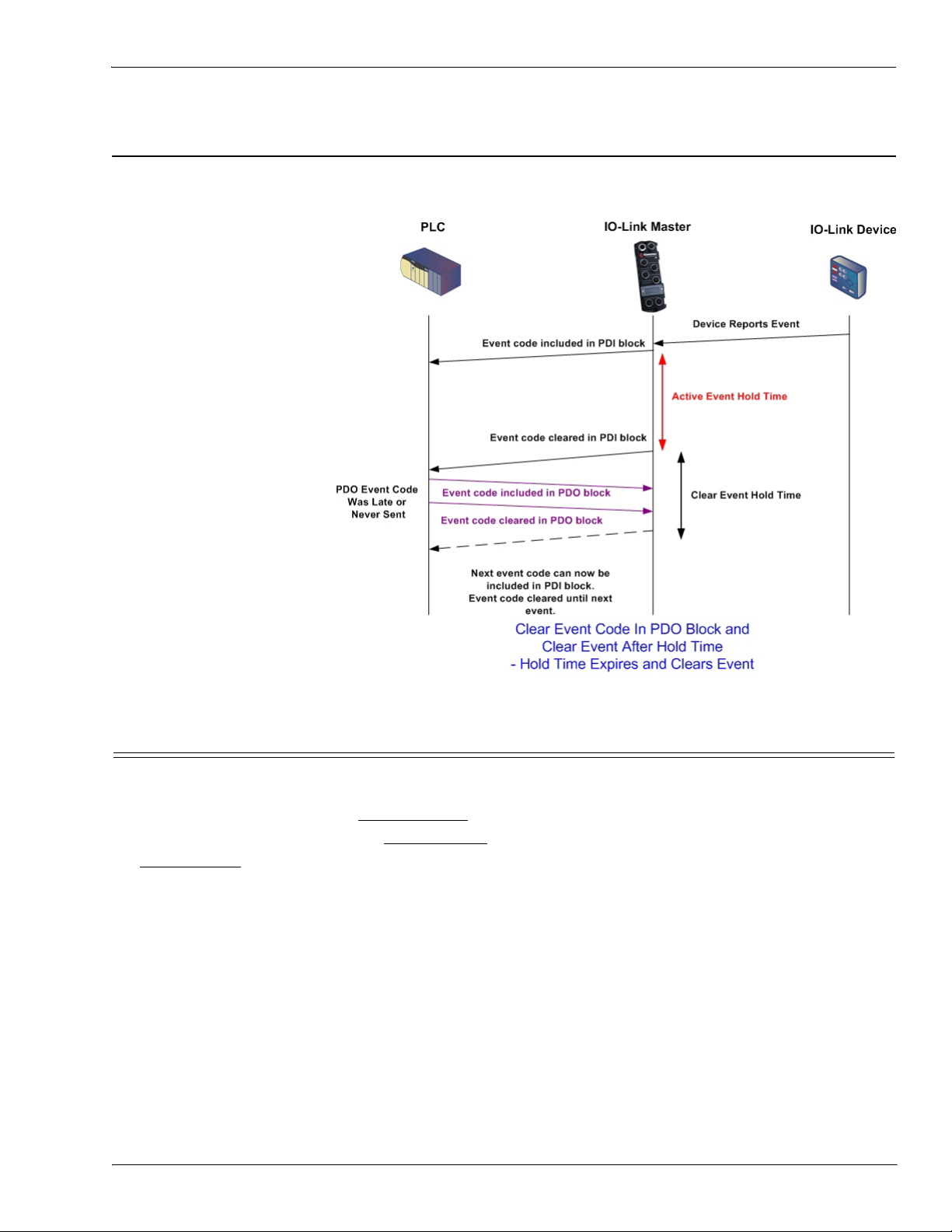

Clear Event Code in PDO Block and Clear Event After Hold Time Process-Hold Time Expires

2.1.4. Clear Event Code in PDO Block and Clear Event After Hold Time ProcessHold Time Expires

This illustrates clearing the event code in the PDO block and clearing the event after the hold time process

with the hold time expired.

2.2. ISDU Handling

The IO-Link Master provides a very flexible ISDU interface that is used by all supported industrial protocols.

The ISDU interface contains the following:

•An ISDU request may contain one or multiple individual ISDU read and/or write commands.

• Individual ISDU command based byte swapping capabilities.

• Variable sized command structures to allow access to wide range of ISDU block sizes.

• A single ISDU request may contain as many ISDU read and/or write commands as allowed by the

industrial protocol payload. For example, if an industrial protocol provides up to 500 byte read/write

payloads, then an ISDU request may contain multiple commands of various lengths that can total up to

500 bytes in length.

• For the ControlLogix family of EtherNet/IP PLCs, both blocking and non-blocking ISDU request methods

are provided.

- The IO-Link Master implements blocking ISDU requests by not responding to an ISDU request

message until all commands have been processed.

- The IO-Link Master implements non-blocking ISDU requests by:

• Responding to an ISDU request message immediately after receiving and verifying the ISDU

request.

• Requiring the PLC to monitor the ISDU request status with read messages. The IO-Link Master

will not return a completed status until all of the ISDU commands have been processed.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 21

Page 22

ISDU Request/Response Structure

2.2.1. ISDU Request/Response Structure

ISDU requests may contain a single command or multiple, nested commands. This subsection discusses the

following:

• 2.2.1.1. Single ISDU Command Request on Page 22

• 2.2.1.2. Multiple ISDU Command Structure on Page 23

2.2.1.1. Single ISDU Command Request

This illustrates a single ISDU command request.

