Comtest Networks MTAS-192 User Manual

MTAS-192 METALLIC TEST ACCESS SYSTEM

Installation

Guide

Date: May 1, 2008

Version: 1.8 Release

Part No.: CT-IG-MTAS192

CT-IG-MTAS192-2008-v1_8.doc

Revision History

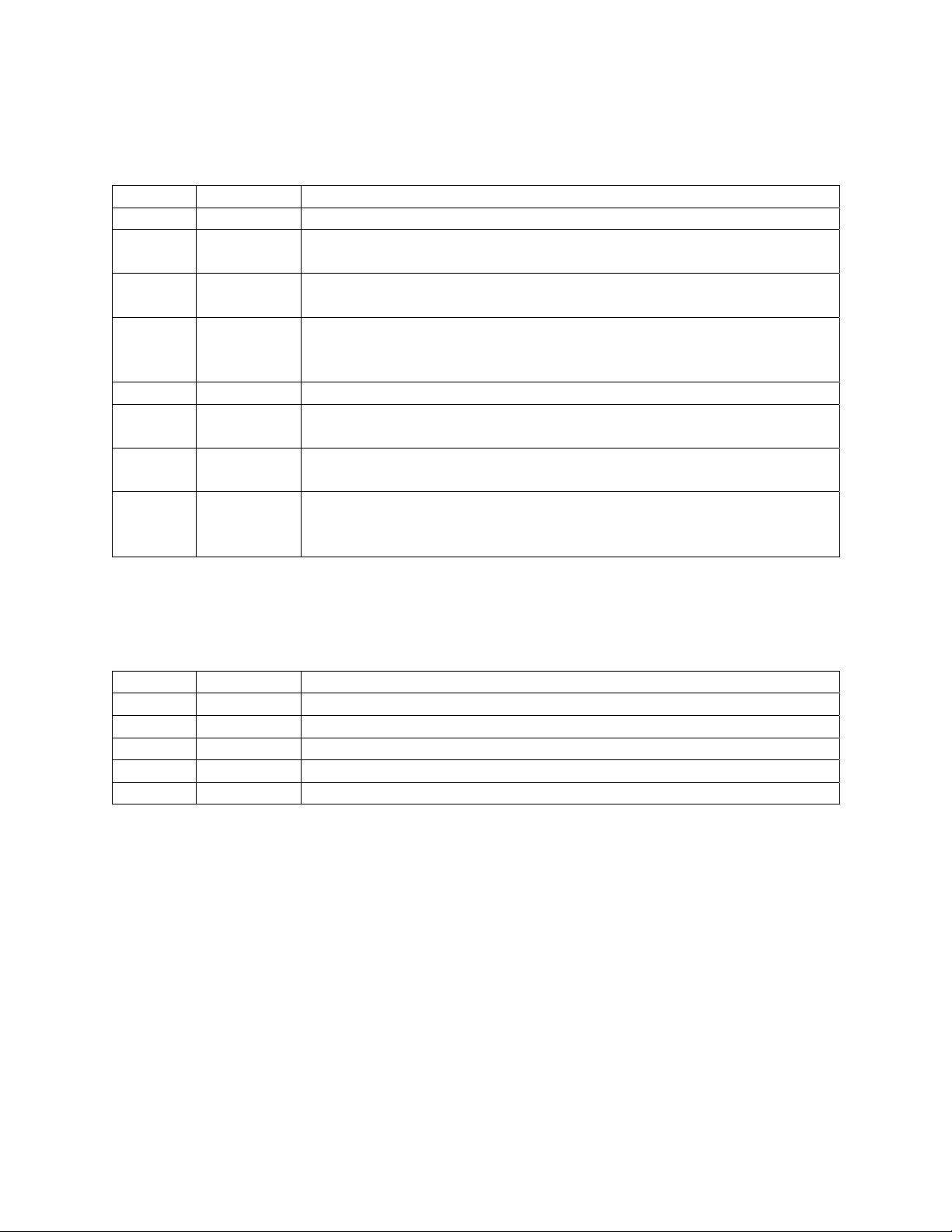

ISSUE DATE REASON FOR CHANGES

1.0 Aug. 2005 Creation

1.1 Dec. 2005 Various Updates and formatting changes

1.2 Jan. 2006 Updated network configuration procedures and cabling

requirements

1.3 Jan. 2006 Added comments required for CSA / UL and a table

summarizing interface cables required / recommended

1.4 Feb. 2006 Updated MS Word source to contain Issue 1.3 PDF content

changes, added Appendix E, updated figures, and added

troubleshooting flowcharts to Chapter 5.

1.5 Apr. 2006 Added additional comments required for CSA / UL in Chapter 2

1.6 Jun. 2006 Added additional comments required for CSA / UL in Chapter 2

and Appendix B

1.7 Mar. 2008 Updated document with reference to new line cards MT-5820V

and MT-5821

1.8 May 2008 Added TAL pin-out wiring configuration for 4-wire applications

in Table 17.

Updated Contact Information in Appendix B.

List of Changes:

PAGE SECTION CHANGE DESCRIPTION

Warnings

Throughout this guide the reader will note various warnings. The purpose of these

warnings is to alert the reader to certain risks that may be encountered during the

installation of the Comtest MTAS-192 shelf in a Central Office environment. They are

categorized in terms of risk of injury to personnel and risk of damage to equipment.

The warnings are listed below from most to least threatening.

Danger: Danger indicates the presence of a hazard that will cause severe injury, death,

or substantial property damage if the hazard is not avoided.

ii

CT-IG-MTAS192-2008-v1_8.doc

Warning: Warning indicates the presence of a hazard that can cause severe injury,

death, or substantial property damage if the hazard is not avoided.

Caution: Caution indicates the presence of a hazard that will or can cause minor injury

or property damage if the hazard is not avoided.

iii

CT-IG-MTAS192-2008-v1_8.doc

Table of Contents

Table of Contents..........................................................................................................v

Chapter 1 Introduction..............................................................................................1

1.1 Overview........................................................................................................1

1.2 The Metallic Test Access System.................................................................. 1

1.3 Hardware Overview ....................................................................................... 3

1.3.1 The MTAS Shelf............................................................................... 3

1.3.2 The Test Access Controller Cards....................................................8

1.3.3 The Line Cards (Splitter Cards and Test Access Only Cards)..........9

Chapter 2 Preparing for Installation ...................................................................... 13

2.1 Installation Personnel................................................................................... 13

2.2 Site Survey .................................................................................................. 13

2.3 Environmental..............................................................................................13

2.4 Tools and Materials Required...................................................................... 13

2.5 Ethernet Requirements................................................................................ 14

2.6 Shelf Power Supply ..................................................................................... 14

2.7 Physical Requirements................................................................................14

2.8 Unpacking....................................................................................................15

2.9 Inspection .................................................................................................... 15

2.10 Packing List ................................................................................................. 15

2.10.1 Shelf ............................................................................................... 15

2.10.2 Cards..............................................................................................16

Chapter 3 Installing the MTAS Shelf......................................................................17

3.1 Mounting the MTAS-192 Shelf.....................................................................17

3.2 Installing the MTAS Circuit Packs................................................................17

Chapter 4 Cabling.................................................................................................... 21

4.1 Backplane Connectors.................................................................................21

4.1.1 MTAS-CM Connectors ................................................................... 24

4.1.2 MTAS-CS Connectors.................................................................... 24

4.1.3 xDSL Filter Card Connectors..........................................................25

4.2 Cabling......................................................................................................... 25

4.2.1 Grounding Connector ..................................................................... 26

v

CT-IG-MTAS192-2008-v1_8.doc

4.2.2 Power Feeds .................................................................................. 26

4.2.3 Connecting Line/Facility and POTS/Equipment RJ-21

Connectors..................................................................................... 28

4.2.4 Connecting to DSL ......................................................................... 29

4.2.5 Connecting to the Control Card......................................................30

4.2.6 Connecting the Test Head to the MTAS-192 Shelf......................... 30

4.2.7 Daisy-chaining Multiple MTAS-192 Shelves................................... 30

4.2.8 Connecting MAJOR and MINOR Alarm Ports ................................ 32

Chapter 5 Activation and Testing .......................................................................... 33

5.1 Introduction.................................................................................................. 33

5.2 Powering the MTAS-192.............................................................................. 33

5.3 Validating Operation of Control Cards and Line Cards................................ 33

5.4 Communicating with the MTAS.................................................................... 36

5.4.1 Via the Ethernet Port ...................................................................... 36

5.4.2 Via the Serial Port........................................................................... 36

5.5 IP Network Configuration............................................................................. 37

Appendix A Specifications......................................................................................... 41

Appendix B Repair and Return Services................................................................... 51

Appendix C Warranty.................................................................................................. 53

Appendix D Acronyms and Abbreviations................................................................ 55

Appendix E Recommended Cabling Practices......................................................... 57

Index 63

# # #

vi

CT-IG-MTAS192-2008-v1_8.doc

Comtest Networks

MTAS-192

Chapter 1

Introduction

1.1 Overview

This chapter provides an introduction to the 192-port Comtest Networks Metallic Test

Access System (MTAS-192).

1.2 The Metallic Test Access System

The MTAS-192 is a high density, modular metallic test access system (MTAS) for DSL

splitter and non-splitter applications. It combines xDSL Splitter, Metallic Test Access

Unit (MTAU), and Splitter/MTAU functionality into a single physical shelf/chassis, the

MTAS-192.