22 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 23

Multiple ISDU Command Structure

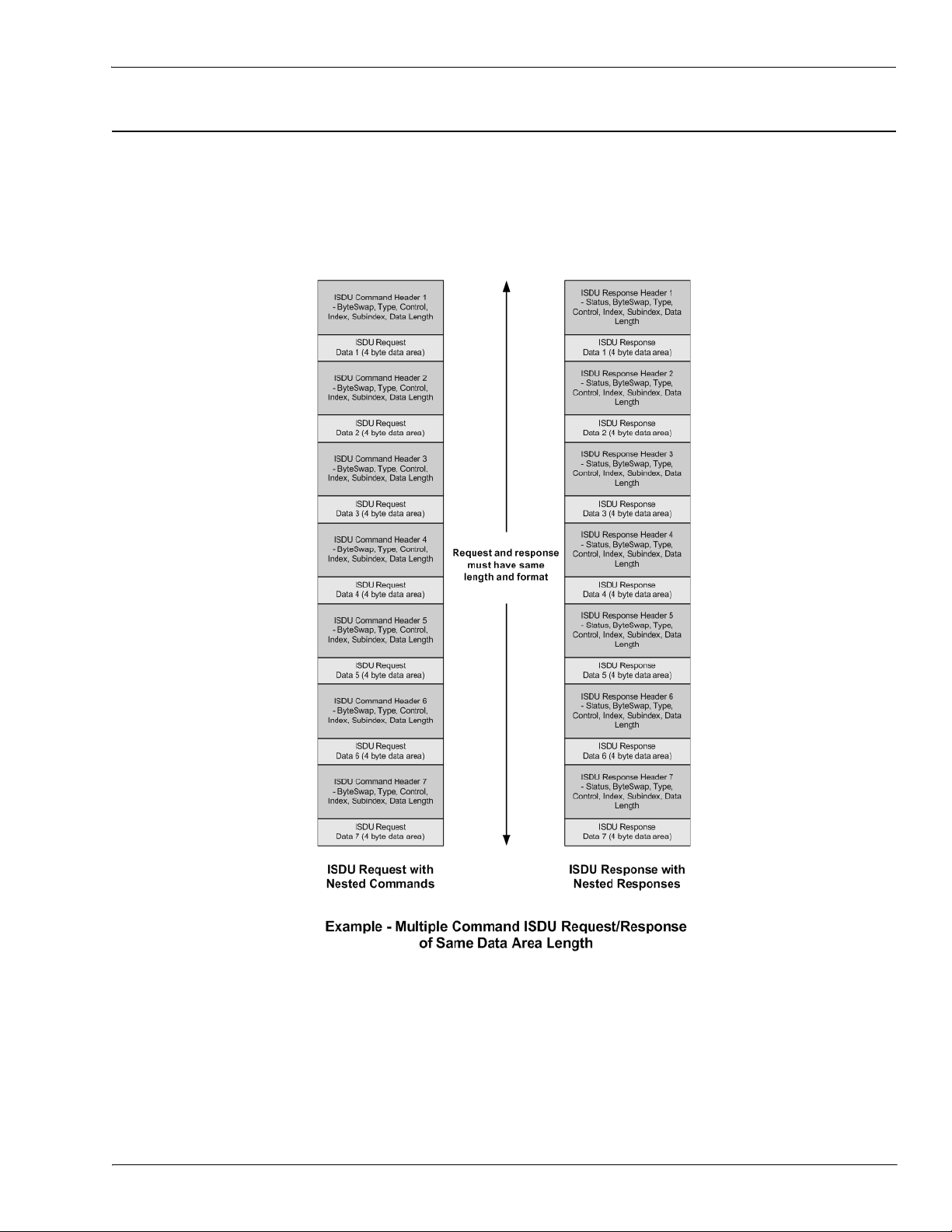

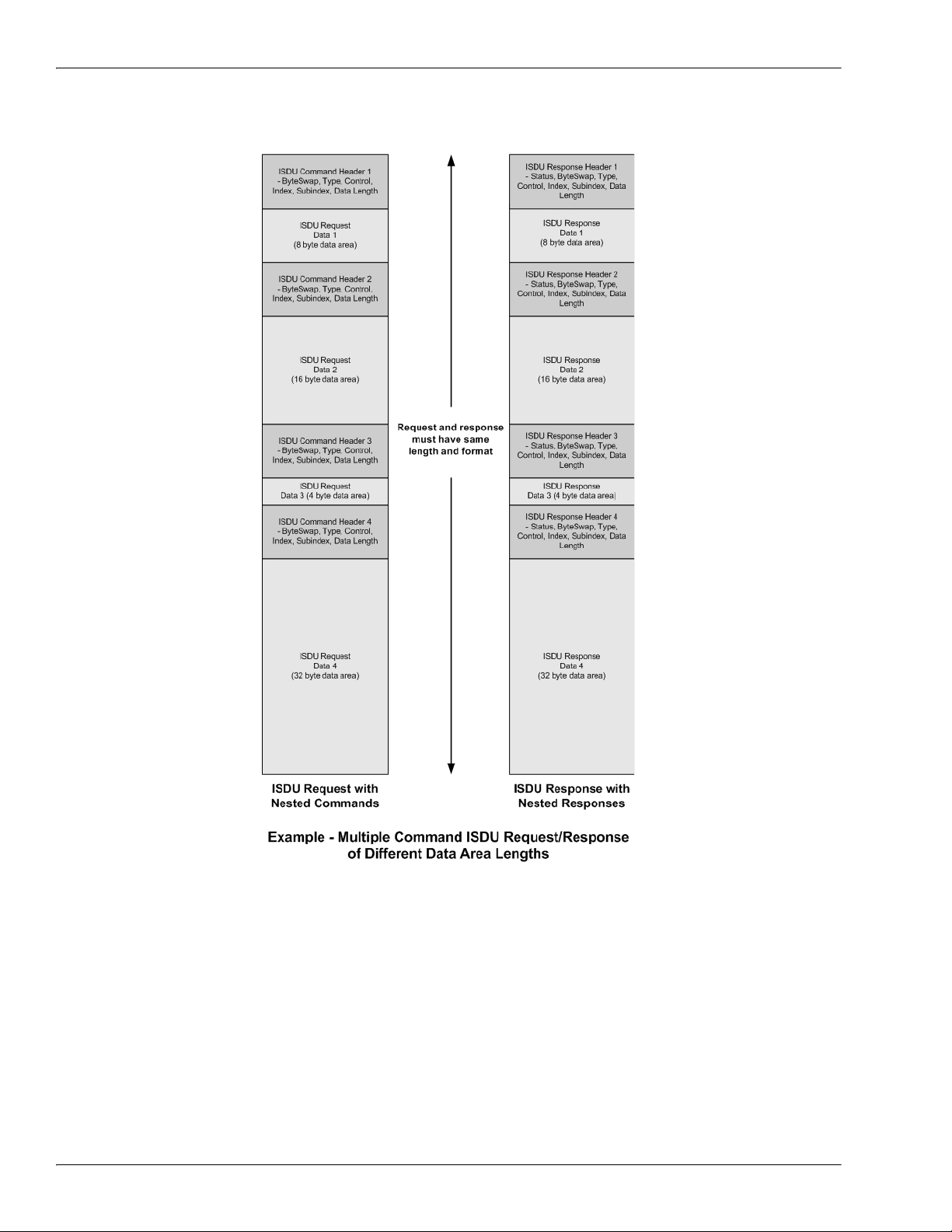

2.2.1.2. Multiple ISDU Command Structure

ISDU requests with multiple commands may consist of commands of the same data size or commands with

different data sizes. The following are two examples of multiple ISDU commands.

• ISDU commands of same data size (Page 23)

• ISDU commands of different data sizes (Page 24)

Multiple Command ISDU Request/Response of Same Data Area Length

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 23

Page 24

Multiple ISDU Command Structure

Multiple Command ISDU Request/Response of Different Data Lengths

24 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 25

ISDU Request Message Format-From PLC to IO-Link Master

2.2.2. ISDU Request Message Format-From PLC to IO-Link Master

Write and read ISDU commands have the same message data format. Each ISDU request message is

comprised of one or more commands. The command(s) can consist of either a series of nested commands or a

single read command.

Note: A list of nested ISDU commands is terminated with either a control field of 0, (single/last operation), or

the end of the message data.

2.2.2.1. Standard ISDU Request Command Format

This table displays a standard ISDU request command format with ControlLogix PLCs.

Name Data Type Parameter Descriptions

Bits 0-3:

0= No byte swapping.

Byte Swapping USINT

RdWrControlType USINT

Index UINT The parameter address of the data object in the IO-Link device.

Subindex UINT

Datalength UINT

Array of

Data

USINTs,

UINTs, or

UDINTs.

1= 16-bit (INT) byte swapping of ISDU data.

2= 32-bit (DINT) byte swapping of ISDU data.

Bits 4-7:

Set to zero. Unused.

Provides the control and type of ISDU command.

Bits 0-3, Type Field:

0 = NOP (No operation)

1 = Read operation

2 = Write operation

3 = Read/Write “OR”

4 = Read/Write “AND”

Bits 4-7, Control Field:

0 = Single/Last Operation (length can vary from to 1 to 232)

1 = Nested batch command – fixed 4 byte data area

2 = Nested batch command – fixed 8 byte data area

3 = Nested batch command – fixed 16 byte data area

4 = Nested batch command – fixed 32 byte data area

5 = Nested batch command – fixed 64 byte data area

6 = Nested batch command – fixed 128 byte data area

7 = Nested batch command – fixed 232 byte data area

The data element address of a structured parameter of the data

object in the IO-Link device.

Length of data to read or write.

For nested batch commands, the data length can vary from 1 to

the fixed data area size.

Size of array is determined by the Control field in

RdWrControlType.

Note: Data is valid only for write commands.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 25

Page 26

Integer (16-Bit Word) ISDU Request Command Format

2.2.2.2. Integer (16-Bit Word) ISDU Request Command Format

This table shows an integer (16 bit word) ISDU request command format with a SLC, MicroLogix, PLC-5, or

Modbus/TCP.

Name Data Type Parameter Description

Provides the control, type and byte swapping of ISDU command

Bits 0-3, Type Field:

0 = NOP (No operation)

1 = Read operation

2 = Write operation

3 = Read/Write “OR”

4 = Read/Write “AND”

Bits 4-7, Control Field:

0 = Single/Last Operation (length can vary from to 1 to 232)

1 = Nested batch command – fixed 4 byte data area

Byte Swapping /

RdWrControlType

UINT

2 = Nested batch command – fixed 8 byte data area

3 = Nested batch command – fixed 16 byte data area

4 = Nested batch command – fixed 32 byte data area

5 = Nested batch command – fixed 64 byte data area

6 = Nested batch command – fixed 128 byte data area

7 = Nested batch command – fixed 232 byte data area

Bits 8-11:

0= No byte swapping.

1= 16-bit (INT) byte swapping of ISDU data.

2= 32-bit (DINT) byte swapping of ISDU data.

Bits 12-15:

Set to zero. Unused.

Index UINT The parameter address of the data object in the IO-Link device.

Subindex UINT

The data element address of a structured parameter of the data

object in the IO-Link device.

Length of data to read or write.

Datalength UINT

For nested batch commands, the data length can vary from 1 to the

fixed data area size.

Data

Array of

USINTs,

UINTs, or

UDINTs.

Size of array is determined by the Control field in

RdWrControlType.

Note: Data is valid only for write commands.

26 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 27

ISDU Response Message Format

2.2.3. ISDU Response Message Format

The ISDU responses have the same data format as requests with the only exception being the returned

command status. Each ISDU response message is comprised of one or more responses to the single and/or

nested command(s) received in the request.

2.2.3.1. Standard ISDU Response Command Format

The following table show the standard ISDU response command format with ControlLogix PLCs.

Name Data Type Parameter Description

Indicates the byte alignment and status of the command response.

Byte swapping, bits 0-3:

0= No byte swapping.

1= 16-bit (INT) byte swapping of TX/RX ISDU data.

Status USINT

RdWrControlType USINT

Index UINT The parameter address of the data object in the IO-Link device.

Subindex UINT

Datalength UINT

Array of

Data

USINTs,

UINTs, or

UDINTs.