2

Figure 1: MTAS-192 (Front Panel)

The MTAS-192 sits between the subscriber lines and the DSLAM (Digital Subscriber

Loop Access Multiplexer), enabling simultaneous voice and data services over the

subscriber’s local loop, in conjunction with remote test access capability for customer

line monitoring and troubleshooting. The MTAS enables the user to non-intrusively

monitor the line or perform intrusive test access upstream and downstream. Test

access functionality can be controlled by any leading broadband test head or

Support System (

The MTAS offers up to 192 two-wire circuits per 3 rack units (RU) of test access and

can be daisy-chained to provide over 2,000 ports per configuration. The MTAS product

family consists of the test access shelf, control modules, and choice of cards for DSL

splitter and non-splitter test access applications. The backplane houses the POTS and

LINE interfaces using standard 50 pin (25 pair) female RJ-21 connectors. The DSL

interface is located on the front of each line card, also using a standard 50 pin (25 pair)

female RJ-21 connector.

OSS) that is compliant with the GR-834 and GR-818 standards.

Operational

June 2006 Installation Guide

1

Comtest Networks

MTAS-192

CT-IG-MTAS192-2008-v1_8.doc

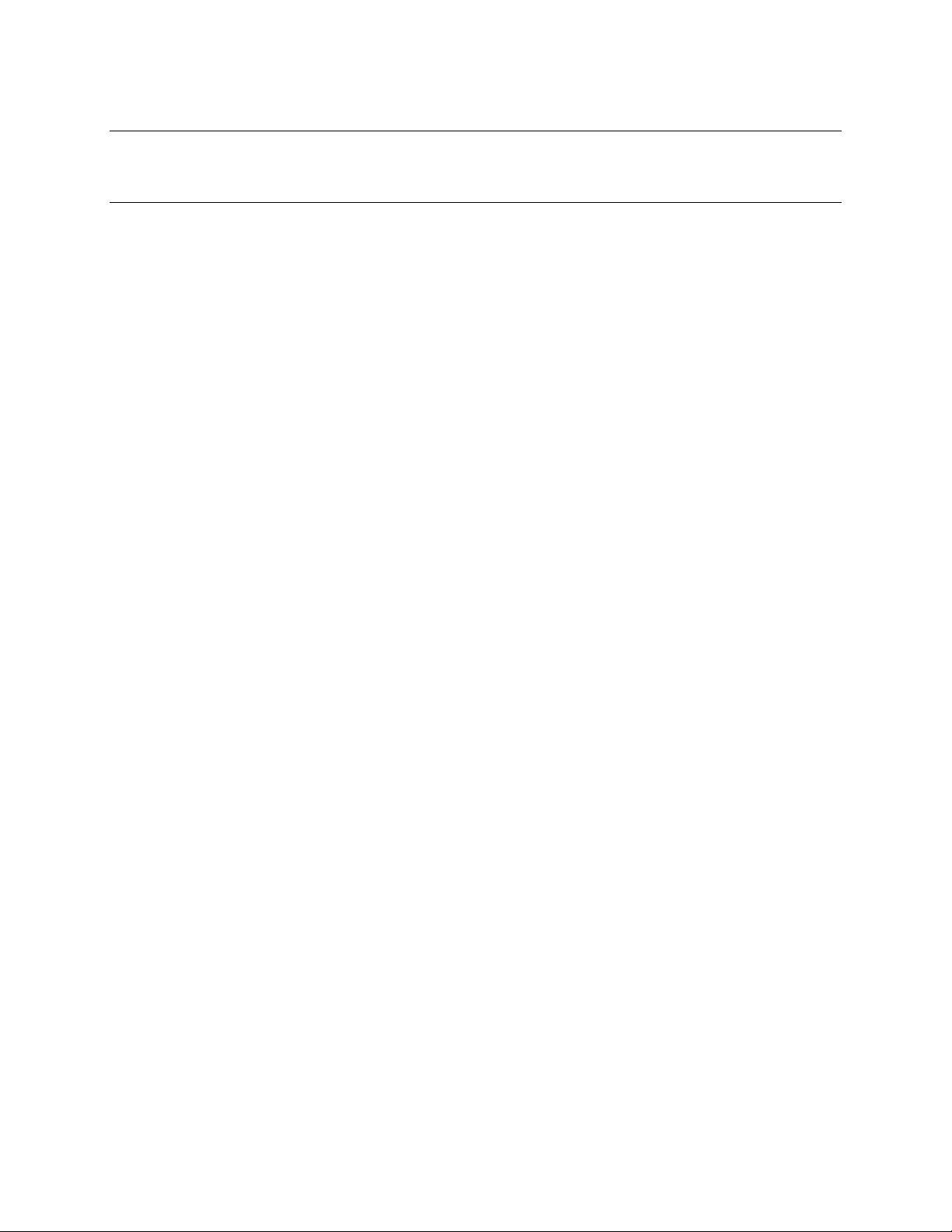

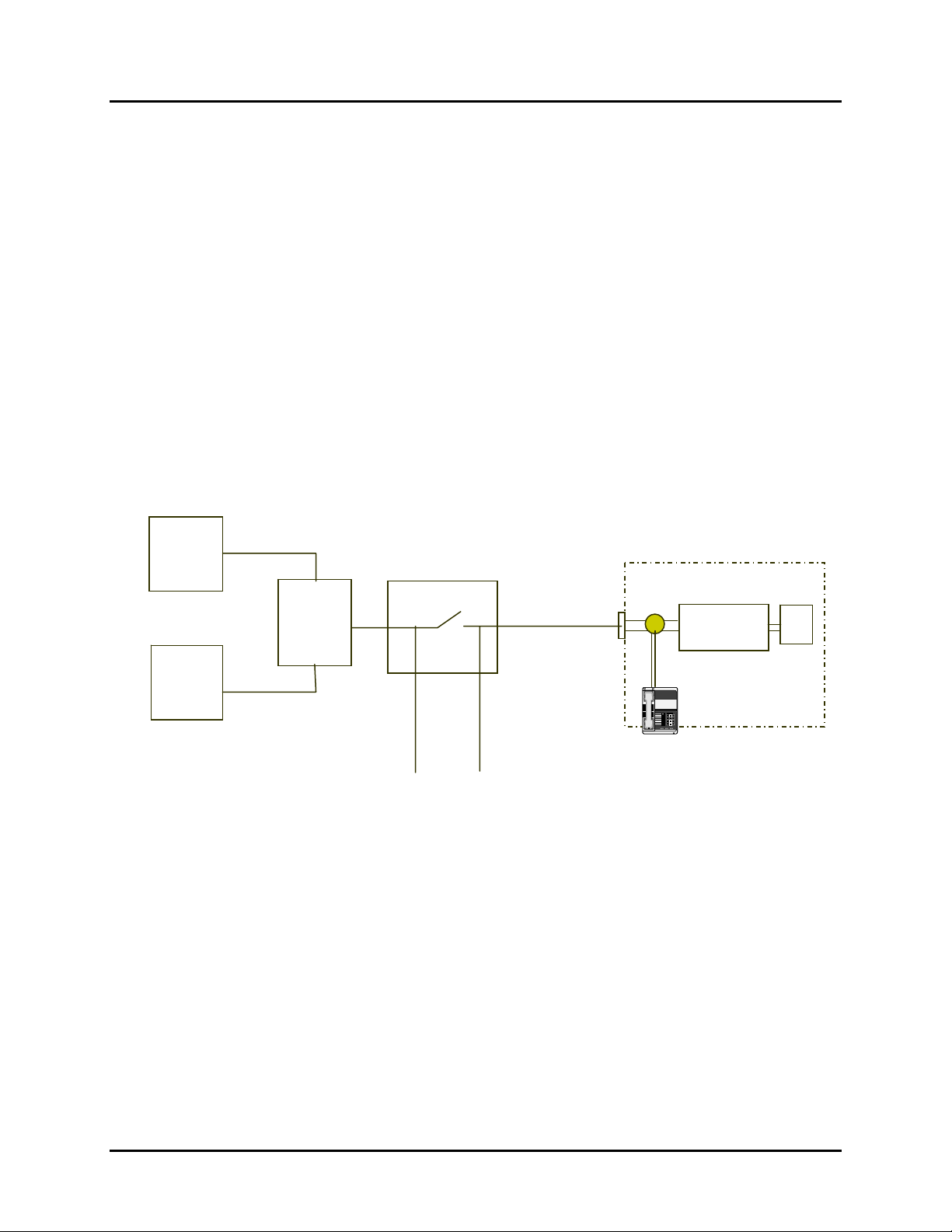

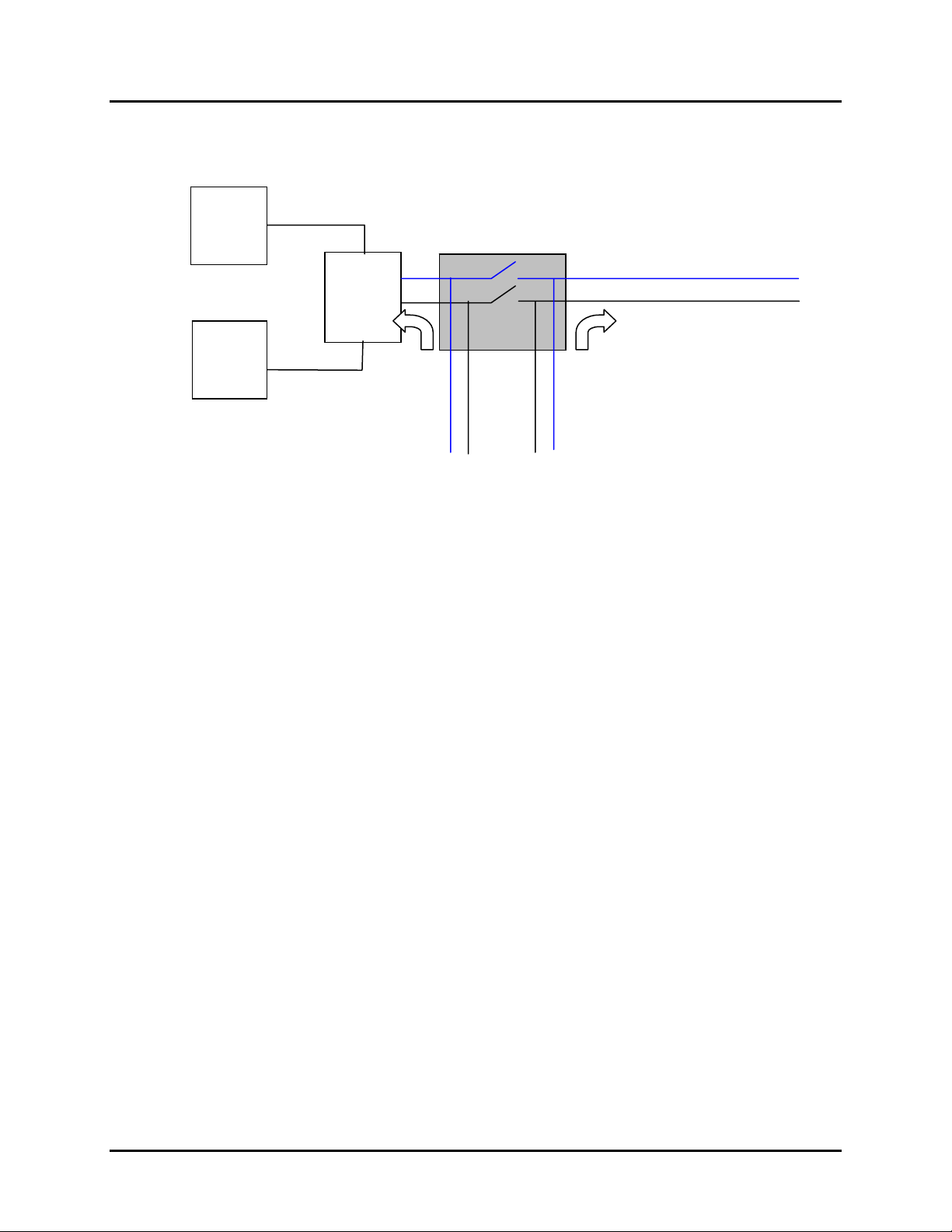

Figure 2: MTAS-192 in the Network

The MTAS-192 provides two (2) four-wire Test Access Paths (TAPs), with monitor,

bridged, look-in, and look-out functionality. The four-wire TAP provides separate look-in

and look-out pairs with access controlled by Transaction Language 1 (TL1) messages

sent over an Ethernet or an RS-232 serial port directly to each MTAS-192 System.

2

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

Comtest Networks

MTAS-192

1.3 Hardware Overview

The MTAS-192 Metallic Test Access System has the following parts.

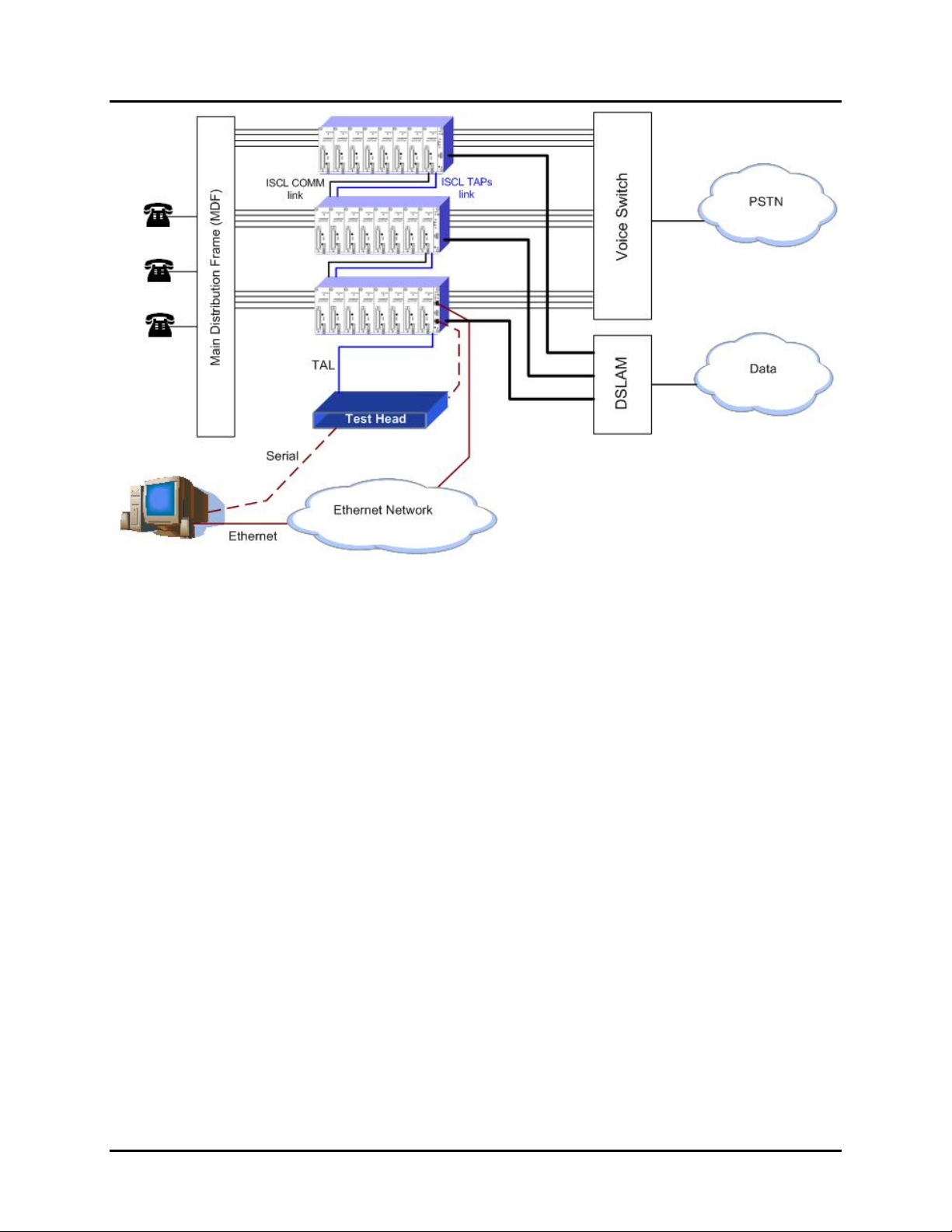

Table 1: Components of the MTAS-192 Metallic Test Access System

Component Model Number

High Density, Test Access Shelf MTAS-192

Test Access Controller Card

Master MTAS-CM

Slave MTAS-CS

North

American

Standard NA-5820

With Test Access MT-5820

Splitter Card

Standard EU-5807

(ADSL2+)

ETSI

with Test Access MT-5807

ISDN With Test Access MT-5821

Splitter Card

(VDSL2)