2= 32-bit (DINT) byte swapping of TX/RX ISDU data.

Status, bits 4-7:

0 = NOP (No operation)

1 = In process (Only valid for non-blocking requests)

2 = Success

3 = Failure: IO-Link device rejected the request.

4 = Timed out: IO-Link device did not respond

Provides the control and type of ISDU request

Bits 0-3, Type Field:

0 = NOP (No operation)

1 = Read operation

2 = Write operation

3 = Read/Write “OR”

4 = Read/Write “AND”

Bits 4-7, Control Field:

0 = Single/Last Operation (length can vary from to 1 to 232)

1 = Nested batch command – fixed 4 byte data area

2 = Nested batch command – fixed 8 byte data area

3 = Nested batch command – fixed 16 byte data area

4 = Nested batch command – fixed 32 byte data area

5 = Nested batch command – fixed 64 byte data area

6 = Nested batch command – fixed 128 byte data area

7 = Nested batch command – fixed 232 byte data area

The data element address of a structured parameter of the data

object in the IO-Link device.

Length of data that was read or written.

For nested batch commands, the data length can vary from 1 to

fixed data area size.

Data required for read commands. Optionally can return the data

of a write command.

The size of the array is determined by the Control field in the

RdWrControlType.

Note: Data field not required for single NOP commands.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 27

Page 28

Integer (16-Bit Word) ISDU Response Command Format

2.2.3.2. Integer (16-Bit Word) ISDU Response Command Format

The following table shows an integer (16-bit word) ISDU response command format with SLC, MicroLogix,

PLC-5, or Modbus/TCP.

Name Data Type Parameter Descriptions

Indicates the control, type, byte swapping and status of the

ISDU command.

Bits 0-3, Type Field:

0 = NOP (No operation)

1 = Read operation

2 = Write operation

3 = Read/Write “OR”

4 = Read/Write “AND”

Bits 4-7, Control Field:

0 = Single/Last Operation (length can vary from to 1 to 232)

1 = Nested batch command – fixed 4 byte data area

2 = Nested batch command – fixed 8 byte data area

Status,

Byte-Swapping,

RdWrControlType

UINT

3 = Nested batch command – fixed 16 byte data area

4 = Nested batch command – fixed 32 byte data area

5 = Nested batch command – fixed 64 byte data area

6 = Nested batch command – fixed 128 byte data area

7 = Nested batch command – fixed 232 byte data area

Byte swapping, bits 8-11:

0= No byte swapping.

1= 16-bit (INT) byte swapping of TX/RX ISDU data.

2= 32-bit (DINT) byte swapping of TX/RX ISDU data.

Status, bits 12-15:

0 = NOP (No operation)

1 = In process (Only valid for non-blocking requests)

2 = Success

3 = Failure: IO-Link device rejected the request.

4 = Timed out: IO-Link device did not respond

Index UINT The parameter address of the data object in the IO-Link device

Subindex UINT

The data element address of a structured parameter of the data

object in the IO-Link device.

Length of data that was read or written.

Datalength UINT

For nested batch commands, the data length can vary from 1 to

fixed data area size.

Data returned for read commands. Contains the data of a write

command.

The size of the array is determined by the Control field in

RdWrControlType.

Data

Array of

USINTs,

UINTs, or

UDINTs

Note: Data field not required for single NOP commands.