North

American

With Test Access MT-5820V

for 2-wire Lines MT-501

Test Access Only Card

for 2- and/or 4-wire Lines MT-502

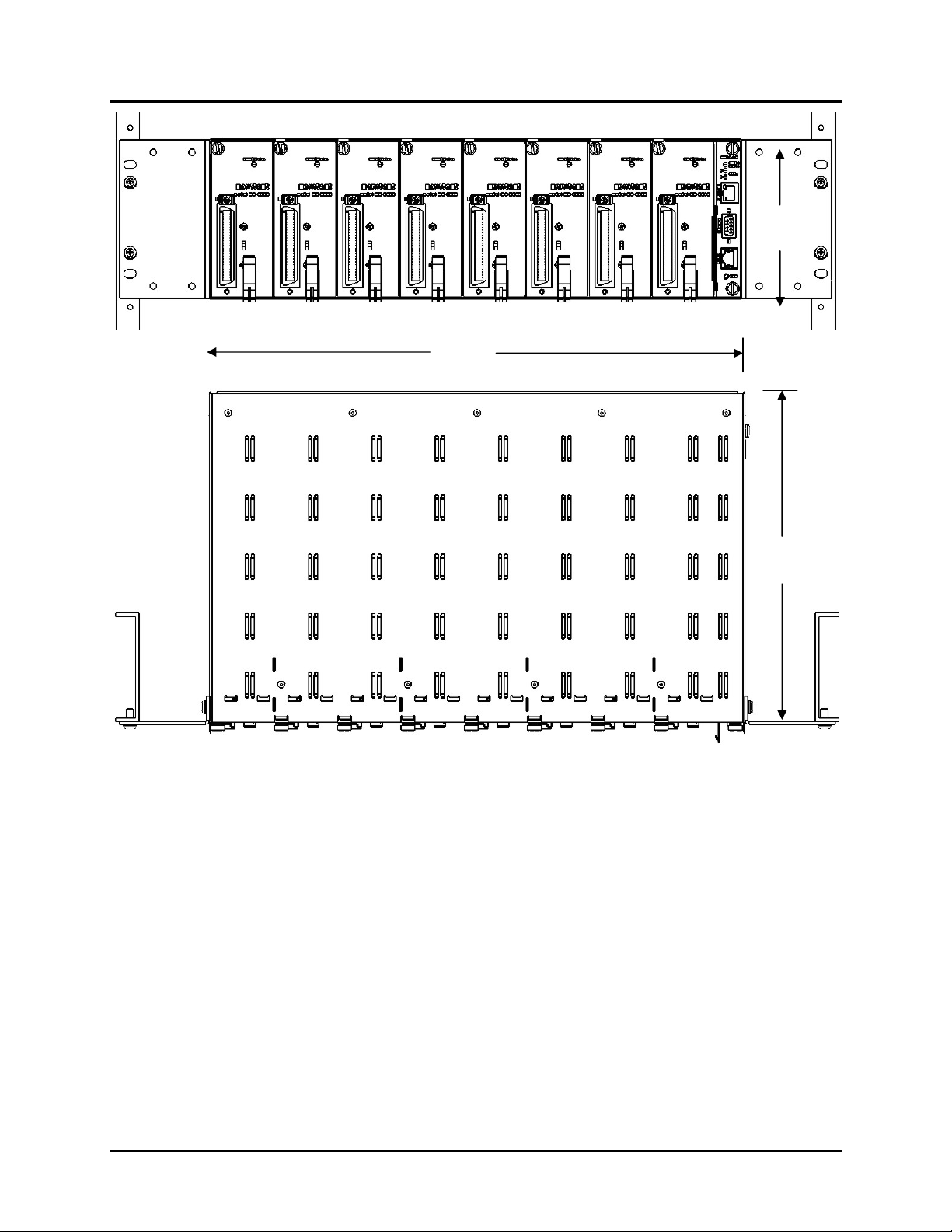

1.3.1 The MTAS Shelf

The MTAS-192 shelf is 3 Rack Units in height and can be rack-mounted in either a 19”

or 23” ANSI- and ETSI-dimensioned equipment rack or cabinet using universal

mounting flanges. The actual dimensions of the shelf are 5.22″ high by 17.3″ wide

(without the mounting flanges) by 10.5″ deep. Refer to Figure 3.

MTAS-192 shelf contains nine card slots. The first eight slots (#1-8, labeled from left to

right) are reserved for line cards, each providing xDSL splitter and/or metallic test

access to 24 2-wire lines. Therefore, one MTAS-192 provides MTA to 192 2-wire lines.

The ninth slot is reserved for the Control Card.

June 2006 Installation Guide

3

Comtest Networks

MTAS-192

CT-IG-MTAS192-2008-v1_8.doc

5.22"

17.3"

10.5"

Figure 3: Front and Top Views of MTAS Shelf Showing Flanges for 23" Rack

The MTAS-192 shelf has eight line card slots (slots #1-8) for up to eight line cards in

any combination of:

• MT-5820(V) North American Splitter with Test Access or

MT-5807 ETSI Splitter with Test Access or

MT-5821 ISDN Splitter with Test Access

• NA-5820 North American Splitter Cards or

EU-5807 ETSI Splitter Cards

• MT-501/MT-502 Test Access only cards

and one slot (slot #9) for either:

• MTAS-CM control card (master) or

• MTAS-CS control card (slave).