28 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 29

ISDU Blocking and Non-Blocking Methods

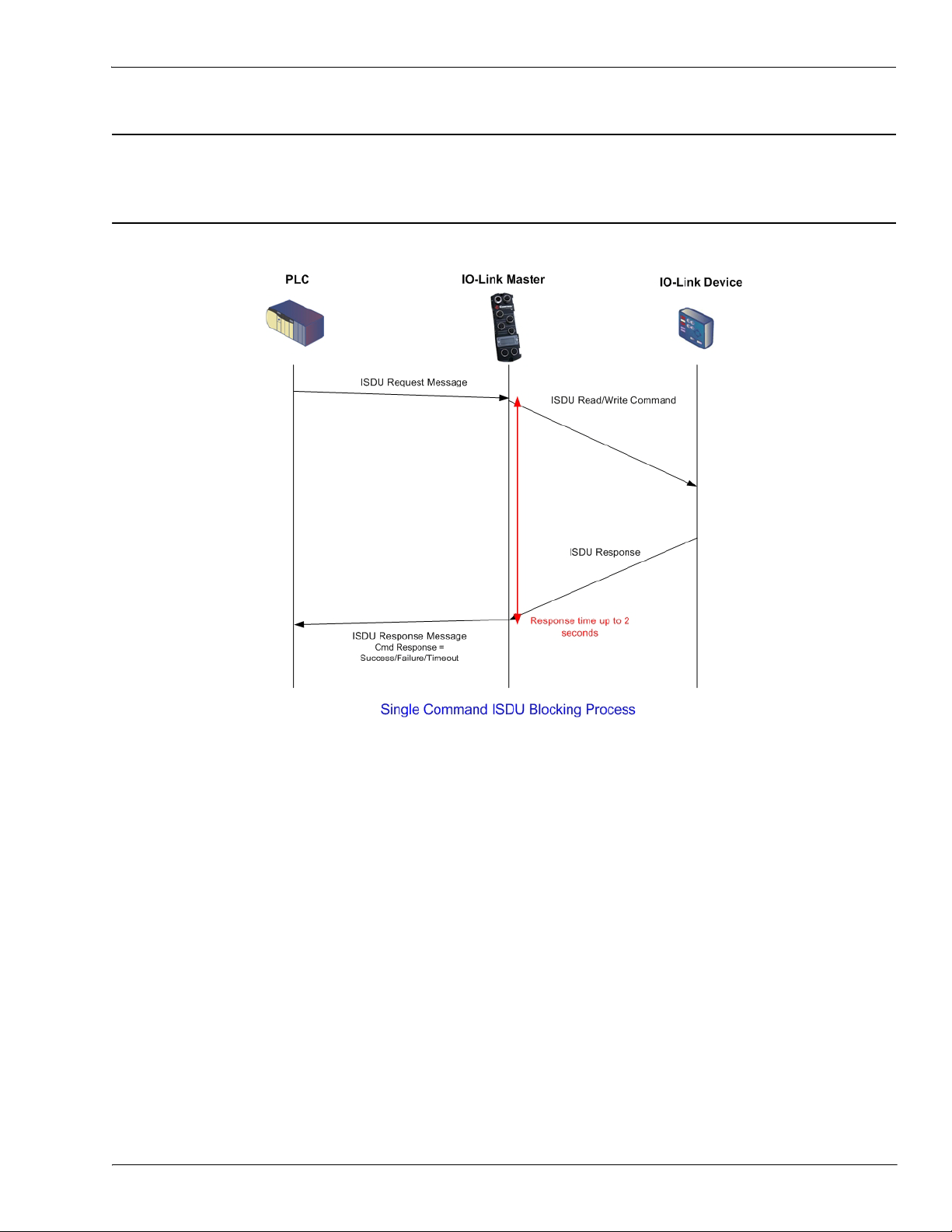

2.2.4. ISDU Blocking and Non-Blocking Methods

The IO-Link Master supports both blocking and non-blocking ISDU requests. The following diagrams

demonstrate how each mode works.

2.2.4.1. Single Command Blocking

The following illustrates the single command blocking method.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 29

Page 30

Multiple Command Blocking

2.2.4.2. Multiple Command Blocking

This illustrates the multiple command blocking method.

30 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 31

2.2.4.3. Single Command Non-Blocking

This illustrates the single command non-blocking method.

Single Command Non-Blocking

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 2. Functionality Descriptions - 31

Page 32

Multiple Command Non-Blocking

2.2.4.4. Multiple Command Non-Blocking

This illustrates the multiple command non-blocking method.

32 - Chapter 2. Functionality Descriptions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 33

Chapter 3. EtherNet/IP CIP Object Definitions

The following are the vendor specific CIP Object definitions as supported in the IO-Link Master:

• 3.1. IO-Link Port Information Object Definition (71 hex)

• 3.2. PDI (Process Data Input) Transfer Object Definition (72 hex) on Page 41

• 3.3. PDO (Process Data Output) Transfer Object Definition (73 hex) on Page 42

• 3.4. ISDU Read/Write Object Definition (74 hex) on Page 43

The following are standard CIP Object Definitions that are supported in the IO-Link Master.

• 3.5. Identity Object (01hex, 1 instance) on Page 45

• 3.6. Message Router Object (02 hex) on Page 48

• 3.7. Connection Manager Object (06 hex) on Page 49

• 3.8. Port Object (F4 hex-1 instance) on Page 50

• 3.9. TCP Object (F5 hex-1 instance) on Page 52

• 3.10. Ethernet Link Object (F6 hex-1 instance) on Page 54

• 3.11. PCCC Object (67 hex-1 instance) on Page 56

3.1. IO-Link Port Information Object Definition (71 hex)

The IO-Link Device Information object defines the attributes by which the PLC can request standard device

information stored in the IO-Link device’s ISDU blocks.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 33

Page 34

Class Attributes

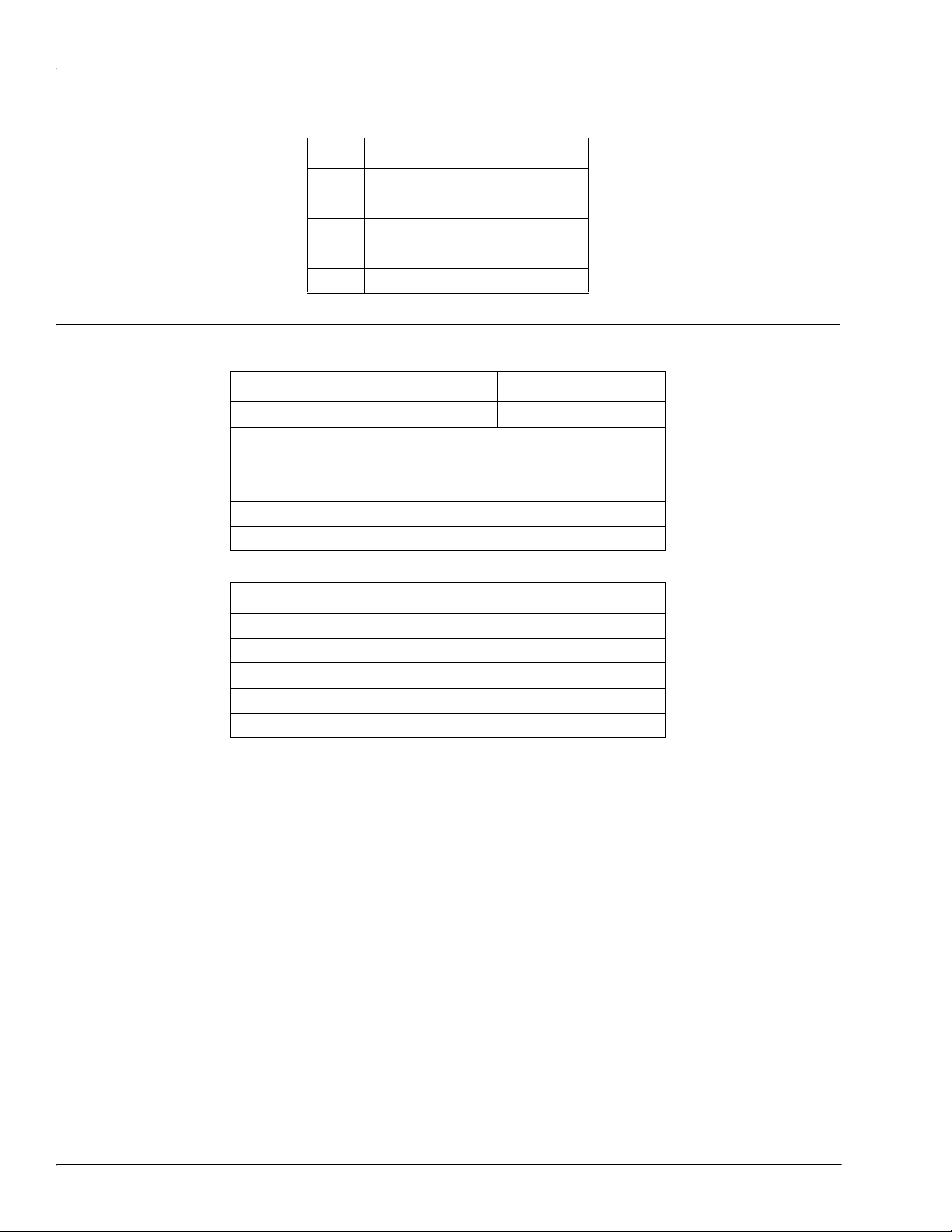

3.1.1. Class Attributes

The following table shows the class attributes for IO-Link port information object definition (71 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 1 Get

2 Max Instance UINT 4 Get

4

3 Num Instances UINT

Note: Instance number determines the

IO-Link port.

Get

34 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 35

Instance Attributes

3.1.2. Instance Attributes

The following table shows the instance attributes for IO-Link port information object definition (71 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Vendor Name Array of 64 SINTs 0-255 Get

2 Vendor Text Array of 64 SINTs 0-255 Get

3 Product Name Array of 64 SINTs 0-255 Get

4 Product Id Array of 64 SINTs 0-255 Get

5 Product Text Array of 64 SINTs 0-255 Get

6 Serial Number Array of 16 SINTs 0-255 Get

7 Hardware Revision Array of 64 SINTs 0-255 Get

8 Firmware Revision Array of 64 SINTs 0-255 Get

9 Device PDI Length INT 0-32 Get

10 Device PDO Length INT 0-32 Get

11 PDI Block Length INT 4-36 Get

12 PDO Block Length INT 0-36 Get

0-108 (8-bit format)

13 Input Assembly PDI Offset INT

14 Input Assembly PDO Offset INT

15 Output Assembly PDO Offset INT

16 Control Flags INT Bit settings Get

0-54(16-bit format)

0-27 (32-bit format)

16-246 (8-bit format)

8-123(16-bit format)

4-62 (32-bit format)

0-102 (8-bit format)

0-51 (16-bit format)

0-26 (32-bit format)

Get

Get

Get

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 35

Page 36

Common Services

3.1.3. Common Services

The following table shows the common services for IO-Link port information object definition (71 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attributes_All

0E hex Ye s Ye s Get_Attribute_Single

36 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 37

Instance Attribute Definitions

3.1.4. Instance Attribute Definitions

These attributes provide access to the standard ISDU information blocks on the IO-Link devices. These

ISDUs are read at IO-Link device initialization time and then provided once the IO-Link device is

operational.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 37

Page 38

Attribute 1-Vendor Name

3.1.4.1. Attribute 1-Vendor Name

Data Attribute 1 - Vendor Name Description

64 ASCII

characters

Requested from ISDU block index 16, contains the Vendor Name

description of the IO-Link device.

3.1.4.2. Attribute 2-Vendor Text

Data Attribute 2 - Vendor Text Description

64 ASCII

characters

Requested from ISDU block index 17, contains the Vendor Text

description of the IO-Link device.

3.1.4.3. Attribute 3-Product Name

Data Attribute 3 - Product Name Description

64 ASCII

characters

Requested from ISDU block index 18, contains the Product Name

description of the IO-Link device.

3.1.4.4. Attribute 4-Product ID

Data Attribute 4 - Product ID Description

64 ASCII

characters

Requested from ISDU block index 19, contains the Product ID

description of the IO-Link device.

3.1.4.5. Attribute 5-Product Text

Data Attribute 5 - Product Text Description

64 ASCII

characters

Requested from ISDU block index 20, contains the Product Text

description of the IO-Link device.

3.1.4.6. Attribute 6-Serial Number

Data Attribute 6 - Serial Number Description

16 ASCII

characters

Requested from ISDU block index 21, contains the Vendor Specific

Serial Number of the IO-Link device.

3.1.4.7. Attribute 7-Hardware Revision

Data Attribute 7 - Hardware Revision Description

64 ASCII

characters

Requested from ISDU block index 22, contains the Hardware

Revision of the IO-Link device.

3.1.4.8. Attribute 8-Firmware Revision

Data Attribute 8 - Firmware Revision Description

64 ASCII

characters

Requested from ISDU block index 23, contains the Firmware

Revision of the IO-Link device.

38 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 39

3.1.4.9. Attribute 9-Device PDI Length

Data Attribute 9 - Device PDI Length Description

Attribute 9-Device PDI Length

INT (0-32)

Requested from ISDU block index 0, sub-index 5. Contains the

number of PDI data bytes provided by the IO-Link device.

3.1.4.10. Attribute 10-Device PDO Length

Data Attribute 10 - Device PDO Length Description

INT

Requested from ISDU block index 0, sub-index 6. Contains the

number of PDO data bytes required by the IO-Link device.

3.1.4.11. Attribute 11-PDI Data Block Length

Data Attribute 11 - PDI Data Block Length Description

The configured PDI block length in units based on the configurable

INT

PDI data format (8-bit, 16-bit, 32-bit). This contains the PDI block

header, (port status, auxiliary bit, event code) status and the PDI

data.

3.1.4.12. Attribute 12-PDO Data Block Length

Data Attribute 12 - PDO Data Block Length Description

The configured PDO data block length in units based on the

INT

configurable PDO data format (8-bit, 16-bit, 32-bit). Depending on

the configuration, this may include both the returned event code and

the PDO data.

3.1.4.13. Attribute 13-Input Assembly PDI Offset

Data Attribute 13 - Input Assembly PDI Offset Description

Based from the start of the first Input Assembly instance, the PDI

data block’s offset for the corresponding port’s PDI data block.