4

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

Comtest Networks

MTAS-192

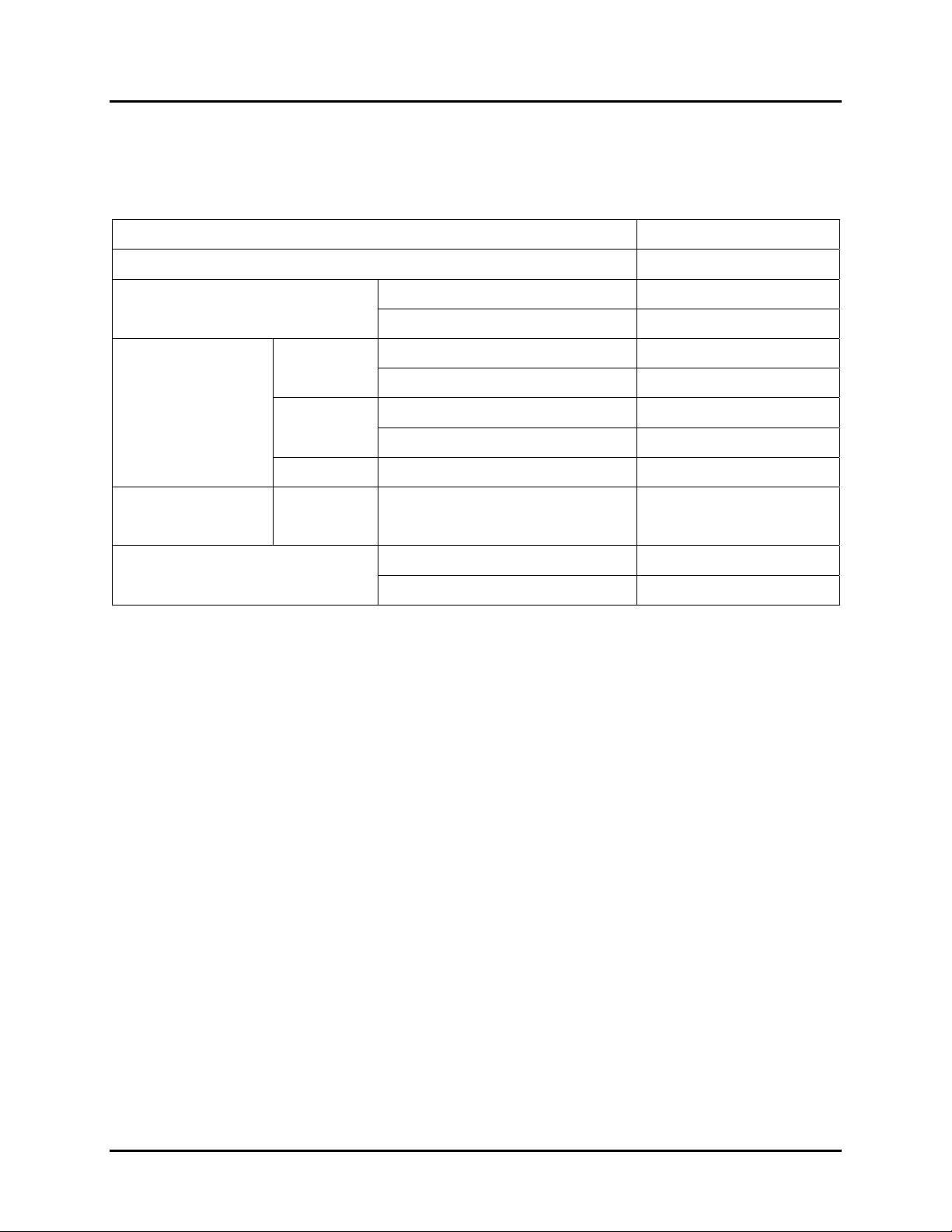

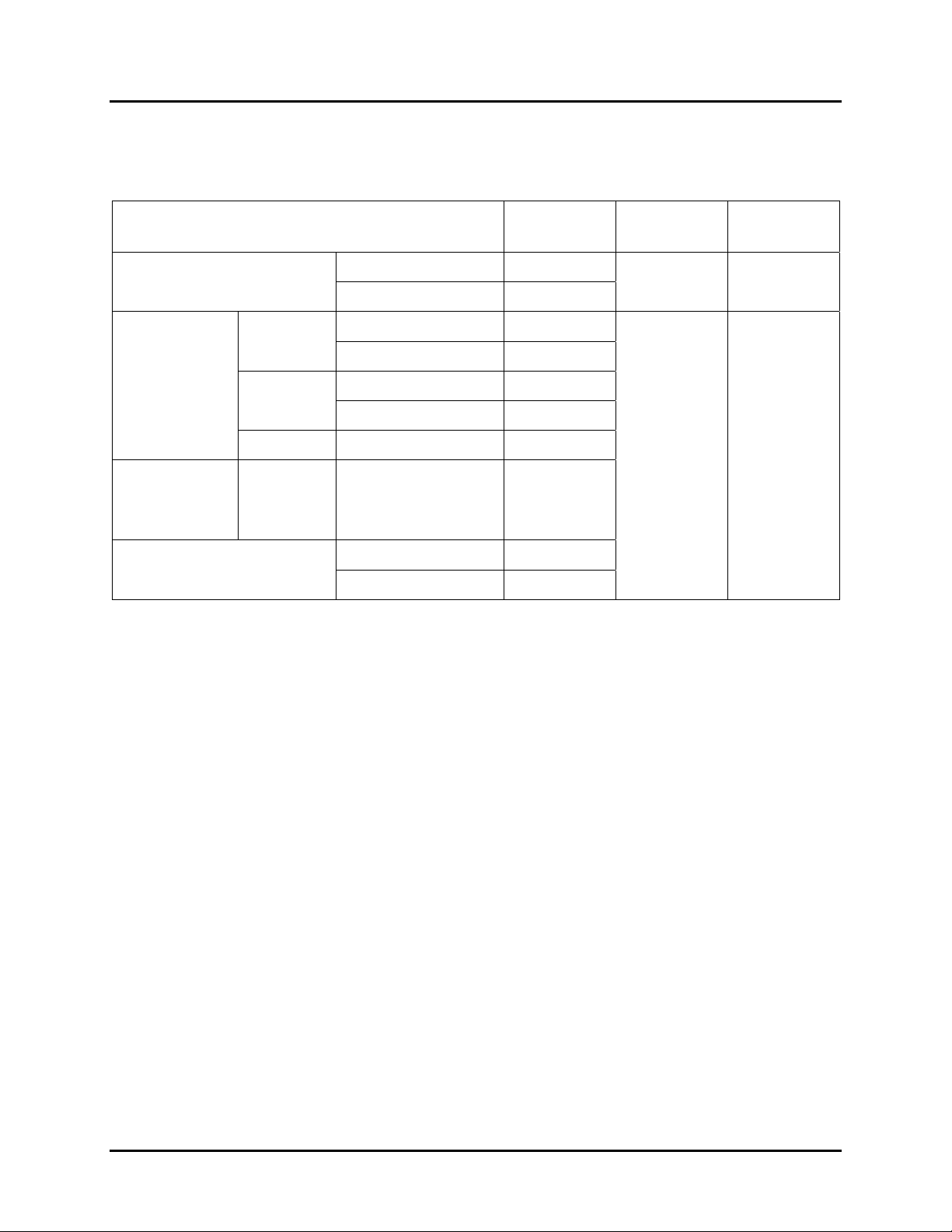

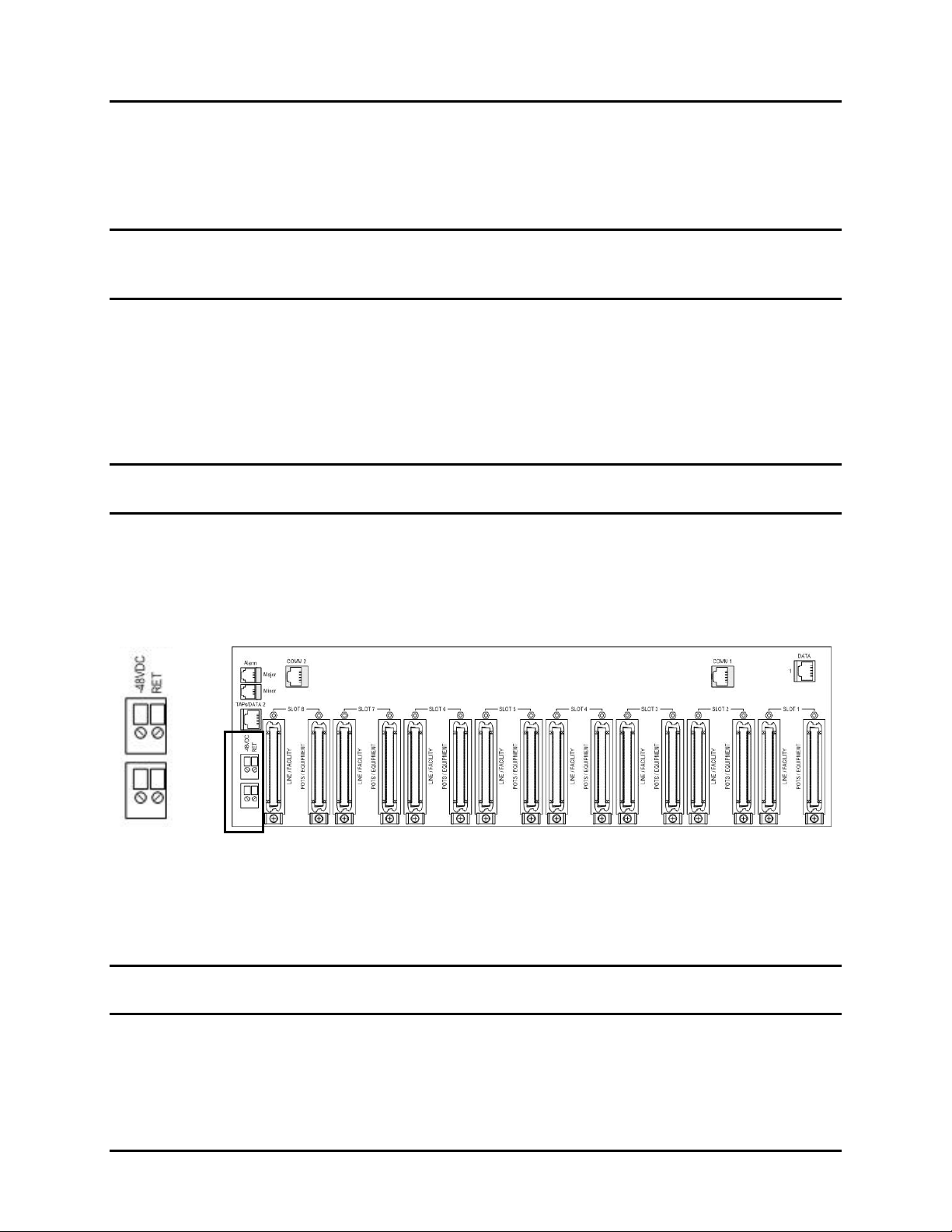

This is summarized in Table 2 below. A sample MTAS-192 system containing eight

MT-5820 line cards is shown in Figure 4 and Figure 5.

Table 2: Card Slot Assignments for the MTAS-192

Component

Test Access Controller

Card

North

Splitter

American

Cards

(ADSL2+)

ETSI

ISDN With Test Access MT-5821

Splitter

Cards

North

American

Model

Number

Master MTAS-CM

Slave MTAS-CS

Type

Controller

Cards

Standard NA-5820

With Test Access MT-5820

Standard EU-5807

with Test Access MT-5807

Line

Cards

With Test Access MT-5820V

Use in

Slot(s)…

9

1-8

(VDSL2)

2-wire MT-501

Test Access Only Card

2- and/or 4-wire MT-502

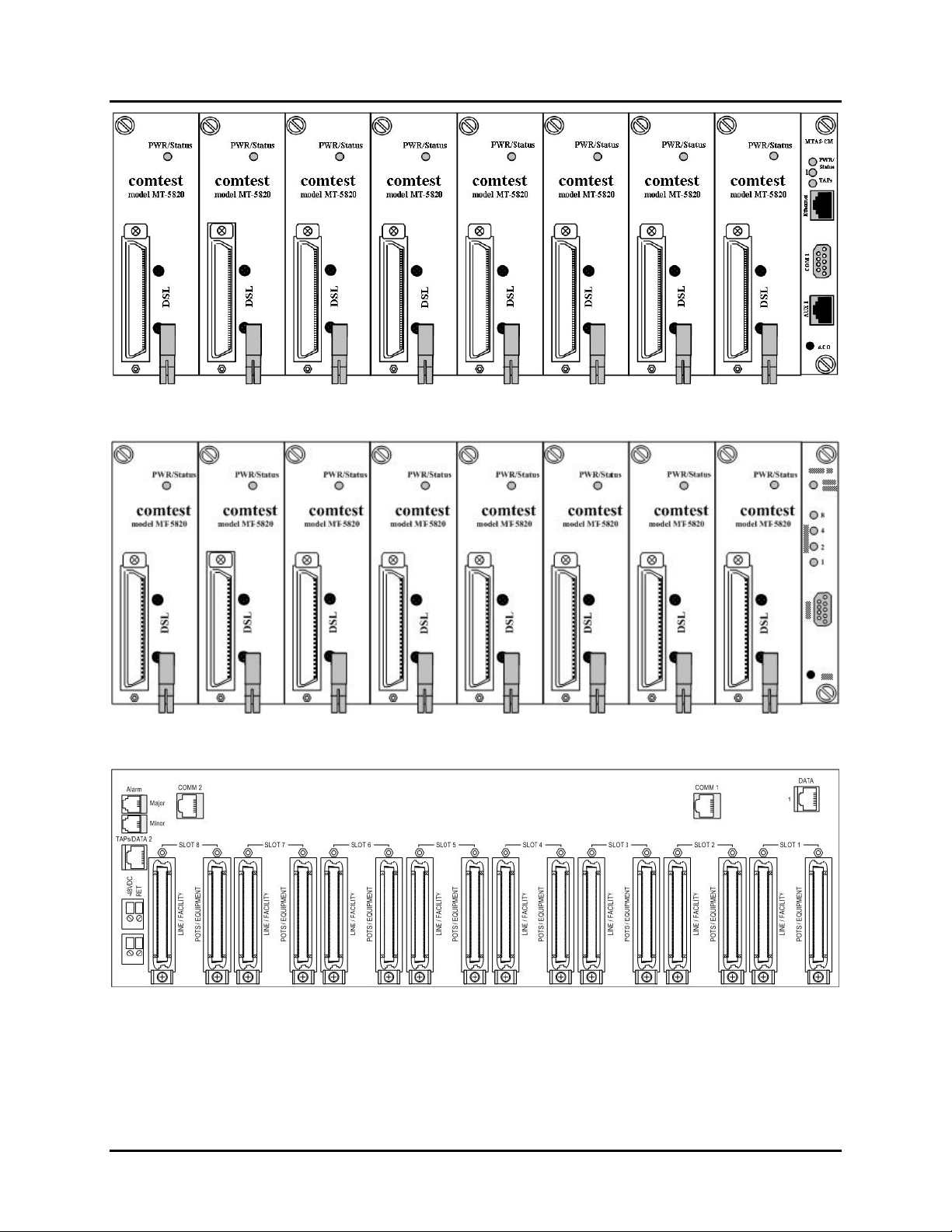

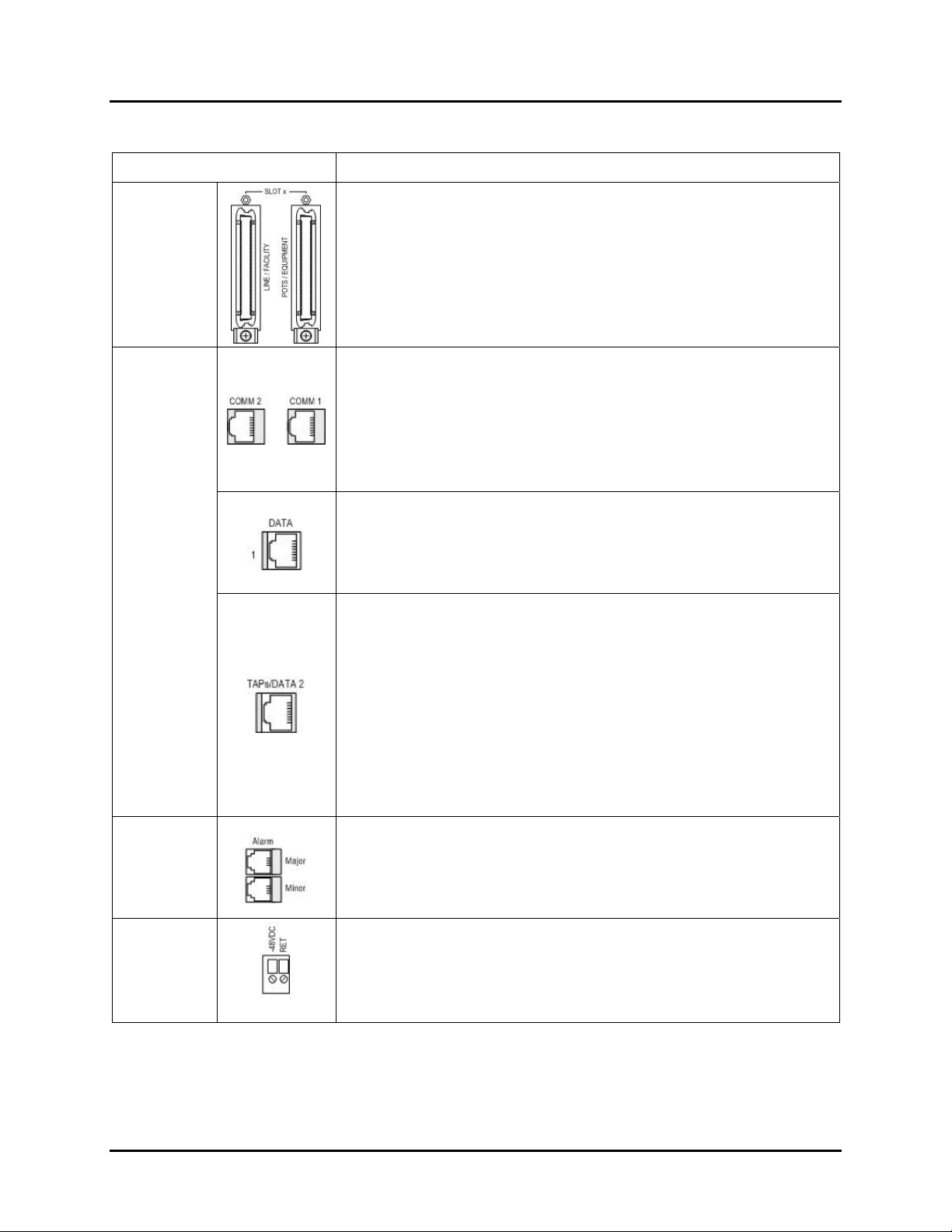

Table 3 lists visible features and interfaces on the rear panel of the MTAS-192 shelf.

The complete rear panel is shown in Figure 6.

June 2006 Installation Guide

5

Comtest Networks

MTAS-192

Figure 4: MTAS-192 Front View with Master Control Card (MTAS-CM)

CT-IG-MTAS192-2008-v1_8.doc

2

Figure 5: MTAS-192 Front View with Slave Control Card (MTAS-CS)

Figure 6: MTAS-192 Rear View

Refer to Chapter 4: Cabling and Appendix A for connector pin-outs. Refer to Chapter 5:

Activation and Testing for LED information.

6

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

Table 3: Rear Panel Connectors of the MTAS-192 Shelf

Connector/Function Description

24 Line/Facility and 24 POTS/Equipment Pairs

RJ-21

(8 sets)

50-pin (25 pair) RJ-21 female connector – 1/ line card slot.

Pairings correspond to eight (8) splitter/TAU line card slots

#1-8 in the shelf.

COMM 1 and COMM 2 for ISCL Bus

RJ-45 shielded female jacks for COMM 1 communications

ports on top right and COMM 2 communications ports on

top left. Used for daisy chaining the ISCL bus from the

chassis (COMM 1 is ISCL bus OUT, COMM 2 is ISCL bus

IN).

DATA 1 for TAL Bus

Comtest Networks

MTAS-192

RJ-45

RJ-11

Dual Wire

Terminal

Header

RJ-45 shielded female jack for DATA 1 TAL extensions

port. Used to extend the TAL bus to the next shelf in a

daisy-chained network.

TAPs / DATA 2 port

RJ-45 shielded female jack. Test Access Link (TAL)

consisting of two 4-wire Test Access Paths (TAPs). Each

TAP delivers simultaneous metallic test access to both the

DSLAM and Line side of a port under test.

For a Stand-alone or master shelf configuration, this port is

used for connection to the test head.

For the slave shelf configuration, this port is the TAL input

connector for a daisy chain.

Major and Minor External Alarm Contacts

RJ-11 female jack. Shelf Major and Minor Alarm outputs.

Normally open, dry contacts for visual and audible alarms.

Located on the top left of the chassis.

Shelf Power

Two sets of -48VDC Battery and Return terminals (for both

A and B power feeds), located on the left side.

June 2006 Installation Guide

7

Comtest Networks

CT-IG-MTAS192-2008-v1_8.doc

MTAS-192

1.3.2 The Test Access Controller Cards

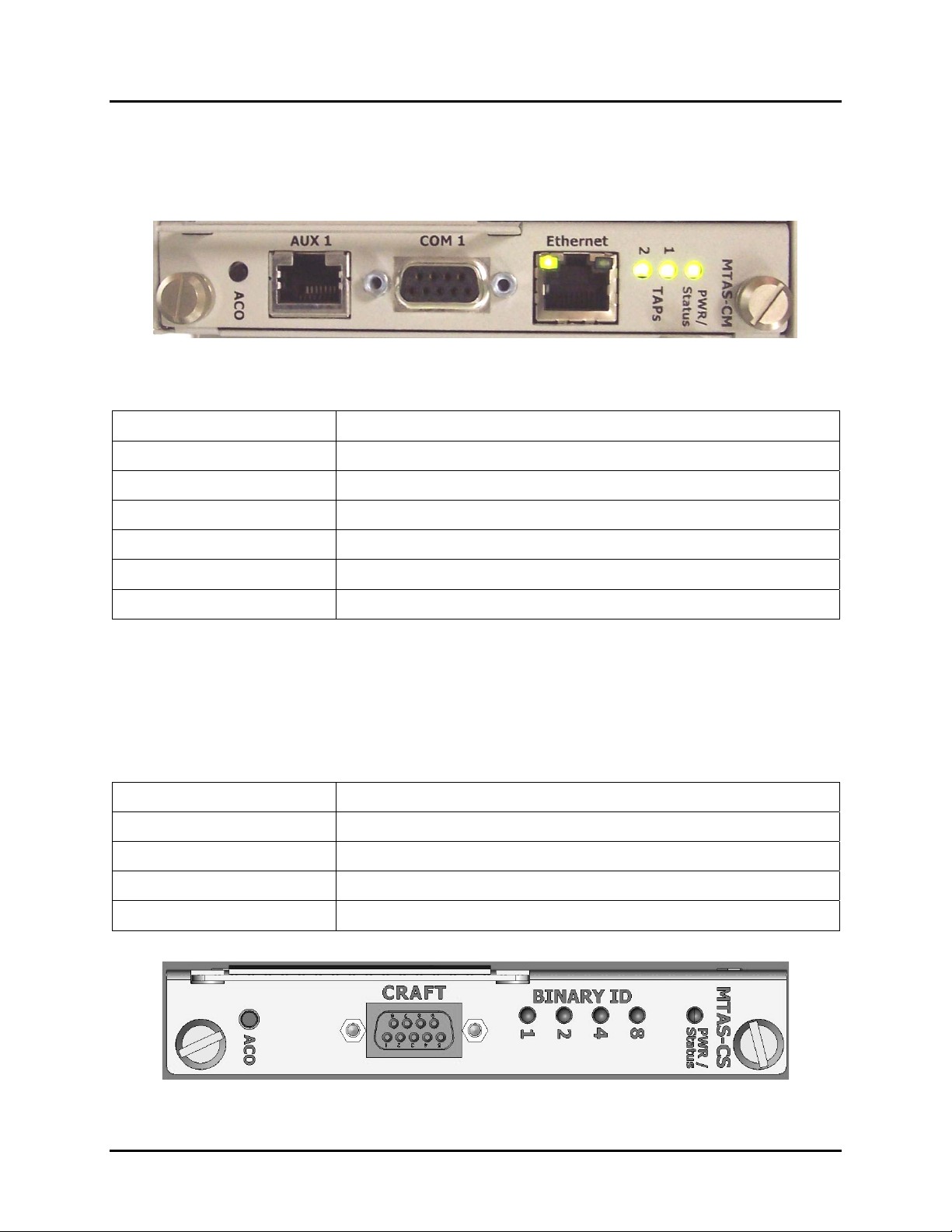

The MTAS-CM (Control Master) card has the following visible features and interfaces

on its front panel.