INT

This index is based on the configurable PDI data format (8-bit, 16bit, 32-bit). To use this offset effectively, it is recommended to set IOLink Master PDI and PDO data as well as the Class 1 I/O connection

all to the same data format.

3.1.4.14. Attribute 14-Input Assembly PDO Offset

Data Attribute 14 - Input Assembly PDO Offset Description

Based from the start of the first Input Assembly instance, the PDO

data block’s offset for the corresponding port’s PDO data block.

INT

This index is based on the configurable PDO data format (8-bit, 16bit, 32-bit). To use this offset effectively, it is recommended to set IOLink Master PDI and PDO data as well as the Class 1 I/O connection

all to the same data format.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 39

Page 40

Attribute 15-Output Assembly PDO Offset

3.1.4.15. Attribute 15-Output Assembly PDO Offset

Data Attribute 15 - Output Assembly PDO Offset Description

Based from the start of the first Output Assembly instance, the PDO

data block’s offset for the corresponding port’s PDO data block.

INT

This index is based on the configurable PDO data format (8-bit, 16bit, 32-bit). To use this offset effectively, it is recommended to set IOLink Master PDI and PDO data as well as the Class 1 I/O connection

all to the same data format.

3.1.4.16. Attribute 16-Control Flags

Data Attribute 16 - Control Flags Description

Bit 0 (01h):

1 = Indicates that the event code to clear is expected in the PDO

block

0 = Indicates that the event code to clear is not expected in the

PDO block. The PDO data block only contains PDO data.

Bit 1 (02h):

INT

(bitmapped

word)

1 = Indicates that the IO-Link device is SIO mode capable

0 = Indicates that the IO-Link device is not SIO mode capable

Bits 2 (04h)

1 = Indicates that Class 1 Rx (receive PDI block) is enabled

0 = Indicates that Class 1 Rx (receive PDI block) is disabled

Bit 3 (08h):

1 = Indicates that Class 1 Tx (transmit PDO) is enabled

0 = Indicates that Class 1 Tx (transmit PDO) is disabled

Bits 4-15: Reserved

40 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 41

PDI (Process Data Input) Transfer Object Definition (72 hex)

3.2. PDI (Process Data Input) Transfer Object Definition (72 hex)

The PDI Transfer object defines the attributes by which the PLC can request the PDI data block from the IOLink Master.

3.2.1. Class Attributes

The following table displays Class Attributes for the PDI Transfer Object Definition (72 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 1 Get

2

3

3.2.2. Instance Attributes

The following table displays Instance Attributes for the PDI Transfer Object Definition (72 hex).

Max Instance UINT 1 Get

Num Instances UINT 1 Get

Attribute ID Name Data Type Length Data Values Access Rule

1 Port 1 PDI data block Array of BYTEs 4-36 bytes 0-255 Get

2

3

4

Port 2 PDI data block Array of BYTEs 4-36 bytes 0-255 Get

Port 3 PDI data block Array of BYTEs 4-36 bytes 0-255 Get

Port 4 PDI data block Array of BYTEs 4-36 bytes 0-255 Get

3.2.3. Common Services

The following table shows Common Services for the PDI Transfer Object Definition (72 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attributes_All

0E hex Yes Yes Get_Attribute_Single

3.2.4. Instance Attribute Definitions - Attribute 1 to 4-PDI Data Blocks

These attributes provide access to the PDI data blocks.

• Get Attribute Single requests return the PDI data block for a specific port.

• Get Attribute All requests return all PDI data blocks from the IO-Link Master.

All PDI data is returned in the configured PDI format (8-bit, 16-bit or 32-bit). Refer to 3.2. PDI (Process Data

Input) Transfer Object Definition (72 hex) on Page 41 for a detailed explanation of the PDI data block.

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 41

Page 42

PDO (Process Data Output) Transfer Object Definition (73 hex)

3.3. PDO (Process Data Output) Transfer Object Definition (73 hex)

The PDO Transfer object defines the attributes by which the PLC can:

• Request the PDO data block from the IO-Link Master.

• Write PDO data block to the IO-Link Master.

3.3.1. Class Attributes

The following table displays the Class Attributes for the PDO Transfer Object Definition (73 hex).

Attribute ID Name Data Type Data Value Access Rule

1

2

3

3.3.2. Instance Attributes

Revision UINT 1 Get

Max Instance UINT 1 Get

Num Instances UINT 1 Get

The following table displays the Instance Attributes for the PDO Transfer Object Definition (73 hex).

Attribute ID Name Data Type Length Data Value Access Rule

1 Port 1 PDO data block Array of BYTEs 0-36 bytes 0-255 Get/Set

2 Port 2 PDO data block Array of BYTEs 0-36 bytes 0-255 Get/Set

3 Port 3 PDO data block Array of BYTEs 0-36 bytes 0-255 Get/Set

4 Port 4 PDO data block Array of BYTEs 0-36 bytes 0-255 Get/Set

3.3.3. Common Services

The following table displays the Common Services for the PDO Transfer Object Definition (73 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attributes_All

0E hex Yes Yes Get_Attribute_Single

10 hex No Yes Set_Attribute_Single

02 hex No Yes Set_Attribute_All

3.3.4. Instance Attribute Definitions - Attribute 1 to 4-PDO Data Blocks

These attributes provide write access to the PDO data blocks.

• Get Attribute Single requests return the current PDO data block for a specific port.

• Get Attribute All requests return all current PDO data blocks from the IO-Link Master.

• Set Attribute Single allows writing the PDO data to one IO-Link port on the IO-Link Master.

• Set Attribute All messages allow writing of PDO data to all IO-Link ports on the IO-Link Master.

42 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 43

ISDU Read/Write Object Definition (74 hex)

All PDO data is received and returned in the configured PDO format (8-bit, 16-bit or 32-bit). Refer to 3.3. PDO

(Process Data Output) Transfer Object Definition (73 hex) on Page 42 for a detailed explanation of the PDO

data block.