Figure 7: Test Access Controller Card MTAS-CM (Control Master) (Rotated 90 Degrees)

Table 4: Features of the MTAS-CM Control Master Card

Item Description

PWR / Status LED One Tri-colour LED to show PWR and Status

TAPs LEDs Two TAPs LEDs to show status of TAPS 1 and 2

Ethernet Female RJ-45 shielded jack for 10/100 BaseT cable

COM 1 Female RS-232 shielded DB-9 connector (debug port)

AUX 1 Female RS-232D shielded RJ-45 connector

ACO (Alarm Cut-off) Push button cutoff switch for audible alarms

More than one MTAS-192 shelf can be daisy-chained into a master/slave configuration.

In such applications, a slave version of the Test Access Controller Card is available

(MTAS-CS). The MTAS-CS (Control Slave) card has the following visible features and

interfaces on its front panel.

Table 5: Features of the MTAS-CS Control Slave Card

Item Description

PWR / Status LED One Tri-colour LED to show PWR and Status

Binary ID LEDs Four LEDs to identify the Shelf ID (1-11)

CRAFT Female RS-232 shielded DB-9 connector (debug port)

ACO (Alarm Cut-off) Push button cutoff switch for audible alarms

Figure 8: Test Access Controller Card MTAS-CS (Control Slave) (Rotated 90 Degrees)

8

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

Comtest Networks

MTAS-192

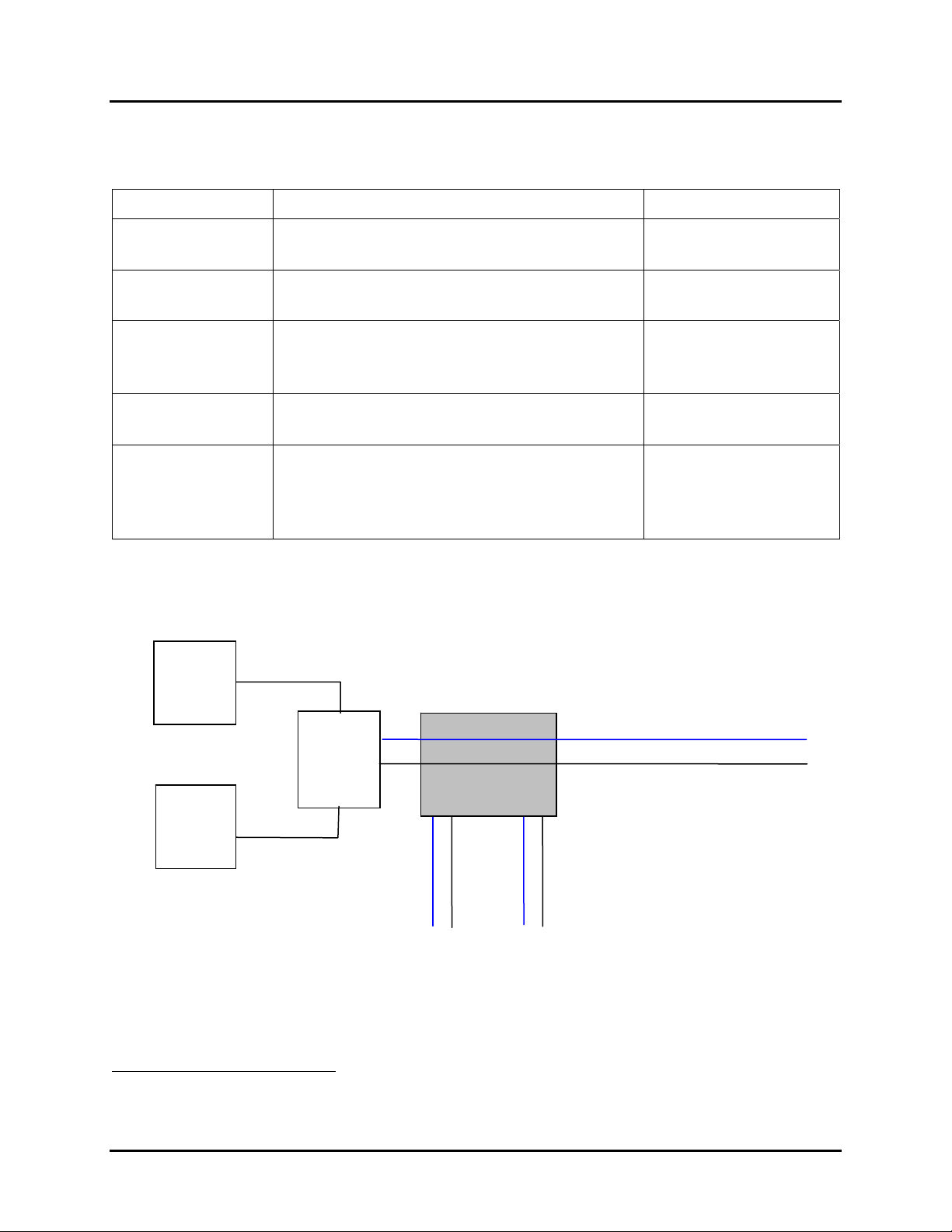

1.3.3 The Line Cards (Splitter Cards and Test Access Only Cards)

There are 6 unique types of line cards divided into 2 categories: Splitter Cards (4

varieties) and Test Access Only Cards (2 varieties) (refer to Table 2).

Each splitter card has a DSL (Digital Subscriber Loop) interface using a standard 50-pin

(25 pair) RJ-21 female connector. In addition, each splitter card has two TAPs (Test

Access Paths) and each TAP consists of 2 pairs of wires (making a 4-wire TAP):

• One for the upstream (Equipment) side called AE

• One for downstream (Facility) side called AF.

The AF (facility) pair is intended for testing on the line (facility) side and it is always used

in any test mode. The AE (equipment) pair is intended for testing on the equipment side.

Equipment Side (E)

(Upstream)

DSLAM

PSTN

Class 5

Splitter

MTAU (MTAS -192)

AE

AF

RTU (Test Head)

Figure 9: Test Access Paths (TAPs)

Facility Side (F)

(Downstream)

CPE

Splitter

DSL

Modem

123

456

789

8#

*

PC

June 2006 Installation Guide

9

Comtest Networks

p

p

g

g

A

CT-IG-MTAS192-2008-v1_8.doc

MTAS-192

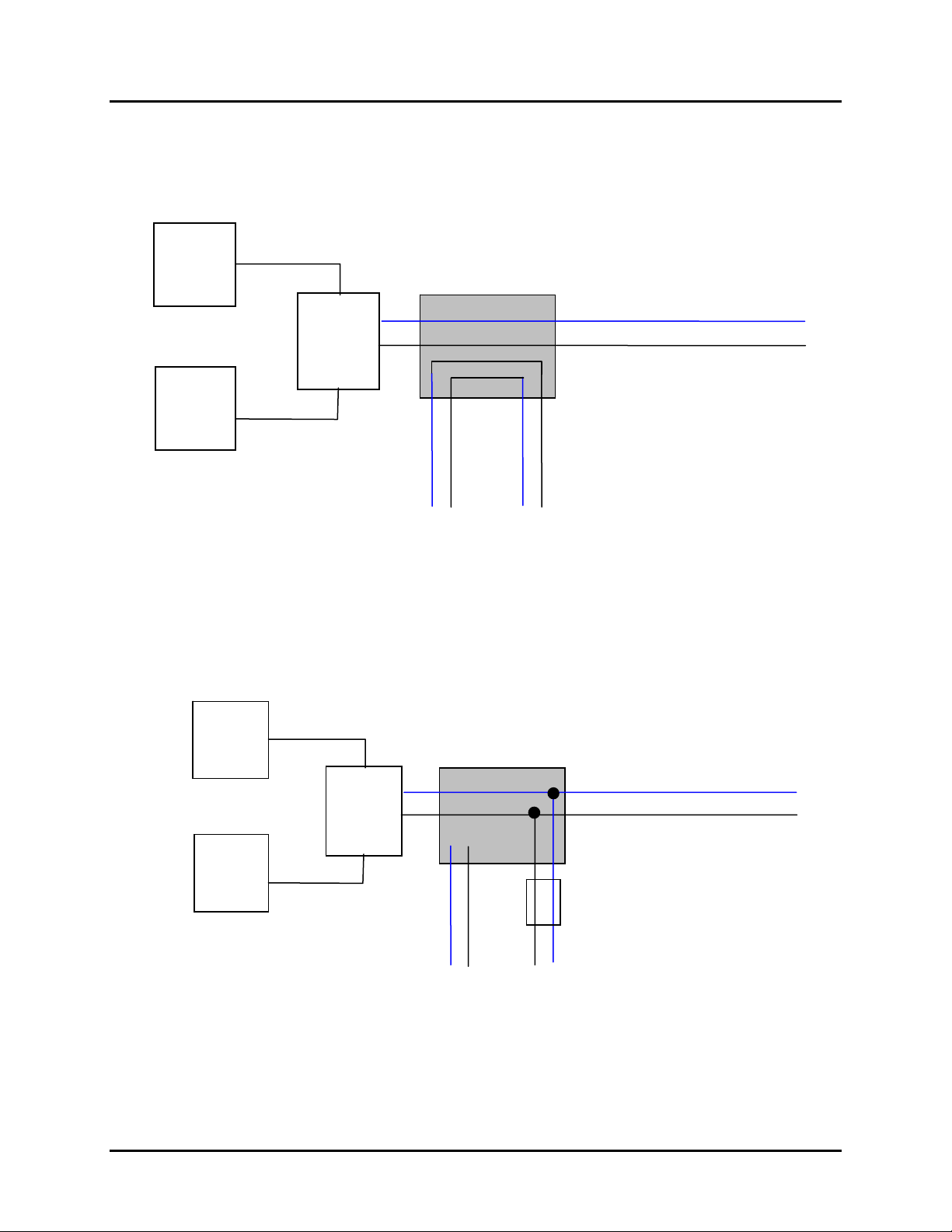

Each splitter card has five (5) modes, which are explained below.