3.4. ISDU Read/Write Object Definition (74 hex)

The ISDU Read/Write object defines the attributes by which the PLC can:

• Send an ISDU request containing one or more read and/or write ISDU commands to an IO-Link device

via the IO-Link Master.

• Request the ISDU response(s) from the IO-Link Master.

• Send both blocking and non-blocking ISDU requests.

Refer to the ISDU Handling chapter for a detailed description of the ISDU functionality.

3.4.1. Class Attributes

The following table shows the Class Attributes for the ISDU Read/Write Object Definition (74 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 1 Get

2

3

Max Instance UINT 4 Get

4

Num Instances UINT

Note: Instance number determines IO-

Link port on the IO-Link Master.

Get

3.4.2. Instance Attributes

The following table shows the Instance Attributes for the ISDU Read/Write Object Definition (74 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1

2

ISDU Response ISDU response data block 0-255 Get

ISDU Read/Write Request ISDU request data block 0-255 Set

3.4.3. Common Services

The following table shows the Common Services for the ISDU Read/Write Object Definition (74 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes No Get_Attributes_All

0E hex Yes Yes Get_Attribute_Single

10 hex No Yes Set_Attribute_Single

02 hex No No Set_Attribute_All

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 43

Page 44

Object Specific Services

3.4.4. Object Specific Services

The following table shows the Object Specific Services for the ISDU Read/Write Object Definition (74 hex).

Service Code Implemented in Class Implemented in Instance Service Name

4B hex No Yes Blocking ISDU Request

The Blocking ISDU Request service allows one message instruction to both send an ISDU request and receive

the response. Using this service causes the message to be active for several seconds.

3.4.5. Instance Attribute Definitions

The following attributes provide access to the ISDU blocks on the IO-Link devices.

3.4.5.1. Attribute 1-ISDU Read/Write Response (Non-Blocking only)

Get Attribute Single messages returns the ISDU response for a specific port through the IO-Link Master. The

response may need to be read multiple times until a response of Success, Failure, or Timed Out has been

received.

3.4.5.2. Attribute 2-ISDU Read/Write Request (Non-blocking only)

Set Attribute Single messages can send read/write type ISDU requests to the IO-Link devices via the IO-Link

Master. The ISDU request message need be sent only once for each ISDU read/write request.

44 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 45

Identity Object (01hex, 1 instance)

3.5. Identity Object (01hex, 1 instance)

The Identity Object provides identification of and general information about the IO-Link Master.

3.5.1. Class Attributes

This table shows the Class Attributes for the Identity Object (01 hex, 1 Instance).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 1 Get

2

3

6

7

3.5.2. Instance Attributes

Max Class UINT 1 Get

Max Instance UINT 1 Get

Maximum Number Class Attribute UINT 7 Get

Maximum Number Instance Attributes UINT 7 Get

This table shows the Instance Attributes for the Identity Object (01 hex, 1 Instance).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Ve n d or ID UINT

2

3

4

5

6 Serial Number UDINT 1-FFFFFFFF hex Get

7

Device Type UINT

Product Code UINT As defined by Comtrol Get

Revision (Product or

Software release)

Structure of:

Major Revision

Minor Revision

Status WORD See Below Get

Product Name

Structure of:

Name Length

Name String

USINT

USINT

USINT

STRING

909

(Comtrol)

2B hex

(Generic Device)

1 to 127

1 to 255

Length of string

See below

Get

Get

Get

Get

Get

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 45

Page 46

Status Word

3.5.3. Status Word

Refer to Page 52 of Volume 3.5 of the CIP Common Specification.

The following applies to the Identity Object status word for the IO-Link Master.

Status Word Bit Setting Description

0 0 Ownership Flag. Does not apply to the IO-Link Master.

1 0 Reserved.

0 IO-Link Master is operating on the default configuration.

2

1

3 0 Reserved.

0101 (0x50) Indicates that there is a major fault (either Bit 10 or Bit 11 is set).

0100 (0x40) Indicates the stored configuration is invalid.

0011 (0x30)

0110 (0x60)

4-7

0000

0

8

1

9 1 Unrecoverable minor fault. Does not apply to the IO-Link Master.

0 No recoverable major fault.

10

1

0 No major unrecoverable fault.

11

1

12-15 0 Reserved.

The IO-Link Master has a configuration other than the default

configuration.

Indicates the system is operational and there are no I/O (Class 1)

connections.

Indicates the system is operational and there is at least one active

I/O (Class 1) connection.

Indicates the system is not operational. It may be in any of the

following states:

• System startup.

• Configuration in process.

•Idle.

• Critical (major) fault.

No recoverable minor fault. No error history entry reported within

the last ten seconds.

Recoverable minor fault. The IO-Link Master has reported an

error within the last ten seconds and a major fault has not been

detected.

A major recoverable fault exists. This is a fault that the IO-Link

Master may be able to recover from by a system reset. If the

system does not recover automatically, a system reset message or a

power cycle of the IO-Link Master may be required.

A major unrecoverable fault has occurred in the IO-Link Master. If

the major fault is not corrected with a system reset or a power

cycle, refer to the User Manual or call Comtrol support.

3.5.4. Common Services

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attribute_All

46 - Chapter 3. EtherNet/IP CIP Object Definitions IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A

Page 47

Common Services

05 hex No Yes Reset

0E hex Yes Yes Get_Attribute_Single

IO-Link Master EtherNet/IP Reference Manual: 2000589 Rev. A Chapter 3. EtherNet/IP CIP Object Definitions - 47

Page 48

Message Router Object (02 hex)

3.6. Message Router Object (02 hex)

The Message Router Object provides a messaging connection point through which a Client may address a

service to any object or instance residing in the physical device.

3.6.1. Class Attributes

This table displays the Class Attributes for the Message Router Object (02 hex).

Attribute ID Name Data Type Data Value Access Rule

1 Revision UINT 1 Get

2

3

4

5

6

7

Max Class UINT 1 Get

Max Instance UINT 1 Get