Table 6: Splitter Card Modes

Mode Description TL1 Command

1

Transparent/

Isolated

Loop-around

High-impedance

Monitor

Bridged Monitor

Split

Equipment Side (E)

(Upstream)

DSLAM

In this mode, all test connections are

released. This is the default mode.

In this mode, the AF and AE sides of a

TAP are looped back at the line card.

This mode uses the AF portion of the TAP

bus and performs a hitless connection to

provide access for monitoring.

This mode connects the AF pair directly to

the circuit under test.

Split Mode access breaks the cable pair to

be tested in two directions, one provided

by AF (towards the customer) and AE

(towards the equipment).

Facility Side (F)

(Downstream)

MTAU (MTAS-192)

ccess Point

DISC-TACC

CONN-LPACC-MET

CONN-TACC-MET

CONN-MON

CHG-SPLIT

2–Wire Circuit

Splitter

Ti

Rin

Ti

Rin

PSTN

Class 5

TT

AE

RR

AF

RTU (Test Head)

Figure 10: Transparent/Isolation Mode

1

TL1 commands are explained in the MTAS-192 User Guide.

10

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

A

pTip

g

g

A

Comtest Networks

MTAS-192

Equipment Side (E)

(Upstream)

DSLAM

PSTN

Class 5

Splitter

MTAU (MTAS-192)

ccess Point

Ti

Rin

TT

AE

Rin

RR

AF

RTU (Test Head)

Figure 11: Loop-Around Mode

Facility Side (F)

(Downstream)

2–Wire Circuit

Equipment Side (E)

(Upstream)

DSLAM

Splitter

MTAU (MTAS-192)

ccess Point

Tip

Ring

Facility Side (F)

(Downstream)

Tip

Ring

2–Wire Circuit

PSTN

Class 5

TT

AE

High (Z) Impedance

RR

AF

RTU (Test Head)

Figure 12: High-Impedance Monitor Mode for the Splitter/Access Two-Wire TAP

June 2006 Installation Guide

11

Comtest Networks

MTAS-192

CT-IG-MTAS192-2008-v1_8.doc

Equipment Side (E)

(Upstream)

DSLAM

PSTN

Figure 13: Split Mode for Testing in Both Directions

Splitter

MTAU (MTAS-192)

4-Wire Access

Tip

Ring

TT

AE

RR

AF

RTU (Test Head)

Facility Side (F)

(Downstream)

Tip

Ring

2–Wire Circuit

Refer to the MTAS User Guide for shelf and TL1 command specifications.

# # #

12

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

Comtest Networks

MTAS-192

Chapter 2

Preparing for Installation

2.1 Installation Personnel

Comtest recommends that all installation activities be conducted by certified central

office (CO) installers.

2.2 Site Survey

Comtest recommends that a site survey be conducted in advance by experienced

personnel to determine and assign the following:

• equipment rack location(s)

• shelf position(s) in the rack

• power distribution panel and fusing

• suitable disconnect device for power feed

• connections to OSS and test head.

2.3 Environmental

The MTAS-192 is designed to be installed in a restricted-access location such as a

Central Office environment or remote hardened enclosures. The MTAS-192 is suitable

for mounting on concrete or other non-combustible surface only. The temperature range

for the MTAS-192 is -40 to +60

2.4 Tools and Materials Required

The MTAS-192 is easy to install. The following equipment is required:

• One (1) large Philips-head (star) screwdriver

• One (1) narrow, long blade slot-edge screwdriver

• Tie wraps for forming and securing various cables to equipment and cable racks

• Bolts for securing the MTAS to the equipment rack

2

degrees Celsius.

• 8-wire CAT5 cable (shielded is recommended) for TAL connections

• 8-wire CAT5 cable (shielded is recommended) for Ethernet and serial

connections

2

To operate in temperatures above this range please contact Comtest Networks

June 2006 Installation Guide

13

Comtest Networks

CT-IG-MTAS192-2008-v1_8.doc

MTAS-192

• RJ-45 plugs (shielded or non-shielded, depending upon CAT5 cable us ed), up to

6 per chassis

• If daisy-chaining MTAS shelves, 8-wire CAT5 shielded cable for COMM

connections is required.

NOTE: For daisy-chain configurations, CAT5 shielded cable is required for COMM

connections and it must be properly grounded on both ends. Refer to Chapter 4 and

Appendix A for more details.

2.5 Ethernet Requirements

The MTAS requires assignment and configuration of a static IP address, subnetwork

mask, and gateway. This information must be obtained prior to the MTAS Activation and

Testing phase of the installation.

NOTE: To be visible to the configuring PC, the PC and master MTAS shelves must

share the same IP subnetwork.

2.6 Shelf Power Supply

The MTAS-192 shelf is powered by standard –48VDC Central Office (CO) battery.

Although the shelf can operate from a single power feed, dual connectors are provided

for A and B power feed redundancy.

Figure 14: Dual Connectors for Power Feed

The power supply breakers/fuses required are minimum 1/2 A to maximum 1A; these

are typically located in the Power Distribution Bay/Block/Center at the top of the

equipment rack.

NOTE: The MTAS-192 power feeds must be connected to an appropriate disconnect

device

2.7 Physical Requirements

The MTAS-192 shelf is adaptable to 19" and 23" racks using universal mounting

flanges.

14

Installation Guide June 2006

CT-IG-MTAS192-2008-v1_8.doc

Comtest Networks

MTAS-192

Each MTAS shelf requires three (3) Rack Units or 5.25 inches of vertical rack space.

The MTAS shelves may be installed directly above or below one another: there is no

vertical spacing required for cooling or cabling.

2.8 Unpacking

The MTAS is shipped in two separate boxes – one contains the MTAS-192 shelf, and

the other contains the circuit packs for the shelf. There are no special handling

requirements for the shelf; however, the circuit packs require standard ESD handling

precautions.

CAUTION: A grounded wrist strap should be worn at all times when handling the circuit

packs. Place cards in or on static bags when working with the cards.

NOTE: After unpacking, do not install the circuit packs into the shelf before the shelf is

mounted in the equipment rack. Mount the MTAS-192 shelf in the rack before inserting

circuit packs.

2.9 Inspection

Step 1. Using standard ESD handling precautions unwrap circuit cards one at a time.

Step 2. Consult the packing list (see section 2.10 Packing List) to verify that all items

have been received as ordered and inspect them for obvious physical damage.

Step 3. If there is damage, re-pack the item in the shipping materials in which it came

in and return to Comtest Networks using the standard defect return procedure

in Appendix B: Repair and Return Services.

Step 4. If there is no damage, go to Chapter 3: Installing the MTAS Shelf.

2.10 Packing List

Please verify the contents of your MTAS-192 shipment against the packing list(s).

2.10.1 Shelf

• One (1) MTAS-192 High Density, Test Access Shelf

• Two (2) universal ANSI ear mounts (flanges) for either 19 or 23" shelves, each

supplied with two (2) screws and two (2) washers

• One (1) ISCL bus terminator (RJ-45 connector 'dongle')

• One (1) Steward EMI (Electro-magnetic Interference) suppressor

• Optional Redundant Power Feed Steward EMI suppressor

• Optional RJ-21 Hex Nut kits

• Optional RJ-21 Angle Shroud kits.

NOTE: Hex Nut and Angle Shroud kits are based on the RJ-21 shroud type (D-type or

Angled) and screw length (0.75" or less than (<) 0.75") used to build the CAT5 RJ-21

24-pair cables that connect to the MTAS backplane POTS, Line, and line card DSL

June 2006 Installation Guide

15

Comtest Networks

MTAS-192

RJ-21 female connectors. The kits consist of:

• Hex Nut kit: 8 hex nuts

• Angled Shroud kit: 8 tie wraps, 8 cable tie mounts.

2.10.2 Cards

• One (1) MTAS-CM Test Access Controller card Master or MTAS-CS Test Access

controller card Slave

• Up to eight line cards in any combination of:

o NA-5820 North American Splitter Card(s) or EU-5807 ETSI Splitter Card(s)

OR

o MT-5820(V) North American Splitter(s) with Test Access or MT-5807 ETSI

Splitters with Test Access or MT-5821 ISDN Splitters with Test Access OR

o MT-501 Test Access only card or MT-502 Test Access only card.

NOTE: There is no dongle/ terminator required for the Test Access Link extender bus.

CT-IG-MTAS192-2008-v1_8.doc

# # #

16

Installation Guide June 2006

Loading...

Loading...